#adiabatic cooling process

Explore tagged Tumblr posts

Text

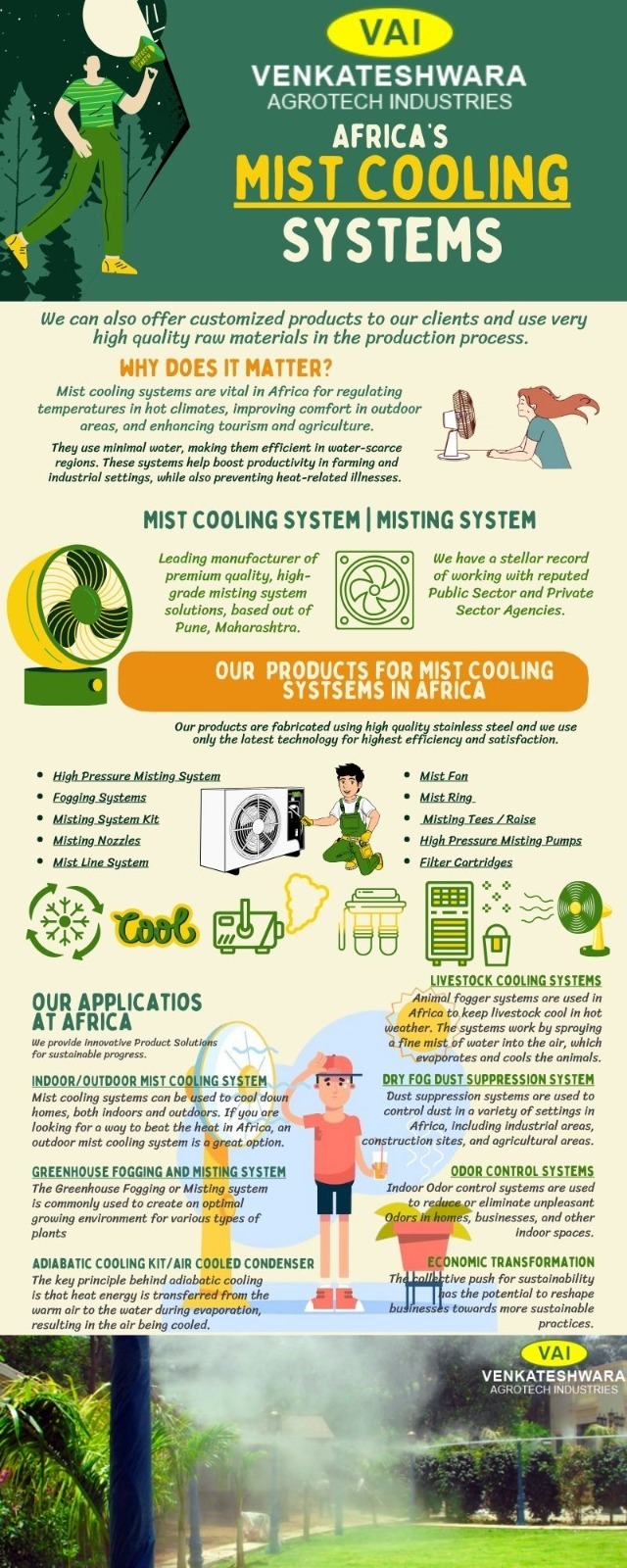

Adiabatic Cooling System | Evaporative Pre Cooling System Manufacturer, Suppliers in Africa

Innovative Cooling and Dust Suppression Solutions in Africa: Leading the Way in Adiabatic and Fogger Systems

Africa’s diverse climates, ranging from arid deserts to tropical regions, present unique challenges in maintaining optimal temperatures for both industrial processes and livestock management. To meet these challenges, advanced cooling technologies such as adiabatic cooling systems and fogger cooling systems have become increasingly important. These technologies not only enhance efficiency but also support animal welfare and environmental sustainability. This article explores the role of adiabatic cooling systems, evaporative pre-cooling, and fogger systems in Africa, highlighting the key manufacturers, suppliers, and exporters in this growing industry.

Adiabatic Cooling Systems: Efficient and Eco-Friendly Solutions

Adiabatic cooling is a highly efficient process that leverages the natural cooling effect of evaporation to reduce air temperatures. This method is particularly valuable in Africa, where high ambient temperatures can put a strain on air-cooled condensers and other industrial cooling systems.

Adiabatic Cooling Process: The adiabatic cooling process involves pre-cooling the air before it enters a condenser or heat exchanger. This is achieved by passing the air through a water-saturated medium, where it loses heat due to evaporation, resulting in a cooler airflow that enhances the efficiency of cooling systems. This process significantly reduces the energy consumption of air conditioning systems and extends the lifespan of industrial equipment.

Adiabatic Cooling Kits: These kits provide a comprehensive solution for retrofitting existing systems or setting up new adiabatic cooling processes. They include all necessary components such as misting nozzles, pumps, filters, and controllers, ensuring easy installation and optimal performance.

Manufacturers and Suppliers in Africa: Africa is home to several leading manufacturers and suppliers of adiabatic cooling systems. These companies offer high-quality products designed to withstand the continent’s challenging environmental conditions, ensuring reliable performance across various industries.

For more information, visit the Adiabatic Cooling System in Africa page.

Evaporative Pre-Cooling Systems: Enhancing Air Conditioning Efficiency

Evaporative pre-cooling systems are a crucial component in optimizing the performance of air conditioning units, especially in hot climates like those found across Africa.

How Evaporative Pre-Cooling Works: Similar to adiabatic cooling, evaporative pre-cooling involves reducing the temperature of incoming air by passing it through a wetted medium. This pre-cooled air then enters the air conditioning unit, where it requires less energy to be further cooled, thus improving the overall efficiency and reducing operational costs.

Manufacturers and Exporters: Africa’s growing market for energy-efficient cooling solutions has led to an increase in local production and export of evaporative pre-cooling systems. These systems are now widely available, with manufacturers offering customized solutions to meet the specific needs of industrial and commercial clients.

Fogger Cooling Systems: Vital for Livestock and Agriculture

In addition to industrial cooling, fogger cooling systems play a significant role in agriculture, particularly in maintaining the health and productivity of livestock. Africa's livestock sector, which includes dairy farms, poultry, swine, and goat farming, benefits greatly from the use of these systems.

Animal and Livestock Fogger Systems: Fogger systems are designed to cool animals in barns, stables, and open-air environments by creating a fine mist that evaporates quickly, lowering the ambient temperature without wetting surfaces. This cooling effect is crucial for preventing heat stress in animals, which can lead to reduced productivity and health issues.

Poultry and Dairy Farm Cooling: Poultry and dairy farms in Africa often rely on fogger cooling systems to maintain optimal temperatures. These systems are tailored to meet the specific requirements of each type of livestock, ensuring that animals remain comfortable even during the hottest months.

Manufacturers and Suppliers in Africa: African manufacturers and suppliers of fogger cooling systems are well-versed in the needs of the local agricultural sector. They provide robust and efficient systems that are easy to maintain and operate, ensuring reliable performance year-round.

For detailed information, visit the Livestock Cooling Systems page.

Dust Suppression Systems: Essential for a Cleaner and Safer Environment

Dust control is another critical application of misting technology, particularly in industries such as mining, construction, and agriculture. Dry fog dust suppression systems are especially effective in controlling airborne particles, reducing health risks, and maintaining environmental standards.

Dry Fog Dust Suppression System: This system generates ultra-fine droplets of water that attach to dust particles, causing them to fall to the ground and preventing them from becoming airborne. This method is highly efficient, using minimal water and avoiding the creation of wet surfaces that could lead to other operational issues.

Design and Implementation: Dry fog dust suppression systems are custom-designed to meet the specific needs of different industries. From mining sites to agricultural fields, these systems help in controlling dust, ensuring a cleaner, safer, and more productive environment.

Manufacturers and Suppliers: Africa's leading manufacturers of dust suppression systems offer innovative solutions that are both effective and environmentally friendly. These companies are at the forefront of developing and supplying systems that meet the stringent demands of industrial operations.

For more on this, visit the Dry Fog Dust Suppression Systems page.

Conclusion

Africa's need for efficient and sustainable cooling and dust suppression solutions is driving the growth of the misting and fogger systems industry. From adiabatic cooling systems and evaporative pre-cooling to livestock fogger systems and dust suppression technologies, the continent's manufacturers, suppliers, and exporters are leading the way in providing high-quality, innovative solutions.

These systems not only enhance industrial efficiency and animal welfare but also contribute to environmental sustainability by reducing energy consumption and improving air quality. Whether you're looking for advanced cooling systems for industrial applications or effective fogger systems for agriculture, Africa's misting technology sector has the expertise and products to meet your needs.

#Adiabatic Cooling System in Africa#adiabatic cooling process#adiabatic cooling kit#Evaporative pre-cooling system#evaporative cooling system manufacturers in Africa#evaporative cooling system suppliers in Africa#evaporative cooling system exporter in Africa#Adiabatic Cooling System manufacturers in Africa#Adiabatic Cooling System suppliers in Africa#Adiabatic Cooling System exporter in Africa#adiabatic cooling system Companies in Africa#air cooled condensers#https://mistcoolingsystemsafrica.com/portfolio/adiabatic-cooling-system-evaporative-pre-cooling-system

0 notes

Text

Adiabatic Cooling System | Evaporative Pre Cooling System Manufacturer, Suppliers in India 9552565674

Adiabatic Cooling System Companies, Manufacturers and suppliers in India. Avaliable Evaporative Pre Cooling System & Adiabatic Cooling Kit, Process for to Improve Your Business. Air Cooled Condensers.

#Adiabatic Cooling System in India#adiabatic cooling process#adiabatic cooling kit#Evaporative pre-cooling system#evaporative cooling system manufacturers in India#evaporative cooling system suppliers in India#evaporative cooling system exporter in India#Adiabatic Cooling System manufacturers in India#Adiabatic Cooling System suppliers in India#Adiabatic Cooling System exporter in India#adiabatic cooling system Companies in India#air cooled condensers

0 notes

Text

Adiabatic Cooling System | Evaporative Pre Cooling System Manufacturer, Suppliers in Gulf

#Adiabatic Cooling System in Gulf#adiabatic cooling process#adiabatic cooling kit#Evaporative pre-cooling system#evaporative cooling system manufacturers in Gulf#evaporative cooling system suppliers in Gulf#evaporative cooling system exporter in Gulf#Adiabatic Cooling System manufacturers in Gulf#Adiabatic Cooling System suppliers in Gulf#Adiabatic Cooling System exporter in Gulf#adiabatic cooling system Companies in Gulf#air cooled condensers#https://mistcoolingsystemsgulf.com/portfolio/adiabatic-cooling-system-evaporative-pre-cooling-system

0 notes

Text

New simulations shed light on stellar destruction by supermassive black holes

Monash University astronomers have contributed to a breakthrough in understanding the dramatic fate of stars that wander too close to supermassive black holes at the centers of galaxies.

Through innovative simulations, an international research team, led by Professor Daniel Price and former student David Liptai from the School of Physics and Astronomy has captured the complex process of how these stars are torn apart and consumed by black holes, providing new insights into the mysterious optical and UV emissions observed during these catastrophic events.

"This is the first self-consistent simulation of a star being tidally disrupted by a supermassive black hole, followed by the evolution of the resulting debris over the course of a year," Professor Price said.

"Our simulations provide a new perspective on the final moments of stars in the vicinity of supermassive black holes," he said.

"By capturing the full evolution of the debris, we can try to connect simulations to the growing number of observed star-shredding events identified with telescope surveys"

The study, published in The Astrophysical Journal Letters, is a significant step forward in astrophysics, opening new avenues for research into the behavior of matter in extreme gravitational fields and the life cycles of stars and black holes.

When a star passes too close to a supermassive black hole, the intense gravitational forces pull it apart in a process known as a tidal disruption event (TDE). The debris from the star forms a stream that eventually feeds the black hole. The debris from the star forms a swirling disk around the black hole, which emits intense radiation across the electromagnetic spectrum. However, many aspects of TDEs remain poorly understood.

The new simulations show that this debris forms an asymmetric bubble around the black hole, reprocessing the energy and producing the observed light curves with lower temperatures, fainter luminosities, and gas velocities of 10,000–20,000 km/s.

"The study helps to explain several puzzling properties of observed TDEs," Professor Price said. "A good analogy is the human body: when we eat lunch, our body temperature does not change much. This is because we reprocess the energy from lunch into infrared wavelengths.

"A TDE is similar, we mostly do not see the black hole stomach eating gas, because it is smothered by material that reemits at optical wavelengths. Our simulations show how this smothering occurs."

Other mysteries explained by the new simulations include:

Why tidal disruption events are observed at optical rather than X-ray wavelengths, where X-rays would be expected from accretion onto a supermassive black hole.

Why the temperatures observed are consistent with the photosphere of a star rather than the expected hot accretion disk.

Why observed star-shredding events are fainter than expected from models of black holes efficiently eating material.

Why the spectra of observed events find material expanding towards us at a few percent of the speed of light (10–20,000 km/s).

TOP IMAGES: Disk formation in an isentropic simulation (radiatively efficient cooling) with a spinning black hole (a = 0.99, θ = 60°). The disk in this case is formed after 90 days and undergoes differential precession, which "tears" the disk into independent rings. Credit: The Astrophysical Journal Letters (2024). DOI: 10.3847/2041-8213/ad6862

LOWER IMAGES: Disk formation in the core of the envelope when an adiabatic simulation is continued with radiatively efficient cooling. We resumed an adiabatic calculation 1 yr after disruption assuming isentropic evolution. Credit: The Astrophysical Journal Letters (2024). DOI: 10.3847/2041-8213/ad6862

youtube

6 notes

·

View notes

Note

Trick or Treat!

-@the-torquedork

You get the Otto cycle! This is an idealized thermodynamic cycle that most closely matches the process used in internal combustion engines. It alternates between adiabatic (no heat transfer with the environment) expansion/compression and isochoric (constant volume) heating/cooling.

6 notes

·

View notes

Text

since there's a lot of confusion in the notes:

no, the water used for cooling does not go back into the river or lake that it came from. microsoft, and many other companies with large server farms, use evaporative (adiabatic) cooling, so the water is lost to the atmosphere

no, 16 oz of water is not used per prompt - the article itself says that 16 oz may be used for between 5 to 50 prompts. this is an average, and it can be as little as 0 during the winter months when outdoor temperatures are enough to cool the computers on their own.

my own thoughts:

AI itself is a neutral tool that is currently being used for some pretty stupid to outright exploitative things. the completely unhelpful chatbot that comes up when you're trying to talk to customer service for a multi-billion dollar company that just doesn't want to pay a real person? get rid of it.

but to say that none of these servers should exist doesn't acknowledge that there are sectors that can provide greater human good by accessing this processing power: AI for cancer detection, AI for ocean exploration, AI for disease prevention and outbreak response...there's a lot of promise and possibility in what we can do for the world with this tool

it's good to be skeptical of new technology, but it's also good to keep in mind that there are existing enterprises that are already actively causing this much damage to the world times ten: cryptocurrency mining still outpaces the environmental impact of AI, and that's purely for the generation of a currency, with no other positive human societal outcomes.

if AI datacenters are going to continue to exist, and they will, then there should be a concerted push for actually building or relocating these servers to cold climates that will require little to no water to function. don't put them in the middle of iowa in 90 degree summers where they're chugging down water that small towns need to survive.

64K notes

·

View notes

Text

This design report concerning the overall system efficiencies and associated with advanced cooling systems in the current market to provide a tool can be used in selecting systems for a given installation. The objective of this study was to review cooling technologies available in the current market and to promote the introduction of advanced cooling technologies. Metals owe their importance to their unique mechanical properties, the combination of high strength with the ability to change shape plastically ductility and malleability). This plasticity enables them to be shaped, e.g. into motor car bodies, tin cans and girders, by processes of mechanical working such as pressing, drawing, rolling and forging. Even more important, this same plasticity gives strong metals their extraordinary toughness, the ability to endure all the knocks and shocks of long rough service without breaking or crumbling away. Corrosion properties are the materials compatibile for the components used for the following items such as compressor, piping, evaporator, and condenser. Safety considerations include toxicity and flammability. With the introduction of Freon, sulfur dioxide rapidly disappeared from the market. Ammonia is still used in some large commercial plants, well away from residential areas, where a leak will not cause widespread injuries.With the Use of highly purified propane gas as a refrigerant is gaining favor, in systems designed for R-12, R-22 or R-134a. Now it is marketed under the trade name Duracool® and it is designated as R-290.. Moreover, propane is nontoxic. The powerful Emissions from automotive air-conditioning are a growing concern because of their impact on climate changet a great extent.. The European Union will phase out refrigerants with a global warming potential (GWP) of more than 150 in automotive air conditioning and other air conditioning sstems from 2011 onwards. According to this it will ban potent greenhouse gases such as the refrigerant to promote safe and energy-efficient refrigerants as HFC-134a—which has a GWP of 1410. The natural refrigerant CO2 (R-744)is the most promising alternative. Carbon dioxide is toxic and potentially lethal in concentrations above 5% by volume non-flammable, non-ozone depleting, has a global warming potential of 1. For cars, residential air conditioning, hot water pumps, commercial refrigeration, and vending machines R-744 can be used as a working fluid in climate control systems. Spray Water with Recirculation and Heating or Cooling To achieve the desired air condition Spray-type humidifiers may use heating or cooling equipment. The heat supplied to or gained from the system is: The ADP (Apparatus Dew-Point Temperature) will be higher than the adiabatic process when the heat is supplied to the system. The contact factor of humidification depends on the process line. In some cases the increase in moisture content is accompanied by sensible cooling and in some others by sensible heating. The ADP (Apparatus Dew-Point Temperature) will be higher than the adiabatic process when the heat is supplied to the system. The contact factor of humidification depends on the process line. In some cases the increase in moisture content is accompanied by sensible cooling and in some others by sensible heating. METALLURGY AND MANUFACTURING Metallurgy today is an applied science. Its fascination lies in the challenge of using science to give mankind the best engineering materials that the laws of nature and the Earth's natural resources will allow. The applied science of metallurgy links the science of metals to the metal industries. This link is only maintained and strengthened by deliberate care and attention, for there is always a tendency for the scientific and industrial sides to drift apart. to commit himself totally to the electrical characteristics of these materials are extremely sensitive to the presence of minute concentrations of impurity atoms, which concentrations may be controlled over very small spatial regions is as natural for the research man. The advent of integrated circuitry that has totally revolutionized the electronics and computer industries and semiconductors have made possible. Read the full article

0 notes

Text

Improve Cooling Efficiency with a Direct Evaporative Cooling System

As energy costs rise, businesses are turning to Direct Evaporative Cooling Systems to maintain optimal temperatures while reducing electricity consumption. These systems use water evaporation to cool the air efficiently, making them ideal for industrial and commercial applications.

Compared to traditional air conditioning, Direct Evaporative Cooling offers a sustainable and cost-effective alternative, improving air quality and reducing carbon footprints. Companies looking for effective cooling solutions should consider this innovative technology.

2. Why an Indirect Evaporative Cooler is a Smart Choice for Large Spaces

A Indirect Evaporative Cooler is perfect for spaces that require efficient cooling without adding excess humidity. Unlike direct cooling systems, indirect coolers use heat exchangers to deliver fresh, cool air without moisture buildup.

This makes them highly effective for offices, data centers, and commercial facilities where air quality is crucial. Businesses investing in these cooling systems can benefit from lower energy bills and a healthier work environment.

3. The Benefits of an Adiabatic Cooler for Industrial Applications

An Adiabatic Cooler is designed to provide maximum cooling efficiency with minimal energy use. These systems leverage the natural process of water evaporation to lower temperatures, making them ideal for industrial and warehouse applications.

By integrating an adiabatic cooling system, businesses can improve productivity, reduce maintenance costs, and create a comfortable working environment while significantly cutting down on energy expenses.

4. How to Choose the Best Industrial Air Cooler at the Right Price

When selecting an industrial air cooler, understanding the Industrial Air Cooler Price is essential to making a cost-effective decision. Factors such as cooling capacity, airflow rate, and energy efficiency play a crucial role in determining the right system for your needs.

Heavy-duty air coolers, like those from Breezair, provide powerful cooling performance, making them a great investment for factories, warehouses, and outdoor cooling applications. Choosing a high-quality air cooler ensures long-term savings and superior cooling performance.

0 notes

Text

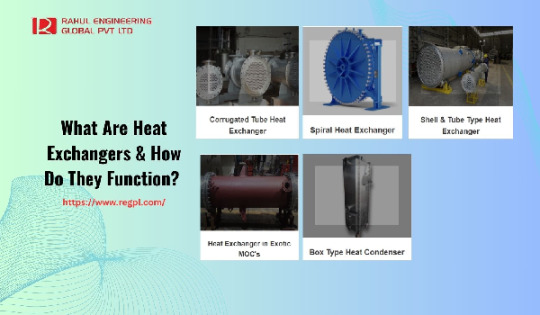

What Are Heat Exchangers & How Do They Function?

Heat exchangers also known as heat transfer systems do what the term involves. They change the temperature of liquids that pass through them. The significant to heat exchangers is the large superficial capacity of copper tubes. Heat is transferred quickly in liquids and gases by conductive and convective mechanisms. Cooling tower manufacturers have found a process to harness this natural phenomenon to provide efficient cooling for industrial uses

What Is A Heat Exchanger?

A heat exchanger is a method that transfers heat from one fluid to additional. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. There are certain categories of heat exchangers, containing the shell-and-tube type, plate type, and tubular finned tube type.

How Does A Heat Exchanger Work?

A heat exchanger is a device that transmissions heat from one fluid to extra. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. A heat exchanger transfers heat from one fluid stream to another through straight physical contact between the dual streams. The main change amid unlike types of heat exchangers is how they are constructed and what type of fluids they use.

For example, a steam producer uses steam as together its contribution and output fluid streams. It consists of tubing coils covering fine tubes called finned tubes with fins attached along their length, so they resemble small radiators. Vapor reaches at one end and departures at the further after being cooled by an outside average, such as water or air passing over these finned tubes inside the coil.

Types of Heat Exchangers

Heat exchangers are plans that transfer heat from one medium to additional. They are used in many uses, including the cooling of engines, gas condensing, and even water heating.

In a heat transfer system, two fluids flow previous each previous. One fluid must be hot, and the additional must be cold. The two fluids should not mix together, so they should have dissimilar densities and viscosities (properties that affect how easily they flow). When they meet inside a manufacturing exchanger, they exchange their heat but not their mass; this is called “adiabatic” exchange (meaning no work was done by friction).

1. Shell & Tube Type Heat Exchanger:

The shell and tube heat exchanger is a widely used design consisting of a cylindrical shell with a bundle of tubes inside. Fluid flows through the tubes, while another fluid surrounds the tubes in the shell. This design allows efficient heat transfer, making it suitable for various industrial applications such as chemical processing and power generation.

2. Corrugated Tube Heat Exchanger:

Corrugated tube heat exchangers feature tubes with a corrugated surface, enhancing heat transfer efficiency. The corrugation disrupts laminar flow, promoting turbulence and improving heat exchange rates. This design is employed in applications where maximizing heat transfer in a compact space is crucial, like HVAC systems and certain chemical processes.

3. Spiral Heat Exchanger:

The spiral heat exchanger has a unique spiral flow path for two fluids, preventing mixing while facilitating efficient heat transfer. Its compact and self-cleaning design makes it suitable for applications with fouling or high-viscosity fluids. Industries like wastewater treatment and pharmaceuticals benefit from the spiral heat exchanger's versatility.

4. Box Type Heat Condenser:

The box type heat condenser is a compact and straightforward design where a fluid undergoes a phase change, typically from vapor to liquid, releasing heat in the process. This type of heat exchanger is commonly used in refrigeration and air conditioning systems, as well as industrial processes requiring condensation.

5. Heat Exchanger in Exotic MOC's (Materials of Construction):

Heat Exchanger in Exotic MOC's can be constructed from exotic materials to withstand corrosive or extreme operating conditions. Exotic MOC's, such as titanium, Hastelloy, or graphite, offer superior resistance to chemical corrosion. These specialized heat exchangers find applications in industries like petrochemicals, pharmaceuticals, and metallurgy where standard materials may not suffice.

Industrial Exchangers

Heat exchangers are used in numerous trades, including oil and gas, chemical, petrochemical, pharmaceutical, and power generation. They can be found in thermal plants, refineries and power stations, and former manufacturing procedures.

Heat exchangers are recycled for heating or cooling fluids or gases. These fluids may be liquids or gases. Heat exchangers are usually used to transport heat from one place to another by changing the heat of one fluid using additional fluid.

Call rahul engineering global pvt ltd today!

Heat exchangers are used to transfer energy concerning double varied forms. The most joint heat exchangers repaired in transporting thermal energy transferred between different fluids in a heat exchange progression. Heat exchangers are allocated into two major classes: “condensers” and “evaporators.” Condensers use steam, while evaporators use air circulated past electrically or gas-fired coils or added reheating devices to transfer heat energy.

Read on to learn more about heat exchangers and their purpose from rahul engineering global pvt ltd

#heatexchangers#bestheatexchangers#heatexchangermanufacture#heatexchangerssupplier#topheatexchangers#regpl#heatexchangersinchakan#heatexchangersinpune

0 notes

Text

Air Conditioner Repair Guide 2023 - hvac

This system normally has a warm exchanger coil, the compressor, and the growth shutoff. It looks and runs similarly as the exterior portion of an air-conditioner. To install the heat pump water heater you have to change the old hot water heater with a brand-new device which is rather costly. The price of the brand-new system may be a lot more than the present water heater.

Heat pumps are ridiculously efficient with the electricity they utilize-- so they can cut your wintertime energy waste pretty significantly and be an extra budget friendly means to heat a home. Prior to we dive into the pros and cons of each choice, it is very important to understand a little about how heatpump and heater technology works-- because they're extremely different. Your well and pump combination need to be huge enough to provide the water required by the heat pump along with your residential water requirements.

Your service provider or tools manufacturer can inform you what degree of water high quality is acceptable and under what situations special heat-exchanger products might be needed. In addition to yearly maintenance, there are a few simple things you can do to ensure dependable and reliable procedures. Make certain to transform or cleanse your air filter every 3 months, as clogged filters will certainly reduce air flow and reduce the efficiency of your system. Additionally, be sure that vents and air registers in your house are not obstructed by furniture or carpets, as poor air movement to or from your unit can shorten tools life-spans and minimize efficiency of the system.

Warm input can be improved if the cooling agent enters the evaporator with a reduced vapor material.

One more way to release the used water is through a denial well, which is a second well that returns the water to the ground.

Both heating & cooling are possible with an incredibly low degree of audio during operation.

Once this is done, you can forget about the thermostat; it will automatically change the system from home heating to cooling down setting or vice versa.

One negative aspect of the subcooling of fluids is that the distinction between the condensing temperature level and the heat-sink temperature level must be larger.

A performance basic specifies examinations and test conditions at which heat pump heating and cooling down capacities and performance are established. The efficiency testing requirements for ground-source systems are CSA C13256 (for hvac secondary loop systems) and CSA C748 (for DX systems). The "energetic cooling" cycle is essentially the reverse of the heating cycle. The refrigerant grabs warmth from the house air and transfers it directly, in DX systems, or to the ground water or antifreeze mixture. The heat is then pumped outside, into a water body or return well (in an open system) or into the below ground piping (in a closed-loop system).

The compressed, fluid cooling agent, in the thermodynamic state known as a saturated fluid, is following transmitted through an expansion shutoff where it undertakes an abrupt reduction in stress. That stress decrease results in the adiabatic flash evaporation of a component of the liquid cooling agent. Advantages of electrical furnaces include their reduced in advance cost and the fact that they are relatively simple to set up.

Choose Your Country/region For Detailed Item Information

This enables the heatpump to run a lot more successfully, with regular effectiveness more than 100%, i.e. extra thermal energy is generated than the amount of electrical power utilized to pump it. Picking the resource and sink for your heatpump system goes a lengthy way in establishing the performance, resources expenses and running prices of your system. This section supplies a brief overview of common sources and sinks for residential applications in Canada. As part of ongoing improvement, the HVAC industry is in the process of transitioning to using a brand-new refrigerant in freshly produced devices, including a/c unit and heatpump. It's called R-454B and is extra lasting than one of the most current cooling agent, R-410A. If you count on your own among that number, you might not know there's an energy-efficient choice for warming your home or water-- heat pumps.

Break Out Awesome Air, And Save Lots Of Power!

It is necessary to deal with your contractor or power advisor to obtain an estimate of the business economics of heatpump in your area, and the potential cost savings you can attain. Similar to air-source heat pump systems, ground-source heatpump have to be made and mounted by certified service providers. Speak with a local heatpump specialist to style, mount and service your equipment to make certain reliable and dependable procedure. Likewise, make sure that all makers' guidelines are complied with very carefully. All installments need to satisfy the demands of CSA C448 Series 16, a setup standard set by the Canadian Specifications Organization. The interior coil is where heat is moved to/from indoor air in specific types of air-source heat pumps.

Nonetheless, electrical furnaces are the least effective sort of heating system, which indicates they can be extremely expensive to run over time. Generally talking, it is not necessary to update the electrical service when installing an air-source add-on heatpump. Nonetheless, the age of the solution and the overall electric load of the house may make it required to upgrade. They are untouched by chemicals found in dirt and have excellent heat-conducting residential properties.

An Air Source Heat Pump Hot Water Heater (ASHPWH) from V-Guard is the best service for readily available hot water. To make sure better energy financial savings, lengthy product life, and convenience, Daikin uses these solutions. Tough and trusted Scroll compressor with high efficiency heat exchanger - reputable and sturdy. The heat pump is the far better alternative for many homeowners, mainly because it's exceptionally efficient and can replace all your various other HVAC devices, also.

For how long do heat pumps last?

Heatpump usually last an average of 15 years, though some can break after a decade. Some of the more recent units being made today can last a bit much longer. The aspect most important in determining the lifespan of your heatpump is maintenance.

For The Length Of Time Do Heatpump Water Heaters Function?

Some heatpump might not last as long if they are not appropriately kept. Given that you use a heat pump year-round for heating & cooling, upkeep is essential. The initial type controls the operation of the electrical resistance additional heating unit. This is the same sort of thermostat that is utilized with an electrical furnace. It turns on different phases of heating systems as the outside temperature level drops progressively reduced. This ensures that the right quantity of supplementary warmth is provided in reaction to outdoor conditions, which takes full advantage of efficiency and conserves you cash.

Tyger Mechanical Solutions

youtube

+15199160882

0 notes

Text

The Efficient Solution for Cooling: Direct and Indirect Evaporative Cooling Systems

As energy efficiency and environmental sustainability take center stage, innovative cooling technologies are becoming the preferred choice for homes and businesses alike. Among these solutions, evaporative cooler air conditioners, direct evaporative cooling systems, and adiabatic coolers stand out for their ability to provide effective cooling while reducing energy consumption.

This article explores how these systems work, their advantages, and their applications in various settings.

What Is an Evaporative Cooler Air Conditioner?

An Evaporative Cooler Air Conditioner is a cooling device that harnesses the natural process of water evaporation to reduce air temperature. Unlike traditional air conditioners, which rely on refrigerants and compressors, evaporative coolers operate using water and airflow, making them more eco-friendly and energy-efficient.

Key Benefits:

Energy Savings: Consumes up to 90% less energy than conventional AC systems.

Environmentally Friendly: Avoids the use of harmful refrigerants, reducing greenhouse gas emissions.

Improved Air Quality: Filters out dust and allergens while adding a touch of moisture to dry air.

Direct Evaporative Cooling Systems: A Closer Look

A direct evaporative cooling system works by drawing warm air through water-saturated pads. As the air passes through, the water evaporates, absorbing heat and significantly lowering the temperature.

How It Works:

Warm air is pulled into the system.

Air passes through wet cooling pads.

The evaporation process cools the air.

The cooled air is distributed into the space.

Ideal Applications:

Residential Spaces: Particularly effective in dry climates where humidity levels are low.

Industrial Settings: Perfect for large open spaces like warehouses and factories.

Outdoor Cooling: Great for patios, sports facilities, and event venues.

However, direct systems increase indoor humidity, which may not be suitable for regions with already high moisture levels.

Understanding Adiabatic Coolers

An adiabatic cooler is another term for an evaporative cooling system, emphasizing its reliance on the adiabatic process. This process involves cooling air through water evaporation without adding external energy, apart from that needed for air movement.

Advantages of Adiabatic Cooling:

Low Operating Costs: Minimal energy requirements lead to significant savings.

Sustainable Cooling: Uses natural evaporation processes, aligning with green building initiatives.

Scalability: Suitable for a range of applications, from residential to industrial cooling.

Key Use Cases:

Data Centers: Maintains optimal temperatures for sensitive equipment.

Commercial Buildings: Provides large-scale cooling while minimizing energy usage.

Greenhouses: Creates a controlled environment for plants without harsh temperature drops.

Conclusion

Whether you're considering a direct evaporative cooling system for your home, an adiabatic cooler for an industrial setup, or an evaporative cooler air conditioner for a small office, these technologies offer numerous benefits. They combine environmental responsibility with practicality, making them a smart choice for the future of cooling.

Ready to embrace efficient, eco-friendly cooling? Explore the options and discover how evaporative cooling can transform your space while benefiting the planet.

0 notes

Text

Adiabatic Cooling System | Evaporative Pre Cooling System Manufacturer, Suppliers in Africa

#Adiabatic Cooling System in Africa#adiabatic cooling process#adiabatic cooling kit#Evaporative pre-cooling system#evaporative cooling system manufacturers in Africa#evaporative cooling system suppliers in Africa#evaporative cooling system exporter in Africa#Adiabatic Cooling System manufacturers in Africa#Adiabatic Cooling System suppliers in Africa#Adiabatic Cooling System exporter in Africa#adiabatic cooling system Companies in Africa#air cooled condensers#https://mistcoolingsystemsafrica.com/portfolio/adiabatic-cooling-system-evaporative-pre-cooling-system

0 notes

Text

How Nscale Strengthens AI Cloud Infrastructure in Europe

Nscale Technology

The AI-engineered hyperscaler. Use the AI cloud platform to access thousands of GPUs customized to your needs.

Features of Nscale

A fully integrated suite of AI services and compute

Utilize a fully integrated platform to manage your AI tasks more effectively, save expenses, and increase income. It platform is intended to make the process of going from development to production easier, regardless of whether you’re using your own AI/ML tools or those that are integrated into Nscale.

Turnkey AI creation and implementation

Users may access a variety of AI/ML tools and resources via the Nscale Marketplace, making model building and deployment effective and scalable.

Dedicated training clusters ready to go

The optimized GPU clusters from its are designed to increase efficiency and shorten model training durations. For a stable infrastructure solution that makes it easy to install, manage, and expand containerized workloads, make the most of Slurm and Kubernetes.

Setting a new standard for inference

Get access to quick, inexpensive, and self-scaling AI inference infrastructure. Using the fast GPUs and sophisticated orchestration tools, it has optimized each tier of the stack for batch and streaming workloads, allowing you to scale your AI inference processes while preserving optimal performance.

Scalable, flexible AI Compute

With the help of cutting-edge cooling technologies, Nscale’s GPU Nodes provide high-performance processing capability designed for AI and high-performance computing (HPC) activities.

Nscale Enhances AI Cloud Infrastructure in Europe

Nscale‘s Glomfjord data center in Norway has showcased its latest GPU cluster, powered by AMD Instinct MI250X accelerators. The world’s best supercomputers use AMD Instinct MI250X GPUs to speed HPC workloads and satisfy AI inference, training, and fine-tuning needs.

It Glomfjord data center, near Norway’s Arctic Circle, enhances energy efficiency by employing local cooling. Innovative adiabatic cooling and 100% renewable energy enable efficient operations, scalable solutions, and an ecologically friendly footprint for the data center.

Nscale is one of the least expensive AI training centers as it has access to some of the most affordable renewable electricity in the world. It are able to provide high-performance, sustainable AI infrastructure faster and more affordably than it rivals because to the vertical integration and inexpensive electricity.

Experts in moving from CUDA to ROCm

It might be difficult to switch your workload from CUDA to ROCm. The staff at Nscale offers the assistance and direction required to ensure a seamless and effective transfer process. To live cluster is prepared for you to experience the potent capabilities of AMD Instinct accelerators, whether you’re wanting to investigate the performance advantages of MI250X or getting ready for the impending release of MI325X.

Built for AI Workloads

The most complex AI workloads may be readily supported by the vertically integrated platform. It offers sophisticated inference services, SLURM-powered AI task scheduling, bare metal and virtualized GPU nodes, and Kubernetes-native services (NKS).

GPU Nodes

The virtualized and bare metal GPU nodes from Nscale are designed for users that want high-performance computing without sacrificing any quality. Your teams can concentrate on creativity while it take care of the complexity with one-click deployment, which lets you set up your infrastructure in a matter of minutes.

For both short-term and long-term projects, it solution guarantees optimal performance with little overhead, whether it is in AI training, deep learning, or data processing.

Nscale’s Kubernetes (NKS)

Using Nscale’s GPU-powered computation, containerized applications may be deployed in a controlled environment using Nscale‘s Kubernetes Service (NKS). The service enables you to rapidly supply worker nodes for expanding AI workloads and offers a highly available control plane.

As a result, cloud-native AI applications may be deployed, scaled, and managed without the hassle of maintaining the supporting infrastructure.

Nscale SLONK

You may utilize and administer your own high-performance computing cluster in the cloud with Nscale SLONK. A wide variety of scientific workloads, including large-scale simulations and AI/ML training, may be scheduled, executed, and monitored using its batch environment and extensive portfolio of AI/ML and HPC tools.

The AI Workload Scheduler is powered by Nscale’s Infrastructure Services. The batch task scheduler SLURM provides access to the computer resources. A combination of open-source and proprietary software makes up the software environment.

Nscale Inference Service

One platform for implementing AI and ML models is the Nscale Inference Service. Developed using Kubernetes and KServe, it makes use of state-of-the-art horizontal and vertical scaling strategies that allow for cost reductions and effective hardware utilization. Its goal is to make the process of putting models into production as efficient as possible.

It offers unparalleled flexibility and control over cost and performance by supporting both serverless and managed computing installations.

Expanding It Reach

Nscale can provide custom GPU clusters at any size because to its expanding pipeline of 1GW+ greenfield facilities in North America and Europe. It are able to provide top-notch infrastructure that satisfies the demands for AI training, fine-tuning, and inference at a reasonable cost and scale because to this capability and it strategic partnerships with leading companies in the sector, including AMD.

With Nscale, you can satisfy sustainability objectives, save expenses, and have a strong, scalable AI infrastructure that expands to match business demands.

Read more on Govindhtech.com

#Nscale#AI#NscaleTechnology#ML#GPUs#AICloud#AMDInstinctMI250X#ROCm#GPUnodes#HPC#News#Technews#Technology#Technologynews#Technologytrends#govindhtech

0 notes

Text

Sify’s Green Data Centers: Pioneering Sustainable IT Infrastructure

As global industries increasingly focus on sustainability and environmental responsibility, data centers—critical to the functioning of our digital economy—have come under scrutiny for their energy consumption and environmental impact. In response, Sify has taken a leadership role in driving sustainability with its Green Data Centers, setting new standards for eco-friendly, efficient IT infrastructure. Sify’s green initiatives not only reduce carbon footprints but also offer businesses a path to achieving their sustainability goals while ensuring high-performance data solutions.

What Are Green Data Centers?

Green Data Centers are designed to minimize environmental impact by utilizing energy-efficient technologies, renewable energy sources, and sustainable practices throughout their operations. They aim to significantly reduce power consumption, limit greenhouse gas emissions, and lower water usage while maintaining the high performance and security that modern businesses require.

Sify's Green Data Centers are a testament to its commitment to eco-conscious innovation, combining technological advancements with sustainability to provide state-of-the-art infrastructure for enterprises.

Key Features of Sify’s Green Data Centers

1. Energy Efficiency

Sify’s Green Data Centers are built with energy efficiency at their core. Advanced cooling systems, energy-efficient servers, and optimized layouts reduce the power usage effectiveness (PUE) to industry-leading levels. This means more of the energy consumed by the data center is used for computing tasks rather than cooling or other auxiliary processes. Additionally, Sify leverages automation and AI-driven systems to monitor and optimize energy usage in real-time.

2. Renewable Energy Integration

A key element of Sify’s sustainability strategy is the integration of renewable energy sources. Sify’s Green Data Centers are powered, in part, by renewable energy such as solar and wind, reducing reliance on fossil fuels. This approach not only cuts carbon emissions but also contributes to long-term cost savings, benefiting both Sify and its clients.

3. Water Conservation

Water usage is a significant concern for traditional data centers, particularly in their cooling processes. Sify addresses this by implementing innovative water-saving technologies, such as adiabatic cooling systems, that use minimal water while still providing effective temperature regulation. Additionally, Sify’s data centers utilize rainwater harvesting and water recycling systems to minimize freshwater consumption.

4. Sustainable Design and Construction

Sify’s Green Data Centers are built with sustainability in mind, from the construction materials used to the overall architectural design. The facilities are designed to maximize natural airflow and reduce the need for artificial lighting and air conditioning. Green building certifications, such as LEED (Leadership in Energy and Environmental Design), are pursued for each facility to ensure adherence to the highest environmental standards.

5. Carbon Footprint Reduction

Through its use of renewable energy, efficient cooling systems, and smart resource management, Sify significantly reduces the carbon footprint of its data centers. This allows clients to align their IT infrastructure with their sustainability goals, helping them lower their Scope 3 emissions and contribute to the global fight against climate change.

6. Circular Economy Approach

Sify is committed to reducing waste and promoting resource efficiency. This is reflected in the company’s use of recyclable materials, the repurposing of obsolete IT equipment, and the careful management of electronic waste. By adopting a circular economy approach, Sify minimizes the environmental impact of its operations throughout the data center lifecycle.

Benefits of Sify’s Green Data Centers for Businesses

1. Cost Efficiency

Energy-efficient operations and the integration of renewable energy sources lead to significant cost savings over time. By reducing energy consumption and operational costs, Sify’s Green Data Centers provide clients with sustainable IT solutions that are not only environmentally responsible but also economically advantageous.

2. Compliance with Environmental Regulations

Businesses are increasingly being held accountable for their environmental impact by both consumers and regulators. Sify’s Green Data Centers help clients stay compliant with growing environmental regulations and sustainability standards, offering a pathway to meet green certifications, carbon reduction targets, and corporate social responsibility (CSR) goals.

3. Enhanced Corporate Reputation

Operating through Sify’s Green Data Centers allows companies to showcase their commitment to sustainability, which is increasingly valued by customers, investors, and stakeholders. Businesses that align with eco-friendly practices are often perceived more positively, which can improve brand reputation and customer loyalty.

4. Scalability and Future-Readiness

While being eco-friendly, Sify’s Green Data Centers do not compromise on performance. They offer scalable, high-performance solutions that can support growing workloads, enabling businesses to expand their IT infrastructure without increasing their environmental footprint. Additionally, Sify’s continuous investment in green technologies ensures that its data centers remain future-ready, adapting to the latest advancements in sustainable IT.

5. Contributing to Global Sustainability Goals

By partnering with Sify’s Green Data Centers, businesses can actively contribute to global sustainability initiatives, such as the United Nations’ Sustainable Development Goals (SDGs) and international efforts to combat climate change. This partnership enhances their environmental, social, and governance (ESG) credentials and positions them as leaders in sustainability.

Sify’s Vision for a Sustainable Future

Sify’s Green Data Centers are more than just a technological innovation—they are part of a larger vision to build a more sustainable and resilient future. By continuing to push the boundaries of green technology and sustainability in the data center space, Sify is helping businesses reduce their environmental impact while enhancing their digital capabilities.

Sify is dedicated to the responsible management of natural resources, and its green initiatives represent a significant step towards a low-carbon, eco-friendly future. With a commitment to innovation, efficiency, and sustainability, Sify’s Green Data Centers are leading the way in transforming the IT infrastructure landscape.

Sify’s Green Data Centers offer a unique combination of high-performance IT infrastructure and environmentally sustainable practices. By investing in energy-efficient technologies, renewable energy sources, and water conservation, Sify ensures that businesses can meet their growing data needs without compromising the environment. As sustainability becomes a critical business priority, Sify stands out as a forward-thinking partner, enabling organizations to achieve both digital transformation and environmental responsibility.

0 notes

Text

The Magic of Evaporative Cooling Systems

The Magic of Evaporative Cooling Systems

In the realm of cooling technologies, one system stands out for its simplicity and effectiveness: the Evaporative Cooling System. This system, also known as adiabatic cooling, is a marvel of engineering that uses the natural process of water evaporation to cool air to a comfortable temperature.Get more news about Evaporative Cooling System,you can vist our website!

The principle behind an Evaporative Cooling System is straightforward. It exploits the fact that when water evaporates, it absorbs heat from its surroundings, thereby cooling the air. This process is the same one that makes you feel cool when you step out of a shower or when sweat evaporates from your skin.

An Evaporative Cooling System typically consists of a fan and a water-soaked pad. As the fan draws air through the pad, the water in the pad evaporates, which cools the air before it is circulated throughout the space2. This simple yet effective system can significantly reduce the temperature of a room or building, making it a popular choice in hot, dry climates.

One of the key advantages of an Evaporative Cooling System is its energy efficiency. Unlike traditional air conditioning systems, which use refrigerants and consume a significant amount of electricity, an Evaporative Cooling System uses water as its refrigerant and consumes much less energy. This makes it a more environmentally friendly option for cooling.

Another advantage is that an Evaporative Cooling System adds moisture to the air, which can be beneficial in dry climates. In contrast, traditional air conditioning systems can make the air dry, which can lead to discomfort, especially for people with dry skin or respiratory issues.

Despite its many advantages, an Evaporative Cooling System is not suitable for all environments. It works best in hot, dry climates where the air has low humidity3. In humid climates, the air is already saturated with moisture, so the water in the system does not evaporate as easily, reducing the cooling effect.

In conclusion, an Evaporative Cooling System is a simple, effective, and energy-efficient solution for cooling in hot, dry climates. It uses the natural process of water evaporation to cool the air, providing comfort while consuming less energy and adding moisture to the air. However, it is not suitable for humid climates, where its cooling effect is reduced. Despite this limitation, the Evaporative Cooling System remains a testament to the power of simple, natural processes harnessed by clever engineering.

0 notes

Text

OUR PRODUCTS:

Adiabatic Cooling System For Chillers

Automatic Tube Cleaning System

Scale & Bio Remover

Electrolytic Scale Remover

Non-Chemical Water Treatment for Cooling Tower

Hydronic System

Adiabatic Pre Cooling System

#Automatic Tube Cleaning System#Adiabatic Cooling System For Chillers#Cooling Tower Water Treatment System#Electrochemical Treatment System#Electrolytic Scale Remover

0 notes