#WPC board

Explore tagged Tumblr posts

Text

Top Reasons That Make WPC Board Popular Among Residential Owners

The WPC board's increasing popularity is attributed to its special blend of durability, environmental sustainability, minimal upkeep, and visual attractiveness. Its ability to withstand water, pests, and inclement weather makes it a popular option for both indoor and outdoor uses. With a growing demand for environmentally friendly and affordable materials, WPC board are becoming increasingly popular as a contemporary option that fulfils these requirements, guaranteeing their sustained rise in popularity.

0 notes

Text

WPC Board Wholesaler in Ranchi Jharkhand

WPC Board Wholesaler in Ranchi Jharkhand atulyam decor. Explore top-quality WPC boards for all your construction needs. Choose atulyam decor for excellence and reliability.

#jharkhand#exterior#exterior design#home design#ranchi#jharkhand politics#WPC#WPC Board#wpc boards#WPC Board Wholesaler#WPC Board Wholesaler in Ranchi

0 notes

Text

6 Essential Things To Know Before Purchasing PVC Foam Board

PVC Foam Board is an excellent polymer board used in various applications. It is ideal for all kinds of cabinetry because it is lightweight, waterproof, and strong.

It can be made in various thicknesses and color and is widely used for panels, cabinet doors, construction, and wall sheeting.

Upheld by observation and a deep dive into its application across industries, here’s the list of all the data and basic perspectives to pay special attention to while purchasing a PVC Foam Board in India.

6 Essential Things To Know Before Purchasing PVC Foam Board

When purchasing certain products such as PVC foam sheets or WPC Door Frame, there’s no doubt that JKD Plastics is the best.

Now coming to the article, If PVC is something new to you, you must understand its basics, such as properties, applications, etc.

How are PVC Foam Boards Made?

Petroleum products, resins, and inorganic chemicals manufacture PVC foam boards. After that, these components are combined under controlled conditions and poured into a mould tailored to the intended use. The compound is warmed during this process, permitting it to be shaped or moulded into the ideal form. After that, it is cooled to harden into the desired shape or profile. Depending on the final application, the finished product can be cut, routed, bent, glued, or left in its original state.

Is PVC Foam Boards Water Resistant?

PVC foam boards resist moisture. They also have a particular composition that makes them water-resistant, preventing them from swelling or changing shape when wet. PVC foam boards absorb less than one percent of water, significantly less than wood.

Are they Sturdy Enough?

The molecular structure of PVC foam sheets ensures they remain firm when cooled. Consequently, they are long-lasting and deformation-resistant unless subjected to extreme heat. These foam boards are known to go on for around thirty to forty years without harm, although typical wearing is obvious.

What Are They Mainly Used For?

PVC foam sheets are used in construction and building, advertising and signage, interiors and furnishings, screen printing and graphics, and the refrigeration industry due to their outdoor-friendly properties.

How Can PVC Foam Boards Be Checked For Quality?

PVC foam sheets are quality checked in various ways by various brands. However, the following are some common tests used to evaluate the performance of PVC foam sheets:

Fire Test: PVC foam sheets used in fire tests must have a class A flame spread rating. PVC froth sheets, when in touch with fire, self-quenches.

Moisture Absorption Test: PVC foam sheets are soaked in water. The weight of the PVC foam sheet before it is submerged in water can be compared to that of post-submerging into the water to detect the rate at which it absorbs moisture. PVC should have a water absorption rate of less than 1%.

Strength Test: To see if the foam sheet can withstand direct impact and heavy weight, it is put through a series of strength testing activities.

What is the Price of PVC Foam Boards?

The plastics with the lowest prices are PVC Foam Sheets. It is once in a while more costly than wood; however, when you represent PVCs’ low maintenance qualities, PVC’s long-term cost is much lower than wood.

Why Should You Go For PVC Foam Board in India

Using these boards for your project is optimal due to their durability. This substance is appropriate for use both inside and outside since it resists moisture. PVC foam board can withstand wear and tear over time because it is resistant to scratches, dents, and other forms of damage. Additionally, due to its lightness and strength, PVC foam board is an excellent choice for projects that require flexibility and durability.

PVC foam board is simple to set up. This material can be effortlessly cut and moulded using standard devices, making it simple even for those with minimum Do-It-Yourself experience. Additionally, mounting PVC foam board is simple with various adhesives or screws. PVC foam board is even more cost-effective because you can save time and money on installation costs.

If you wish to own the best PVC foam board or WPC Door Frame, JKD Plastics always delivers the best quality output. After learning about the numerous benefits, it’s normal that you would consider exploring or purchasing a product. Still, you should always go for the best.

Source URL : https://tealfeed.com/6-essential-things-know-purchasing-pvc-b8fcx

#pvc foam board#wpc door frame#wpc manufacturers in india#wpc board#pvc trim board#wpc moulding#wpc doors#pvc foam board exporters in india#wpc chokhat#pvc foam board in india

0 notes

Text

Best 3D Wall Panel Manufacturer in Delhi

leading 3D Wall Panel Manufacturer companies of India having technical merriment rooted at the very zenith of its working hierarchy. Our diverse business interests include PVC Sheet, PVC Panels, Wall Panels Marble Sheets, Laminated Sheet,3D White Panels, 3D HD Sheets, PVC Door, WPC Door, WPC Door Frame, WPC Board, Charcoal Sheet, 3D Foam stickers, Wallpaper, Artificial Grass, ALL IN ONE Bond, etc. We showcase a range of world-class premium products with uncountable designs, colors, textures, and finishes Our products are widely used in homes, schools, offices, showrooms, production plants, hotels, marriage palaces, etc. We have been developing the array from the best possible quality raw materials for adding strength, durability, and performance to the same. Our patrons can avail the range in varied specifications from us as per the demand and need. Founded in 2019, The Bansal Group is one of the leading manufacturing companies of India having technical merriment rooted at the very zenith of its working hierarchy.

Visit Us: 3D Wall Panel Manufacturer

Contact Information:

HEAD OFFICE: Sunam-Mansa Road, Cheema - 148029 (Pb.) India

Phone Number

+91-98759-85955 Anju Sharma (Marketing Head)

Email Address

#leading 3D Wall Panel Manufacturer companies of India having technical merriment rooted at the very zenith of its working hierarchy. Our div#PVC Panels#Wall Panels Marble Sheets#Laminated Sheet#3D White Panels#3D HD Sheets#PVC Door#WPC Door#WPC Door Frame#WPC Board#Charcoal Sheet#3D Foam stickers#Wallpaper#Artificial Grass#ALL IN ONE Bond#etc. We showcase a range of world-class premium products with uncountable designs#colors#textures#and finishes Our products are widely used in homes#schools#offices#showrooms#production plants#hotels#marriage palaces#etc. We have been developing the array from the best possible quality raw materials for adding strength#durability#and performance to the same. Our patrons can avail the range in varied specifications from us as per the demand and need. Founded in 2019#The Bansal Group is one of the leading manufacturing companies of India having technical merriment rooted at the very zenith of its working#Visit Us: 3D Wall Panel Manufacturer

1 note

·

View note

Text

WPC Doors And Frames manufactured by Alstone are 100% waterproof and come with a lot of benefits. With features like Fire retardant, distortion resistant, and great adaptability to outdoor conditions it makes it irreplaceable as compared to other types of Doors.

1 note

·

View note

Text

How to Choose the Best WPC Doors for Your Needs

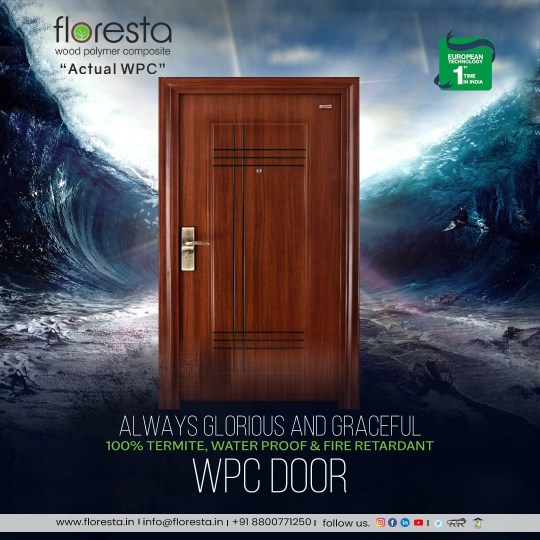

WPC Doors, also known as Wood Plastic Composite doors, have become a popular choice for modern homeowners due to their durability, strength, and low maintenance. They are an ideal replacement for traditional wooden doors, as they offer better resistance to moisture, pests, and other environmental factors. However, with so many options available on the market, it can be challenging to choose the best WPC doors for your needs. In this blog post, we will discuss some key factors that you should consider when selecting WPC doors, and why Floresta Doors is the best WPC company in India.

1. Quality of Material:

The first and foremost factor to consider when selecting WPC doors is the quality of the material used in their production. WPC doors are made by blending wood fibers and thermoplastics, such as PVC, to create a composite material that is both strong and durable. Therefore, it is crucial to choose a WPC company that uses high-quality wood fibers and thermoplastics to ensure the longevity and performance of its products. Floresta Doors uses only the best quality raw materials to manufacture their WPC doors, making them an ideal choice for homeowners who are looking for long-lasting and low-maintenance doors.

2. Design and Style:

The design and style of WPC doors are also essential factors to consider when selecting them. They should complement the overall aesthetics of your home and reflect your personal style. Floresta Doors offers a wide range of WPC door designs and styles to choose from, including flush doors, paneled doors, and designer doors. They also provide customization options to create bespoke designs that perfectly match your requirements.

3. Durability and Resistance:

WPC doors are known for their durability and resistance to environmental factors such as moisture, heat, and pests. Therefore, it is important to choose a WPC company that offers doors that are highly resistant to these factors. Floresta Doors offers WPC doors that are 100% waterproof, termite-proof, and fire-retardant, making them ideal for homes located in areas prone to heavy rainfall or humidity.

4. Maintenance:

Another important factor to consider when selecting WPC doors is their maintenance requirements. Unlike traditional wooden doors, WPC doors require very little maintenance and are easy to clean. However, it is still important to choose a WPC company that provides proper maintenance instructions and after-sales support. Floresta Doors offers comprehensive maintenance instructions and after-sales support to ensure that its customers get the best value for their money.

5. Price:

Finally, price is also an important factor to consider when selecting WPC doors. While WPC doors are generally more expensive than traditional wooden doors, they offer better value in the long run due to their durability and low maintenance requirements. Floresta Doors offers WPC doors at competitive prices, making them an affordable choice for homeowners who are looking for high-quality doors that will last for years.

In conclusion, selecting the best WPC doors for your needs requires careful consideration of various factors, such as quality of material, design and style, durability and resistance, maintenance, and price. Floresta Doors is the best WPC company in India that offers high-quality WPC doors that meet all these requirements and more. With their wide range of designs, customization options, and after-sales support, Floresta Doors is the perfect choice for homeowners who want to invest in durable and low-maintenance doors that will enhance the aesthetics and value of their homes.

Also, Read:

Advantages of Using WPC Boards in Your Home and Office

WPC Decking vs Composite Decking: Which is Right for You?

Follow us:

Instagram

Facebook

LinkedIn

Pinterest

Youtube

Originally Published at: https://florestaproducts.blogspot.com/2023/05/How-to-Choose-the-Best-WPC-Doors-for-Your-Needs.html

0 notes

Text

WPC boards also have interior applications. Some prominent application areas are modular kitchen, wall paneling, wardrobes, window and door frames, bathroom cabinets, railings, office furniture, and industrial section.

WPC boards are also used commercially in advertising. In addition, they are used in making sign boards, exhibition stands, graphics, and display boards.

Wood Plastic Composite is a highly durable and secure material used for cladding purposes. Check out the Advantages and Disadvantages of WPC Boards.

0 notes

Text

Amulya Mica Synchronized Collection: Coordinated Elegance in Laminate Harmony

Discover elevated interiors with Amulya Mica's Synchronized Collection—perfectly coordinated laminates that redefine aesthetics. Immerse yourself in exceptional designs and unparalleled quality, transforming your living spaces with a harmonious blend of style and functionality. Explore the epitome of laminate excellence and elevate your home with the timeless beauty of the Synchronized Collection.

#Amulya Mica#wpc pvc board price#best laminate brand#pvc board sheet#pvc board for kitchen#digital laminates#laminate for walls#laminate designs

2 notes

·

View notes

Text

Denwud: Premium WPC Boards for Durable & Stylish Interiors

Denwud is a trusted name in the industry, offering top-quality WPC boards that combine the strength of wood with the durability of plastic. As a leading provider of eco-friendly building materials, we ensure that our WPC boards are water-resistant, termite-proof, and highly durable, making them perfect for both interior and exterior applications.

Whether you're designing modular kitchens, furniture, wall paneling, or outdoor decking, Denwud’s WPC boards provide a long-lasting and low-maintenance solution. These boards are resistant to moisture, fire, and harsh weather conditions, making them ideal for residential and commercial spaces.

0 notes

Text

When you design furniture for your office or home the durability and quality are the most important factors. Furniture that is built to stand any test will not only helps save money, but increases the functional and aesthetic worth of your home or office. This is why plywood boards take the center stage, especially ones that are termite-proof. These boards are changing the way furniture is made because they offer unmatched resistance to pests, as well as the promise of long-lasting durability.

In this article we will look at the reasons why termite proof plywood boards are essential for furniture that will last a lifetime along with their advantages and how they can be paired together with laminate designs to make stylish and durable interiors.

The Importance of Termite-Proof Plywood Boards

Termites are known for their destructive effects on furniture made of wood, and which can cause severe damage over the course of time. The traditional wood might not have the necessary resistance to fight termites, resulting in weak structures and the necessity to make frequent repair or replacing.

A termite proof plywood boards, however made of special treatments to repel termites efficiently. These boards guarantee that your furniture will remain strong and durable for a long time which makes them an excellent investment for contemporary interiors.

The advantages of termite proof plywood boards are:

Durability Enhances durability as well as resistance against termites.

Cost-Effectiveness Cost-Effectiveness: Lower maintenance costs throughout the duration of the furniture's life.

Eco-Friendliness Numerous options are created using sustainable practices.

Flexibility It is a great choice for many applications including wardrobes to cabinets.

Benefits of Using Plywood Boards for Long-Lasting Furniture

Strength and Stability termite proof plywood boards are constructed with numerous different layers of wood veneers that are glued together in alternate grain directions. This unique design provides extraordinary stability and strength which makes them perfect for furniture that is subject to everyday use and wear.

Resistance to Warping and Cracking As opposed to the solid timber, plywood boards are not as susceptible to shrinking, warping, or cracking with time. That makes them an solid option for furniture in environments that have fluctuating temperatures or humidity levels.

Laminates Enhanced with Laminate Designs Combining termite proof plywood boards with high-end laminate designs can enhance the aesthetic appeal for your furnishings. The vast selection of latest laminates designs by Amulya Mica ensures you'll find the perfect fit to the interior style you prefer regardless of whether it's minimalist contemporary or traditional.

Customizable Solutions By using plywood boards, customizing your home is easy. When you're creating modern kitchen units, beautiful wardrobes or elegant furniture, these tables provide the flexibility of design and function.

Combining Plywood boards with Laminates of High-Quality

The right laminate can turn furniture into works of art. Best Laminates in India by Amulya Mica are known for their quality and selection. Utilizing termite resistant plywood boards as the base, and then embellishing them with matte, high-gloss or texture laminates, you will get a seamless mix of durability and style.

Popular laminate options include:

Matte High Gloss Ideal for contemporary interiors with a sleek and modern look.

Textured Laminates Gives the look and feel of furniture.

Matte Laminates ideal for delicate, understated elegant design.

Applications of Termite-Proof Plywood Boards in Furniture

Kitchen Cabinets Kitchens are extremely susceptible to termite infestations because of water and food debris left behind. The termite resistant plywood boards are a lifesaver for this type of situation as they provide a strong base that can be used to create laminate designs that increase the aesthetic appeal of your kitchen.

Wardrobes and Storage Units Make sturdy storage solutions using plywood boards that will withstand termite damage, making sure that your cabinets and wardrobes remain in great condition.

Office Furniture For office spaces, aesthetics and durability work hand-in-hand. Utilizing termite proof plywood boards paired with the Latest laminates by Amulya Mica ensures that your workplace is stylish and professional.

Doors and Frames You can pair plywood boards with Amulya Mica's amulya wpc frame for doors to get a termite-resistant waterproof, and long-lasting door frame. Its amulya wpc door frame price is affordable and offers excellent value to consumers who are concerned about quality.

Why Choose Amulya Mica for Plywood Boards and Laminates?

Amulya Mica is a trusted brand in the world in the field of Best Laminates in India and offers a wide selection of plywood boards, doors, and laminates. Their termite-proof products are made to be compliant with international standards and guarantee both aesthetics and quality.

What makes Amulya Mica apart?

Creative Designs Keep up-to-date with the latest laminate Designs that will suit any fashion.

Durability Durability: Products that last a long time and made to withstand harsh conditions.

Affordability Pricing that is competitive includes amulya wpc door frame price amulya wpc door frame price and other product categories.

Sustainability Green methods of manufacturing.

Tips for Maintaining Termite-Proof Plywood Boards

To make the most from your termite resistant plywood boards, be sure to follow these guidelines for maintenance:

Cleansing regularly Clean surfaces using a damp or dry cloth to keep dust from building up.

Avoid exposure to moisture Use coasters and mats to stop water damage.

Regular Inspections Look for wear and address them immediately.

Polishing Maintain laminates looking fresh by polishing them regularly.

Final Thoughts

The termite-proof plywood boards are the foundation of sturdy and beautiful furniture. They are not just a shield against pests, but also provide the flexibility, strength and aesthetic worth. When you pair the boards Amulya Mica's laminate designs, you can build furniture that is distinctive while being able to stand the years.

With a focus on quality innovation, sustainability, and quality, Amulya Mica offers everything you require to create interiors that reflect your personal style and fulfill your practical needs. Explore their selection from Best Laminates in India, amulya wpc door frame price, and the latest designs of laminates to make your space more beautiful today.

Learn More :-

Green Plywood Boards : A Step Toward Environmentally Safe Interiors

Why Laminate Designs are a Great Fit for PVC Sheets and Plywood Boards in Creating Sleek, Modern Interior

#plywood boards#amulya wpc door frame price#laminate designs#Best Laminates in India#latest laminates design#pvc laminate#advance pvc laminate#1 mm laminate#0.8 mm laminate#latest mica design

0 notes

Text

How to Safeguard Your Home Interiors During Flood Situations?

Floods can wreak havoc on homes, especially when it comes to interiors. Furniture, cabinets, and fixtures are often the first casualties, leading to significant damage and costly repairs. However, with thoughtful planning and the right materials, you can design interiors that are resilient to water damage. Here are expert recommendations to protect and rescue your home interiors in flood-prone areas.

1. Use 0.8 Density Boards for Inner Cabinet Sections

The inner portions of cabinets are often the most susceptible to water damage due to their porous nature. Opting for boards with a density of 0.8 ensures better resistance against swelling and warping. These boards are less likely to absorb water, maintaining their structural integrity even during prolonged exposure to moisture.

2. Protect Doors and Exposed Sides with 3-Layer WPC Color Boards

Doors and exposed cabinet sides are frequently in contact with water during floods. Using 3-layer WPC (Wood Plastic Composite) color boards offers excellent water resistance. These boards are not only durable but also aesthetically pleasing, ensuring that your interiors remain stylish and functional even in challenging conditions.

3. Opt for Stainless Steel 304-Grade Hardware and Accessories

Floodwater can cause regular metal fittings and accessories to corrode or rust. Investing in stainless steel hardware of 304-grade ensures long-term durability and resistance to rust, even in high-moisture environments. This type of hardware is ideal for hinges, handles, and drawer slides, offering reliability and longevity.

4. Fully Factory-Built Interiors for Precision and Sealing

Factory-built interiors are crafted under controlled conditions, ensuring precision and tight seals that can withstand water exposure. Unlike on-site installations, factory-made products are less prone to gaps and inconsistencies, providing better protection against water ingress.

5. Focus on Resilience Over Cosmetic Flaws

In flood-prone areas, it’s important to prioritize resilience over minor cosmetic imperfections like scratches or external strokes. By choosing materials and finishes designed to endure harsh conditions, you can safeguard up to 80% of your home interiors, minimizing losses during floods.

6. Use Elevated Furniture Designs

Opt for furniture with elevated designs that keep the base off the floor. Raised legs made of waterproof materials like metal or treated wood can protect your furniture from direct contact with water during floods.

7. Seal Wall and Floor Joints

Water often seeps through joints between walls and floors. Properly sealing these joints with waterproof sealants can reduce the risk of water ingress and damage to interiors.

8. Choose Water-Resistant Flooring Materials

Opt for flooring materials such as vitrified tiles, natural stone, or treated hardwood, which are more resistant to water damage. Avoid carpets or untreated wooden floors in flood-prone areas as they can absorb moisture and deteriorate quickly.

9. Install Water-Resistant Wall Cladding

Using water-resistant cladding materials like PVC panels or treated wood can protect your walls from moisture damage. These materials are easy to clean and maintain, even after exposure to floodwaters.

10. Incorporate Modular Furniture

Modular furniture, crafted with water-resistant materials, can be easily moved or lifted during flooding. These designs are not only practical but also add flexibility to your interior layout.

11. Use Waterproof Paints and Finishes

Applying waterproof paints and finishes to walls and furniture can create an additional layer of protection against water damage. These coatings can help prevent swelling, peeling, and discoloration caused by prolonged exposure to moisture.

12. Invest in Floating Shelves and Wall-Mounted Units

Floating shelves and wall-mounted cabinets keep valuables and essentials above potential flood levels. These features ensure that important items remain safe and accessible during flood situations.

13. Reinforce Baseboards and Skirting with Waterproof Materials

Floodwater often damages baseboards and skirting, leading to costly repairs. Reinforcing these areas with waterproof materials like PVC or treated wood can significantly reduce the impact of water exposure.

14. Choose Compact and Minimalist Designs

Compact and minimalist furniture designs are easier to move and protect during floods. This approach also reduces the number of items susceptible to damage, making cleanup and recovery quicker and more efficient.

15. Install Built-In Storage with Raised Bases

Built-in storage solutions, such as wardrobes and cabinets with raised bases, keep contents above flood levels. Elevated designs provide added security for stored items, minimizing damage to valuables.

Final Thoughts

Flood-resistant interiors are not just about damage control; they’re about peace of mind. By incorporating these strategies and materials into your home design, you can significantly reduce the impact of floods on your living space. Preparing for the unexpected is the key to ensuring your home remains a sanctuary, no matter the weather.

For more expert advice and solutions tailored to your needs, reach out to professional interior designers who specialize in resilient home designs

#furniture#kerala#interior designer kerala#interior design#Floods can wreak havoc on homes#especially when it comes to interiors. Furniture#cabinets#and fixtures are often the first casualties#leading to significant damage and costly repairs. However#with thoughtful planning and the right materials#you can design interiors that are resilient to water damage. Here are expert recommendations to protect and rescue your home interiors in f#1. Use 0.8 Density Boards for Inner Cabinet Sections#The inner portions of cabinets are often the most susceptible to water damage due to their porous nature. Opting for boards with a density#maintaining their structural integrity even during prolonged exposure to moisture.#2. Protect Doors and Exposed Sides with 3-Layer WPC Color Boards#Doors and exposed cabinet sides are frequently in contact with water during floods. Using 3-layer WPC (Wood Plastic Composite) color boards#ensuring that your interiors remain stylish and functional even in challenging conditions.#3. Opt for Stainless Steel 304-Grade Hardware and Accessories#Floodwater can cause regular metal fittings and accessories to corrode or rust. Investing in stainless steel hardware of 304-grade ensures#even in high-moisture environments. This type of hardware is ideal for hinges#handles#and drawer slides#offering reliability and longevity.#4. Fully Factory-Built Interiors for Precision and Sealing#Factory-built interiors are crafted under controlled conditions#ensuring precision and tight seals that can withstand water exposure. Unlike on-site installations#factory-made products are less prone to gaps and inconsistencies#providing better protection against water ingress.#5. Focus on Resilience Over Cosmetic Flaws#In flood-prone areas

0 notes

Text

How Did WPC Door Frames Revolutionize Interior Spaces?

The need for long-lasting, aesthetically beautiful, and environmentally responsible materials has led to creative solutions in the constantly changing fields of interior design and construction. The WPC door frame is one such innovation in the building sector. The innovative material known as Wood Plastic Composite, or WPC, combines the best features of plastic and wood to create a durable and eco-friendly door frame replacement. This paper explores the advantages and adaptability of WPC frames, emphasizing the combination of PVC trim boards with WPC doors.

The Evolution of Door Frames

The shift from regular wooden door jambs to the more contemporary and sturdy WPC (Wood Plastic Composite) entryway outlines denotes a huge defining moment in the improvement of building materials. Classic and inviting in design, traditional door frames are made mostly of wood and have an enduring charm. But as both builders and homeowners have discovered, these timber frameworks have intrinsic weaknesses that over time may jeopardize their structural stability.One of the most difficult issues with standard wood entryway outlines is their weakness to clamminess. Since wood is a characteristic material, it can ingest dampness and produce issues like distorting, enlarging, and decaying. Furthermore, the lifetime of conventional timber door frames is seriously threatened by the ongoing danger posed by termites. These reasons made it necessary to investigate substitute materials that could be able to get around these restrictions and offer a more durable answer for building projects. The invention of polyvinyl chloride, or PVC, trim boards was a commendable advancement in the hunt for sturdy and weatherproof door frames. When it comes to extending the life of door frames, PVC has changed the game due to its resistance to moisture, insects, and rot. PVC trim boards provided a degree of protection that was previously unachievable by addressing major flaws with conventional hardwood frames. Essentially, the subtle distinctions between WPC and PVC foam board highlight how crucial it is to match material selections to the particular requirements of any building project in order to achieve the best possible performance, sustainability, and visual appeal.

Benefits of Composite Door Frames

WPC door frames are long-lasting and durable because they are built to last. They have remarkable resilience from the mix of plastic and wood, which keeps them from warping, rotting, or decaying. Over a building's life, this longevity factor drastically lowers maintenance expenses.

Resistance to Moisture

Conventional wood door frames are quite vulnerable to moisture, which can cause swelling and warping. WPC is a great option for places that are frequently exposed to water or have high humidity levels since it offers an impermeable barrier against moisture, along with the added benefit of PVC trim boards.

Termite and Insect Resistance

Wood fibers that are repulsive to termites and insects are frequently used to treat or replace the wood component in WPC door frames. This built-in resistance provides an additional line of defense against typical problems with standard timber door frames.

Eco-Friendly Alternative

WPC door frames stand out as an eco-friendly option in light of the increased emphasis on sustainable construction methods. Because recycled plastic is used, it lessens its influence on the environment, making it a responsible choice for both homeowners and builders.

Design Flexibility

There are many different design options available with WPC frames. The material is pliable and can be molded into a wide range of sizes and forms, enabling complex patterns and personalization. Because of its adaptability to a wide range of aesthetic tastes, WPC frames may be used in any decor.

How Do WPC Doors Create A Perfect Match?

\WPC door frames have many benefits, and WPC doors are the ideal match. Together, they create a symbiotic connection that improves interior spaces' appearance and functionality. Choosing wood-plastic composite (WPC) for the door and door frame guarantees a balanced and uniform material mix. This consistency improves the overall aesthetic coherence of the door assembly in addition to adding to its structural soundness. A comprehensive design approach is made possible by the smooth integration of WPC doors into WPC frames, resulting in a cohesive and aesthetically beautiful interior that enhances the surrounding architecture. Additionally, builders and consumers may customize components like color, texture, and design to fit specific aesthetic preferences because of the great degree of customization allowed by WPC doors, which mirrors the flexibility of its frame counterparts. Because of its uniformity, all-encompassing style, and adaptability, WPC doors are a great option for anybody looking for an all-encompassing and aesthetically pleasing internal space solution.

Conclusion

The introduction of WPC door frames, which provide a robust, visually beautiful, and ecologically friendly substitute for conventional timber frames, has unquestionably transformed interior spaces. The advantages are multiplied when PVC trim boards and WPC doors are combined, forming a synergistic interaction that improves both functionality and aesthetic appeal. WPC frames and doors are a testament to cutting-edge building materials because of their resilience to moisture and insects, as well as their eco-friendliness and adaptability in design. WPC turns out to be the ideal fit for builders and homeowners looking for robust and sustainable solutions since it offers a thorough and innovative approach to contemporary interior design.

#PVC foam board#PVC foam board exporters in India#PVC foam board in India#WPC board#WPC manufacturers in India#WPC door frame#WPC chokhat#WPC moulding#WPC doors#PVC trim board

0 notes

Text

Alstone WPC PRESENTATION BY Mukesh Kharbanda

WPC (Wood Polymer Composite) solid board is a Green Product, which is a complete replacement of Plywood and Timber. Nowadays, WPC boards are widely used for all internal as well as external applications”, such as building façade, Ceiling, flooring, furniture and others buildingConstruction needs.

0 notes

Text

pvc boards in kerala

Denwud specializes in top-quality construction and furnishing solutions, offering a wide range of materials for modern building needs. Our WPC boards and PVC foam boards are ideal for durable, eco-friendly construction, while our PVC foam sheets near me provide versatility for various applications. As trusted multiwood dealers, Denwud is committed to providing high-performance, water-resistant, and termite-proof options that fit your exact requirements. Whether you’re crafting interiors or building exteriors, our innovative materials ensure exceptional quality and style. Choose Denwud for reliable, cutting-edge construction and furnishing solutions tailored to elevate your projects.

#wpc boards in kerala#multiwood brands#multiwood brands in kerala#multiwood dealers#pvc boards in kerala#pvc foam board#wpc boards#multiwood sheets#foam sheets in kerala#pvc foam sheet near me

0 notes

Text

How to Select the Right Plywood Substitute for Furniture and Construction

Plywood has been a cornerstone material in furniture and construction for decades, prized for its versatility and strength. However, growing concerns about deforestation, sustainability, and durability have prompted a shift toward substitutes of plywood. These alternatives are not only eco-friendly but also offer unique advantages that meet modern construction and furniture demands.

If you’re considering making the switch, this guide will help you understand how to choose the right plywood substitute, with a focus on WPC Boards and why brands like Floresta are leading the way in offering high-quality alternatives.

Why Look for Substitutes of Plywood?

Before diving into the options, it’s important to understand why people are turning away from traditional plywood:

Environmental Impact: The production of plywood requires cutting down trees, contributing to deforestation.

Water Resistance Issues: Plywood is prone to warping and damage when exposed to moisture for prolonged periods.

Durability Concerns: Over time, plywood may delaminate or lose its structural integrity.

Sustainability Needs: Eco-conscious consumers and builders prefer materials with a smaller environmental footprint.

What Are the Best Substitutes of Plywood?

Among the available options, WPC Boards stand out as one of the best substitutes for plywood, offering numerous benefits. Let’s explore why WPC Boards and other alternatives should be considered for furniture and construction projects.

1. WPC Boards: A Sustainable Powerhouse

WPC (Wood-Plastic Composite) Boards are a modern, eco-friendly alternative to plywood. Made from a blend of wood fibers and thermoplastics, WPC Boards offer:

Moisture Resistance: Unlike plywood, WPC Boards are completely waterproof, making them ideal for kitchens, bathrooms, and outdoor use.

Termite Proofing: WPC Boards are resistant to termites and pests, ensuring durability over time.

Eco-Friendly Nature: By using recycled materials, WPC Boards help reduce environmental impact.

Versatility: WPC Boards are suitable for furniture, wall paneling, flooring, and other applications.

Floresta: A Trusted Name in WPC Boards

When it comes to high-quality WPC Boards, Floresta is a market leader. Their boards are known for their superior strength, finish, and durability, making them a go-to choice for modern construction and design projects.

2. MDF (Medium-Density Fiberboard)

MDF is another popular substitute for plywood, created by compressing wood fibers with resin and wax. It is ideal for furniture due to its smooth surface and ease of painting or laminating.

Best Use: Interior furniture, cabinetry, and decorative items.

Drawback: MDF is not water-resistant and may swell when exposed to moisture.

3. Particleboard

Particleboard is an economical alternative to plywood, made from compressed wood particles and adhesive.

Best Use: Budget-friendly furniture and temporary construction.

Drawback: Limited durability and poor moisture resistance compared to WPC Boards.

4. Bamboo Boards

Bamboo boards are sustainable and durable alternatives to plywood, crafted from natural bamboo fibers.

Best Use: Eco-friendly furniture and decor.

Drawback: Higher cost compared to other substitutes.

How to Choose the Right Plywood Substitute

Selecting the best alternative depends on your project requirements. Here’s a step-by-step guide:

1. Consider the Application

For furniture that requires water resistance (e.g., kitchen cabinets), opt for WPC Boards.

For decorative items or budget-friendly options, MDF or particleboard can work.

2. Evaluate Durability Needs

If long-term durability is a priority, WPC Boards are an excellent choice.

For short-term or temporary needs, particleboard may suffice.

3. Check Environmental Impact

For sustainable construction, materials like WPC Boards and bamboo boards are ideal.

Ensure the supplier, such as Floresta, follows eco-friendly manufacturing processes.

4. Compare Costs

WPC Boards may have a higher upfront cost, but their durability and low maintenance make them cost-effective in the long run.

5. Aesthetic Appeal

Consider finishes and designs available. WPC Boards from Floresta offer a variety of finishes to suit different aesthetics.

Conclusion

As sustainability and durability become top priorities in furniture and construction, substitutes of plywood like WPC Boards are paving the way for eco-friendly innovation. Among the available options, WPC Boards offer unmatched benefits, including moisture resistance, termite proofing, and sustainability.

Brands like Floresta are leading the charge by delivering high-quality WPC Boards tailored for modern needs. Whether you’re designing furniture, constructing a home, or planning an eco-friendly project, WPC Boards are a reliable and stylish choice.

Explore the possibilities with Floresta’s premium WPC Boards and embrace the future of sustainable materials!

Also, Read:

The Durability of WPC Boards: How They Outperform Traditional Materials

How to Choose the Right Waterproof Plywood Alternative for Your Needs

Originally published at https://florestaproducts.blogspot.com

0 notes

Text

Because they are flexible, thermoplastic, and long-lasting, WPC Boards from Instawud are the ideal alternative to plywood and wood. They have a high level of resistance against termites, wetness, and harsh weather. They won't split, crumble, decay, or warp. They can be utilized for a variety of indoor and outdoor projects, including shutters, furniture, partitions, racks, and shelves.

1 note

·

View note