#Xylan coating

Explore tagged Tumblr posts

Text

Heavy Hex Nuts Manufacturer and Exporter from India | Bigboltnut

We are a Largest Manufacturer and exporter of heavy hex nuts in India. These nuts usre used in construction, ship making, marine, and oil gas industry. Bigboltnut manufacture grades of heavy hex nuts like 8, 10, 12. These heavy nuts grades are used in the anchor bolt threaded road, Astm studs blots and nuts that is used in chemical petrochemical industry. Nuts infrastrucre are multiple coated with Xylan coated because to the safety of hydrogen embrittlement post galvanising process. These coating are used when customers requirement. We also offer coating in blue, yellow, blacks as per our customers requirements. we are exporting these Nuts to many countries like USA, Europe and middle east.

Source Url: https://www.bigboltnut.com/product/heavy-hex-nuts.html

0 notes

Text

B7 Blue PTFE Coated Threaded Rods

#B7 blue PTFE Coated Threaded Rods#Ptfe Coated Fasteners#steel threaded rod with teflon coating#Xylan Stud Bolts

0 notes

Text

Xylan coatings fasteners |Roll fast

Xylan coatings with their popular grades such as Xylan 1424 and Xylan 1070 provide lubrication and controlled friction, wear resistance, heat resistance, non-stick and release properties. Xylan is used in a wide range of industries including automotive, oil & gas, food, aerospace and rubber manufacturing. Xylan coatings are dry-film lubricants combined in a matrix with high-temperature organic polymers developed to provide unique and desirable properties.

0 notes

Text

The Bahco Ergo Bypass Pruner PX-M2

Every gardener needs a trusty tool to make their gardening life easier. Let’s talk about “The Bahco Ergo Bypass Pruner PX-M2” today.

The Bahco Ergo Bypass Pruner PX-M2 is a game-changer for any gardener, whether you're a professional or a home gardener. Its professional-grade, ergonomic design is specifically crafted to reduce wrist and arm strain, making pruning tasks much more comfortable and efficient. The medium-sized handles are perfect for those with medium-sized hands, and the soft grip cover provides even more comfort during use. The medium-sized blades coated with Xylan can cut branches up to 3/4 inch thick with ease, and the fiberglass-reinforced plastic handles make this tool durable and long-lasting. Plus, with virtually every part available on Amazon, this pruner is a wise investment for any gardener looking for a reliable and efficient tool.

View the product here

There are more “Hand Pruning Shears” product suggestions you can check here

If you have found this post helpful, please share the post with others. And visit www.yardener.com for more information that is available for fully free.

#gardeningtools#gardenlife#yardener#gardeninginformation#garden#gardening#gardendesign#gardeningtips

1 note

·

View note

Text

Long Lasting Premium Xylan Coating 35 Cm Non-Stick Flat Pan RF7371 Royalford

SUITABLE FOR MULTIPLE COOKTOPS – The Royalford non-stick Tawa is suitable for multiple types of cooktops such as gas, ceramic, halogen, hotplate, and modular cooktops. This ensures easy cooking for all types of kitchens! It is great food cooking all types of dough-based foods. EVEN COOKING FROM DURABLE MATERIAL – The Royalford Tawa is made of strong and durable material with a non-stick coating that is easy to handle and cook with

0 notes

Text

Ananka

Q1) Are there hex bolts with specialized coatings for enhanced durability?

Ans) Certainly, hex bolts are available with specialized coatings intended to augment their durability and corrosion resistance across various environments. These coatings provide an extra layer of defense against factors such as moisture, chemicals, and other corrosive agents. Several common specialized coatings for hex bolts include:

1. Zinc Coating (Galvanized): Zinc coating, often referred to as galvanization, is a prevalent method for boosting the corrosion resistance of hex bolts. Galvanized hex bolts are enveloped in a layer of zinc that serves as a sacrificial barrier against corrosion. This coating is especially effective in environments prone to moisture and atmospheric exposure.

2. Cadmium Plating: Cadmium plating is an alternative choice for augmenting corrosion resistance. Hex bolts with cadmium coatings provide robust protection in environments with high corrosion rates, such as marine applications. However, cadmium is a toxic material, and its usage is restricted in some regions due to environmental concerns.

3. Xylan Coating: Xylan, a fluoropolymer-based coating, delivers exceptional corrosion resistance alongside non-stick properties. Hex bolts coated with Xylan are frequently employed in situations requiring resistance to chemicals, heat, and harsh surroundings.

4. Dacromet Coating: Dacromet is an inorganic, water-based coating that offers notable corrosion resistance and strong adhesion. It excels at safeguarding against salt spray and other corrosive substances.

5. Phosphate Coating: Phosphate coatings create a layer of phosphate crystals on the hex bolt's surface. These coatings heighten both lubrication and corrosion resistance, making them apt for applications involving sliding or moving components.

6. Teflon Coating (PTFE): Teflon, or PTFE (polytetrafluoroethylene), coatings bring forth superb non-stick attributes and resistance to chemicals and elevated temperatures. Hex bolts coated with PTFE are often chosen for scenarios where achieving adequate lubrication proves challenging.

7. Epoxy Coating: Epoxy coatings furnish robust defense against corrosion and environmental variables. They are commonly found in industrial and marine applications that demand substantial durability.

8. Nickel Coating: Nickel coatings contribute to both corrosion resistance and aesthetic appeal. They are frequently employed in decorative and marine settings.

9. Stainless Steel: While not conventionally deemed a coating, employing stainless steel hex bolts ensures inherent corrosion resistance. Stainless steel contains chromium, which generates a protective oxide layer halting rust and corrosion.

When opting for specialized coated hex bolts, it's pivotal to assess the specific environmental circumstances and requisites of your particular application. Different coatings provide varying degrees of safeguarding and performance, making the selection of the appropriate coating pivotal in ensuring that hex bolts maintain enhanced longevity within their designated environment.

Elevator Bolt Manufacturers in Mumbai

Q2) How do you choose between standard hex nuts and flange nuts?

Ans) The decision between standard hex nuts and flange nuts hinges on the distinct needs of your application and the advantages each type offers. Here are key considerations to factor in when making your selection:

Standard Hex Nuts:

1. Versatile Application: Standard hex nuts, also known as hexagon nuts or regular nuts, are versatile and commonly used across various contexts. They enjoy wide availability.

2. Simplicity: Standard hex nuts are straightforward to work with, designed to match standard hex bolts and threaded rods.

3. Cost-Effectiveness: Generally, standard hex nuts are more budget-friendly compared to specialized alternatives like flange nuts.

4. Space Constraints: Standard hex nuts feature a lower profile than flange nuts, which proves advantageous in situations with confined space or limited clearance.

5. Load Distribution: Although not as comprehensive as flange nuts, standard hex nuts still distribute loads across the threaded connection.

Flange Nuts:

1. Integrated Washer: Flange nuts possess an integrated washer-like flange at their base. This flange spreads the load over a larger surface area, mitigating the risk of the nut digging into softer materials and ensuring a more secure linkage.

2. Resistance to Vibration: The flange of a flange nut effectively counters loosening due to vibrations, rendering them apt for scenarios where movement or vibration is a concern.

3. Sealing Properties: Flange nuts can offer a certain degree of sealing between the nut and the connected surface, forestalling the entry of moisture or debris into the threaded connection.

4. Temperature Adaptability: Flange nuts exhibit enhanced resistance to temperature-related expansion and contraction, making them fitting for applications subjected to temperature fluctuations.

5. Reduced Surface Impact: The expanded flange bestows more uniform pressure dispersion, curbing the possibility of surface impairment to the fastened material.

6. Elevated Strength: In certain instances, flange nuts can yield higher strength on account of the enlarged bearing surface.

Factors for Consideration:

1. Application Prerequisites: Evaluate your application's distinct demands. Should you require augmented load dispersion, vibration resistance, or sealing, flange nuts might be the more appropriate choice.

2. Spatial Limitations: In cases of confined space, standard hex nuts could be more favorable due to their lesser profile.

3. Budget Considerations: Given that flange nuts are generally pricier than standard hex nuts, financial considerations may factor into your choice.

4. Material Compatibility: Ensure that the selected nut type aligns with the material you're fastening and the kind of bolt or threaded rod being utilized.

Ultimately, your selection between standard hex nuts and flange nuts hinges on the balancing of cost, functionality, and the distinct requisites of your application. It's advisable to seek insights from engineering professionals or fastening system experts to make an educated decision grounded in your unique circumstances.

Hex Nut Suppliers

Q3) What are the implications of using oversized or undersized plain washers?

Ans) Using oversized or undersized plain washers can have various implications on the effectiveness and safety of the fastening system. Here's how both scenarios can impact the application:

Oversized Plain Washers:

1. Load Distribution: Oversized washers can provide better load distribution across the connected surfaces. This can help reduce the pressure on the material being fastened and prevent surface damage or deformation.

2. Stability: The larger diameter of oversized washers can improve the stability of the connection by increasing the bearing surface area.

3. Vibration Damping: Larger washers might offer better vibration damping properties, which can be beneficial in applications where vibration is a concern.

4. Clearance Issues: However, using oversized washers can lead to clearance issues in tight spaces or applications with limited room for the washer to fit.

5. Aesthetics: Oversized washers might not have a neat appearance and could affect the overall aesthetics of the assembly.

Undersized Plain Washers:

1. Load Distribution: Undersized washers might not distribute the load evenly across the connected surfaces, leading to localized pressure points that can cause surface damage or material deformation.

2. Reduced Stability: Smaller washers have a smaller bearing surface area, which can reduce the stability of the connection and potentially lead to bolt or nut loosening.

3. Vibration Issues: Undersized washers may not provide effective vibration damping, increasing the risk of fastener loosening due to vibrations.

4. Compromised Sealing: In applications where sealing is important, using undersized washers might compromise the effectiveness of the seal between the fastener and the connected surface.

5. Potential for Nut/Bolt Failure: In extreme cases, the use of significantly undersized washers might increase the risk of nut or bolt failure due to inadequate load distribution.

Choosing the Right Size:

1. It's essential to choose plain washers of an appropriate size that match the diameter of the bolt or screw being used. The washer's outer diameter should not exceed the diameter of the connected material.

2. Consider the specific requirements of the application, load, vibrations, and any space limitations when selecting the washer size.

3. Follow manufacturer guidelines and industry standards to ensure proper washer size selection.

In summary, the implications of using oversized or undersized plain washers can affect load distribution, stability, vibration resistance, clearance, aesthetics, and even the overall integrity of the fastening system. It's crucial to carefully select the appropriate washer size based on the application's needs and follow best practices to ensure a secure and effective connection.

Carbon Steel Fasteners

Q4) How do you choose between standard stud bolts and fully threaded studs?

Ans) Choosing between standard stud bolts and fully threaded studs depends on the specific application, requirements, and structural considerations. Here are some factors to consider when making this decision:

Standard Stud Bolts:

1. Load Distribution: Standard stud bolts typically have a threaded portion at both ends and an unthreaded portion (the shank) in the middle. This unthreaded portion can provide improved load distribution and reduce stress concentrations in the connected components.

2. Assembly Ease: The unthreaded shank of standard stud bolts allows for easier assembly and disassembly. Nuts can be threaded onto the stud more easily without encountering resistance from threads on the entire length.

3. Thread Engagement: Standard stud bolts provide better thread engagement within the nut due to the unthreaded shank. This can enhance the overall stability and reliability of the connection.

4. Torque Transmission: The unthreaded shank of standard stud bolts allows for efficient torque transmission during tightening, reducing the risk of overloading or damaging the components being connected.

5. Application Flexibility: Standard stud bolts are versatile and suitable for various applications where load distribution, ease of assembly, and torque transmission are critical.

Fully Threaded Studs:

1. Threaded Engagement: Fully threaded studs have threads along their entire length, providing more threads to engage with nuts or threaded holes. This can offer increased resistance against loosening in dynamic or vibrating environments.

2. Length Adjustment: Fully threaded studs allow for precise length adjustment by threading the nut along the entire length. This can be beneficial when the connected components need to be precisely positioned.

3. Space Constraints: In applications with limited space, fully threaded studs can be advantageous as they eliminate the need for a nut on one end, potentially saving space.

4. Shear Strength: In applications requiring shear strength, fully threaded studs may have a more uniform cross-sectional area along their length, potentially providing higher shear resistance compared to standard studs.

5.Specific Design Requirements: Some applications may require fully threaded studs due to design constraints or specific assembly requirements.

Choosing Between Them:

1. Load Distribution and Stability: If load distribution and stability are critical, standard stud bolts with unthreaded shanks are often preferred.

2. Vibration and Dynamic Loads: For applications with significant vibration or dynamic loads, fully threaded studs might offer better resistance against loosening.

3. Ease of Assembly: Standard stud bolts can offer easier assembly and disassembly due to the unthreaded shank.

4. Precise Positioning: If precise positioning is required, fully threaded studs allow for more precise length adjustment.

5. Application Constraints: Consider space constraints, shear strength requirements, and other specific application factors when making the choice.

Ultimately, the decision depends on the specific needs of your application. Assess the load distribution, assembly requirements, space constraints, and other relevant factors to determine whether standard stud bolts or fully threaded studs are the better fit for your particular situation.

Inconel Bolts Price

0 notes

Text

Benefits of Xylan ®️Coating. Control friction and lubrication. Preventing friction is especially important for the lifespan extension of many machine parts.

We are experts in coating services for the Food, Pharma, Medical, Chemical, Automobiles, Packaging & Textile Industries.

📞 contact number :+91 9482547777

📩Email id: [email protected]

🌍Website: https://www.dixitsurfacetechnology.com/

join with us:

https://www.linkedin.com/in/dixit-surface-technology-70013924a/

#vaccumroller#xylancoating#foodgradecoating#nonstickcoating#TeflonCoating#industrialcoating#surfacecoating#coating

0 notes

Text

Exciting News! Introducing our revolutionary Teflon ®️ coating on mould ,say goodbey to clogged mould and hello to unmatched performance!

One stop solution for all your coating requirements like Teflon ®️ coating,Food grade coating, Non-stick coating,Xylan ®️ coating,Halar coating and many more. 📞 Contact number:+91 9845255225 📩 Email id : [email protected] 🌎 Website :www.hvmsurfacecoatings.com/ Follow for more updates: https://www.facebook.com/profile.php?id=100083305150721 https://www.instagram.com/hvmsurfaceengineering/ https://twitter.com/HVMsurfaceEng https://www.linkedin.com/in/hvm-surface-engineering-151a6a241/ https://in.pinterest.com/HVMsurfaceengineeing/

#mould#tefloncoating#xylancoating#foodgradecoating#shotblasting#glassbeadblasting#surfacecoating#industrialcoating#ceramiccoating

0 notes

Text

Teflon ®️coating is also known as an anti-rusting coating or paint protection coating. Technically, Teflon®️ is a chemically synthesized form of the fluoropolymer.

We are masters in all types of coating services like Teflon®️ coating, Food grade coating, Nonstick coating, Xylan®️ coating, Halar coating, PTFE coating, PVC coating and more.

📞contact number :+91 94809 55999

📩Mail Id :[email protected]

🌍Website :https://www.ananyacoatings.com/

Follow us on:

https://www.linkedin.com/in/ananya-fluoro-polymer-coatings-63342124b/

#sealers#tefloncoating#foodgradecoating#nonstickcoating#industrialcoating#surfacecoating#shotblasting

0 notes

Text

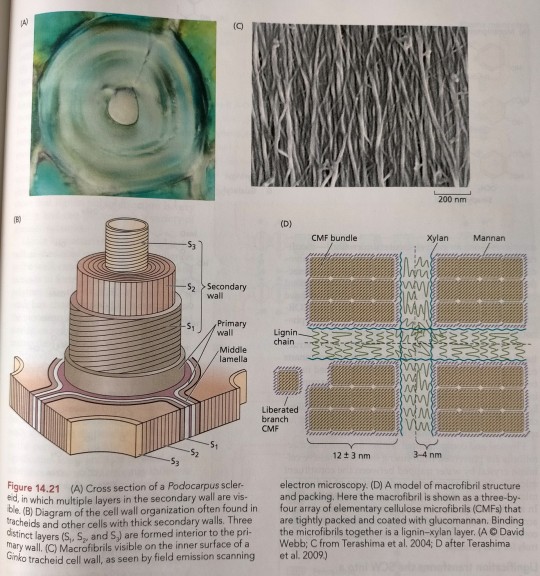

The secondary cell wall (SCW) is a hierarchical structure assembled by some living cells inside the primary cell wall after wall expansion has ceased (Figure 14.21A and B). (...) The best-studied SCWs consist of sequentially formed concentric layers named S1, S2, S3, and so on, but the number of layers varies with cell type (see Figure 14.21B). (...) SCW lamellae contain highly aligned cellulose microfibrils that are assembled into tightly packed macrofibrils, which in turn coalign with each other and are separated by hemicellulose and lignin (Figure 14.21C). (...) One model by Terashima and coworkers (Figure 14.21D) illustrates some basic concepts of macrofibril construction at the nanoscale, but details of the model are hypothetical, and alternative relationships among cellulose, hemicellulose, and lignin have been proposed. (...) The model shown in Figure 14.21D indicates a structured arrangement of matrix polymers, with glucomannans coating the macrofibril surface, xylans positioned in the next layer, and lignin linking xylans and filling the remaining side between macrofibrils.

"Plant Physiology and Development" int'l 6e - Taiz, L., Zeiger, E., Møller, I.M., Murphy, A.

#book quotes#plant physiology and development#nonfiction#textbook#plant cells#cell wall#microscopy#podocarpus#microfibril#macrofibril#cell growth#hemicellulose#lignin#terashima#ginkgo#glucomannan#xylan

0 notes

Text

Xylan Coating oven, Xylan Coating oven Manufacturers, Suppliers in India

Xylan Coating Oven work well in every application, where you need non-stick and dry lubrication products for heat treatment and curing metal coats. Available specially in Gas Fired & Electrical Model for High Temperature. Halar Coating Oven, Geomet Coating Oven, Dacromet Coating Oven, PVDF, PTFE Coating Oven, PFA Coating Oven etc.

0 notes

Photo

Finishing a batch of blue Xylan, a @ppgindustries coating for fasteners #iacoatings #coating #ppg #whitford #xylan #industrial #fasteners #hardware #nutsandbolts #houston #texas #htx (at IA Coatings) https://www.instagram.com/p/CSZQbGNrwii/?utm_medium=tumblr

1 note

·

View note

Text

Wholesale Xylan Coated Threaded Rods Stud Bolt

#Blue Teflon Steel Threaded Rod#TEFLON COATED Stud Bolt#TEFLON COATED Threaded Rods#XYLAN Coated Stud Bolt#XYLAN Coated threaded rod

0 notes

Text

Stainless Steel Bolts | Roll Fast

Roll-fast is a manufacturer and supplier of different stainless steel fasteners. These bolts or screws are offered in A4-70, A4-80, B8, B8M Class 1 and Class 2, and SS316S31 grades. Stainless steel bolts are polished or ground after forging and other activities to provide them with a bright finish. Sometimes customers require stainless steel bolts to be Xylan coated to provide an added layer on top of the surface's bright finish. These bolts & nuts are manufactured only by the hot forging process.

visit source url : https://www.roll-fast.com/products/standard-bolts/stainless-steel-bolts.html

0 notes

Photo

PTFE Coatings Services, Fluoro Polymer Ptfe Coating Services,Xylan Coating Services,Halar coating, Non stick coating based in Bengaluru,PTFE Coatings Services ,halar coating, Xylan Coating Services, teflon coatings,pvc coating,dupont coating,polymed coating,aluminium oxide blasting,glass bead blasting,corrosion resistant coatings, non stick coatings, chemical resistant coatings, Fluoro Polymer Ptfe Coating Services,tank coatings, release coatings, Non stick coating, protective coatings bangalore karnataka,india,http://www.ananyacoatings.com

0 notes

Link

RPI India provides a full range Of PTFE Coated Bolts And Nuts, Teflon coated bolts and nuts , PTFE Coated Stud Bolts in best price. PTFE coated fastener’s provides exceptional corrosion resistance, low coefficient of friction, consistent tensioning and subsequent ease of installation and removal. Extensive testing and field use have proven that the future of Teflon Coated B7 Stud Bolts lies with Fluoropolymer coatings. PTFE coated B7 studs with 2H nuts are widely used in various applications.

#Teflon coated bolts and nuts#Zinc flake coating Mumbai#xylan coated fasteners#Zinc flake coatings Mumbai

0 notes