#Variable Frequency Drive

Explore tagged Tumblr posts

Text

Invt Ht Invt 3175A 3 Phase Variable Frequency Drive - Auto2mation

The INVT HT INVT 3175A 3 Phase Variable Frequency Drive is designed to deliver reliable and efficient motor control in industrial applications. It supports high-performance operation with precise speed control, energy savings, and reduced motor wear. Ideal for pumps, fans, and conveyor systems, this VFD helps improve productivity and system stability. With its robust design, the INVT HT 3175A ensures consistent performance even in demanding environments. Easy to install and user-friendly, it integrates smoothly into existing automation systems. For dependable variable frequency drive solutions, choose Auto2mation, your trusted partner in industrial automation components.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#equipment#automation equipment#Invt#Variable Frequency Drive

0 notes

Text

Variable Frequency Drive for 3-Phase Motor

Discover how a Variable Frequency Drive (VFD) enhances the performance and energy efficiency of 3-phase motors by controlling speed, torque, and power consumption.

0 notes

Text

Variable Frequency Drive (VFD)

Amtech Electronics India Limited is a leading Variable Frequency Drive (VFD) manufacturer in India, established in 1987 and headquartered in Gandhinagar. Specializing in motor control and automation solutions, the company offers a wide range of VFDs, including the Axpert-Eazy+ Series (0.75–2100 kW) and Regenerative VFDs (4Q Series), designed for energy efficiency, precision control, and compliance with global standards like IEEE-519:2014 for harmonics. Their products cater to industries such as cement, automotive, and renewable energy, with clients including Ambuja Cement and Bajaj Auto.

Amtech’s VFDs feature advanced technologies like IGBT-based PWM control, sensorless vector control, and low harmonic distortion (<5%), ensuring robust performance in harsh environments. The company is ISO 9001:2015 certified and adheres to international safety norms (CE, UL, CSA), with a focus on green technology and energy-saving solutions. Their portfolio also includes medium-voltage drives, soft starters, and power quality products like Active Harmonic Filters, supporting India’s Make in India initiative.

With over three decades of expertise, Amtech combines innovation with reliability, making it a trusted partner for industrial automation and sustainable motor control solutions. For more details contact us!

#Variable Frequency Drive (VFD)#Variable Frequency Drive#Variable Frequency Drive Manufacturer#vfd#VFD Manufacturer#VFD Manufacturer in India

1 note

·

View note

Text

Unlock Efficiency with Premium Variable Frequency Drives (VFDs)

Variable Frequency Drives (VFDs) are essential for optimizing motor control and enhancing energy efficiency in industrial, marine, and commercial applications. At Aeliya Marine, we offer an extensive selection of high-quality VFDs designed to meet your specific operational needs.

What is a Variable Frequency Drive (VFD)?

A Variable Frequency Drive is an advanced device that controls the speed and torque of electric motors by varying the frequency and voltage supplied. By doing so, it enables:

Energy Savings : Reduces power consumption during low-load conditions.

Improved Motor Lifespan : Minimizes wear and tear through controlled operations.

Enhanced Process Control : Offers precise adjustments for various applications.

Why Choose VFDs from Aeliya Marine?

Superior Quality : Our VFDs are sourced from trusted manufacturers, ensuring top-notch reliability and performance.

Versatility : Suitable for a wide range of applications, from industrial machinery to marine systems.

User-Friendly Features : Intuitive controls and robust designs for seamless integration.

Durability : Built to withstand demanding environments and operate efficiently under harsh conditions.

Applications of VFDs

Industrial Operations : Control conveyor belts, pumps, fans, and more with precision and efficiency.

Marine Vessels : Optimize engine performance while reducing fuel consumption.

HVAC Systems : Maintain optimal climate control with energy-efficient motor operations.

Manufacturing Units : Streamline processes by adjusting motor speeds to match production demands.

Advantages of Using VFDs

Cost Savings : Cut energy bills significantly with efficient motor control.

Reduced Maintenance : Protect motors from sudden power surges and mechanical stress.

Environmental Benefits : Lower energy usage contributes to a greener operation.

Our Collection of VFDs

At Aeliya Marine, we offer a diverse range of VFDs tailored for various needs. From compact models for small-scale applications to heavy-duty drives for industrial setups, you’ll find the perfect solution to boost your system's efficiency.

Why Aeliya Marine is Your Trusted Partner

Global Reach : Serving customers across industries and locations worldwide.

Expert Support : Our team is here to assist with selecting the right VFD and providing installation guidance.

Customer Satisfaction : Committed to delivering high-quality products and exceptional service.

Take Control of Your Operations Today

Explore our collection of Variable Frequency Drives and revolutionize the way you manage energy and motor performance. With Aeliya Marine, you get cutting-edge technology and trusted reliability.

Empower your operations with smarter solutions for a sustainable future.

#industrial equipment#industrialautomation#automation#industrial spare parts#industrial and marine automation#marine automation#Variable Frequency Drive

0 notes

Text

The Power of VFDs: How Variable Frequency Drives Enhance Industrial Performance

In the Scope of industrial automation, efficiency and control are crucial for optimizing performance and reducing operational costs. Variable Frequency Drives (VFDs) have emerged as a powerful tool in achieving these goals. By allowing precise control over motor speed and torque, VFDs enhance industrial performance across a wide range of applications. This blog explores how VFDs work, their benefits, and their impact on industrial processes.

What Are Variable Frequency Drives (VFDs)?

Variable Frequency Drives (VFDs) are electronic devices used to control the speed and moment of electric motors by varying the frequency and voltage supplied to the motor. Unlike traditional motor control systems that operate at a fixed speed, VFDs adjust motor speed dynamically, based on the specific needs of the application.

A VFD system typically consists of three main components:

Rectifier: Converts incoming AC power to DC power.

DC Bus: Filters and smooths the DC power.

Inverter: Converts DC power back to AC power at the desired frequency and voltage.

How VFDs Enhance Industrial Performance

Energy Efficiency: VFDs are famous for their energy-saving capabilities. By adjusting the motor speed to match the load requirements, VFDs reduce energy consumption. For example, in applications such as fans and pumps, where speed adjustments can lead to significant energy savings, VFDs help lower electricity costs and improve overall energy efficiency.

Improved Process Control: With VFDs, operators can fine-tune motor speeds to optimize process performance. This precise control ensures that machinery operates at the optimal speed for various production stages, leading to enhanced product quality and reduced wear and tear on equipment.

Extended Equipment Life: VFDs reduce mechanical stress on motors and associated components by allowing gradual acceleration and deceleration. This minimizes the impact of sudden starts and stops, extending the lifespan of equipment and reducing maintenance needs.

Reduced Operational Costs: By improving energy efficiency and reducing maintenance requirements, VFDs help lower overall operational costs. The initial investment in VFD technology is often offset by long-term savings in energy bills and maintenance expenses.

Enhanced Flexibility: VFDs offer flexibility in industrial applications, allowing for easy adjustments to motor speed and performance. This flexibility is beneficial for processes that require variable speeds or frequent changes in operational conditions.

Noise Reduction: VFDs can help reduce noise levels in industrial environments by controlling motor speed more smoothly. This is particularly useful in applications where noise reduction is a priority, such as in HVAC systems and manufacturing facilities.

Improved Safety: By providing smoother starts and stops, VFDs contribute to safer operation. This gradual control reduces the risk of mechanical failures and accidents associated with abrupt changes in motor speed.

Applications of VFDs

VFDs are employed across various industries, including:

Manufacturing: For controlling transport belts, pumps, and fans.

HVAC: In heating, ventilation, and air conditioning systems to regulate airflow and temperature.

Water Treatment: To manage pumps and motors in water and wastewater treatment facilities.

Mining: For controlling crushers, mills, and other mining equipment.

Future Trends in VFD Technology

As technology continues to advance, VFDs are becoming increasingly sophisticated. Future trends include:

Integration with IoT: Enhanced connectivity for remote monitoring and control.

Advanced Analytics: Data-driven insights for predictive maintenance and process optimization.

Improved Energy Efficiency: More efficient designs and energy-saving features.

0 notes

Text

youtube

0 notes

Text

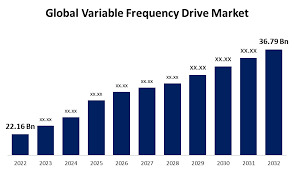

Variable Frequency Drive Market Will Reach USD 35.34 Billion By 2030

The variable frequency drive market is witnessing growth and is projected to reach USD 35.34 billion by 2030. This can be credited to the growing need for energy-effective electrical equipment like fans, motors, and pumps, and rising government guidelines in this field. Fast industrial development is also one of the major reasons propelling the need for these drives. With more and more sectors…

View On WordPress

#energy efficiency#HVAC#industrial applications#Key players#Manufacturing#market trends#Motor Control#Oil & Gas#Variable Frequency Drive#VFD Market

0 notes

Text

https://bresdel.com/blogs/1080730/VFD-Market-Expansion-Fueled-by-Energy-Efficiency-Initiatives-Worldwide

#Variable Frequency Drive Market Share#Variable Frequency Drive Market Trends#Variable Frequency Drive Market Growth

0 notes

Text

Enhancing AHU Performance with PLC-Based Control Systems

Imagine a world where your building breathes in oxygen. Where comfort meets air quality, and where energy is saved. It is the world where AHUs and PLC control systems are the starting point of everything in the domain of Energy management systems.

These AHU controllers (Air Handling Units) are the primary components of any new HVAC system. They serve as the lungs. But to make those lungs breathe better, smarter, and cleaner, you need a brain—enter the Programmable Logic Controllers (PLC).

#plc#plc system#AHU controllers#Programmable Logic Controllers (PLC)#HVAC system.#Energy management systems#IoT enabled PLC#VFDs (Variable Frequency Drives)#PLC automation system#IEC 61131-3 standard

0 notes

Text

Invt HT Invt 3175A 3 Phase Variable Frequency Drive by Auto2mation delivers reliable motor control for industrial applications. With advanced vector control technology, this VFD offers smooth acceleration, precise speed regulation, and strong torque output. Its robust design ensures stable operation under harsh conditions, while built‑in protection features guard against overload, short‑circuit, and overheating. Featuring a user‑friendly interface and flexible communication options, it integrates easily into existing control systems. Compact size saves panel space, and high energy efficiency reduces power costs. The Invt HT 3175A VFD is ideal for pumps, fans, conveyors, and other 3‑phase motor‑driven equipment seeking performance and durability.

#industrial automation#industrial equipment#industrial spare parts#industrial#automation#industrial and marine automation#industrial parts supplier#industrial innovation#automation solutions#Marine Automation#marine equipment#marine spare parts#auto2mation#Invt#Variable Frequency Drive

0 notes

Text

Choosing the Right Variable Frequency Drive Supplier for Your Company

Introduction

Efficiency and energy saving are more today than ever a requirement in the current industrial era. One of the best methods of doing the same is through the utilization of a Variable Frequency Drive (VFD). A VFD helps in electric motor speed control to save energy and prolong equipment life. Nonetheless, in the case of gaining the best from it, selection of a correct variable frequency drive supplier is important. An optimum-quality supplier will give the best products, excellent support, and proper prices.

What is a variable frequency drive?

A Variable Frequency Drive is an electrical driver utilized to vary the torque and speed of an electric motor by modifying the frequency and voltage fed to the motor. A VFD finds widespread applications in manufacturing, air conditioning and ventilation, heating, agriculture, and many more applications. A VFD saves costs on operation and energy and makes the system function at an optimal level by varying the speed of the motor.

Why It Is Vital to Select the Correct Variable Frequency Drive Supplier

It is vital to select the correct variable frequency drive supplier for several reasons. A correct supplier will ensure that you procure quality and reliable VFDs that meet your specific requirements. They provide after-sales service, technical assistance, and warranty to protect your investment.

Considerations While Selecting a Variable Frequency Drive Supplier

1. Product Quality and Reliability

A good VFD is meant to deliver smooth and consistent operation in the long term. Purchase products from a company that trades in well-established brands. There are design features in good-quality drives like overload protection, ease of programming, and efficient cooling systems.

2. Technical Support and Expertise

VFDs can be challenging to install and operate. Your variable frequency drive supplier must be capable of offering efficient technical support in selection, installation, and troubleshooting. You desire suppliers with experienced personnel who can walk you through it.

3. Product Range

Different applications require different types of VFDs. You need to work with a supplier who has a broad portfolio of products, from low-voltage to medium-voltage, and also custom products. This will enable you to obtain a drive that is an ideal fit for your needs.

4. Competitive Pricing

Price is a concern when purchasing VFDs. Compare prices from various suppliers to get the best price. A good variable frequency drive supplier should have reasonable prices without affecting quality.

5. Warranty and After-Sales Service

A good supplier should warranty their products. This ensures that the VFDs are of quality. Also, ask if the supplier has after-sales services, such as maintenance and provision of spare parts.

6. Customer Reviews and Reputation

Prior to a purchase, look up customer testimonials and reviews. A reliable variable frequency drive supplier will have positive customer testimonials. Online forums, social media, and review websites can provide information about a supplier’s reputation.

Advantages of Purchasing from a Reliable Variable Frequency Drive Supplier

1. Energy Efficiency

A quality VFD from a trusted supplier ensures maximum energy savings.

2. Extended Equipment Life

By regulating motor speed, VFDs decrease equipment wear and tear. Your equipment will be shielded from undue stress and damage by drives that a quality variable frequency drive supplier will deliver.

3. Enhanced Process Control

VFDs offer high accuracy in control of motor speed, and this enhances the performance of the overall system. Across manufacturing, HVAC, and water treatment, a good VFD promotes productivity and efficiency.

4. Reduced Maintenance Costs

A well-constructed VFD minimizes electrical and mechanical stress on motors, thus requiring fewer repairs. Buying from a reputable variable frequency drive supplier ensures that you are the owner of a product that will serve you for a long time without the need for regular maintenance.

How to Shop for the Best Variable Frequency Drive Supplier

1. Shop Online

Use search engines, review sites, and internet discussion boards to search for high-rated VFD suppliers. Locate companies with excellent ratings and customer reviews.

2. Check Certifications

An industry-competent variable frequency drive supplier ought to be confident to provide compliant products with the appropriate quality and safety level.

3. Ask Reference

Business associates, trading partners, and peers may refer actual suppliers in their experience.

4. Quote and Compare

Obtain quotations from a minimum of three different suppliers and compare price, warranty, and service before making the decision.

Conclusion

Choosing a reputable variable frequency drive supplier is what will result in high-performance VFDs that enhance energy efficiency, extend equipment life, and provide improved control of operations. Depending on the quality of products, technical support, prices, and customer ratings, you can find a reputable supplier that meets your business. Take your time and be cautious in your research to choose an option that will be a long-term investment for your business. Originally Published Here:-https://nmagroup.in/variable-frequency-drive-supplier-for-your-business/

0 notes

Text

Top Benefits of Using VFDs in Your Facility

Today, with a focus on energy efficiency, automation, and cost savings, companies in all industries are seeking to optimize their operations and minimize their environmental footprint. One of the most effective technologies that has changed how electric motors are operated in facilities is VFD (Variable Frequency Drive).

A VFD adjusts an electric motor's speed by altering the supplied frequency and voltage. In other words, it can vary the speed of the motor to meet the needs of the process or equipment. In the past, and before the use of VFD technology, motors would always operate at full speed, even when not required, wasting a lot of electricity.

With VFD technology, motors can vary their speed based on real-time demand and achieve maximum efficiency. The use of such technology is benefiting many types of facilities, including manufacturing plants, commercial buildings, and agricultural operations. This is why demand for good variable frequency drive manufacturers has also increased. Knowing about the benefits of VFDs is important for facilities.

Extend the Lifespan of Equipment

Motors that start and stop suddenly or operate at high speeds continuously wear out sooner and experience more stress. A VFD assists in starting it slowly and operating it at lower speeds in a controlled way. The soft start feature and smooth operation lower mechanical stress, which equates to less wear and tear on motor components like bearings, gears, and belts.

A VFD from reputable variable frequency drive manufacturers extends the life of your equipment. Additionally, fewer breakdowns mean lower repair costs, less downtime, and less maintenance costs. Ultimately, this can result in more reliable and stable operations of your facilities over time.

Less Demand for Peak Energy

Generally, the electric service companies impose higher charges on the consumers during the peak hours of electricity consumption. The activation of motors at full speed causes an instantaneous jump in heavy energy consumption, along with greater bills to the utilities.

The VFDs reduce the peaks by starting the motor slowly instead of running it at speed. They ensure a controlled speed. That could make a huge difference in your energy bills, especially with several motors running at the same time. Better management of peak demand would lead to avoiding penalties from the power company and lower overall costs of electricity. Explore multiple variable frequency drive manufacturers and buy from the one that provides the best quality.

Reduced Emissions

Using less energy is not only a money saver, but it also protects the environment. When your facility uses less electricity, you are reducing the demand on power plants, which typically burn fossil fuels in generating energy. Less energy used means there is a reduction in the number of greenhouse gases, including carbon dioxide, emitted into the atmosphere.

When your facility implements VFDs from VFD manufacturers, it can help mitigate climate change and meet environmental standards or goals. Governments and industry organizations promote energy efficiency technology now. Therefore, by utilizing VFDs, you can help meet that requirement and perhaps gain a green certification.

Less Noisy Operation

Conventional motor systems can be quite noisy, particularly when running at full speed. This noise can be excessive, especially in office buildings, commercial kitchens, or in residential spaces near some sort of industrial facility. Since VFDs allow motors to run at lower speeds when they may not need to run full power, they also reduce noise levels. A quieter operation helps create a better working environment for the employee and is more acceptable in noise-sensitive locations.

0 notes

Text

The Role of a Variable Frequency Drive Manufacturer in Modern Industrial Applications

Variable Frequency Drives (VFDs) have proven essential in industrial automation because they improve both energy efficiency and operational flexibility. The principal role of a Variable Frequency Drive manufacturer lies in creating essential devices to manage electric motor speed and torque through their design and production stages. Such industrial applications as manufacturing and HVAC systems and water treatment plants with renewable power setups prove that variable frequency drives transform system dynamics while improving power management.

This article covers essential VFD manufacturing aspects together with device advantages while explaining why selecting the correct manufacturer matches your business requirements.

What is a Variable Frequency Drive (VFD)?

Variable frequency drive manufacturer operate as electronic controllers which manage electric motor speed and torque performance through voltage and frequency power adjustments. Businesses gain efficiency while reducing power usage through the adjustable capabilities of this modulation.

Key Components of a VFD include:

Rectifier: The device transforms alternating current power to generate direct current power.

DC Bus: Stores the converted power.

Inverter: An inverter changes direct current power to alternating current with programmable frequency together with voltage parameters.

Benefits of Using a Variable Frequency Drive

Energy Efficiency

Variable frequency drive manufacturer deliver substantial energy savings through speed control following actual usage patterns which leads to reduced electricity expenses in high-energy industrial contexts.

Extended Equipment Life

Machines benefit from increased longevity because Variable frequency drive manufacturer deliver smooth acceleration and deceleration sequences which minimize mechanical component damage.

Enhanced Process Control

Controlled speed and torque capabilities enable operators to refine manufacturing processes thus leading to better quality outputs.

Reduced Operating Costs

The simultaneous reduction of energy bills and maintenance fees yields important financial savings in operating costs.

Eco-Friendly Operation

Environmental sustainability benefits from Variable frequency drive manufacturer

because they decrease energy use and reduce greenhouse gas emissions.

Key Industries Benefiting from VFDs

Manufacturing:

The control of conveyors along with pumps and fans in automotive textiles and food processing industries depends on VFD devices for efficient production cycles.

HVAC Systems:

The operation of fans and compressors depends on VFDs which enable correct speed control for both devices to maintain optimal indoor climate conditions.

Water Treatment:

Variable Frequency Drives serve to control motors and pumps for improving the operational efficiency of water supply programs and sewage systems.

Renewable Energy:

VFDs function in solar and wind energy systems to optimize inverter and generator operations for maximum power outcomes.

How to Choose the Right Variable Frequency Drive Manufacturer

1. Product Range and Customization

Select a manufacturer which delivers their products across a broad range that encompasses low-voltage medium-voltage and high-performance VFDs. Special customization functions enable manufacturers to meet unique industry conditions.

2. Reliability and Durability

Choose manufacturers who demonstrate a strong history of building durable reliable equipment designed to face demanding industrial applications.

3. Energy Efficiency Features

The inclusion of future-minded technologies through energy recovery systems and advanced motor control algorithms enables manufacturers to achieve maximum system efficiency in their designs.

4. Technical Support and After-Sales Service

A successful operation requires complete assistance from the supplier that includes installation setup as well as problem-solving support and equipment maintenance assistance.

5. Certifications and Compliance

Makers should require manufacturers to establish conformity with international standards, including ISO, IEC, and CE standards which prove their quality and product safety requirements.

Innovations in Variable Frequency Drive Technology

The ongoing development of variable frequency drive technology influences how we automate industrial systems. Here are some emerging trends:

IoT-Enabled VFDs

Current variable frequency drives on the market integrate IoT functionality to allow remote device monitoring combined with predictive maintenance abilities and real-time output analysis.

AI and Machine Learning Integration

Through artificial intelligence integration Variable Frequency Drives can match operational needs by adjusting performance levels for optimized operational results.

Compact and Modular Designs

Manufacturers are focusing on creating smaller, modular VFDs that are easier to install and maintain.

The Future of VFD Manufacturing

The demand for Variable Frequency Drives is going to be a significant growth, mainly because energy costs are going up, the push for sustainability, and also the advancements in automation technologies. VFD manufacturers like Folinn are best suited to lead the growth curve through consistent innovative and reliable solutions.

Conclusion

Variable Frequency Drives are a part of the modern industrial system that provides energy efficiency, versatile process control, and cost savings like no other equipment. Choosing the right manufacturer is very important for the success and longevity of your equipment.

A trusted variable frequency drive manufacturer, Folinn is one of the top representatives of the industry, utilizing advanced technology, robust performance, and eco-friendly designs to deliver to a wide range of industry demands worldwide.

1 note

·

View note

Text

Model Part Number

IP20 rated enclosure

🚨ODV-3-843700-3F12-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-843700-3R12-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODV-3-844800-3F12-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-844800-3R12-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

IP55 / NEMA12 rated enclosure

🚨ODV-3-843700-3F1N-MN (300HP 370A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-843700-3R1N-MN (300HP 370A 380-480V 3Ph High Performance EMC Filter)

🚨ODV-3-844800-3F1N-MN (400HP 480A 380-480V 3Ph Standard EMC Filter)

🚨ODV-3-844800-3R1N-MN (400HP 480A 380-480V 3Ph High Performance EMC Filter)

The VFD Exchange

#vfds#drives#variable#frequency#drive#invertekdrives#industrialcontrols#electricmotor#automation#fans#pumps#compressors#farming#irrigation#ventilation#hvac#speed#torque#optidrive#invertek#electrical#motors

0 notes

Text

Driving Energy Savings: Insights into the Global Variable Frequency Drive Market

The global variable frequency drive market size is estimated to reach USD 39.67 billion by 2030, registering a CAGR of 5.9% from 2025 to 2030, according to a new report by Grand View Research, Inc. The rapid development of semiconductor technology and rising consumer awareness of the benefits of energy-efficient products are two factors anticipated to fuel the expansion of the market. Similarly, the rising energy demand worldwide and the use of variable frequency drives (VFDs) to regulate the flow and speed of the fan to prevent energy loss are anticipated to promote the growth of the global market in the years to come.

More than 90% of the energy expended in the U.S. is used by residential refrigeration and HVAC systems equipment. VFDs aid in managing the speed of the motor in HVAC systems and reduces power consumption, which is expected to boost the growth of the market. Rising awareness about conserving energy and approaches to reducing excessive energy consumption is expected to increase demand for these devices. Additionally, rising demand for variable frequency drives from the food and beverage, automotive, and oil and gas industries are anticipated to promote market expansion.

The expansion of the market is anticipated to be hampered by the high cost of the product and maintenance. Furthermore, a workforce shortage is anticipated to pose a threat to market expansion. However, rising expenditure in the distribution and power generation industry as well as rising global oil & gas extraction operations are likely to open up new prospects for market participants in variable frequency drive in the years to come.

The global COVID-19 pandemic has had a big impact on the growth of the VFD market. In the industrial sector, variable frequency drives are frequently employed. The government's stringent lockdown and the closure of factories, however, reduced demand for variable frequency drives. In the 2nd quarter of 2022, the market for VFDs is anticipated to expand as previously halted production activities resume, thus reviving the market growth.

Variable Frequency Drive Market Report Highlights

By end-use, the oil & gas segment held the largest revenue share in 2024.

The AC drives segment dominated the market with more than 68.9% share in 2024 and is expected to continue leading the market with increasing demand from the industrial sector for equipment with less noise and maintenance.

Asia Pacific dominated the market with a revenue share of 34.5% in 2024. This can be attributed to rapid industrialization in emerging economies and increasing demand from the water treatment sector.

Variable Frequency Drive Market Segmentation

Grand View Research has segmented the global variable frequency drive market based on product type, power range, application, end-use and region:

Variable Frequency Drive Product Type Outlook (Revenue, USD Billion, 2018 - 2030)

AC Drives

DC Drives

Servo Drives

Variable Frequency Drive Power Range Outlook (Revenue, USD Billion, 2018 - 2030)

Micro (0-5 kW)

Low (6-40 kW)

Medium (41-200 kW)

High (>200 kW)

Variable Frequency Drive Application Outlook (Revenue, USD Billion, 2018 - 2030)

Pumps

Electric Fans

Conveyors

HVAC

Extruders

Others

Variable Frequency Drive End Use Outlook (Revenue, USD Billion, 2018 - 2030)

Oil & Gas

Power Generation

Industrial

Infrastructure

Automotive

Food & Beverages

Others

Variable Frequency Drive Regional Outlook (Revenue, USD Billion, 2018 - 2030)

North America

US

Canada

Mexico

Europe

Germany

UK

France

Asia Pacific

China

Japan

India

South Korea

Australia

Latin America

Brazil

Middle East and Africa (MEA)

KSA

UAE

South Africa

Order a free sample PDF of the Variable Frequency Drive Market Intelligence Study, published by Grand View Research.

0 notes

Text

The Evolution and Advantages of a VFD Pump in Industrial Applications

The introduction of Variable Frequency Drive (VFD) pumps is considered a tremendous advancement in pump technology. Unlike standard pumps that function at a fixed speed, VFD pumps can control the speed of their motors to match variable requirements this feature proves to be a remarkable development in energy savings and improves efficiency during operation. In today's time, the importance of this capability is more than ever since sustainability and cost-effectiveness spell the very life of industry. VFD pumps optimize the speed control of the pump motor, thereby minimizing energy consumption and reducing the number of components that wear down improve process control, thus proving its worth in all industries.

#Automation#PLC#VFD#Automotive#Tech#information technology#technolgy#plc automation#vfdsystem#vfd#Variable Frequency Drive (VFD)#acdrives#ac drives#allen bradley#Rockwell Automation

1 note

·

View note