#TitaniumAlloy

Explore tagged Tumblr posts

Text

#TitaniumAlloy#MedicalTitanium#DentalTitanium#TI6AL4V#BiocompatibleMaterials#MedicalInnovation#DentalTechnology#TitaniumImplants#MedicalMaterials#DentalMaterials

0 notes

Text

Customized Titanium Springs in Various Colors

Please contact HOSN to fabricate custom titanium spring and gauge sizes. … Titanium springs can have several different purposes and various colors.

0 notes

Text

🤩Upgrade your SHOEI Motorcycle Helmet with SPARTS Titanium Alloy Screws and make your ride stand out! 🏍️💨

1 note

·

View note

Text

Titanium Alloys: Advancements and Trends in Monroe, NC

Titanium Alloys: Advancements and Trends in Monroe, NC

Monroe, North Carolina, has become a significant player in the production and innovation of titanium materials, particularly in the form of titanium alloys. These alloys are increasingly critical in industries like aerospace, automotive, medical devices, and energy, where strength, lightness, and corrosion resistance are essential.

One of the key advancements in titanium alloys in Monroe is the development of high-performance materials that can withstand extreme conditions. For example, aerospace companies in Monroe are utilizing titanium materials to create lighter, stronger parts for aircraft, significantly reducing fuel consumption while maintaining structural integrity. The aerospace sector benefits greatly from titanium alloys due to their ability to endure high temperatures and aggressive environments, which is essential for modern aircraft designs.

Additionally, titanium materials are playing a crucial role in the medical field. In Monroe, local manufacturers are leading the charge in producing titanium alloys for use in implants, prosthetics, and other medical devices. These titanium materials are biocompatible, meaning they are less likely to cause adverse reactions when implanted into the human body. As medical technologies advance, Monroe's manufacturers are continuously improving the strength and flexibility of titanium alloys, making them even more effective for long-term use in the body.

The automotive industry in Monroe has also seen a surge in titanium materials usage. The demand for lightweight yet durable materials has led to the increased incorporation of titanium alloys in vehicle components. These alloys help manufacturers create stronger, lighter vehicles, improving fuel efficiency and reducing carbon footprints. Monroe-based companies are at the forefront of producing titanium alloys that contribute to the evolving landscape of sustainable automotive manufacturing.

A key trend in Monroe is the focus on sustainable titanium production. As the demand for titanium materials continues to rise, companies in Monroe are investing in technologies that reduce waste and energy consumption. This commitment to sustainability ensures that the production of titanium alloys remains efficient and environmentally friendly, supporting both local industries and global markets.

In conclusion, Monroe, NC, is driving innovation in titanium materials and titanium alloys, with advancements that support industries like aerospace, automotive, and healthcare. As technology progresses, Monroe will likely continue to lead the way in creating stronger, more sustainable titanium solutions that shape the future of manufacturing.

0 notes

Text

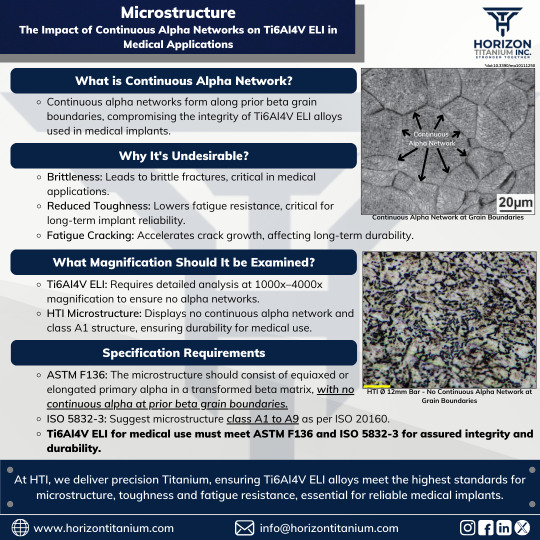

Microstructure Insights: Ti6Al4V ELI – Why Continuous Alpha Networks Matter

In industries like medical and aerospace, material performance is critical. The microstructure of Ti6Al4V ELI plays a crucial role in ensuring safety and durability. But have you ever wondered why continuous alpha networks can pose a significant issue? Here's why:

➡️ They create brittle points, increasing the risk of failure. ➡️ They reduce toughness and fatigue resistance. ➡️ They provide pathways for fatigue cracking, compromising durability.

Why is it important to examine the microstructure at higher resolutions?

Ti6Al4V ELI has a very fine microstructure in the annealed condition, making it difficult to assess the alpha network and phase distribution at lower magnifications (100x-500x). To accurately determine if a continuous alpha network has formed and to analyze the distribution of alpha and beta phases, it's essential to use magnifications of at least 1000x or higher.

Want to learn more about how detailed analysis can prevent material failures? Drop a comment or contact us at [email protected]. Let’s discuss your challenges!

#KnowYourTitanium#Titanium#TitaniumAlloys#Microstructure#Metallurgy#Ti6Al4VELI#MaterialScience#MedicalGradeTitanium#AlphaNetworkImpact#FatigueResistance#FractureToughness#FailurePrevention#HighResolutionAnalysis#AdvancedMaterials#EngineeringInsights#TitaniumFatigue#MicrostructureAnalysis#MaterialDurability#HorizonTitanium#StrongerTogether

0 notes

Text

For over 40 years, Bansal Brothers has led as India's premier ferro titanium manufacturer, supplying top-quality products globally. With three advanced furnaces producing 7400 metric tonnes annually, we offer custom-grade ferro titanium tailored precisely to your requirements. Count on our expertise for durable steel alloys. 👷🏻♂️

for more details visit us - https://www.ferrotitanium.in/

#ferrotitanium#titaniumalloys#steelalloys#bansalbrothers#ferro titanium producers#ferro titanium manufacturer#ferro titanium powder

0 notes

Text

The Discord number police got me a while back, but I forgot to update things here. If you want to find me on Discord, my address is titaniumalloy now. It's the most reliable way of getting my attention about things.

1 note

·

View note

Text

The products just processed by 5-axis CNC will dazzle your titanium alloy eyes!

🔥The 5-axis CNC is meticulously crafted, and the finished products shine like titanium stars✨! The pinnacle of mechanical art will dazzle your eyes! 🚀 #CNCMiracle #TitaniumAlloy Light #CraftsmanshipPeak

0 notes

Text

Introducing our Subsea Thruster, an innovative underwater propeller system that utilizes high-quality materials such as titanium, aluminum, and stainless steel, resulting in a durable product that can withstand the harsh conditions of the ocean.

The titanium components provide exceptional strength and corrosion resistance, making it perfect for use in saltwater environments. The aluminum parts offer excellent conductivity and durability, while the stainless steel components ensure a long-lasting product that is both reliable and efficient.

Our Subsea Thruster is designed for deep-sea exploration and marine engineering applications, such as underwater cable laying, oceanic research, and offshore oil and gas operations. It can also be used in aquaculture, underwater rescue missions, and other marine-related fields.

With its strong and durable construction, our Subsea Thruster guarantees maximum performance and reliability, ensuring that your underwater projects are completed efficiently and safely. Invest in our Subsea Thruster today and discover a new level of underwater propulsion technology that meets your needs.

Contact us at [email protected] to get more details.

0 notes

Text

Titanium alloys Suppliers and Exporters in India

"Titanium alloys: Where strength meets lightness and corrosion resistance."

"When it comes to high-performance materials, titanium alloys are a cut above the rest."

"For a metal that's tough as nails but light as a feather, look no further than titanium alloys."

Titanium is a chemical element with the symbol Ti and atomic number 22. It is a lustrous, silver-colored transition metal with a low density and high strength. Titanium is known for its excellent corrosion resistance, making it popular in many industrial, medical, and aerospace applications.

Titanium alloys are a combination of titanium with one or more other elements, such as aluminum, vanadium, or molybdenum. The addition of these elements can improve the mechanical properties of titanium, such as its strength, toughness, and ductility, making it even more suitable for various applications.

Get more info: https://www.gauravsteel.com/Titanium-Alloy.html

#Titaniumalloys#titanium#india#supplier#export

1 note

·

View note

Text

Titanium Alloy Springs Green Color

Titanium alloy springs are widely used in the bicycle,motorcycle,automotive industry.

Titanium Alloy Springs Green Color

0 notes

Photo

The titanium plates on the below picture are what we sent to a Singapore customer. Before production and shipment, we conducted strict inspections, including the chemical composition and mechanical properties of the material, as well as the size and appearance of the finished products. The test results are perfect, and we also provide the test results to customer too.

0 notes

Text

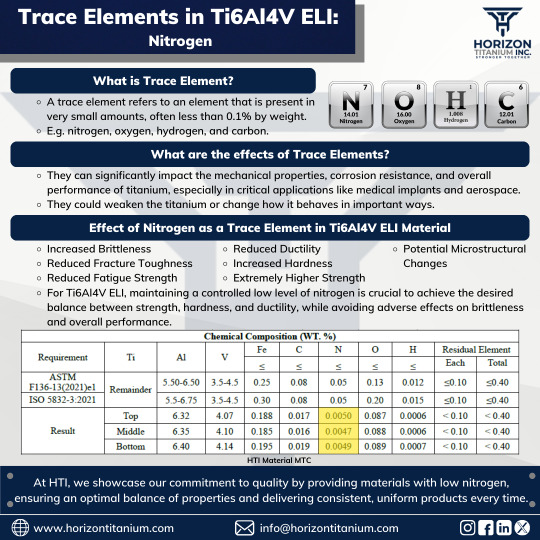

Trace Elements in Ti6Al4V ELI: The Impact of Nitrogen

When it comes to titanium alloys like Ti6Al4V ELI, trace elements such as nitrogen can have a significant impact on the material's mechanical properties. In this post, we dive deep into how trace amounts of nitrogen affect brittleness, fracture toughness, and strength.

Why does this matter?

1. Nitrogen can make your titanium alloy stronger, but there’s a balance! Too much can make it brittle. Too little, and you might lose strength. The key is finding that perfect balance. 2. In medical-grade titanium like Ti6Al4V ELI, precision is everything, and keeping nitrogen levels controlled ensures your material performs under the most demanding conditions.

Did you know? If the nitrogen content is low but your material still boasts high strength, you’re working with premium titanium! This means the strength is purely from the titanium and not from unwanted nitride phases like titanium nitride, which could weaken the material's long-term performance.

At HTI, we deliver consistent quality, ensuring that the material you get is optimized for strength, ductility, and durability—making it perfect for critical applications like medical implants.

For more technical insights, check out the composition chart in the post!

Let’s talk titanium! Have questions about material quality or trace elements? Drop a comment or reach out at [email protected]

#KnowYourTitanium#Titanium#Ti6Al4VELI#MaterialScience#TraceElements#NitrogenImpact#ChemicalComposition#MedicalGradeTitanium#Metallurgy#EngineeringExcellence#AdvancedMaterials#QualityControl#TitaniumStrength#TitaniumAlloys#PrecisionEngineering#HorizonTitanium#StrongerTogether

0 notes

Text

Titanium Alloy Market 2020 | Industry Demand, Fastest Growth, Opportunities Analysis and Forecast To 2026

The newly added Titanium Alloy Market research report by Value Market Research disclose all the important information associated with the market such as value, growth factor, trends, market share, size, and challenges for the forecasted timeline 2019-2026. Further, this report also highlights smart strategy adopted by major players and also their market share. Basically, this report is designed to give a proper understanding of industry structure and competition intensity attractiveness.

The research report also covers the comprehensive profiles of the key players in the market and an in-depth view of the competitive landscape worldwide. The major players in the titanium alloy market include PCC, VSMPO-AVISMA, ATI, Carpenter, Alcoa, BAOTAI, Western Superconducting, Western Metal, TG, Advanced Metallurgical.S. This section includes a holistic view of the competitive landscape that includes various strategic developments such as key mergers & acquisitions, future capacities, partnerships, financial overviews, collaborations, new product developments, new product launches, and other developments.

Get more information on "Global Titanium Alloy Market Research Report" by requesting FREE Sample Copy at https://www.valuemarketresearch.com/contact/titanium-alloy-market/download-sample

Market Dynamics

Rising applications in automotive, aerospace, and medical application are driving the growth of the market. Titanium alloy is broadly demanded across these industries due to its excellent mechanical and physical properties. Geographically, Asia Pacific is projected to grow at the fastest pace during the forecast period. The growing trends of aerospace, marine, and automobile industry in the region, along with rising demand for titanium implants, are the factors that are expected to propel market growth within the region. Furthermore, a growing study on a titanium alloy for innovative product development is likely to act as an opportunity for the market. However, the premium pricing of titanium alloys is predicted to act as a restraint for the market. The report covers Porter’s Five Forces Model, Market Attractiveness Analysis and Value Chain analysis. These tools help to get a clear picture of the industry’s structure and evaluate the competition attractiveness at a global level. Additionally, these tools also give inclusive assessment of each segment in the global market of titanium alloy.

Browse Global Titanium Alloy Market Research Report with detailed TOC at https://www.valuemarketresearch.com/report/titanium-alloy-market

Market Segmentation

The report segments the titanium alloy market and analyses it with respect to the geography, intending to keep the marketer informed and help them identify the target demographics for the product or service. By Type

Plate

Bar

Tube

Others

By Applications

Aero Aviation

Industrial

Medical

Others

Regional Analysis

This section covers regional segmentation which accentuates on current and future demand for aerosol valve market across North America, Europe, Asia-Pacific, Latin America, and Middle East & Africa. Further, the report focuses on demand for individual application segment across all the prominent regions.

Purchase Complete Global Titanium Alloy Market Research Report at https://www.valuemarketresearch.com/contact/titanium-alloy-market/buy-now

About Us:

Value Market Research was established with the vision to ease decision making and empower the strategists by providing them with holistic market information.

We facilitate clients with syndicate research reports and customized research reports on 25+ industries with global as well as regional coverage.

Contact:

Value Market Research

401/402, TFM, Nagras Road, Aundh, Pune-7.

Maharashtra, INDIA.

Tel: +1-888-294-1147

Email: [email protected]

Website: https://www.valuemarketresearch.com

#TitaniumAlloyMarketSize#TitaniumAlloyMarketShare#TitaniumAlloyIndustryReport#TitaniumAlloyReport#TitaniumAlloy#TitaniumAlloyMarket

0 notes

Photo

Talk about a match made in heaven! Our Tungsten colored @cerakote Hybrid stabilizers pair up beautifully with the Anthracite Grey Riser on the @athensarchery TAP Edition Ridge 34. https://titaniumarcheryproducts.com/collections/target-stabilizers/products/the-hybrid-target-stabilizer?variant=19241768812598 #archerylife #bowhuntingwhitetails #bowhunter #bowhunting #archery #athensarchery #titaniumarcheryproducts #tap #tappedout #cerakote #highperformance #titanium #titaniumalloy https://www.instagram.com/p/BtTaOPrhH2F/?utm_source=ig_tumblr_share&igshid=q4vby33pa9kj

#archerylife#bowhuntingwhitetails#bowhunter#bowhunting#archery#athensarchery#titaniumarcheryproducts#tap#tappedout#cerakote#highperformance#titanium#titaniumalloy

0 notes

Text

Improve Your Products by Titanium Grade 2 and 5 Tubes by Special Metal Alloys.

Best uses of Titanium Tubes The Titanium Tubes for Your Industry it is always a wise decision to take Titanium tubes from Special Metals for your next project for wonderful results, and seamless profit.

Whenever we think of titanium, the one thing that passes on our mind is the strength, the durability, the corrosion resistance nature it provides to the whole metallic industry is just phenomenal.

And apart from all the features of Titanium grade 2 and grade 5 are of more significance when this graded titanium is molded into best pipes of different diameters, it solves the purpose of many industrialists in water and Petrochemical sectors.

Titanium Tubes are best suited for aerospace, and military uses. When titanium is alloyed with aluminum and vanadium it is transformed into more strong tubes of grade 2 and 5 while it stays lighter over steel with low density. These grades are more commonly used in saline water and freshwater industries due to their corrosion resistance nature.

SM alloy’s best pick-ups

SM alloys or the Special Metal is known to provide the focused inventory of Titanium molded tubes in numerous forms and diameters. SMalloys is one of the leading, biggest supplier of titanium tubes in UAE, Qatar, Oman, Yemen, Greece, Mexico, and many other offshore countries. We have gathered the best lot of supreme engineers and trained laborer's for the best Titanium Tube in the globe.

We have the best planning for the future generation industrial needs, and our only business policy to serve the quality product at a reasonable rate. Special Metals are the leading Titanium Tube Supplier, not only in India but globally trusted for Titanium tube supplies and timely delivery.

Titanium is a Low density but very strong metal, and that needs special care at the manufacturing level, which is met by our step checking methods at units. The sheer hard work of Special Metal has earned its global mark for quality Titanium Tube Supply by us.

#titanium tubes#titanium tubes manufacturer#titanium tubes supplier#titanium tubes manufacturer in india#titanium tubes supplier in India#titanium tubes manufacturer and supplier#Titanium metal#titanium metal supplier#titanium suppliers#Titanium Manufacture Titaniumalloy TitaniumSupplier#titanium alloy

0 notes