Don't wanna be here? Send us removal request.

Text

How to choose the process and particle size of NPK fertilizer production line?

At present, there are three main processes of NPK fertilizer production line: ammoniation granulation, spray granulation and tower granulation. 1. Fertilizer efficiency period: spray granulation > tower granulation > ammoniation granulation, so spray granulation is suitable for long-term crop base fertilizer, ammoniation granulation is suitable for long-term crop. 2. Stability: high tower granulation > spray granulation > ammoniation granulation, high tower granulation particles are smoother, low water content, not easy to agglomerate, each particle nutrient is uniform, easy to spread evenly. 3. The choice of particle size: large particle compound fertilizer can be used as base fertilizer to prolong fertilizer efficiency, while small particle compound fertilizer can be used as topdressing to accelerate fertilizer efficiency.

2 notes

·

View notes

Text

NPK fertilizer production line factory teaches you to identify true and false compound fertilizer

1. Look NPK fertilizer production line factory tutor you see if the outer package is marked with three certificates (production license, fertilizer registration certificate, product certificate) and the executive standard number, and whether the manufacturer, production location and contact number are marked. The bag label should indicate the total nutrient content and formula, such as total nitrogen should be marked in a significant position. The total nutrient on the bag label refers to the sum of nitrogen, phosphorus and potassium. If the medium and trace elements are included in it, it is misleading and deceiving farmers. In addition, don't be misled by exaggerated advertising and exquisite packaging, pay attention to the internal quality of the product. 2 pinch The manufacture of compound fertilizer has to go through a set of complex NPK fertilizer production line process, whether it is extrusion granulation or disc granulation, the particles are not only more uniform, but also have a certain strength. If the size of the particles is uneven, the color is mixed with a lot of mixed colors, and there is a lot of dust in the package, the particles will disperse or form lumps when kneaded (rubbed) by hand. Even after 30 minutes of dissolution, there is still a lot of residue. This kind of compound fertilizer is of poor quality. Don't buy it. 3 smell Good compound fertilizer components are relatively stable, in the packaging will not decompose, melt, so there will be no odor, ammonia smell. If ammonia and acid taste are found, the quality of the product is not up to standard, so it is necessary to buy it carefully. 4 letters We should establish brand awareness and purchase brand compound fertilizer. The formation of brand is the sublimation of corporate image. The manufacturers of general brand products are large in scale and standardized in management. Enterprises pay attention to quality management and product inspection. Compared with non brand products, product quality has a more reliable guarantee. The more attention npk production line manufacturers pay to image, the more product quality can be guaranteed.

0 notes

Photo

0 notes

Text

What are the problems in the production of organic fertilizer?

First of all, there are no national standards for organic fertilizer products, only industry standards. The production of organic fertilizer does not need administrative permission, the production threshold is low, and the production methods are various. At present, there are many small workshops, the production equipment is simple, and the product quality is difficult to guarantee. Secondly, some manufacturers are one-sided pursuit of appearance, do not pay attention to internal quality. At present, when farmers choose organic fertilizer in the market, they mostly judge the quality of organic fertilizer products based on the perceptual knowledge of particle appearance and packaging. They think that the products with black, shiny, smooth and uniform particle appearance are good products. Due to the diversity of raw materials, there are some differences in appearance and internal quality of commercial organic fertilizer made from different raw materials.

Third, the fermentation process is ignored in the production. The commercialization, scale and standardization of organic fertilizer in China have just started, and some production lines have not carried out strict high-temperature fermentation, which makes it difficult for organic fertilizer products to meet the requirements of harmless. Good technological process of compost fermentation Fourth, the nutrient content of pure organic fertilizer is low, and its efficiency is not as fast as that of chemical fertilizer after application. Fifthly, organic fertilizer packaging label confusion. Individual enterprises mark the contents of organic matter, humic acid, amino acids, animal protein, vitamins and so on, and count them as the total nutrient content to mislead consumers. Sixth, the transportation cost is high. Organic fertilizer does not enjoy the preferential transportation price of chemical fertilizer through railway transportation. The transportation cost is relatively high, which makes the retail price of commercial organic fertilizer much higher than the price of raw materials. Seventh, the granulation efficiency of organic fertilizer production is low, especially for those organic fertilizers with high organic matter content, more than 50% of them have to return to granulation, which greatly reduces the production efficiency and increases the production cost.

0 notes

Text

Equipment and process design of environmental protection NPK fertilizer production line

NPK fertilizer production line mainly carries out dust-proof and environmental protection transformation for each process, improves the environmental protection performance of each process device and the whole production line, solves the dust pollution problem in the production process of NPK compound fertilizer, and makes the production line meet the existing environmental protection requirements.

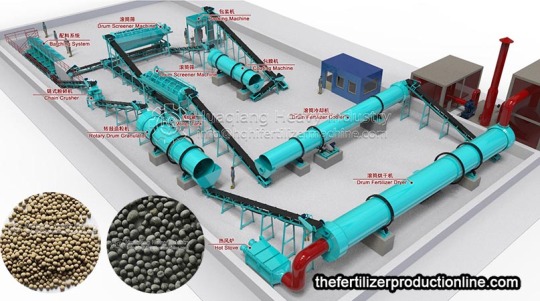

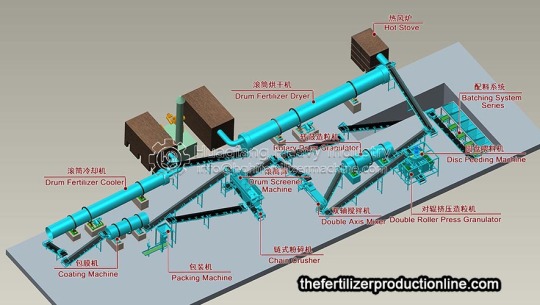

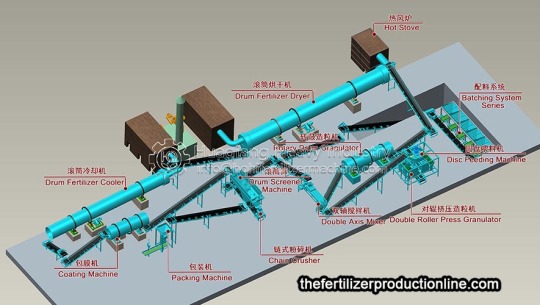

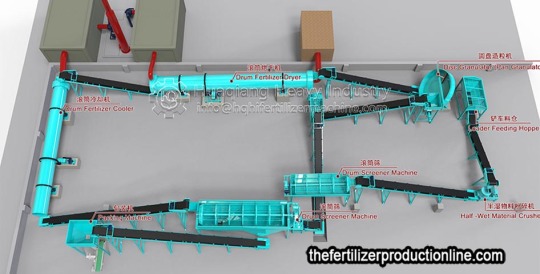

The NPK fertilizer production line includes raw material batching machine, fertilizer mixer machine, crusher, rotary drum granulator, particle dryer, particle cooler, coating machine for finished product, and quantitative packaging machine for finished product.

The NPK fertilizer production line designed and produced by Huaqiang fertilizer equipment manufacturer has the advantages of less investment, quick effect and good economic benefit. The whole set of equipment has compact process layout, scientific and reasonable, and advanced technology. Energy saving, no waste discharge, stable operation, reliable operation, convenient maintenance. Wide adaptability of raw materials, suitable for compound fertilizer, medicine, chemical industry, feed and other raw materials granulation, product granulation rate is high.

0 notes

Text

NPK fertilizer production line equipment process

The process flow of NPK fertilizer production line can be divided into: raw material batching, raw material mixing, raw material granulation, particle drying, particle cooling, particle grading, finished product coating and finished product packaging.

NPK fertilizer production line matching raw material mixer: mix the prepared raw materials evenly to improve the overall uniform fertilizer efficiency content of fertilizer particles. NPK fertilizer equipment raw material granulation: evenly mixed raw material into the granulator granulation. Granule drying: the granule made by granulator is sent to the dryer to dry the moisture contained in the granule, so as to increase the granule strength and facilitate the preservation.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. mainly produces organic fertilizer machines: disc granulator, npk fertilizer granulator, double roller granulator, organic fertilizer granulator machine, drum granulator, flat die pelleting machine, and ring die pelleting machine, vermicelli machine, fertilizer mixer machine, fermentation compost turning machine, coating machine, packaging machine, etc., and sells 1-200000 NPK fertilizer production line, organic fertilizer production line, bio organic fertilizer production line, BB fertilizer complete equipment. Our products are energy-saving, convenient, environmental protection and efficient, and have reached the leading level of the same industry in the world. Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. has a superb technical team, domestic and foreign first-class partners, scientific and standardized customer training system. We look forward to cooperating with you!

0 notes

Text

How much does it cost to produce 10000 tons of organic fertilizer per year

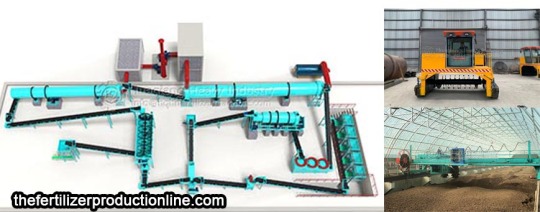

The main equipments of the 10000 ton organic fertilizer production line are trough tipper, semi wet material grinder, mixer, granulator, dryer, cooler, screening machine, coating machine, etc.

1. A small-scale production line with an annual output of 10000 tons of organic fertilizer needs about 220000 tons. In the production process, rain proof steel greenhouse should be built to ensure that the fermented fertilizer or cost fertilizer will not be wet by rain. 2. Labor wages, organic fertilizer raw materials, biological bacteria are the scope to be considered, as well as depreciation, electricity, miscellaneous expenses of organic fertilizer. 3. To open a small organic fertilizer plant, the production line of organic fertilizer with an annual output of less than 10000 tons is generally enough, and the plant site is usually built near the raw materials. 4. The small-scale organic fertilizer factory digests and produces manure raw materials such as chicken manure, duck manure, pig manure, cow manure and crude fiber raw materials to produce organic fertilizer. The fertilizer production machine investment is small, the production cost is low, the operation is easy, and the return is rich.

0 notes

Text

Drying method of raw materials for organic fertilizer production

The drying method of organic fertilizer production is a common processing method. Dehydrated feces are easy to store and transport. Drying method forks can be divided into natural drying method and mechanical drying method. Natural drying method: The collected fresh manure is dried separately, or mixed with a certain proportion of wheat bran + mix well and spread in a dry place. Rely on the sun to dry. After drying, it is sieved to remove impurities, then crushed, and placed in a dry place for feed. This method is often used in summer.

Mechanical drying method: mechanical treatment mainly includes high temperature drying and drying puffing drying. High-temperature drying uses the heat generated by coal, oil, and electricity for artificial drying. The dryers are mostly drum type fertilizer production machine. The chicken manure is dried by the drum and subjected to high temperature in a short time. The moisture in chicken manure can be reduced to about 8%. Drying and puffing drying is the use of both thermal effect and spray mechanical effect. The livestock and poultry manure can both deodorize and sterilize thoroughly. Meet the requirements of sanitation and epidemic prevention and commercial feed. The characteristic of the mechanical drying method is that it can be produced in large quantities, is not affected by the weather, and can achieve the effects of deodorization and sterilization at the same time. But the one-time investment is large. The energy consumption is large, it is easy to cause secondary pollution to the environment, and part of the nitrogen will be lost.

0 notes

Text

Fermentation process of organic fertilizer production

The purpose of organic fertilizer production and fermentation is to reduce volatile substances and odor in waste, kill parasite eggs and pathogenic microorganisms, and achieve the goal of harmless. At the same time, the properties of organic materials become loose and dispersed, mineralize and release nutrients such as N, P and K, which is convenient for storage and use.

Composting fermentation process generally includes fermentation, turning over, aeration and other links. In the process of compost fermentation, the aerobic fermentation environment is formed in the fermentation compost body by means of forced oxygen supply such as dumping and aeration by fertilizer production machine. The supply of oxygen and the degree of heat preservation in fermentation workshop have great influence on the temperature rise of compost. According to the change of temperature, moisture, oxygen content and other parameters of composting fertilizer, the process control can be carried out in time, so that the composting temperature can rise to 60-70 ℃. The composting cycle is generally 15-20 days. After a cycle of composting, the moisture content after fermentation is greatly reduced (generally less than 40%).

0 notes

Text

Invest in a small organic fertilizer production line

Small scale organic fertilizer production line is designed for just starting users. Considering that users are worried about the high price of organic fertilizer equipment due to the lack of economic capital at the beginning of plant construction, but there is no place to deal with the manure of their own farms, which pollutes the environment, and there is stink in a few miles, our company has designed a small scale organic fertilizer production line for chicken manure, It can not only solve the problem of less investment and quick return, but also do not have to worry about the problem of sales (self use or local sales). The whole set of powdery organic fertilizer production line is about 100000 yuan. Low cost investment can not only solve the problem of environmental pollution, but also increase the income. It is a good project for our farmers to get rich.

The organic fertilizer production machine customized by Huaqiang Heavy Industry can effectively save costs. First of all, the customized equipment can effectively use the space, and the space is small, which can reduce the investment in land construction. Secondly, in the organic fertilizer production line, there are a lot of equipment, which need to be connected in series with conveyors. In a reasonable space, the utilization rate of the conveyor is also improved, and the conveyor is not wasted, which also saves a lot of costs. .

0 notes

Text

Design of complete set of equipment for cattle manure organic fertilizer production line

Raw materials for organic fertilizer production generally refer to fermentable organic organic solid wastes, such as animal manure, domestic waste, sludge straw, industrial waste fly ash, etc. The raw materials enter the fermentation site for aerobic fermentation. The aerobic fermentation process depends on the scale of production. Small-scale (1-3 million tons/year) composting yard uses flat-ground piles and turns piles with wheeled pile turning machines. The medium-sized (30,000-80,000 tons/year) composting plant adopts flat-land composting and pool composting, and turning the piles using wheel-type composting machines and rail type composting machines. Large-scale (over 100,000 tons/year) compost using pool composting and aerobic composting towers. Take small-scale as an example: the raw materials are screened to remove inorganic impurities and then composted. When composting, aerobic bacteria should be added. During the composting process, the pile must be turned over. Generally a cycle (7-12 days) is turned over 4-5 times to be organic. The evaluation index of fertilizer ripening. The cooked organic fertilizer should be crushed, and the size of the crushed ground should be above 60 mesh to enter the granulation process.

The granulation process starts with the mixing. The mixing is to uniformly mix the raw materials and additives required for the granulation process, and use the conveyor belt to send the raw materials to the raw material pulverizer for raw material pulverization.

The purpose of raw material crushing is to crush the granulated raw materials to the purpose of granulating demand. After crushing, the raw materials are sent to the granulator fertilizer production machine through the conveyor belt for granulation. The granulation process of organic fertilizer generally adopts disc granulator and drum granulator. Both processes are agglomeration granulation processes. In the granulation process, water needs to be added for granulation, and steam can be added if conditions permit. Adding water must be atomized, the better the atomization effect, the higher the ball formation rate.

After the granulation is completed, the conveyor belt is used to send it to the drying fertilizer production machine for drying. Drying is to use the hot air stove to generate hot air and then take the hot air into the dryer under the action of the induced draft fan to exchange heat and take away the moisture in the granular fertilizer.

The dried fertilizer is sent to the cooler with a belt conveyor. The cooling is to use an induced draft fan to pass the cold air flow through the fertilizer curtain in the cooling machine to take away the hot gas, so that the fertilizer is completely dried.

The dried fertilizer is sent to the grading sieve by the lift-lift-machine. The purpose of grading is to sort out the granular powder needed for commercial fertilizer, and sort the finished fertilizer to the storage bin for packaging. In the re-sieving process, the fine particles and large particles enter the return material pulverizer for pulverization, and the powder material enters the return material belt conveyor and is sent to the granulator for re-granulation.

The dust removal chamber is to take the hot air blower and the cold air blower to take out the dust and use the principle of reducing the wind speed to reduce the dust, the air is emptied, and the dust is collected and then the granulator is used for granulation.

0 notes

Text

Pig manure organic fertilizer produced by organic fertilizer production machine

How much does it cost to set up a simple small organic fertilizer processing plant? Investment income estimation of new organic fertilizer plant. Organic fertilizer production machine for pig manure, chicken manure, cow manure, sheep manure and other livestock manure, mushroom residue, Chinese medicine residue, crop straw organic fertilizer waste 10 hours can complete harmless treatment, a single shift only needs 2-4 people can complete the annual output of 10000-30000 tons of organic fertilizer production task.

Labor cost: single shift production, 5 people per shift, salary 2000 yuan, then labor cost: 20 yuan / ton of finished products;

After depreciation cost of organic fertilizer production machine and civil engineering plant: the equipment is depreciated by 10 years and the plant is depreciated by 15 years, then the equipment is depreciated by 750000 yuan: 15 yuan / ton of finished products; Plant 500000

Small scale powdery organic fertilizer production line is generally about 100000 yuan, which can be completed by only using the compost turner, pulverizer, mixer, screening machine and packaging machine. Such as the production of granular organic fertilizer, according to the actual needs and requirements of customers to add equipment. Therefore, according to the actual needs, the price of a complete set of organic fertilizer equipment ranges from tens of thousands to hundreds of thousands.

0 notes

Text

Complete equipment for bio organic fertilizer production

Characteristics of bio organic fertilizer production: Eco organic fertilizer has complete nutrient elements, which can improve the soil and improve the soil hardening caused by the use of chemical fertilizer. According to their own materials and local sales market to choose equipment, save money more. In the bio organic fertilizer production, we should not think that the manufacturers who provide technical formula are good. Generally, the equipment manufacturers are specialized in research, and they will not set up a special research team to study the formula of organic fertilizer, so these are generally some general data.

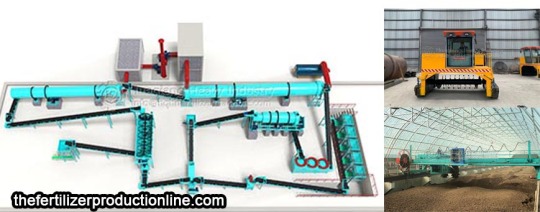

Production process of bio organic fertilizer Organic waste treatment - inoculation (adding bacteria agent) - stacking fermentation - turning (turning plate) - Continuous Fermentation - discharging - post-treatment (drying - crushing - screening / granulation - Detection - Packaging - finished products) - bio organic fertilizer

Small scale powdered bio organic fertilizer production line is generally about 100000 yuan, which can be completed by only using the dumper, pulverizer, mixer, screening machine and packaging machine. Such as the production of granular organic fertilizer, according to the actual needs and requirements of customers to add equipment. Therefore, according to the actual needs, the price of the whole set of organic fertilizer production machine ranges from tens of thousands to hundreds of thousands.

0 notes

Link

The cage crusher is a medium-sized horizontal cage crusher. Cage crusher is mainly used for fine crushing, and it can also play a role of mixing evenly. This machine is designed according to the principle of impact crushing. The two sets of cage bars inside and outside rotate at a high speed. The material is crushed by the cage bars from the inside out. It has a simple structure, high crushing efficiency, good sealing performance, stable operation and convenient Features such as easy cleaning and maintenance.

Zhengzhou Huaqiang Heavy Industry Technology Co., Ltd. adheres to market orientation, innovation and development, quality and survival, and perfect after-sales service to win the trust of customers. We mainly produce fertilizer granulator, crusher, mixer, conveyor, compost windrow turner, double roller granulator, coating machine, packaging machine, dryer, cooler, screening machine, as well as different types of fertilizer production lines, including organic fertilizer production line, bio organic fertilizer production line, NPK fertilizer production line, BB fertilizer production line. Warmly welcome people from all walks of life to visit the company, mutual benefit, win-win, create a better!

0 notes

Text

Technological process of complete set of equipment for small chicken manure organic fertilizer production line

Chicken manure organic fertilizer production line, organic fertilizer mainly comes from plants and (or) animals, applied to the soil to provide plant nutrition as its main function of carbon materials. Through the processing of biological substances, animal and plant wastes and plant residues, the toxic and harmful substances are eliminated, which are rich in a large number of beneficial substances, including a variety of organic acids, peptides and rich nutrients including nitrogen, phosphorus and potassium. Technological process of complete set of equipment for small chicken manure organic fertilizer production line

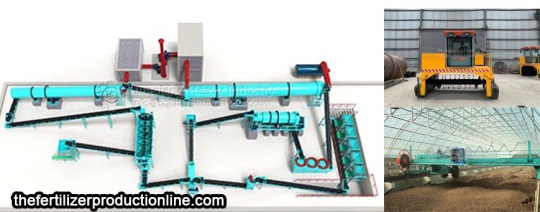

1. Fermentation compost windrow turner: it can ferment and turn the materials in the fermentation process. 2. Crusher: crushing high humidity materials and other raw materials in the production of organic fertilizer. 3. Mixer: to mix a variety of raw materials. 4. Granulator: Granulation of mixed materials; easy to separate and package. 5. Dryer: drying granular materials with certain humidity. 6. Cooler: it can quickly cool the dried materials and increase the production efficiency. 7. Screening machine: screen and grade the finished fertilizer. 8. Coating machine: the particles are coated outside to prevent the caking of fertilizer. 9. Automatic weighing and packaging machine: quantitative bagging and packaging of finished products.

0 notes

Text

Process flow of complete sets of equipment for small scale organic fertilizer production line

Small chicken manure organic fertilizer production line and small pig manure organic fertilizer production line process: raw material drying, crushing, batching and mixing system this system consists of dryer, organic fertilizer pulverizer, inorganic crusher, electronic batching scale and mixing mixer, and the raw materials are organic matter (livestock manure, sludge, etc.), bentonite, inorganic nutrients (nitrogen fertilizer, potassium fertilizer, potassium fertilizer, etc.) Phosphorus fertilizer) and trace elements. The dried organic matter and inorganic nutrients are crushed to fine powder by organic and inorganic crushers, and then they are respectively fed into electronic batching scale for batching. The prepared materials are fed into mixer for mixing, and then sent to the next process granulator for granulation by conveying equipment.

The granulation process of granulation system is the key process. The productivity, particle strength and particle shape of organic fertilizer granulator directly affect the quality of final product. At present, there are mainly drum granulator, roller extrusion granulator and disc granulator.

Features of organic fertilizer granulator: the production capacity can reach 2-5 tons per hour, the granulation rate can reach 98%, the particle size can be adjusted at will, and the production line with an annual output of about 5000 tons organic manure production has less investment and fast return effect.

0 notes