#Torque Sensor Market

Explore tagged Tumblr posts

Text

Torque Sensor Market: Current Analysis and Forecast (2024-2032)

According to the UnivDatos Market Insights analysis, the increasing adoption in the automotive industry for fuel-efficient vehicles, the rising demand for precise measurement in industrial automation, and advancements in medical devices requiring high-precision torque control will drive the global scenario of the Torque Sensor market. As per their “Torque Sensor Market” report, the global market was valued at USD 7.8 Billion in 2023, growing at a CAGR of 5.8% during the forecast period from 2024 - 2032 to reach USD XX Billion by 2032.

The torque sensor market is witnessing robust growth, driven by the increasing demand for precise torque measurement across various industries such as automotive, aerospace, and industrial automation. In the automotive sector, the need for accurate torque measurement is paramount for optimizing engine performance, improving fuel efficiency, and ensuring the reliability of vehicle components. The rise in electric and hybrid vehicle adoption further amplifies this demand, as these vehicles require advanced torque measurement solutions to manage electric motor performance and battery efficiency. Technological advancements in sensor design, including wireless and non-contact torque sensors, are enhancing the efficiency and performance of these applications.

In the industrial sector, torque sensors are integral to the automation and robotics industries, where precision and efficiency are critical. The adoption of Industry 4.0 practices has led to increased utilization of torque sensors in manufacturing processes to ensure operational accuracy and product quality. Additionally, the aerospace and defense sectors rely on torque sensors for testing and monitoring aircraft components, ensuring safety and performance standards are met. These sectors' focus on innovation and high-performance standards continues to drive the adoption of advanced torque sensor technologies.

Looking forward, the torque sensor market is poised for sustained growth. Companies are investing heavily in research and development to create innovative, cost-effective torque sensors that cater to the evolving needs of various industries. Expansion into emerging markets, particularly in the Asia-Pacific region, offers significant growth potential due to rapid industrialization and increasing automotive production. Moreover, strategic partnerships and collaborations are facilitating the development of integrated solutions, enhancing value for end-users. Overall, the market's future looks promising with continued technological advancements and strategic investments from key industry players.

Increasing Adoption in the Automotive Industry:

The automotive industry is a significant driver for the torque sensor market. As the demand for high-performance and fuel-efficient vehicles increases, manufacturers are integrating advanced torque sensors to monitor and optimize engine and drivetrain performance. These sensors play a crucial role in electric vehicles (EVs) and hybrid vehicles, which require precise torque measurements to enhance energy efficiency and performance.

Example: The European Union's "Green Deal" and the accompanying "Fit for 55" package aim to reduce greenhouse gas emissions by 55% by 2030. These policies include stringent regulations on vehicle emissions and fuel efficiency, pushing automakers to adopt advanced technologies, including torque sensors, to meet these targets.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=63672

Growing Demand in Industrial Automation:

Industrial automation is another key driver for the torque sensor market. With the rise of Industry 4.0, there is a growing need for accurate and real-time torque measurement in various automated processes. Torque sensors are essential in ensuring the proper functioning and safety of automated machinery, leading to improved productivity and reduced downtime in manufacturing and production facilities.

Example: The German government's "Industrie 4.0" initiative supports the widespread adoption of advanced manufacturing technologies, including torque sensors. This policy includes financial incentives and subsidies for companies investing in automation and smart factory technologies, encouraging the integration of torque sensors in industrial applications.

Advancements in Medical Devices:

The medical sector is increasingly utilizing torque sensors in various applications, such as robotic surgery, prosthetics, and rehabilitation devices. The precise measurement of torque is critical in these applications to ensure the safety and effectiveness of medical devices. As the healthcare industry continues to advance, the demand for high-precision torque sensors is expected to grow significantly.

Example: The U.S. Food and Drug Administration (FDA) has implemented policies that support the development and approval of advanced medical devices, including those that use torque sensors. The FDA's Breakthrough Devices Program, for instance, provides expedited review and approval processes for innovative medical technologies, encouraging the adoption of advanced sensors in medical devices.

Conclusion

The torque sensor market is experiencing significant growth driven by three major factors: the increasing adoption in the automotive industry, the growing demand in industrial automation, and advancements in medical devices. Government policies play a pivotal role in accelerating this growth by providing regulatory support and financial incentives. The European Union's "Green Deal" and "Fit for 55" package are pushing the automotive sector towards greater efficiency and lower emissions, thereby fostering the adoption of torque sensors. Similarly, Germany's "Industrie 4.0" initiative is promoting the integration of advanced manufacturing technologies, including torque sensors, in industrial automation. In the medical sector, the U.S. FDA's supportive policies for innovative medical devices are encouraging the use of precise torque measurement technologies in cutting-edge medical applications. These combined efforts are shaping a robust and dynamic torque sensor market, poised for continued expansion and innovation.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

[155 Pages Report] According to MarketsandMarkets, the torque sensor market size is projected to grow from USD 6.8 billion in 2021 to USD 9.0 billion by 2026

0 notes

Text

Automotive Steering Torque Sensors Market is Estimated to Witness High Growth Owing to Increasing Demand

Automotive steering torque sensors play an important role in steering systems by directly measuring the rotational forces applied to the steering shaft. They are primarily utilized in advanced driver assistance systems such as electronic power steering, automobile stability control, and anti-lock braking systems. The growing emphasis on vehicle safety and introduction of autonomous driving technologies are expected to drive the demand for automotive steering torque sensors over the forecast period.

The Global Automotive Steering Torque Sensors Market is estimated to be valued at US$ 8589.78 Mn in 2024 and is expected to exhibit a CAGR of 7.9% over the forecast period 2024 to 2031.

Key Takeaways Key players operating in the Automotive Steering Torque Sensors are Robert Bosch Gmbh, Denso Corporation, Crane Electronics, Honeywell International, Sensor Technology, Valeo, TE Connectivity, Kistler Instruments Pvt. Ltd., Norbar Torque Tools Ltd., Bourns, Inc., Advanced Micro Electronics Co. Ltd., Methode Electronics, Inc., and others. The key players are focused on developing innovative torque sensors with enhanced accuracy and durability.

The Automotive Steering Torque Sensors Market Size is expected to create significant opportunities for automotive steering torque sensor manufacturers. Furthermore, the increasing adoption of autonomous vehicles will further propel the demand.

Globally, the Asia Pacific region dominated the market and is expected to exhibit the highest CAGR during the forecast period. China, Japan, and India have emerged as major markets for automotive steering torque sensors owing to increasing automotive production and sales.

Market drivers The increasing demand for advanced driver assistance systems in passenger and commercial vehicles is a major factor driving the growth of automotive steering torque sensors market. Features like stability control, traction control, anti-lock braking help in improving road safety. Furthermore, the growing adoption of electric power steering systems that utilize torque sensor technology is also fueling the market growth. Stringent safety norms especially in European and North American regions have further promoted the integration of torque sensors in vehicle steering systems.

PEST Analysis Political: The Automotive Steering Torque Sensors Market Size And Trends is governed by strict regulations regarding automotive safety and emissions. Manufacturers must comply with regulations for vehicle automation, driver assistance systems and functional safety standards.

Economic: The global economy recovery is driving automotive production and sales which is positively impacting the demand for automotive steering torque sensors. rising disposable incomes in developing countries is increasing vehicle ownership.

Social: Technology features such as driver assistance, autonomous driving, and connected vehicles are increasingly being adopted. Sensors play a key role providing input data to driver assistance systems. Safety and reliability are important considerations for consumers.

Technological: Advancements in sensor design, materials, and manufacturing processes are improving sensor accuracy, response time and durability. Technologies integrating multiple sensors and software are enabling advanced driver assistance and autonomous driving capabilities. Connectivity integration in sensors allows remote diagnostics.

In terms of value, Asia Pacific holds the largest share of the automotive steering torque sensors market due to high production volumes in China, India, Japan and South Korea. Europe is also a major region supported by strong automotive manufacturing presence in Germany, France, Italy and UK.

North America is anticipated to exhibit the fastest growth during the forecast period owing to rising demands for electric and autonomous vehicles in the US and Canada. Government mandates and investments to develop autonomous vehicle infrastructure will drive additional sensor needs in the region. Get More Insights On, Automotive Steering Torque Sensors Market About Author: Money Singh is a seasoned content writer with over four years of experience in the market research sector. Her expertise spans various industries, including food and beverages, biotechnology, chemical and materials, defense and aerospace, consumer goods, etc. (https://www.linkedin.com/in/money-singh-590844163

#Automotive Steering Torque Sensors Market Trends#Automotive Steering Torque Sensors Market Share#Automotive Steering Torque Sensors#Automotive Steering Torque Sensors Market

0 notes

Text

EPS Torque Sensor Market

0 notes

Link

Rotating Torque Sensors Market Research Study 2023 - Overview Rotating Torque Sensors market exhibits comprehensive information that is a valuable source of insightful data for business strategists during the decade 2019-2029. On the basis of historical data, Rotating Torque Sen

0 notes

Text

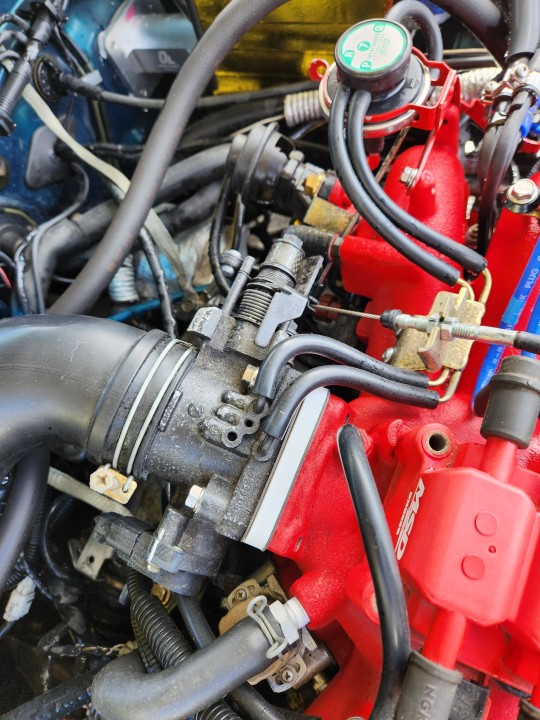

Since there has been some interest in my current intake, here is it broke down. I have tried numerous setups but this custom OEM+ version is the best and passes stupid SMOG visual check.

I also intensely studied the 2.5RS forums and looked at dyno charts showing that this IS the best when combined with a 2.25" cat back exhaust and equal length headers. Trust me!

This was a lot work as well as trial and error and willingness to start over again and redo it again several times. I think this was also the lightest combo if you trying to reduce weight.

One of a kind custom intake for the naturally aspirated Subaru EJ25D....

First up is you need the intake tract/duct and hoses from an earlier model Subaru Impreza or any Subaru that has this intake tube vs the stock version with the "torque box" behind the throttle body. Junkyard is your best buddy.

I had expensive high performance mandrel bent blah blah blah intakes which I constantly struggled with keeping the metal tubing cool (I used a laser temp gauge). This plastic is basically the same but rarely gets too hot to touch. So, actually a cold air intake if you keep reading.

Since the entire manifold needed to come out, I painted it wrinkle red and polished the runners and throttle inlet.

The reason I removed the manifold was to install stainless studs to make installing the 10mm thick teflon spacers and 2 sets of gaskets easier. Similar to 8mm Grimmspeed phenolic (previously installed) but thicker. This mod makes a big difference, the entire manifold now stays cool. No more engine block heat soak, only ambient engine bay heat.

"For every 5 degree reduction in temperature, increases power by 1%"

You have to extend the EGR tube and possibly grind your ignition coil pack mounts lower. Because the entire manifold assembly will be sitting ~12mm higher.

I was fortunate enough to work with the gasket maker. So he made 10mm teflon intake manifold spacers and a matching prototype 10mm throttle body spacer! Again 2 gaskets to ensure no leaks. Not sure if these were ever made available afterwards since I was the first car.

This spacer combo increased plenum volume as well as helped to keep heat transfer drastically reduced.

Using my custom ported, polished and knife edged throttle body that I did myself with the coolant hose permanently bypassed and the cruise control bits removed. Keep in mind you will need longer bolts if you use a spacer here. Definitely improved throttle response after just the throttle body swap.

I scored this GC8 v3 factory resonator/cold air intake inlet from the UK. It's what goes with those fender plugs. Grabs cold air from inside the fender behind the corner light up high, so no chance of sucking up water. FWIW, You really shouldn't just delete the "snorkus", seriously, it's just gonna mess up your MAF sensor.

I was also able to make the resonator from a SVX work in the 04 Outback with some persuasion. It too takes air from the same location but the box was hard to cram in the fender.

The intake tract will work with whatever air filter box but in order to use the EUDM WRX intake inlet/resonator you will need the matching filter housing box from an earlier model or have to drill a new mounting hole. You will need both halves!

BEST panel filter on the market IS made by Grimmspeed! Don't waste your money on any other filter! I also added a Filter Wears waterproof inlet cover/pre-filter to the resonator just incase of water spray. The factory option fender plug fills that hole.

And I'm not sure if this was an upgrade or not but here is the JDM JECS MAF I am also using. Used DEI gold heat reflective tape to keep it cool and extend the life. Possibly more consistent/accurate readings?

The only other things installed are a Weapon R catch can to the PVC, which DOES keep some crap out of the intake tract and off the throttle body but probably no real performance advantage. Plus a heat/flame resistant "sock", same as around my fluid reservoirs, over the bendy/flexible bit of the intake tract just after the MAF. That area is prone to splitting/cracking with heat and age!

Now for treasure at the end of the rainbow! I am actually gonna give you nerds the mother fucking part numbers! These can be life savers when searching for parts.

*You might have to make or reuse your PVC, crankcase, IAC valve hoses. So grab whatever is attached if your at the junkyard or hit up the auto parts store.

•Subaru PN's:

Intake duct/tract (EJ22): 14457AA111

Air filter housing/box: A53FA02 (upper) & A53FA01 (lower)

Fender resonator/snorkus (UK WRX): A21FA03 or A32FA01 or A21FA00

Fender plug: 46059FA000

•Grimmspeed PN's:

Dry-Con Air Filter: 060092

Intake manifold spacers (8mm phenolic): 015001

#subaru#custom#intake#mods#how to#diy#fyi#upgrades#naturally aspirated#ej25d#90s japanese cars#impreza#legacy gt#forester#my car#mecha gt#cold air intake#car parts#part numbers#oem+#the more you know#knowledge#tutorial#hp gains#boxer engine#subie#subienation#modified cars#2nd gen#bk6

20 notes

·

View notes

Photo

New Post has been published on https://www.vividracing.com/blog/139824-2/

In 2022, car enthusiasts all over the United States were anxiously awaiting the arrival of the Nissan Z. In the new Z, not 400Z, it seems Nissan answered all of our prayers. Equipped with a 3.0L VR30DDTT Twin Turbo V6 and a 6 speed FS6R31 manual transmission, the new Z34 (Kouki Z34) seemed to fill all the gaps Nissan left in the Zenki Z34 and R35 that left true drivers wanting more. With a power output at an even 400hp (298kw; 406ps) and 350 ftlbs (475 N-m 48 kg-m) of torque, the new Z34 was unlike any of its predecessors and a breath of fresh air in the middle of the ‘Sports Car Electrification Movement’. Nissan then broke some hearts, mine included, when they announced the 420hp, 384ftlb Z34 Nismo would be equipped with a rebadged Mercedes 9G-Tronic automatic transmission manufactured under Jatco as the JR913E and that there would be no manual option for the Nismo Z. Their reasoning: Even with more power, the automatic sport model would be faster in the ¼ mile than a manual Nismo, and they feared consumers would care.

Fast forward to release day, and the reasonably priced Nissan Z saw dealer markups of over $70,000 over MSRP on what could be Nissan’s final true sports car. Somehow, clout and fear of missing out beat common sense and they sold like hotcakes. So much so, that as of the writing of this article, the least expensive USED Nissan Z on the market is being offered at $7,000 above NEW MSRP. Now to bring it all into perspective, if you were an early buyer of a Nissan Z, you’re punching in Audi RS5 Coupe, BMW M4 Competition xDrive, and C8 Corvette territory price-wise, except you likely have cloth seats, less power, and are a good deal slower from 0-60 than your newly priced out competition… and the EFI scientist here at Vivid Racing just can’t let you go out like that.

Interested in this Nissan Z Tuning Box? Order Here

While we have options for your interior woes, and styling upgrades that make the car look the part of the markup, we were focused on two things and two things only: horsepower and torque… and drivability (I’m aware that’s three things). When this Two-tone Ikazuchi Yellow Tricoat / Super Black Kouki Z34 rolled into our dyno lab, we were impressed. It put down an underrated 405hp and 475ftlbs of torque through the automatic transmission, which was more than we all expected. Immediately wanting to unlock the ECU and start our flash process, the customer let us know the factory warranty was very important to him and that he would like to keep it. Luckily here at VR Tuned, we have developed a Warranty-safe tune with our VR Tuned Tuning Box. Basically, this system acts as a piggy back. It requires no cutting or splicing and does not modify the way any of the factory sensors work. Instead, through science and electrical engineering and magic, it provides safe, modified data to the factory ECU, allowing us modify boost, fuel and spark strategies that ultimately results in a 65hp increase over stock and 85 more ftlbs or torque through our VR Forged wheels.

To make it more user-friendly for the driver, we included optional Bluetooth control for both iOS and Android platforms, allowing the user to quickly change between 7 performance maps, or simply turn the tuning box off for emissions purposes from their phone. With 3 active drive modes (Race, Sport, and Eco) included, and German tuning box construction, we feel Vivid Racing has crafted the ultimate tuning solution for Nissan Z owners looking to retain their factory warranty. We also found the best exhaust system for making big power, and the best suspension system to keep it all under control, so there’s no need to take it one step at a time. The next stop for us and the Z should be a track day, so subscribe if you want to see more.

So whether you want to be the talk of the town at the next local cars and coffee, or you want to take a few hot laps around the track in extreme comfort, shoot me an email at [email protected] to get your Z right.

Product Featured: VR Tuned ECU Tuning Box Kit V2 Nissan Z | 400Z

2 notes

·

View notes

Text

The Car Modification Industry: A Thriving Market of Innovation and Customization

The car modification industry is a booming sector where automotive enthusiasts and professionals work to enhance vehicles beyond factory specifications. From performance upgrades to aesthetic enhancements, this industry caters to a diverse range of car owners seeking personalization and improved functionality.

The Growing Popularity of Car Modifications

Car modifications have gained widespread popularity due to advancements in technology and an increasing demand for customized vehicles. The industry thrives on car enthusiasts, tuning professionals, and aftermarket manufacturers who continually push the boundaries of what’s possible.

Types of Car Modifications

1. Performance Enhancements

Upgrading a vehicle’s performance is one of the most sought-after modifications. These upgrades improve speed, handling, and efficiency, making cars more powerful and enjoyable to drive.

Engine Tuning: Adjusting the ECU (Engine Control Unit) to optimize fuel consumption, horsepower, and torque.

Turbochargers and Superchargers: Adding forced induction systems to boost power output significantly.

Exhaust System Upgrades: Installing high-performance exhausts for better airflow and sound.

Suspension Modifications: Lowering or stiffening the suspension to enhance handling and aerodynamics.

2. Aesthetic Modifications

Many car owners focus on visual upgrades to give their vehicles a unique and stylish look.

Custom Paint Jobs & Wraps: Personalized color schemes, matte finishes, and vinyl wraps for a distinct appearance.

Body Kits & Spoilers: Enhancing aerodynamics while adding an aggressive look.

LED & HID Lighting: Improved visibility and a modern touch with upgraded headlights and taillights.

Alloy Wheels & Custom Rims: A popular upgrade for a sportier and more premium look.

3. Interior Customization

Modifications aren't limited to the exterior; many car enthusiasts revamp their interiors for better comfort and style.

Premium Leather Upholstery: High-quality materials for a luxurious feel.

Advanced Infotainment Systems: Touchscreen displays, premium audio setups, and smart integration.

Custom Steering Wheels & Pedals: Sportier designs for better grip and control.

Ambient Lighting: LED strips to create a modern atmosphere inside the car.

4. Safety & Technology Upgrades

Modern technology has allowed car modifications to go beyond aesthetics and performance. Safety and tech upgrades enhance driving experiences while ensuring greater protection.

ADAS (Advanced Driver Assistance Systems): Lane assist, automatic braking, and parking sensors.

Dash Cams & Security Systems: Recording incidents for safety and legal purposes.

Run-Flat Tires & Brake Upgrades: Enhancing safety with durable tires and better braking performance.

Smart Keyless Entry & Push-Start Systems: Convenience and improved security.

The Legal Aspects of Car Modifications

While car modifications offer exciting opportunities for enhancement, there are legal considerations that vary by region.

Emission Regulations: Some modifications, like removing catalytic converters, can violate emission laws.

Noise Restrictions: Modified exhausts and sound systems must comply with legal decibel limits.

Street Legality: Lowered cars, extreme tinting, and certain lighting mods may be restricted in some states.

Insurance Implications: Many modifications impact vehicle insurance policies and coverage.

The Aftermarket Industry and Its Role in Car Modifications

The automotive aftermarket industry plays a crucial role in car modifications. This multi-billion-dollar market provides aftermarket parts, tuning services, and customization options.

OEM vs. Aftermarket Parts: Aftermarket parts offer performance enhancements but may not always meet manufacturer standards.

Tuning Shops & Custom Builders: Professional services for installing and optimizing modifications.

Online Marketplaces: Platforms like eBay, Amazon, and specialty stores offer a wide range of modding options.

The Future of the Car Modification Industry

The car modification industry is continuously evolving, driven by new technologies and sustainability efforts.

Electric Vehicle (EV) Modifications: Custom battery packs, regenerative braking systems, and aerodynamic enhancements.

3D Printing in Custom Parts: On-demand production of unique parts at lower costs.

Eco-Friendly Modifications: Hybrid engine conversions, sustainable materials, and biofuel adaptations.

AI-Powered Performance Tuning: Intelligent systems optimizing vehicle performance in real-time.

Conclusion

The car modification industry offers endless possibilities for enthusiasts looking to enhance their vehicles. Whether it’s for performance, aesthetics, safety, or technology, modifications provide a way to personalize and upgrade cars beyond factory limits. As the industry grows, staying updated with the latest trends and regulations ensures a rewarding and legally compliant modding experience.

1 note

·

View note

Link

0 notes

Text

[155 Pages Report] According to MarketsandMarkets, the torque sensor market size is projected to grow from USD 6.8 billion in 2021 to USD 9.0 billion by 2026; it is expected to grow at a Compound Annual Growth Rate (CAGR) of 5.7% from 2021 to 2026.

0 notes

Text

Gear Motors Market: Trends, Key Innovations Reshaping the Industry - UnivDatos

The global Gear Motors Market is in the middle of a transition, as more innovations emerge, and new sectors rise to prominence while other industries decline slowly. With industries all over the world adopting automation digitalization and technological advancement, the gear motors market is still growing and incorporating new trends that are key to the future of the market. The current nature of developments in the gear motors industry, along with its innovations, has been the focus of this article; their significance in distinct areas is also discussed.

The integration of smart gears is perhaps one of the key driving forces in the current gear motors market. It is part of the more extensive Industry 4.0, No movement, gear motors being outfitted with sensors, connectivity options, and IoT to facilitate real-time monitoring of gear motors to predict when they need repairs and for remote control. This trend is making gear motors evolve from being mere mechanical devices and switching them into smart devices that can monitor, analyze, and self-adjust to improve their performance, reliability, and efficiency.

Request To Download Sample of This Strategic Report - https://univdatos.com/reports/gear-motors-market-2?popup=report-enquiry&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Smart gear motors are the most useful in industries that require motors to operate 24/7 and be as reliable as possible – industries that deal with/ manufacturing, handling of material, and renewable energy. Smart gear motor solutions give real-time data and efficiency measurements including the temperature, vibration, and torque so that operators can note inconsistencies before they cause damage. Out of this capability, gear motor durability is enhanced besides benefiting from cost savings due to reduced forced maintenance and energy usage.

Energy Efficiency and Sustainability

With changes in attitude towards energy usage and the well-being of the environment, there is a growing need for gear motors that are energy efficient. The management systems that are in demand today are those that can lead to a decrease in carbon emissions, and the optimization of expenses, and therefore energy efficiency becomes the key goal. To meet consumers’ demand and changes in technology and application of equipment where gear motors have been used, manufacturers of gear motors have developed high-efficiency gear motors, built with new and improved materials, and with more efficient gear arrangements that result in energy loss.

Customization and Industry-Specific Solutions

Another sustainable trend in the gear motors market is the rising interest in specialty products that may be developed to meet the requirements of corresponding industries. That is why, although standard gear motors are still in great demand, there is a present trend in the development of gear motors for specific applications. This trend is however especially apparent in some industries like the automotive industry, food and beverages, and equipment manufacturing industries where there is a need to meet specific operational difficulties by use of specific gear motors.

Technological Advancements and Innovation

Disruptive technological advancement remains a mainstay for the gear motors market given that products are being advanced based on material science, manufacturing technology, and IOT among other fields. Probably, the novel utilized area is an application of new material, including high-strength alloy and composite, which can realize high durability, lightweight, and high performance. These materials are however crucial in applications where gear motors are likely to operate at large loads, hot environments, or where they are likely to be exposed to corrosive agents.

Focusing on regional development and rising markets

Currently, the growth of the gear motors market is observed in regions such as Asia-Pacific, North America, and Europe due to industrialization infrastructural development and the growing trend of automation. Thus, Asia-Pacific is set to become one of the dominant markets of gear motors with countries like China, India, and Japan increasing their investments in the manufacturing industry, automotive market, and renewable energy sources. The increased industrial development along with urbanization is a concern for gear motors in material handling to power generation across the region

Ask for Report Customization - https://univdatos.com/reports/gear-motors-market-2?popup=report-enquiry&utm_source=LinkSJ&utm_medium=Snehal&utm_campaign=Snehal&utm_id=snehal

Conclusion

The global gear motors market is at present in a phase of evolution, owing to the advancements in technology, the shifting trend in the industry, and the increased consciousness towards environmental sustainability. Several trends like smart and energy-efficient technologies and the need for personalized systems are the industry drivers. Manufacturers are constantly advancing and adjusting to these trends, and therefore the market for gear motors is anticipated to maintain steady growth and open new opportunities for the various industries.

0 notes

Text

#Global EPS Torque Sensor Market Size#Share#Trends#Growth#Industry Analysis#Key Players#Revenue#Future Development & Forecast

0 notes

Text

https://introspectivemarketresearch.com/reports/torque-sensor-market/

0 notes

Text

Why Businesses Are Investing in Collaborative Robots for Increased Efficiency

The global collaborative robot (cobot) market is witnessing unprecedented growth, with an estimated valuation of $15.3 billion by 2034, advancing at a CAGR of 26.1% from 2024 to 2034. The increasing reliance on automation, workforce safety, and ergonomic work conditions are key drivers fueling this expansion.

Why Are Collaborative Robots in High Demand?

Collaborative robots are designed to work alongside human operators rather than replacing them, enhancing workplace efficiency while ensuring safety. Unlike traditional industrial robots, cobots come with force-limiting sensors and easy-to-use programming interfaces, making them more adaptable across industries.

Industries such as automotive, electronics & semiconductors, healthcare, and aerospace are increasingly integrating cobots to improve production efficiency, reduce operational costs, and enhance product quality.

Key Market Drivers Fueling Growth

1. Increased Demand for Automation

With rising labor costs and supply chain complexities, businesses are turning to cobots for their adaptability, ease of programming, and ability to perform repetitive tasks with precision. Their flexibility makes them ideal for dynamic industries like consumer electronics and automotive manufacturing.

2. Workplace Safety & Ergonomics

Organizations are prioritizing workplace safety and employee well-being, making cobots a crucial investment. Equipped with advanced safety features such as torque and velocity limiting, cobots ensure safe interaction with human workers.

For instance, ABB’s GoFa collaborative robot, launched in 2023, features advanced safety functions for material handling and assembly, demonstrating the industry's push towards safer work environments.

Electronics & Semiconductor Industry: A Major Growth Sector

The electronics & semiconductor industry held a 26.5% market share in 2023 and is expected to expand at a 30.9% CAGR. The demand for high precision and consistent quality in microchip and circuit board assembly is driving cobot adoption in this sector.

Regional Outlook: Why Asia Pacific is Leading the Market

Asia Pacific accounted for 34.2% of the global collaborative robot market in 2023 and is projected to grow at a CAGR of 28.9%. Countries like China, Japan, South Korea, and India are at the forefront of cobot adoption due to their massive manufacturing industries and increasing demand for automation.

Key Players Shaping the Collaborative Robot Market

The global cobot market is dominated by ABB, KUKA AG, FANUC CORPORATION, Kawasaki Heavy Industries Ltd., and Mitsubishi Electric Corporation, which together hold 55-60% market share. These companies are actively investing in R&D, strategic collaborations, and product innovations to expand their foothold in the industry.

Final Thoughts: The Bright Future of Cobots

As businesses continue to embrace automation, collaborative robots are poised to redefine the future of work. From increasing efficiency and workplace safety to supporting diverse industry applications, cobots are becoming indispensable assets.

The next decade promises exciting advancements, with AI-driven enhancements and seamless human-robot collaboration paving the way for a more automated and efficient industrial landscape.

0 notes

Text

Nissan Magnite in Nepal: A Comprehensive Overview of the Compact SUV Revolution

Introduction

The Nissan Magnite has become a game-changer in the compact SUV market, making waves with its bold design, innovative features, and unbeatable value proposition. This model has been particularly popular in Nepal, where the demand for compact, feature-rich vehicles is skyrocketing. With its stylish exterior, comfortable interiors, and advanced technologies, the Nissan Magnite in Nepal has positioned itself as a top choice for urban and semi-urban drivers. Let's explore what makes this vehicle stand out in the competitive landscape of Nepal's automotive market.

The Nissan Magnite is a compact SUV introduced as an affordable yet stylish option for buyers looking for practicality and premium features.

Key Features of the Nissan Magnite

The Nissan Magnite offers bold design, spacious interiors, turbocharged performance, advanced tech features, and impressive fuel efficiency.

Design and Aesthetics

The Magnite boasts a bold, aggressive design with sharp character lines, a sleek grille, and stylish LED headlamps. Its futuristic looks and sporty stance set it apart in a crowded segment. The elevated ground clearance of 205mm adds to its SUV appeal, making it suitable for urban roads and Nepal's uneven terrains.

Interior Comfort and Space

The Nissan Magnite offers a spacious cabin with ample legroom and headroom. Its premium fabric upholstery, ergonomically designed seats, and modern dashboard enhance the driving experience. The vehicle also includes a multifunctional steering wheel, push-button start, and an 8-inch infotainment system with Android Auto and Apple CarPlay compatibility.

Performance and Engine

The 1.0-liter turbocharged petrol engine that powers the Magnite produces strong performance. With 100 PS of power and 160 Nm of torque, the SUV offers an excellent power and fuel efficiency balance. Customers can have a smooth CVT automatic transmission or a 5-speed manual transmission.

Safety and Reliability

Safety is a priority in the Nissan Magnite, which features dual airbags, ABS with EBD, a standard rearview camera, and rear parking sensors. Higher variants offer features like a 360-degree camera, vehicle dynamic control (VDC), and tire pressure monitoring systems, making it one of the safest options in its segment.

Nissan Magnite Variants Available in Nepal

Several Nissan Magnite models suit a range of consumer demands and price ranges. These include:

XE Base Variant: An entry-level option for budget-conscious buyers.

XL Mid Variant: Offers additional comfort and convenience features.

XV Premium Variant: Packed with advanced tech and luxury features for premium buyers.

Each variant is available in manual and CVT automatic options, ensuring flexibility for diverse customer preferences.

Nissan Magnite Price in Nepal

The affordability of the Nissan Magnite has been a significant factor in its success. As of 2025, the Nissan Magnite price in Nepal ranges from NPR 30 lakhs to NPR 46 lakhs, depending on the variant and features. Here's a breakdown:

Variant Price Range (NPR)

XE Base 30,00,000 – 32,00,000

XL Mid 35,00,000 – 38,00,000

XV Premium 42,00,000 – 46,00,000

The pricing strategy ensures that the Magnite remains competitive while delivering excellent value for money.

Why Nissan Magnite is Perfect for Nepal

Nissan Magnite is perfect for Nepal with its affordability, compact design, and rugged performance.

Adaptability to Nepalese Roads

Nepal's diverse topography, ranging from flat plains to rugged mountainous terrains, demands vehicles with high ground clearance and reliable performance. The Magnite's robust suspension system and 205mm ground clearance make it ideal for navigating these challenging conditions.

Fuel Efficiency

Petrol prices are a significant concern for Nepalese drivers, so the Nissan Magnite's fuel efficiency of around 20 km/l (under standard driving conditions) is a significant selling point.

Compact Dimensions

Urban areas in Nepal, such as Kathmandu and Pokhara, often face traffic congestion and limited parking spaces. The Magnite's compact dimensions make it an excellent choice for city driving and parking.

After-Sales Service and Maintenance

Nissan's strong dealership and service network in Nepal ensures Magnite owners access to reliable after-sales support. Spare parts are affordable and readily available, enhancing the vehicle's appeal.

For More Details, Click Here

0 notes

Text

0 notes