#Titanium Implants Manufacturer

Explore tagged Tumblr posts

Text

An International Standard Range of Hand Fracture Plate

Hand fracture plate finds application for fixing fractures in the phalanges and other small hand bones. These plates have an anatomically contoured structure and are fabricated having locking holes. This ensures rigid fixation and optimum compression. It prevents vibration loosening and re-fracture. Hand fracture plates are available in different sizes and structures as required according to the type and severity of the fracture. Siora Surgicals Pvt. Ltd. is a trustworthy manufacturer of a CE-certified range of trauma implants including hand locking plates. Having an in-house production facility, the company is also known to be a leading OEM/contract manufacturing service provider across the globe.

#Locking Hand Plate#2.0 mm locking hand plate#Hand Locking System#Locking Hand System#Locking Plate for Hand Fracture#Hand Fracture System#Locking Plates for Hand Surgery#Locking Plate for Hand Fracture Titanium#Hand Fracture Implants#Hand Plating System#Microlock#Hand Fracture Plate#Trauma Implants#Orthopedic Trauma Implants#Orthopaedic Trauma Implants#Orthopedic Implants India#Top Orthopedic Implant Companies in India#Orthopedic Implants Manufacturers#Orthopedic Manufacturers in India

0 notes

Note

ok I occasionally see the posts about implanting a permanent chastity cage and I think to myself. Interesting idea, but how could actually be done?

Is it like a big piercing? Screwed into the pelvic bone? Permanently secured normal cage?

Of course it's just a fantasy, but I think taking it a bit further, sorting out the technical issues could be interesting and maybe make some good content/captions. (I'm very obviously from stem background)

🔏 I'm from a manufacturing background, so I understand trying to work out puzzles such as these.

The idea of some kind of medically installed device came about after I had had several dreams of @mrs--edge taking me to some clinic, usually ending with me waking up in a cold sweat 😅. I didn't know how they worked; it was just a recurring dream.

I guess after thinking about it, I have a vague concept of a titanium tube, attached to rings that have been grafted or implanted inside my body to keep them from being removed.

However, knowing what I do about medical implants, this is one of those concepts that needs at least some "willing suspension of disbelief" for the sake of the narrative.

99 notes

·

View notes

Text

Laser technique uncovers how titanium's electron behavior influences its physical properties

A research team at Yokohama National University has developed a way to study how the orientation and behavior of electrons in titanium influence its physical characteristics. Their findings, published in Communications Physics on December 18, 2024, could pave the way for the development of more advanced and efficient titanium alloys. Titanium is a very valuable metal because of its remarkable resistance to chemical corrosion, lightweight nature, and high strength-to-weight ratio. Its biocompatibility makes it ideal for medical applications, such as implants, prosthetics, and artificial bones, while its strength and durability are useful in aerospace and precision manufacturing. To get an idea of how titanium's atoms and electrons generate these properties, the researchers used a process called high harmonic generation.

Read more.

#Materials Science#Science#Lasers#Titanium#Electrons#Materials characterization#Computational materials Science#Yokohama National University

22 notes

·

View notes

Text

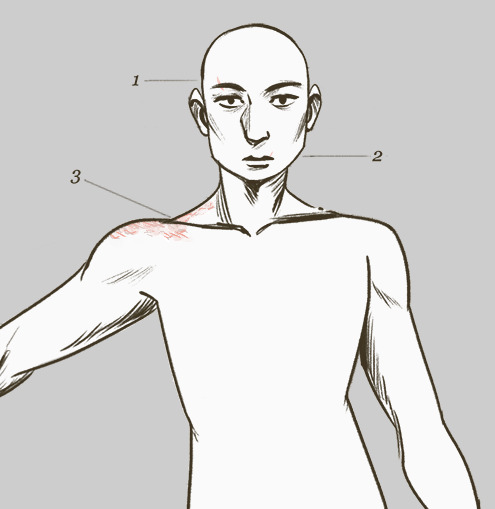

this is a breakdown and reference sheet of shepard's scars throughout the timeline of the series including where the scars were acquired and any additional physical or relevant psychological details. tw for medical trauma and mentions of sterilization** ahead. major plot spoilers also ahead. full view on images recommended.

MASS EFFECT 1

the use of shields and medi-gel can heal most moderate injuries when used in a timely manner. Scarification is still mostly permanent but proper treatment can speed up the healing process.

¹ˑ eyebrow scar, acquired from a husk on eden prime. ²ˑ lip scar, a minor injury during basic training after enlisting. ³ˑ scar tissue from the remains of a severe injury caused by thresher maw acid on akuze. the coloration has mostly faded to her skin tone but the texture is still rough. shepard is very rarely seen wearing tank tops to keep the injury concealed considering how quick people are to want to talk about akuze, which she is not interested in doing.

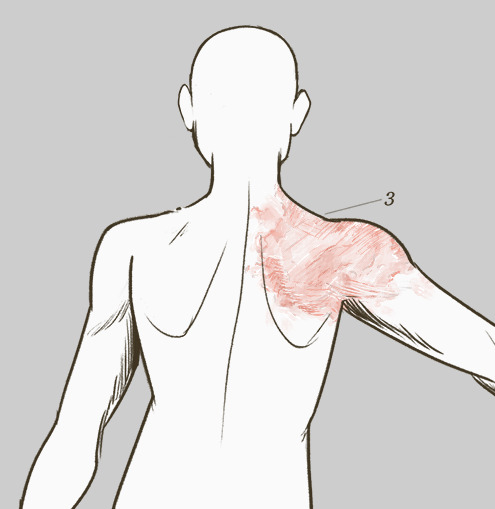

MASS EFFECT 2 / 3

after undergoing reconstruction through the lazarus project, shepard is missing her previously notable scars. her official cause of death was asphyxiation as she ran out of oxygen while breaking atmosphere; the velocity of falling from orbit burned her body beyond recognition and the force of impact when she finally landed crushed the majority of her bones. her skull was heavily fractured but her helmet miraculously prevented her brain from being severely damaged.

¹ˑ reconstruction scars, a series of strange scars from newly placed skin grafts which did not have time to properly heal. they give an oddly manufactured appearance to her as they follow natural forms and planes of the body (much like seams on a production mold would). in anything other than bright light, they give off a faint orange glow due to the cybernetics underneath. shepard is highly self conscious about these scars; mental stress seems to make them more prominent. ²ˑ enhanced optics, the first of several implanted cybernetics, these ocular implants allow for quicker visual recognition and scanning and are able to enhance mental processing to a faster rate. these implants allow her to make quick tactical decisions and auto focus on targets for her (adrenaline rush ability). ³ˑ titanium reinforced skeleton, only around 10% of shepard's skeleton is made of her original bones. titanium was used as a reinforcement material due to the heavy impact of front line combat shepard regularly faces. after full augmentation and skeletal restructuring, shepard weighs significantly more than a regular human of her height and build. ⁴ˑ heavy muscle weave, (NOT upgraded) her muscles have been perforated with micro-fibers which greatly increase her natural strength and reduce exhaustion and muscle fatigue. these enhancements can be physically upgraded, along with bone and skin weaves, but shepard decisively chooses not to augment herself any further. ⁵ˑ **most organ systems were returned to functionality, with the exception of the epidermis and skeletal system needing to be fully replaced, however her reproductive system is no longer functional. shepard no longer experiences a menstrual cycle and will never be able to conceive children.

POST MASS EFFECT 3

the consequences of choosing to destroy the reapers are both physically present in the galaxy, but also marked upon shepard herself. her body was found among the citadel wreckage, severely injured and barely alive after massive trauma to the body and brain as well as the catalyst disabling her more intricate cybernetics. shepard's 'recovery' is limited by the available resources in the wake of the aftermath; she is in critical care for minimum three months, repairing her cybernetic-reliant organ systems. intensive physical therapy is needed for several months following to adapt to her new prosthetics and regain her strength. recovery is ongoing.

¹ˑ heavy scar tissue from multiple sources, some injury from the impact of the beam which transported her to the citadel, the majority being from the explosion within the catalyst. ²ˑ reconstruction scars still present but faded, continuing to fade with time. ³ˑ cybernetic implants now mostly defunct. through gene therapy, transplants, and extensive hospitalization, her body has learned to cope without the more intricate implants. some of the less advanced ones were able to be technologically repaired. ⁴ˑ amputated arm, replaced with mechanical prosthetic. her right arm was crushed under a bulkhead on impact from explosion; it was amputated on the scene of recovering her body from the wreckage. ⁵ˑ severed leg from initial explosion, replaced with mechanical prosthetic. the wound was mostly cauterized from the heat of the blast, preventing her from dying of blood loss in the wreckage.

#⟡°⋄ ◜ headcanon . ◞#⟡°⋄ ◜ meta . ◞#medical trauma tw.#pregnancy tw.#long post.#me after working really hard on this for multiple days: please clap :')))#everyone who knows me: SHUT UP ABOUT THE FRANKENSTIEN PARALELLS SHUT UP ABOUT SHEPARD BEING THE MODERN PROMETHEUS#for all intents and purposes (and in my game canon frankly) shepard should be dead at the end of me3#but that's no fun in rp lmao

26 notes

·

View notes

Text

Touareg™ OS Dental Implants in Hyderabad | Adin Dental Implants India

The Touareg™ OS implants stand at the forefront of dental technology, featuring the revolutionary OsseoFix™ by Adin. This titanium implant surface treatment employs a gritting process with calcium phosphate media, meticulously crafted to achieve optimal roughness levels for seamless osseointegration. Notably, the OsseoFix™ is not only technologically advanced but also biocompatible.

Highlighting a myriad of advantages, the Touareg™ OS dental implants showcase double lead threads (2×1.2mm), ensuring exceptional primary stability, even in challenging type IV bone conditions. These implants possess bone-condensing properties, self-tapping capabilities, and a unique redirecting feature for precise placement. The built-in platform switching enhances adaptability, while the design facilitates minimally invasive surgery. Immediate function/loading capability streamlines the process, and a single restorative/prosthetic platform ensures simplicity in restoration procedures. Overall, the Touareg™ OS implants epitomize a comprehensive solution, seamlessly integrating innovation, adaptability, and efficiency into the realm of dental implantology.

To know more-

#dentistry#implantology#dental implants#dentalcare#dental implant#adindentalimplants#dentist#adindentalimplantsindia

2 notes

·

View notes

Text

Available in stainless steel and titanium, 2.4MM Safety Lock Duraline Distal Radius Kopis Plates ...

3 notes

·

View notes

Text

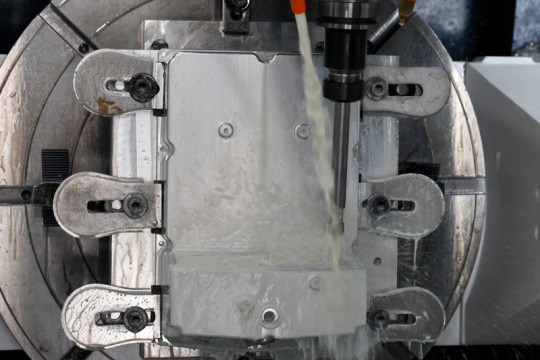

The Applications of 5 axis machining Across Industries

The keys to success in the field of advanced manufacturing are accuracy and effectiveness. 5 axis machining services are a ground-breaking strategy that has expanded the potential for producing complicated and sophisticated components. In this article, we explore the realm of 5-axis machining, examining its advantages, uses, and the radical changes it has brought about across several sectors.

5-axis Machining: Beyond Traditional Boundaries

To obtain the required form, traditional machining techniques frequently entail moving the workpiece along many axes. However, these techniques have drawbacks when it comes to creating intricate geometries. This is where 5-axis machining comes into play, expanding the realm of what is feasible.

5-axis machining adds two rotating axes (usually A and B), in contrast to 3-axis machining, which moves the workpiece along three linear axes (X, Y, and Z). This gives the tool an unmatched degree of flexibility in its movement, allowing it to approach the workpiece from several angles and orientations. A capacity for producing complex designs, speeding up production, and requiring fewer setups overall is the outcome.

5-axis Machining Shining Applications

· Aerospace: The aircraft sector requires complex, lightweight, yet robust components. In materials like titanium and aluminum, 5 axis machining enables the production of complicated geometries that are essential for airplane and spacecraft parts.

· Medical: The medical industry benefits from the accuracy of 5-axis machining in generating patient-specific components and sophisticated designs that support greater biocompatibility. This includes orthopedic implants and medical gadgets.

· Automobile: Precision 5-axis machining is utilized to create molds, prototypes, and crucial engine components in the highly competitive automobile industry, improving performance and reducing weight.

· Even in the creative sectors, such as art and design, 5-axis machining has a role. By using technology, designers, and artists can bring their imaginative ideas to life by producing elaborate sculptures, molds, and architectural models.

The Challenges and Innovations Ahead

5-axis machining is a constantly evolving field, much like any cutting-edge technology. Its capabilities are being further improved by advancements in automation, real-time monitoring, and adaptive toolpaths, which are turning it into a crucial resource in the industrial environment. Nevertheless, there are still issues like programming complexity and greater startup costs. To fully utilize the potential of 5-axis machining services at the 5 axis CNC machining center, it is imperative to understand the complexities of programming and engage in training.

Follow our Facebook and Twitter for more information about our product.

#5 axis machining#5 axis machining services#5 Axis CNC Machining Center#Custom 5 Axis Machining services#5 Axis CNC Machine Shop#5 Axis Machining Center

3 notes

·

View notes

Text

Maximizing the Capabilities of SLTL Laser Cutting Machines

SLTL laser cutting machines are cutting-edge tools that utilize laser beams to precisely cut through various materials. These machines offer several features that make them highly efficient and versatile. They are equipped with advanced control systems, high-power lasers, and intelligent software for optimal performance. Additionally, they often come with automated features like material handling systems and real-time monitoring capabilities.

The advantages of using SLTL laser cutting machines are numerous.

high precision and accuracy, allowing for intricate and complex designs

clean cuts with minimal material wastage

fast cutting speeds,.

can work with a wide range of metals, including Aluminum,Copper,Iron, Steel, Brass, Bronze, Silver, Gold, etc

Overall, SLTL laser cutting machines provide efficiency, flexibility, and quality in cutting.

youtube

To unleash the full potential of SLTL laser cutting machines, businesses can take several steps:

Upgrade the software and hardware

Keeping the machines up to date with the latest software and hardware upgrades ensures optimal performance. This includes installing the latest control systems, software updates, and laser sources. Upgrades can enhance cutting precision, speed, and overall efficiency.

Optimize the cutting parameters

Fine-tuning the cutting parameters, such as laser power, cutting speed, and focus, can improve the quality and efficiency of the cutting process. Conducting tests and experiments to find the optimal settings for different materials and thicknesses is crucial.

Train operators to maximize efficiency

Providing comprehensive training to operators is essential for utilizing the full potential of SLTL laser cutting machines. Operators should be well-versed in machine operation, maintenance, and troubleshooting. Continuous training and skill development can ensure efficient operation and minimize downtime.

SLTL laser cutting machines find extensive applications in various industries, including:

Automotive industry

These machines are used for cutting components like body panels, frames, and exhaust systems. The high precision and speed of SLTL laser cutting machines enable the automotive industry to achieve superior quality and efficiency in manufacturing processes.

Aerospace industry

SLTL laser cutting machines play a crucial role in aerospace manufacturing. They are utilized for cutting complex shapes in materials like aluminum, titanium, and composite materials. These machines enable the production of lightweight components with high structural integrity, meeting the stringent requirements of the aerospace industry.

Medical industry

SLTL laser cutting machines are employed in the medical field for cutting surgical instruments, implants, and medical devices. The precise cutting capabilities of these machines ensure accurate and reliable production of medical equipment, contributing to improved patient outcomes.

In conclusion, unleashing the potential of SLTL laser cutting machines can bring significant advantages to businesses across various industries. These machines offer high precision, clean cuts, and fast cutting speeds. By upgrading software and hardware, optimizing cutting parameters, and training operators, businesses can maximize the efficiency and productivity of these machines. Furthermore, SLTL laser cutting machines find applications in the automotive, aerospace, and medical industries, enabling superior quality and advanced manufacturing capabilities.

#cnc laser cutting machines#laser cutting machines#fiber laser cutting machines#laser machine#Youtube

2 notes

·

View notes

Text

Unlocking the Perfect Smile: The Marvels of Implant Abutments

Dental implants are a popular restorative option for patients with missing teeth. An implant consists of a small titanium post that is surgically inserted into the jawbone, which serves as the root of the tooth. After the implant has been placed, an abutment is attached to it, which connects the implant to the implant crown. In this blog, we will explore what an abutment is, its role in implant dentistry, and the types of implant abutments available.

What is an Abutment in Dental Implant?

An abutment in a dental implant is a connector that attaches to the implant post and protrudes above the gum line. The implant abutment serves as a foundation for the implant crown, which is the visible part of the tooth restoration. The abutment can be made of different materials, including titanium, zirconia, or porcelain. It is usually placed after the implant post has integrated into the jawbone.

Role of Abutment in Dental Implant

The abutment in dental implant plays a crucial role in implant dentistry. It connects the implant post to the implant crown and serves as a support for the crown. The abutment is designed to fit precisely with the implant post and the implant crown to ensure stability and prevent any movement. It is also responsible for creating an aesthetic appearance that matches the surrounding natural teeth.

Types of Implant Abutments

There are different types of implant abutments available, depending on the implant system and the patient's needs. Here are some of the commonly used implant abutments:

Stock Abutments: Stock abutments are pre-manufactured abutments that come in different shapes and sizes. They are available for most implant systems and can be used in standard cases. Stock abutments are a cost-effective option, but they may not provide the best aesthetic results.

Custom Abutments: Custom abutments are made specifically for a patient's implant case. They are designed to match the contours of the implant post and the implant crown, providing better aesthetic results. Custom abutments are more expensive than stock abutments, but they offer better outcomes.

Angled Abutments: Angled abutments are used in cases where the implant post is not placed vertically. They allow for proper alignment of the implant crown and improve the aesthetic appearance of the restoration.

Implant Abutment Crown

The implant abutment crown is the visible part of the tooth restoration that attaches to the abutment. It is usually made of porcelain or ceramic material, which provides an aesthetic appearance that matches the surrounding natural teeth. The implant abutment crown is designed to fit precisely with the abutment and provide stability and support.

Conclusion

An abutment in a dental implant plays a vital role in implant dentistry. It connects the implant post to the implant crown and provides stability and support for the restoration. Choosing the right type of implant abutment depends on the implant system and the patient's needs. Monumental Dental Engineering offers a wide range of implant abutments and dental milling machines to meet the needs of dentists and dental laboratories. With the right equipment and materials, you can provide your patients with the best possible dental care.

3 notes

·

View notes

Text

An Educational Blog on Spinal Implants | Siora Surgicals

The spine is a marvel of engineering that provides structure, flexibility, and protection for our spinal cord. But like any complex system, it can wear down or become injured. When conservative treatments like physical therapy or medication fall short, Spine implants offer a vital option for restoring stability and alleviating pain. In this blog, we will have a quick look at spinal implants including their function, types, and risks associated.

#Spine Implants Name#Spine Implants#Spine Implants Manufacturer#Spine Implants Manufacturer in India#Spinal Implants Manufacturers#Spinal Implant Distributors#Titanium Spinal Implants#Spinal Implants Cost#Spine Implants Price List#Spinal Implant Price List#Spine Implant Cost in India#Titanium Spinal Implants Cost#Spine Screw Price

0 notes

Text

Titanium Metal - Qualities As Well As Uses

Pure titanium is a light-weight, tough, silvery-white, shiny metal. It has unique strength as well as deterioration resistance homes and also a high stamina to weight proportion.

The name Titanium itself is stemmed from the name of God of planet 'Titan" in Greek folklore. The name implies stamina.

Titanium is a chemical element with the sign Ti. It has an atomic number of 22, inhabits team 4, duration 4, and also block d in the periodic table and is classified as a transition steel.

Titanium is the 9th most abundant element in the Planet's crust but is by no means discovered it its pure kind. Its major minerals are anatase, brookite, ilmenite, perovskite, rutile, titanite, too lots of iron ores. Rutile as well as ilmenite are its economically important minerals.

Considerable deposits of ilmenite are found in Western Australia, Canada, China, India, Mozambique, New Zealand, Norway, as well as Ukraine. Substantial amounts of rutile are mined in The United States and Canada and South Africa.

Titanium Tube

One of the most considerable residential properties of Titanium are its strength, its resistance to rust as well as it stamina to weight proportion.

Titanium is 45% lighter than steel but it is just as strong. It is only 60% heavier than aluminium but is 100% more powerful.

Titanium is basically as immune to rust as platinum, and can holding up against acids, salt services, as well as also the extremely destructive chlorine gas.

The humane blend of light weight as well as wonderful stamina in addition to its resistance to rust and also warmth makes it ideal for airplane, spacecrafts projectiles and so on. In sports it is used for making light as well as solid noises, bicycle frameworks, golf clubs etc. Titanium likewise discovers use in making eyewear structures, light-weight laptops, bone and oral implants in medicine.

Titanium vanadium alloys are extensively made use of in aviation in the manufacture of landing gear, hydraulic tubing, fire walls, etc.

Yet probably the really business and also mass intake oriented use of titanium began with the crafting of titanium jewelry as well as today Titanium precious jewelry industry is amongst the fastest growing market sector in fashion jewelry industries.

Titanium is honored with almost all the high qualities important to become an appropriate medium for crafting precious jewelry. It is solid and long lasting, it is immune to rust, and it is hypoallergenic significance that it does not established off allergies with the skin.

A gorgeous, putty-grey shade differentiates titanium from the silver, gold as well as platinum used in jewelry. With different types of gloss it can be given either a matte or a glossy coating.

Titanium Sheet

The setting of Titanium in the periodic table (team 4, period 4, and also block d) identifies it as a change metal. Among the common residential or commercial properties shared by all change steels is that they are able to develop colored substances primarily by anodizing. The process entails producing oxide layers of different density and refractive residential properties on the steel surface. This characteristic is used for crafting titanium precious jewelry in practically every shade of the rainbow.

Titanium is utilized for crafting precious jewelry items like jewelry, pendants, bracelets, rings, wedding bands, money clips and so on.

The metal is frequently viewed as an icon of toughness as well as indestructibility and also this has made titanium wedding bands a preferred option for pairs that desire their marriages to continue to be as strong as well as indestructible.

There is a particular magical top quality concerning titanium as well as it seems specifically appropriate that titanium (before it was so named) was found by a male of God-Reverend William Gregor-in Cornwall, England, back in 1790. It is likewise proper that 5 years later the metal was in fact called titanium, after the Titans, the Greek gods of planet by the German chemist Martin Heinrich Klaproth.

2 notes

·

View notes

Text

For literally everyone in the comments worrying about pins and joint replacements and staples and surgical clips and markers …. It is EXTREMELY uncommon for modern orthopedic hardware, surgical clips, pins, or markers to be incompatible with MRI. In most cases these days non-magnetic metals such as titanium are used, and so although they show artefact on the imaging the devices themselves will not harm you!

Pacemakers, stimulators, etc are a different story, as often they themselves are controlled through the skin by a programming magnet, and so MRIs can really mess them up if they do not have an MRI mode. This should be discussed with your doctor, and if needed they radiology facility can always check with the manufacturer.

Not to say you shouldn’t make sure the technicians and docs are aware of your implant/surgical history - of course you should! But when it comes to most modern implantable hardware, an MRI is not problem.

*booking an mri* what if I accidentally have a pacemaker. what if I got secret bone surgery and forgot about the pins

70K notes

·

View notes

Text

3D Printing Materials Market Future Trends: Advanced Polymers, Metal Powders, and Bio-Compatible Innovations

The 3D printing industry is experiencing an unprecedented surge, transforming manufacturing, healthcare, automotive, aerospace, and consumer goods sectors. Central to this revolution is the development of advanced 3D printing materials. As new materials emerge, offering better strength, flexibility, and eco-friendliness, the market is poised for rapid expansion. This article delves into the future trends shaping the 3D printing materials market, from sustainable materials to high-performance composites.

Rising Demand for Sustainable and Biodegradable Materials Environmental concerns and regulatory pressure are driving the shift towards sustainable 3D printing materials. Companies are investing in biodegradable and recyclable materials such as PLA (Polylactic Acid) and bio-composites. Researchers are also exploring algae-based filaments, hemp-based resins, and recycled plastics to minimize environmental impact. As sustainability becomes a priority, bio-based materials will gain widespread adoption in industries striving for greener solutions. Advances in Metal 3D Printing Materials Metal 3D printing is revolutionizing industries like aerospace, medical, and automotive by enabling complex and lightweight structures. The demand for high-performance metal powders, such as titanium, aluminum, and stainless steel, is increasing. Innovations in metal 3D printing are also making way for materials with enhanced thermal and mechanical properties, allowing manufacturers to produce stronger, more durable components with precision. Smart Materials and Nanotechnology Integration The integration of smart materials in 3D printing is a game-changer. Shape-memory alloys, self-healing polymers, and conductive filaments are gaining traction for advanced applications. These materials can adapt to environmental changes, improving functionality in industries like robotics, medical devices, and wearable technology. Additionally, nanotechnology is enhancing material properties, making 3D-printed objects more resilient, lightweight, and multifunctional. Customization and Industry-Specific Material Developmen tOne of the biggest advantages of 3D printing is the ability to customize materials for specific applications. Industries such as healthcare and aerospace require highly specialized materials with unique properties. For instance, biocompatible resins are crucial for medical implants, while flame-retardant filaments are necessary for aerospace components. Future advancements will focus on tailored material formulations that meet stringent industry requirements, enabling further adoption. Cost Reduction and Improved Production Efficiency One of the main challenges in 3D printing has been the high cost of materials. However, as production techniques improve and supply chains expand, the costs of high-performance 3D printing materials are expected to decrease. Advancements in material recycling and the development of hybrid materials will further drive affordability, making 3D printing a viable alternative to traditional manufacturing for mass production. Conclusion The future of the 3D printing materials market is shaped by sustainability, innovation, and industry-specific advancements. With growing investments in smart materials, metal powders, and eco-friendly alternatives, the industry is set to witness rapid expansion. As costs decrease and material performance improves, 3D printing will continue to redefine manufacturing, paving the way for a more efficient and sustainable future.

0 notes

Text

Cleaning up critical minerals and materials production, using microwave plasma

New Post has been published on https://sunalei.org/news/cleaning-up-critical-minerals-and-materials-production-using-microwave-plasma/

Cleaning up critical minerals and materials production, using microwave plasma

The push to bring manufacturing back to the U.S. is running up against an unfortunate truth: The processes for making many critical materials today create toxic byproducts and other environmental hazards. That’s true for commonly used industrial metals like nickel and titanium, as well as specialty minerals, materials, and coatings that go into batteries, advanced electronics, and defense applications.

Now 6K, founded by former MIT research scientist Kamal Hadidi, is using a new production process to bring critical materials production back to America without the toxic byproducts.

The company is actively scaling its microwave plasma technology, which it calls UniMelt, to transform the way critical minerals are processed, creating new domestic supply chains in the process. UniMelt uses beams of tightly controlled thermal plasma to melt or vaporize precursor materials into particles with precise sizes and crystalline phases.

The technology converts metals, such as titanium, nickel, and refractory alloys, into particles optimized for additive manufacturing for a range of industrial applications. It is also being used to create battery materials for electric vehicles, grid infrastructure, and data centers.

“The markets and critical materials we are focused on are important for not just economic reasons but also U.S. national security, because the bulk of these materials are manufactured today in nonfriendly countries,” 6K CEO Saurabh Ullal says. “Now, the [U.S. government] and our growing customer base can leverage this technology invented at MIT to make the U.S. less dependent on these nonfriendly countries, ensuring supply chain independence now and in the future.”

Named after the 6,000-degree temperature of its plasma, 6K is currently selling its high-performance metal powders to parts manufacturers as well as defense, automotive, medical, and oil and gas companies for use in applications from engine components and medical implants to rockets. To scale its battery materials business, 6K is also building a 100,000-square-foot production facility in Jackson, Tennessee, which will begin construction later this year.

A weekend project

Between 1994 and 2007, Hadidi worked at the Plasma Science and Fusion Center (PFSC), where he developed plasma technologies for a range of applications, including hydrogen production, fuel reforming, and detecting environmental toxins. His first company was founded in 2000 out of the PFSC to detect mercury in coal-fired power plants’ smokestacks.

“I loved working at MIT,” Hadidi says. “It’s an amazing place that really challenges you. Just being there is so stimulating because everyone’s trying to come up with new solutions and connect dots between different fields.”

Hadidi also began using high-frequency microwave plasmas to create nanomaterials for use in optical applications. He wasn’t a materials expert, so he collaborated with Professor Eric Jordan, a materials synthesis expert from the University of Connecticut, and the researchers started working on nights and weekends in the PSFC to develop the idea further, eventually patenting the technology.

Hadidi officially founded the company as Amastan in 2007, exploring the use of his microwave plasma technology, later named UniMelt for “uniform melt state process,” to make a host of different materials as part of a government grant he and Jordan received.

The researchers soon realized the microwave plasma technology had several advantages over traditional production techniques for certain materials. For one, it could eliminate several high-energy steps of conventional processes, reducing production times from days to hours in some cases. For batteries and certain critical minerals, the process also works with recycled feedstocks. Amastan was renamed 6K in 2019.

Early on, Hadidi produced metal powders used in additive manufacturing through a process called spheroidization, which results in dense, spherical powders that flow well and make high-performance 3D-printed parts.

Following another grant, Hadidi explored methods for producing a type of battery cathode made from lithium, nickel, manganese, and cobalt (NMC). The standard process for making NMCs involved chemical synthesis, precipitation, heat treatment, and a lot of water. 6K is able to reduce many of those steps, speeding up production and lowering costs while also being more sustainable.

“Our technology completely eliminates toxic waste and recycles all of the byproducts back through the process to utilize everything, including water,” Ullal says.

Scaling domestic production

Today, 6K’s additive manufacturing arm operates out of a factory in Pennsylvania. The company’s critical minerals processing, refining, and recycling systems can produce about 400 tons of material per year and can be used to make more than a dozen types of metal powders. The company also has 33,000-square-foot battery center in North Andover, Massachusetts, where it produces battery cathode materials for its energy storage and mobility customers.

The Tennessee facility will be used to produce battery cathode materials and represents a massive step up in throughput. The company says it will be able to produce 13,000 tons of material annually when construction is complete next year.

“I’m happy if what I started brings something positive to society, and I’m extremely thankful to all the people that helped me,” says Hadidi, who left the company in 2019. “I’m an entrepreneur at heart. I like to make things. But that doesn’t mean I always succeed. It’s personally very satisfying to see this make an impact.”

The 6K team says its technology can also create a variety of specialty ceramics, advanced coatings, and nanoengineered materials. They say it may also be used to eliminate PFAS, or “forever chemicals,” though that work is at an early stage.

The company recently received a grant to demonstrate a process for recycling critical materials from military depots to produce aerospace and defense products, creating a new value stream for these materials that would otherwise deteriorate or go to landfill. That work is consistent with the company’s motto, “We take nothing from the ground and put nothing into the ground.”

The company’s additive division recently received a $23.4 Defense Production Act grant “that will enable us to double processing capacity in the next three years,” Ullal says. “The next step is to scale battery materials production to the tens of thousands of tons per year. At this point, it’s a scale-up of known processes, and we just need to execute. The idea of creating a circular economy is near and dear to us because that’s how we’ve built this company and that’s how we generate value: addressing our U.S. national security concerns and protecting the planet as well.”

0 notes

Text

Pediatric Safety Lock Hip Plates 2.7MM are available in stainless and titanium ...

2 notes

·

View notes

Text

Bone Fixation Plates Market Trends: Exploring Key Drivers, Technological Advancements, and Future Outlook for 2025

The Bone Fixation Plates Market has witnessed significant developments over recent years, reflecting innovations in the medical and orthopedic devices industry. These advancements have spurred growth, expanding applications in surgeries related to bone fractures, deformities, and joint replacements. With the increasing demand for efficient treatment options and an aging global population, the market has experienced robust expansion, driven by advancements in materials, technologies, and surgical techniques. These plates, which are essential for stabilizing bone fractures and ensuring proper healing, are becoming more sophisticated, offering better outcomes for patients. As the market evolves, it is crucial to understand the factors that contribute to this growth.

Technological Advancements and Product Innovations

One of the primary drivers of the bone fixation plates market is the continuous technological innovation within the healthcare sector. New materials like titanium and bioresorbable polymers are being increasingly used to develop lightweight, strong, and flexible plates. These advancements not only enhance the functionality of the plates but also reduce complications such as infection and rejection. Additionally, the integration of 3D printing technology has revolutionized the customization of bone plates, allowing surgeons to tailor implants specifically to the patient's needs. This has made surgeries safer, more efficient, and with improved recovery outcomes.

Market Growth and Demand Drivers

As the global population ages, the prevalence of bone-related issues, including fractures and degenerative diseases, is on the rise. This demographic shift is significantly influencing the demand for bone fixation plates, as more people require treatment for bone fractures and joint reconstruction. In addition to aging populations, the increasing incidence of traumatic injuries, especially in developing regions with growing industrialization, is further driving the demand for these devices. The rise in healthcare spending and improvements in medical insurance coverage also play a crucial role in supporting market growth.

Regulatory Landscape and Market Challenges

While the growth prospects are positive, the bone fixation plates market faces challenges, particularly in the form of stringent regulatory requirements. Regulatory bodies like the FDA (Food and Drug Administration) and the European Medicines Agency (EMA) require thorough clinical testing and approvals before new products can be introduced to the market. These regulations ensure patient safety but also create barriers for small players looking to enter the market. Moreover, the complexity and cost of advanced manufacturing processes can also limit the growth of certain market segments.

Competitive Landscape and Key Players

The competitive landscape in the bone fixation plates market is becoming more intense, with numerous global and regional players vying for market share. Leading companies like DePuy Synthes, Stryker Corporation, Zimmer Biomet, and Medtronic continue to innovate and expand their product portfolios to stay ahead of the competition. These companies focus on improving the durability, design, and overall performance of their fixation plates. Strategic collaborations, mergers, and acquisitions are also common in the industry, as companies aim to expand their geographical reach and offer enhanced product solutions.

Future Outlook and Emerging Trends

Looking ahead, the bone fixation plates market is poised for further growth, driven by technological advancements, improved healthcare infrastructure, and rising patient awareness. Key trends include the increasing adoption of minimally invasive surgery, which reduces recovery times and promotes faster healing. Furthermore, the growing popularity of customized implants tailored to individual patients’ needs is likely to enhance the efficacy of treatments. The market’s expansion will also be facilitated by the rising demand for arthroplasty and reconstructive surgeries.

Conclusion

In conclusion, the Bone Fixation Plates Market is witnessing significant transformations, driven by advancements in material science, surgical procedures, and the rising global demand for orthopedic solutions. As innovations continue to shape the future of the market, the focus will remain on enhancing patient outcomes, reducing recovery times, and offering more customized treatment options. These trends will lead to an evolving and dynamic market that offers numerous growth opportunities for both established and emerging players.

0 notes