#Ptfe Coated Fasteners

Explore tagged Tumblr posts

Text

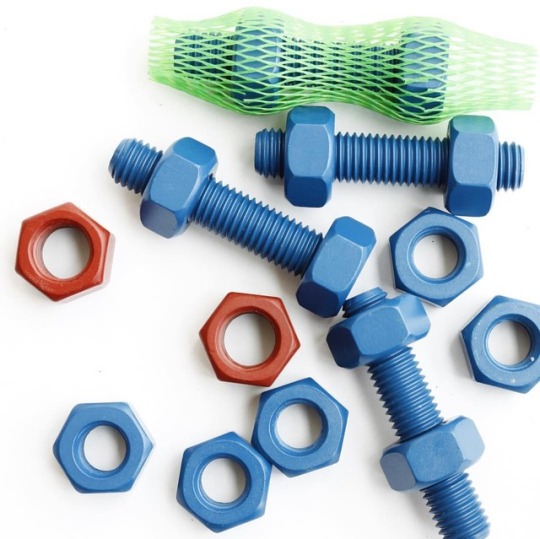

B7 Blue PTFE Coated Threaded Rods

#B7 blue PTFE Coated Threaded Rods#Ptfe Coated Fasteners#steel threaded rod with teflon coating#Xylan Stud Bolts

0 notes

Text

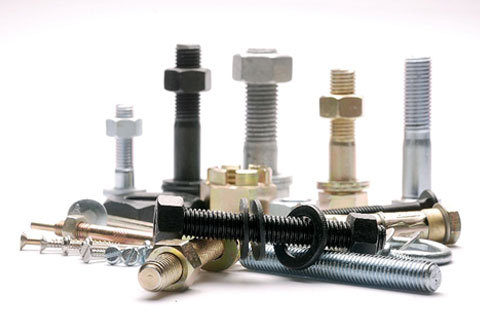

Standard bolts | Roll Fast

Roll-fast takes pride in being the largest manufacturer and supplier of standard bolts in India. Standard bolts are a fundamental element in construction and engineering, serving as the primary method for fastening and securing components in a wide range of applications. These bolts come in various types, each designed to meet specific requirements and standards, ensuring reliability and consistency in performance. Their standardized manufacturing processes ensure consistency, quality, and safety, making them a cornerstone of modern engineering and construction practices. We also do various finishes and colors according to the specifications and needs of the customer. We provide Self-finish or natural finish, Zinc plated, yellow Zinc, blue Zinc, black, Hot Dip Galvanized (HDG), Geomat, PTFE, Xylon coating, etc. Visit us to know more.

visit source url : https://www.roll-fast.com/products/standard-bolts.html

0 notes

Text

Hastelloy B3 Fasteners Suppliers

The Deep Steel Center is one of the extraordinary Suppliers and Manufacturers of Hastelloy B3 Fasteners. We give the entire level of adding in different points of view, sizes, types, and decisions. Our offered Fasteners have huge security from hydrochloric staggering at all concentrations and temperatures. Hastelloy B3 Fasteners are made by utilizing ideal-quality, unrefined substances. These things are utilized in decreasing acid affiliations and locking the fasteners of warming stuff. Hastelloy B3 Secure Fasteners are conveyed using a mix containing nickel and molybdenum as the base part and movements of cobalt and tungsten. Our offered substances are normal for exceptional hydrochloric harming, sulfuric acids, hydrobromic shocking, acidic deplorable, phosphoric harming, and formic harming. These grains offer mind-blowing strength and goodness in any acidic or decreasing medium.

Hastelloy B3 Fasteners push smooth coordination through welding gear and diminish tipping in contact tips. We are a proactive connection that offers Hastelloy B3 Fasteners and other quality things that meet and beat client unequivocal necessities and, as such, affirm full-scale satisfaction. We provide an enormous level of materials, like Hastelloy B3 Fasteners. Our offered Fasteners show sensational security from pitting, opening, disintegrating, and stress-use breaking in any chloride-containing conditions.

Standard Specification For Hastelloy B3 Fasteners

Specifications

ASTM B574 / ASME SB574

Fasteners size

Bolt / Screw Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Nuts Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Washers Size : M3 – M56 | 3/6″ to 2″ | Custom Sizes Machine Screws Size : M1.6 – M12 Self Tapping Screw Size : No.2 – No. 14

Fasteners Length

3 mm to 200 mm

Fastener Threads

UNF, BSW, BSF, METRIC, UNC or as required

Standard of High Nickel Alloy Fasteners

DIN : DIN 934, DIN 931, DIN 970, DIN 933 UTS : UNEF, NPT, UNC, UNS, UNF, NPTF ISO : JIS standards, ISO 4033, ISO 4032, ANSI – American National Standards Institute ASME B18.5 ANSI B 28.2.4 1M as per defined in ASME B16.5 standard Stud Bolt length ANSI B 18.2.4 2M as per defined in ASME B18.2.2 Hex nuts

Dimensions

DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3

Surface Coating

Ptfe Coated High Nickel Alloy Fasteners Phosphate Coating Teflon Coating Zinc Coating Hot Dipped Galvanizing Coating Cadmium Coating Xylon Coating

Fasteners Finishing

High Nickel Alloy : Self-Colour, Passivated, Bright Zinc Plated (BZP), Hot Dip Galvanised (HDG), High Nickel Alloy, Sherardized, some special one like DACROMET Geometry and Mechanically Applied coating ,Dacroment, nickel plated, anodizing, plated zinc-nickel Zinc (blue, black, yellow, white), black oxide.

For more information:

Visit website: https://www.deepsteelalloys.com/hastelloy-alloy-b3-fasteners-supplier.html

#Hastelloy B3 Fasteners Manufacturers#Hastelloy B3 Fasteners Suppliers#Hastelloy B3 Fasteners Stockists#Hastelloy B3 Fasteners Exporters#Hastelloy B3 Fasteners Manufacturers in India#Hastelloy B3 Fasteners Suppliers in India#Hastelloy B3 Fasteners Stockists in India#Hastelloy B3 Fasteners Exporters in India#Hastelloy B3 Fasteners Manufacturers in Mumbai#Hastelloy B3 Fasteners Suppliers in Mumbai#Hastelloy B3 Fasteners Stockists in Mumbai#Hastelloy B3 Fasteners Exporters in Mumbai

0 notes

Text

What You Need to Know About PTFE Coating Services in Ohio

If you're in Ohio and looking to enhance the performance and durability of your products and components, PTFE (polytetrafluoroethylene) coating services can be a game-changer. PTFE, often recognized by its brand name Teflon, offers a protective and functional coating that can elevate ordinary items to exceptional levels. In this comprehensive guide, we'll dive into the essential aspects of PTFE Coating Services in Ohio, shedding light on the benefits and considerations you should keep in mind.

Understanding PTFE Coating Services

What is PTFE?

PTFE stands for Polytetrafluoroethylene, a synthetic fluoropolymer of tetrafluoroethylene. It is renowned for its exceptional non-stick properties, chemical resistance, and high-temperature tolerance. These characteristics make PTFE a sought-after material for coating various surfaces and components.

The Versatility of PTFE Coating

PTFE coating services offer versatility that is hard to match. Whether you're in the automotive, aerospace, or food processing industry, PTFE coatings can enhance the performance and durability of your equipment. Here's a glimpse of where PTFE coatings shine:

1. Automotive Industry

In the automotive sector, PTFE coatings are widely used on engine components, such as pistons and gaskets, to reduce friction and improve fuel efficiency. These coatings also provide excellent corrosion resistance, ensuring the longevity of critical parts.

2. Aerospace Applications

In aerospace, where precision and reliability are paramount, PTFE coatings play a crucial role. They are applied to critical components like bearings and fasteners, enhancing their performance under extreme conditions.

3. Food Processing

PTFE's non-stick properties find extensive use in the food processing industry. Conveyor belts, baking molds, and cookware coated with PTFE ensure easy release of food products and simplify the cleaning process.

Benefits of Choosing PTFE Coating Services

When you opt for PTFE coating services from Euclid Refinishing Company, you unlock a myriad of benefits:

1. Exceptional Non-Stick Properties

PTFE coatings provide a non-stick surface that prevents adhesion, making it ideal for cookware and industrial applications alike.

2. Corrosion Resistance

PTFE coatings offer outstanding resistance to chemicals and corrosion, ensuring the longevity of coated components.

3. High-Temperature Tolerance

With the ability to withstand extreme temperatures, PTFE coatings are invaluable in applications that involve exposure to heat.

4. Reduced Friction

In machinery and automotive applications, PTFE coatings reduce friction, leading to improved efficiency and reduced wear and tear.

Why Choose Euclid Refinishing Company?

At Euclid Refinishing Company, we take immense pride in being Ohio's premier provider of PTFE coating services. Our commitment to excellence and unmatched expertise in the field makes us the top choice for industries across the state. Here's why you should choose us:

Extensive Experience

With years of experience in the industry, we understand the unique coating needs of various sectors. Our team of experts has successfully executed numerous projects, delivering exceptional results every time.

Cutting-Edge Technology

We invest in state-of-the-art equipment and stay updated with the latest advancements in PTFE coating technology. This ensures that our clients benefit from the most innovative and effective solutions.

Customized Solutions

We recognize that each project is unique. That's why we offer customized PTFE coating solutions tailored to your specific requirements. Our flexibility and attention to detail set us apart.

Quality Assurance

Quality is at the core of everything we do. Our rigorous quality control processes guarantee that every coated component meets the highest standards of excellence.

Contact Euclid Refinishing Company Today!

Ready to experience the exceptional benefits of PTFE coating services in Ohio? Contact Euclid Refinishing Company now and let us transform your industrial processes. Reach out to us at (440) 275-3356 and speak to our experts. Your success is our priority, and we're here to take your operations to the next level with top-tier PTFE coating solutions.

In conclusion, when it comes to PTFE coating services in Ohio, Euclid Refinishing Company is your trusted partner. Our expertise, commitment to quality, and dedication to meeting your unique needs make us the number-one choice for industries seeking top-notch PTFE coating solutions. Don't compromise on quality; choose Euclid Refinishing Company, Inc for all your coating needs.

Resource URL: https://bit.ly/3sSVb2J

0 notes

Photo

#exclusive #studbolts and #nuts with #xylan #coating #fasteners #red #bluexylan #ptfe #coated #fastenersaresexy #boltsandnuts #manufacturer #boltport #mumbai #india (at BoltPort Fasteners LLP)

Boltport is a premium Xylan Coated Fasteners Manufacturer and Supplier from Mumbai, India.

#red#ptfe#boltsandnuts#studbolts#fasteners#bluexylan#boltport#xylan#nuts#coated#manufacturer#mumbai#coating#india#exclusive#fastenersaresexy

1 note

·

View note

Text

Nickel Plated Fasteners – The next generation fasteners for industries

Fasteners are holding many mega structures together that are beyond explanation. You will find today, there are dedicated companies who are working on developing next generation fasteners to meet the rising demands in the market. Nickel Plated Fasteners are some what considered to be the next gen thing. You can rely on their durability and efficiency against corrosion. There are not many things that are dedicatedly developed to meet the current and future needs. But in case of fasteners, today people are thinking in such direction and taking utmost care in developing new products.

PTFE Coated Fasteners are another perfect example, which can be really effective with its own set of features. These usually provide

1. Exceptional corrosion resistance

2. Low coefficient of friction,

3. Consistent tensioning and

4. Subsequent ease of installation and removal

You can today get all these wonderful fasteners for your work directly home delivered with the efficient websites that are working 24X7 to provide good customer service. Nickel Plated Fasteners are showing good results in the long run. Therefore, many companies with some specific conditions prefer to use these fasteners for their structural purposes.

You can visit hex-bolt.com for more details on different kinds of fasteners and the subsequent use of those products for your work. They are an established company working dedicatedly to provide online delivery of all types of fasteners that are used for industrial and commercial purposes. You can check on a variety of different priced products that will be helpful and equivalent to your current needs.

0 notes

Text

Arabian Arrow Supply and Services - Tailor Made Products and You Partner of Choice!

Arabian Arrow Supply and Services Company Limited is a renowned manufacturer and authorized distributor company as well as a stockist for all industrial, electrical, mechanical instrumentation, and industrial parts and accessories. Being based in the Eastern Province of Saudi Arabia and catering to all the leading international branded manufacturers this company has recently crossed 16 years of excellence.

Some of the well-known and established products and inventory include the Stainless Steel Cable tie, SS Straps and bands, SS clips and buckles, Fire Blanket Fabrics, Firestop sealant, Nylon and Canon Ferrule Printers, and so on. We dynamically fabricate innovative products and being the foremost manufacturer we are engaged in offering an exclusive collection to our honored clientele. Our infrastructure and state-of-the-art manufacturing facilities are to be talked about and all our instrumentation passes through rigorous quality checks conducted by experienced quality analysts.

We manufacture quality products with the fastest and best delivery practices and have carved out a niche in affordable fire-stopping solutions, Cable tie distributorship, SS identification systems, cable accessories, and much more. We are also known for high volumes of inventory that are supplied to leading brands and we are proud to be their sole source. Within the Saudi Arabian market and the Middle East market, we get an overwhelming response and are striving to increase the same potential more geographically apart from the ancient routes of the USA, UK, and Italy.

Leveraging on our expertise we can cater to the finest quality of products for our patrons. All our products are precisely engineered with cutting technology at our disposal. We are known across the Industry for our robust construction, durability, optimum performance, and competitive pricing. We offer guidance to our clients and adapt the best practices in our processes for enhancing client satisfaction at our touch points.

Our Product Category includes –

Variety with Utility

Band-IT SS- These fastening products are mostly used in heavy-duty applications where there is no tolerance for failure. With products like BAND- IT BALL – LOK TIES, Ultra LOK ties, SS color bands, Stainless steel Buckles, and tightening and hand tools, it is ensured that the clamping force is forced out across the full perimeter of the contact area of the items they are joining. This allows joining without any alteration and these engineered solutions are not just going to let you down.

3M Fire Stop- These products are manufactured with total precision and prevent the spread of fire, smoke, or any toxic gases and come with a lot of technical expertise. There are fire barrier devices, duct wraps, composite sheets, fire stop identification labels, fire rated foam, mouldable Putty, and sealants.

Fothergill Fire Blanket- We also specialize in fabrics for high-temperature applications and they prove cost-effective in many cases. The defense glass roving, aerospace woven fabrics, high temperature fire blankets, PTFE Elastomer coatings, and hybrid fiber blends are specially developed and satisfy all our client's special requirements. They contribute to overall lightweight and some of them are increasingly being specified in various applications like aerospace and severe heat environment.

Cobra Nylon Fasteners -This range has cable ties which is a fasteners for holding items together primarily electrical cables and wires. The cobra cable ties are easy to use and known for their building strength. Similarly, there are adhesive mounts that find their use in a wide range of applications and help in bonding a wide variety of substrates. It has another advantage of resisting flex and vibration and has excellent cohesive strength. The Cobra Nylon Fasteners are made of reinforced nylon that offers maximum holding power. The nylon material prevents any kind of loosening from vibration.

youtube

0 notes

Text

Benefits of Xylan™ Coatings. Control friction and lubrication. Preventing friction is especially important for the lifespan extension of many machine parts. Even simple things like bolts and their fasteners last much longer if they are protected by a thin film of Xylan industrial coating.

We are master in coating services for the Teflon coating, Food grade coating, Nonstick coating, Xylan coating, Halar coating, PTFE coating, PVC coating and the powder coating.

#shoe#shoe_mould#xylan_coating#halar_coating#foodgrade_coating#pfa_coating#nonstick_coating#Teflon_Coating#teflon_lining#pfa_lining#pu_coating#pu_lining#pvc_coating#PTFE_Coating#powder_coating#spring_coating#shot_blasting#Sand_Blasting#glassbend_blasting#coating_indsutry#Ananya

0 notes

Text

Coated Fasteners: Comprehensive Guide

Introduction

Fasteners are critical components in a variety of industries, ensuring the strength and stability of assemblies. To enhance their durability, resistance to environmental factors, and aesthetic appeal, fasteners are often coated. This blog delves into coated fasteners, focusing on their types, applications, and benefits, while also spotlighting Ananka Group as a leading coated fastener manufacturer in India.

India has emerged as a global hub for manufacturing high-quality fasteners. Among these, coated fasteners are a specialty, with manufacturers focusing on advanced technologies to ensure durability and reliability. Renowned manufacturers, like Ananka Group, provide a vast range of coated fasteners that meet international standards such as ASTM, ISO, and DIN. With state-of-the-art facilities and rigorous quality checks, these manufacturers cater to industries such as automotive, construction, marine, aerospace, and more.

Why Coated Fasteners?

Fasteners are exposed to various environmental and operational conditions, including moisture, heat, chemicals, and mechanical stress. Coating serves several purposes:

Corrosion Resistance: Prevents rust and degradation in harsh environments.

Enhanced Durability: Increases lifespan by protecting the base material.

Improved Aesthetics: Provides an appealing finish.

Reduced Friction: Facilitates smoother tightening and loosening processes.

Types of Coated Fasteners

Coated fasteners are available in various types, each tailored for specific applications and environments:

1. Blue Zinc Plated Fasteners

Features: A blue-tinted coating provides moderate corrosion resistance while enhancing aesthetic appeal.

Applications: Commonly used in automotive and construction industries.

2. Hot Dip Galvanized Fasteners

Features: A thick zinc coating applied by dipping in molten zinc, providing excellent corrosion resistance.

Applications: Ideal for outdoor use, including bridges, towers, and fences.

3. PTFE Coated Fasteners

Features: Non-stick, low-friction coating that resists chemicals and high temperatures.

Applications: Found in chemical plants, marine environments, and oil & gas industries.

4. Yellow Zinc Plated Fasteners

Features: Golden hue adds aesthetic value while providing corrosion resistance.

Applications: Used in decorative and structural applications.

5. Aluminium Zinc Flake Coated Fasteners

Features: Combines aluminium and zinc flake layers for superior corrosion resistance without hydrogen embrittlement.

Applications: Commonly utilized in the automotive and wind energy industries.

6. Black Phosphate Fasteners

Features: Offers moderate corrosion resistance with a matte black finish.

Applications: Widely employed in the automotive and electronics sectors.

7. Zinc Cobalt Plated Fasteners

Features: Enhanced corrosion resistance compared to standard zinc plating.

Applications: Popular in the automotive sector for under-the-hood components.

8. Black Zinc Plated Fasteners

Features: Provides a sleek black appearance with good corrosion resistance.

Applications: Used in architectural and decorative projects.

9. Zinc Plated Fasteners

Features: Economical coating offering basic corrosion protection.

Applications: Suitable for indoor use in furniture and appliances.

10. Nickel-Plated Fasteners

Features: Highly durable and resistant to corrosion and wear.

Applications: Commonly used in electronics and decorative applications.

Benefits of Coated Fasteners

Extended Lifespan: Coatings significantly increase the longevity of fasteners.

Cost-Effective: Reduces maintenance and replacement costs.

Environment-Specific Protection: Tailored coatings provide protection in specific conditions, such as saltwater or high temperatures.

Enhanced Performance: Reduces wear and tear on mating parts.

Manufacturing Excellence: Ananka Group

Ananka Group is a renowned manufacturer and supplier of high-quality coated fasteners in India. With cutting-edge technology and stringent quality controls, the company produces a wide range of coated fasteners tailored to diverse industrial needs. Key features include:

State-of-the-Art Facility: Advanced machinery ensures precision and uniform coating.

Custom Solutions: Tailored coating solutions for specific applications.

Global Reach: Exporting coated fasteners to countries worldwide.

Quality Assurance: Products meet international standards, including ASTM, DIN, and ISO.

Applications of Coated Fasteners

Coated fasteners find applications across various industries:

Construction: Bridges, buildings, and infrastructure.

Automotive: Chassis, engines, and decorative elements.

Marine: Ships, docks, and offshore platforms.

Oil & Gas: Pipelines, rigs, and refineries.

Electronics: Circuit boards and enclosures.

Conclusion

Coated fasteners are indispensable in modern industries, offering unparalleled durability, resistance, and functionality. Selecting the right type of coating is crucial for optimal performance in specific environments. With Ananka Group’s expertise in manufacturing coated fasteners, customers can be assured of top-notch quality and reliability.

FAQs

Q1: What are coated fasteners?

Coated fasteners are fasteners with a protective layer to enhance their resistance to environmental factors, improve performance, and extend their lifespan.

Q2: How do I choose the right coating for my fasteners?

Consider the application environment, required corrosion resistance, and budget. For example, PTFE is ideal for chemical resistance, while hot-dip galvanizing suits outdoor use.

Q3: Are coated fasteners more expensive?

While the initial cost might be higher than uncoated fasteners, their extended lifespan and reduced maintenance costs make them cost-effective in the long run.

Q4: Can coated fasteners be used in marine environments?

Yes, coatings like PTFE and hot-dip galvanizing are suitable for marine environments due to their high corrosion resistance.

Q5: Does Ananka Group offer customized coating solutions?

Yes, Ananka Group provides tailored coating solutions to meet specific industrial requirements.

#anankafasteners#ananka#manufacturer#fasteners#supplier#mumbai#hex#bolt#usa#uk#Coatedfasteners#fastenersmanufacurer

0 notes

Text

ASTM A193 Grade B7 | Roll Fast

ASTM A193 grade B7 covers fasteners of chromium-molybdenum alloy steel. These fasteners found their utilize in chemical and petroleum development applications. They are made after treating (warm treatment) and extinguishing to obtain the perfect mechanical properties and hardness. B7 is one of the most grade utilized in A193 gr b7 and is basically executed in zinc plating, zinc coating, hot-dip galvanizing, PTFE coating or coated, and xylan coating to anticipate corrosion.

visit source URL: https://www.roll-fast.com/astm-a193-grade-b7.html

0 notes

Text

Know All About the A193 B8m -A prefect Stainless steel

A193 B8m specifications are used in oil and chemical structure applications. ASTM standards cover high-temperature or high-pressure stainless steel and alloy steel such as B7 bars. STM A193 carbonless and stainless steel rods and bolts are used to connect flanges, valves, pressure vessels, and fittings to high temperature and high-pressure services.In 1936, specificationA193 B8m was approved. This specification is commonly utilized in structural applications in the petroleum and chemical industries. Fasteners for pressure vessels, valves, flanges, and fittings are included in this specification. This material is often available at thread pitches, but for use in conventional applications, threads larger than 1 inch are specified as eight threads per TPI).There are several grades to the A193 specification with different chemical compositions, mechanical properties, and high temperature properties. The most common grade in the A193 specification is Class B7, but there are several others.Fasteners based on Spec A193 are commonly specified, manufactured, and supplied as heavy hexagon bolts or threaded rods and bolts (weekend thread bolts). The carbon steel flanges manufacturers in india offer a series of bent bolts (U, L, or J), threaded rods at one or both ends, and heavy, non-hexagonal head bolts. All screws, rods, and bolts must be flushed.ASTM A962 is a related standard that covers a set of general requirements related to A193. Section 13 of the A962 specification corresponds to the shape and class of the wire. The threads must be in accordance with ASME B1.1, Class 2A, and can be cutting or coil type. If the diameter is 1 inch or less, the National Unified Coarse (UNC) thread chain is used, and if the diameter is larger than 1 inch, the 8UN (8UN) thread chain is used unless otherwise stated.CoatingCertain grades of fasteners made with ASTM A193 (hot-dip galvanized, mechanically galvanised) or F1941 (mechanically galvanized) can be galvanized (cold or electro-galvanized). Teflon, xylan, and PTFE coatings are also often utilized with A193V, in addition to cadmium coatings.Product labelThe quality code and the stainless steel carriage bolt manufacturers‘ identification information both apply to the screw head and one end of the threaded rod and bolt. Section 17 of the A193 B8m specification describes the omission of product marks on the fasteners and the tolerance for marking very small diameters elsewhere, but rarely the work. Dual grade marks are permitted as long as the fasteners meet all the requirements of both specifications.Dimension exampleUnless otherwise stated, plug screws must be dimensional heavy hexagons covered with A193 B8m. A193 rods and bolts are typically measured from first thread to first thread instead of full length, including the sloping ends.The high tensile fasteners manufacturers in india can manufacture all kinds of fasteners such as studs, hex bolts, flange bolts, flat nuts and washers, flange nuts and spring washers, non-standard products.Durable and strong fasteners for customers at the most competitive market prices in the world. The stainless steel flanges manufacturers in india manufactured a wide range of hex nuts and bolts under the best guidance and gained the highest reputation.

0 notes

Text

Benefits Of Solid Dry Film Lubricant Services

When oil or grease is applied to a bearing or gear, it can create a protective fluid film. This solid dry film lubricant in Cleveland protects the bearing or gear from wear, migration, and debris. However, when machinery is exposed to extreme temperatures, load, or wear, the liquid can change its fluid state and no longer offer protection.

Reduced Wear and Friction

Dry film lubricants offer a durable alternative to greases and oils. They have low coefficients of friction and can operate at higher temperatures than oil or grease. They are commonly used for metal-to-metal contact applications that require tribological protection from seizing and galling, as well as in release coatings. They also have excellent chemical and corrosion resistance.

These coatings are made up of a resin matrix that binds lubricating powders like graphite, MoS2, and PTFE to the substrate surface. They form a layer of lubricant that can be applied in thin films to prevent friction between mating surfaces and to improve lubrication efficiency. The material’s crystalline structure allows these coatings to shear into stacks of layers that slide easily against each other, creating a dry lubricant film. The layer-to-layer adherence of the dry film coating is what reduces wear and friction.

Reduced Downtime

Proper lubrication is critical to the safety and efficiency of machinery and equipment. Inefficient lubrication can result in downtime, part failure, equipment breakdown, and increased maintenance costs. Solid dry film lubricant services are formulated to reduce friction and wear on mating surfaces, avoiding the problems associated with fluid lubrication. They can be applied by a variety of methods, including spray, brush, and dipping.

Synthetic lubricants are formulated with additives to increase their performance in areas where petroleum based products may not be suitable. These lubricants typically offer superior resistance to abrasion, corrosion, and chemical attack, and are compatible with a wide range of processes. These lubricants are resistant to wear, galling, seizing, corrosion and temperatures, and can be used for fasteners, fabricated metal parts, chemical processing, semiconductor, and high temperature applications.

Also, read about Types of Solid Dry Film Lubricant Services

Reduced Maintenance Costs

Solid film lubricants provide a more robust product alternative to oils and greases for many applications. They can protect tooling and components from galling, seizing, fretting and corrosion. In addition, these coatings are able to operate in extreme temperature ranges and oxidizing environments that regular fluid lubricants cannot tolerate. They can also resist out-gassing under vacuum, making them ideal for aerospace and military applications. Dry film lubricants consist of a thin, firmly bonded film of a solid lubricating material, such as molybdenum disulfide or graphite, that is adhered to the substrate with a resin binder.

Increased Durability

There are a variety of dry film lubricant coatings available to protect and improve the performance of metal surfaces. These coatings, which are commonly formulated with different combinations of PTFE, graphite and Molybdenum Disulfide, offer high resistance to corrosion, wear, friction and extreme temperatures. Each dry film lubricant coating has unique properties that require proper selection and application for each specific surface. This is especially true for metallic or nonmetallic substrates, the operating temperature range, and the expected lubrication performance levels.

Euclid Refinishing Company, Inc. can help you determine which dry film lubricant coating is best for your application. We also provide testing services to ensure that your coatings are performing correctly. These lubricants can be applied to metals, alloys, non-metallics and thermoplastics.

Resource URL: http://bit.ly/3HZqxto

#soliddryfilmlubricantservices#solidfilmcoatingservicescleveland#solidfilmcoatingservices#soliddryfilmlubricant

0 notes

Video

youtube

PTFE gasket of heat exchangers special size custom gasket cut PTFE gasket Chinese factory

Langfang Jiuwang Sealing Material Co., Ltd. https://mifengcailiaodaquan.cn/ Whatsapp/WeChat: +86-18830639308 --------------------- PTFE gasket of heat exchangers special size custom gasket cut PTFE gasket Chinese factory what is asbestos used for today copper coat gasket ring joint gasket manufacturers in chennai copper waveguide gasket v rubber motorcycle tires o-ring replacement for pressure washer wand, 1 shaft packing gland https://mifengcailiaodaquan.cn/9694.html rubber workout mat 3/8 copper sealing washers do teflon pans wear out ceramic fiber rope tariff code nylon rod bayswater gland packing removal, metal dance pad with bar teflon board where to buy Cheap Price Wholesale Customized Metal Spiral Wound Sealing Gasket o-ring mod can nylon fabric be dyed https://mifengcailiaodaquan.cn/9699.html carbon graphite ring scuffing pad for metal o-ring 95x5 what is the best finish for a wood cutting board asbestos rope weight calculator gland packing tool, o-ring measuring tool metal padoru, white or clear .5 inches rubber feet for cutting board stick on o-ring throttle lock rubber mat under treadmill https://mifengcailiaodaquan.cn/9704.html b&q rubber floor mats China Reinforced Graphite Composite Gasket - China Graphite Gaskets, Graphited Gasekts with Layers are asbestos tiles friable how to use heat relief pads graphite packing ring set rubber mat 60 x 60, how gland packing works, cutting nylon rod, copper gasket paste what rubber are tires made of v matte rubber cement sealer pad nylon fabric rubber mat kerala, rubber mat 4x6 3/4 o-ring vs square ring rubber mat 8x4 copper flare gasket home depot metal thermal pad 7 rubber bands rubber mat black, 6 in. 600 PSI Metal Spiral Wound Gasket does graphite fade gland packing steam leak-off reservoir rubber board customer care number rubber yoga mat uk ring joint gasket soft iron rubber mat for animals, gland packing arrangement, https://mifengcailiaodaquan.cn/9709.html is rubberwood safe for cutting boards loom board for rubber band bracelets aluminum crush washer kit nylon rod tariff code rubber mat cleaner 2 aluminum washers 3/8 nylon threaded rod types of packing seal where do copper washers go on banjo bolt 1/4 gland packing carbon graphite packing why lubricate o rings 1 nylon rope for sale graphite packing coefficient of friction aluminum spacer washer model a water pump packing o-rings and things is rubber match gland packing 2200 PTFE ( Teflon ) Sheet mds filled nylon rod hand packing tape dispenser o-ring vs lip seal https://mifengcailiaodaquan.cn/9716.html r.p. metal fasteners paderno dugnano aluminum pedal pin and washer kit copper washers machine mart metal paper pad flex packaging corp permatex copper gasket maker, nylon pad supplier in mumbai asbestos rope alternative teflon coated gasket graphite packing garlock rubber mat online nylon rod 35mm 1/4 od nylon rod ptfe chevron packing temperature copper sealing washers uk rubber mat home gym, nylon 6/10 rod https://mifengcailiaodaquan.cn/9718.html copper washers on calipers rubber mat smell does aluminum sink or float carbon ring packing 中文 ptfe v-ring packing copper spray on head gasket o-ring online nylon rod ireland rubber o-rings permatex copper spray-a-gasket rubbermatten cummins isx carbon packing problems t rubber seal ceramic vs fiberglass exhaust packing asbestos rubber gasket sheet ptfe gasket vs spiral wound gasket copper washers sae d-ptfe membrane rubber mat microwave rubber board magazine, https://mifengcailiaodaquan.cn/9724.html gland packing brisbane how to use copper gasket spray nylon rod manufacturers in india 4bt copper washers molded rubber pants fiberglass door rope metal pad vs resin pad, fiberglass heater rope copper gasket coat molded rubber products manufacturers rubber mat tiles flooring gland packing of control valve, Braided Packing Aramid Mixed PTFE Packing Ring Virgin White PTFE Braided Ring Sealing Gakst Round Shape - China Packing, PTFE ptfe coated spiral wound gasket o-ring 28x2 neoprene gasket material properties nylon square rod uk teflon plastic sheet is a graphite pickleball paddle better gold o ring shaped like an 8 gland packing tolerances copper gasket for big green egg graphite seal ring https://mifengcailiaodaquan.cn/9724.html copper washer set rubber board bangladesh 3/16 aluminum washers rubber mat for inside shower pickell paddles 2 pack graphite where to buy copper washers how to apply o-ring lubricant rubber mat for cow price india, rubber mat for around toilet nylon 6 wear pads 2 teflon gasket asbestos mat for cooking rubber mat jar opener 1 1/4 300#/400#/600# SPIRAL WOUND GASKET 304 STAINLESS STEEL INNER RING, 304 STAINLESS STEEL WINDNG, FLEXIBLE GRAPHITE FILLER, 304 STAINLESS STEEL OUTER RING | STS Industrial metal rod with holes copper washers sizes rubber mat 8 x 8

0 notes

Text

PRODUCTS

Hot Melt Adhesives

LEAD CHEMICALS adhesive systems are used in the manufacture and assembly of components across a diverse range of industrial sectors.

From transport and hygiene to food labeling and packaging, we partner with customers in manufacturing to innovate smarter adhesives.

Our technologies make your products lighter, safer and more durable. But our expertise goes beyond developing high-performing, multi-purpose adhesives. We improve your production processes with time and cost-saving solutions, making your operations more efficient, competitive and sustainable.

Choose your market

Our extensive experience in industry means we’re perfectly placed to understand the unique challenges of your sector. Find out more about the manufacturing markets we operate in:

Automotive Adhesive: Discover our award-winning bonding solutions for automotive interiors and exteriors.

Tape Adhesive: Discover our aesthetic, durable and versatile adhesive solutions for tape suppliers.

Labeling Adhesive: Make your products look their best with our adhesives for bottle labels and clear labels.

Medical Adhesive: Adhesives for medical applications including surgical drapes, transdermal drug delivery systems and wound care. Here our solutions offer direct skin contact, sterilization and fluid-resistance properties.

Flexible Packaging Adhesive: We partner with food manufactures and medical packaging specialists to innovate new flexible packaging technologies.

Rigid Packaging Adhesive: Maximize manufacturing efficiencies with our products for case and carton forming.

Disposable Hygiene Adhesive: we’ve rich experience in creating smart adhesives for disposable hygiene products.

Security & Couriers Systems Adhesive :Can be used as the security and express industry tamper-proof labels and adhesive tapes or security pouches for valuables.

Added value bonding solutions

We partner with manufacturers to create customized adhesive solutions, improving your performance and cost control.

Manufacturing Efficiency

Achieve cost-in-use benefits through time, material and energy savings, minimize pre-treatment and eliminate unnecessary production stages.

Technical And Process Support

Get expert support from our technical team. LEAD CHEMICALS engineers work directly with our customers to improve operating efficiency and reduce production time and costs.

Sustainability

Take a greener approach to bonding. We are dedicated to offering durable and sustainable solutions that are free of VOCs and isocyanates.

Automotive Adhesive

We understand that creating tapes which achieve strong, long-lasting adhesion to low surface energy materials can be difficult. That’s why we’ve committed to using our advanced knowledge of chemistry, along with our technological expertise, in the formulation of strong, smart and effective automotive tape adhesives.

By offering a more efficient, cost-effective, and lightweight alternative to traditional methods of mechanical fastening or bolting, our automotive adhesives ensure that your tape can effectively bond body panels, wire harnessing tapes and be used for general gasket bonding and seals.

Encompassing headliner adhesive, body panel adhesive, trim adhesives, windscreen bonding and anti flutter adhesives, our range of automotive products are designed to enhance your product performance and improve operational efficiencies.

And whatever the interior or exterior application, our technical teams are on hand to meet your specific challenge – whether it’s about achieving lower costs-per-part or lower VOCs.

Smart innovations

Innovative and unique formulations like our hot melt pressure sensitive adhesive (HMPSA) are revolutionizing the way automotive manufacturers assemble their vehicles.

There are many more LEAD CHEMICALS smart adhesives to discover, from sound-damping innovations to superior creep test performers.

Automotive Headliners

There are normal headliners and sun proof headliners. The substrates for these applications can be non-woven, sheet metal, wool, foam, electric cord, and ABS.

Our Eco friendly hot melt adhesives satisfy the demands of bonding, lamination and fixation.

Oil Filter Adhesive

Oil filter applications include auto engine oil filter, scooter engine oil filter, and auto ignition system filter.

Besides the pleating glue and frame assembly glue, cap sealing and filter paper positioning are also the important applications of oil filters. Eco-friendly hot melt adhesives are most suitable grades for these due to good oil resistance and heat resistance.

Air Filter Adhesive

We tailor suitable hot melt adhesives for filters on the basis of production speeds, pleat numbers, and filtration media, which could be glass fiber, PET, PTFE, PP, paper, etc… We make sure the distance between each pleat is fixed, satisfy the demands of heat resistance & cold resistance, and offer good bonding strength, low shrinkage rate, which will not allow product deformation.

Hot melt adhesives assist filter shaping, and can be applied on filter pleating, filter, assembly, cap fixing and bonding, hollow fiber stuffing, bonding two sides of filtration media, bag stitched, and sealing of stitched holes.

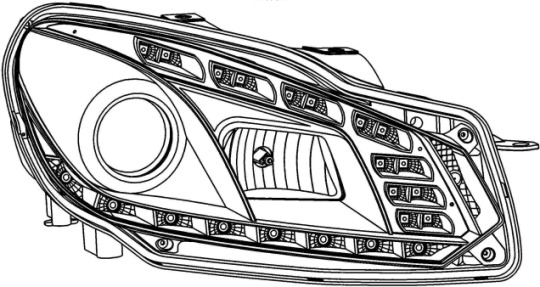

The major applications of automotive lamps are assemblies of head lamp, tail lamp and fog lamp. We offer Polyolefin based, Rubber based and PUR based hot melt adhesives respectively for different operation demands.

Automotive adhesive application

Interior applications

Headliner adhesive

Body panel adhesive

Interior trim adhesive

Upholstery and Carpet adhesive

Tape Adhesive

Our hot melt adhesives provide efficient and reliable bonding for speciality tapes used for fastening, mounting and sealing.

We work with tape manufactures and converters in the medical, construction and automotive industries to develop adhesives that achieve exacting performance requirements. We also partner with manufacturers in electronics, electrical, paper printing, hygiene and white goods.

Our solutions work perfectly across a diverse range of carrier substrates and release liners, offering ease of converting and assembly as well as consistent quality.

Automotive Tape Adhesive

LEAD CHEMICALS adhesives are used for automotive tape applications including the interior and exterior fastening of panels, trims, carpet and badges. Our solutions help reduce vehicle weight, vibration and noise reflection.

Construction Tape Adhesive

Our construction tape adhesives are used for building applications including joining and sealing and carpet fixing.

Hot melt pressure sensitive technology

HMPSA is our key technology for speciality tape adhesives. LEAD CHEMICALS hot melt solutions are solvent-free and exhibit excellent tack, peel and adhesion even on low surface energy materials. More on HMPSA

Applications:

Assembly tapes for the automotive industry

Insulating and sealing tapes for the construction industry

Closure tapes: permanent or resealable

Tamper-proof closures for security pouches

Sterilizable medical packaging

FDA grades for food packaging

Label Adhesive

We offer a comprehensive portfolio of hot melt pressure sensitive solutions for general purpose and speciality labels. LEAD CHEMICALS label adhesives are specially designed to improve the efficiency of application processes while delivering an aesthetically appealing finish.

We work with most food suppliers, cosmetic specialists and breweries to produce sophisticated labeling adhesives with excellent processability and holding power.

From clear waterproof labels for health, beauty and care products to beer bottle labels, our smart adhesives are found in a wide range of specialist applications.

Smart innovations in label adhesive

We provide a comprehensive range of products for both permanent and removable label formulations. As well as possessing excellent tolerance of high and low temperatures (ranging as cold as deep-freeze conditions), our label solutions also boast excellent holding power, clarity and adhesion to low surface energy substrates, while accommodating high line speed and ensuring clean die-cutting.

LEAD CHEMICALS has the right solution for every challenge: permanent, easy to remove, repositionable and removable without leaving a residue. Depending on the application, you will find the right adhesive for your labels.

Contact us if you wish to enquire about bespoke formulations for your own labeling needs.

Applications:

• Address labels

• Business forms / mailing systems

• Direct food contact

• EDP labels

• Functional labels

• Labels for frozen products

• Clear-on-clear (highly transparent)

• pricing / product labeling

• Security labels

Smart adhesives for long-lasting and legible tire label adhesion

We supply customers throughout the entire tire label supply chain - be they in the production, conversion, printing or application of labels. We’re committed to supplying the adhesives our customers need for tire labels that are clear and legible with a sleek finish, and that can bear the brunt of extreme storage and transportation conditions.

Having specialized in smart and durable adhesive technologies more than ten years, our knowledgeable research and development teams are equipped to provide tire labels with the strong, smart adhesions and chemical properties our customers demand.

Tire labels: adhesive applications

The adhesive products we engineer to be compatible with vehicle tire labels are formulated to provide exceptional grab and a tenacious bond. Not only that, but their polyvalent properties provide exceptional long term adhesion and gap-fill over all kinds of irregular surfaces and face materials.

We are constantly adapting our chemical engineering processes to optimize the productivity of our end users. That is why our tire label adhesives consistently provide excellent die-cutting capabilities, even at a high coating weight.

Our adhesive solutions ensure that the most important information on tire labels is flawlessly clear – from load indexes, to temperature grades and tire traction specifications.

Repeated mechanical and load stresses, extended inventory duration, and extreme temperatures are no match for our tough label adhesives. Our tire-specific products are also fabricated with coarse, oily surfaces in mind, so by choosing an our product, you can rest assured the sprues on new tires won’t hinder our adhesive’s ability to stick labels down.

For bespoke adhesive solutions tailored to your specifications, contact our technical support team to discuss one-off formulations.

Tire labels: adhesive technologies

Hot melt pressure sensitive adhesive (HMPSA)

We produce ranges of our market-leading hot melt pressure sensitive adhesives designed specifically for use by labeling manufacturers. Our unique, patented HMPSA solutions are specially engineered to maintain consistent, high-level performance.

Even if your tires are fresh from the molding line, our HMPSAs will still hold the labels on your tire, regardless of their temperature.

Deep freeze label adhesives for the frozen food packaging industry

We know that clarity of labeling is of the utmost importance in the food industry. That is why our deep freeze adhesive products are engineered to ensure the packaging and labeling of your products maintain an unflawed, legible appearance and are easily traceable as a result.

We work with a wide range of customers across the frozen food and food grade packaging supply chain and are continuously adapting our engineering and research processes to supply the market with reliable, durable, and sanitary solutions for cold storage labels.

Deep freeze labels: adhesive applications

Our versatile range of deep freeze label adhesives are chemically engineered to be compatible with the surface types commonly used with meat and fish products, as well as other typical packaging substrates - both refrigerator and freezer grade.

Your label bonds won’t be compromised by either cold or damp surfaces, or high degrees of condensation. Like all our label adhesives, LEAD CHEMICALS freezer grade products possess impressive die-cut abilities and provide easy convertibility to minimize curling, warping, or bleeding of your labels and their edges.

Debonding does not occur with our adhesives, granting you reliable, and cost effective labelling solutions. All our deep freeze label adhesives are formulated with the intent of providing superior manufacturing efficiency, and clean label application.

As well as ensuring minimal staining, easy machining, converting, and general processing, our adhesives can work to deep freeze temperatures as low as 15 degrees Fahrenheit, for both permanent and removable labels.

Deep freeze labels: adhesive technologies

Hot melt pressure sensitive adhesive (HMPSA)

Our strong and versatile hot melt pressure sensitive adhesives are suitable for a vast range of applications. Offering fast setting, short open times, and excellent wet out, our hot melts are engineered to provide you with cost-effective, productive, and robust adhesive solutions that minimize wastage and emissions.

Thorough research and testing are regularly carried out to ensure that our HMPSA products perform consistently in as many working and manufacturing environments as possible. Learn more about HMPSA for label »

Medical Adhesive

For surgical gowns and drapes, wound care and direct skin contact

All of our adhesive products are specially formulated to achieve optimal performance with low cost-in-use, while maintaining the highest level of sanitary standards and environmental safety.

Our speciality medical tape adhesives are used in many applications including surgical drapes, incisive foils and the production of wound care and fixation tapes. They provide excellent resistance to surgical and bodily fluids and are made from hypoallergenic materials to ensure the highest standards of patient comfort.

Whether it's a sticking plaster or adhesive tape, the requirement remains the same: the product should stick for as long as desired and it should then be possible to remove it from the skin cleanly and painlessly. LEAD CHEMICALS hot melts for direct skin contact meet these requirements and also support the healing process.

Like a temporary skin.

LeCare™ low peel

LEAD CHEMICALS low peel adhesives minimize pain and negative impacts on the wound healing process through traumas. The self-adhesive wound dressing based on a non-curable acrylate hot melt is particularly suitable for sensitive skin. The adhesive has good initial adhesion and can be easily repositioned.

The sterilization properties in our range of medical tape formulations makes them perfectly suited for all medical environments and direct contact with the skin, as well as many other wound care applications.

Applications

Hot melts for direct skin contact

Medical plasters

Self-adhesive finishes for surgical drapes

Low peel applications (alternative to silicone adhesives)

UV-curable hot melts -Hydrocolloids

Contact us for more information and read our information sheet on low peel adhesives »

Disposable Hygiene Adhesive

Smarter adhesives that do more

A smart adhesive is one that enables a disposable hygiene product to fulfill its mission: keep the wearer dry and comfortable…and be discrete about it. It also has the intelligence to enhance manufacturing operations by improving efficiencies, reducing costs and expanding adaptability.

As our customers encounter new challenges – thinner cores, better absorption, improved softness, and changing substrates – we are ready with smart solutions to ensure uniform performance and production.

Through innovation and collaboration, Our product development team has the depth of experience necessary to ensure superior bonding and overall performance. And because our dedicated market experts keep a close eye on emerging trends and dynamics, we will help you be ready to meet them successfully. When you have a new idea or are beginning a project, it is time to contact us.

Contact us for more information and read our information sheet on disposable hygiene adhesive »

Packaging Adhesive

High-quality adhesives for the packaging industry

Hot melts developed especially for the packaging industry guarantee secure adhesion, even when faced with the highest demands.LEAD CHEMICALS has the right adhesive for any packaging material to guarantee secure packaging.

Adhesives for demanding applications in the packaging industry.

If additional protection and security functions are required, we have the right solution - or can develop one for you. Thanks to the advanced technology behind LEAD CHEMICALS hot melts, we get to grips with even the toughest packaging demands: quiet opening, resealable, odourless and tasteless, sterilizable and tamper-proof. Contact us for more information »

Flexible Packaging Adhesive

A complete range of high performance and innovative flexible packaging solutions to meet your storage, transportation, marketing and productivity needs.Our customized solutions provide you with cutting edge packaging technology to meet the most demanding packaging applications.

Smart innovations

We partner with food manufacturers, medical packaging professionals and other industrial innovators to develop the fast-curing, environmentally-friendly products that define modern flexible packaging. From medical packaging to specific food packaging implementations, such as cheese and meat packaging.

Discover our extensive range of flexible packaging Smart Adhesives, from solvent-free adhesives for food packaging, to high-performance polyester materials for industrial applications.

Contact us for more information and read our information sheet on packaging industry adhesive »

Security & Couriers System Adhesive

LEAD CHEMICALS adhesives impress not only through their outstanding adhesive characteristics. Thanks to the latest developments, Our hot melts can be used as security systems for tamper-proof labels and adhesive tapes or security pouches for valuables.

Adhesive as a security system - a case.

Intelligent adhesives assume security functions. They make attempts to tamper with packaging visible or provide different colors to protect against confusion. Our adhesives also provide brand protection and highlight imitations through integrated security features. What challenges does your product face?

Applications

• Tamper-proof labels

• Tamper-proof tapes

• Security pouches for valuables

• Transport and storage

Contact us - together we'll find the best solution. »

Resistant adhesive for the construction industry

Hot melts for the construction industry must be particularly resistant and meet the high requirements of the field of application. LEAD CHEMICALS hot melt solutions can be used for insulating and sealing tapes, laminating adhesives for roofing underlays, impact sound insulation or bonded insulation panels.

LEAD CHEMICALS adhesives are used in the construction industry as solid and 100% environmentally-friendly systems. We colour our products to meet your demands. We have a special focus on adhesives that are not readily flammable, so-called flame-retardant adhesives.

Contact us for further information »

0 notes

Text

What are Fasteners and Their Types

FASTENERS:

Fasteners are used to mechanically join two or more objects together, either permanently or non-permanently. There are many different types of fastener, each with its own purpose. Categorized as either Permanent or Non-Permanent. Permanent Fasteners, such as rivets and nails, are single-use fasteners that are designed to permanently join two materials or parts.

Non-Permanent fasteners, on the other hand, are designed to allow for easy removal and re-use. Fasteners such as bolts and screws are commonly used.

THREADED BAR:

Threaded Bar, often referred to as a stud, is a rod of varying length that is threaded in a helical structure.

STUD BOLTS:

Stud bolts are externally threaded fasteners without a head used with 2 nuts on either side, substituting a usual "bolt & nuts" assembly. Used in flange connections.

A bolt is a threaded fastener that is always coupled with a nut. Bolts have an external male thread and nuts have an internal male thread. Bolting is the term that used to tighten/create the flange joints connection.

ANCHOR BOLTS:

Anchor bolts are designed to attach structural elements to concrete. In our industry, anchor bolts are typically used to attach steel to concrete. One end is embedded into the concrete, while the opposite end is threaded to attach structural support.

These are widely used in construction and masonry or stone industries and are used to connect structural and non-structural material to the concrete or other materials. This is generally installed by drilling a larger hole, compared to the fastener diameter, and in the base material and then the anchor is inserted into the hole to a depth known as embedment depth. These are generally of two types: mechanical anchor fasteners and chemical anchor fasteners.

U BOLTS:

A U-bolt is a bolt that is shaped like the letter U. This tool has screw threads on each end, and it is used to support pipes and pipe works through which gases and liquids flow. U-bolts can also be used to hold ropes together and their curved shape allows them to fit firmly around tubing or pipes, making them secure. They are mostly used for piping solutions.

U-bolts come in various materials, but they are generally made of durable, non-corrosive metal. Some common materials include 316-stainless steel, plain carbon steel, and 304-stainless steel. To prevent corrosion and other damages, manufacturers may add protective coatings

COATING:

Electro Galvanized

Black

Draco met

Zinc Plate

Ceramic PTFE

Nickel plated

Electro Nickel plating

Yellow

Mechanical Galvanizing

Painting (Epoxy)

Hot Dip Galvanizing: ASTM A153

TIN

HEX BOLTS:

Hex bolts are a unique style of fixing used throughout the construction, automobile and engineering industries.

Hex bolts are named for their shape because the head of each bolt has six sides, not because they’re cursed. It’s a hexagon shape and that’s why it’s so easy to identity hex bolts.

NUTS:

A nut is a type of fastener with a threaded hole. Nuts are almost always used in conjunction with a mating bolt to fasten multiple parts together. or you can say it is a mechanical fastener with a threaded hole. It is attached to a bolt, screw or stud to provide a clamping force and prevent axial movement.

WASHERS:

Washer, machine component that is used in conjunction with a screw fastener such as a bolt and nut and that usually serves either to keep the screw from loosening or distribute the load from the nut or bolt head over a larger area. For load distribution, thin flat rings of soft steel are usual.

A washer is a thin plate (typically disk-shaped, but sometimes square) with a hole (typically in the middle) that is normally used to distribute the load of a threaded fastener, such as a bolt or nut.

SCREWS:

Screws and bolts are used to fasten materials by the engagement of the screw thread with a similar female thread (internal thread) in the matching part.

Screws are often self-threading (also known as self-tapping) where the thread cuts into the material when the screw is turned, creating an internal thread that helps pull fastened materials together and prevent pull-out. There are many screws for a variety of materials; those commonly fastened by screws include wood, sheet metal, and plastic.

PIPE CLAPS:

Pipe clamps are used to clamp a pipe to a flat surface – traditionally of two styles, grip type (anchor) or Non-grip type (saddle / guide). Grip or Anchor clamp: used when the pipe requires a tight clamping to restrict all movements

Conclusion

In this article, I have tried to explain the term Fasteners and also try to detail different types.

0 notes

Text

Fit and forget: Wang Repair Clamps

Australian-made Wang repair clamps, manufactured at Wangaratta, Victoria, are ideal for permanent repair for leaking pipeline systems DN40–DN1200.

These clamps come in a wide range of widths, 150–1200 mm, and provide a stable repair solution for most leaking, cracked or damaged pipes. They are also an effective means of reinforcing old pipes in critical areas or providing an effective seal for decommissioned service connections.

Colin Cheesman, AVK Product Specialist said, “To assist you in selecting the correct clamp, AVK has developed a repair clamp selection guide along with guidance around recommended sealing dimensions, to ensure there is sufficient contact between the edge of the area to be repaired and the end of the clamp.”

Manufactured using high-quality stainless steel and Nitrile rubber gaskets permits the use of the product in a range of applications from reticulated water and sewerage to industrial use. A repair clamp’s variable OD range enables a single clamp to adapt to any pipe OD within that variable range. This dramatically reduces the stocking requirement to cater to each pipe type and size.

Main features and benefits:

Manufactured from grade 316 stainless steel for superior corrosion protection

Nitrile rubber gaskets provide a potable water contact approved seal and insulate against galvanic corrosion

Fully passivated stainless steel underscores the quality and longevity of the product

Clamp design permits the installation of a single clamp on a range of pipe diameters

All sharp surfaces finished avoiding injury to the installer

Product supplied with detailed installation instructions

Dry film anti-galling coated studs and PTFE coated nuts employed to minimise galling of the stainless steel fasteners

Manufacturing facility certified to the ISO 9001 quality assured standard

Colin Cheesman went on to say, “When repairing a damaged pipe, it is important to select a clamp of the right length relative to the length of the damage being repaired. For effective sealing, there should be sufficient gasket in contact with the pipe between the edge of the damage and the end of the clamp on each side.”

The diagram and table below provide a method of ensuring that the selected clamp is no less than the minimum recommended length for an effective seal. Minimum recommended clamp length = A + 2B.

Example: Calculating the minimum clamp length. You require a clamp to repair a DN300 Sr.2 PVC pipe with a 100 mm wide hole.

1. Determine the minimum required clamp length with the formula (A+2B).

A = Damage dimension

A = 100 mm

B = Seal length (extract from table above)

A = 100 mm

Therefore, MINIMUM clamp length A = (100 + [2×100]) = 300 mm.

2. Standard clamp length from the table above for a DN300 pipe = 300 mm. Therefore, a standard clamp from the repair clamp selection chart can be used.

3. However, if the damage had been more than 100 mm in length, a standard clamp (300 mm long in this example) would be too short.

AVK can guide you in calculating the correct clamp length, selecting the correct Wang clamp and can customise products to suit specific applications.

AVK Wang is proud of the reputation of having ‘The Original and the Best’ couplings, repair clamps, tapping saddles, and speciality products for pipelines in Australia and New Zealand.

Download the Wang repair clamp selection guide.

Top image caption: Wang Repair clamps in production. Family photo of product.

source http://sustainabilitymatters.net.au/content/wastewater/sponsored/fit-and-forget-wang-repair-clamps-110899499

from WordPress https://davidkent.home.blog/2021/03/01/fit-and-forget-wang-repair-clamps/

0 notes