#ac induction motors

Explore tagged Tumblr posts

Text

How to Choose the Right Vibratory Motor: A Complete Overview

A proper vibratory motor selection is critical to the performance and life of your equipment. Whatever your industry – whether manufacturing, construction or food processing – knowing the factors that go into this selection process can help you improve your operations. The following is a checklist of considerations to help you make an informed decision.

#electric motors#vibratory motors manufacturers#ac motors manufacturers in india#ac induction motors

0 notes

Text

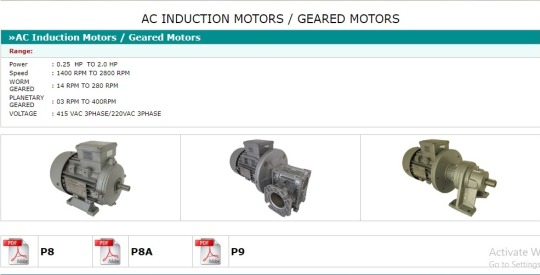

AC Induction motors manufacturers Exporters

0 notes

Text

0 notes

Text

Unleash the power of efficiency with our three-phase AC motors! Designed for durability and peak performance, they're perfect for your industrial needs. Explore now at www.cntecho.com 🚀🔧 #ThreePhaseMotors #IndustrialSolutions #EfficientPerformance

#titecho#cntecho#motor#pump#ac motor#single phase motor#three phase motor#3 phase motor#1 phase motor#induction motor#electric motor#hollow shaft motor#female shaft motor#inner shaft motor#Asynchronous motor

1 note

·

View note

Text

Exporters of 3 Phase AC Induction Motor, Manufacturers of 3 Phase AC Induction Motor

Exporters of 3 Phase AC Induction Motor

.

The Sabar Group journey commenced in the year 1975, when sabar started its first unit for the manufacture of water pumps. Unbounded passion, unmatched skill and uncompromising quality control led the group from one success to another.

.

The ISO Certification and ISI & CE Marks and achievement of 5 star rating were just an affirmation that sabar is the signature of quality.

.

The path of progress has been marked by many milestones wherein consolidation and diversification have been the mantra. The foray into the export market confirmed the global vision of the company. The Group’s uncompromising commitment to quality

.

Manufacturers of 3 Phase AC Induction Motor

Our product range:

** Submersible pumpset

** Submersible motor

** Submersible pump Stainless Steel

** Monoblock Pumpset

** Openwell submersible Pumpset

** uPVC Pipe / uPVC column / Riser pipes / uPVC Casing pipes

** AC Induction Motor – Three Phase

** Submersible cable

.

3 Phase Induction Motor

Contact us :

Company: Sabar Pumps

Address: A2, 3912, Phase-IV, G.I.D.C. Estate,

Vatva – Ahmedabad – 382 445, Gujarat (INDIA)

.

Contact: +91 79 25840213 / +91 79 25840261

.

Email: [email protected] , [email protected]

Website : www.sabarpumps.com

#Exporters of 3 Phase AC Induction Motor#Manufacturers of 3 Phase AC Induction Motor#3 Phase Induction Motor

0 notes

Text

3 m ·

Shared with Public

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#Hi-TechAutomation #DrugFreeIndia

Delta drives are microprocessor-based motor drives, widely used to control speed of industrial AC motors.

An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and generate energy efficiently. decrease mechanical stress on motor control applications. optimize the operation of various applications relying on electric motors

Delta connected motor will draw more line current, so the torque it produces will also be higher compared to the Star connection of the same motor. So the answer to this question is Delta connection.

A variable frequency drive (VFD) refers to AC drives only and a variable speed drive (VSD) refers to either AC Drives or DC Drives. VFDs vary the speed of an AC motor by varying the frequency to the motor. VSDs referring to DC motors vary the speed by varying the voltage to the motor.

AC motor. The AC electric motor used in a VFD system is usually a three-phase induction motor. Some types of single-phase motors or synchronous motors can be advantageous in some situations, but generally three-phase induction motors are preferred as the most economical.

Like

Comment

Share

#bestindustry#bestoffers#OnTimeDelivery#bestprice#goodservice#donateorgansavelife#Hi-TechAutomation#DrugFreeIndia#Delta drives are microprocessor-based motor drives#widely used to control speed of industrial AC motors.#An AC drive is a device used to control the speed of an electrical motor in order to: enhance process control. reduce energy usage and gene#Delta connected motor will draw more line current#so the torque it produces will also be higher compared to the Star connection of the same motor. So the answer to this question is Delta co#A variable frequency drive (VFD) refers to AC drives only and a variable speed drive (VSD) refers to either AC Drives or DC Drives. VFDs va#AC motor. The AC electric motor used in a VFD system is usually a three-phase induction motor. Some types of single-phase motors or synchro#but generally three-phase induction motors are preferred as the most economical.

0 notes

Text

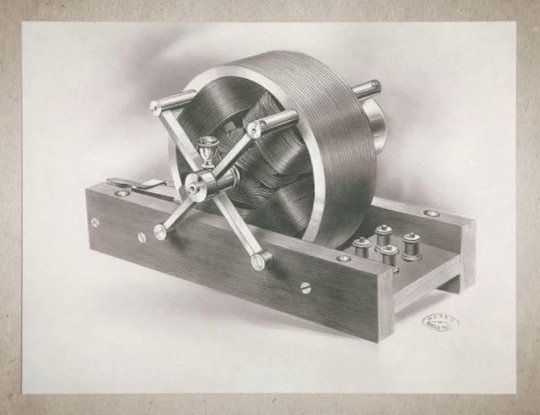

One of the Greatest Inventions of All Time

Nikola Tesla has many revolutionary inventions to his credit, but he is best known for his pioneering work in the development and promotion of alternating current (AC) electrical systems. Tesla's innovations in AC technology revolutionized the generation, transmission, and distribution of electrical power, becoming the foundation for the modern electrical power systems that we use today.

There is a common misconception made that Tesla was the first to invent, or discover, AC, but this is not true. It is well-known that Hippolyte Pixii was the first to discover AC in 1832. Pixii was an instrument maker from Paris who built an early form of an alternating current electrical generator (based on the principle of electromagnetic induction discovered by Michael Faraday), and thus started a new industry in power transmission. Tesla was not the first to discover or invent an AC motor, but he was the first to invent a practical AC induction motor with commercial value that could outperform all other motors. It must be noted that Italian inventor Galileo Ferraris also invented an induction motor similar to Tesla's, but it had no commercial value, and he even admitted himself that it was useless. Tesla's induction motor operates on the principle of electromagnetic induction, properly utilizing a rotating magnetic field that induces a current in a stationary conductor, resulting in rotational motion. The utilization of the rotating magnetic field makes the motor more simple, robust, versatile, efficient, and cost effective in that it has less moving parts reducing the likelihood of mechanical failure (as was common in other motors).

Tesla's induction motor became a fundamental component in the field of electrical engineering and is used today in various applications, being one of the most widely used devices in the world. The motors play a crucial role in transmitting electrical power to homes and businesses. They are commonly used in power generation plants to convert mechanical energy into electrical energy, which is then transmitted through the power grid for distribution to various locations. Induction motors are also widely employed in appliances and machinery within homes and businesses for various applications. These applications include conveyor systems, hoists, cranes, lifts, pumps, fans, ventilation systems, compressors, manufacturing machinery, wind turbines, washing machines, refrigerators, garbage disposals, microwaves, dishwashers, vacuums, air conditioners, robotics, electric vehicles, trains, power tools, printers, etc. Basically, anything that requires a spinning action for power.

The induction motor is widely considered one of the most important inventions in the history of electrical engineering. Its importance lies in its transformative impact on industries, its efficiency and reliability, and its role in the broader electrification of society.

#nikola tesla#science#history#invention#discovery#induction motor#electricity#power#goat#ahead of his time#ahead of our time

152 notes

·

View notes

Text

Even BMW—a company that literally has "motor" for a middle name—only deigns to reveal on its i3 product page that the motor is “AC synchronous.” Meanwhile, the engine in the base-model 3 Series a few clicks over is described as a “2.0-liter BMW TwinPower Turbo inline 4-cylinder, 16-valve 180-hp engine that combines a twin-scroll turbocharger with variable valve control (Double-VANOS and Valvetronic) and high-precision direct injection.” That's before the site goes on to describe the engine’s electronic throttle control, auto start-stop function, direct ignition system with knock control, electronically controlled engine cooling (map cooling), brake energy regeneration, and driving dynamics control with Eco Pro, Comfort, and Sport settings.

But then, it's hard to blame people for not giving a damn. Most consumers—hell, even car geeks—don’t possess the knowledge or vocabulary to authoritatively converse about electric motors, and on the surface, there would seem to be precious little indication that there’s even anything meaningful to discuss about them. It’s a lot harder to get excited about, say, the difference between permanent magnets and AC induction than it is between V8s and twin-turbo sixes. The fact that carmakers and the media don’t billboard motor innovation naturally leads the public to assume that there’s nothing much going on there.

interesting the way marketing focuses on the battery, which obviously has been the major development in the tech overall

33 notes

·

View notes

Text

Me when the history class doesn’t talk about tesla’s inventions like bro literally invented AC electricity, wifi, wireless technology, remote controls, tesla coils, hydroelectricity, X-ray technology, neon and fluorescent lights, spark plugs, induction motors, alternators, and the radio

WDYM YOU’RE NOT GONNA MENTION HIM DURING THE SECOND INDUSTRIAL REVOLUTION?????

#ap us history#apush#history#ap history#history class#science#nikola tesla#tesla#ap world history#world history#european history#us history#american history#industrial revolution#second industrial revolution#the gilded age#guilded age#technology#technology and innovation

6 notes

·

View notes

Text

Understanding Load Banks: The Unsung Heroes of Power Testing

When we think about power systems, we often focus on generators, UPS systems, and renewable energy sources like solar or wind. But behind the scenes, there's an unsung hero that plays a critical role in ensuring these systems perform reliably— the load bank.

What Exactly is a Load Bank?

A load bank is a device designed to test and verify the performance of electrical power sources by simulating real-world electrical loads. In simple terms, it’s like a stress test for your power equipment, ensuring that when you need them the most, they’ll perform without a hitch.

Why Are Load Banks So Important?

Reliability: By simulating various load conditions, load banks help ensure that your generators, UPS systems, and other power sources can handle their intended loads without failure. This is especially crucial in mission-critical environments like data centers, hospitals, and industrial facilities.

Preventive Maintenance: Regular load bank testing can identify potential issues before they become costly problems. It’s like giving your power system a regular check-up to keep it in peak condition.

Compliance: Many industries have strict regulations requiring regular load testing to meet safety and performance standards. Load banks help you stay compliant and avoid penalties.

Types of Load Banks:

Resistive Load Banks: These are used to simulate a purely resistive load, converting electrical energy into heat. Ideal for testing the basic capacity of your power source.

Reactive Load Banks: These simulate the inductive and capacitive loads you’d find in real-world scenarios, like those from motors and transformers.

Resistive/Reactive Load Banks: A combination of the two, these provide a more comprehensive testing environment.

Where Are Load Banks Used?

Load banks find their application in a variety of settings:

Data Centers: Where uninterrupted power is critical, load banks ensure backup systems are up to the task.

Hospitals: Load banks test emergency power systems, ensuring they’re ready to kick in during an outage.

Renewable Energy Systems: They help validate the performance and reliability of systems like solar panels and wind turbines under different load conditions.

In Summary

Load banks may not be the stars of the power system world, but they play a vital role in ensuring the systems we rely on every day are ready to perform when needed. Regular load testing can mean the difference between seamless operation and catastrophic failure.

So next time you think about your power systems, remember the quiet work of the load bank—keeping the lights on when it matters most.

2 notes

·

View notes

Text

How does an engine contribute to a car's powertrain?

The powertrain in a vehicle is the system responsible for generating power and delivering it to the wheels to propel the vehicle forward. The operation of a powertrain can vary depending on whether the vehicle is powered by an internal combustion engine (ICE) or an electric motor (in the case of electric vehicles). Here's a general overview of how a powertrain works in both types of vehicles:

Internal Combustion Engine (ICE) Vehicle - Combustion Process: In an ICE vehicle, the powertrain starts with the combustion process in the engine. Fuel (gasoline or diesel) mixes with air in the combustion chamber and is ignited by spark plugs (in gasoline engines) or compression (in diesel engines).

Power Generation: The combustion process generates energy in the form of mechanical power, causing pistons to move up and down within the cylinders of the engine. This motion drives the crankshaft, converting linear motion into rotational motion.

Transmission: The rotational motion from the crankshaft is transmitted to the transmission, which consists of gears that allow the driver to select different ratios (speeds). This enables the engine to operate efficiently across a range of vehicle speeds.

Drivetrain: The transmission sends power to the drivetrain components, including the driveshaft, differential, and axles, which transfer power to the wheels. The differential allows the wheels to rotate at different speeds, enabling smooth turns.

Wheel Movement: The power transmitted through the drivetrain causes the wheels to rotate, propelling the vehicle forward or backward depending on the gear selection and throttle input from the driver.

Electric Vehicle (EV) -

Battery Pack: The primary source of power for the EV, storing electricity in chemical form.Powers the electric motor and provides electricity for all electronic devices within the EV.

Battery Management System (BMS): Monitors battery cell conditions, including voltage, current, temperature, and state of charge (SoC).It protects the battery against overcharging, deep discharging, and overheating and helps balance the charge across cells. Ensures optimal performance and longevity of the battery by regulating its environment.

Inverter: Converts DC from the battery pack into AC to drive the electric motor.Adjusts the frequency and amplitude of the AC output to control the motor’s speed and torque. Critical for translating electrical energy into mechanical energy efficiently.

Onboard Charger: Facilitates the conversion of external AC (from the grid) to DC to charge the battery pack. Integrated within the vehicle, allowing for charging from standard electrical outlets or specialized EV charging stations. Manages charging rate based on battery status to ensure safe and efficient charging.

DC-DC Converter: Steps down the high-voltage DC from the battery pack to the lower-voltage DC needed for the vehicle's auxiliary systems, such as lighting, infotainment, and climate control. Ensures compatibility between the high-voltage battery system and low-voltage electronic components.

Electric Motor: Converts electrical energy into mechanical energy to propel the vehicle. It can be of various types, such as induction motors or permanent magnet synchronous motors, each offering different efficiencies and characteristics. Typically provides instant torque, resulting in rapid acceleration.

Vehicle Control Unit (VCU): The central computer or electronic control unit (ECU) that governs the EV's systems. Processes inputs from the vehicle’s sensors and driver inputs to manage power delivery, regenerative braking, and vehicle dynamics. Ensures optimal performance, energy efficiency, and safety.

Power Distribution Unit (PDU): Manages electrical power distribution from the battery to the EV’s various systems. Ensures that components such as the electric motor, onboard charger, and DC-DC converter receive the power they need to operate efficiently. Protects the vehicle's electrical systems by regulating current flow and preventing electrical faults.

In both ICE vehicles and EVs, the powertrain's components work together to convert energy into motion, enabling the vehicle to move efficiently and effectively. However, the specific technologies and processes involved differ significantly between the two propulsion systems.

#electric powertrain technology#conventional powertrain#Electric vehicle components#revolo hybrid car kit#ev powertrain development services#software (SW) platforms for all Electric vehicles components#Battery Management Systems#Inverter#Smart Charger#VCU solutions

3 notes

·

View notes

Text

7 Key Features of Vibratory Motors That Enhance Industrial Efficiency

In today’s industrial landscape, vibratory motors play a pivotal role in ensuring smooth operations across various sectors. These motors, designed for specific applications, are known for their efficiency and versatility. Whether you’re new to the concept or looking to expand your understanding, this blog will guide you through the key features of vibratory motors and their impact on industrial efficiency. Shrirang Enterprise, a trusted name in the field, brings you high-quality vibratory motors to meet your operational needs.

0 notes

Text

AC Induction motors manufacturers Exporters india

0 notes

Text

Pihu Refrigeration and Electricals Indore 7000453295

Air Conditioner, Fridge, Refrigerator, washing Machine, Geyser, Electric Geyser, Gas Geyser, Solar Heater, Water purifier, RO system , Microwave, micro own, all home Appliances Repair and services near me Indore.

#washing machine#water pump motor#indore#visi cooler#induction#viral#the virgin suicides#video#video games#funny#so hot 🔥🔥🔥#history#house of the dragon#hazbin hotel#ac#fridge#freeze#fashion#food#football#fanart#film#fanfic#f1#fan#spilled ink#stri2

1 note

·

View note

Note

Sydney Trains M set

Class of electric train operating in Sydney, Australia

The Sydney Trains M sets, also referred to as the Millennium trains, are a class of electric multiple units that operate on the Sydney Trains network. Built by EDi Rail between 2002 and 2005, the first sets initially entered service under the CityRail brand on 1 July 2002 after short delays due to electrical defects. The M sets were built as "fourth generation" trains for Sydney's suburban rail fleet, replacing the 1960s Tulloch carriages and providing extra capacity on the suburban rail network. The sets currently operate on the T2 Inner West & Leppington, T3 Bankstown, T5 Cumberland, T7 Olympic Park and T8 Airport & South lines.

Quick Facts M set, In service ...

M set

M32 at Sydney Central

Lower deck

In service

2002–present

Manufacturer

EDi Rail

Built at

Cardiff

Replaced

Tulloch carriages

Constructed

2002–2005

Entered service

1 July 2002

Number built

141 carriages

Number in service

140 carriages

Formation

35 4-car sets

Fleet numbers

D1001–D1041, D1043–D1060, D1062–D1073 (driving trailers)

N1501–N1540, N1543–N1560, N1562–N1573 (motor cars)

M1–M35 (full 4-car sets)

Capacity

452

Operators

Sydney Trains

Depots

Auburn

Lines served

Inner West & Leppington

Bankstown

Cumberland

Olympic Park

Airport & South

Specifications

Car body construction

Stainless steel

Train length

81.55 m (267 ft 6+5⁄8 in)

Car length

20,532 mm (67 ft 4+3⁄8 in) (D)

20,243 mm (66 ft 5 in) (N)

Width

3.03 m (9 ft 11+1⁄4 in)

Height

4,381 mm (14 ft 4+1⁄2 in)

Doors

Plug-style, 2 per side

Wheel diameter

940 mm (37 in)

Maximum speed

130 km/h (81 mph) (design)

115 km/h (71 mph) (service)

Weight

207 t (204 long tons; 228 short tons)

Traction system

Alstom ONIX 1500 2-level IGBT–VVVF

Traction motors

8 × Alstom 4-EXA-2144 226 kW (303 hp) 3-phase AC induction motor

Power output

1,808 kW (2,425 hp)

Electric system(s)

1,500 V DC (nominal) from overhead catenary

Current collector(s)

Pantograph

UIC classification

2′2′+Bo′Bo′+Bo′Bo′+2′2′

Braking system(s)

Automatic air, electropneumatic and regenerative

Coupling system

Scharfenberg coupler

Track gauge

1,435 mm (4 ft 8+1⁄2 in) standard gauge

Close

Design

Vestibule

The Millennium train, like the entire Sydney Trains fleet and electric NSW TrainLink fleet, is a double decker. It is a four car consist, with the middle two cars being non-control motor cars and the two outer cars being driving control trailer cars fitted with the pantograph. The Millennium train was the first to be equipped with an AC drive system unlike the Tangara, which has a DC drive system. The sets usually operate in eight-car formations with two four-car sets combined. While the Millennium train concept is an evolution of the Tangara concept (manufactured by A Goninan & Co), the Millennium train introduced new features such as internal electronic destination indicators, automated digital voice announcements for upcoming stops, a return to reversible seating, surveillance cameras, wider stairways, a new safety yellow colour scheme, and push-button opened internal doors. The Millennium Train also introduced crumple zones to absorb impact in a collision. Interiors were designed by Transport Design International.

The train also features emergency help points, allowing passengers to contact the train crew in an emergency. The help points are located on the sides of the stairwell to the upper deck. There are actually two help points in the same location, with a large one at face height with a microphone and speaker, and a lower one with a microphone only. There are also emergency door releases which were retrofitted to the trains. These allow passengers to manually open the doors in an emergency, as recommended in the report for the Waterfall rail accident. The retrofit program was stated as having been completed in November 2014.

Like with the T, A and B sets, the M sets feature Scharfenberg couplers.

M sets are 3.03 metres (9 ft 11+1⁄4 in) wide, being classed by Transport for NSW as medium width trains, which allows them to operate within the whole Sydney Trains suburban network.

Unlike sets M2–M35, set M1 has a slightly different interior design with differently coloured doors and different seat handles for unknown reasons.

Delivery

Stairwell

The cars were constructed by EDi Rail at Cardiff Workshops. The contract included a 15-year maintenance agreement with EDi Rail to maintain the trains at a specialised maintenance centre at Eveleigh. During testing and initial revenue service, they ran as four car sets, with eight car sets commencing service towards the end of 2002 after further testing. All 35 four car sets were delivered by October 2005.

The initial order signed in October 1998 was for 81 carriages, in December 2002 an option was taken up for an additional 60. In February 2017, Sydney Trains exercised an option to extend Downer's maintenance of the trains for a further 10 years.

Criticisms

The Millennium trains were criticised for having several technical problems and causing problems with Sydney Trains, they were referred to in the media reports as The "Mi-lemon" and "Millenni-Bug" as a result. Some of the problems were caused by insufficient power supply on the overhead to cope with the power demands of the more technologically advanced trains causing them to shut down. Software bugs also contributed to the trains' poor reliability.

The Millennium trains were withdrawn from service in April 2003 while the problems were being rectified and a full audit was carried out. They were subsequently reintroduced into service in June 2003 and have since been operating on the T2 Inner West & Leppington, T3 Bankstown, T6 Carlingford, T7 Olympic Park and T8 Airport & South lines. After the new timetable was released on 26 November 2017, M sets began as 4-car services on the T5 Cumberland line on both weekdays & weekends, along with a few 8-car Waratahs.

In service

External Carriage Camera Trial

Trial cameras

In late 2008, two Millennium trains were fitted with external cameras atop of carriages near the doors, testing their use for the then-future Waratah trains. These cameras were subsequently incorporated into the final design of the Waratah train.

Lines serviced

The Millennium trains typically operate on the following lines (normally described as Sector 2):

T2 Inner West & Leppington Line: Leppington or Parramatta to City Circle via Granville

T3 Bankstown Line: Liverpool or Lidcombe to City Circle via Bankstown

T5 Cumberland Line: Leppington to Richmond

T7 Olympic Park Line: Shuttle from Lidcombe to Olympic Park on weekdays

T8 Airport & South Line: Macarthur to City Circle via Airport or Sydenham

Maintenance Depots

The trains were originally maintained at Eveleigh Maintenance Centre.

As with all other trains, these trains are not exclusively kept in Auburn overnight. They only need to return to the depot for maintenance, and at other times, they may be stabled at various yards on the lines that they operate, such as Liverpool and Leppington yards -Anastasia the train girl

I won’t be able to post as much cause mental issues plus I just came out to a friend as trans so I have to deal with that to

sorry for taking so long to respond! I've been busy lately.

9/10 good train (minus the bugs)

(also i hope all goes well for you! I enjoy your train asks, but don't feel bad if you don't want to send them as often.)

#trains#this one was cool#it seemed to sort of introduce concepts that were perfected for modern trains#so that's cool

3 notes

·

View notes

Text

Exporters of 3 Phase AC Induction Motor, Manufacturers of 3 Phase AC Induction Motor

Exporters of 3 Phase AC Induction Motor

.

The Sabar Group journey commenced in the year 1975, when sabar started its first unit for the manufacture of water pumps. Unbounded passion, unmatched skill and uncompromising quality control led the group from one success to another.

.

The ISO Certification and ISI & CE Marks and achievement of 5 star rating were just an affirmation that sabar is the signature of quality.

.

The path of progress has been marked by many milestones wherein consolidation and diversification have been the mantra. The foray into the export market confirmed the global vision of the company. The Group’s uncompromising commitment to quality

.

Manufacturers of 3 Phase AC Induction Motor

Our product range:

** Submersible pumpset

** Submersible motor

** Submersible pump Stainless Steel

** Monoblock Pumpset

** Openwell submersible Pumpset

** uPVC Pipe / uPVC column / Riser pipes / uPVC Casing pipes

** AC Induction Motor – Three Phase

** Submersible cable

.

3 Phase Induction Motor

Contact us :

Company: Sabar Pumps

Address: A2, 3912, Phase-IV, G.I.D.C. Estate,

Vatva – Ahmedabad – 382 445, Gujarat (INDIA)

.

Contact: +91 79 25840213 / +91 79 25840261

.

Email: [email protected] , [email protected]

Website : www.sabarpumps.com

0 notes