#Waterproofing Chemicals Market Trends

Text

Sales of Waterproofing Chemicals Predicted to Boom in Asia-Pacific in Near Future

With the expansion of the manufacturing and construction industries, on account of the implementation of favorable policies such as ‘Zero Effect and Zero Defect’ by the governments of several countries, the demand for waterproofing chemicals is surging sharply across the world. Moreover, many regulatory authorities and bodies are enacting several guidelines for curbing the escalating pollution levels and creating a model that incentivizes the construction of green and energy-efficient buildings.

This is consequently boosting the demand for waterproofing chemicals around the world. Additionally, the governments of various emerging economies are implementing initiatives for providing basic infrastructure facilities such as access to proper and well-developed roads, concrete-based homes, and better irrigation networks. This is fueling the expansion of the infrastructure and industrial sector, which is, in turn, propelling the requirement for waterproofing chemicals across the globe. Furthermore, these chemicals help authorities mitigate the rapid environmental degradation.

Due to the above-mentioned factors, the global waterproofing chemicals market is set for lucrative growth in the coming years. Waterproofing chemicals are primarily used for protecting buildings from water seepage, as seepages can drastically reduce the overall lifespan of a building and cause health, metal, and electrical hazards. These chemicals also increase the durability of a structure, when they are applied on the exterior. They also increase the shelf life of concrete structures and reduce the maintenance costs of buildings.

Roofing, building structures, walls, and tunnels and landfills are the major application areas of waterproofing chemicals. Amongst these, the usage of these chemicals was the highest in roofing applications in the past. As roof is the most important segment of a building because of its direct exposure to varying weather conditions, waterproofing chemicals are extensively used in roofing applications. Polymer (PVC, EPDM, and TPO) and bitumen (APP and SBS) are the two most widely used types of waterproofing chemicals globally.

Between these two, the demand for bitumen was found to be higher all over the world during the past few years. On the other hand, the sales of polymers will be higher all over the world in the future years, as per the estimates of P&S Intelligence, a market research company based in India. Globally, the sales of waterproofing chemicals were observed to be the highest in the Asia-Pacific (APAC) region in the past.

Moreover, the waterproofing chemicals market is predicted to demonstrate the fastest growth in this region in the forthcoming years as well. This will be a result of the rising requirement for compliance with international manufacturing standards, the surging investments being made in infrastructural development projects, and the presence of a large consumer base in the regional countries. In APAC, the sales of these chemicals were the highest in China in the past.

Hence, it can be said without any hesitation that the demand for waterproofing chemicals will shoot up all over the world in the future years, mainly because of the surging number of construction and infrastructural development projects around the world.

Source: P&S Intelligence

#Waterproofing Chemicals Market Share#Waterproofing Chemicals Market Size#Waterproofing Chemicals Market Growth#Waterproofing Chemicals Market Applications#Waterproofing Chemicals Market Trends

1 note

·

View note

Text

#Waterproofing Chemicals Market#Waterproofing Chemicals Market Trends#Waterproofing Chemicals Market Growth#Waterproofing Chemicals Market Industry#Waterproofing Chemicals Market Research

0 notes

Text

Seamless Protection: Exploring the Polyurea Coatings Market

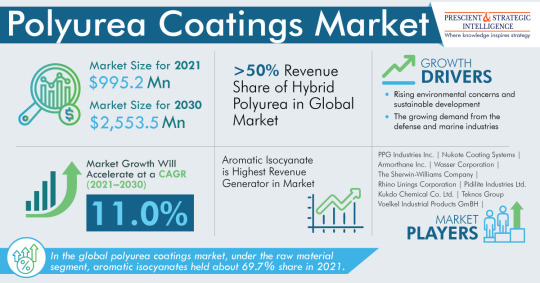

The size of the polyurea coatings market was USD 995.2 million in the recent past, and it will power at a rate of 11% and reach a value of USD 2,553.5 million by 2030, according to P&S Intelligence.

The automotive and transportation sector had the second-largest share, of about 26%. Polyurea coatings are used on the exteriors of vehicles, such as two-wheelers and trucks. They are usually seen on the chassis, driveshafts, gearboxes, and engines, as they provide good resistance to the exterior thermal and physical pressure.

To receive free sample pages of this report@ https://www.psmarketresearch.com/market-analysis/polyurea-coatings-market/report-sample

Consequently, polyurea coatings are becoming popular among automakers. China, Germany and Japan are the top three passenger vehicle producers. Consequently, polyurea coatings’ applications have advanced greatly in these countries. Volkswagen, Mercedes, Audi, Porsche, Opel, and BMW are all part of Germany's extremely competitive automobile industry.

This industry generates about USD 468.5 billion, which accounts to about 20% of the total revenue of the German industry.

Aromatic isocyanates are formulated with the use of benzene and toluene as raw materials. Methylenediphenyl disocyanate and Toulenedisocyanate are two of the most-common aromatic isocyanates used in the construction industry.

The weather of Europe and North America is favorable for the use of aromatic polyurea coatings, which are less expensive than aliphatic substitutions. Aromatic isocyanates are used as a basecoat, meaning they are the first layer applied to any surface. Consequently, they are widely used in vehicles, that is the reason aromatic polyurea coatings market size will grow rapidly.

The requirement for polyurea coating will surge in the APAC with a rate of 11.9% in the years to come. The high-pace monetary growth and substantial investment by private and government companies in numerous sectors, such as maritime, manufacturing, automotive, and construction, are driving the regional demand for industrial coatings.

It is because of the increasing ecological concerns and requirement for sustainable expansion, polyurea coatings had a major place in the coatings sector, garnering high investment in R&D.

#Polyurea coatings#Protective coatings#Industrial applications#Corrosion resistance#Waterproofing solutions#Abrasion resistance#Coating technology#Surface protection#Infrastructure maintenance#Automotive coatings#Flooring solutions#Market trends#Seamless coatings#Chemical resistance#Environmental durability#Spray-on coatings#Application versatility#Market growth#Coating innovation#Future of polyurea coatings.

0 notes

Text

Makeup Maintenance Tips for the Most Awaited D-Day of Your Life!

Whoever said that makeup is an art had it completely right.! With lip gloss on and a gorgeous smile on your face, you can almost conquer the world! If you are one of those who struggle with makeup, we are going to make your life easier with the Best Makeup Artist tips and tricks to make you look instantly glamorous. With the help of these suggestions, you can set your makeup to last longer.

Here are the Best Makeup Tips and Tricks for Every Woman should Know

Want to look prim and proper all day? If you're wondering what techniques to employ to make your makeup last longer, this read has you covered. Listed below are some simple tricks to prolong the effect of your makeup and keep it intact so you look dazzling and flawless all day.

1. Be Light on Foundations

There's something about trends that makes us redefine ourselves in a whole new way. While heavy, full-finish foundations were essential in any previous look, today's women are more receptive to flaws and embrace them by giving their faces minimal to medium coverage. BB creams are a great way to add glow to your face. You can also opt for effective concealers to cover blemishes and layer with a light foundation.

2. Choose Durable Products

To ensure that your makeup lasts all day, you should choose products that offer the best long-wear formulas. Before you buy makeup products, look for ingredients with staying power. Nourishing ingredients oil can help extend the shelf life of products.

3. Prepare with a Primer

The first layer as a base helps the makeup adhere longer and eliminates the possibility of melting. For the upcoming layers, it creates an incredible foundation. With so many products on the market, there is the easy availability of some amazing luxury products like Estee Lauder, Bobbi Brown, Urban Decay, Makeup Forever, MAC, NARS, Fenty, HUDA, Benefit, Charlotte tilbury, etc.

4. Avoid Putting on too much Makeup

As you apply your makeup products, start with a thin layer and use your finger or a makeup sponge to apply the product to your skin. Opt for long-lasting products like waterproof mascara or long-lasting eyeliner, lip liner or lip tints that provide intense pigment without too many layers.

5. Use Waterproof Products

Who loves those panda eyes? No one! So definitely use waterproof formulas as they really help the makeup stick. Avoid watery liquid eyeliners as they are more likely to melt.

6. Use Blotting Paper to Remove Excess Oil

Oil buildup on the skin is one of the main causes of makeup melting throughout the day. Use blotting paper to remove oil buildup on your face. If your skin is naturally oily, use a matte finish or oil-free primer or foundation to prevent excess oil from building up and smudging your makeup.

7. Finish Off with a Setting Spray

Sealing your look is the most vital and effective step in keeping summer makeup woes at bay. While it adds a protective layer to your makeup, it also helps set the foundation to keep you carefree throughout the day.

8. Use Products Formulated for your Skin Type

Using beauty products that suit your skin type keeps your makeup looking fresh throughout the day. If you have dry skin, opt for hydrating makeup products like liquid foundations with hyaluronic acid. Nourishing dry skin with added hydration prevents makeup from chipping and peeling throughout the day. If your skin is prone to oil buildup and breakouts, use a mattifying powder foundation with salicylic acid. As a chemical exfoliant, salicylic acid helps fight blemishes and controls oil production on the skin.

#best makeup artist for bridal#best makeup artist in india#best bridal look#bridal beauty services#bridal makeup#bridal face look#brioso services#bridal fashion#wedding makeup#indian wedding

2 notes

·

View notes

Text

Hazardous Label Market Outlook: Global Trends and Forecast Analysis (2023-2032)

The Hazardous Label Market is projected to grow from USD 1579.7 million in 2024 to an estimated USD 1909.74 million by 2032, with a compound annual growth rate (CAGR) of 2.4% from 2024 to 2032.

The hazardous label market is experiencing steady growth, driven by increasing regulations and safety standards across various industries such as chemicals, pharmaceuticals, agriculture, and manufacturing. Hazardous labels are critical for ensuring the safe handling, storage, and transportation of materials that pose risks to human health, the environment, or property. These labels provide clear identification of hazardous substances and communicate vital information regarding toxicity, flammability, corrosiveness, or other dangers, in compliance with international standards such as the Globally Harmonized System of Classification and Labeling of Chemicals (GHS), OSHA regulations, and other regional mandates. As global trade expands and the movement of hazardous materials becomes more frequent, the demand for accurate and compliant labeling has grown substantially.

Technological advancements in printing and labeling solutions, including durable materials such as waterproof, tear-resistant, and chemical-resistant substrates, are enhancing the performance and reliability of hazardous labels. Additionally, the rise of digital printing technologies allows for quicker turnaround times, customizable labeling options, and improved compliance with stringent labeling regulations. In industries like pharmaceuticals and chemicals, where accurate labeling is critical for regulatory compliance and safety, companies are increasingly investing in sophisticated label solutions to ensure that their products are labeled correctly throughout their supply chains.

Here are the key findings from the study of the hazardous label market:

Growing Regulatory Requirements: The market is being driven by the increasing stringency of regulations across various industries such as chemicals, pharmaceuticals, agriculture, and manufacturing. Compliance with safety standards like the Globally Harmonized System (GHS), OSHA, and other regional regulations is essential for ensuring the safe handling, storage, and transportation of hazardous materials, fueling the demand for accurate and compliant labeling solutions.

Advancements in Durable Labeling Materials: The need for labels that can withstand harsh environments has led to innovations in durable materials. Waterproof, chemical-resistant, tear-proof, and temperature-resistant labels are becoming standard in industries dealing with hazardous substances. These advancements ensure that labels remain legible and intact under extreme conditions, preventing safety risks and non-compliance issues.

Rise of Digital Printing Technologies: The adoption of digital printing technologies is transforming the hazardous label market by offering enhanced customization, faster turnaround times, and more precise labeling options. Digital printing allows for variable data printing, which is crucial for industries where regulatory information needs to be frequently updated. This flexibility and efficiency are helping companies meet evolving regulatory standards.

Increased Focus on Sustainability: There is growing demand for eco-friendly hazardous labels, driven by environmental concerns and corporate sustainability initiatives. Companies are exploring the use of sustainable materials, such as biodegradable or recyclable label substrates, to reduce their environmental impact while maintaining compliance with safety standards.

Strong Growth in Emerging Markets: The hazardous label market is witnessing rapid growth in regions like Asia-Pacific and Latin America, driven by rising industrialization and stricter regulatory frameworks for hazardous materials. These regions are increasingly adopting international safety standards, creating significant opportunities for growth in the hazardous labeling industry.

These findings highlight the market's expansion as industries worldwide prioritize safety, compliance, and sustainability in hazardous material management.

Key Player Analysis:

3M Company

Avery Dennison Corporation

Brady Worldwide, Inc.

CCL Industries Corp.

HERMA GmbH

PPG Industries, Inc.

Reliance Label Solution, Inc.

SATO Asia Pacific Pte. Ltd

UPM Raflatac

Weber Packaging Solutions, Inc.

More About Report- https://www.credenceresearch.com/report/hazardous-label-market

The hazardous label market is characterized by a competitive landscape with both global and regional players vying for market share, driven by increasing safety regulations and the demand for durable, compliant labeling solutions. Key players in the market are focusing on product innovation, expanding their geographical presence, and enhancing production capabilities to meet the rising demand for hazardous labels across various industries, including chemicals, pharmaceuticals, agriculture, and manufacturing.

Key Players and Market Leaders: Major players such as 3M, Avery Dennison, Brady Corporation, CCL Industries, and Intertape Polymer Group are prominent in the hazardous label market. These companies hold a significant market share due to their established product portfolios, global reach, and continuous investment in research and development. These market leaders offer a wide range of hazardous labels that comply with international standards such as GHS, OSHA, and REACH, ensuring their products meet the stringent requirements of safety and durability.

Product Innovation and Technology: Companies are increasingly investing in advanced materials and technologies to offer durable, high-performance labels. Innovation in waterproof, chemical-resistant, heat-resistant, and tear-proof labeling materials has become a critical differentiator. Additionally, digital printing technology is a key area of focus, enabling faster production times, cost efficiency, and high customization. This allows manufacturers to offer variable data printing, which is particularly important for industries where labels need to be updated frequently based on regulatory requirements.

Strategic Collaborations and Acquisitions: To strengthen their market position, many key players are engaging in strategic partnerships, mergers, and acquisitions. These moves help companies expand their product portfolios, enter new geographical markets, and leverage new technologies. For example, acquisitions of smaller, specialized labeling companies allow larger players to gain access to niche markets and cutting-edge technologies, enhancing their competitive edge.

Regional Competition: While North America and Europe dominate the hazardous label market due to stringent regulations and a well-established industrial base, companies are increasingly targeting growth in emerging regions such as Asia-Pacific and Latin America. These regions are experiencing rapid industrialization and stricter enforcement of safety standards, presenting lucrative opportunities for market players. Regional competitors, especially in Asia, are also gaining ground by offering cost-effective labeling solutions that meet local regulatory requirements, creating a more competitive environment.

Sustainability Initiatives: As sustainability becomes a global priority, companies are differentiating themselves by offering eco-friendly hazardous labels. These include labels made from biodegradable or recyclable materials that meet regulatory standards while minimizing environmental impact. This shift towards sustainable solutions is becoming an important factor in the competitive landscape, with companies that successfully innovate in this area gaining a distinct advantage.

In summary, the hazardous label market is highly competitive, with key players focusing on innovation, strategic expansions, and sustainable practices to capture market share. The ongoing shift towards more stringent safety regulations and environmental responsibility is likely to continue shaping the competitive dynamics of the market in the coming years.

Segmentation:

By Printing Technology:

Flexographic,

Digital,

Offset,

By Material Type:

Paper,

Plastic,

By End-Use:

Chemicals,

Pharmaceuticals,

Manufacturing,

Browse the full report – https://www.credenceresearch.com/report/hazardous-label-market

Browse Our Blog: https://www.linkedin.com/pulse/hazardous-label-market-outlook-global-trends-forecast-fyq2f

Contact Us:

Phone: +91 6232 49 3207

Email: [email protected]

Website: https://www.credenceresearch.com

0 notes

Text

Exploring Growth Trends in the Waterproofing Admixture Market: 2024-2034 Forecast

The global waterproofing admixture market has been experiencing substantial growth and transformation from 2021 to 2031. Waterproofing admixtures are crucial components used in construction to enhance the water resistance of concrete and other building materials. They are integral to improving the durability and longevity of structures exposed to harsh weather conditions, moisture, and water ingress.

The global waterproofing admixture market was projected to attain US$ 3.7 billion in 2020. It is anticipated to garner a 7.9% CAGR from 2021 to 2031 and by 2031, the market is likely to attain US$ 8.5 billion by 2031.

The adoption of governmental laws governing VOC emissions and the increase in consumer knowledge of waterproofing admixtures are factors that are limiting demand. Nonetheless, the increasing possibility of high-performance concrete buildings in the regional housing market has greatly increased demand in Europe.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/waterproofing-admixture-market.html

Market Segmentation

The waterproofing admixture market can be segmented based on several criteria:

By Service Type:

Integral Admixtures: These are mixed directly with concrete to provide waterproofing properties.

Surface Applied Admixtures: These are applied to the surface of concrete structures to provide a waterproof layer.

Grouts and Sealants: Used for filling joints and cracks to prevent water ingress.

By Sourcing Type:

Chemical Admixtures: Includes admixtures like polymer-based, crystalline-based, and others.

Natural Admixtures: Derived from natural sources, such as certain types of clay and minerals.

By Application:

Residential Construction: Used in homes and apartments to prevent water damage.

Commercial Construction: Applied in offices, shopping malls, and other commercial buildings.

Industrial Construction: Used in warehouses, factories, and industrial plants.

Infrastructure Projects: Includes bridges, tunnels, and dams.

By Industry Vertical:

Construction & Real Estate

Transportation

Energy & Utilities

Others (e.g., marine, agriculture)

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominated by the U.S. and Canada, this region is characterized by significant investments in infrastructure and residential projects. The market is driven by stringent building codes and regulations.

Europe: The European market benefits from advanced construction technologies and a focus on sustainable building practices. Countries like Germany, France, and the UK are key contributors.

Asia-Pacific: This region is expected to witness the highest growth rate due to rapid urbanization, increasing infrastructure projects, and a booming real estate sector. China and India are prominent markets.

Latin America: Growth in this region is fueled by increasing construction activities and investments in infrastructure development.

Middle East & Africa: The market is growing due to infrastructural developments and the need for durable construction solutions in extreme weather conditions.

Market Drivers and Challenges

Drivers:

Growing Urbanization: The rapid growth of urban areas increases the demand for new construction and infrastructure, boosting the need for waterproofing solutions.

Infrastructure Development: Investments in infrastructure projects, such as roads, bridges, and tunnels, drive the demand for waterproofing admixtures.

Regulatory Standards: Stringent building codes and standards for water resistance contribute to market growth.

Challenges:

High Costs: The high cost of advanced waterproofing technologies can be a barrier for some segments of the market.

Environmental Concerns: The environmental impact of chemical admixtures poses challenges, leading to a growing preference for eco-friendly solutions.

Market Trends

Sustainable Solutions: There is an increasing demand for eco-friendly and sustainable waterproofing admixtures, driven by environmental regulations and consumer preferences.

Technological Advancements: Innovations in admixture formulations and application technologies are enhancing performance and ease of use.

Increased Awareness: Growing awareness about the benefits of waterproofing in enhancing the durability of structures is driving market growth.

Future Outlook

The future of the waterproofing admixture market looks promising, with continued growth driven by ongoing construction activities, infrastructural developments, and advancements in technology. The focus will likely shift towards more sustainable and cost-effective solutions, with increased emphasis on reducing environmental impact.

Key Market Study Points

The market is expected to reach USD 8.5 billion by 2031, growing at a CAGR of 7.9%.

Asia-Pacific will lead in growth due to rapid urbanization and infrastructure development.

Sustainable and eco-friendly solutions are becoming increasingly important in the market.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=7436<ype=S

Competitive Landscape

The competitive landscape of the waterproofing admixture market includes major players such as BASF SE, Sika AG, CEMEX S.A.B. de C.V., and Mapei S.p.A. These companies are focusing on innovation, strategic partnerships, and expanding their product portfolios to maintain a competitive edge.

Recent Developments

Recent developments in the market include the introduction of advanced admixture technologies, collaborations for research and development, and the launch of eco-friendly products. Companies are also investing in expanding their production capacities to meet the growing demand.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Rubber-coated fabrics Market: Stretching its Potential with Steady 3.6% Annual Growth

Introduction

Rubber-coated fabrics are integral to a wide range of applications, from protective clothing and industrial coverings to automotive components. The market for these versatile materials is expanding, driven by their unique properties and increasing adoption across various sectors. This article explores the growth trajectory of the rubber-coated fabric market, highlighting key trends and future projections.

Current Market Trends

Market Size and Growth Rate

As of 2023, the rubber-coated fabric market is valued at USD 6.0 billion. It is expected to grow at a compound annual growth rate (CAGR) of 3.6%, reaching USD 7.8 billion by 2030. This growth is fueled by the expanding use of rubber-coated fabrics in numerous applications and industries.

Key Industry Drivers

The demand for rubber-coated fabrics is driven by several factors, including their durability, flexibility, and resistance to various environmental conditions. Industries such as automotive, construction, and textile manufacturing are major consumers of these materials, further boosting market growth.

Download Sample Report @ https://intentmarketresearch.com/request-sample/rubber-coated-fabric-market-3218.html

Market Segmentation

By Application

Rubber-coated fabrics are used in a variety of applications, including:

Automotive: For seat covers, airbags, and weather-resistant parts.

Construction: For tarpaulins, waterproof coverings, and protective gear.

Textiles: For fashion items, industrial uniforms, and accessories.

By Type of Rubber

Different types of rubber are used in coating fabrics, including:

Natural Rubber: Known for its elasticity and resilience.

Synthetic Rubber: Offers specific properties like oil resistance and durability.

By Region

The market is segmented geographically into:

North America: Strong demand driven by automotive and construction sectors.

Europe: Growth influenced by stringent environmental regulations and technological advancements.

Asia-Pacific: Rapid expansion due to industrial growth and increasing infrastructure projects.

Latin America and Middle East & Africa: Emerging markets with growing adoption rates.

Technological Advancements

Innovations in Coating Technologies

Recent advancements in coating technologies have improved the performance and versatility of rubber-coated fabrics. Innovations such as enhanced adhesion techniques and the development of new rubber compounds are driving market growth.

Impact on Product Performance

Technological improvements have led to better resistance to abrasion, weathering, and chemical exposure, making rubber-coated fabrics more suitable for demanding applications.

Market Share Analysis

Market share analysis reveals a competitive landscape with key players investing in research and development, expanding their product portfolios, and entering new markets to strengthen their positions.

Economic Impact

Contribution to Different Sectors

The rubber-coated fabric industry significantly contributes to various sectors by providing essential materials for protective clothing, industrial applications, and consumer products.

Job Creation and Industry Growth

The industry's growth has led to job creation in manufacturing, research and development, and sales, contributing to overall economic development.

Environmental Impact

Sustainability of Rubber-Coated Fabrics

The environmental impact of rubber-coated fabrics is a growing concern. Manufacturers are focusing on sustainability by using eco-friendly materials and processes.

Eco-Friendly Manufacturing Practices

Efforts are being made to reduce waste, recycle materials, and lower the carbon footprint of manufacturing processes, making rubber-coated fabrics more environmentally sustainable.

Access Full Report @ https://intentmarketresearch.com/latest-reports/rubber-coated-fabric-market-3218.html

Challenges Facing the Market

Raw Material Costs

Fluctuations in the cost of raw materials, such as rubber and chemicals, can impact the pricing and profitability of rubber-coated fabrics.

Regulatory Issues

Compliance with environmental and safety regulations is essential for manufacturers. Navigating these regulations can be challenging and may affect market dynamics.

Opportunities for Growth

Emerging Markets

Emerging markets, particularly in Asia-Pacific and Latin America, present significant growth opportunities due to industrialization and infrastructure development.

Technological Innovations

Continued innovation in coating technologies and material science offers opportunities for developing advanced products with enhanced properties and applications.

Future Market Projections

Forecasting Market Trends

The rubber-coated fabric market is expected to continue its growth trajectory, driven by technological advancements and increasing demand across various industries.

Expected Market Size by 2030

With a projected CAGR of 3.6%, the market is set to reach USD 7.8 billion by 2030, reflecting ongoing growth and expansion.

Consumer Guide

Choosing the Right Rubber-Coated Fabric

When selecting rubber-coated fabrics, consider factors such as durability, resistance to environmental conditions, and specific application requirements.

Factors to Consider

Key considerations include the type of rubber used, coating technology, and the intended use of the fabric. Consulting with suppliers and reviewing product specifications can help make an informed choice.

Competitive Landscape

Analysis of Major Competitors

The competitive landscape of the rubber-coated fabric market includes several key players with diverse strategies. Analyzing their strengths, weaknesses, and market strategies provides insights into the industry's dynamics.

Strategic Initiatives

Companies are pursuing various strategic initiatives, such as partnerships, acquisitions, and investments in R&D, to enhance their market positions and drive growth.

Conclusion

The rubber-coated fabric market is poised for significant growth, driven by technological advancements, increasing demand, and evolving industry needs. As the market expands, opportunities for innovation and development will continue to emerge, shaping the future of this dynamic sector.

Contact Us

US: +1 463-583-2713

0 notes

Text

Neoprene Rubber Prices | Pricing | Trend | News | Database | Chart | Forecast

The neoprene rubber market plays a crucial role in various industries due to its versatility, resilience, and wide range of applications. Neoprene, a synthetic rubber, is known for its resistance to oil, chemicals, heat, and weathering, making it a valuable material for industries such as automotive, construction, electronics, and textiles. However, the prices of neoprene rubber are influenced by several factors, including raw material costs, production processes, market demand, supply chain dynamics, and global economic trends. Understanding the trends and factors driving neoprene rubber prices is essential for businesses that rely on this material for manufacturing and product development.

One of the primary factors affecting neoprene rubber prices is the cost of raw materials, particularly chloroprene, the key ingredient in neoprene production. Chloroprene is derived from petrochemicals, and its prices fluctuate based on crude oil prices, which are subject to global market forces. When crude oil prices rise, the cost of producing chloroprene increases, which, in turn, leads to higher neoprene rubber prices. On the other hand, when crude oil prices stabilize or decline, manufacturers may benefit from reduced production costs, potentially lowering neoprene prices. As a result, fluctuations in oil prices can significantly impact the neoprene rubber market, creating volatility in pricing.

Get Real Time Prices for Neoprene Rubber: https://www.chemanalyst.com/Pricing-data/neoprene-rubber-1309

Another critical factor influencing neoprene rubber prices is the overall demand from various end-use industries. Neoprene is widely used in automotive applications, such as seals, gaskets, and hoses, due to its durability and resistance to extreme conditions. The automotive industry's demand for neoprene rubber is closely tied to the production of vehicles, which can be affected by factors like economic growth, consumer spending, and supply chain disruptions. Similarly, the construction industry relies on neoprene for insulation, sealing, and waterproofing applications. Any changes in construction activity, whether due to economic factors or shifts in government infrastructure spending, can influence the demand for neoprene and, consequently, its price.

In addition to demand from traditional industries, neoprene rubber is increasingly finding applications in the electronics and medical sectors. For instance, neoprene is used in the production of flexible cables, connectors, and medical devices due to its electrical insulation properties and biocompatibility. As these industries expand, the demand for neoprene rubber is expected to grow, potentially driving up prices. Conversely, any slowdown in these sectors could lead to reduced demand and downward pressure on neoprene prices. The development of new technologies and innovations that utilize neoprene in novel applications could also impact the market by creating new avenues for growth or competition from alternative materials.

Supply chain dynamics play a significant role in neoprene rubber pricing. The production of neoprene is concentrated in a few regions, with major producers located in countries such as China, Japan, and the United States. Any disruptions in the supply chain, such as factory closures, transportation bottlenecks, or geopolitical tensions, can lead to supply shortages and price increases. For example, the COVID-19 pandemic highlighted the vulnerability of global supply chains, causing delays in the production and distribution of neoprene rubber. Such disruptions can create temporary spikes in prices as manufacturers struggle to meet demand.

Global economic conditions also have a profound effect on neoprene rubber prices. During periods of economic growth, industries that rely on neoprene, such as automotive and construction, typically experience increased production and investment, leading to higher demand for raw materials like neoprene. This increased demand can push prices upward, especially if supply is limited. Conversely, during economic downturns, demand for neoprene may decrease as industries scale back production, leading to potential price reductions. Additionally, inflationary pressures, exchange rate fluctuations, and trade policies can further complicate the pricing landscape for neoprene rubber.

Environmental regulations and sustainability concerns are increasingly shaping the neoprene rubber market. As governments and industries worldwide place greater emphasis on reducing carbon emissions and minimizing environmental impact, there is growing pressure on manufacturers to adopt more sustainable production practices. This shift may lead to increased production costs for neoprene rubber if manufacturers need to invest in cleaner technologies or meet stricter regulatory requirements. In turn, these additional costs may be passed on to consumers in the form of higher neoprene prices. On the other hand, companies that successfully implement cost-effective, eco-friendly production methods may be able to offer competitive pricing while meeting sustainability goals.

Another factor that could influence neoprene rubber prices is the development of alternative materials. While neoprene remains a popular choice for many applications, there are ongoing efforts to develop synthetic rubbers that offer similar properties at a lower cost or with improved environmental performance. If these alternatives gain traction, they could potentially reduce demand for neoprene rubber, leading to downward pressure on prices. However, neoprene’s unique combination of properties, such as its resistance to oil, chemicals, and weathering, makes it difficult to replace in certain applications, ensuring continued demand in key markets.

Overall, the neoprene rubber market is subject to a complex interplay of factors that influence its pricing. Raw material costs, market demand, supply chain dynamics, global economic conditions, environmental regulations, and the emergence of alternative materials all play a role in determining neoprene prices. For businesses that rely on neoprene rubber for their products, staying informed about these factors is crucial for managing costs and maintaining competitiveness in a rapidly changing market. As industries continue to evolve and new applications for neoprene are developed, the pricing dynamics of this versatile material are likely to remain fluid, requiring close monitoring and strategic planning.

Get Real Time Prices for Neoprene Rubber: https://www.chemanalyst.com/Pricing-data/neoprene-rubber-1309

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Neoprene Rubber#Neoprene Rubber Price#Neoprene Rubber Prices#Neoprene Rubber Pricing#Neoprene Rubber News#Neoprene Rubber Price Monitor

0 notes

Text

The Dye Sublimation Paper Market Has Been Gaining Significant Traction Over The Past Few Years

The dye sublimation paper market has been gaining significant traction over the past few years owing to the increasing demand for various textile printing applications. Dye sublimation paper is used for dye sublimation printing which involves the transfer of dye from the paper to the fabric by application of heat without using liquids. It offers benefits such as high image quality, ability to print on various fabric types, no need for pre or post-treatment of fabric. The rising trends of customized printed apparel has boosted the demand for dye sublimation paper.

Key Takeaways

Key players operating in the dye sublimation paper are Campbell Soup Company, Nestlé S.A., The Kraft Heinz Company, Pacific Foods of Oregon, Bar Harbor Foods, BUMBLE BEE Seafoods, More Than Gourmet, Kettle Cuisine, Bonafide Provisions, College Inn. Key players are focusing on developing innovative product offerings and strengthening their distribution networks to cater to the rising demand.

Dye Sublimation Paper Market Size adoption by sports apparel and promotional products manufacturers. Furthermore, expansion in regions such as Asia Pacific and Latin America driven by growing textile industries will continue to present lucrative growth prospects over the forecast period.

Global expansion of the market will be largely influenced by growing urbanization, rising consumer spending on customized and fashionable apparel, increasing industrial applications of digital textile printing, and policy support for growth of domestic textile industries especially in developing economies.

Market Drivers

The primary driver contributing to the growth of dye sublimation paper market is the rising application of digital textile printing in the apparel and soft signage industries. Dye sublimation printing enables fabric decoration and customization which has increased its adoption over traditional printing methods. Furthermore, the ability to print on various fabric types without requiring pretreatment or chemicals has augmented the application in industries such as sportswear, home furnishings, technical textiles. This has boosted the demand for specialized dye sublimation paper, thereby fueling market growth.

PEST Analysis

Political: The Dye Sublimation Paper Market Size And Trends is impacted by regulatory policies and standards set by governmental agencies regarding usage of environment friendly and sustainable materials in packaging industry.

Economic: Economic growth along with improving disposites incomes boost consumer spending on decorative and photo prints using dye sublimation paper. Fluctuations in paper raw material costs affect profitability of manufacturers.

Social: Increasing population and rapid urbanization create demand for large format decorative and signage prints. Growing e-commerce sector fuels usage of dye sublimation printed banners and signages for branding and campaigns.

Technological: Advances in digital printing technologies help produce vibrant, detailed and durable prints on dye sublimation paper. Investments in R&D of UV resistant and waterproof dye sublimation papers widen their end use applications.

Geographical Regions with High Concentration:

North America holds the largest share of the global dye sublimation paper market, followed by Europe and Asia Pacific. Abundant availability of raw materials and presence of major manufacturers make North America an attractive market for dye sublimation paper.

Fastest Growing Region:

Asia Pacific region is projected to grow at the highest CAGR during the forecast period due to increasing industrial and commercial construction activities in China, India and other developing nations. Rapid infrastructure development and economic growth expand the demand for signage, banners and displays using dye sublimation printing.

Get More Insights On, Dye Sublimation Paper Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

#Dye Sublimation Paper Market Size#Dye Sublimation Paper Market Trends#Dye Sublimation Paper Market Demand#Dye Sublimation Paper#Dye Sublimation Paper Market

0 notes

Text

The Role of TPU Film in Advances in Medical Device Technology

Introduction to TPU Film in Medical Devices

Thermoplastic polyurethane (TPU) film has revolutionized medical device technology with its impressive range of properties and applications. TPU, a versatile material known for its elasticity, chemical resistance, and durability, has become a cornerstone in developing innovative medical devices. This article explores the critical role TPU film plays in advancing medical device technology, emphasizing its benefits, applications, and market dynamics.

Key Properties of TPU Film

TPU film stands out due to its unique combination of mechanical properties, making it ideal for medical applications. Its elasticity allows it to stretch and recover without permanent deformation, which is crucial for devices that need to maintain shape and function over time. Additionally, TPU's chemical resistance ensures that it can withstand exposure to various medical fluids and cleaning agents without degrading. Its biocompatibility is another significant advantage, ensuring that it does not provoke adverse reactions when in contact with human tissues. These properties collectively contribute to the efficacy and safety of medical devices incorporating TPU film.

Applications of TPU Film in Medical Devices

TPU film is utilized in a broad spectrum of medical devices, from wound dressings and catheter tubes to flexible electronics and protective coverings. One of the most notable applications is in wound care products, where TPU film is used to create breathable, waterproof, and flexible dressings that promote faster healing and better patient comfort. In catheter tubes, TPU’s flexibility and durability ensure smooth, reliable performance while minimizing the risk of complications. Additionally, TPU film is employed in the production of medical device housings and protective layers, providing enhanced durability and resistance to external stresses.

Impact on Device Performance and Patient Outcomes

The integration of TPU film into medical devices has had a profound impact on both device performance and patient outcomes. For example, TPU film’s flexibility and strength contribute to improved device functionality, reducing the risk of malfunction and enhancing reliability. This is particularly important in critical applications where device failure could lead to severe consequences. From a patient perspective, TPU film's biocompatibility and comfort features lead to less irritation and a better overall experience with medical devices, facilitating quicker recovery and improved quality of life.

TPU Film Pricing and Market Trends

The pricing of TPU film sheets plays a crucial role in the accessibility and adoption of TPU-based medical devices. The cost of thermoplastic polyurethane sheets can vary based on factors such as thickness, width, and the specific requirements of the medical application. Generally, the price reflects the quality and properties of the film, including its biocompatibility and resistance characteristics. Market trends indicate a growing demand for TPU films in medical applications, driven by advancements in medical technology and an increasing emphasis on patient comfort and device performance.

TPU Film Manufacturers and Their Contribution

In India, the role of TPU film roll manufacturers is pivotal in meeting the growing demand for high-quality TPU films used in medical devices. These manufacturers are equipped with advanced technology to produce TPU films with consistent quality and tailored properties. Their expertise ensures that the TPU films meet stringent medical standards and specifications, supporting the development of innovative and reliable medical devices. The presence of a skilled TPU film roll manufacturer in India also contributes to cost competitiveness in the global market, providing an edge in both innovation and pricing.

Advantages of TPU Film Over Other Materials

Comparing TPU film to other materials used in medical devices highlights its numerous advantages. Unlike traditional materials like silicone or PVC, TPU offers superior elasticity, allowing for more flexible and lightweight designs. Its resistance to abrasion and chemicals further sets it apart, ensuring longer-lasting and more durable medical devices. Additionally, TPU’s ability to be processed into thin, transparent films makes it ideal for applications where visibility and precision are critical. These advantages make TPU a preferred choice for many Thermoplastic polyurethane sheet manufacturers seeking to enhance device performance and patient safety.

Future Prospects and Innovations

Looking ahead, the role of TPU film in medical device technology is expected to expand further with ongoing advancements in material science and manufacturing techniques. Innovations in TPU formulations could lead to new applications and improved properties, such as enhanced biocompatibility or specialized resistance to specific medical environments. Additionally, advancements in manufacturing technologies may reduce production costs and increase accessibility, allowing for even broader adoption of TPU-based medical devices. The continuous evolution of TPU film technology holds promise for further advancements in medical care and device performance.

Conclusion

In summary, TPU film has made significant contributions to the advancement of medical device technology, offering a unique combination of properties that enhance device performance and patient outcomes. The versatility and durability of TPU make it an invaluable material in the medical field, with applications spanning wound care, catheter tubes, and beyond. Economic factors such as Thermoplastic polyurethane sheets price and the role of TPU film roll manufacturers in India also play a crucial role in shaping the market dynamics and accessibility of these advanced materials. As technology continues to evolve, TPU film is poised to remain a key player in the development of innovative and effective medical devices.

The ongoing exploration of TPU film's potential and the continuous improvements in manufacturing processes will likely drive further advancements in medical technology, ultimately benefiting both patients and healthcare providers alike.

Frequently Asked Questions (FAQs)

What factors influence the price of TPU sheets?

The price of TPU sheets is influenced by factors such as raw material costs, manufacturing processes, scale of production, and any custom formulations. High-quality TPU sheets often have a higher price due to their superior properties and the technology used in their production.

Are there TPU film roll manufacturers in India, and how do they contribute to the medical industry?

Yes, TPU film roll manufacturers in India are playing a significant role in the medical industry by providing high-quality TPU film rolls at competitive prices. They contribute to the industry by making affordable and reliable TPU films available to local medical device manufacturers, supporting the growth of the healthcare sector.

What are some common applications of TPU film in medical technology?

Common applications of TPU film in medical technology include wound dressings, surgical drapes, flexible tubing, and catheters. Its versatility and beneficial properties make it suitable for a wide range of medical device applications.

#thermoplastic polyurethane sheet manufacturers#thermoplastic polyurethane sheets price#tpu film roll Manufacturer in India

0 notes

Text

Constructive Chemistry: Unveiling the Innovations in Building Materials

The global Construction Chemicals Market was valued at USD 87.50 billion in 2023 and is projected to reach USD 159.28 billion by 2031, growing at a CAGR of 7.77% from 2024 to 2031.

This comprehensive research study on the global Construction Chemicals market offers detailed analyses of market trends, prominent drivers, and future growth prospects, providing readers with an extensive understanding of the market environment necessary for informed business decisions. Covering various aspects such as estimated market sizing, strategies employed by leading companies, restraining factors, and challenges faced by market participants, the report equips stakeholders with actionable insights.

Get a New Look of Sample PDF:

https://www.kingsresearch.com/request-sample/construction-chemicals-market-644

Market Forecast and Trends

Precise market forecasts and identification of emerging trends enable stakeholders to anticipate the industry’s future trajectory and develop strategic tactics accordingly, providing a competitive edge in a dynamic business landscape.

Regional and Segment Analysis

The study facilitates industry participants in identifying high-growth regions and profitable market segments through region-specific and segment-by-segment analysis. This information aids in devising effective marketing strategies and product lineups tailored to the preferences and needs of diverse target audiences across major regions including North America, Europe, Asia Pacific, Latin America, and the Middle East & Africa.

Investment and Expansion Opportunities

The research report unveils prospective areas for investment and business growth in the global Construction Chemicals market, enabling strategic decision-making for readers seeking to expand into new markets or introduce new products.

Competitive Analysis

In-depth competitive analysis profiles major market competitors and evaluates their strategies, weaknesses, and market shares. Insights into top business strategies employed by key players such as partnerships, alliances, mergers, acquisitions, product innovations, and development empower industry participants to benchmark their businesses against rivals and devise winning strategies for market differentiation.

The major players in the Construction Chemicals Market are:

BASF SE

Dow

RPM International Inc.

Saint-Gobain

MAPEI Corporation

Ardex Group

Fosroc, Inc.

B. FULLER COMPANY

Bostik

Reasons to Purchase This Report:

Futureproof Decisions: Gain precise market forecasts and identify emerging trends to confidently navigate the future of the Construction Chemicals market.

Competitive Advantage: Outperform rivals with a comprehensive competitive analysis, revealing their strategies and market share.

Growth Catalysts Exposed: Uncover the key factors driving market expansion and leverage them to propel your business forward.

Profitable Opportunities: Pinpoint high-growth regions and lucrative market segments through in-depth regional and segment analysis.

Investment Guidance: Strategically plan investments and expansions in the global Construction Chemicals market with insights on potential growth areas.

Informed Decisions: Utilize precise market forecasts and in-depth analysis to make data-driven business decisions.

Market Expertise: Deepen your understanding of market trends and growth drivers for a comprehensive market landscape overview.

Actionable Insights: Gain practical takeaways from the report's competitive analysis, market sizing, and future projections.

The global Construction Chemicals Market is segmented as:

By Type

Adhesives

Concrete Protective Coatings

Bonding agents

Admixtures

Waterproofing

Anchoring materials

By Application

Commercial & Infrastructure

Residential

By Region

North America

U.S.

Canada

Mexico

Europe

France

U.K.

Spain

Germany

Italy

Russia

Rest of Europe

Asia-Pacific

China

Japan

India

South Korea

Rest of Asia-Pacific

Middle East & Africa

GCC

North Africa

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America

0 notes

Text

Global Construction Chemicals Market Trends, Demand and Forecast 2030

Global Construction Chemicals Market size was valued at USD 74.88 billion in 2022, expected to reach USD 123.93 billion in 2030 with a CAGR of 6.5% for the forecast period between 2023 and 2030. Construction chemicals are suitable for a wide range of solutions that are imperatively important in various sorts of construction projects. Construction chemicals are available in numerous varieties that provide effective solutions to infrastructure projects by extending the life and strength of such projects. Construction chemicals are available in different form of categories that are incorporated as hardening agents, coating solutions, waterproofing, etc.

Construction Chemicals Incorporated as Polymer Modified Mortar in the Construction Industry

Different types of construction chemicals are employed during infrastructure construction in various building stages. The explosion in urban population along with developing bridges, tunnels, and dams are prominently driving the construction chemical market. Conventional binders are lacking the strength characteristics and the replacement of such binders with polymers form a new type of polymer-modified mortar. Adding polymers subsequently improves the adhesion characteristics of mortar, imparting toughness, tensile strength, and resistance to few degraded chemicals. Polymer-modified mortar is often commercially available with all suitable ingredients to form strong admixtures.

The Biden administration has cleared a huge amount of USD 550 billion to substantially upgrade infrastructure projects, including roads, bridges, dams, etc. A long bridge in Saudia Arabia is coming into existence, connecting the intersection with the Riyadh-Jeddah highway.

Download sample report- https://www.marketsandata.com/industry-reports/construction-chemicals-market

The Applications of Construction Chemicals in Developing Concrete Curing Compounds

The advancement in creating chemical compounds with mixtures provides impeccable strength, thereby ensuring a smooth appearance on the surface. Concrete curing compounds are one kind of substance that comprises essential waxes, natural resins, and solvents of high volatility. The applied compound on the fresh concrete surface forms a moisture retention film, providing heat reflectance and a visible appearance. The addition of construction chemicals also assists in enhancing chemical resistance, impact, and abrasion resistance and is extensively used on industrial and factory floors.

The United States is recognized as the second largest chemical producing company, accounting for around USD 517 shipments in 2021. During the same year, the chemical industry in the United States reached 10% of all goods exports, where the contribution achieved USD 153 billion. With more than USD 30 billion in investments, the chemical sector to expand capacity and derive towards sustainability.

Construction Chemicals as Dry Mortars for Developing Innovative Building Materials

The strength of commercial as well as residential buildings is subsequently enhanced by incorporating cement and gypsum-based dry mortars. Different formulations are explored for creating dry building materials with significant properties like water retention, utmost strength, and excellent workability. The proper composition of dry mortars delivers distinctive textures in cement, and improves the cohesiveness and appearance of building materials. In forming dry mortars, the microscopic air bubbles should be uniformly distributed that improves workability. Ashland has developed a series of products that substantially assist in controlling rheology, water retention, workability, adhesive strength, deposition, and suspension while minimizing the challenges. Their trademark Aqualon product delivers numerous features like enhancing workability and providing phenomenal properties to dry-mixed building products.

Rise in Construction Activities are Amplifying the Market Growth

Construction chemicals such as water repellants, mortar admixtures, and efflorescence control are chemical substances deployed in the building & construction industry to enhance the tensile strength and performance of building materials, including cement and concrete. Furthermore, the increasing deployment of construction chemicals ensures superior strength, efficient workability, and excellent weather resistance. As a result, construction chemicals are vital for building & construction applications such as residential, commercial, industrial, and infrastructure to ensure excellent resistance. The increasing demand for larger commercial spaces, rising investments in parks, and the ongoing development of mixed-use commercial buildings are the prominent aspects amplifying the commercial construction industry.

For instance, in quarter 2 of 2023, construction of various commercial projects commenced at the global level, including Wadala GST Office Building in India (project completion year 2026), The Great Park Framework Green Space Community in the United States (project completion year 2030), and Forma Mixed-Use Development in Canada (project completion year 2028) are under various stages of construction. Henceforth, the booming development of new building & construction projects is spurring the demand for construction chemicals to ensure superior protection from the external environment. Therefore, the rise in the building & construction activities is propelling the construction chemicals market growth.

Significant Share of the Asia-Pacific in the Overall Market

The building & construction sector in Asia-Pacific is a key industry contributing to the overall economic growth of Asia-Pacific. The growth of construction activities in the Asia-Pacific buildings, surging public-private partnerships for infrastructure development projects, and the construction of new educational institutes.

For instance, as of November 2023, construction projects such as the Yamaguchi City Government Building in Japan (project completion year 2025) and Don Mueang–Suvarnabhumi–U-Tapao High-Speed Railway in Thailand (project completion year 2029) are under the development stage. Moreover, according to the recent statistics published by Invest India, a government of India nodal agency, India’s building & construction sector is projected to reach USD 1.4 trillion in 2025. The prime factors that will drive the growth of the Indian construction industry include an increase in policy support to ensure the rapid pace of infrastructure development projects, the growing population, and the robustly expanding industrial facilities. As a result, the flourishing building & construction activities in the Asia Pacific region are augmenting the demand for construction chemicals, this, in turn, is driving the market growth.

Download Free Sample Report

Impact of COVID-19

The outbreak of COVID-19 has severely impacted numerous sectors and human livelihood where every person was vulnerable to infectious disease. The shutdown of industrial operations due to imposed lockdowns and a workforce impacted numerous sectors, including construction chemicals. The closure of real estate business and workable construction industry has significantly impacted the growth of construction chemicals market. For illustration, according to the data published by Knauf Insulation., a leading insulation company, in 2020, the European Union construction industry registered a decline of 5.1% as compared to the year 2019 as major construction projects associated with high-rise building, infrastructure projects, and commercial buildings were halted in the region.

Likewise, the production of construction chemicals manufacturing facilities was halted since it did not fall under the category of essential products, thereby impacting the overall global supply of construction chemicals. This restricted the growth of the market in the year 2020. But with the ease in imposed conditions the real estate sectors started to recover economy and launched new projects that led it back to the track of development. Consequently, the construction chemicals market has incredible potential with the growth and demand of smart solutions for buildings and constructions.

Report Scope

“Construction Chemicals Market Assessment, Opportunities and Forecast, 2016-2030F”, is a comprehensive report by Markets and data, providing in-depth analysis and qualitative & quantitative assessment of the current state of the Construction Chemicals Market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities and forecast between 2023 and 2030. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/construction-chemicals-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

#Real Estate#Chemicals and Materials#Construction Chemicals Market#Construction Chemicals Market Demands#Construction Chemicals Market Trends

0 notes

Text

Waterproofing Membrane - Key Players Business Strategies Study Report 2024-2033

The waterproofing membrane is a thin layer of water-resistant or waterproof material that is applied to the surface of an object to prevent water from penetrating it. Waterproofing membranes are often used on roofs, walls, and floors to prevent water damage.

Unlock Growth Potential in Your Industry – Get Your Sample Report Now@https://www.globalinsightservices.com/reports/waterproofing-membrane-market/?utm_source=PranaliP-organic

Key Trends

There are several key trends in waterproofing membrane technology. One is the development of more effective and durable membranes. Another is the development of membranes that are easier to install and that have fewer seams. Still, another is the development of membranes that are more resistant to chemicals and UV radiation.

0 notes

Text

Sealing Coatings Market Industry Competition Analysis, Revenue and Forecast Till 2032

The Reports and Insights, a leading market research company, has recently releases report titled “Sealing Coatings Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2024-2032.” The study provides a detailed analysis of the industry, including the global Sealing Coatings Market Trends share, size, and growth forecasts. The report also includes competitor and regional analysis and highlights the latest advancements in the market.

Report Highlights:

How big is the Sealing Coatings Market?

The sealing coatings market size reached US$ 14.9 Billion in 2023. Looking forward, Reports and Insights expects the market to reach US$ 21.4 Billion by 2032, exhibiting a growth rate (CAGR) of 4.1% during 2024-2032.

What are Sealing Coatings?

Sealing coatings are substances applied to surfaces to form a protective layer that guards against moisture, chemicals, corrosion, and other environmental factors. They are utilized on various surfaces like concrete, metal, and wood to prevent harm and prolong the lifespan of the substrate. Commonly used in construction, automotive, and industrial sectors, these coatings enhance durability and preserve the aesthetic appeal of surfaces.

Request for a sample copy with detail analysis: https://www.reportsandinsights.com/sample-request/1788

What are the growth prospects and trends in the Sealing Coatings industry?

The sealing coatings market growth is driven by various factors. The sealing coatings market is experiencing consistent growth due to rising demand for protective coatings across industries like construction, automotive, and manufacturing. These coatings safeguard surfaces against corrosion, moisture, and environmental damage, boosting the longevity of materials. As technology advances and sustainability gains importance, the sealing coatings market is poised for further expansion, offering a variety of solutions to meet the diverse needs of various industries. Hence, all these factors contribute to sealing coatings market growth.

What is included in market segmentation?

The report has segmented the market into the following categories:

Resin Type:

Acrylic

Silicone

Polyurethane

Epoxy

Others

Substrate:

Metal

Concrete & Masonry

Wood

Plastic

Others

End-Use Industry:

Building & Construction

Automotive

Industrial

Marine

Aerospace

Electrical & Electronics

Others

Application:

Roofing

Flooring

Walls & Ceilings

Windows & Doors

Tank Linings

Others

Technology:

Water-based

Solvent-based

Radiation-cured

Powder-based

Others

Sales Channel:

Direct Sales

Distributor Sales

Online Sales

Price Range:

Economy

Mid-Range

Premium

Functionality:

Waterproofing

Corrosion Resistance

Thermal Resistance

Chemical Resistance

Others

Curing Type:

Air Cure

Heat Cure

Moisture Cure

Others

Segmentation By Region:

North America:

United States

Canada

Europe:

Germany

United Kingdom

France

Italy

Spain

Russia

Poland

BENELUX

NORDIC

Rest of Europe

Asia Pacific:

China

Japan

India

South Korea

ASEAN

Australia & New Zealand

Rest of Asia Pacific

Latin America:

Brazil

Mexico

Argentina

Rest of Latin America

Middle East & Africa:

Saudi Arabia

South Africa

United Arab Emirates

Israel

Rest of MEA

Who are the key players operating in the industry?

The report covers the major market players including:

3M Company

Akzo Nobel N.V.

Axalta Coating Systems

BASF SE

Dow Inc.

Henkel AG & Co. KGaA

Hempel A/S

Jotun Group

Nippon Paint Holdings Co., Ltd.

PPG Industries, Inc.

RPM International Inc.

Sherwin-Williams Company

Sika AG

Tikkurila Oyj

Wacker Chemie AG

View Full Report: https://www.reportsandinsights.com/report/Sealing Coatings-market

If you require any specific information that is not covered currently within the scope of the report, we will provide the same as a part of the customization.

About Us:

Reports and Insights consistently mееt international benchmarks in the market research industry and maintain a kееn focus on providing only the highest quality of reports and analysis outlooks across markets, industries, domains, sectors, and verticals. We have bееn catering to varying market nееds and do not compromise on quality and research efforts in our objective to deliver only the very best to our clients globally.

Our offerings include comprehensive market intelligence in the form of research reports, production cost reports, feasibility studies, and consulting services. Our team, which includes experienced researchers and analysts from various industries, is dedicated to providing high-quality data and insights to our clientele, ranging from small and medium businesses to Fortune 1000 corporations.

Contact Us:

Reports and Insights Business Research Pvt. Ltd.

1820 Avenue M, Brooklyn, NY, 11230, United States

Contact No: +1-(347)-748-1518

Email: [email protected]

Website: https://www.reportsandinsights.com/

Follow us on LinkedIn: https://www.linkedin.com/company/report-and-insights/

Follow us on twitter: https://twitter.com/ReportsandInsi1

0 notes

Text

The Rise of Perundurai as a Hub for Industrial Fabrics: A Supplier's Perspective – agaltextiles.in

Introduction:

Perundurai, a bustling industrial town in Tamil Nadu, India, has been quietly rising as a key player in the industrial fabric sector. Known for its strategic location near major transport routes and its robust infrastructure, Perundurai offers a prime spot for industries, including textile manufacturing. In this blog post, we'll explore why an industrial fabrics supplier in Perundurai stands out in the competitive market, the types of products available, and how businesses can benefit from partnering with a supplier based in this region.

Why Perundurai?

1. Strategic Location: Nestled near major highways and close to ports such as Cochin and Chennai, Perundurai is ideally situated for both the import of raw materials and the export of finished products. This accessibility reduces transportation time and costs, a crucial factor in the just-in-time supply chain management prevalent in textile industries.

2. Robust Infrastructure: Perundurai’s industrial estate is supported by Erode District’s proactive policies aimed at boosting industrial growth. The availability of essential services, including steady electricity, water supply, and logistics facilities, makes it a conducive environment for manufacturing operations.

3. Skilled Labor: The region benefits from a pool of skilled labor nurtured by educational and vocational training centers focusing on textile technology. This talent availability is vital for maintaining quality and innovation in industrial fabric production.

What We Offer:

As a leading industrial fabrics supplier based in Perundurai, we specialize in producing a wide range of high-quality fabrics tailored to meet the diverse needs of various industries. Our product lineup includes:

- Technical Textiles: Used in automotive, construction, and healthcare sectors, these textiles offer characteristics such as high tensile strength, durability, and resistance to environmental factors.

- Woven and Non-Woven Fabrics: Suitable for applications ranging from filtration to upholstery, our range ensures versatility and performance.

- Protective Clothing Materials: We provide fabrics that are flame retardant, chemical resistant, and waterproof, crucial for safety in industries like chemical processing and metallurgy.

- Custom Solutions: Understanding that each industry has unique needs, we also offer custom fabric solutions developed in collaboration with our clients to meet specific requirements.

Partnering with Us:

Choosing us as your industrial fabrics supplier means more than just receiving high-quality products. It means entering into a partnership that values:

- Customer Service: Our commitment to customer satisfaction ensures a responsive and supportive service experience.

- Innovation: We continually invest in research and development to stay ahead of industry trends and technological advancements.

- Sustainability: Recognizing the importance of environmental stewardship, we adopt sustainable practices in our manufacturing processes to minimize impact on the environment.

Conclusion:

Perundurai’s growth into a hub for industrial fabrics is supported by its excellent infrastructure, strategic location, and a thriving ecosystem conducive to textile manufacturing. As a supplier based in this vibrant town, we are poised to offer top-notch products and services that cater to the demanding needs of modern industries. Whether you're looking to streamline your supply chain, innovate your product offerings, or ensure the sustainability of your operations, partnering with a Perundurai-based supplier like us could be the strategic advantage your business needs.

📞 Call: +91 95666 50070

📧 Email: [email protected]

🌐 Visit our Website: http://agaltextiles.in/

Address:

Agal textiles

165/6, S.F.No.792/3B, T.K Sellappan Complex,

M.C.Road, Raja street,

Perundurai, 638052

#perundurai#agal textiles#erode#finished fabric supplier#fabric supplier#greige fabric suppliers in erode#home textiles#Greige Fabric Suppliers in Perundurai#institutional fabrics supplier in Erode

0 notes

Text

Future Trends and Growth Projections in the Textile Waterproofing Agents Market

The global high-speed rail coating market, valued at USD 900 million in 2023, is projected to grow at a compound annual growth rate (CAGR) of 6.2% from 2024 to 2034. By the end of this forecast period, the market is expected to reach USD 1.8 billion.

The surge in need for environmentally-friendly water repellency is boosting the textile waterproofing agents market revenue. Eco-friendly perfluorinated compound-free water repellents are in high demand in the textiles sector due to rise in the number of environmentally conscious consumers. This trend is leading to the high adoption of C0 textile hydrophobic treatments.

Download Sample of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=86336

Market Segmentation

By Service Type

Durable Water Repellent (DWR) Coatings: These agents are commonly used for outdoor clothing and gear, providing long-lasting water repellency.

Polyurethane (PU) Coatings: Widely used for both apparel and industrial applications, offering flexibility and durability.

Fluoropolymer Coatings: Known for their superior water repellency and stain resistance, often used in high-performance outdoor wear.

By Sourcing Type

Natural Waterproofing Agents: Derived from natural sources, these are gaining popularity due to the rising demand for sustainable and eco-friendly products.

Synthetic Waterproofing Agents: These include chemically synthesized agents, which are more widely used due to their efficiency and cost-effectiveness.

By Application