#Welding Electrode Manufacturers in USA

Explore tagged Tumblr posts

Text

The Lifeline of Industrial Sector: Unveiling the Secrets of Steel Plate Manufacturing

Piping Projects is one of the most trusted Steel Plate Manufacturers in USA. Steel plates function efficiently in various environments and have good corrosion resistance. The most skilled workers are hard at work, ensuring that all quality standards satisfy the customer's demands. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

Steel Plate Manufacturers metal plates using steel that can be formed into more intricate products through cutting and fabrication. Steel plates come in a range of thicknesses and may be made to any desired width or length. The alloy steel plate acquires particular constraints and qualities by adding these components. Also, We lead Welding Electrode Manufacturers in USA.

We are also a market-leading provider of carbon steel, alloy steel, and Stainless Steel Plate with ASME Quality and ISO 9001:2015 Certifications. The AS plate is alloyed with 1% to 50% elements. Steel Plates production is necessary for a structure to be dependable and long-lasting. Because of their extreme robustness and durability, these plates are crucial for manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

The Significance of Steel Plate Manufacturing

The production of steel plates is essential to many different sectors. Its importance is seen in some ways:

Infrastructure Development: Steel Plate Suppliers, which are frequently used in the construction of buildings, bridges, and roads, provide the framework for the development of infrastructure. Steel plates' durability and adaptability guarantee the lifetime and safety of these kinds of constructions.

Automotive Industry: The transportation sector uses steel plates extensively because they give transport structure and body parts the strength and crash resistance they need. Steel plates' low weight and strength combination helps improve passenger safety and fuel economy.

Shipbuilding: Steel plates are a significant component of ships built in the marine industry. Because of their superior structural integrity and immunity to corrosion, these plates are perfect for withstanding opposing marine conditions and preserving sailors' safety.

Energy Sector: In the energy industry, steel plates are crucial, especially for offshore oil rigs, pipelines, and power plants. Their great tensile strength and tolerance to high temperatures and pressure make energy production efficient and dependable.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

These plates are thicker than foils but thinner than ordinary steel plates. Stainless steel plates are widely known for their strong resistance to corrosion and work very well in various challenging conditions. Texas's top steel plate supplier, PipingProjects.us, offers premium plates for various commercial and construction applications.

Steel Plate Manufacturer in California

Our experts are dedicated to maintaining the highest quality standards, making us a leading Steel Plate Supplier in California. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. The welding process used to join these plates is standard.

Steel Plate Manufacturer in Florida

We produce seamless and welded steel plates under stringent quality control guidelines and standards that provide good surface and near-dimensional tolerances. We are a market-leading Steel Plate Manufacturer in Florida, offering solutions on a worldwide scale, with ASME Quality and ISO 9001:2015 Certifications.

Steel Plate Manufacturer in New York

As among the best Steel Plate Suppliers in New York, we have experienced staff members dedicated to maintaining the best calibre requirements. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. These plates are welded using standard welding techniques.

Common Uses For Stainless Steel Plate

The planning and constructing a building's external features, such as the exterior, roof, railings, doors, and windows, is called architecture.

Equipment for meal preparation, sinks, and appliances are all part of the food service setup.

Oil and gas, chemical processing, medical, and shipping equipment.

Application, Energy Management, and Manufacturing Automation.

Producing steel plates is a multi-step, specialised procedure to provide high-quality plates appropriate for various industrial uses. Identifying the best raw materials determines the quality of Steel Plate Supplier in USA. Based on the intended use, manufacturers carefully evaluate strength, durability, and corrosion resistance when selecting the steel alloy.

To Know More, Visit us,

Product: Steel Plate Manufacturers USA

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Welding Electrode Manufacturers in USA#Stainless Steel Plate#Steel Plate Weight Chart#Steel Plate Suppliers#Steel Plate Manufacturer in Texas#Steel Plate Manufacturer in California#Steel Plate Manufacturer in Florida#Steel Plate Manufacturer in New York#Steel Plate Supplier in USA

0 notes

Text

The Evolution and Impact of Bolt Manufacturers in India: A Comprehensive Overview

Jinnox Bolt is a leading Bolt Manufacturers in India, known for quality, innovation and customer satisfaction. Since it started, we have been catering top-quality fasteners to various industries such as automobile, construction, aerospace etc. We have modernized and well-equipped manufacturing facilities, with the latest equipment to manufacture high-quality bolts as per international standards.

The Evolution of Bolt Manufacturing in India

Bolt manufacturing company in India has undergone substantial transformation since its inception. Historically, the industry was characterized by small-scale operations with limited technological advancements. However, with globalization and increased industrial demands, the sector has evolved into a sophisticated, high-tech industry.

The 1990s marked a turning point for Indian manufacturing, including bolt production, as economic liberalization opened the doors to foreign investments and technology transfers. This period saw the introduction of advanced machinery and automated processes, enhancing production capabilities and quality standards. Today, Indian Bolt Manufacturers are equipped with state-of-the-art technology, ensuring precision and efficiency in their operations.

Key Players and Their Contributions

Several prominent players in the Indian bolt manufacturing industry have contributed to its growth and global competitiveness. Companies like Jinnox Bolt, among others, have been at the forefront, offering a diverse range of high-quality bolts and fasteners. These manufacturers not only cater to domestic needs but also export to international markets, showcasing India’s manufacturing prowess.

Jinnox Bolt, for example, has established itself as a leader in the production of welding electrodes, which are integral to bolt manufacturing. The company’s commitment to quality and innovation has set a benchmark in the industry, reflecting the broader trend of excellence among Indian manufacturers.

Challenges and Opportunities

Despite significant advancements, the bolt supplier in India faces several challenges. Fluctuations in raw material prices, particularly steel, can impact production costs and profitability. Additionally, maintaining consistency in quality while scaling up production remains a challenge for many manufacturers.

However, these challenges also present opportunities for growth and innovation. Investing in research and development can lead to the creation of new bolt designs and materials that address current limitations. Moreover, expanding into emerging markets and diversifying product offerings can help manufacturers mitigate risks and capitalize on new opportunities.

Countries we supply bolts

Bolt Manufacturers in UAE

Bolt Manufacturers in Australia

Bolt Manufacturers in South Africa

Bolt Manufacturers in USA

Bolt Manufacturers in Qatar

Impact on the Construction and Automotive Industries

Bolt Manufacturer in India plays a pivotal role in the construction and automotive sectors, among others. In construction, bolts are essential for the assembly of structures, including bridges, buildings, and machinery. High-strength bolts are particularly crucial for ensuring structural integrity and safety.

In the automotive industry, bolts are integral to vehicle assembly and maintenance. The demand for reliable and high-quality bolts drives innovation and standards within the industry. As the automotive sector evolves with new technologies and designs, bolt manufacturers must adapt to meet changing requirements and specifications.

Conclusion

Bolt suppliers in India have come a long way from their humble beginnings, evolving into a vital component of the global manufacturing landscape. With advancements in technology, a focus on quality, and a commitment to innovation, the industry is well-positioned for future growth and success. As Indian manufacturers continue to push boundaries and explore new opportunities, the impact of bolts on various sectors will remain profound, underscoring their importance in the modern world.

#Bolt Manufacturers in India#bolt manufacturer#bolt supplier#bolt manufacturers#bolts#bolt suppliers

0 notes

Text

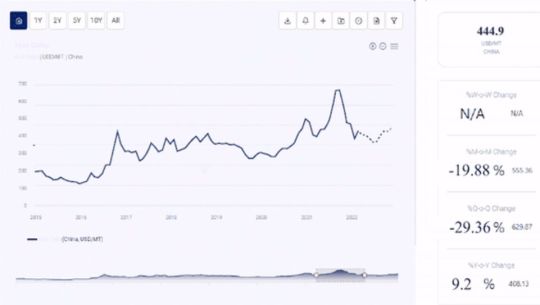

Navigating Steel Wire Rod Prices: Unveiling Trends and Insights for Informed Market Analysis, Research, and Procurement

In H1’23, steel wire rod prices in Asia increased due to high demand from downstream sectors and steady production activities. However, the second quarter saw challenges with slow movement in cement and construction industries. In Europe, the market was stable in the first quarter, affected by weak buying potential and a lack of new orders. Strikes, rising inflation, and economic uncertainties influenced the mixed trend in the second quarter. In North America, the first quarter showed price incline supported by rising feedstock prices and strong domestic demand. But the second quarter saw a decline due to the sliding economy and low construction activities.

Request for Free Sample: https://www.procurementresource.com/resource-center/steel-wire-rod-price-trends/pricerequest

Definition

Steel wire rod is a semi-finished metal product made from hot-rolled steel billets or blooms. It has a round cross-section and is characterized by its small diameter, typically ranging from 5.5 to 14 millimeters. Steel wire rods are widely used in various industries, including construction, automotive, and manufacturing. They serve as the primary raw material for producing a wide range of steel wire products, such as nails, screws, fencing, springs, and reinforcement materials. The quality and properties of steel wire rod play a crucial role in determining the final product's performance and durability.

Key Details About the Steel wire rod Price Trend:

Procurement Resource does an in-depth analysis of the price trend to bring forth the monthly, quarterly, half-yearly, and yearly information on steel wire rod in its latest pricing dashboard. The detailed assessment deeply explores the facts about the product, price change over the weeks, months, and years, key players, industrial uses, and drivers propelling the market and price trends.

Each price record is linked to an easy-to-use graphing device dated back to 2014, which offers a series of functionalities; customization of price currencies and units and downloading of price information as Excel files that can be used offline.

The steel wire rod Price chart, including India steel wire rod price, USA steel wire rod price, pricing database, and analysis can prove valuable for procurement managers, directors, and decision-makers to build up their strongly backed-up strategic insights to attain progress and profitability in the business.

Industrial Uses Impacting the Steel Wire Rod Price Trend:

Steel wire rods have a wide range of industrial applications due to their strength, flexibility, and adaptability. They serve as a crucial raw material in various industries, including construction, automotive, manufacturing, and telecommunications. In construction, steel wire rods are used for reinforcement in concrete structures, fencing, and mesh products. In the automotive industry, they find application in tire cord, springs, and wire ropes. Steel wire rods are utilized in the production of cables and electrical wires for power transmission and telecommunications. They are also essential in manufacturing fasteners, welding electrodes, and various components for machinery and equipment. The diverse applications of steel wire rods make them indispensable in modern industrial processes.

Key Players:

ArcelorMittal S.A.

Bridon-Bekaert Ropes Group

Heico Companies Metal Processing Group

Optimus Steel

KOBE STEEL LTD

WireCo World Group Inc

JFE Steel Corporation

Nippon Steel Corporation

News and recent development:

A license to produce a comprehensive range of IS 7904 grade steel wire rods, which are used in bridge cables and tire reinforcement materials, has been granted to the state-run Bhilai Steel Plant (BSP) an arm of state-run Steel Authority of India Limited (SAIL),in Chhattisgarh. (Dated: 20 March 2023)

About Us:

Procurement Resource offers in-depth research on product pricing and market insights for more than 500 chemicals, commodities, and utilities updated daily, weekly, monthly, and annually. It is a cost-effective, one-stop solution for all your market research requirements, irrespective of which part of the value chain you represent.

We have a team of highly experienced analysts who perform comprehensive research to deliver our clients the newest and most up-to-date market reports, cost models, price analysis, benchmarking, and category insights, which help in streamlining the procurement process for our clientele. Our team tracks the prices and production costs of a wide variety of goods and commodities, hence, providing you with the latest and consistent data.

To get real-time facts and insights to help our customers, we work with a varied range of procurement teams across industries. At Procurement Resource, we support our clients, with up-to-date and pioneering practices in the industry, to understand procurement methods, supply chain, and industry trends, so that they can build strategies to achieve maximum growth.

Contact Us:

Company Name: Procurement Resource Contact Person: Chris Byrd Email: [email protected] Toll-Free Number: USA & Canada – Phone no: +1 307 363 1045 | UK – Phone no: +44 7537 132103 | Asia-Pacific (APAC) – Phone no: +91 1203185500 Address: 30 North Gould Street, Sheridan, WY 82801, USA

Reference Link: https://theprocurementexpert.com/steel-wire-rod-prices/

1 note

·

View note

Photo

## PROJECTION WELDING ELECTRODES-PARENTNASHIK## Best quality projection welding electrodes assembly, body, upper adapter cap, insulation sleeve, location pins, ceramic pins for nut & stud welding. - From M4 to M12, Contact - @shreekantpatilparamount , @parentnashik Leading manufacturer, supplier & exporter of projection welding, resistance spot welding spare parts, consumables in Nashik (India).

#projection#welding#electrodes#nut#stud#elkonite#spares#consumables#insulation sleeve#location#pin#ceramic pins#bush#upper cap#lower body#supplier#manufacturer#exporter#USA#Europe#India#automotive#automobile#nut welding#stud welding#Nashik#Ambad MIDC

2 notes

·

View notes

Text

Metal working tools

We "US Shop Tools" manufacturer & Supplier Of Best Round Jaws, Lathe jaws, Strong Chuck jaws, Soft & Hard jaws, Nuts, Machine tools, Metalworking, etc. based in USA

In metal working tools , only inert gases or gas mixtures such as argon and helium are used as shielding gas.

However, in MAG (Metal Active Gas), a similar welding procedure, active gas mixtures like argon, carbon dioxide, and oxygen have been mainly created for welding steels.

This guide explores what a MIG welding machine is, along with its features, and how the MIG welding machine is useful for the welding industry.

What Is MIG Welding?

MIG welding is a process that creates an electric arc between an expendable MIG electrode wire and the piece of metal(s), thereby heating the metal(s), melting, and joining them.

Together with the wire electrode, a shielding gas is passed through the welding gun, protecting the process from contamination via the atmosphere.

Typical MIG welding machine gun has several essential parts:

A control switch,

Contact tip,

Power cable,

Gas nozzle,

An electrode lead and liner,

And a gas hose.

The trigger, or control switch, when pushed by the engineer, activates the wire feed, power supply, and the shielding gas flow, thereby igniting an electric arc.

The contact tip – which is usually made of copper and, at times, treated chemically to decrease spray – is attached to the power source of the welding machine. Now you Can Buy machine tools for sale

This is done through the power cord, and the tip then transfers electrical energy to the electrode as it conducts into the welding area.

Applications

Most industrial sectors generally use MIG/MAG. Furthermore, it accounts for over 50% of the total deposited weld metal.

(For instance, it is used for mild steel, low alloy, and stainless steel, for copper, for aluminum, nickel, and their alloys.)

There are 4 main parts of the MIG welder needed for welding.

The first one is the welding power supply, which delivers electricity to generate heat. Also, there’s the wire feed system that supplies the wire from a coil to the welded joint.

The third part is a handlebar housing a trigger that regulates the wire feed system, which moves the wire from a spool to the welding joint. A shielding gas protecting the weld from the air is the fourth part.

MIG and MAG

MIG and MAG welding machines are gas metal arc welding (GMAW) procedures.

Such processes make use of the heat generated by a direct current arc between a melting metal electrode and a piece of metal – both of which melt together to produce a weld pool that combines to create a joint.

Only inert gases or gas mixtures such as argon and helium are used as shielding gas in MIG welding.

In MAG, active gas mixtures like argon, carbon dioxide, and oxygen have been primarily developed for welding steels.

Common Industries That Use MIG Welding

Automotive industry

MIG welding is popularly used in repairing cars, motorcycles, motor homes, trucks, and SUVs. Because MIG welding can offer a solid weld makes it a perfect process for building and mending the body and internal part of any automobile.

Construction

In construction, the standard metal that’s being used is steel. Though MIG welding was developed originally for non-ferrous metals, it is now being utilized for steel.

Highly productive manufacturing

This involves the production of a product on a large scale. The fact that MIG welding is inexpensive and fast makes it valuable for use in high-volume manufacturing. Also, it can be used on different types of metals like steel, carbon steel, magnesium, nickel, aluminum, and other alloys.

1 note

·

View note

Text

HDPE Pipe Welding Machine

HDPE pipe fittings

Get together Your Torch Effectively by opting for the Right Welding Unit Principles of Welding along with Varieties of Welding Machines:

HDPE pipe fittings

Any time it comes to welding machines, it is significant to know what sort of connection will be doing work very best in properly hooking upwards your flashlight. In obtain to ascertain this, you first have to familiarize yourself with the actual basics of welding in addition to the types of welding devices. Whether you're brand-new to TIG and MEJ welding and/or a get better at fabricator, it might be difficult in order to discern between the significant array of adapters as well as fittings. In addition, suppliers have taken benefit from inverter technology and generated some sort of number of different patterns for welding machines. Typically the type of machine utilized is dependent on the particular specific welding technique.

Recognize About TIG and also MEJ Welding Methods:

TIG along with MIG welding are generally approaches that were invented from the 1940's to meet typically the enhanced demand for guns. TIG is usually primarily applied in the modern aviation sector, while MIG welding ended up being used to increase often the speed associated with weapon manufacturing.

MIG compared to TIG Welding:

TIG rapid tungsten inert gas welding

Uses a new tungsten electrode that isn't eaten during the welding course of action Provides shielding with the mix argon, hydrogen, in addition to a helium gas mixture Best for employ upon materials like magnesium, metal, copper, alloys, steel

MEJ - metal inert fuel welding

One of the actual speediest welding processes offered Runs on the metal electrode in which greatly improves as a for filler injections material to the weld as well as is consumed along the way Argon gas is either employed alone or combined using breathable oxygen, carbon dioxide, or maybe helium

Great things about TIG and also MIG Welding:

TIG welding produces good quality welds, makes less sprinkle, and possesses a lower disposition pace. It can also help make welds with out filler material and has much more specific control of the high temperature on the electrode. On the particular other hand, MIG welding is cheaper, easier to be able to learn, much better for property use, and requires a lesser amount of cleanup. Overall, although MEJ welding is much straightforward, TIG welding produces larger quality welds.

Decide in the Type of Interconnection it is advisable to Hook up your own personal Torch:

After getting a far better idea of what variety of welding machine anyone have, you can discover what kind of link you need to get together your TIG torch. About older models, the flashlight is bolted onto the equipment with a threaded button airport. On newer welding equipment, however, the DINSE design connector is made use of, which is a twist-locking quick disconnect system. Dinse connectors come in possibly small (9. 5mm height pin) or the a lot more common large (12. 7mm diameter pin). A number of products use what is acknowledged while Gas through Dinse relationship, which means this torch's shield gasoline offer flows directly throughout the Dinse connector. Another type regarding common connector is typically the Tweco variety, or Usa style, divide pin tip, which likewise twists along with locks straight into place.

Throughout addition, you must think about the type of TIG torch you could have, as distinct torches will vary adapter internet connections at the unit conclusion. TIG torches be met with both water-cooled or air-cooled. The idea is recommended to sooner or later change your welding machine for you to accept any Dinse type connector, rendering it simple to help switch from one flashlight to another. For elderly fashion machines with threaded buttons, use a stud-to-Dinse female conversion software to up grade the connection. Intended for models with a Tweco model connection, use an assembler which mounts onto often the machine for converting to some sort of Dinse style select.

1 note

·

View note

Text

Global Lanthanum Market Emerging Factor’s Analysis 2022

The group of seventeen rare earth metals on the periodic table includes the chemical element Lanthanum Market, which is a rare earth. The metal is typically present in mixtures with cerium and other rare earth elements in some rare earth minerals. Catalysts, lighter ignition components, medications, and tig welding electrodes are just a few of the many uses for lanthanum.

With lanthanum being the second-most common rare earth metal used in numerous automotive and aerospace applications, the lanthanum market has been steadily expanding globally. Due to the significant demand for rare earth metals from a variety of industries, including consumer electronics and hybrid electric vehicles, lanthanum is now in high demand.

Request the sample copy of report @ https://www.persistencemarketresearch.com/samples/4321

Numerous factors such as the growth of the electronics, electric vehicle and the automotive industry are expected to drive the demand for lanthanum over the next few years. Growing market share of rare earth metal catalysts has also contributed to the growth of the market.

For in-depth competitive analysis, Check Pre-Book here@ https://www.persistencemarketresearch.com/checkout/4321

However, factors such as environmental risk regarding the production of rare earth metals as well as depleting reserves all over the world are expected to slow down the growth of the market. Recycling of rare earth metals from E-waste are expected to compensate for the environmental risks generated from conventional production processes, thereby providing new opportunities to the growth of the lanthanum market.

Some of the key manufacturers of this industry are

Beijing Cerametek Materials

Cathay Advanced Materials Limited

Haihang Industry

Less Common Metals

and Sigma-Aldrich Corporation

Browse full report@ https://www.persistencemarketresearch.com/market-research/lanthanum-market.asp

Asia Pacific was the largest consumer for lanthanum owing to their availability of raw materials, especially in countries such as Japan and China. Future market growth is expected to be from North America owing to decreasing dependency on Chinese exports. The market condition for the production and exploration of rare earth oxides in North America, particularly the U.S. has become favorable owing to decreased Chinese exports.

Related Reports

High Speed Diesel Market

Ketonic Resin Market

Refined Glycerin Market

Agricultural Lime Market

About Us:

Persistence Market Research is here to provide companies a one-stop solution with regards to bettering customer experience. It does engage in gathering appropriate feedback after getting through personalized customer interactions for adding value to customers’ experience by acting as the “missing” link between “customer relationships” and “business outcomes’. The best possible returns are assured therein.

Contact Us:

Persistence Market Research Address – 305 Broadway, 7th Floor, New York City, NY 10007 United States U.S. Ph. – +1-646-568-7751 USA-Canada Toll-free – +1 800-961-0353 Sales – [email protected] Website – https://www.persistencemarketresearch.com

0 notes

Text

Tungsten Rod Applications And Properties

Tungsten rod is an ideal material to make thermal conductors, welding electrodes, headpieces for the industries of quartz, stirring bars for smelting, heavy hammers, fasteners, etc.CHEMETAL USA is a leading tungsten supplier and manufacturer in worldwide. Please check our tungsten rod to learn more information about tungsten rod products.

https://www.chemetalusa.com/tungsten-rod-applications-and-properties/

0 notes

Text

Welding Consumables Market Business Strategies, Growth Rate And Forecast till 2025

September 15, 2021: The welding consumables market includes welding equipment consumables, and services. Welding consumables are materials such as alloys, minerals and metals that are used to amalgamate thermoplastic and metal components. Welding consumables account for the lions share of the global welding industry in terms of profits compared to equipment and services. Technological advancement of welding methods is expected to drive the market growth over the forecast period. The global market has been facing dramatic change to flux and solid cored wired from electrodes owing to advanced production efficiency in welding consumables. Growing Innovation in developing new techniques for welding is anticipated to boost the market growth and create opportunities over the next few years. Increasing demand owing to growing in residential and commercial building constructions is estimated to positively impact and can attributed as the major driving factor.

Increasing demand from growing end use industries including transportation, mainly in emerging economies such as China, India, Thailand, and Singapore is expected to propel the global welding consumables market over the forecast period. Growing population along with increase in disposable income of people can be attributed to the aforementioned driver. New Infrastructural projects coupled with government investment to develop cities is anticipated to drive the market demand for global welding consumables. Welding steel plays a major role in the global market owing to high demand and need of steel in various industrial and manufacturing processes.

Request a Free Sample Copy of this Report @ https://www.millioninsights.com/industry-reports/welding-consumables-market-size/request-sample

Welding is extensively used in metal and steel industries for fabrication processes. The impact of welding process on the metal sector is dependent on the total parts manufactured in the process. Industries are expected to prefer welding process over other conventional fabrication process including soldering and brazing, since they are more efficient, offer higher product strength and accounts for less production cost.

Lack of Skilled labor in industries pertaining to handling the welding products coupled with high labor cost is expected to pose a major challenge and restraint for the market growth over the forecast period. Based on the product type, the welding consumables market has been segmented into solid wires, stick electrodes, saw wires and fluxes, flux cored wires. Stick electrodes segment holds the largest market share in the global industry owing to high demand and prevalence of welding in regions including Africa and Middle East. These electrodes are mainly used as a low cost alternative for welding process Wires and fluxes are expected to witness significant growth rate over the forecast period owing to increasing demand from consumer appliances and automotive segments. Flux-cored wires provide clean and strong welds, and high deposition rate. Efficient performance and higher productivity of wires and fluxes is estimated to be the key factors driving the market growth.

On the basis of application, the market has been classified into building & construction, automotive & transportation, defense & aerospace, and marine applications. Building and construction is expected to dominate the global market owing to increasing infrastructure projects and manufacturing industries. Regional initiatives such as Make in India campaigns are expected to boost the manufacturing sector in the country thereby resulting in an increased demand for welding processes. Automotive and transportation is expected to witness significant growth rate owing to increasing technological developments and launch of new vehicles into the market. Increasing investments in oil & gas and energy sectors is estimated to propel the global welding consumables market.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/welding-consumables-market-size

Asia pacific is expected to hold the largest market in the global industry owing to high prevalence of end use industries. Growing manufacturing sector coupled with government initiatives is expected to be the major factor driving the market growth in this region. Africa and Middle East is anticipated to witness high growth rate owing to raw materials availability and increasing automotive industry demand.

Key market vendors in the global welding consumables market include Lincoln Electric, ESAB, Vorarc Welding CC, Illinois Tool Work, and Promax Welding. Other industry participants include DAIHEN Corporation, Obara Corporation, Kiswel Inc, Kobe Steel Limited, Royal Arc Electrodes Limited, Arcsel LLC, and Corodur Fulldraht GmbH.

The key market players have developed their own distribution networks, as distribution is a critical success factor in this industry. For instance, ESAB, Voestalpine, and Lincoln Electric have a network of independent distributors and wholly owned subsidiaries to supply finished consumables to end-users in the country.

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email: [email protected]

0 notes

Text

Steel Tube Manufacturers: Pioneering Sustainability in the Age of Industrial Progress

Piping Projects is one of the leading Steel Tube Manufacturers in USA. We manufacture and supply a wide range of steel tubes, including carbon, seamless and welded, with wall thicknesses up to 40 mm and OD ranges of 12.7 mm to 906 mm. We use different materials to manufacture steel tubes. Pipingprojects.us is a top Steel Tube Supplier in USA. We use premium quality raw materials which enhance the durability and performance of Steel Tube.

Various materials and grades such as Brass, copper, stainless steel 304/304L, 316L, duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 to manufacture Steel Tubes.

In a world where environmental concerns are at the forefront of global discussions, industries are under increasing pressure to innovate and embrace sustainable practices.

Steel Tube Manufacturers have stepped up to the challenge, playing a vital role in pioneering sustainability in the age of industrial progress. Let's explore how these manufacturers lead the way towards a greener future.

The Evolution of Steel Tube Manufacturing:

Steel tube manufacturing has come a long way from its traditional roots, with modern techniques and technologies revolutionizing the industry. Here's how steel tube manufacturers are embracing sustainability:

1. Use of Recycled Materials:

Steel Tube Manufacturer are increasingly turning to recycled materials to reduce their environmental impact.

Manufacturers are reducing waste and conserving natural resources by incorporating recycled steel into their production processes.

2. Energy-Efficient Practices:

Energy consumption plays a significant role in the manufacturing process. Steel Tube Supplier are investing in energy-efficient technologies to minimize their carbon footprint.

Manufacturers are making significant strides towards sustainability by optimizing their operations and utilizing renewable energy sources.

3. Waste Management and Recycling:

Waste management is a critical aspect of sustainability in manufacturing. Steel tube manufacturers are implementing robust recycling programs to minimize waste generation.

By reusing scrap materials and adopting circular economy principles, manufacturers are reducing landfill waste and promoting a more sustainable approach to production.

Innovations in Sustainable Steel Tube Production:

In addition to adopting eco-friendly practices, steel tube manufacturers drive innovation in sustainable production methods. Here are some notable advancements:

1. Green Coating Technologies:

Manufacturers are developing environmentally friendly coating technologies that reduce the use of harmful chemicals and emissions.

These green coatings enhance the longevity of steel tubes and contribute to a cleaner, more sustainable manufacturing process.

2. Lightweighting and Material Optimization:

Steel tube manufacturers focus on lightweight solutions and material optimization to reduce energy consumption during transportation.

Manufacturers contribute to lower fuel consumption and emissions in the transportation sector by designing lighter tubes without compromising strength.

Conclusion:

Steel tube manufacturers are at the forefront of sustainability in the industrial landscape, spearheading innovation and embracing eco-friendly practices. By prioritizing using recycled materials, implementing energy-efficient measures, and driving advancements in sustainable production methods, these manufacturers are setting a new standard for environmentally conscious manufacturing. As we look to the future, it's clear that steel tube manufacturers will continue to play a pivotal role in shaping a more sustainable and resilient industrial sector. We are also USA top Welding Electrode Manufacturers.

Website: pipingprojects.us

#Steel Tube Manufacturers in USA#Steel Tube Supplier in USA#Steel Tube Manufacturers#Steel Tube Manufacturer#Steel Tube Supplier#Steel Tube Suppliers#Welding Electrode Manufacturers

0 notes

Text

Global Welding Wires & Welding Electrode Market to Witness Robust Expansion Throughout the Forecast Period 2021- 2027

Research reports on the 'Global Welding Wires & Welding Electrode Market' provide a complete study of broad market share, market segmentation and global market participants. This report was created with the help of primary and secondary research methods. This report provides an in-depth study of qualitative and quantitative analysis of supply chain, consumer requirements and consumer demand.

Increased competition between the organizational and non-organization sectors and high raw material costs are expected to curb future market growth. The growing interest in segment products and demand generation in developing countries will further accelerate market growth during the forecast period. This report covers all aspects of the Welding Wires & Welding Electrode industry, including market sales, technical thinking, and business profiles.

Key Players Mentioned:

Gloden Bridge,Tianjin Bridge,Weld Atlantic,Shandong Solid Solider,Shandong Juli Welding,Zhujiang Xiangjiang Welding,Wuhan Temo Welding,Changzhou Huatong Welding,Colfax Corporation,ITW,Kobelco,Lincoln Electric,KaynakTekni?iSanayi ve TicaretA.?,Voestalpine,Sandvik,Gedik Welding,CORODUR,Jinglei Welding

For Right Perspective & Competitive Insights, Request a Sample @: https://imrmarketreports.com/request/14113

This report provides a thorough overview of the competitive landscape of global Welding Wires & Welding Electrode Market and a detailed business profile of notable players in the market. Using industry standard tools like Porter's five force analysis and SWOT analysis, analysts in the report measure threats and weaknesses in key companies. The market report covers all key parameters such as product innovation, market strategy for leading companies, market share, revenue generation, the latest research and development and market expert perspectives.

Product Segment Analysis:

Welding Wires

Welding Electrode

Application Segment Analysis:

Automotive,Construction,Aerospace & Defense,Shipbuilding,Pipe

Regional Segment Analysis: USA, Europe, Japan, China, India, South East Asia

The Global Welding Wires & Welding Electrode Market Report was produced through extensive primary and secondary studies. The report also focuses on qualitative and quantitative assessments by analyzing data collected from industry analysts and market participants across key points in the industry's value chain, growth aspects, utilization and manufacturing capabilities.

Get Your Copy at a Discounted Rate!!! Limited Time Offer!!!: https://imrmarketreports.com/discount/14113

This report analyzes the factors affecting the Welding Wires & Welding Electrode Market in terms of supply and demand and further assesses the market dynamics affecting the market during the forecast period e.g. drivers, restraints, opportunities and future trends. The report also provides Porter's five forces analysis of global scenarios.

The Report allows you to:

- Formulate significant competitor information, analysis and insights to improve your R&D strategy.

- Identify potentially strong product portfolios emerging players and create effective response strategies to gain a competitive edge.

- Identify and understand important and diverse types of Welding Wires & Welding Electrode under development

- Develop market entry and market expansion strategies

- Identify the main players with the most promising pipeline to effectively plan mergers and acquisitions.

- In-depth analysis of the product's current development phase, area, and expected release date.

Key Points covered in the Welding Wires & Welding Electrode Market Report Coverage:

1 Market share study of the top manufacturing players

2 Market share debts for the regional and country level segments

3 Premeditated references for the new competitors

4 Competitive landscaping planning the key common trends

5 Tactical endorsements in key business segments based on the market estimations

6 Market Trends (Constraints, Drivers, Opportunities, Threats, Challenges, recommendations and Investment Opportunities)

7 Company profiling with detailed strategies, financial and latest developments

8 Supply chain trends mapping the latest technological advancements

About Us:

IMR Market Reports is a visionary market research company who is ready to assist their clients to grow their business by offering strategies through our market research reports for gaining success. We have a well experienced team, who work efficiently and provides complete excellent research data in a complete sync to provide overall coverage and accurate market insights on various industries.

Contact Us:

Aditya Patil

Business Development Executive

Office Address: Office No 15, Vrundavan Commercial Complex, DP Road, Kothrud, Pune, India - 411038

Contact No:

USA: +1 (773)-382-1047

APAC: +91-818-009-6367

0 notes

Photo

https://paramountenterprises.wixsite.com/spotwelding/projection-welding-electrode/

Leading manufacturer,supplier & exporter of Elkonite electrodes for projection welding with excellent quality. Contact-Paramount Enterprises, Nashik @shreekantpatilparamount , @parentnashik

#parentnashik#paramount enterprises#supplier#manufacturer#exporter#projection welding electrodes#elkonite electrodes#location pins#insulation bush#sleeves#resistance#welding#nut#stud#copper#us#USA#EUROPE#INDIA

1 note

·

View note

Text

Welding Consumables Market Determined by Business Summary, Industry Profile Details By 2025

The Welding Consumables Market includes welding equipment consumables, and services. Welding consumables are materials such as alloys, minerals and metals that are used to amalgamate thermoplastic and metal components. Welding consumables account for the lions share of the global welding industry in terms of profits compared to equipment and services. Technological advancement of welding methods is expected to drive the market growth over the forecast period. The global market has been facing dramatic change to flux and solid cored wired from electrodes owing to advanced production efficiency in welding consumables. Growing Innovation in developing new techniques for welding is anticipated to boost the market growth and create opportunities over the next few years. Increasing demand owing to growing in residential and commercial building constructions is estimated to positively impact and can attributed as the major driving factor.

Increasing demand from growing end use industries including transportation, mainly in emerging economies such as China, India, Thailand, and Singapore is expected to propel the global welding consumables market over the forecast period. Growing population along with increase in disposable income of people can be attributed to the aforementioned driver. New Infrastructural projects coupled with government investment to develop cities is anticipated to drive the market demand for global welding consumables. Welding steel plays a major role in the global market owing to high demand and need of steel in various industrial and manufacturing processes.

Welding is extensively used in metal and steel industries for fabrication processes. The impact of welding process on the metal sector is dependent on the total parts manufactured in the process. Industries are expected to prefer welding process over other conventional fabrication process including soldering and brazing, since they are more efficient, offer higher product strength and accounts for less production cost.

Access Sample Report of this report @ https://www.millioninsights.com/industry-reports/welding-consumables-market-size/request-sample

Lack of Skilled labor in industries pertaining to handling the welding products coupled with high labor cost is expected to pose a major challenge and restraint for the market growth over the forecast period. Based on the product type, the welding consumables market has been segmented into solid wires, stick electrodes, saw wires and fluxes, flux cored wires. Stick electrodes segment holds the largest market share in the global industry owing to high demand and prevalence of welding in regions including Africa and Middle East. These electrodes are mainly used as a low cost alternative for welding process Wires and fluxes are expected to witness significant growth rate over the forecast period owing to increasing demand from consumer appliances and automotive segments. Flux-cored wires provide clean and strong welds, and high deposition rate. Efficient performance and higher productivity of wires and fluxes is estimated to be the key factors driving the market growth.

On the basis of application, the market has been classified into building & construction, automotive & transportation, defense & aerospace, and marine applications. Building and construction is expected to dominate the global market owing to increasing infrastructure projects and manufacturing industries. Regional initiatives such as Make in India campaigns are expected to boost the manufacturing sector in the country thereby resulting in an increased demand for welding processes. Automotive and transportation is expected to witness significant growth rate owing to increasing technological developments and launch of new vehicles into the market. Increasing investments in oil & gas and energy sectors is estimated to propel the global welding consumables market

Asia pacific is expected to hold the largest market in the global industry owing to high prevalence of end use industries. Growing manufacturing sector coupled with government initiatives is expected to be the major factor driving the market growth in this region. Africa and Middle East is anticipated to witness high growth rate owing to raw materials availability and increasing automotive industry demand.

Key market vendors in the global welding consumables market include Lincoln Electric, ESAB, Vorarc Welding CC, Illinois Tool Work, and Promax Welding. Other industry participants include DAIHEN Corporation, Obara Corporation, Kiswel Inc, Kobe Steel Limited, Royal Arc Electrodes Limited, Arcsel LLC, and Corodur Fulldraht GmbH

The key market players have developed their own distribution networks, as distribution is a critical success factor in this industry. For instance, ESAB, Voestalpine, and Lincoln Electric have a network of independent distributors and wholly owned subsidiaries to supply finished consumables to end-users in the country.

Browse Full Report With TOC @ https://www.millioninsights.com/industry-reports/welding-consumables-market-size

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email: [email protected]

0 notes

Text

Welding Consumables Market by Type, Application, Technologies, Growth Rate, Trends and Investment Opportunities to 2025 | Adroit Market Research

Welding Consumables Market Report offers a comprehensive and detailed insight into the market landscape and aids in grasping the complete understanding of the market over a global landscape. The report offers an all-inclusive detailed account of the global trends and scope of the Welding Consumables market. The report offers a thorough explanation of the history of the Welding Consumables market over the past years and also has a thorough forecast rendition up to the year 2025.

The Welding Consumables Market Report presents emerging trends and market dynamics regarding drivers, opportunities, and challenges. The report covers the details of suppliers, consumers, and the level of competition. It also includes Welding Consumables Market Size, Revenue, Share, Industry Growth Rate, and Revenue. The Welding Consumables market report has an essential list of key aspects of Welding Consumables that includes leading market players along with their profiles and key financial data.

Get Sample Copy of this report @ https://www.adroitmarketresearch.com/contacts/request-sample/1528

Quantitative information includes estimates of the Welding Consumables market and forecasts for the coming years at the global level, broken down by key segments covered by the study, as well as by major regions and countries. Income and consumption assessment, annual growth analysis, price assessment and trend analysis, etc. Will be part of the quantitative information for the mentioned segments and regions / countries.

The major types mentioned in the report are: Bohler Welding, Hyundai, Lincoln Electric, Air Liquide, ARCON Welding, Denyo, Fronius International, Illinois Tool Work, Kemppi, Kobelco, Panasonic, and Tianjin Bridge Welding Materials Group.

Qualitative information will cover key market constraints and market growth potential, regulatory scenario, value chain and supply chain analysis, export and import analysis, attractive investment proposals, and Porter's five forces analysis. others will be part of quality information. Further, a qualitative rationale for the assessments for each segment and region will be given.

The study will also present key companies operating in the industry, their product / business portfolio, market share, financial position, regional share, segment revenue, SWOT analysis, key strategies, including mergers and acquisitions, product development, joint ventures and partnerships. as well as extensions. among other things, as well as their latest news. The study will also provide a list of new players in the Welding Consumables market.

Key segments of the global welding consumables market

End-user Overview, 2015-2025 (USD Billion)

Aerospace & Defense

Automotive

Construction

Marine

Others

Type Overview, 2015-2025 (USD Billion)

Stick Electrodes

Solid Wires

Flux Cored Wires

Saw Wires & Fluxes

ACCESS FULL REPORT @ https://www.adroitmarketresearch.com/industry-reports/welding-consumables-market

Region-based Analysis: Global Welding Consumables Market

Further in the report, report readers are also presented with veritable insights and workable details on elaborate regional developments across the five major regional hubs such as Europe, North America, APAC, MEA and South America.

Table of Content (TOC):

Chapter 1 Introduction and Overview

Chapter 2 Industry Cost Structure and Economic Impact

Chapter 3 Rising Trends and New Technologies with Major key players

Chapter 4 Global Welding Consumables Market Analysis, Trends, Growth Factor

Chapter 5 Welding Consumables Market Application and Business with Potential Analysis

Chapter 6 Global Welding Consumables Market Segment, Type, Application

Chapter 7 Global Welding Consumables Market Analysis (by Application, Type, End User)

Chapter 8 Major Key Vendors Analysis of Welding Consumables Market

Chapter 9 Development Trend of Analysis

Chapter 10 Conclusion

Make an Inquiry of the Welding Consumables Market Report @ https://www.adroitmarketresearch.com/contacts/enquiry-before-buying/1528

About Us :

Adroit Market Research is an India-based business analytics and consulting company incorporated in 2018. Our target audience is a wide range of corporations, manufacturing companies, product/technology development institutions and industry associations that require understanding of a market's size, key trends, participants and future outlook of an industry. We intend to become our clients' knowledge partner and provide them with valuable market insights to help create opportunities that increase their revenues. We follow a code - Explore, Learn and Transform. At our core, we are curious people who love to identify and understand industry patterns, create an insightful study around our findings and churn out money-making roadmaps.

Contact Us :

Ryan Johnson Account Manager Global 3131 McKinney Ave Ste 600, Dallas, TX75204, U.S.A. Phone No.: USA: +1 972-362 -8199/ +91 9665341414

0 notes

Text

Spot Welder - Custom Metal Work - Trenton, NJ

Join manufacturer of research laboratory ventilation products including laboratory bench hoods, ventilation fans, heater-fan-light combinations, fresh air systems, heat recovery ventilation and energy recovery ventilation systems, clean room isolators, racks, chambers, and more. Work from drawings, blueprints, process sheets, job specifications and verbal instructions. Do basic mathematics, set up equipment, and operate metal forming and spot welding equipment. Perform a variety of weldments which may involve a diverse combination of parts where assemblies may be clamped or involve jigs and fixtures. Recommend new jigs and fixtures designs. Determine number of welding points and contact. Regulate current and set automatic timing. Rig equipment for holding and positioning electrodes. Operate forming equipment to shape and form a variety of parts. Inspect pieces and check parts with templates, specifications and blueprints. THIS COMPANY IS KNOWN FOR: 1. Its transparent and open communication. 2. Balanced work-life. 3. Company paid training and mentoring employee development 4. Rewards and recognition for positive performance. 5. Team unity. According to Michael Poh, Positive Work Environment Guru, these factors make this place ideal. Stable employer with lots of work, OT available, family healthcare benefits, training programs, paid holidays and paid vacation, modern equipment in a clean environment. For complete details contact Kevin Hoffman at: (609) 584-9000 ext 243 Or, submit resume online at: dmc9.com/kgh/app.asp Or email to: 1000045841_10007366 AT najbcareers303.com Please reference #41380198 when responding. Education Requirements: High School Minimum Experience Requirements: 2-5 years Job City Location: Trenton Job State Location: NJ Job Country Location: USA Salary Range: $50,000to $75,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Spot Welder Welding Sheet Metal MIG TIG #DiedreMoire #WelderJobs #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499. Reference : Spot Welder - Custom Metal Work - Trenton, NJ jobs from Latest listings added - JobsAggregation http://jobsaggregation.com/jobs/technology/spot-welder-custom-metal-work-trenton-nj_i10295

0 notes

Text

Spot Welder - Custom Metal Work - Trenton, NJ

Join manufacturer of research laboratory ventilation products including laboratory bench hoods, ventilation fans, heater-fan-light combinations, fresh air systems, heat recovery ventilation and energy recovery ventilation systems, clean room isolators, racks, chambers, and more. Work from drawings, blueprints, process sheets, job specifications and verbal instructions. Do basic mathematics, set up equipment, and operate metal forming and spot welding equipment. Perform a variety of weldments which may involve a diverse combination of parts where assemblies may be clamped or involve jigs and fixtures. Recommend new jigs and fixtures designs. Determine number of welding points and contact. Regulate current and set automatic timing. Rig equipment for holding and positioning electrodes. Operate forming equipment to shape and form a variety of parts. Inspect pieces and check parts with templates, specifications and blueprints. THIS COMPANY IS KNOWN FOR: 1. Its transparent and open communication. 2. Balanced work-life. 3. Company paid training and mentoring employee development 4. Rewards and recognition for positive performance. 5. Team unity. According to Michael Poh, Positive Work Environment Guru, these factors make this place ideal. Stable employer with lots of work, OT available, family healthcare benefits, training programs, paid holidays and paid vacation, modern equipment in a clean environment. For complete details contact Kevin Hoffman at: (609) 584-9000 ext 243 Or, submit resume online at: dmc9.com/kgh/app.asp Or email to: 1000045841_10007366 AT najbcareers303.com Please reference #41380198 when responding. Education Requirements: High School Minimum Experience Requirements: 2-5 years Job City Location: Trenton Job State Location: NJ Job Country Location: USA Salary Range: $50,000to $75,000 Diedre Moire Corporation, Inc. Diedremoire_dot_com WE ARE AN EQUAL OPPORTUNITY EMPLOYER and our employment decisions are made without regard to race, color, religion, age, sex, national origin, handicap, disability or marital status. We reasonably accommodate individuals with handicaps, disabilities and bona fide religious beliefs. Jobs Career Position Hiring. CONSIDERED EXPERIENCE INCLUDES: Spot Welder Welding Sheet Metal MIG TIG #DiedreMoire #WelderJobs #JobSearch #JobHunt #JobOpening #Hiring #Job #Jobs #Careers #Employment #jobposting DISCLAIMER: We will make every effort to consider applications for all available positions and shall use one or more of the contact methods and addresses indicated in resume or online application. Indicated location may be proximate or may be desirable point of embarkation for paid or unpaid relocation to another venue. Job descriptions may fit single or multiple presently available or anticipated positions and are NOT an offer of employment or contract implied or otherwise. Described compensation is not definite nor precise and may be estimated and approximate and is negotiable depending on market conditions and candidate availability and other factors and is solely at the discretion of employers. Linguistics used herein may use First Person Singular and First Person Plural grammatical person construction for and with the meaning of Third Person Singular and Third Person Plural references. We reserves the right to amend and change responsibilities to meet business and organizational needs as necessary. Response to a specific posting or advertisement may result in consideration for other opportunities and not necessarily the incentive or basis of the response. Nothing herein is or may be considered a promise, guarantee, offer, pledge, agreement, contract, or oath. If you submit an application or resume which contains your email address, we will use that email address to communicate with you about this and other positions. We use an email quality control service to maintain security and a remove and dead address filter. To cancel receiving email communications, simply send an email from your address with the word "remove" in the subject line to pleaseremove_AT_candseek4.com Or, visit the website at jobbankremove_dot_com. If you have further concern regarding email received from us, call (609) 584-5499. Reference : Spot Welder - Custom Metal Work - Trenton, NJ jobs Source: http://jobrealtime.com/jobs/technology/spot-welder-custom-metal-work-trenton-nj_i11009

0 notes