#Windrower Market Size

Explore tagged Tumblr posts

Text

0 notes

Text

Organic fertilizer is an indispensable part of agricultural production, and the evaluation of its production efficiency and economic benefits is very important for fertilizer manufacturers. From the perspective of science popularization, this paper discusses how to evaluate the production efficiency and economic benefits of organic fertilizer equipment, and draws out relevant keywords.

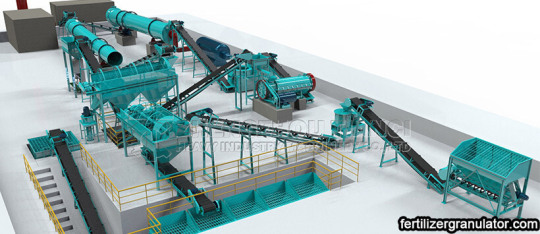

First, we need to understand the basic production process of organic fertilizer. The production of organic fertilizer mainly includes the collection and treatment of raw materials, fermentation, crushing, mixing, granulation, drying, screening and packaging steps. Each step requires corresponding equipment support, and the efficiency of these equipment directly affects the efficiency of the entire production line.

The selection and configuration of fertilizer production line is the key to improve production efficiency. For example, the Organic Fertilizer Production Line needs to be able to adapt to different raw material characteristics and Production needs, including a variety of Fertilizer Granulating production lines such as rollers, disks, and new organic fertilizers. The automation degree, equipment stability and maintenance cost of the production line are all important indicators to evaluate its production efficiency.

In the fermentation process, the role of Compost Turning Machine (such as Windrow Compost Turning Machine) is to ensure uniform fermentation and improve fermentation efficiency. The efficiency and effect of the turnover machine directly affect the fermentation quality of organic fertilizer, and then affect the quality of the final product and the production cost.

Fertilizer granulation Machine series equipment, such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine, is the key equipment to make organic fertilizer into pellets. The performance of the granulator directly affects the molding rate and uniformity of the particles, and then affects the market competitiveness of the product.

Fertilizer mixers, such as the Horizontal Ribbon Mixer and the Double Shafts Paddles Mixer, are used to mix different ingredients to ensure an even nutrient composition of organic fertilizers. The mixing efficiency and uniformity of the mixer are important links to ensure product quality.

Fertilizer Screening machines, including Rotary Screening Machine and Vibration Screening Machine, are used to separate fertilizer particles of different sizes to improve product uniformity and market competitiveness.

Fertilizer drying and cooling Machine machinery, such as Rotary Dryer Machine and Rotary Cooler Machine, is used to control the moisture content of fertilizer, prevent caking and improve storage stability.

Other supporting equipment, such as Uniform Feeder, ensures the continuity and uniformity of raw material supply, which is essential to improve the overall efficiency of the production line.

When evaluating the production efficiency of organic fertilizer equipment, we need to consider the production capacity, energy consumption, ease of operation, maintenance costs and environmental impact of the equipment. The evaluation of economic benefits needs to consider the investment cost of equipment, operating costs, product prices and market demand and other factors.

By taking the above factors into consideration, we can conduct a comprehensive evaluation of the production efficiency and economic benefits of organic fertilizer equipment. This not only helps to improve production efficiency and reduce costs, but also improves the market competitiveness of products and ultimately achieves sustainable economic benefits.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#Fertilizer Granules Compaction Machine

0 notes

Text

In modern agricultural production, the disposal of chicken manure has always been a difficult problem. However, with the continuous development of organic fertilizer granulation technology, this problem has been effectively solved. By converting chicken manure into organic fertilizer, it not only solves the problem of environmental pollution, but also brings additional economic benefits to chicken farms.

First of all, the establishment of Organic Fertilizer Production Line is the key to achieve this transformation. Production lines usually include raw material preparation, fermentation, crushing, mixing, granulation, drying, screening and packaging. At the raw material preparation stage, fresh chicken manure is dehydrated and fermented to reduce odors and improve the stability of organic matter. During the fermentation process, the Windrow Compost Turning Machine can be used to increase oxygen and accelerate the decomposition of organic matter.

Next comes the crushing process, where Cage Crusher plays an important role in crushing the fermented material to a size suitable for granulation. The pulverized material passes to the Horizontal Ribbon Mixer, where it is mixed with other nutrients such as NPK fertilizers produced on the NPK Fertilizer Production Line to prepare for granulation.

Granulation is a crucial step in the production of organic fertilizer, where the Flat-Die Pellet Machine forms the mixture into pellets that have good physical properties and are easy to apply and store. The produced particles are then dried in a Rotary Dryer Machine to reduce the moisture content and improve the preservation of the fertilizer.

The dried organic fertilizer particles are screened by Rotary Screening Machine to ensure that the particle size is consistent and in line with market standards. Finally, Uniform Feeder will uniformly feed the sieved particles into the packaging system, complete the packaging, ready for sale.

Through this series of processing processes, the manure from the chicken farm is no longer waste, but becomes an efficient organic fertilizer. This fertilizer can not only improve soil structure and increase crop yields, but also reduce the use of chemical fertilizers, thus reducing the environmental impact.

In addition, the organic fertilizer granulation recycling mode also helps to improve the economic benefits of chicken farms. By selling organic fertilizer, chicken farms can obtain an additional source of income. At the same time, because the use of organic fertilizers reduces the dependence on chemical fertilizers, it also reduces the cost of agricultural production.

In short, the application of organic fertilizer granulation technology not only solves the problem of manure treatment in chicken farms, but also realizes the recycling of resources, which brings double benefits of environmental protection and economic benefits to chicken farms. With the continuous progress of technology and the increasingly mature market, organic fertilizer granulation will certainly play an increasingly important role in modern agricultural production.

#Organic Fertilizer Production Line#Windrow Compost Turning Machine#Cage Crusher#Horizontal Ribbon Mixer#NPK Fertilizer Production Line#Flat-Die Pellet Machine#Rotary Screening Machine#Uniform Feeder

0 notes

Text

In modern agricultural production, the conversion of chicken manure into organic fertilizer is an important work that is both environmentally friendly and economical. This not only reduces environmental pollution, but also provides valuable nutrients for farmland. This paper will introduce in detail the seven key steps of chicken manure treatment into organic fertilizer, as well as the key words involved in the equipment.

Step 1: Raw material collection and pretreatment

First, we need to collect fresh chicken manure and conduct preliminary screening and decontamination. This step ensures the smooth progress of the subsequent treatment process and also lays the foundation for improving the quality of the fertilizer.

Step 2: Compost and turn the pile

Next, pile the pre-treated chicken manure into strips and use the Windrow Compost Turning Machine to turn the piles. This process increases oxygen and speeds up the breakdown of organic matter while reducing undesirable odors.

Step 3: Crushing treatment

The chicken manure that has been turned over needs to be crushed to facilitate subsequent mixing and granulation. The Compost Crusher is used here.It can crush the material to the appropriate particle size.

Step 4: Mix and stir

The crushed material will be mixed with other organic or inorganic additives to ensure the nutrient balance of the fertilizer. A Horizontal Ribbon Mixer or a Double Shafts Paddles Mixer are commonly used in this process to ensure that the material is mixed evenly.

Step 5: Granulation molding

The evenly mixed material will enter the granulation stage. The Flat-Die Pellet Machine or Rotary Drum Granulator in the Organic Fertilizer Production Line can granulate the material for subsequent drying and packaging.

Step 6: Drying and cooling

Freshly granulated fertilizer usually contains high moisture and needs to be dried by Rotary Dryer Machine and then cooled to room temperature in Rotary Cooler Machine to ensure the stability of fertilizer and easy storage.

Step 7: Screening and packaging

Finally, the dried and cooled fertilizer particles are screened by Rotary Screening Machine, unqualified particles are removed, and packaged according to specifications, and finally formed into commercial organic fertilizers sold on the market.

Through these seven steps, chicken manure is transformed into an efficient organic fertilizer that provides important nutrient support for agricultural production. This process not only reflects the advanced concept of agricultural waste resources, but also shows the important role of modern agricultural equipment in agricultural production.

0 notes

Text

With the increasing attention to environmental protection and sustainable development, organic fertilizer has been widely concerned because of its ability to improve soil structure and crop quality. The establishment of an efficient Organic Fertilizer Production Line can not only meet the market demand, but also promote the green development of agriculture.

1. Planning and design

First, you need detailed planning and design of the Organic Fertilizer Production Line. This includes determining the size of the production line, the capacity, the process flow and the equipment required. In the planning process, factors such as the source, cost and transportation of raw materials should be fully considered to ensure the economic benefits and sustainability of the production line.

2. Selection of fertilizer production line

The fertilizer production line is the core part of the entire production process. Depending on your Production needs, you can choose from different types of Fertilizer Production lines, such as NPK Fertilizer Production Line, Organic Fertilizer Production Line, etc. These lines typically include raw material handling, mixing, granulation, drying, cooling and packaging. Choosing the right production line can greatly improve production efficiency and product quality.

3. Application of Rotary Drum Granulator

Rotary Drum Granulator is one of a series of fertilizer granulators that granulates raw materials through a rotating drum. The granulator is suitable for a variety of raw materials, including organic and Complex fertilizers. The advantages of Rotary Drum Granulator are its efficient granulation capacity and low energy consumption, which can meet the needs of large-scale production.

4. The importance of Windrow Compost Turning Machine

In the production process of organic fertilizer, the Windrow Compost Turning Machine plays a vital role. By turning the compost, it promotes the decomposition of organic matter and the activity of microorganisms, thus accelerating the maturation process of the compost. This equipment not only improves the quality and efficiency of the compost, but also helps to reduce undesirable odors and environmental pollution.

5. Innovation of Organic-Inorganic Fertilizer Compound Fertilizer

Organic-Inorganic Fertilizer Compound Fertilizer is a product that combines the advantages of organic and inorganic fertilizers. It can provide a variety of nutrients needed by plants, while improving the soil structure and improving the resistance of crops to disease. When establishing Organic Fertilizer Production Line, considering the production of organic and inorganic compound fertilizers can increase the market competitiveness of your products.

Conclusion

The establishment of Organic Fertilizer Production Line is a systematic project, which requires comprehensive consideration of many factors such as raw materials, equipment, process and market. By selecting the right Fertilizer Line, pelletizer, tiller and compound fertilizer technology, you can build an efficient, environmentally friendly and market-competitive Organic Fertilizer Production Line. This can not only meet the needs of modern agriculture for fertilizer, but also contribute to the sustainable development of agriculture.

#Organic Fertilizer Production Line#NPK Fertilizer Production Line#Rotary Drum Granulator#Windrow Compost Turning Machine

0 notes

Text

Hay and Forage Rakes Market is estimated to Witness Steady Growth Due to Growing Dairy Farm Industry

The hay and forage rakes market has been growing significantly over the past couple of years. Hay and forage rakes are agricultural equipment used for collecting and accumulating wet or dry hay, straw or silage during harvesting into windrow. They are widely used for their capacity to handle various crop types gently without substantial losses and offer high work rates. Owing to their ability to pick up and gather hay and forage crops smoothly and uniformly, they help improve efficiency and consistency during harvesting. The global hay and forage rakes market size was valued at US$ 1.84 billion in 2023 and is expected to reach US$ 2.49 billion by 2031, growing at a compound annual growth rate (CAGR) of 3.8% from 2024 to 2031.

Key players operating in the hay and forage rakes market are Philips Healthcare, Cerner Corporation, Agfa Healthcare, Fujifilm Holdings Corporation, Allscripts Healthcare Solutions Inc., Sectra, Epic Systems Corporation, General Electric Company, Siemens AG, McKesson Corporation, Wellbeing Software, Merge Healthcare Incorporated, Medinformatix Inc., eRAD, Inc., and RamSoft Inc. Key Takeaways Key players: Key players operating in the hay and forage rakes market are Philips Healthcare, Cerner Corporation, Agfa Healthcare, Fujifilm Holdings Corporation, Allscripts Healthcare Solutions Inc., Sectra, Epic Systems Corporation, General Electric Company, Siemens AG, McKesson Corporation, Wellbeing Software, Merge Healthcare Incorporated, Medinformatix Inc., eRAD, Inc., and RamSoft Inc. Key opportunities: Growing adoption of mechanization in agriculture and rise in precision farming are expected to offer lucrative opportunities for players in the global hay and forage rakes market over the forecast period. Global expansion: Increasing export of dairy products worldwide is driving the demand for quality fodder like hay and silage. Hay and Forage Rakes Market Size is further propelling equipment manufacturers to expand their global footprint. Market drivers: The dairy industry has been growing at a notable pace over the past few years. Rising dairy production is increasing the demand for high-quality hay and silage, which is the primary driving force for the sales of hay and forage rakes globally. PEST Analysis Political: Agriculture is a regulated industry, and changes in farm bills and subsidies can impact demand for hay and forage rakes. Tariffs on imported goods could also influence prices. Economic: Overall economic conditions determine discretionary farm spending. During periods of economic recession or uncertainty, equipment purchases may be deferred to prioritize other expenses. Declining crop prices could dampen demand. Social: Changes affecting the agriculture labor force, such as an aging farmer population, can drive Hay and Forage Rakes Companies for machinery that reduces physical work requirements. Health and safety regulations may require equipment upgrades. Technological: Advances in engine efficiency and autonomous functionality are enhancing rake productivity. Variable-rate and GPS technologies optimize field coverage and decrease waste. Connected equipment platforms facilitate equipment monitoring and maintenance planning. Geographical regions: North America and Europe are major markets due to large-scale farming operations and agricultural mechanization. The U.S. is the largest country market globally. Asia Pacific is growing rapidly led by increases in livestock production and government support for agriculture infrastructure modernization in China and India. Fastest growing region: Asia Pacific is projected to have the fastest CAGR during the forecast period. Population and income growth are increasing demand for animal products and the need to expand forage harvesting capacity in the region's developing economies. Government efforts to boost productivity through farm mechanization will further support market expansion.

Get more insights on Hay And Forage Rakes Market

Alice Mutum is a seasoned senior content editor at Coherent Market Insights, leveraging extensive expertise gained from her previous role as a content writer. With seven years in content development, Alice masterfully employs SEO best practices and cutting-edge digital marketing strategies to craft high-ranking, impactful content. As an editor, she meticulously ensures flawless grammar and punctuation, precise data accuracy, and perfect alignment with audience needs in every research report. Alice's dedication to excellence and her strategic approach to content make her an invaluable asset in the world of market insights.

(LinkedIn: www.linkedin.com/in/alice-mutum-3b247b137 )

#Coherent Market Insights#Hay And Forage Rakes Market#Hay And Forage Rakes#Agricultural Equipment#Hay Harvesting#Forage Harvesting#Farm Implements#Hay Tools#Raking Equipment#Windrower

0 notes

Text

0 notes

Text

Windrower Market, Growth, Innovation by Experts, Competitive Landscape and Outlook 2029

Windrower Market Overview:

For the global industry’s Windrower market analysis, a research team did thorough primary and secondary research. Secondary research was carried out in order to supplement existing data, segment the market, estimate overall market size, and anticipate market size and growth rate.

Expected Growth is expected to be 4% during the forecast period and the Windrower market size is expected to reach nearly US$ xx by 2029.

Primary and secondary research is used to identify market leaders, while primary and secondary research is used to assess market revenue. In-depth interviews with important thought leaders and industry professionals, such as experienced front-line staff, CEOs, and marketing executives, were conducted as part of the core research. Primary research comprised in-depth interviews with key thought leaders and industry professionals, such as experienced front-line staff, CEOs, and marketing executives, while secondary research included a review of the main manufacturers’ annual and financial reports. Secondary data is used to calculate global market percentage splits, market shares, growth rates, and breakdowns, which are then compared to primary data.

Request a Free Sample Copy or View Report Summary:

Market Scope:

By defining and assessing market segments and predicting market size, the study aids comprehension of the Global Windrower Market dynamic structure. In addition, the report includes a competitive analysis of significant firms based on pricing, financial state, application expansion ambitions, and geographical presence. The research also includes a PESTLE analysis to help shareholders prioritize their efforts and investments in the Global Windrower Market.

External and internal factors that are predicted to have a positive or negative impact on enterprises have been researched, presenting decision-makers with a clear picture of the sector’s future. By studying market segments and projecting Windrower Market size, the study also assists in understanding the dynamic structure of the Global Windrower Market. The study acts as a resource for investors by depicting the competitive analysis of prominent businesses in the Global Windrower Market based on price, financial status, growth strategies, and geographical presence.

Market Segmentation:

Segment by type Below 2m, 2 - 4m, 4 - 6m, Above 6m

Segment by Applications Agricultural Production, Garden Trimming, Others.

Windrower Market Key Players:

Major Key Players are Agriway (Italy), Gomselmash (Belarus), Atelier 3T (France), Case IH (USA), Challenger (Australia), ATESPAR Motor Vehicles (Turkey), ELHO Oy Ab (Finland), Conor Engineering (Ireland), FA.MA. (Italy), D. Gutzwiller SAS (France), Schulte Industries (Canada), Wintersteiger AG (Austria), John Deere (USA), Minos Agricultural Machinery (Turkey), Marsaglia (Italy), Rostselmash (Russia), MacDon Industries Ltd. (Canada), and Others and Others.

Regional Analysis:

A study of the Windrower Market at the national level focuses on categories indicated as potentially high-growth, nations with the biggest market share, and countries with the highest development potential. North America (USA, Canada), South America, Asia Pacific (China, Japan, India, Korea), Europe (Germany, UK, France, Italy), and Other nations are the geographical breakdowns in the Windrower Market study.

To Gain More Insights into the Market Analysis, Browse Summary of the Research Report:

COVID-19 Impact Analysis on Windrower Market: The report covers COVID-19 impact on Windrower market.

Key Questions Answered in the Windrower Market Report are:

What will be the Windrower market’s CAGR throughout the projected period?

Which market category emerged as the market leader in the Windrower market?

Who are the key players in the Windrower market?

How big will the Windrower market be in 2029?

Which firm had the biggest market share in the Windrower market?

About Us

Market Report Service began its journey in 2021 with a simple goal to help entrepreneurs know market insights effortlessly. It is a platform that serves businesses with accurate analysis and market insights reports that help in making smart decisions.

Contact Us:

(+1) 479 715 4209

0 notes

Text

How to choose fertilizer manufacturing process plant

Fertilizer promotes the development of ecological agriculture, and the demand is huge. Investment in building fertilizer plants has become a popular project. Some investors want to build small-scale fertilizer manufacturing process to save costs, while some investors in fertilizer plants are going to build large-scale fertilizer plants to save unit production costs.

So what should we pay attention to when purchasing fertilizer manufacturing process plant? Here are some notes.

1. Determine the type of fertilizer and producton site. Determining whether to produce organic fertilizer or compound fertilizer affects the choice of site. If organic fertilizer is produced, it should not be too far from the farm where raw materials are provided. The type of fertilizer determines whether compound fertilizer equipment or organic fertilizer equipment is needed. Different types of fertilizer equipment also have differences.

2. Determine the fertilizer granulator machine. Granulation is the key link in fertilizer production and plays an important role in the quality of manufactured fertilizer. Fertilizer granules are cylindrical, spherical and flat spherical in shape. The granules produced by granulators of different shapes are different. The choice of granulator is related to the scale of fertilizer plant construction and local market. Fertilizer factories have different investment scales, different production processes, and different supporting equipment.

If a small fertilizer plant is to be built, it is suggested to configure simple machinery and equipment to reduce investment in equipment. The small fertilizer production line is composed of crusher, mixer, granulator, drum screener and automatic packing machine. If organic fertilizer fermentation is needed, it can be carried out with batten fermentation and windrow turning machine. The advantages are that they are more in line with the principle of aerobic fermentation. It is not easy to form anaerobic fermentation. The fermentation is full and complete, and the fermentation speed is fast. Forklift trucks can also be used instead of turner (the effect is not as good as turner), which can be adopted in terms of saving investment. According to the local environmental protection requirements, choose dust removal settings, where environmental protection requirements are high, choose heavy dust settings to meet the local emission quality standards.

Investment in large and medium-sized fertilizer plants, fertilizer production equipment can choose turning machine, automatic batching system, loader feeding hopper, crusher, mixer, granulator, dryer, hot stove, cooler, feeder, screener, cyclone dust collector, packing machine, etc. Increase mechanical automation, save manpower and cost. Organic fertilizer tank fermentation, can choose simple compost turning machine, double screws compost turning machine (suitable for large yield).

3. Determine the manufacturer of fertilizer manufacturing process plant. Several fertilizer machine manufacturers were inspected, and the strength, scale and reputation of the manufacturer of fertilizer equipment were fully understood. It is better to inspect the production workshop, finishing workshop and assembly workshop of the enterprise, to know the product quality, processing equipment, production process of the enterprise, and whether the fertilizer equipment produced by the manufacturer is professional. Referring to the customer cases that the manufacturer has completed, on-site test machine, the production site can best show the real operation of the equipment. Looking for fertilizer equipment suppliers with perfect after-sales service, suppliers provide professional technicians to guide customers to install and debug equipment, so that the equipment can operate normally, and provide corresponding training services.

4. Determine the safety performance of fertilizer manufacturing process plant. Safety is the first, before purchasing, we need to consider whether the production line has safety devices, whether the machine design is reasonable, whether safety factors are taken into account, whether the parts are not welded properly, whether the bolts are tightened, whether there is pollution, and so on. In addition, whether the overall operation of the equipment is smooth and whether the design of the production line is reasonable are also matters needing attention, because it relates to the efficiency and quality of the operation of the equipment. With the permission of the manufacturer, the operator can try to operate it in practice and feel its state conveniently.

Powerful organic fertilizer production equipment enterprises can customize their own equipment configurations for different customers according to their needs, and users can choose their own equipment according to their own needs. Zhengzhou Tianci Heavy Industry Machinery Co., Ltd. We provide customers with process design, equipment manufacturing, installation and commissioning, with full one-stop services. We are a leading agricultural equipment manufacturer in China, has strong technical strength in fertilizer machines. We have exported to many countries, India, Korea, Vietnam, Pakistan, Malaysia, Kenya, Sudan, Egypt, Algeria, Russia, Ukraine, Turkey, Spain, etc. Any question, welcome to contact us.

1 note

·

View note

Text

WHAT EXACTLY IS AN ORGANIC WASTE CONVERTER, AND HOW DOES IT WORK?

Organic waste converter modelsFinal words

The Organic Waste Converter Machine is a system that helps the composting process. Composting is bacteria and fungus decomposing organic waste in the presence of oxygen to produce an organic fertilizer known as compost. Composting has become much easier with the invention of this machine. This machine composts a large quantity of biodegradable solid waste. Composting was done at home before its creation, and it took a long time to produce the results.

Organic waste converter turns organic waste such as vegetables, meat, bakery trash, leaves, fruits and fruit skins, and flowers into helpful compost that may be utilized in organic farming. Composters and converters are two terms that are often used together. Some converters can be used for both solid and liquid organic waste treatment and recycling. Converters are self-contained systems that may execute several tasks, including waste separation, shredding or crushing, filtering, dewatering, mixing, and curing. The technology has found use in several industries that create organic waste due to the vast range of functions available on converters.

The organic waste converter technology benefits residential estates, restaurants, food canteens, shopping malls, educational institutes, municipal corporations, vegetable markets, fish markets, military bases, naval bases, and temples.

When composting waste, it’s essential to remember that the carbon-to-nitrogen ratio needs to be managed appropriately. Composting will take longer if there is a lot of carbon, and if there is too much nitrogen, the process will stink. The moisture content and oxygen concentration of the pile are other crucial considerations. When composting, all of these considerations must be factored in. Composting by hand is often a difficult task. As a result, an organic waste composter may be considered.

SMART Xpress Composter

Mechanical composting is the most efficient way to dispose of garbage in cities. A built-in shredder and a cylindrical container are included in the design. The churning method breaks down trash by crushing and mixing it simultaneously, reducing volume and speeding up pre-decomposition. The Organic Waste Composter’s heating element provides extra heat to maximize the action of the microorganisms and speed up the composting process, resulting in ready-to-use compost.

KEY FEATURES

Built-in shredder with the ergonomic position

Quiet and odorless operating

The composting process takes 3–4 days.

Designed to meet the most stringent safety requirements

A single machine may handle the whole composting process.

The VFD system regulates and maintains consistent mixing.

Covered Aerated Static Pile Composter

Windrow composting has been enhanced with aerated static pile composting. The waste is piled in rows here as well. However, an air pipe is installed beneath the table to supplement oxygen supply and avoid creating anaerobic conditions.Typically, a blower is used to pull air through the pile. The blower capacity is determined by the decaying waste’s defined oxygen demand characteristics.

The airflow rates can be changed depending on the rotting stage, and the temperature reached in the waste’s core.To do this, suitable probes may be inserted into the piles, then linked to a microcontroller to control the blower.

KEY FEATURES

Rapid Biodegradation Process Control

Ideal for facilities that process wet materials

Suitable for large volumes of feedstocks

ASP facilities can be indoor windrow composting operations or outdoor windrow composting operations.

SMART Drum Composter

The machine is built on the concept of combining a whole composting system into a single unit. The waste is initially fed into a shredding mechanism, which decreases the size of the waste and increases the surface area available to microorganisms for rapid composting. Because aerobic composting is an exothermic process, it creates heat, which aids in the removal of moisture through evaporation, resulting in dry, ready-to-use compost in a matter of days. From the discharge end, the compost may be discharged at consistent levels. The composting chamber’s air exchanges guarantee that there is enough air available for aerobic composting.

KEY FEATURES

Shredding mechanism that is ergonomically positioned

Quiet and odorless operating

The composting process takes 10–12 days.

Highest safety standards were used in the design.

In a single machine, a complete composting system

SMART Batch Composter

The machine comprises a shredder and a mixer for mixing and shredding waste into uniform sizes simultaneously. The machine also incorporates the composting culture and dry materials such as dried leaves, sawdust, and other dry materials into the shredded waste for moisture absorption.

KEY FEATURES

The operation is essential and straightforward.

A 10- to 12-day composting cycle is required

Safety features built-in

Pre-programmed batch time on the control panel

The technique used in organic waste converters is ecologically beneficial. This technique is a viable alternative to landfill dumping and incineration as means of organic waste disposal. Converters minimize pollutants and generate compost, which is a valuable end product. Composting systems and capacity differ across converters. In India, Smart Enviro Systems is the leading manufacturer of food waste composting machine. Our employees’ willingness to contribute to environmentally sustainable business ideas by recycling waste drives our success.

#Composter machine#organic waste composter machine#organic waste converter#composting machine#organic waste compost machine#food waste composter#food waste compost machine#Waste Composter#composting machine price

0 notes

Link

The cage crusher is a medium-sized horizontal cage crusher. Cage crusher is mainly used for fine crushing, and it can also play a role of mixing evenly. This machine is designed according to the principle of impact crushing. The two sets of cage bars inside and outside rotate at a high speed. The material is crushed by the cage bars from the inside out. It has a simple structure, high crushing efficiency, good sealing performance, stable operation and convenient Features such as easy cleaning and maintenance.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, double roller granulator, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer production line, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

0 notes

Text

The compound fertilizer granulator uses the double roller extrusion granulator

Compared with other granulation methods, the double roller granulator is no need for fuel oil, gas and other drying measures. The production only needs electricity and a small amount of cooling water (for roller cooling), and the power consumption per ton of product is only about 30 kW / h.

The only disadvantage of double roller extrusion granulation is that the shape of the product is irregular, but the irregular shape has no effect on the application of fertilizer, and the dressing process can be added to further round the particles. The chemical fertilizer produced by extrusion fertilizer granulation machine has enough strength, less dust, no caking, narrow particle size distribution and good fluidity, so it has good economic benefits.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulation machine, crusher, mixer, conveyor, compost windrow turner, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer manufacturing process, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

0 notes

Text

In modern agricultural production, organic fertilizers are gaining more and more attention for their ability to improve soil structure, improve crop quality and promote sustainable agricultural development. There are many types of organic fertilizers, but those in greatest demand tend to be those that can quickly improve soil fertility and provide comprehensive nutrition. According to the report of Zhiyan Consulting, in 2023, China's organic fertilizer production (converted into nitrogen, phosphorus and potassium) is 18.28 million tons, the demand (converted into nitrogen, phosphorus and potassium) is 17.92 million tons, and the market size is 141.39 billion yuan. This data shows that the market demand for organic fertilizers is expanding.

The diversification of Organic Fertilizer Production Line is the key to meet the needs of different types of organic fertilizer. The Bulk Blending Fertilizer Production Line, for example, is capable of producing fertilizers with a variety of organic and inorganic ingredients that can be tailored to the needs of different soils and crops. This flexibility makes the blend fertilizer in high demand in the market, which has a significant impact on the distribution strategy. Distributors need to connect with diverse farmers and understand their specific needs in order to provide the most appropriate products.

Organic and inorganic compound fertilizers are also very popular in the market because they combine the advantages of organic and inorganic fertilizers and can provide all the major and trace elements needed by crops. The production of this Fertilizer usually requires fertilizer granulation production lines, such as Fertilizer Granules Compaction Machine and Flat-Die Pellet Machine, to ensure the uniformity of fertilizer particles and the consistency of quality. The high demand for this fertilizer has driven the development of distribution strategies towards more specialization and customization.

The Windrow Compost Turning Machine also plays an important role in the production of organic fertilizers, which can improve the fermentation efficiency and quality of the compost. The application of this equipment makes the production of organic fertilizers based on compost more efficient, thus meeting the market demand for efficient organic fertilizers.

Finally, fertilizer shredders such as Cage Crusher and Chain Crusher are also indispensable in the production of organic fertilizers. They are able to crush raw materials into fine particles suitable for further processing, which is essential for improving the uniformity and effectiveness of fertilizers. As the market demand for high-quality organic fertilizers increases, the use of these devices is becoming more common, affecting distribution strategies and making distributors more focused on the quality and effectiveness of their products.

In summary, the types of organic fertilizers in greatest demand tend to be those that provide overall nutrition, improve soil structure, and meet the needs of specific crops. The impact of this on the distribution strategy is mainly reflected in the need for more specialized and customized services, as well as the continuous updating and optimization of production technology. As the market continues to evolve, distributors and producers need to work closely together to meet changing market demands.

0 notes

Text

As an indispensable part of modern agricultural production, the organic fertilizer industry has a wide range of supplies, covering many links from the collection and processing of raw materials to the production and sales of finished products. This paper will analyze the supply range of organic fertilizer industry in detail from the production process, technical application and market demand of organic fertilizer.

First, the production of organic fertilizers begins with an abundant source of raw materials. This includes livestock manure, agricultural waste, industrial by-products, household waste and municipal sludge. These raw materials are professionally treated and transformed into organic fertilizers rich in organic matter and microorganisms. For example, using livestock manure and agricultural waste through fermentation processes, commercial organic fertilizers and bio-organic fertilizers can be produced, which can be directly used to improve soil structure and increase crop yields.

In terms of technical application, Organic Fertilizer Production Line adopts advanced fermentation control, nutrient balance and automated packaging technology to ensure product quality and consistency. The application of these technologies not only improves the production efficiency, but also ensures the environmental protection and effectiveness of organic fertilizers. For example, through the use of Windrow Compost Turning machines and fertilizer shredders, organic waste can be efficiently treated and converted to produce high-quality organic fertilizers.

On the market demand side, with the increasing attention to healthy food and sustainable agricultural practices, the demand for organic fertilizers is growing. According to the report of Zhiyan Consulting, in 2023, China's organic fertilizer production (converted into nitrogen, phosphorus and potassium) is 18.28 million tons, the demand (converted into nitrogen, phosphorus and potassium) is 17.92 million tons, and the market size is 141.39 billion yuan. This data shows the huge market potential and supply scope of the organic fertilizer industry.

Finally, the range of supply in the organic fertilizer industry is also reflected in its positive impact on the environment. The use of organic fertilizers helps to reduce the use of fertilizers and reduce the negative impact of agricultural production on the environment. At the same time, by recycling and utilizing organic waste, the organic fertilizer industry also contributes to the circular economy and sustainable development.

To sum up, the supply range of the organic fertilizer industry covers many aspects from the collection and processing of raw materials to the production and sale of finished products, as well as the positive impact on the environment. With the advancement of technology and the growth of market demand, the organic fertilizer industry is expected to play a greater role in the future, providing support for the sustainable development of agriculture.

0 notes

Text

Organic fertilizer is an important auxiliary material in agricultural production, the scientific design of its production process is of great significance to improve fertilizer effect and reduce production cost. This paper will discuss how to design an efficient Organic Fertilizer Production Line from a scientific and practical point of view, and focus on the key fertilizer granulator equipment.

1. Raw material selection and treatment The first step in designing an Organic Fertilizer Production Line is choosing the right raw materials. Raw materials can include animal manure, crop straw, urban organic waste, etc. These raw materials need to be pre-treated, such as crushing, removing impurities, adjusting water and carbon nitrogen ratio, etc., to ensure the smooth progress of the subsequent production process.

2. Application of Fertilizer Granules Compaction Machine Fertilizer Granules Compaction Machine is one of the key equipment in Organic Fertilizer Production Line. It squeezes the raw material into a granular shape by means of two rollers rotating in opposite directions. This granulator is suitable for processing a variety of organic and inorganic raw materials, and can produce fertilizer particles of uniform size and moderate strength, and improve the application effect and market competitiveness of fertilizer.

3. High efficiency of Flat Die Pellet Machine A Flat-die Pellet Machine is another commonly used granulation device that comppresses raw materials into pellets through a Flat-die with multiple holes. This equipment is particularly suitable for the production of high-density, high-hardness organic fertilizer particles, suitable for large-scale production, can significantly improve production efficiency and product quality.

4. Versatility of Rotary Drum Granulator Rotary Drum Granulator graines raw materials by tumbling a rotating drum with the material inside. This granulator has a wide range of applications and can handle many different types of feedstock, including organic and Complex fertilizers. The advantages of Rotary Drum Granulator are its continuous production capacity and low energy consumption.

5. Environmental benefits of Windrow Compost Turning Machine The Windrow Compost Turning Machine plays an important role in the Organic Fertilizer Production Line. By turning the compost, it promotes the decomposition of organic matter and the activity of microorganisms, and accelerates the maturation process of the compost. This equipment not only improves the quality and efficiency of compost, but also helps to reduce bad odor and environmental pollution, and is a key equipment to achieve environmental protection of organic fertilizer production.

Conclusion Designing Organic Fertilizer Production Line is a complex process involving raw material selection, equipment configuration, process flow and environmental protection measures. Through Fertilizer Granules Compaction Machine, Flat-Die Pellet Machine, Rotary Drum Granulator, and Windrow Compost Turning The reasonable selection and configuration of key equipment such as Machine can build an efficient and environmentally friendly Organic Fertilizer Production Line. This can not only improve the efficiency and quality of fertilizer production, but also promote the sustainable development of agriculture.

#Organic Fertilizer Production Line#Fertilizer Granules Compaction Machine#Flat-Die Pellet Machine#Rotary Drum Granulator#Windrow Compost Turning Machine

0 notes

Photo

Forming mechanism of double roller fertilizer pellet machine: the powder material moves along the roll surface and begins to slide relatively. When it enters the bite angle, the material does not slide relatively and begins to be compressed. The effect is continuous. From the beginning of compression to the end of compression to the minimum volume, the mass of the material in the unit arc length between the rolls remains unchanged, while the density changes from small to large. That is to say, the mechanism of double roller granulator is pure volume action. The pressure acting on the cavity granular material is indirectly formed at a certain height on the roll, and its size depends on the shape, length, volume of the cavity, the filling degree of the material and the properties of the material to be treated. The double roller extrusion granulator is a kind of fertilizer granulator independently developed by Zhengzhou Huaqiang fertilizer granulator Machinery Co., Ltd., and has obtained the new patent certificate. Zhengzhou Huaqiang fertilizer granulator has been used by many manufacturers, and the product quality is guaranteed. The granulator machine for fertilizer is suitable for unit element fertilizer and multi-element compound fertilizer with ammonium bicarbonate, urea, ammonium chloride, ammonium phosphate and potassium chloride as base materials. It has high particle strength and no need of drying equipment, which greatly reduces the production cost.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce organic fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, double roller granulator, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer production line, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

0 notes