#Wood And Plywood Cutting Machine

Explore tagged Tumblr posts

Text

Woodworking Machinery | Woodworking Machines in India

Garnet India offers top-notch woodworking Machines, including panel saws, edge banders, and machines for working with wood, bamboo, and modular furniture.

woodworking machine manufacturing in near me, wood working machine, edge banding machine price, Edge banding machine price in india, Edge banding machine manufacturers in india, automatic edge banding machine price in india, Woodworking Machinery Manufacturers in India, Panel Saw, Edge Bander, CNC Router, Hot And Cold Press, Circular Saw, Vacuum Press, Spindle Moulder, Wood working Machines, Furniture & Carpenter Machinery, Dust Collector, Drum Sander, Band Saw, Spindal Moulder, Wooden Furniture Making Machines, Wood And Plywood Cutting Machine, Woodworking Machinery, wood machine manufacturer, wood machine manufacturer india, panel saw manufacturers Price, Machinery manufacturers, Wooden furniture manufacturing machines, edgebander machine, dust collection, edge banding equipment, edge banding machine, edgebanding machines, woodworking machines, wood carpentry machines, table saw machine, table for saw machine, panel saw machine, dust collecting machine, wood work machinery, finger jointer, carpentry machines, sheet cutting machine, india machine, pvc edge band machine, woodworking machinery manufacturers in ahmedabad, panel saw machine, panelsaw, panel saw machine manufacturer, panel saw machine price, panel saw machine price in india

#woodworking machine manufacturing in near me#wood working machine#edge banding machine price#Edge banding machine price in india#Edge banding machine manufacturers in india#automatic edge banding machine price in india#Woodworking Machinery Manufacturers in India#Panel Saw#Edge Bander#CNC Router#Hot And Cold Press#Circular Saw#Vacuum Press#Spindle Moulder#Wood working Machines#Furniture & Carpenter Machinery#Dust Collector#Drum Sander#Band Saw#Spindal Moulder#Wooden Furniture Making Machines#Wood And Plywood Cutting Machine#Woodworking Machinery#wood machine manufacturer#wood machine manufacturer india#panel saw manufacturers Price#Machinery manufacturers#Wooden furniture manufacturing machines#edgebander machine#dust collection

0 notes

Text

I got this ~1950s mini sewing machine when someone was giving it away locally, so I've started restoring it. This is before...

There was live woodworm eating into the wood panels, the paint was flaking off, and there were rust spots on the exposed metal. The mechanism was actually in decent working order though.

I started with the wood. For the base I just ordered a piece of plywood cut to the right size, because I don't have a table saw to easily cut down big panels.

For the table, I laser-cut layers of 2mm plywood in slightly different sizes to create the right profile in the sides of the slot. Here it is before and after sanding the edges to nice curves.

Today I got started on the metalwork. First, dissassembling everything. It was scary but I took lots of pictures to keep track of how everything goes back together, so I can hopefully retrace my steps later.

The hardest part was removing the hand-crank wheel. It was really tightly wedged and I ended up having to hammer the metal in the centre of the wheel to release it. 😬

But it all came apart with no damage eventually.

Today I stripped off the flaking paint. Just many rounds of applying paint stripper, waiting, scrubbing, and repeating. Eventually got it all cleared off though.

Next will be cleaning all the other parts of rust, and then repainting. I won't be able to exactly match the old colour so I'm thinking I might do something totally different, but I haven't decided yet.

16 notes

·

View notes

Note

I'm involved in a project that requires casting some residential circular-arch doors out of concrete, one side at a time. I was considering designing the embellishments with digital tools and having them cut with a CNC machine for the mold, but it seems like a lot of trouble and I already know how to design things in the physical world. My question: what did you carve your beautiful embellished doors from, was it expensive, and do you think it'd work to cast a rubber mold from?

That sounds like a really cool project!

The carved panels on the doors I made were made in mdf-board. It's pretty cheap, about the same as plywood, and you can carve it like wood with a multitool - with the right bit, it's pretty fast work! (I talk about the different bits I use in this post.)

As long as the relief doesn't have any wierdly angled deep nooks and crannies, you should absolutely be able to make a rubber cast from it! Especially if you put down a base coat of somewhat glossy paint first, to make all the surfaces smooth and non-porous!

(Mandatory word of caution - carving mdf means a lot of sawdust, and it's a health-hazard to breathe it in. So do it outside, if you can, and wear a mask and goggles!)

The board on the doors is actually quite thin, about 10-12mm - the layered paint helps accentuate the 3D depth of the carvings. If you want a physically deeper relief, it'll be more work to carve it and the mdf sheets are more expensive the thicker they are.

That said, even a relatively shallow pattern can be very striking!

This divider was carved from 10mm mdf, so the carvings are just a few mm deep, but even without paint, it makes for a pretty effect! 🙂

If you do go ahead with it, feel free to share pictures! I'd love to see what you end up making! 😀

14 notes

·

View notes

Text

Pooja Room Work At Hyderabd

Pooja room design work at Beeramguda, Hyderabad - Moderate ganapati structure cutting and bells as per the customer request. Work done with Plywood and Takewood colour decolam.

Fully closer box type open floor pooja room design at Pragati nagar, Kukatpally. Two doored hand cutting designery work at nuwood. Inside one shelf, two drawer's to keep pooja items seperatly.

Pooja room desing work at Bachupally, Hyderabad. Customer intrested to keep swastik, Om and poorna kumbham's on it. Meterial used white decolam, plywood.

Pooja room design work at Lingampally, Hyderabad.Full Ganesha, Om with Marwadi design. Plywood with Chocolate colour decolam.

Pooja room design Ameenpur, Beeramguda Hyderabad. Two Ganesha CNC Cutting designery doors with flower designs. Used plywood and chocolate colour decolam

Pooja Shelf designery work at Borabanda, Hyderabad. Swastik and Om Machine cutting, Used Pink colured decolam and plywood.

Pooja Shelf design at Kukatpally Housing Board Colony, Hyderabad. CNC cutting ganesha on plywood covered with takewood decolam.

Small Pooja box doors design work on takewood done at Jalavayu vihar colony, JNTU Kukatpally, Hyderabad.

Full size pooja room doors work at sainagar colony, Pragatinagar, Kukatpally, Hyderabad. CNC cutting on Gurjan plywood pasted white decolam.

Full sized pooja room doors Tamil Om (lord murugan emblem), Swasthik, lotus flower on top bells gold coloured. CNC cutting on nuwood matt finish black and gold colour used.

Box type pooja room design work at Rainbow vista villas, Kukatpally, Hyderabad. Chain with bells, Om, Swasthik, Ganesha, Poorna kumbham and Pooja lamps work done on Plywood and red decolam.

Pooja room and arch design at SR Nagar, Ameerpet, Hyderabad. Wall sides covered with plywood and doors added, chain bells, two sides ganesha and poorna kumbham.

Pooja room doors work at Srinagar colony, Ameerpet, Hyderabad. Chain bells, ganesha, Om and poorna kumbham. Used ash colour decolam greenply plywood.

Pooja room design cnc cutting on century plywood with half white decolam work at Chintal, Balanagar, Hyderabad.

Pooja room work at Motinagar , Hyderabad. Chain bells, ganesha, Om and poorna kumbham. Used back blue lighting ash colour decolam greenply plywood.

Pooja room doors at Beeramguda, Lingampally, Hyderabad. CNC cutting flowewrs, bells ganesha's. Used Gurjan 710 plywood rose wood colour decolam.

Pooja room design raw map to design ganesha, om, chain bells and poorna kumbham for cnc cutting.

Full box pooja room design work at Ameerpet. Open floor room design four sides covered with greenply plywood,Top side temple top design. Chain bells, Ganesha, Om, Poorna kumbhams and two draws for pooja essencials to keep. Used plywood and maroon colour decolam.

Takewood Carving full sized doors with arch work at Balanagar. Pooja lamps, Ganesha and Bells design carved on takewood used spray polish for shining.

Home Decode - Wardrobe | Cubboards Designs Hyderabad

Cub board work at Bollaram Alwal. Gurjan plywood with decolam white and yellow combination to match room colours.

Bedroom wardrobes work at Bollaram, Alwal. White decolam with white and pink rainbow line to match room colours as per customer interested.

Bed room wardrobe work at Alwal. Gurjan plywood with red and white decolam for white background room.

Bed room Wordrobe with middle dressing included with drawers at Alwal. Greenply plywood with red decolam and stainless steel handles. Customer special interest on red due to her flore marble are white ceiling white.

Bedroom Wordrobe work at Kompally. Gurjan plywood with takewood and chocolate colored decolam at first floor.

Bed room Cubboard work at Suchtra circle Hyderabad. 18mm plywood with white and chocolate colored decolam y shaped design and stainless steel handles with openeble two mirrors almara type.

Bedroom Cubboard work at Banjara Hills. Customer most enthusiast on music, we Disigned for him a Seperate cool design with white glowsy finish decolam and light blue matching for their bed with dressing table incuded with 2 drawers.

Wordrobe work at Banjara hills, Customer is a doctor he wanted a glowsy finish work. we used High glosy orage decolam with panther strikes, Moderated small doors with sqare shaped knobs, bottom stainless steel long handles.

Bedroom cubboard work at Kalyan nagar, Motinagar Hyderabad. White decolam with chocolate colour strips.

Master Bedroom Wordrobe work at Beeramguda, Hyderabad. White and chocolate coloured decolam as per the customer interest.

Sliding Wordrobe work near TV9, Banjarahills, Hyderabad. Blue and White decolam with dressing table included. Stainless stell sliding handles and master strokes at bottom and top with middle round white design.

Bed Room Cubboard work at Godavarikhani, Telangana. Gurjan plywood Pink Structred and white decolam combination 12" stainless steel handles 6 mm Grue Model.

Bed room wardrobe work at Banjarahills, Hyderabad. 18 mm Gurjan plywood with two Almarahs white and Meroon coloured decolam doors, included cnc edge cutting edge for dressing table with two drawers with copper colour handles.

Crockery unit design Nizampet Hyderabad. Ceiling flap with cubboards, side shelf doors, microwave oven placement. Takewood with cholate mix, White and cream colour high glossy decolam for dining hall.

Master bedroom sliding door wardrobe work at Nizampet Hyderabad. Takewood with cholate mix, White and cream colour high glossy decolam for light yellow background wall coloured bed room.

crockery unit design work nizampet Hyderabad. Sajja with cubboards, side shelf doors, microwave oven placement. Takewood with cholate mix, White and cream colour high glossy decolam for dining hall.

Master Bedroom Sliding wardrobe design work at Nizampet Hyderabad. Ceiling flap with cubboards, Takewood with cholate mix, White and cream colour high glossy decolam for bedroom with sliding handles.

Sliding wardrobe work for children bedroom at Hanamkonda. Sliding doors with takewood meroon shade decolam .

Children Bedroom wardrobe work at Balaji Hills, Nizampet, Hyderabad. Digital decolam with white background, blue flowers, butterflies and ash shades.

Multi colour sliding wardrobe work at Yousufguda. On Greenply Plywood Orange, Green and Pink decolam with sliding handles with soft close channels.

Master bedroom cubboard design work at Chintal, Hyderabad. Black and white decolam as per the customer believe's Astrology.

Master bedroom sliding doors with soft closer wardrobe work at Sanathnagar, Hyderabad. Century plywood with White and takewood decolam.

Master bedroom cubboard with sliding and soft closer work at Cherlapally, Hyderabad. White and rose wood decolam.

Sliding Wardrobe design at Vinayaka Nagar, ECIL, Hyderabad. Black and Digital decolam with soft close sliding.

Bedroom Profile Wardrobe Sliding soft closer work at Srinagar Colony, Hyderabad. Red rosewood, Glossy white Acrolic Sheets with Alluminium Borders.

Bedroom Wardrobe work at Banjrahills, Hyderabad. High glossy white and grey decolam with long wood handles.

Children bedroom cubboard work at Miyapur. High glow takewood and black mixing decolam with dressing room .

Master bedroom cubboard work at Lingampally, Bhel, Hyderabad. Sliding soft closer wardrobe with Takewood dark with Cream colour decolam.

Kitchen cubboard work at Bollaram, Alwal, Hyderabad. Kitchen grocery keeping cubboards with White and Grey coloured decolam.

18 notes

·

View notes

Text

DIY Salvaged Spool Ottoman

Project by Shelly:

i know ottomans aren’t the most indispensable piece of furniture in the house, but is it criminal to say they bring me the most joy? i think upholstery maven shelly (aka ModHomeEcTeacher) would agree with me; she’s made a whole collection of smart looking ottomans using a range of found fabrics and materials. i am so excited to follow her instructions and craft an adorable plaid ottoman of my very own, just in time to welcome fall. click here to see more of shelly’s amazing work, including her tutorials on everything from upholstering with rugs to aligning atomic legs. thanks, shelly! –kate

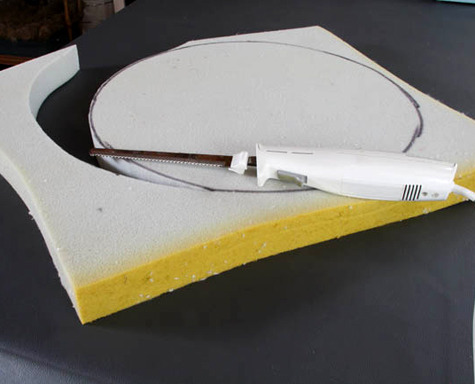

When Lowes stopped selling the pre-cut wood circles I used to construct my ottoman frames, it was a dark day. I soon discovered that cutting perfect circles with a hand-held jigsaw wasn’t easy, or even really possible. Weeks later, while roaming the store searching for an alternative, I discovered the empty electrical spools that are routinely discarded. Two perfectly cut round pieces of 5/8” plywood with a removable cardboard cylinder in the middle? Now we’re talking. With a tiny bit of carpentry, I came up with a way to easily re-work these into frames for my upholstered ottomans. I would label this as a mid-level DIY project that you could complete in a weekend. Once you get the hang of it, you these would make fantastic handmade gifts for friends and family. –Shelly

Materials:

-1 20” diameter empty electrical wire spool (hardware stores usually throw these out, so ask about picking them up instead) -8 pre cut 1”x 2”x 6” pieces of wood (a hardware store will cut these for you) -Wood glue -32 1 ¾” screws -A piece of foam (anywhere from 3” to 6” thick and at least ½” larger all around than the wood) -Spray adhesive (Elmers makes a spray adhesive available at the craft store) -Scrap fabric ( this to attach around the ottoman frame measuring about 8” x 65”. An option would be to use a bendable piece of cardboard) -1 ½ yard of cotton or dacron batting -1 ½ yard of 54” wide fabric -¾” yard of scrap fabric to cover the bottom of the finished ottoman -Thread and straight pins -Staples -4 screw on leg plates (hardware store) -4 fabulous ottoman legs (look around for good legs on cruddy, inexpensive Goodwill furniture)

Tools:

-Big marker -Drill -3/32” drill bit and a 3/8” drill bit -Electric knife -Electric stapler -Scissors -Measuring tape -Flat head screwdriver -Pliers (crescent or needle nose) -Sewing machine

Instructions:

Making the frame:

1. Take the spool apart and make a pattern by tracing the circle on a large piece of paper, adding ½” all around for the seam allowance. The pattern will be used for cutting out the foam, batting, fabric and a dustcover for the bottom. Lay aside.

2. Glue and screw 6-8 posts evenly around the outside edge of one wooden circle, then add the other piece of wood on top of the posts and attach. Be sure to keep the wood circles aligned.

Padding:

1. Use the staple gun to attach the long piece of cotton muslin around the outside edges of the top and bottom circles. Keep fabric pulled taut. The fabric serves to fill in the open spaces between the support posts. Cut off excess fabric. (Option: use bendable cardboard)

2. Trace the pattern onto the foam and cut the foam using the electric knife. Keep the knife blades perpendicular to the foam to get a crisp, even cut.

3. Use spray adhesive to glue the foam to the top of the ottoman frame.

4. Trace the pattern onto the batting, cut out. Also, cut out a long strip of batting equal to the total height of the ottoman, from the top of the foam to the bottom edge, plus two extra inches.

5. Pin the batting strip to the batting circle, starting 1” from the short end of the strip and ending 1” from the other end. Stitch in place.

6. Remove from under the sewing machine and stitch the open seam closed and go back and complete stitching that section of the band to the batting top.

7. Trim off the excess seam allowance, turn the batting covering right side out and pull it down on top of the ottoman frame.

8. Measure and mark the batting band (all the way around the covering ) so that it will be stapled evenly from the top seam to the bottom EDGE of the frame. Do not attach the batting to the underneath side of the wood. Attach it to the edge and cut off the excess batting.

Sewing and Upholstering:

1. To make the fabric covering, which is a bit like a snug slipcover, trace the pattern onto the fabric and cut it out. You’ll need to cut a band of fabric 3” longer than the height of the ottoman and 5” wider than the circumference. If you need to stitch two pieces together to get a long enough piece for the band, split the circumference measurement in two and add 3 extra inches to each piece.

2. To prepare the fabric covering for stitching, fold one short end of the cut fabric band over 1” with wrong sides together. With the right side of the band to the right side of the fabric circle, patterns matching, pin and begin stitching at the folded short edge all the way around to the other short end. Overlap the excess fabric 2” past the folded short end. Cut off any excess fabric beyond the 2”. Pin and stitch the overlapping fabric to the seam.

3. Turn the fabric covering right side out and topstitch the folded seam closed from the bottom of the band to the top seam.

4. Pull the fabric covering down over the dacron covered ottoman. Adjust the fabric pattern and straighten so the pattern or plaid is aligned.

5. Pull the fabric down firmly and staple in place evenly and snugly.

Upholstery Tip: It works best to start with one section and attach with a few staples, move to the opposite side and do the same. Then repeat for the other sides. Attach the fabric between the set staples by smoothing and easing in the fabric.

Attach Legs:

1. Measure and mark the bottom of the ottoman base for leg attachment. Place the leg plates on the marks to make sure they are equidistant from each other. Mark the center hole of the plates. Use the 3/8”drill bit to drill out the center hole. You can also do this step prior to putting the fabric on (as shown below).

2. Cut out a dustcover from scrap fabric and attach it to the bottom of the ottoman by folding the edge under ½”.

3. Locate the drilled holes, line the leg plates up, screw the leg plates on using a Phillips head screwdriver or the drill. Attach the legs to the plates.

VOILA!

4 notes

·

View notes

Text

How to choose materials from Ekintop office furniture manufacturers?

Three basic materials are used in the Ekintop office furniture manufacturer namely: wood, plastic and metal.

However,Ekintop office furniture manufacturer will recommend you wood.wood is used almost universally for fine furniture because it is easily worked, it is highly decorative and it is a poor conductor of heart. Therefore, normal changes in air temperature do not make wood unpleasantly hot or cold to the touch. It is comparatively noiseless under movement or impact. It is easily repaired. Wood piece can be easily fastened together with nails,screws, dowels, and glue.

The three main parts of a tree are roots, trunk, and crown.

The trunk is cut into logs that are further processed into solid lumber and veneers for plywood. Other parts of the tree are cut into chips for making particle board. Plywood is a sheet material designed to take advantage of the fact that wood is very strong in the direction of the grain and that it shrinks very little in that direction. It is made by gluing alternate layers of wood at right angles to one another. Consequently, the strength properties tend to be more nearly equal across the width and length of the sheet. It also tends to be more stable than solid boards. So it is also Ekintop office furniture manufacturers one of the best-selling varieties.

This construction gives plywood a number of other properties that make it especially useful as a cabinet making material. Unlike solid lumber, it has no tendency to check and split near the ends, even when nails are driven near the end. It is available with a number of attractive wood veneers on the surface. One of its biggest advantages as a cabinet material is that it is available presented in large sheets and is ready to be cut to finished sizes. It is very stable, with little tendency to warp since it has no grain direction. Medium density fiberboard is similar to particle board in appearance and application, but it is made from wood fibers. This construction results in a smoother surface finish than particle board, especially on exposed edges. It enjoys great popularity in Ekintop office furniture manufactures because its smooth surface allows a wood-grain appearance on paper for a book. It has excellent machining qualities and is often used in core stock for plywood.

Although it is somewhat more expensive than particle board, medium density fiberboard can be used anywhere that particle board is used in cabinets. It is especially popular for drawer sides for low-priced cabinets and is available in standard drawer-side widths, preprocessed grooves for the drawer bottom and a wood grain printed on the surface.

Plastic materials are widely used in Ekintop office furniture manufacturers. Plastic is a synthetic material and there are two types: thermoplastic and thermosetting which cannot be reshaped. Common uses for plastics include: plastic laming, urethane foams for cushioning, resins to bond wood flakes together to make hard board and particle board and polyvinyl glues for assembling. Many plastics are also used in wood finishing. In addition to this, plastic parts are also used in furniture in board combination with wood. Many of the ornate decorative items for drawers, doors and picture or mirror frames are made of molded plastic.

All of the common metals including steel, aluminum, copper, and brass are used in a wide variety of ways in Ekintop office furniture manufacturer. Metal parts were first introduced into furniture cautiously as decorative accessories or as strengthening elements, but furniture made entirely of metal became common in the 19th century. Its use is currently accelerating as the cost of wood rises with increasing scarcity. Not only metals are used in furniture that is make of wood primarily, but also a great deal of furniture particularly for Ekintop office furniture manufacturer, is make entirely of metal.

0 notes

Text

Cabinet Manufacturers Melbourne – What Do You Need To Know

Cabinets play an urgent part in both private and commercial spaces, serving as basic capacity arrangements whereas improving the stylish offer of a room. Cabinet producers specialize in creating pieces that are not fair useful but moreover reflect the individual fashion of the client, guaranteeing a consistent mix of common sense and beauty.

Crafting customization

One of the trademarks of advanced cabinet plan is customization. Cabinet producers or Cabinet Manufacturers Melbourne work closely with clients to get it their interesting needs, inclinations, and the space’s measurements. From smooth, moderate plans to lavish, conventional styles, the conceivable outcomes are perpetual for Cabinet Design and Manufacture Melbourne. Materials such as strong wood, plywood, MDF, and metal are chosen based on solidness, budget, and plan prerequisites, guaranteeing cabinets stand the test of time.

Innovative fabricating processes

Advancements in innovation have revolutionized Cabinet Design and Manufacture Melbourne. Accuracy cutting with CNC machines, eco-friendly wraps up, and strong equipment guarantee high-quality cabinets that adjust with industry measures. Producers too center on maintainability, utilizing reused materials and non-toxic wraps up to decrease natural impact.

Design patterns forming the industry

Modern cabinet plans by top Cabinet Manufacturers Melbourne emphasize straightforwardness, clean lines, and unbiased tones. Handle-less cabinets, soft-close instruments, and built-in lighting have ended up prevalent for their smooth, modern request. On the other hand, conventional cabinets with perplexing carvings and wealthy wooden surfaces stay immortal classics.

Choosing the right manufacturer

When selecting the right Cabinet Manufacturers Melbourne, see for companies that offer a comprehensive prepare, from plan discussion to establishment. Check their portfolio, materials utilized, and client audits to guarantee quality craftsmanship.

Whether you are overhauling your kitchen, washroom, or office, cabinets are more than fair storage they are an expression of your taste and a key component of Cabinet Design and Manufacture Melbourne. A trusted cabinet producer can change your vision into reality, mixing usefulness with imaginativeness.

#cabinet design and manufacture melbourne#custom cabinet & joinery design melbourne#custom cabinetry design melbourne#custom bathroom vanities melbourne

0 notes

Text

The Essentials of Circular Knives and Blades for Cutting.

Explore the fundamentals of circular knives and blades for cutting. Gain valuable knowledge to improve your cutting techniques and equipment selection.

In the world of manufacturing and industrial applications, precision cutting tools are vital for achieving optimal results. Among the most widely used tools for precision cutting are circular knives and circular blades. While both share similar circular designs, each type of blade has unique features that make it suitable for specific tasks. This comprehensive guide delves into the functionality, uses, and advantages of circular knives and circular blades, helping you understand which tool is best for your cutting needs.

What Are Circular Knives?

Circular knives are rotary cutting tools characterized by their circular shape and sharp edges. These knives are typically used in applications that require continuous, smooth, and efficient cuts. The round design of these knives allows for an uninterrupted cutting process, making them ideal for industries that deal with high-volume production or delicate materials.

Circular knives are commonly used in industries such as:

Packaging: Circular knives are essential in the packaging industry, where they are used for cutting various materials such as cardboard, paper, plastic films, and more. The ability to cut with precision and speed ensures that packaging processes are carried out effectively.

Textiles and Fabrics: In the textile industry, circular knives are used to cut fabrics, leather, and other flexible materials. Their sharp, rotating blades make it easy to slice through multiple layers at once, improving production speed and reducing material waste.

Printing and Paper: Circular knives are used in printing presses and paper cutting machines. The blades are capable of cutting through large rolls of paper or other materials in one smooth motion, ensuring high-quality results.

What Are Circular Blades?

Circular blades are similar to circular knives in shape but are typically used in a wider range of cutting tools, such as saws, grinders, and rotary cutters. Circular blades have a fixed or rotating configuration and are designed for cutting a variety of materials, including metals, wood, and plastic.

Some key applications of circular blades include:

Woodworking: In the woodworking industry, circular blades are used in saws for cutting through wood, plywood, and other similar materials. The blades are designed to handle tough materials while delivering clean and precise cuts.

Metalworking: Circular blades are commonly used for cutting through metals in the manufacturing and metalworking industries. Whether it’s cutting sheet metal, pipes, or other metal components, circular blades provide the strength and sharpness needed for accurate cuts.

Concrete Cutting: Specialized circular blades are used in concrete cutting, especially in construction and demolition. These blades are designed with diamond-tipped edges that allow them to slice through tough materials such as concrete, asphalt, and stone.

Key Differences Between Circular Knives and Circular Blades

While circular knives and circular blades may look similar, they are designed for different applications. Here’s a breakdown of the key differences:

Design and Functionality:

Circular knives are typically designed for continuous rotary motion, making them ideal for slicing through flexible materials such as paper, fabric, and plastic films.

Circular blades are generally used in more rigid cutting tools like saws, grinders, and rotary cutters. They are versatile enough to cut through both soft and hard materials, such as wood, metal, and concrete.

Material Compatibility:

Circular knives are usually employed in industries where precision cutting of delicate materials is crucial. They are frequently used in packaging, textiles, and printing, where the material needs to be sliced smoothly without fraying or damaging the edges.

Circular blades are typically used in construction, woodworking, and metalworking, where tougher materials need to be cut. The blades are often made of durable materials like high-carbon steel, carbide, or diamond for improved longevity and cutting power.

Cutting Speed and Efficiency:

Circular knives are designed to operate at high speeds and deliver continuous cuts, allowing for high productivity in environments like packaging and textile manufacturing.

Circular blades, depending on the application, are typically slower but more powerful. The emphasis with circular blades is on strength and endurance, especially when cutting through tougher materials.

Benefits of Circular Knives and Circular Blades

Both circular knives and circular blades offer several benefits, making them indispensable tools in various industries. Here are some of the advantages:

Precision and Accuracy: Both tools are designed for highly accurate cuts. Circular knives, with their rotating blades, are ideal for smooth, precise cuts on flexible materials. Circular blades, on the other hand, provide clean cuts on tougher materials.

Durability: Both circular knives and circular blades are built to withstand heavy use and maintain sharpness over time. High-quality materials such as steel, carbide, and diamond are often used in their construction, ensuring durability and long-lasting performance.

Efficiency: Circular knives and circular blades are both designed to maximize efficiency in production processes. Circular knives ensure continuous, smooth cuts, increasing the speed of cutting processes in industries such as packaging and textiles. Circular blades, with their power and strength, enable efficient cutting of tougher materials, leading to reduced downtime and fewer blade replacements.

Versatility: Circular knives and circular blades come in a variety of sizes, shapes, and materials, making them suitable for a wide range of applications. Whether you’re cutting paper, fabric, wood, metal, or concrete, there’s a circular blade or knife designed for the job.

Choosing the Right Circular Knife or Circular Blade for Your Needs

When selecting a circular knife or circular blade for your application, there are several factors to consider:

Material Type: Consider the material you’ll be cutting. If you’re working with flexible materials such as paper or fabric, a circular knife may be the best option. For tougher materials like wood, metal, or concrete, a circular blade is more appropriate.

Cutting Speed: Circular knives are designed for high-speed, continuous cutting. If your production process requires fast, uninterrupted cuts, a circular knife may be ideal. For tasks that demand strength and power over speed, a circular blade will provide the durability you need.

Blade Material: The material of the blade impacts its longevity and performance. High-carbon steel blades are durable and effective for general cutting needs, while carbide and diamond blades are suitable for more demanding applications such as metalworking and concrete cutting.

Blade Size and Configuration: Choose the appropriate size and configuration for your specific cutting needs. Circular knives typically come in smaller sizes suited for precise cuts, while circular blades range from small to large, depending on the thickness and hardness of the material being cut.

Both circular knives and circular blades are essential tools in many industrial sectors, providing efficiency, precision, and durability in cutting operations. Whether you need to cut delicate fabrics or tough metals, selecting the right tool for the job can significantly improve productivity and reduce operational costs. By understanding the unique features and applications of each, you can make an informed decision and ensure your cutting processes run smoothly.

Explore our selection of high-quality circular knives and circular blades today and discover the ideal solution for your cutting needs. With the right tools in hand, you can achieve flawless cuts, enhance production speed, and maintain the high standards required in your industry.

Visit : https://www.perfectknives.net/circular-knives.php

Contact : +91 9822050035

0 notes

Text

CNC Wood Router Machine in Maharashtra

Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Maharashtra, India Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. We offer a wide range of Mini Tabletop CNC Router, CNC Engraving & Router Machine 2D/3D, CNC Rotary Wood Router Machine, CNC Engraving & Router Machine, 4 Axis CNC Router, CNC Router with Wood Turning Lathe, CNC Router for Door Lock Hole and Hinge. CNC Router with Saw Blades, CNC Router Double Head with Drilling Head, For Sewing Machine Wooden Table Top Making Industries, ATC CNC Router With Automatic Tool Changer, CNC Machine for Horizontal Wood Processing, CNC Router Machine with CCD Camera Customized, CNC Router Machine, CNC Router for Pattern Industries. Success Technologies presents the CNC Wood Router Machine, an advanced solution designed to meet the needs of professionals in the woodworking industry. With its high precision, versatility, and automation, our CNC routers offer the perfect blend of performance and cost-effectiveness for woodworking businesses, manufacturers, and hobbyists alike. Process of CNC Wood Routing: The process of CNC wood routing begins with creating a design on a computer software, typically CAD (Computer-Aided Design) software. The design is then transferred to the CNC machine using G-code, which instructs the router on how to carve or cut the wood. The router uses a rotating cutting tool to follow the programmed path, achieving precise shapes and cuts based on the design specifications. The entire process is automated, reducing human error and ensuring high efficiency. Applications: Furniture Making Cabinet Making Signage Wood Carving Architectural Woodworking Custom Designs FAQS: What types of materials can be cut with a CNC wood router? CNC wood routers can cut a variety of materials, including wood, MDF, plywood, acrylics, plastics, and other composites. How precise is the CNC wood router? The CNC wood router offers high precision with minimal tolerance, ensuring that each cut is exact and consistent for even the most intricate designs. Success Technologies is a Supplier of CNC Wood Router Machine in Maharashtra, India Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#4AxisCNCRouter#Achalpur#Ahmedabad#Ahmednagar#Akola#Ambarnath#Amravati#ATCCNCRouterWithAutomaticToolChanger#Aurangabad#Badlapur#Barshi#Beed#Bhiwandi-Nizampur#Bhusawal#Chandrapur#CNCEngraving&RouterMachine#CNCEngraving&RouterMachine2D/3D#CNCMachineforHorizontalWoodProcessing#CNCRotaryWoodRouterMachine#CNCRouterDoubleHeadwithDrillingHead#CNCRouterforDoorLockHoleandHinge.CNCRouterwithSawBlades#CNCRouterforPatternIndustries#CNCRouterMachine#CNCRouterMachinewithCCDCameraCustomized#CNCRouterwithWoodTurningLathe#CNCWoodRouterMachineinAhmedabad#CNCWoodRouterMachineinGujarat#CNCWoodRouterMachineinIndia#CNCWoodRouterMachineinMaharashtra#Dhule

0 notes

Text

Automatic Edge Banding Machine for Sale

Woodworking has always been a craft that requires precision, skill, and attention to detail. Whether you’re a professional carpenter or a DIY enthusiast, the quality of your finished product depends on the accuracy of your work. One crucial aspect of woodworking is edge banding, which involves applying a thin strip of material to the exposed edges of a wooden panel to enhance its appearance and durability. In the past, edge banding was a labor-intensive and time-consuming process, but thanks to technological advancements, we now have automatic edge banding machines that have revolutionized the woodworking industry.

Automatic Edge Banding Machine

An automatic edge banding machine is a piece of equipment used in woodworking and furniture manufacturing to apply decorative edging to the edges of panels, such as plywood, particleboard, or MDF (medium-density fiberboard). Edge banding is applied to give a finished look to the edges of panels, protect them from moisture and wear, and enhance their aesthetic appeal.

These machines typically consist of a conveyor belt system that feeds the panels through various stations. The process usually involves applying adhesive to the edge of the panel, then feeding the edge banding material (usually made of PVC, ABS, wood veneer, or melamine) through a heating element to activate the adhesive and bond the banding to the panel’s edge. The excess banding material is then trimmed and shaped to create a clean, finished edge.

Automatic edge banding machines offer several advantages over manual edge banding techniques, including increased speed, consistency, and precision. They are commonly used in large-scale production settings where efficiency and quality are paramount.

How Automatic Edge Banding Machines Work

Automatic edge banding machines are designed to automate the entire edge banding process, from applying the adhesive to trimming the excess material. These machines are equipped with a conveyor belt system that transports the wooden panel through various stages of the edge banding process.

The first step is the application of adhesive to the edge of the wooden panel. The machine uses a precise mechanism to apply the adhesive evenly and consistently. Once the adhesive is applied, the machine automatically feeds the edge banding material onto the panel, aligning it perfectly with the edges.

Next, the machine applies pressure to ensure proper adhesion between the panel and the edge banding material. This step is crucial to ensure a strong bond and prevent any peeling or lifting of the edge banding.

After the adhesive has dried, the machine trims the excess edge banding material using precision cutting tools.

Benefits of Automatic Edge Banding Machines

The introduction of automatic edge banding machines has brought numerous benefits to the woodworking industry. Here are some of the key advantages:

Increased Efficiency: Automatic edge banding machines significantly reduce the time and effort required for edge banding. With their automated features, these machines can complete the edge banding process in a fraction of the time compared to manual methods.

Improved Precision: These machines are equipped with advanced sensors and mechanisms that ensure precise application of adhesive and alignment of the edge banding material. This results in a consistent and high-quality finish.

Enhanced Productivity: By automating the edge banding process, these machines allow woodworkers to focus on other aspects of their work, thereby increasing overall productivity.

Cost Savings: While the initial investment in an automatic edge banding machine may seem significant, it pays off in the long run. These machines reduce material waste and minimize the need for manual labor, resulting in cost savings for woodworking businesses.

Versatility: Automatic edge banding machines can handle a wide range of edge banding materials, including PVC, ABS, wood veneer, and melamine. This versatility allows woodworkers to work with different materials and achieve various design aesthetics.

Applications Of Edge Banding Machine

Edge banding machines are mainly used for banding the edges of various panel furniture. For instance, cabinets, wardrobes, shelves, custom furniture, office furniture, tables, chairs, windows, doors, cupboards, and other wood products.This machine is suitable for linear edge banding and edge banding materials of solid wood board, fiberboard, particle board and other plate workpieces.

Available solid wood strips, pvc, melamine, veneer strips, etc.

1. What types of edge banding materials can automatic edge banding machines handle?

Automatic edge banding machines can handle a variety of edge banding materials, including PVC, ABS, wood veneer, and melamine. This versatility allows woodworkers to choose the most suitable material for their project.

2. Are automatic edge banding machines easy to operate?

Yes, automatic edge banding machines are designed to be user-friendly and easy to operate. They come with intuitive controls and clear instructions, making them accessible to both professionals and DIY enthusiasts.

3. Can automatic edge banding machines handle curved edges?

Yes, some automatic edge banding machines are equipped with special mechanisms that allow them to handle curved edges. These machines can adapt to the shape of the panel, ensuring a seamless edge banding finish.

4. How long does it take to complete the edge banding process with an automatic edge banding machine?

The time required to complete the edge banding process with an automatic edge banding machine depends on various factors, such as the size of the panel, the complexity of the design, and the type of edge banding material used.

5. Are automatic edge banding machines suitable for small woodworking businesses?

Yes, automatic edge banding machines are suitable for small woodworking businesses. While they may require an initial investment, they offer long-term cost savings and increased productivity. These machines streamline the edge banding process, allowing small businesses to complete projects more efficiently and deliver high-quality results.

So, if you’re looking to enhance the quality and efficiency of your woodworking projects, consider investing in an automatic edge banding machine. With its advanced features and capabilities, this machine will streamline your edge banding process and help you achieve professional results. Say goodbye to tedious manual labor and welcome the future of woodworking with an automatic edge banding machine. Remember, woodworking is an art, and the tools you use play a crucial role in the final outcome. Embrace technology, embrace precision, and embrace the power of automatic edge banding machines. Your woodworking projects will never be the same again.

0 notes

Text

Plywood Cutting Machine | Plywood Saw Cutting Machine | Manufacturer

Plywood cutting machine designed for precision and efficiency. Ideal for woodworking shops and construction projects, to meet your cutting needs. - Power – Main Saw 7.5HP and Scoring Saw – 1.5 HP - Pneumatic Clamping system for board holding - Cast Iron Type internal structure - All Motors are 415V/50hz Motors are CG/Havells/ABB

#Plywood Machine#Plywood Machine Price in India#Plywood Machine Price#Mini plywood Cutter Machine#Plywood cutting machine Manufacturers#Plywood cutting machine Manufacturers near me#Industrial plywood cutting machine in Delhi#plywood cutting machine in Odisha#Plywood cutting machine in Odisha price#plywood cutting machine in Andhra Pradesh#Plywood cutting machine in Andhra Pradesh price#Best plywood cutting machine in Andhra Pradesh#plywood cutting machine in Telangana#Plywood cutting machine in Telangana price#plywood cutting machine in Haryana#Industrial plywood cutting machine in Haryana#Plywood cutting machine in Haryana price#plywood cutting machine price in India#plywood cutting machine table saw#plywood cutting machine low price#plywood machine manufacturers#Plywood Machine manufacturers in Yamunanagar#wood cutting machine in Ahmedabad#wood cutting machine in Bangalore#plywood cutting machine manufacturers in India#plywood cutting machine manufacturers#Plywood Cutting Machinery Price#Plywood Cutting Machine Punjab#Plywood Cutting Machine Maharashtra#Plywood Cutting Machine Tamil Nadu

0 notes

Text

A Guide to Panel Saw Machines: Your Ultimate Solution for Precision Cutting

At Shree Umiya F-Tech Machines | Umaboy Group, we pride ourselves on delivering innovative and high-performance panel saw machines to meet the diverse needs of industries worldwide. Whether you're a furniture manufacturer or a woodworker looking for precision, our range of panel saw machines offers efficiency and reliability for all your cutting requirements.

What is a Panel Saw Machine?

A panel saw machine is a versatile tool designed to cut large sheets of material like wood, MDF, and plywood into smaller, precise pieces. It is widely used in carpentry, furniture manufacturing, and other wood-based industries due to its ability to deliver accurate cuts effortlessly.

Key Features of Our Panel Saw Machines

Precision Cutting: Engineered to deliver smooth and accurate cuts for various panel materials.

Durability: Built with robust materials to ensure long-term performance and reliability.

Ease of Use: User-friendly designs to simplify operations, even for beginners.

Customizable Options: Tailored to meet the specific needs of industries and individual projects.

Why Choose Shree Umiya F-Tech Machines?

As a leading panel saw machine manufacturer and supplier, we offer:

High-Quality Products: Advanced technology and superior craftsmanship.

Industry Expertise: Over years of experience in designing machines for optimal performance.

Customer Support: Dedicated service to assist you from selection to after-sales maintenance.

Applications of Panel Saw Machines

Furniture Making: Perfect for cutting wood panels for cabinets, tables, and other furniture pieces.

Interior Designing: Ideal for precise cuts required in decorative projects.

Carpentry Workshops: Ensures efficient and professional-grade results.

Our Promise to You

At Shree Umiya F-Tech Machines | Umaboy Group, we are committed to excellence. We not only provide top-tier panel saw machines but also offer valuable insights to help you maximize your investment. Whether you're seeking panel saw machine suppliers or require custom solutions, we've got you covered.

Conclusion

A reliable panel saw machine is a must-have for industries focused on precision and productivity. Shree Umiya F-Tech Machines stands out as a trusted name in the field, providing cutting-edge solutions tailored to your needs. Choose us for superior craftsmanship, unparalleled quality, and seamless operations.

Ready to transform your work efficiency? Reach out to Shree Umiya F-Tech Machines | Umaboy Group today

0 notes

Text

Panel Saw Machine Supplier in India: Golden Machinery

Golden Machinery, a trusted name in the woodworking industry, offers the best panel saw machine in India. Designed to meet the demands of precision cutting, these machines are perfect for processing wood panels, including plywood, MDF, and particleboard. Built with a robust construction and advanced features like an electronic digital readout for tilt adjustment and a fine setting rip fence, these machines ensure accurate and smooth cuts every time. As a leading panel saw machine supplier, Golden Machinery combines quality, durability, and competitive panel saw machine prices to support businesses in furniture manufacturing and construction

#industrial machine tool suppliers#machine tool suppliers in india#panel saw machine#panel saw machine price#panel saw machine supplier#best panel saw machine in India

0 notes

Text

CNC Wood Router Machine in Mumbai:

Mumbai, a bustling hub of commerce and industry, is home to a growing demand for precision machinery in the woodworking sector. As industries evolve, the need for advanced technology that combines precision, speed, and versatility has become paramount. CNC Wood Router Machines are at the forefront of this transformation, revolutionizing the way woodcraft is approached. Truway Machinery, a trusted name in Mumbai, is proud to offer top-of-the-line CNC Wood Router Machines to cater to diverse industrial and creative needs.

What is a CNC Wood Router Machine?

A CNC (Computer Numerical Control) Wood Router Machine is an advanced tool that automates the process of cutting, carving, engraving, and shaping wood. Unlike traditional manual methods, CNC machines operate using programmed instructions, ensuring unmatched precision and consistency. These machines are ideal for crafting intricate designs, creating custom furniture, signage, and a variety of wooden products.

Why Choose Truway Machinery for CNC Wood Router Machines in Mumbai?

At Truway Machinery, we understand the unique requirements of our clients. Whether you're a small business owner, a large-scale manufacturer, or an artisan, our CNC Wood Router Machines are designed to meet your needs with precision and reliability. Here's why Truway Machinery stands out:

High-Quality Machines Our CNC Wood Router Machines are built with robust components and cutting-edge technology to deliver consistent performance. We ensure our machines meet international standards, giving you an edge over your competitors.

Versatility Across Applications Truway Machinery's CNC Wood Routers are suitable for a wide range of applications, including furniture making, cabinetry, sign carving, and architectural woodwork.

User-Friendly Interface Our machines are designed with an intuitive interface, making them easy to operate even for those new to CNC technology. This reduces the learning curve and ensures seamless integration into your workflow.

Affordable Solutions We provide cost-effective CNC Wood Router Machine in Mumbai without compromising on quality. Our goal is to empower businesses in Mumbai to access advanced technology within their budget.

Exceptional After-Sales Support Truway Machinery believes in building long-term relationships with our clients. Our dedicated after-sales support ensures your machine operates at peak performance, minimizing downtime and maximizing productivity.

Features of Truway Machinery's CNC Wood Router Machines

High Precision and Accuracy Equipped with advanced cutting tools and guided by computer programming, our CNC routers deliver detailed and intricate designs with impeccable accuracy.

Durable Build Constructed with industrial-grade materials, our CNC machines are built to withstand rigorous use, ensuring longevity and reliability.

Advanced Spindle Options Truway's CNC machines come with powerful spindles that can handle different types of wood, from soft plywood to dense hardwoods, with ease.

Customizable Designs With our CNC Wood Router Machines, you can create customized designs tailored to specific client needs, adding value to your services.

Energy Efficiency Designed to minimize energy consumption, our CNC machines help reduce operational costs while maintaining top-notch performance.

Applications of CNC Wood Router Machines in Mumbai

Furniture Manufacturing Mumbai's furniture market thrives on innovation and quality. CNC routers allow manufacturers to produce intricate designs and uniform components, ensuring a perfect fit and finish every time.

Interior Design CNC Wood Routers are indispensable for creating custom wood panels, decorative trims, and unique architectural elements, making them a favorite among interior designers.

Signage and Advertising From 3D lettering to carved signs, CNC routers enable businesses to create eye-catching advertising materials with precision.

Artisan and Handcrafted Products Artisans and small-scale craftsmen in Mumbai can use CNC technology to bring their creative visions to life, scaling up production without sacrificing quality.

Industrial Applications Beyond aesthetics, CNC routers are used in creating molds, patterns, and prototypes for various industrial purposes.

Benefits of Investing in CNC Wood Router Machines

Increased Productivity Automation allows for faster production times, enabling businesses to take on more projects and meet tight deadlines.

Cost Efficiency By reducing material wastage and labor costs, CNC routers offer a higher return on investment.

Enhanced Precision Eliminate human error and achieve flawless designs with every cut.

Scalability Whether you need one product or thousands, CNC routers can handle varied production volumes efficiently.

Eco-Friendly Production Minimized waste and optimized energy use contribute to environmentally responsible operations.

Truway Machinery: Your Trusted Partner in CNC Technology

At Truway Machinery, we believe that technology should empower creativity and efficiency. Our CNC Wood Router Machines are a testament to this philosophy, offering the perfect blend of innovation and practicality. Serving clients across Mumbai, we take pride in helping businesses unlock their full potential with cutting-edge machinery.

Our team of experts is always available to guide you in selecting the right machine, providing training, and ensuring you get the most out of your investment.

Conclusion

In a city as dynamic as Mumbai, staying ahead in the woodworking industry requires embracing advanced technology. Truway Machinery’s CNC Wood Router Machines are designed to give businesses the competitive edge they need. Whether you're looking to enhance production, improve precision, or explore new creative possibilities, our machines are the ideal choice.

Ready to take your woodworking to the next level? Contact Truway Machinery today to learn more about our CNC Wood Router Machines and how they can transform your business. Let’s carve a future of innovation and success together!

0 notes

Text

CNC Wood Router Machine in Madhya Pradesh

Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Madhya Pradesh, India. Our Registered Office and Manufacturing Unit are located in Ahmedabad, Gujarat, India. We offer a wide range of Mini Tabletop CNC Router, CNC Engraving & Router Machine 2D/3D, CNC Rotary Wood Router Machine, CNC Engraving & Router Machine, 4 Axis CNC Router, CNC Router with Wood Turning Lathe, CNC Router for Door Lock Hole and Hinge. CNC Router with Saw Blades, CNC Router Double Head with Drilling Head, For Sewing Machine Wooden Table Top Making Industries, ATC CNC Router With Automatic Tool Changer, CNC Machine for Horizontal Wood Processing, CNC Router Machine with CCD Camera Customized, CNC Router Machine, CNC Router for Pattern Industries. A CNC Wood Router Machine is a computer-controlled cutting machine used in woodworking to precisely cut, carve, engrave, and shape wood. This versatile machine can perform a wide range of tasks, from basic cutting to complex 3D carving. The CNC (Computer Numerical Control) system enables high precision and repeatability, making it ideal for both small-scale and large-scale production environments. Features: Equipped with advanced CNC technology for superior accuracy in every cut, carve, and engraving. Easy-to-use software and intuitive controls for both beginners and professionals. Automatic tool changer reduces downtime and optimizes production efficiency. Capable of cutting, engraving, and carving various materials, including wood, MDF, and plywood. Built with durable materials for long-lasting, high-performance operation. Operates at high speeds, reducing production time and improving output. Dust collection system effectively removes sawdust and debris for a clean working environment. Applications: Furniture Making Cabinet Making Signage Wood Carving Architectural Woodworking Custom Designs What types of materials can a CNC Wood Router Machine cut? The CNC Wood Router Machine can cut wood, MDF, plywood, acrylic, plastic, and other soft to medium-hard materials with high precision. How does the CNC router work? The CNC Wood Router works by following pre-programmed designs from CAD or CAM software. The machine cuts, carves, or engraves the material based on the design input, ensuring precision with each pass. Is the CNC Wood Router Machine difficult to operate? No, Success Technologies' CNC Wood Router Machines come with user-friendly software and controls that make it easy to learn and operate, even for beginners. Success Technologies is a Manufacturer, and Supplier of CNC Wood Router Machine in Madhya Pradesh, India Including Agar, Malwa, Alirajpur, Anuppur, Ashoknagar, Balaghat, Barwan, Betul, Bhind, Bhopal, Burhanpur, Chhatarpur, Chhindwara, Damoh, Datia, Dewas, Dhar, Dindori, East Nimar, Guna, Gwalior, Harda, Hoshangabad, Indore, Jabalpur, Jhabua, Katni, Mandla, Mandsaur, Morena, Narsinghpur, Neemuch, Niwari, Panna, Raisen, Rajgarh, Ratlam, Rewa, Satna, Sehore, Seoni, Shahdol, Shajapur, Sheopur, Shivpuri, Sidhi, Singrauli, Ujjain, Umaria, Vidisha, West Nimar. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

#Agar#Ahmedabad#Alirajpur#Anuppur#Ashoknagar#Balaghat#Barwan#Betul#Bhind#Bhopal#Burhanpur#Chhatarpur#Chhindwara#CNCWoodRouterMachine#CNCWoodRouterMachineinMadhyaPradesh#Damoh#Datia#Dewas#Dhar#Dindori#EastNimar#Exporter#ExporterofCNCWoodRouterMachine#Gujarat#Guna#Gwalior#Harda#Hoshangabad#India#Indore

0 notes

Text

4×8 Flatbed Laser CNC Engraving Cutting Machine

In the world of precision cutting and engraving, a 4×8 flatbed laser CNC engraving cutting machine is a game-changer. Whether you’re a professional engraver or a hobbyist looking to explore the possibilities of laser cutting and engraving, investing in this advanced machine can revolutionize your craft.

4×8 Flatbed Laser CNC Engraving Cutting Machine

A 4×8 flatbed laser CNC engraving cutting machine is a versatile tool that combines the precision of laser technology with the automation of computer numerical control (CNC). This machine features a large flatbed surface, measuring 4 feet by 8 feet, which allows for the cutting and engraving of various materials with ease. The laser beam is controlled by a CNC system, which follows a pre-programmed design to create intricate patterns, shapes, and engravings on the material’s surface.

The 4×8 refers to the bed size, which is 4 feet by 8 feet (approximately 1.2 meters by 2.4 meters). This large working area is ideal for handling large sheets of material. The power of the laser affects the types of materials you can cut and the thickness. Typical power ranges from 40W for light engraving up to 150W or more for cutting thicker materials.

Applications Laser engraving and cutting machine:

4×8 flatbed laser CNC engraving and cutting machine can significantly enhance your production capabilities, providing high precision and versatility for a wide range of applications.

Advertising Industry: acrylic engraving and cutting, cutting and engraving of double- color plate and other advertising material

Leather Processing Industry: leather, fabric carved hollow

Arts And Crafts Industry: paper cutting, wood, bamboo products, leather, shell, ivory and other materials’ engraving and cutting

Model Industry: construction model, aviation and maritime models, wooden toys’ cutting.

Packaging Industry: printed rubber plate engraving and cutting, plywood cutting and laser cutter template cutting.

Decoration Industry: electrical and electronic industry materials engraving and cutting.

Advantages of 4×8 Laser CNC Engraving Cutting Machines

1. Precision and Accuracy

One of the key advantages of 4×8 flatbed laser engraving cutting machines is their exceptional precision and accuracy. The combination of laser technology and CNC control ensures that every cut and engraving is executed with utmost precision. This level of accuracy allows for intricate and complex designs, giving you the freedom to create stunning and detailed artwork.

2. Versatility

4×8 flatbed laser CNC engraving cutting machines are incredibly versatile, capable of working with a wide range of materials. From wood and acrylic to metal and leather, these machines can handle various materials with ease. This versatility opens up endless possibilities for your projects, whether you’re creating signage, personalized gifts, or intricate artwork.

3. Speed and Efficiency

Compared to traditional cutting and engraving methods, 4×8 flatbed laser CNC engraving cutting machines offer significantly faster speeds and higher productivity. The combination of laser technology and CNC automation allows for swift and precise cutting and engraving processes. This means you can take on larger projects and meet tight deadlines without compromising on quality.

4. Customization Options

4×8 flatbed laser CNC engraving cutting machines can be customized to suit your specific needs and requirements. You can choose the laser power, cutting speed, and engraving depth that best aligns with your projects. This customization ensures that you have the right settings to achieve the desired results, whether you’re working on delicate engravings or robust cutting tasks.

5. Ease of Use

Despite their advanced capabilities, 4×8 flatbed laser CNC engraving cutting machines are designed to be user-friendly. The CNC software allows for easy design creation and modification, and the machine’s interface is intuitive and straightforward. This means that even beginners can quickly learn how to operate the machine and unleash their creativity without any technical hurdles.

laser CNC engraving and cutting machine FAQ

1. What materials can I work with using a 4×8 flatbed laser CNC engraving cutting machine?

A 4×8 flatbed laser CNC engraving cutting machine can work with a wide range of materials, including wood, acrylic, metal, leather, fabric, paper, and more. The versatility of these machines allows you to explore various creative possibilities.

2. Can I create intricate designs and engravings with a 4×8 flatbed laser CNC engraving cutting machine?

Absolutely! The precision and accuracy of these machines make it possible to create intricate and detailed designs and engravings. Whether you’re working on fine jewelry pieces or intricate signage, a 4×8 flatbed laser CNC engraving cutting machine can handle the task with ease.

3. How long does it take to learn how to operate a 4×8 flatbed laser CNC engraving cutting machine?

The learning curve for operating a 4×8 flatbed laser CNC engraving cutting machine can vary depending on your prior experience and familiarity with similar technologies. However, these machines are designed to be user-friendly, and with proper training and practice, you can quickly learn how to operate them effectively.

4. Can I customize the settings of a 4×8 flatbed laser CNC engraving cutting machine?

Yes, you can customize the settings of a 4×8 flatbed laser CNC engraving cutting machine to suit your specific needs. You can adjust parameters such as laser power, cutting speed, and engraving depth to achieve the desired results for your projects.

5. How do I maintain a 4×8 flatbed laser CNC engraving cutting machine?

Regular maintenance is essential to ensure the optimal performance and longevity of your machine. This includes cleaning the machine regularly, checking and replacing consumables (such as lenses and mirrors), and following the manufacturer’s guidelines for maintenance. It’s also advisable to have a reliable technical support system in place for any troubleshooting or assistance you may need.

0 notes