#regpl

Explore tagged Tumblr posts

Text

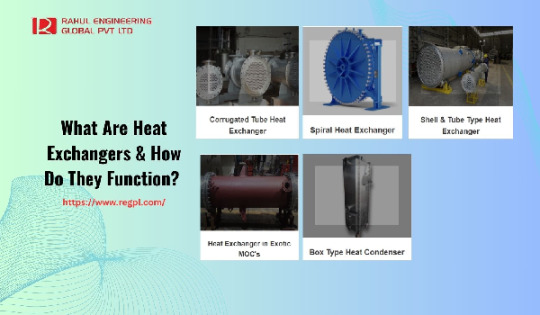

What Are Heat Exchangers & How Do They Function?

Heat exchangers also known as heat transfer systems do what the term involves. They change the temperature of liquids that pass through them. The significant to heat exchangers is the large superficial capacity of copper tubes. Heat is transferred quickly in liquids and gases by conductive and convective mechanisms. Cooling tower manufacturers have found a process to harness this natural phenomenon to provide efficient cooling for industrial uses

What Is A Heat Exchanger?

A heat exchanger is a method that transfers heat from one fluid to additional. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. There are certain categories of heat exchangers, containing the shell-and-tube type, plate type, and tubular finned tube type.

How Does A Heat Exchanger Work?

A heat exchanger is a device that transmissions heat from one fluid to extra. The fluid may be a gas or liquid, which can transmission heat by convection, conduction, or radiation. A heat exchanger transfers heat from one fluid stream to another through straight physical contact between the dual streams. The main change amid unlike types of heat exchangers is how they are constructed and what type of fluids they use.

For example, a steam producer uses steam as together its contribution and output fluid streams. It consists of tubing coils covering fine tubes called finned tubes with fins attached along their length, so they resemble small radiators. Vapor reaches at one end and departures at the further after being cooled by an outside average, such as water or air passing over these finned tubes inside the coil.

Types of Heat Exchangers

Heat exchangers are plans that transfer heat from one medium to additional. They are used in many uses, including the cooling of engines, gas condensing, and even water heating.

In a heat transfer system, two fluids flow previous each previous. One fluid must be hot, and the additional must be cold. The two fluids should not mix together, so they should have dissimilar densities and viscosities (properties that affect how easily they flow). When they meet inside a manufacturing exchanger, they exchange their heat but not their mass; this is called “adiabatic” exchange (meaning no work was done by friction).

1. Shell & Tube Type Heat Exchanger:

The shell and tube heat exchanger is a widely used design consisting of a cylindrical shell with a bundle of tubes inside. Fluid flows through the tubes, while another fluid surrounds the tubes in the shell. This design allows efficient heat transfer, making it suitable for various industrial applications such as chemical processing and power generation.

2. Corrugated Tube Heat Exchanger:

Corrugated tube heat exchangers feature tubes with a corrugated surface, enhancing heat transfer efficiency. The corrugation disrupts laminar flow, promoting turbulence and improving heat exchange rates. This design is employed in applications where maximizing heat transfer in a compact space is crucial, like HVAC systems and certain chemical processes.

3. Spiral Heat Exchanger:

The spiral heat exchanger has a unique spiral flow path for two fluids, preventing mixing while facilitating efficient heat transfer. Its compact and self-cleaning design makes it suitable for applications with fouling or high-viscosity fluids. Industries like wastewater treatment and pharmaceuticals benefit from the spiral heat exchanger's versatility.

4. Box Type Heat Condenser:

The box type heat condenser is a compact and straightforward design where a fluid undergoes a phase change, typically from vapor to liquid, releasing heat in the process. This type of heat exchanger is commonly used in refrigeration and air conditioning systems, as well as industrial processes requiring condensation.

5. Heat Exchanger in Exotic MOC's (Materials of Construction):

Heat Exchanger in Exotic MOC's can be constructed from exotic materials to withstand corrosive or extreme operating conditions. Exotic MOC's, such as titanium, Hastelloy, or graphite, offer superior resistance to chemical corrosion. These specialized heat exchangers find applications in industries like petrochemicals, pharmaceuticals, and metallurgy where standard materials may not suffice.

Industrial Exchangers

Heat exchangers are used in numerous trades, including oil and gas, chemical, petrochemical, pharmaceutical, and power generation. They can be found in thermal plants, refineries and power stations, and former manufacturing procedures.

Heat exchangers are recycled for heating or cooling fluids or gases. These fluids may be liquids or gases. Heat exchangers are usually used to transport heat from one place to another by changing the heat of one fluid using additional fluid.

Call rahul engineering global pvt ltd today!

Heat exchangers are used to transfer energy concerning double varied forms. The most joint heat exchangers repaired in transporting thermal energy transferred between different fluids in a heat exchange progression. Heat exchangers are allocated into two major classes: “condensers” and “evaporators.” Condensers use steam, while evaporators use air circulated past electrically or gas-fired coils or added reheating devices to transfer heat energy.

Read on to learn more about heat exchangers and their purpose from rahul engineering global pvt ltd

#heatexchangers#bestheatexchangers#heatexchangermanufacture#heatexchangerssupplier#topheatexchangers#regpl#heatexchangersinchakan#heatexchangersinpune

0 notes

Text

A Guide to Understanding the Design and Applications of the Box Type Condenser: An Exploration

The box-type condensers are very essential in the thermal management of various industrial and commercial applications, wherein they are simply referred to as box-type condensers or merely condensers in HVAC systems. Let's find out the features and uses of box-type condensers and why they are important for HVAC systems.

What are box-type Type Condensers? Box-type condensers are modules in air conditioning and refrigeration systems used to abbreviate refrigerant vapor into liquid. They got the name "box type" because of their normally enclosed, small design that wraps up all the parts requisite for concentration and heat exchangers.

How do they function? Heat Exchanger: Box-type condensers work with the principle of heat exchanger. The hot refrigerant vapor from the compressor enters the condenser coils in the box-type unit. Condensation: Depending on the condenser type, heat is lost by the refrigerant vapor while it is traveling through coils and abbreviating into liquid form. Cooling: During condensation, latent heat from the refrigerant is given out and dissipated through the fins or tubes into the condenser. As a result, the refrigerant can be cooled again and set up to start the cycle. Key Features and Components Coils: Inside the condenser box, these are normally copper or aluminum and effectively conduct the heat from the refrigerant to the surrounding medium. Fans of Water Flow: In an air-cooled system, box condensers are fitted with fans that force the ambient air over the coils, while in a water system, they are cooled by having the water flow through the coils. Enclosure: The process guides air or water flow via the condenser coils in a box-type condenser and ensures the enclosure protects all the interior components and promotes effective heat exchanger performance. Applications Box-type condensers for integral components in many HVAC applications include commercial refrigeration. Low-temperature refrigeration systems are used in supermarkets, restaurants, and cold storage facilities. Air conditioning systems form a huge part of domestic and commercial air conditioners, which help make indoor temperatures bearable by extracting heat. It finds applications in chemical processing and manufacturing facilities, and industrial cooling is used where exact temperature control is required in processes. Heat Pumps: Box-type condensers play a crucial role in heat pumps by facilitating the transfer of heat between different environments. Considerations When choosing or maintaining box-type condensers, considerations include: Ensure that the size and capacity suit the air conditioning or refrigeration system in which it is installed. Maintenance: Cleanliness of coils and fans should be ensured to gain maximum heat transfer efficiency and extend the life of the condenser. Environmental Factors: This condenser will work best considering the outside variables like humidity and ambient temperature. Conclusion Box-type condensers have uppermost importance in every HVAC system; in their absence, no effective heat transfer and standard functioning of the air conditioning or refrigeration systems could be sought. Notwithstanding their small size, their efficient heat exchanger properties make them perfect in service for innumerable uses in different sectors of the economy. By selecting the appropriate condenser regarding the requirements and understanding of how it works, a guarantee is given for full, reliable, and efficient operation of the thermal management systems. Rahul Engineering Global Pvt. Ltd. specializes in providing advanced and high-quality box-type condensers in Pune, India, solutions for various industries.

0 notes

Text

What is a Chemical Reactor?

A chemical reactor is an enclosed capacity in which a chemical answer invoices home. In chemical engineering, it's commonly implicit to be a procedure vessel used to carry out a chemical reply, which is one of the classic unit operations in chemical process analysis. Chemical reactors are used in multiplex manufacturing processes. Though, they've certain limitations that you must keep in mind. Flow rate of reactants can be precisely skillful and the creation inclines to be of advanced quality than in batch operations. They also allow fever to be kept ceaseless added willingly.

The Advantages of Using Chemical Reactors for Manufacturing Processes

Chemical reactors are a vital part of accoutrements in legion mechanical processes, from chemical affair to food processing. These machines are designed to ease chemical answers between different outfit, creating new admixtures or altering the chattels of existing bones. The use of chemical reactors offers several advantages for mechanical employments. Chemical reactors are used in a variety of processes to change reactants into produces. They're the heart of any chemical factory. It's essential to have the right reactor for your process. The type of response, chemistry, and operating conditions determine which reactor is the elegant for you. The right choice of a reactor will help you increase the productiveness and profitability of your manufactory. You can buy chemical reactors from fat record at a competitive price.

Reactors come in different designs and sizes. There are batch, nonstop, and circle reactors. Batch reactors are the simplest and contain a demagogue. They also have jackets where serviceability can be applied to heat or cool the response mass. They're generally used to prepare chemicals and in the pharmaceutical assiduity. Nonstop and circle reactors are more advanced than batch reactors. These reactors can run as a nonstop operation, and they can control the hearthstone time. The product feature is better-quality than that of a batch reactor. They also bear lower volume to achieve the same position of conversion.

Chemical Reactors Can Help Improved Product Quality

Chemical reactors can help ameliorate the quality of products produced in artificial processes. By precisely controlling the conditions within the reactor, similar as temperature, pressure, and response time, manufacturers can insure that the asked chemical responses do with maximum effectiveness. This can lead to advanced yields, better product thickness, and smaller contaminations.

Chemical Reactors Can Enhanced Safety and effectiveness

The use of chemical reactors can also enhance safety and effectiveness in artificial processes. By containing the chemical response within a unrestricted vessel, the threat of accidents and exposure to dangerous accoutrements is reduced. The controlled terrain within the reactor can also ameliorate the effectiveness of the response, reducing the quantum of energy and raw accoutrements needed to produce the asked outgrowth.

Rahul Engineering Global Pvt.Ltd. Offers a wide range of chemical reactors for artificial operations, including batch reactors, nonstop reactors, and airman scale reactor. Their platoon of experts can help companies elect the most applicable reactor for their specific requirements, considering factors similar as response time, temperature, and pressure conditions. With Rahul Engineering Global Pvt.Ltd. high-quality outfit and support, companies can achieve bettered product quality, safety, and effectiveness in their artificial processes.

#chemicalreactor#chemical#reactor#regpl#rahulenginerring#manufacturecompanyinpune#manufacturecompanyinindia#manufacturecompanyinchakan#manufacturecompany

0 notes

Text

Why use corrugated tubes in heat exchangers?

The Corrugated Tube Heat Exchanger, distinguished by its unique design and superior heat transfer efficiency, enjoys higher demand compared to plate-type heat exchangers. If you seek such advantages, look no further than Process Engineers and Associates. As premier manufacturers of Corrugated Tube Heat Exchangers in Pune, we leverage our extensive industry expertise to provide robust and dependable solutions tailored to meet a wide array of industry requirements.

Corrugated tubes are integral components within heat exchangers, crucial for optimizing heat transfer efficiency. At Rahul Engineering Global Pvt. Ltd., our corrugated tubes are meticulously crafted to enhance thermal performance. These tubes feature a unique corrugated structure that significantly increases surface area, facilitating improved heat exchange compared to conventional smooth tubes.

Engineered with precision and using high-quality materials, our corrugated tubes ensure durability and reliability in diverse industrial settings. The corrugated design induces turbulence within the fluid flow, promoting efficient mixing and heat transfer between the fluid inside the tube and the surrounding medium.

The advantages of utilizing corrugated tubes in heat exchangers include enhanced thermal efficiency, reduced fouling, and minimized pressure drop. These benefits make our corrugated tubes ideal for a wide range of applications across industries such as HVAC, chemical processing, power generation, and more.

At Rahul Engineering Global Pvt. Ltd., we prioritize innovation and excellence, delivering corrugated tubes that surpass industry standards and cater to the specific needs of our clients. With our expertise and commitment to quality, we provide reliable solutions for efficient heat exchange processes.

Primary Motives for Choosing Corrugated Tube Heat Exchangers:

Increased Efficiency: Using it may prevent viscous fluids and suspensions from creating an insulating boundary layer on the tube surface, which ensure better efficiency.

Streamlined Maintenance and Cleaning: With no moving components, these heat exchangers facilitate effortless inspection, cleaning, and maintenance, resulting in substantial savings in terms of plant resources, manpower, and costs.

Ease the Process: With Industrial Corrugated Tube Heat Exchanger, heat transferring between fluids or gases becomes easier. Corrugated tube heat exchangers offer several benefits compared to traditional smooth tube heat exchangers:

Enhanced Heat Transfer: The corrugated design of the tubes increases the surface area available for heat transfer. This results in improved heat transfer efficiency, allowing for better performance in terms of heating or cooling.

Reduced Fouling: The corrugated structure disrupts laminar flow and helps prevent fouling by promoting turbulence, which reduces the buildup of deposits on the tube surface. This leads to longer intervals between cleaning and maintenance, reducing downtime and operating costs.

Compact Design: Corrugated tube heat exchangers typically have a more compact design compared to traditional smooth tube heat exchangers. This allows for more efficient use of space, making them suitable for applications where space is limited.

Higher Thermal Efficiency: The enhanced heat transfer capabilities of corrugated tube heat exchangers result in higher thermal efficiency, meaning they can achieve the desired temperature change with less energy input compared to smooth tube heat exchangers.

Improved Resistance to Thermal Stress: The corrugated design provides greater structural strength and flexibility, allowing the heat exchanger to better withstand thermal stress and pressure fluctuations. This can contribute to longer equipment lifespan and reduced maintenance costs.

Versatility: Corrugated tube heat exchangers can be designed and manufactured to meet specific application requirements, including variations in material, size, and configuration. This makes them versatile and adaptable to a wide range of industrial processes and operating conditions.

Cost-effectiveness: While the initial investment may be slightly higher compared to smooth tube heat exchangers, the long-term benefits, including improved efficiency, reduced maintenance, and longer equipment lifespan, often result in overall cost savings over the life of the equipment.

Overall, corrugated tube heat exchangers offer a combination of improved heat transfer efficiency, reduced fouling, compact design, and versatility, making them a preferred choice for many industrial heating and cooling applications.

Dial Our Number Now!

Rahul Engineering Global Pvt. Ltd. is the best Corrugated Tube Heat Exchanger Supplier, Manufacturer Company in Pune, India.As leading exporters and suppliers of Corrugated Tube Heat Exchangers in India, we assure prompt delivery and comprehensive customer assistance. Reach out to us with your inquiries or call us for further information.

#regpl.com#regpl#heatexchangers#heatexchanger#heat#exchangers#corrugatedtubeheatexchanger#supplier#manufacturecompanyinindia#manufacturecompanyinpune#manufacturecompanyinchakan

0 notes

Text

Pushing Boundaries: Recent Innovations in Heat Exchanger Technology

In the ever-evolving landscape of engineering and thermal sciences, heat exchangers continue to play a pivotal role in facilitating energy transfer across various industries. As demands for efficiency, sustainability, and reliability increase, engineers and researchers are constantly pushing the boundaries of heat exchanger technology. In this blog, we'll delve into some of the recent innovations and advancements that are revolutionizing the field, enhancing efficiency, and reliability in diverse applications.

Micro channel Heat Exchangers:

One notable innovation in heat exchanger technology is the emergence of microchannel heat exchangers. These compact devices feature numerous small channels with hydraulic diameters typically less than 1 mm, allowing for efficient heat transfer with minimal fluid volume. Microchannel heat exchangers offer advantages such as reduced size, weight, and refrigerant charge, making them ideal for applications in automotive air conditioning, electronics cooling, and aerospace systems. Recent research focuses on optimizing flow distribution, surface enhancements, and manufacturing techniques to further improve performance and reliability.

Additive Manufacturing (3D Printing):

The advent of additive manufacturing techniques, particularly 3D printing, has revolutionized heat exchanger design and production. Engineers can now create complex geometries with intricate internal passages, tailored to specific heat transfer requirements. Additive manufacturing enables rapid prototyping, customization, and cost-effective production of heat exchangers with enhanced performance and reliability. This technology opens doors to novel designs, such as lattice structures and optimized flow patterns, which maximize heat transfer efficiency while minimizing pressure drop and material usage.

Enhanced Surface Coatings and Materials:

Advancements in surface coatings and materials are driving significant improvements in heat exchanger performance and durability. Nanotechnology-based coatings, such as hydrophobic or hydrophilic surfaces, promote heat transfer enhancement, anti-corrosion properties, and fouling resistance. Additionally, the development of high-performance materials, including advanced alloys, ceramics, and polymers, offers superior thermal conductivity, corrosion resistance, and mechanical strength. These materials extend the lifespan of heat exchangers, reduce maintenance requirements, and enhance overall reliability in harsh operating environments.

Computational Fluid Dynamics (CFD) and Machine Learning:

The integration of computational fluid dynamics (CFD) simulations and machine learning algorithms is revolutionizing heat exchanger design and optimization. Engineers can simulate fluid flow, heat transfer, and thermodynamic performance with unprecedented accuracy, allowing for virtual prototyping and performance prediction. Machine learning algorithms analyze vast datasets to identify optimal designs, operating conditions, and maintenance strategies, leading to significant improvements in efficiency and reliability. This synergistic approach accelerates innovation cycles and enables the development of next-generation heat exchangers tailored to specific applications and requirements.

Modular and Flexible Designs:

In response to evolving industry needs and dynamic operating conditions, heat exchanger manufacturers are increasingly adopting modular and flexible design concepts. Modular heat exchangers consist of standardized components that can be easily configured and assembled to meet diverse application requirements. This approach allows for scalability, customization, and quick deployment, reducing lead times and installation costs. Moreover, flexible designs accommodate variations in operating parameters, fluid properties, and environmental conditions, ensuring optimal performance and reliability across a range of applications.

Conclusion:

The landscape of heat exchanger technology is undergoing rapid transformation, driven by a relentless pursuit of efficiency, sustainability, and reliability. Recent innovations such as microchannel designs, additive manufacturing, advanced coatings, computational modeling, and modular architectures are revolutionizing the field, enabling engineers to tackle complex thermal challenges with unprecedented precision and effectiveness. As these advancements continue to unfold, the future holds promise for even greater leaps in heat exchanger performance, ushering in an era of enhanced energy efficiency and sustainability across industries.

Rahul Engineering Global Pvt. Ltd. specializes in providing innovative and high-quality heat exchangers in pune solutions for various industries. Our state-of-the-art designs and innovative technology ensure optimal thermal performance, efficiency, and reliability. Whether its shell and tube, plate, finned tube, or custom-designed heat exchangers, we deliver tailored solutions to meet our clients' specific requirements. With a commitment to excellence and customer satisfaction, Rahul Engineering Global Pvt. Ltd. is your trusted partner for all your heat exchanger needs.

For any inquiries, collaborations, or questions about our products and services, feel free to reach out to us:

Email: [email protected]

Phone: +91 98900 87871

Address: Plot No. 6, Gat No. 627/2/2/6, Pune -410501, Nashik Highway, Kuruli, Chakan, Maharashtra,India

0 notes

Text

Working and Applications of a Distillation Column

The separation process, which has been a pillar of the chemical and industrial sectors for hundreds of years, is essential in various applications. Be it the purification of water, the refinement of crude oil, or even the production of alcoholic beverages, a distillation column plays a very significant role in separating mixtures based on differences in boiling points. This blog will further explain how a distillation column works, its mechanisms and values, and the exact science behind this remarkable procedure.

What does the term 'distillation column' mean?

A normal simple distillation column is simply a vertical vessel designed to separate a liquid mixture into its pure components by manipulating the differences in boiling points of the substances that comprise the mixture.

Applications of Distillation Columns

From the separation and purification of substances based on boiling points, distillation columns nowadays find their application in almost every industry. The applications of a distillation column vary from simple everyday product applications to complicated industrial processes. The major uses of the distillation column are as follows:

Petroleum Refining: Perhaps one of the most familiar uses of distillation columns is petroleum refining. Crude oil contains a mixture of hydrocarbons at a wide range of boiling points. The distillation column will fractionate crude oil into fractions like gasoline, diesel, and kerosene, among others, with heavier products like lubricating oils and bitumen. After that, fractions can be subjected to further processing and purification.

Chemical Manufacturing: Application in the chemical industry is huge, particularly in separating and purifying many chemicals and chemical intermediates. They are also helpful in the production of high-purity chemicals, solvents, and intermediates that later will become raw materials for other chemical processes.

Alcohol Production: Perhaps the central process of alcoholic beverage production is that of distillation. This involves heating the fermented liquids in a column of distillation, separating the alcohol from water and other components, and raising the alcohol content for whiskey, vodka, and rum types.

Pharmaceuticals: Pharmaceutical industries employ distillation columns to purify drugs, separate their intermediates, and prepare high-purity solvents and reagents. Separation of the different components in the mixture assures safe and useful pharmaceutical products.

Food and Beverage Industry: The columns purify and concentrate food and beverage products. They regard the processes of concentrated fruit juices, essential oils, and flavor extracts.

Natural Gas Processing: The crude natural gas being dispensed contains NGLs, which are refined via distillation columns into propane, butane, and ethane. These liquefied natural gases have uses in industries such as fuel, feedstock for petrochemical production, and heating.

Aromatics Production: distillation columns for separating and purifying aromatic compounds in plastics, polymers, and synthetic fiber production.

Water Desalination: The processes may be used to remove salts and other impurities from seawater to give fresh water. Though other methods of desalination, such as reverse osmosis, are more prevalent, distillation is still a very viable alternative in some instances.

Biofuel Production: During the production of biofuels, distillation columns play their part in the process of producing ethanol from renewable sources like corn and sugarcane. This results in contaminated biomass fermentation with alcohol, generally an aqueous solution, which needs to be distilled to separate ethanol and concentrate it.

Environmental Applications: The distillation columns could further be used in ecological remediation for polluted liquids by separating contaminants from clean water or any other clean solvents.

Distillation is used in the perfume and fragrance industries to recover essential oils from plant materials, which are used in perfumes and fragrances, cosmetics, and aromatherapy products.

Waste Management: A few uses of distillation columns exist in some waste management processes to separate either valuable materials or components from the waste streams; this aids in resource recovery and minimizes the impact on the environment. These applications only prove the wide-ranging importance of the distillation column across industries. With improving technology and design comes the improvement of competence in distillation procedures, making this parting technique essential to various industrial processes and a wide array of everyday products. Components of the Distillation Column

There are just a few components that make up a distillation column. Each contribution makes for efficiency and accuracy in the separation process.

Reboiler: It is located at the bottom of the distillation column and provides heat. The heat from the reboiler vaporizes the liquid mixture and initiates the separation process.

Column Body: The distillation column is composed of a series of trays or packing materials. Such trays or packings, do provide surface area for vaporization, condensation, and mass transfer. The column is divided into several sections, sometimes referred to as "stages," all having particular functions.

Distillation Trays or Packing: These trays or packing inside a column act as surfaces for vaporization and concentration. The trays have holes that allow the passage of vapor to the top, and the packing is typical of resources that allow large surface areas to come into contact with rising vapor and descendant liquid.

Distillate Outlet: This is a point at which the detached and cleaned mechanisms (distillate) exit the column. It is usually located at the top of the column.

Bottoms Outlet: The bottom part of the column is fitted with an outlet for discharge of the remaining mixture, which may further contain higher-boiling mechanisms or scums.

The Distillation Process: Fractional Distillation

Fractional distillation is the most frequently used type of industrial and laboratory method. It conducts a series of cycles of vaporization and condensation inside the column, with each cycle contributing to separation. How it works:

Boiling: The liquid mixture at the base of the column is heated in the reboiler. The component with the lowest boiling point starts to boil and ascends the column.

Mass Transfer: During the rise of vapor from the column, it comes into contact with the liquid either on trays or stuffing. As the vapor condenses, releasing heat and transferring energy to the liquid, so does the mass transfer, which causes higher boiling mechanisms to condense and flow back down.

Equilibrium and Enrichment: At each stage of the column, equilibrium between the vapor and liquid phases is established. The vapor enriches in a lower-boiling component; the liquid enriches in a higher-boiling component.

Multistage Process: This process is repeated in each stage of the column, where the vapor becomes progressively more concentrated in the lower-boiling component as it rises and the liquid becomes progressively more concentrated in the higher-boiling component as it falls.

Separation: Finally, the rich vapor exits the column top with the distillate outlet. Condensed, it comprises purified distillate. While this is happening, the residual mixture in the liquid phase, called "bottoms," comes out of the column via the bottoms outlet.

Conclusion

Rahul Engineering Global Private Limited is a top manufacturing company, specializing in the design, fabrication, and installation of excellent distillation columns in Pune, India. With a strong promise of excellence and client gratification

0 notes

Text

What are the main advantages of horizontal storage tanks?

Components of the horizontal storage tank include the elliptical tank, base support, flange, level meter, top inlet, outlet, and other inlets. Let us look at some of the prime advantages and benefits of a horizontal storage tank. and outlet ports. The composition structure is simple and easy for the operator to get started, as long as the daily maintenance can be carried out. In the production process, there is a staff to inspect the weld seam of the equipment, thus making the equipment more and more stable, safe, and reliable.

Calm mobility and transportation

Horizontal storage tanks are greatly used in the agricultural and beverage industries since they are best suited for storing liquids like water and chemicals. Their design and shape make horizontal steel storage tanks much easier to transport and move than vertical tanks. That easy supply makes horizontal tanks very attractive for those who need to house or conveyance liquids regularly. Horizontal storage tanks can be connected underground or above ground and are used in a variety of industries for the storage of light and heavy petroleum products, chemical solutions, water, food products, and other liquid products. Otherwise, for underground storage, it is assumed that horizontal steel tanks have a quantity of coatings and insulation to prevent erosion.

Height is no longer a factor.

If you’re facing height restrictions in your plant, factory, or vehicle, a vertical tank may cause more trouble than its worth. The horizontal storage tank design uses less vertical space, so you don’t have to worry if you are a small to medium-sized process. It more easily fits where you need it to and eliminates the risks of allocating a tank that’s a few inches too tall.

Temperature Control

Temperature is a key factor to consider if you’re in the dairy, wine, brewery, and beverage processing businesses. The shape and orientation of stainless steel horizontal storage tanks make them faster and more well-organized in heating and cooling liquids and upholding the desired temperature during storage and transportation.

Less personnel are needed.

Given how they are designed and considering that they are less cumbersome to move around from one place to another, horizontal storage tanks require less manpower to manage them. This will leave you and your employees with enough time for other important tasks and projects.

Efficient and cost-effective

Since horizontal storage tanks have a greater percentage of surface area coverage, they are capable of transhipping their products more professionally than perpendicular tanks. Besides, there are fewer charges for transportation with horizontal tanks, and they can add vertical agitation easily, making them cost-effective.

Low cost and long life.

Buying Used Horizontal Storage Tanks

Need a great horizontal storage tank? Look no further than Rahul Engineering. The company manufactures horizontal storage tanks from carbon and stainless steel, available in a variety of sizes. Below is the inventory of horizontal tanks. Let us help you.

Interested in learning more about our horizontal storage tanks for sale and what they can do for you? Contact us today to secure an expert discussion!

#horizontalstoragetank#horizontalstorage#storagetank#tank#horizontalstoragetankmanufacture#horizontalstoragetanksuppliers#regpl#regpl.com#advantages#Rahul Engineering Global Pvt. Ltd.#Rahul Engineering

0 notes