#Waterproofing Chemicals Market Industry

Text

#Waterproofing Chemicals Market#Waterproofing Chemicals Market Trends#Waterproofing Chemicals Market Growth#Waterproofing Chemicals Market Industry#Waterproofing Chemicals Market Research

0 notes

Text

Seamless Protection: Exploring the Polyurea Coatings Market

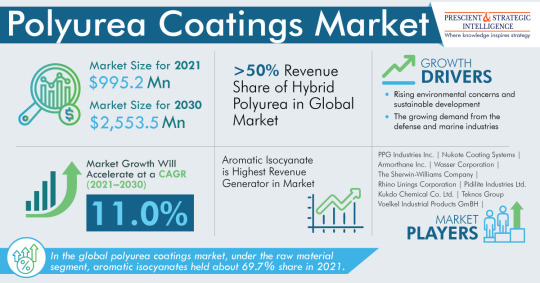

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry.

This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry.

Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry.

The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly.

The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings.

It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Text

WNBA players advertising Glossier sweat-proof sports makeup is a step back for women's health.

"Sweat-proof" makeup has per- and polyfluoroalkyl substances (PFAS) which cross the blood-brain barrier and bioaccumulate. PFAS is almost never listed on the labels of products that contain it. The only way to find out if a product has PFAS is to test it in a lab. PFAS gives products that "forever" quality found in sweat-proof, waterproof, and long-lasting makeup. But PFAS is also found in some makeup products that aren't advertised as sweat-proof, waterproof, or long-lasting. PFAS is a forever chemical that cannot be broken down, removed from the body, or "detoxed" in any way. PFAS is neurotoxic and linked to cancer and birth defects.

From Harvard Public Health: "The PFAS class, which includes more than 4,700 compounds, is linked to serious health issues, including cancer, obesity, decreased fertility, and a weakened immune system. In addition to menstrual products, PFAS often show up in foundations, mascaras, and lip products, especially those that are marketed as waterproof, sweatproof, or shimmery."

PFAS is also found in nail and hair products.

Popular Nike and Adidas sports bras and leggings contain extremely toxic levels of BPA that can cause cancer.

The cancer rate among retired female athletes seems much higher than the cancer rate of average women.

The WNBA doesn't even offer a pension or health insurance for retired players.

WNBA players are completely reliant on sponsored products to make money. A number of those products from large companies are toxic.

Sports capitalism promotes wealth first and health last.

The days of sports capitalism are numbered. There's probably only 2 or 3 years before the industry begins to collapse. The WNBA will collapse, too, unless it creates a plan to reorganize the league around ecological economic principles.

Cathy Engelbert is not going to make a plan like that. She's only here to decorate her corporate portfolio for a few years and then leave for a different industry.

10 notes

·

View notes

Text

Application of bitumen in building

Bitumen has numerous applications in the construction industry, primarily serving as an adhesive and waterproofing material. Its versatile properties make it indispensable in various building-related functions. Here are some key applications of bitumen in construction:

1. Roofing and Waterproofing:

Bitumen 60/70 is extensively used in roofing systems to provide waterproof membranes for flat roofs. Traditional bitumen roofing membranes consist of layers of bitumen sprayed with aggregate, with a carrier fabric made of polyester or glass in between. Polymer-modified bitumen sheets have become the standard for flat roof waterproofing. Bituminous roofing membranes can also be recycled easily, enhancing their sustainability.

2. Wall Sealing:

Bitumen 60/70 plays a crucial role in sealing walls, providing protection against water and moisture intrusion. It is applied to substrates such as bathrooms and toilets, which are constantly exposed to moisture, to prevent water penetration and safeguard the underlying structures.

3. Floor and Wall Insulation:

Bitumen 80/100 insulation is widely employed for building waterproofing, both horizontally and vertically. It effectively prevents water penetration into floorboards and walls, offering reliable protection. Bitumen's chemical and physical properties make it easy to work with and highly durable.

4. Sound Insulation:

Bitumen's sound-absorbing properties find applications beyond construction. It helps reduce noise transmission, such as the sound of footsteps under floor coverings. Special tar mats in cars and elevators utilize Bitumen 80/100 for sound insulation.

5. Electrical Cable Insulation:

Bitumen's low electrical conductivity makes it suitable for use as an insulating material for electrical cables. It helps protect the cables and prevent electrical hazards.

6. Other Uses:

Bitumen 80/100 & bitumen 60/70 finds application in various other areas, such as the paper industry and the manufacturing of paints and varnishes. Its thermal insulation properties are beneficial in different contexts.

From an ecological standpoint, bitumen is highly regarded for its long lifespan. It remains a popular construction material, with significant demand both domestically and in international markets. The producer of bitumen in Iran exports a large percentage of its production to other countries such as Singapore, Dubai, Panama.

In residential construction, plastic-modified bitumen (KMB) coatings are commonly used for insulation. They compete with bitumen-free FPD (Flexible Polymer Disc) seals, which are easier to apply and offer faster repair options.

Overall, the applications of bitumen in the construction industry are extensive, ranging from roofing and waterproofing to sound insulation and electrical cable insulation. Its versatility and durability make it a valuable material in various building-related functions.

Important Considerations Before Using Bitumen:

1. Surface Preparation:

Before applying bitumen, it is crucial to ensure that the surface is clean, dry, and free from any contaminants. Even the presence of dust, dirt, or grease can hinder the adhesion of the bitumen coating and compromise the effectiveness of the seal. Additionally, the surface should be free from frost. If there are old incompatible coatings, they must be removed. In the case of older buildings, previous applications of bituminous paints may not provide a suitable surface for polymer-modified bitumen (PMB) coatings.

2. Repairing Cracks and Unevenness:

Prior to applying bitumen, any cracks or unevenness on the surface should be repaired using appropriate materials like repair mortar or leveling compounds. This ensures a smooth and uniform surface, promoting better adhesion and a more effective seal.

3. Additional Preparatory Measures:

In some cases, additional preparatory measures may be necessary. One option is to use a layer of synthetic resin on the coarse-pored bed or to apply a sealing slurry. A sealing slurry is a waterproof mixture of cement and plastic that allows water vapor to pass through. The advantage of using a sealing slurry is that it can adhere well to old bituminous coatings, providing an ideal substrate for applying a thick new bituminous coating.

By following these steps and ensuring proper surface preparation, you can optimize the adhesion and effectiveness of bitumen coatings in various applications.

What are the suitable means for repairing cracks and unevenness on the surface before applying bitumen?

There are several suitable means for repairing cracks and unevenness on the surface before applying bitumen. The choice of repair method depends on the severity of the damage and the specific requirements of the project. Here are some common methods for repairing cracks and unevenness:

1. Crack Fillers and Sealants:

For smaller cracks, crack fillers or sealants can be used. These materials, such as asphalt-based crack fillers or specialized concrete crack sealants, are designed to fill and seal cracks, preventing water infiltration and further damage. They are typically applied using a caulk gun or trowel.

2. Repair Mortar:

Repair mortars are suitable for filling larger cracks, holes, or areas of unevenness. These mortars are made from a blend of cement, sand, and additives to enhance adhesion and strength. They can be mixed with water to create a workable paste and then applied to the damaged areas using a trowel or other appropriate tools. Repair mortars are commonly used for repairing concrete surfaces.

3. Leveling Compounds:

Leveling compounds, also known as self-leveling underlayments or floor levelers, are used to create a smooth and level surface. These compounds are typically made from a blend of cement, fine aggregates, and additives. They have a fluid consistency that allows them to flow and self-level over uneven areas. Leveling compounds are commonly used to repair uneven concrete or subfloor surfaces before applying flooring materials.

4. Patching Mixtures:

Patching mixtures, such as asphalt patching compounds or repair mixes, are specifically designed for repairing asphalt surfaces. They typically contain a combination of asphalt binder, aggregates, and additives. These mixtures can be applied to fill potholes, repair damaged areas, or smooth out unevenness in asphalt surfaces.

5. Resurfacing:

In cases where the damage or unevenness is more extensive, resurfacing the entire surface may be necessary. This involves applying a new layer of bitumen or asphalt mixture over the existing surface to create a smooth and uniform finish. Resurfacing can help address multiple issues, including cracks, potholes, and unevenness.

It's important to follow the manufacturer's instructions and best practices when using any repair materials. Additionally, proper surface preparation, including cleaning and removing loose debris, is essential before applying any repair method.

ATDM CO is a manufacturer and exporter of Bitumen 60/70, offering three different quality grades available in drums, bags, and bulk quantities. Our products are classified into premium, second, and third types, each with varying production costs and facilities. We provide a wide range of options to accommodate different customer needs and volume requirements.

#bitumen#bitumen 60/70#bitumen 80/100#bitumen 60/70 specs#bitumen penetration grade 60/70#bitumen 60/70 specification#bitumen 60 70#atdm co llc.

2 notes

·

View notes

Text

SAFETY APRONS & THEIR USES

Safety aprons are an essential piece of Personal Protective Equipment (PPE) for anyone working with or near powerful industrial chemicals. Common solvents, cleaners, and disinfectants can pose a severe threat to your health, and accidents with flying grease, oil, and other dangerous fluids are not uncommon. A good quality safety apron will provide you with the necessary protection from these hazards. It is crucial to choose a safety apron made from a breathable material to avoid causing skin irritation. The apron should also be long enough to protect your entire torso, and the straps should be adjustable to get a snug fit. When used properly, a safety apron can help keep you safe from harm in potentially hazardous situations.

When selecting an apron, choosing one that is appropriate for the task and fits properly is crucial. Aprons should be replaced when they become damaged or worn out. Workers should also be sure to wash their aprons after each use.

Different Types of Safety Aprons and Their Uses:

There are many different types of safety aprons on the market today. Some are designed for distinct purposes, while others can be used for several applications.

Aprons are used in many workplaces to protect employees' clothes from spills, dirt, and other debris. They are also commonly worn by chefs and other food service workers to prevent them from contacting food that may contain bacteria or contaminants. Safety aprons can also be worn to protect against fire or heat. Some manufacturers even create specialized aprons for particular industries, such as construction or laboratory work. Whatever the specific purpose, safety aprons play a significant role in workplace safety.

Chemical Resistant Aprons

These aprons are made of chemical-resistant polyvinyl chloride (PVC) and are a staple in many industries that require protection against harsh chemicals and other liquids. This chemical-resistant apron is known for its flexibility and resistance to a variety of liquids, including fats, grease, oils, acids, alcohol, and alkalis. As a result, the PVC apron is an ideal choice for those working in the chemical processing or petrochemical industries.

In addition to its practical benefits, the PVC apron is also known for its comfort and style. The apron's flexibility allows it to move with the body, making it comfortable to wear for long periods. It is available in various colors and designs, making it possible to find an apron that fits any personal style. Whether you need protection from harmful chemicals or are simply looking for an attractive and practical piece of clothing for your everyday work, the PVC apron is an excellent choice.

Water-resistant Apron

When it comes to protecting your clothing from spills and stains, water-resistant aprons made of Polyethylene Vinyl Acetate (PEVA) and PVC are second to none. These aprons are made from high-quality material and versatile enough to be used for several purposes. They are ideal for use in the kitchen, when cleaning or butchering, as well as for pet grooming, gardening, etc. The waterproof quality makes them more durable.

While the PEVA material prevents liquid permeation and contamination, the PVC aprons are designed for a smooth finish to prevent bacterial growth. These aprons are essential for anyone looking to protect their clothes from dirt and stains.

Heavy-duty Waterproof Apron

Aprons are not just for the kitchen anymore! With the Heavy Duty Vinyl Water-Proof Apron, you can have the durability and long life of an industrial apron and the comfort and fit of an apron perfect for your kitchen. These aprons are normally made from vinyl for added durability and come with heavy-duty braided neck and waist straps that are adjustable for a perfect fit.

With so many uses, including food processing, deep freezing, chemical processing, dish-washing, and more, the heavy-duty vinyl waterproof apron is a must-have for anyone who wants to keep their clothes clean and protected.

Disposable Apron

For many jobs, a disposable apron is the best option to keep your clothes clean and protected. They are inexpensive and come in various colors and styles to suit any need. They are also convenient because they can be quickly removed and disposed of when the job is done, minimizing washing expenses.

Disposable aprons are essential for anyone who wants to protect their clothing from stains and damage. Whether you are washing dishes, industrial cleaning, bussing tables, painting, or working in the salon or the kitchen, disposable aprons are a convenient way to keep your clothes clean and dry.

Conclusion

If you are looking for a reliable and affordable safety apron, we will get you covered. www.yoursafetyproducts.co.in has a wide selection of aprons to choose from depending on brands, material, and price range to find the perfect one for your needs. Whether you need an apron for industrial use or want something to protect your clothes at home, visit www.yoursafetyproducts.co.in for more information.

2 notes

·

View notes

Text

Industrial, Cleaning, Oil Field, Water treatment, Painting, Food, Mining, Construction, Power plant, Ceramic Chemicals Dubai, UAE | Coil cutting Service Dubai, UAE

The chemical industry in Dubai and the United Arab Emirates (UAE) is a vital component of the country's economy, as it is used in a wide range of industries such as construction, manufacturing, and oil and gas. The region is known for its high-quality chemicals, which are exported to various countries worldwide. However, with so many chemical suppliers in the market, it can be challenging to find the right one that meets your needs. This is why it is important to have a reliable and trustworthy chemical supplier that you can count on for all of your chemical needs.

In this blog post, we will discuss the role of chemical suppliers in Dubai and the UAE, the factors to consider when selecting a chemical supplier, and key players in the chemical supplier market. We'll also give tips on how to research and compare chemical suppliers in the region, so you can make an informed decision when choosing the right supplier for your business.

The role of chemical suppliers in Dubai and the UAE

The role of chemical suppliers in Dubai and the UAE is to provide a variety of chemical products to different industries in the region. These products include raw materials, industrial chemicals, and specialty chemicals that are used in a wide range of applications.

Construction industry is one of the major industries that rely on chemical suppliers in Dubai and the UAE. These chemicals are used in the production of construction materials such as cement, concrete, and asphalt. They are also used in the construction process, for example, as a waterproofing agent, fire-resistant coating, and for surface treatment.

Manufacturing industry is another sector that heavily depends on chemical suppliers. Chemicals are used in the production of various products such as plastics, textiles, and pharmaceuticals. These chemicals play a crucial role in the manufacturing process, as they are used as raw materials, catalysts, and intermediates.

Oil and gas industry is also a major user of chemicals. In the exploration, production, and refining process of oil and gas, various chemicals are used. These chemicals are used for drilling, production enhancement, and refining process.

Specialty chemicals are also an important part of the chemical industry in Dubai and the UAE. These chemicals have specific properties and are used for specific applications, such as in the food and beverage industry, personal care products, and agriculture.

In summary, chemical suppliers in Dubai and the UAE play a crucial role in supplying a wide range of chemicals to various industries, which in turn, enables the smooth functioning of these industries, and contributes to the overall economic growth of the region.

Choosing a chemical supplier in Dubai and the UAE

Choosing a chemical supplier in Dubai and the UAE can be a challenging task due to the large number of suppliers in the market. However, by considering the following factors, you can ensure that you select a supplier that meets your needs and provides you with high-quality chemicals at a reasonable price.

Quality: The quality of the chemicals supplied is of utmost importance. Make sure that the supplier has a good reputation in the market and that their chemicals meet the required industry standards.

Price: Compare the prices of different suppliers and choose one that offers competitive prices without compromising on quality.

Customer Service: A good supplier should provide excellent customer service, including timely delivery of products and prompt response to any queries or concerns you may have.

Certifications: Ensure that the supplier is certified by relevant authorities and that their chemicals have passed all necessary safety and quality tests.

Product Range: Check if the supplier has a wide range of products, so you can find all the chemicals you need from a single supplier, which can save you time and money.

Location: It is important to consider the location of the supplier, as this can affect delivery times and costs.

Environmental & Safety Consideration: Consider the supplier's environmental and safety policies, to ensure that the supplier is following the regulations and not impacting the environment negatively.

When researching potential suppliers, it is important to read reviews, check their websites, and ask for references from other businesses that have used their services. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs.

Key players in the chemical supplier market in Dubai and the UAE

Dubai and the UAE have a large number of chemical suppliers, but some stand out as key players in the market. Here are a few examples of major chemical suppliers in the region:

Al Rama International: Al Rama International Chemical Suppliers Company in Dubai, UAE. We are Specialized Chemicals Our Service Industrial Chemical, Cleaning Chemical, Oil field Chemical, Water treatment Chemical, Painting Chemical, Food Chemical, Mining Chemical, Construction Chemical, Power plant Chemical, Ceramic Chemical in Dubai, UAE. Al Rama has been a significant player in the G.C.C. & East African chemical trade, for over 20 years. We stock a wide variety of products ranging from food ingredients, oil exploration chemicals, sanitization chemicals, petroleum derivatives and industrial process raw materials. We possess extensive in-house expertise in blending and repacking of various products. Our facilities include open, closed ambient storage, as well as temperature-controlled storage. We operate our own fleet of road tankers, ISO tanks and pick-up trucks, to ensure full supply chain traceability.

Gulf Petrochem Group: Based in Dubai, Gulf Petrochem is a leading supplier of industrial and specialty chemicals in the region. They have a wide range of products, including petrochemicals, base oils, and lubricants. They also have a strong presence in the Africa, Asia, and Europe market.

National Chemical Corporation (NCC): NCC is a well-established chemical supplier based in Abu Dhabi. They have a wide range of products, including specialty chemicals, petrochemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

Emirates National Chemical Industries (ENCI): ENCI is a leading chemical supplier based in Dubai. They have a wide range of products, including petrochemicals, specialty chemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

These are just a few examples of major chemical suppliers in Dubai and the UAE. There are many other suppliers in the market, and it's important to research and compare different suppliers to find the one that best meets your needs.

Conclusion

In conclusion, chemical suppliers play a crucial role in the UAE and Dubai by supplying a wide range of chemicals to various industries. These industries include construction, manufacturing, oil and gas and specialty chemicals. When choosing a chemical supplier in Dubai, UAE, it is important to consider factors such as quality, price, customer service, certifications, product range, location and environmental & safety consideration. The key players in the chemical supplier market in Dubai and the UAE include Gulf Petrochem Group, National Chemical Corporation (NCC), Emirates National Chemical Industries (ENCI), and Al Rama International. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs and helps you to run your business efficiently.

#Chemical Suppliers#Industrial Chemicals#Cleaning Chemicals#Oil Field Chemicals#Bulk Chemicals#Water Treatment Chemicals#Painting Chemicals#Food Chemicals#Mining Chemicals#Construction Chemicals#Ceramic Chemicals#Powerplant Chemicals#Coil Cutting Service

2 notes

·

View notes

Text

Industrial Roofing Contractors Sydney

Industrial Roofing Contractors in Sydney: Ensuring Durability and Safety

Industrial Roofing Contractors Sydney is a critical aspect of any large-scale commercial or manufacturing facility. In a city as bustling as Sydney, where numerous industries thrive, having a reliable and durable roofing system is essential. Industrial roofing contractors in Sydney specialize in providing services tailored to the specific needs of industrial structures, ensuring long-lasting protection from the elements and contributing to the safety and efficiency of operations.

Why Industrial Roofing is Crucial

Industrial buildings differ from residential or commercial properties in terms of scale, functionality, and design requirements. These buildings house complex machinery, heavy materials, and large workforces, often requiring specialized roofing systems capable of withstanding harsh environmental conditions. Factors like high winds, temperature fluctuations, and even chemical exposure are common challenges faced by industrial roofs.

A robust industrial roofing system must also account for safety regulations. Contractors in Sydney are required to comply with local building codes and industry standards, ensuring that roofs not only perform optimally but also meet legal requirements for safety. For businesses, choosing the right roofing contractor is vital to minimizing risks, reducing downtime, and preventing costly repairs or replacements in the future.

Services Provided by Industrial Roofing Contractors

Roof Installation and Replacement

Industrial roofing contractors in Sydney offer installation services for new builds and replacement services for aging roofs. Whether it’s a metal roof, thermoplastic polyolefin (TPO) membrane, or an asphalt roofing system, contractors tailor their materials and techniques to suit each specific project. Durability, insulation, and energy efficiency are common considerations.

Roof Repair and Maintenance

Sydney's weather can be unpredictable, and exposure to sun, rain, and wind can cause wear and tear. Regular inspections and prompt repairs are essential for maintaining a functional industrial roof. Roofing contractors provide routine maintenance services, such as patching leaks, sealing seams, and cleaning drainage systems to ensure the longevity of the roof.

Roof Coating and Waterproofing

To extend the life of a roof, many industrial roofing contractors in Sydney offer protective coatings and waterproofing solutions. These coatings can reflect UV rays, reduce heat absorption, and improve the building’s energy efficiency. Waterproofing prevents moisture infiltration, which is crucial in maintaining the structural integrity of industrial buildings.

Skylight Installation and Ventilation Solutions

Ventilation is an important consideration in industrial roofing. Proper ventilation systems help regulate indoor temperatures and reduce the buildup of moisture, preventing mold growth and structural damage. Contractors often install skylights or ventilation systems to improve natural lighting and air circulation within the building, enhancing the overall work environment.

Choosing the Right Contractor

Given the importance of industrial roofing, it is essential to choose a contractor who has the expertise and experience in handling large-scale projects. In Sydney, the competitive market means that businesses have a wide selection of contractors to choose from, but it’s important to ensure the contractor is fully licensed and insured.

When selecting an industrial roofing contractor, consider:

Experience and Reputation: Look for contractors with a proven track record in the industry.

Local Knowledge: Contractors familiar with Sydney’s climate can recommend materials and systems suited to the region's specific weather patterns.

Cost and Budgeting: Ensure that the contractor provides transparent pricing and options that fit within your budget, without compromising quality.

Warranty and After-Service: Reliable contractors offer warranties on both materials and labor, providing peace of mind for years to come.

Conclusion

Industrial Roofing Contractors Sydney play a vital role in ensuring the safety and durability of large industrial buildings. From installation and repairs to maintenance and energy-efficient upgrades, these professionals provide tailored solutions that meet the specific needs of industrial properties. By choosing a qualified and experienced contractor, businesses can protect their investments and ensure that their operations continue without disruption.

#sydney's roofing specialists#commercial metal roofing sydney#sydney roofing company#metal roof repair

0 notes

Text

Hazardous Label Market Outlook: Global Trends and Forecast Analysis (2023-2032)

The Hazardous Label Market is projected to grow from USD 1579.7 million in 2024 to an estimated USD 1909.74 million by 2032, with a compound annual growth rate (CAGR) of 2.4% from 2024 to 2032.

The hazardous label market is experiencing steady growth, driven by increasing regulations and safety standards across various industries such as chemicals, pharmaceuticals, agriculture, and manufacturing. Hazardous labels are critical for ensuring the safe handling, storage, and transportation of materials that pose risks to human health, the environment, or property. These labels provide clear identification of hazardous substances and communicate vital information regarding toxicity, flammability, corrosiveness, or other dangers, in compliance with international standards such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), OSHA regulations, and other regional mandates. As global trade expands and the movement of hazardous materials becomes more frequent, the demand for accurate and compliant labeling has grown substantially.

Technological advancements in printing and labeling solutions, including durable materials such as waterproof, tear-resistant, and chemical-resistant substrates, are enhancing the performance and reliability of hazardous labels. Additionally, the rise of digital printing technologies allows for quicker turnaround times, customizable labeling options, and improved compliance with stringent labeling regulations. In industries like pharmaceuticals and chemicals, where accurate labeling is critical for regulatory compliance and safety, companies are increasingly investing in sophisticated label solutions to ensure that their products are labeled correctly throughout their supply chains.

Here are the key findings from the study of the hazardous label market:

Growing Regulatory Requirements: The market is being driven by the increasing stringency of regulations across various industries such as chemicals, pharmaceuticals, agriculture, and manufacturing. Compliance with safety standards like the Globally Harmonized System (GHS), OSHA, and other regional regulations is essential for ensuring the safe handling, storage, and transportation of hazardous materials, fueling the demand for accurate and compliant labeling solutions.

Advancements in Durable Labeling Materials: The need for labels that can withstand harsh environments has led to innovations in durable materials. Waterproof, chemical-resistant, tear-proof, and temperature-resistant labels are becoming standard in industries dealing with hazardous substances. These advancements ensure that labels remain legible and intact under extreme conditions, preventing safety risks and non-compliance issues.

Rise of Digital Printing Technologies: The adoption of digital printing technologies is transforming the hazardous label market by offering enhanced customization, faster turnaround times, and more precise labeling options. Digital printing allows for variable data printing, which is crucial for industries where regulatory information needs to be frequently updated. This flexibility and efficiency are helping companies meet evolving regulatory standards.

Increased Focus on Sustainability: There is growing demand for eco-friendly hazardous labels, driven by environmental concerns and corporate sustainability initiatives. Companies are exploring the use of sustainable materials, such as biodegradable or recyclable label substrates, to reduce their environmental impact while maintaining compliance with safety standards.

Strong Growth in Emerging Markets: The hazardous label market is witnessing rapid growth in regions like Asia-Pacific and Latin America, driven by rising industrialization and stricter regulatory frameworks for hazardous materials. These regions are increasingly adopting international safety standards, creating significant opportunities for growth in the hazardous labeling industry.

These findings highlight the market's expansion as industries worldwide prioritize safety, compliance, and sustainability in hazardous material management.

Key Player Analysis:

3M Company

Avery Dennison Corporation

Brady Worldwide, Inc.

CCL Industries Corp.

HERMA GmbH

PPG Industries, Inc.

Reliance Label Solution, Inc.

SATO Asia Pacific Pte. Ltd

UPM Raflatac

Weber Packaging Solutions, Inc.

More About Report- https://www.credenceresearch.com/report/hazardous-label-market

The hazardous label market is characterized by a competitive landscape with both global and regional players vying for market share, driven by increasing safety regulations and the demand for durable, compliant labeling solutions. Key players in the market are focusing on product innovation, expanding their geographical presence, and enhancing production capabilities to meet the rising demand for hazardous labels across various industries, including chemicals, pharmaceuticals, agriculture, and manufacturing.

Key Players and Market Leaders: Major players such as 3M, Avery Dennison, Brady Corporation, CCL Industries, and Intertape Polymer Group are prominent in the hazardous label market. These companies hold a significant market share due to their established product portfolios, global reach, and continuous investment in research and development. These market leaders offer a wide range of hazardous labels that comply with international standards such as GHS, OSHA, and REACH, ensuring their products meet the stringent requirements of safety and durability.

Product Innovation and Technology: Companies are increasingly investing in advanced materials and technologies to offer durable, high-performance labels. Innovation in waterproof, chemical-resistant, heat-resistant, and tear-proof labeling materials has become a critical differentiator. Additionally, digital printing technology is a key area of focus, enabling faster production times, cost efficiency, and high customization. This allows manufacturers to offer variable data printing, which is particularly important for industries where labels need to be updated frequently based on regulatory requirements.

Strategic Collaborations and Acquisitions: To strengthen their market position, many key players are engaging in strategic partnerships, mergers, and acquisitions. These moves help companies expand their product portfolios, enter new geographical markets, and leverage new technologies. For example, acquisitions of smaller, specialized labeling companies allow larger players to gain access to niche markets and cutting-edge technologies, enhancing their competitive edge.

Regional Competition: While North America and Europe dominate the hazardous label market due to stringent regulations and a well-established industrial base, companies are increasingly targeting growth in emerging regions such as Asia-Pacific and Latin America. These regions are experiencing rapid industrialization and stricter enforcement of safety standards, presenting lucrative opportunities for market players. Regional competitors, especially in Asia, are also gaining ground by offering cost-effective labeling solutions that meet local regulatory requirements, creating a more competitive environment.

Sustainability Initiatives: As sustainability becomes a global priority, companies are differentiating themselves by offering eco-friendly hazardous labels. These include labels made from biodegradable or recyclable materials that meet regulatory standards while minimizing environmental impact. This shift towards sustainable solutions is becoming an important factor in the competitive landscape, with companies that successfully innovate in this area gaining a distinct advantage.

In summary, the hazardous label market is highly competitive, with key players focusing on innovation, strategic expansions, and sustainable practices to capture market share. The ongoing shift towards more stringent safety regulations and environmental responsibility is likely to continue shaping the competitive dynamics of the market in the coming years.

Segmentation:

By Printing Technology:

Flexographic,

Digital,

Offset,

By Material Type:

Paper,

Plastic,

By End-Use:

Chemicals,

Pharmaceuticals,

Manufacturing,

Browse the full report – https://www.credenceresearch.com/report/hazardous-label-market

Browse Our Blog: https://www.linkedin.com/pulse/hazardous-label-market-outlook-global-trends-forecast-fyq2f

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Effective Dampproofing: Protect Your Home with Cera Chem Solutions

Moisture: The Invisible Enemy in Your Home

As Homeowners, we often focus on visible problems — a leaky roof, peeling paint, or cracked walls. But there’s a silent destroyer lurking within our homes that can cause far more damage if left unchecked: hidden moisture. At Cera Chem, with our 32 years of experience in construction chemicals, we’ve seen firsthand the devastating effects of uncontrolled dampness. Today, we’re sharing our expertise to help you protect your most valuable asset — your home.

The Hidden Dangers of Dampness

1. Structural Damage: Excess moisture can weaken your home’s foundation, leading to costly repairs.

2. Health Hazards: Damp environments breed mold and mildew, triggering allergies and respiratory issues.

3. Energy Inefficiency: Moisture in walls reduces insulation effectiveness.

4. Aesthetic Issues: Water stains, peeling wallpaper, and bubbling paint can ruin your home’s appearance.

5. Property Devaluation: Persistent dampness can significantly decrease your home’s market value.

Don’t wait until it’s too late. The key to protecting your home is early detection and effective treatment. That’s where Cera Chem’s cutting-edge Dampproof solutions come in.

Introducing Cera Chem’s Dampproof Series:

1. Dampproof: Our flagship 2K, aqueous, epoxy-based treatment

- Perfect for both internal and external surfaces

- Non-toxic and non-hazardous

- Excellent water penetration resistance

- Anti-fungal and algae-resistant

- Superior bonding and crack-bridging properties

2. Dampproof FR: 1K, fiber-enriched, PU dispersion-based coat

- Easy application for DIY enthusiasts

- Outstanding UV resistance for long-lasting protection

- Forms a flexible, resilient surface

- Simple spot repairs for damaged areas

3. Dampproof AR: 1K, hybrid acrylic-based solution

- Single-component for hassle-free application

- Water-thinnable for easy DIY use

- Excellent substrate bonding

- Effective crack-bridging capabilities

Why Choose Cera Chem’s Dampproof Solutions?

With over three decades in the industry, we understand that every home is unique. That’s why we’ve developed a range of solutions to address various dampness issues. Whether you’re dealing with internal moisture problems, external water penetration, or need a quick DIY fix, our Dampproof Series has you covered.

Ready to take control of your home’s moisture issues? Visit our website or contact our expert team today to learn more about how Cera Chem’s Dampproof solutions can protect your home and enhance your quality of life. Don’t wait for water damage to strike — act now and experience the Cera Chem difference!

For More Details:

Call us at: 98404 80307

Email: [email protected]

Visit Website: https://cerachemindia.com/

#Cerachem #admixtures #bestadmixtures #tileadhesive #admixtureproduct #ceraplast #constructionchemical #constructionwork #architecture #architect #civilengineer #waterreducer #concreteadmixture #concretesolution #buildingsolution #buildingmaterial #tileinstallation #buildingmaintenance #waterproofingexperts #waterproofing #waterproofingsolution #waterproofingmaterial #flooring #concrete #cracks #repairs #crackreduce #crackreducematerial #tilegrouting #tilejointfiller #jointfiller #tilejoint #tilegrout #epoxyjointfiller #epoxyfiller #epoxytilejoint #dampproof #dampproofing #dampproofingsolution #constructionaids #protectivecoating

0 notes

Text

Exploring Growth Trends in the Waterproofing Admixture Market: 2024-2034 Forecast

The global waterproofing admixture market has been experiencing substantial growth and transformation from 2021 to 2031. Waterproofing admixtures are crucial components used in construction to enhance the water resistance of concrete and other building materials. They are integral to improving the durability and longevity of structures exposed to harsh weather conditions, moisture, and water ingress.

The global waterproofing admixture market was projected to attain US$ 3.7 billion in 2020. It is anticipated to garner a 7.9% CAGR from 2021 to 2031 and by 2031, the market is likely to attain US$ 8.5 billion by 2031.

The adoption of governmental laws governing VOC emissions and the increase in consumer knowledge of waterproofing admixtures are factors that are limiting demand. Nonetheless, the increasing possibility of high-performance concrete buildings in the regional housing market has greatly increased demand in Europe.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/waterproofing-admixture-market.html

Market Segmentation

The waterproofing admixture market can be segmented based on several criteria:

By Service Type:

Integral Admixtures: These are mixed directly with concrete to provide waterproofing properties.

Surface Applied Admixtures: These are applied to the surface of concrete structures to provide a waterproof layer.

Grouts and Sealants: Used for filling joints and cracks to prevent water ingress.

By Sourcing Type:

Chemical Admixtures: Includes admixtures like polymer-based, crystalline-based, and others.

Natural Admixtures: Derived from natural sources, such as certain types of clay and minerals.

By Application:

Residential Construction: Used in homes and apartments to prevent water damage.

Commercial Construction: Applied in offices, shopping malls, and other commercial buildings.

Industrial Construction: Used in warehouses, factories, and industrial plants.

Infrastructure Projects: Includes bridges, tunnels, and dams.

By Industry Vertical:

Construction & Real Estate

Transportation

Energy & Utilities

Others (e.g., marine, agriculture)

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominated by the U.S. and Canada, this region is characterized by significant investments in infrastructure and residential projects. The market is driven by stringent building codes and regulations.

Europe: The European market benefits from advanced construction technologies and a focus on sustainable building practices. Countries like Germany, France, and the UK are key contributors.

Asia-Pacific: This region is expected to witness the highest growth rate due to rapid urbanization, increasing infrastructure projects, and a booming real estate sector. China and India are prominent markets.

Latin America: Growth in this region is fueled by increasing construction activities and investments in infrastructure development.

Middle East & Africa: The market is growing due to infrastructural developments and the need for durable construction solutions in extreme weather conditions.

Market Drivers and Challenges

Drivers:

Growing Urbanization: The rapid growth of urban areas increases the demand for new construction and infrastructure, boosting the need for waterproofing solutions.

Infrastructure Development: Investments in infrastructure projects, such as roads, bridges, and tunnels, drive the demand for waterproofing admixtures.

Regulatory Standards: Stringent building codes and standards for water resistance contribute to market growth.

Challenges:

High Costs: The high cost of advanced waterproofing technologies can be a barrier for some segments of the market.

Environmental Concerns: The environmental impact of chemical admixtures poses challenges, leading to a growing preference for eco-friendly solutions.

Market Trends

Sustainable Solutions: There is an increasing demand for eco-friendly and sustainable waterproofing admixtures, driven by environmental regulations and consumer preferences.

Technological Advancements: Innovations in admixture formulations and application technologies are enhancing performance and ease of use.

Increased Awareness: Growing awareness about the benefits of waterproofing in enhancing the durability of structures is driving market growth.

Future Outlook

The future of the waterproofing admixture market looks promising, with continued growth driven by ongoing construction activities, infrastructural developments, and advancements in technology. The focus will likely shift towards more sustainable and cost-effective solutions, with increased emphasis on reducing environmental impact.

Key Market Study Points

The market is expected to reach USD 8.5 billion by 2031, growing at a CAGR of 7.9%.

Asia-Pacific will lead in growth due to rapid urbanization and infrastructure development.

Sustainable and eco-friendly solutions are becoming increasingly important in the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=7436<ype=S

Competitive Landscape

The competitive landscape of the waterproofing admixture market includes major players such as BASF SE, Sika AG, CEMEX S.A.B. de C.V., and Mapei S.p.A. These companies are focusing on innovation, strategic partnerships, and expanding their product portfolios to maintain a competitive edge.

Recent Developments

Recent developments in the market include the introduction of advanced admixture technologies, collaborations for research and development, and the launch of eco-friendly products. Companies are also investing in expanding their production capacities to meet the growing demand.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

How to Choose the Right MAPEI Waterproofing Solution

In the world of waterproofing systems which of course floods the markets today, MAPEI waterproofing is excellent because of its product and efficiency. MAPEI, an international company in the construction chemicals industry has come up with waterproofing products that cater to various markets. Forum, in this blog, we will discuss what MAPEI waterproofing involves, what it is used for, and how one can select the appropriate product for the job.

When selecting a MAPEI waterproofing solution, several factors should be considered:

Project Requirements

Surface Preparation

Application Method

Durability and Longevity

Cost and Availability

Environmental Considerations

Thus, it can be stated that MAPEI waterproofing enhances the opportunity to protect the building and structures from water penetration. They offer products of different varieties belonging to the waterproofing industry and hence have emerged as market leaders. From designing a home to carrying out construction projects of offices, buildings, and infrastructures, MAPEI comes in with exceptional waterproofing technologies that can help deliver a lasting seal against water seepage.

0 notes

Text

Expert Tips for Selecting the Ideal Grease for Your Machinery

One of the major precautions regarding machinery maintenance is lubrication. Grease as a lubricant has an important role in lessening friction from jolts and reducing wear and tear in equipment to ensure any type of equipment would last longer than expected. But with many grease types in the market, making a selection may pose much more difficulty. Ensuring to select the best grease means being able to give top-notch performance and longevity to your equipment. Following are a few expert tips to select the perfect grease for your machinery.

1. Know What Grease Lubricants Do

It is important to understand the role of grease lubricants in machines. Grease acts as a barrier between the moving parts in contact, thus reducing friction and wear. It provides a seal to prevent intrusion from dirt, dust, or water. The best grease will accord your machine the most flow in its operation, thus enhancing its efficiency through reduced chances of malfunction. Besides, the lubricants of grease provide huge resistance to environmental factors like changes in temperature and resistance toward chemical contact, which is appropriate for industrial use.

2. Types of Grease Lubricants

Understanding the different types of grease is important in choosing the most suitable type for use in your machines. Generally, grease lubricants are classified based on the thickener, base oil, and additives that make them up. The following are some of the most common types:

Lithium Grease: This is one of the most-used greases and offers good multi-purpose performance, not only at a wide temperature range but also for stability, water resistance, and durability, making it ideal in automotive and general machinery applications.

Calcium Grease: Calcium-based grease enjoys very good water resistance and is suitable for marine equipment and applications entailing high moisture exposure. Calcium-based greases tend to have a limited operating temperature range and are not normally used in high-temperature applications.

Aluminum Complex Grease: This kind of grease has very, very good temperature resistance and excellent oxidation stability, thus being ideal for use in severe applications. It is also good for water resistance and can be applied to both automotive and industrial applications.

Polyurea Grease: Polyurea-based greases typically have long-lasting performance under difficult conditions such as high temperatures; hence, they apply in sealed-for-life bearings, electric motors, and high-speed applications.

Silicone Grease: It is waterproof, chemical-resistant, and withstands a wide range of temperatures; hence, it is quite suitable in special applications such as electrical connectors, seals, and even medical devices.

Each of them has different features, and their use depends on matching the right type of grease to the particular needs of your machinery.

3. Operating Conditions

The operating conditions in the area where your machinery works form the basis on which the correct grease will be selected. Consider environmental exposure, along with temperature, speed and load, among other factors. For example:

Temperature: The machinery which operates under high temperatures requires greases that will not break down in maintaining consistency and performance. Generally, aluminium complexes or polyurea greases usually work great with applications involving high temperatures.

Speed: The requirement for greases is to have low viscosity to reduce friction so that high-speed machinery can operate smoothly. Lighter base oils are used in greases in most high-speed applications, such as lithium-based grease.

Load: Those under high load conditions will have requirements to apply greases with extreme pressure additives that prevent wear and tear. Aluminium complex and polyurea greases are the normally applied ones in those situations.

Environment: Other environmental factors affecting the performance of greases are water, dust, and chemicals. Calcium and silicone greases have better water resistance, while polyurea and aluminium complex greases are resistant to chemicals.

4. Additives in Grease

Most greases carry additives to improve performance. Such additives may allow the grease to operate in more extreme conditions of temperature, pressure, etc., and may provide additional protection to machinery. Common additives are:

Anti-Wear Additives: Anti-wear additives decrease wear on contacting surfaces of machinery components under heavy load.

Oxidation Inhibitors: Greases with oxidation inhibitors prevent the thickener and base oil from breaking down, hence prolonging the life of the lubricant.

Rust and Corrosion Inhibitors: For machinery that could be subjected to moisture or being in heavy environmental conditions, rust and corrosion inhibitors prove quite important in protecting metal surfaces.

Extreme Pressure (EP) Additives: These are necessary where machinery is under heavy loads; the additives form a film of protection that would ensure no surface damage occurs under pressure.

5. Consistency and Viscosity of the Grease

The consistency and viscosity of the grease are other factors in selecting the proper product. The consistency of grease is measured by a scale proposed by the National Lubricating Grease Institute, and the rating varies from 000-colloquially speaking, very fluid-up to 6-very hard. For most industrial and automotive applications, NLGI 2 grease is normally used because its consistency gives a very good balance that performs satisfactorily under most conditions.

The viscosity of the base oil in the grease will affect its flow characteristics in applications, which in turn will determine the extent of friction reduction between moving parts. High-speed machinery applications call for a lower-viscosity grease, while applications with low operating speeds or carrying high loads should be treated with thicker greases with higher viscosity to provide the needed protection.

6. Compatibility with Seals and Materials

Incompatible grease degrades the seals and further causes leaks and equipment failure. Always check the manufacturer's guidelines to determine the type of grease that can be safely used with your equipment.

7. Application Method

Application method will also have a bearing on which type of grease you use. Some greases are only compatible with automatic lubrication systems, while others may be better suited for use in manual applications. Be sure the grease you decide on is compatible and can be readily applied via a grease gun, automated system or by hand.

8. Lubrication Frequency

Consider the greasing frequency of the machinery. For instance, some greases have longer service intervals, such as polyurea and silicone greases that may seldom need replacement. On the other hand, extremely severe conditions that affect the machinery may require more frequency of lubrication.

You may also like: Points To Keep In Mind For Choosing Royal Enfield Engine Oil

Conclusion

The right type of grease for the machinery will save it and give it a long life. Knowing the variants of grease lubricants, considering the operating conditions, and getting the right additives will help in smooth functioning and increased efficiency. Always consult your machinery manufacturer's recommendations and take expert advice to select an ideal grease which would meet all the specific demands of your equipment.

0 notes

Text

Informative Report on PFAS Chemical Material Market | Bis Research

Per- and polyfluoroalkyl substances (PFAS) are a class of synthetic chemicals that have seen extensive global application across various industries and consumer products.

These substances are commonly found in items such as non-stick cookware, water-resistant clothing, stain-resistant carpets, certain cosmetics, firefighting foams, and products designed to repel grease, water, and oil.

The PFAS chemicals market is projected to reach $51,727.5 million by 2034 from $29,500.0 million in 2023, growing at a CAGR of 5.19% during the forecast period 2024-2034

Overview

Per- and polyfluoroalkyl substances (PFAS) are a group of synthetic chemicals that have been manufactured and used in various industries since the 1940s. These chemicals are characterized by their strong carbon-fluorine bonds, making them highly resistant to heat, water, and oil. PFAS are commonly referred to as "forever chemicals" due to their persistence in the environment and resistance to natural degradation.

Types of PFAS

Perfluoroalkyl substances: Fully fluorinated carbon chains.

Polyfluoroalkyl substances: Partially fluorinated carbon chains.

Properties and Uses

Non Stick Cookwares - PTFE (Teflon) coatings are made with PFAS chemicals.

Waterproofing- Used in clothing, furniture, and carpets to resist water and stains.

Firefighting Foam- Aqueous film-forming foams (AFFFs) containing PFAS are effective at suppressing fuel fires.

Electronics- PFAS are used in wiring and semiconductor manufacturing due to their insulating and heat-resistant properties.

Download our Report to know more !

Key Features and Benefits for PFAS Chemical Material

Key Features and Benefits

Key features are as follows

Chemical Stability

Hydrophobic and Lipophilic Stability

Thermal Resistance

Low Surface Energy

Electrical Insulation

Chemical Inertness

Key Benefits are as follows

Consumer Product Enhancement

Industrial Applications

Medical and Healthcare Uses

Electronics and Electrical Industry

Food Packaging

Visit our sample page click here !

Market Segmentation for PFAS Chemical Material

1 By Application

Blowing Agents, Refrigerants and Coolants, and Flame Retardants to Lead the Market - Blowing agents, refrigerants, coolants, and flame retardants are expected to dominate the PFAS chemicals market by application, given their essential roles in high-demand industries such as construction, electronics, and automotive. The unique properties of PFAS chemicals, such as thermal stability, non-flammability, and durability, make them critical in enhancing product performance. For instance, blowing agents are pivotal in creating insulating foams that boost energy efficiency, while refrigerants and coolants are vital for thermal regulation in various systems. Flame retardants contribute significantly to safety standards across numerous applications.

2 By Product - Others Segment to Lead the Market

The other segment is expected to lead the PFAS chemicals market by product due to its broad applicability and distinctive chemical properties. This category includes specialized PFAS compounds that do not fall under conventional classifications but are essential for industries requiring advanced performance and versatility.

By Region- Asia-Pacific Region to Lead the Market

The Asia-Pacific region is positioned to lead the PFAS chemicals market, driven by rapid industrialization, urbanization, and the growth of key sectors such as electronics, textiles, and automotive manufacturing. Countries such as China, Japan, and South Korea are significant consumers of PFAS chemicals, essential in applications such as water and stain repellents, firefighting foams, and semiconductor production

Visit our Advanced Materials Chemical Vertical Page here !

Key Players

3M

AGC Inc.

Archroma

Arkema

BASF

Bayer AG

BIONA JERSÍN s.r.o.

The Chemours Company

Market Drivers for PFAS Chemical Material

1 Growing demand for Non Stick and Strain Resistant Products

Consumer Goods: The increasing demand for non-stick cookware, water-resistant textiles, and stain-resistant fabrics is a significant driver for PFAS chemicals.

Home Furnishings: Carpets, upholstery, and other home textiles benefit from PFAS coatings, enhancing their durability and stain resistance.

2 Expanding Use in the Automotive and Aerospace Industries

High-Performance Materials: PFAS materials are used in automotive and aerospace sectors for seals, gaskets, hoses, and lightweight components.

Fuel Resistance: PFAS-based components that resist exposure to fuels, oils, and other chemicals are critical for engine performance and efficiency.

3. Increased Adoption in Electronics and Semiconductors

Electrical Insulation: PFAS materials are widely used in the electronics industry due to their excellent insulating properties, making them ideal for use in wiring, cables, and connectors.

Semiconductor Manufacturing: The semiconductor industry requires materials with high purity, chemical resistance, and stability, all of which PFAS provide, ensuring their continued use in the production of microchips and other components.

4 Growth in Food Packaging and Food Safety Concerns

Grease-Resistant Packaging: The food packaging industry continues to rely on PFAS materials for grease-proof and water-resistant packaging, which helps extend the shelf life of food products and maintain quality during transportation and storage.

Regulatory Compliance in Packaging: PFAS coatings in food packaging also provide a barrier against contaminants and help meet stringent food safety regulations.

Conclusion

The market for PFAS Chemical Material s is poised for significant growth, driven by a confluence of regulatory pressures, increasing consumer demand for sustainable practices, and the urgent global need to address climate change. As innovation in materials science and manufacturing processes continues to advance, low carbon materials are becoming more accessible and cost-effective, further accelerating their adoption.

0 notes

Text

Top Technical Textile Products Shaping Various Industries Essential Technical Textiles Products for Modern Industry Needs

Technical textiles have radically transformed the textile industry by putting functionality before aesthetics. The prominent characteristics of these types of high-end products essentially aim at tackling critical technical and engineering issues that in turn benefit different industries, making them essential in various industries. Pidilite’s advanced technical textiles products are designed to meet these modern industry needs with unparalleled efficiency and reliability.

Pidilite’s Expertise in Technical Textiles Products

Advanced Coating Solutions

Pidilite offers cutting-edge technologies like acrylic binders and VAM emulsions that enhance the performance of technical textiles. Products such as Pidicryl 3640 H provide durable, hard films suitable for a variety of substrates, including textiles and metals, ensuring long-lasting performance and stability.

Innovative Functional Additives

Pidilite's assortment covers chemicals like fire retardants, antimicrobial agents, and water repellents. Texeltek AM 700 and Texeltek DE 3236, for example, provide fundamental features such as antimicrobial protection and oil and water repellency, thus being vital for many uses in technical textiles.

Customisable Solutions

Pidilite develops custom-made solutions tailored to specific needs, from textile coatings to binding agents. With products like Pidicryl 3699, which offers flexibility and durability, Pidilite ensures that their technical textile products meet the precise requirements of diverse industries.

Pidilite offers a wide range of technical textiles products for different applications like:

Nonwoven Wadding for insulation and padding

Curtain Fabrics to enhance durability and performance

Shoe Sole Boards to provide sturdy and reliable support

Flocking Binders to secure flocked textiles

Textile Coatings for improved fabric performance

Carpet Backing to add strength and durability

Tent Coatings for waterproofing for outdoor use

Soft Luggage to add resilience and flexibility

Flame Retardant Finishes for safety applications

Water Repellents to protect against moisture

Antimicrobial Finishes to enhance hygiene and longevity

Oil Repellent Coatings to prevent stains and damage

Why Choose Pidilite Industrial Products?

Superior Quality and Performance

Pidilite has gained its reputation due to the use of the highest quality materials and the superior performance of the products. The Pidicryl 3681 and Teknotex WR 830 are both products that exhibit the commitment of Pidilite to delivering exceptional functionality and thus prove its dedication in achieving the highest possible utility and strength in textiles.

Customer-Centric Innovation

Pidilite's top concern is to know what the clients want and then to make products that will fulfil their needs. Teknotex AM 300 is one such product that the company, through their collaborative method, manages to follow the unique needs of different industries, enhancing production efficiency and product value.

Global Expertise and Reach

With a global footprint, Pidilite provides innovative textile solutions across various markets. Their extensive experience and diverse product range, including Jowat hot melts and Teknotex antimicrobial agents, make Pidilite a trusted partner in the technical textiles sector.

Conclusion

Pidilite’s advanced technical textiles products are essential for meeting the modern industry's demands for high-performance and functional fabrics. With innovative technologies, a customer-centric approach, and a global reach, Pidilite provides reliable solutions that drive efficiency and value across each application of technical textiles. Choose Pidilite for superior technical textile solutions that stand the test of time.

0 notes

Text

Rubber-coated fabrics Market: Stretching its Potential with Steady 3.6% Annual Growth

Introduction

Rubber-coated fabrics are integral to a wide range of applications, from protective clothing and industrial coverings to automotive components. The market for these versatile materials is expanding, driven by their unique properties and increasing adoption across various sectors. This article explores the growth trajectory of the rubber-coated fabric market, highlighting key trends and future projections.

Current Market Trends

Market Size and Growth Rate

As of 2023, the rubber-coated fabric market is valued at USD 6.0 billion. It is expected to grow at a compound annual growth rate (CAGR) of 3.6%, reaching USD 7.8 billion by 2030. This growth is fueled by the expanding use of rubber-coated fabrics in numerous applications and industries.

Key Industry Drivers

The demand for rubber-coated fabrics is driven by several factors, including their durability, flexibility, and resistance to various environmental conditions. Industries such as automotive, construction, and textile manufacturing are major consumers of these materials, further boosting market growth.

Download Sample Report @ https://intentmarketresearch.com/request-sample/rubber-coated-fabric-market-3218.html

Market Segmentation

By Application

Rubber-coated fabrics are used in a variety of applications, including:

Automotive: For seat covers, airbags, and weather-resistant parts.

Construction: For tarpaulins, waterproof coverings, and protective gear.

Textiles: For fashion items, industrial uniforms, and accessories.

By Type of Rubber

Different types of rubber are used in coating fabrics, including:

Natural Rubber: Known for its elasticity and resilience.

Synthetic Rubber: Offers specific properties like oil resistance and durability.

By Region

The market is segmented geographically into:

North America: Strong demand driven by automotive and construction sectors.

Europe: Growth influenced by stringent environmental regulations and technological advancements.

Asia-Pacific: Rapid expansion due to industrial growth and increasing infrastructure projects.

Latin America and Middle East & Africa: Emerging markets with growing adoption rates.

Technological Advancements

Innovations in Coating Technologies

Recent advancements in coating technologies have improved the performance and versatility of rubber-coated fabrics. Innovations such as enhanced adhesion techniques and the development of new rubber compounds are driving market growth.

Impact on Product Performance

Technological improvements have led to better resistance to abrasion, weathering, and chemical exposure, making rubber-coated fabrics more suitable for demanding applications.

Market Share Analysis

Market share analysis reveals a competitive landscape with key players investing in research and development, expanding their product portfolios, and entering new markets to strengthen their positions.

Economic Impact

Contribution to Different Sectors

The rubber-coated fabric industry significantly contributes to various sectors by providing essential materials for protective clothing, industrial applications, and consumer products.

Job Creation and Industry Growth

The industry's growth has led to job creation in manufacturing, research and development, and sales, contributing to overall economic development.

Environmental Impact

Sustainability of Rubber-Coated Fabrics

The environmental impact of rubber-coated fabrics is a growing concern. Manufacturers are focusing on sustainability by using eco-friendly materials and processes.

Eco-Friendly Manufacturing Practices

Efforts are being made to reduce waste, recycle materials, and lower the carbon footprint of manufacturing processes, making rubber-coated fabrics more environmentally sustainable.

Access Full Report @ https://intentmarketresearch.com/latest-reports/rubber-coated-fabric-market-3218.html

Challenges Facing the Market

Raw Material Costs

Fluctuations in the cost of raw materials, such as rubber and chemicals, can impact the pricing and profitability of rubber-coated fabrics.

Regulatory Issues

Compliance with environmental and safety regulations is essential for manufacturers. Navigating these regulations can be challenging and may affect market dynamics.

Opportunities for Growth

Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities due to industrialization and infrastructure development.

Technological Innovations

Continued innovation in coating technologies and material science offers opportunities for developing advanced products with enhanced properties and applications.

Future Market Projections

Forecasting Market Trends

The rubber-coated fabric market is expected to continue its growth trajectory, driven by technological advancements and increasing demand across various industries.

Expected Market Size by 2030

With a projected CAGR of 3.6%, the market is set to reach USD 7.8 billion by 2030, reflecting ongoing growth and expansion.

Consumer Guide

Choosing the Right Rubber-Coated Fabric

When selecting rubber-coated fabrics, consider factors such as durability, resistance to environmental conditions, and specific application requirements.

Factors to Consider

Key considerations include the type of rubber used, coating technology, and the intended use of the fabric. Consulting with suppliers and reviewing product specifications can help make an informed choice.

Competitive Landscape

Analysis of Major Competitors

The competitive landscape of the rubber-coated fabric market includes several key players with diverse strategies. Analyzing their strengths, weaknesses, and market strategies provides insights into the industry's dynamics.

Strategic Initiatives

Companies are pursuing various strategic initiatives, such as partnerships, acquisitions, and investments in R&D, to enhance their market positions and drive growth.

Conclusion

The rubber-coated fabric market is poised for significant growth, driven by technological advancements, increasing demand, and evolving industry needs. As the market expands, opportunities for innovation and development will continue to emerge, shaping the future of this dynamic sector.

Contact Us

US: +1 463-583-2713

0 notes

Text

Neoprene Rubber Prices | Pricing | Trend | News | Database | Chart | Forecast

The neoprene rubber market plays a crucial role in various industries due to its versatility, resilience, and wide range of applications. Neoprene, a synthetic rubber, is known for its resistance to oil, chemicals, heat, and weathering, making it a valuable material for industries such as automotive, construction, electronics, and textiles. However, the prices of neoprene rubber are influenced by several factors, including raw material costs, production processes, market demand, supply chain dynamics, and global economic trends. Understanding the trends and factors driving neoprene rubber prices is essential for businesses that rely on this material for manufacturing and product development.

One of the primary factors affecting neoprene rubber prices is the cost of raw materials, particularly chloroprene, the key ingredient in neoprene production. Chloroprene is derived from petrochemicals, and its prices fluctuate based on crude oil prices, which are subject to global market forces. When crude oil prices rise, the cost of producing chloroprene increases, which, in turn, leads to higher neoprene rubber prices. On the other hand, when crude oil prices stabilize or decline, manufacturers may benefit from reduced production costs, potentially lowering neoprene prices. As a result, fluctuations in oil prices can significantly impact the neoprene rubber market, creating volatility in pricing.

Get Real Time Prices for Neoprene Rubber: https://www.chemanalyst.com/Pricing-data/neoprene-rubber-1309

Another critical factor influencing neoprene rubber prices is the overall demand from various end-use industries. Neoprene is widely used in automotive applications, such as seals, gaskets, and hoses, due to its durability and resistance to extreme conditions. The automotive industry's demand for neoprene rubber is closely tied to the production of vehicles, which can be affected by factors like economic growth, consumer spending, and supply chain disruptions. Similarly, the construction industry relies on neoprene for insulation, sealing, and waterproofing applications. Any changes in construction activity, whether due to economic factors or shifts in government infrastructure spending, can influence the demand for neoprene and, consequently, its price.