#Titanium Alloy GR 5

Explore tagged Tumblr posts

Text

Titanium Alloy GR 2, GR 5, GR 7 Round Bar Exporters in Malaysia - Jay Steel Corporation

In state-of-the-art years, the decision for titanium alloys throughout numerous industries has surged due to their superior features, together with a high strength-to-weight ratio, outstanding corrosion resistance, and the capability to face up to excessive temperatures. These attributes make titanium alloys mainly appealing for applications in aerospace, vehicle, chemical processing, and scientific fields. Among the various grades, GR 2, GR 5, and GR 7 stand out for their unique characteristics. Consequently, Malaysia has emerged as a key hub for the manufacture and export of those alloys, with agencies like Jay Steel Corporation most important the manner.

Understanding Titanium Alloys

Before diving into the specifics of each grade, it's miles essential to understand what titanium alloys are and why they may be treasured in commercial programs:

Titanium Alloy GR 2: This is a commercially herbal titanium alloy identified for its super corrosion resistance and ductility. It is typically used in chemical processing, shipping boxes, and different specific settings in which entering touch with corrosive materials is a threat.

Titanium alloy GR 5: Often referred to as Ti-6Al-4V is one of the most extensively used titanium alloys. It has an aggregate of titanium, aluminum, and vanadium that reveals better hardness and electrical. This makes GR 5 best for aerospace, automobile, and scientific applications.

Titanium Alloy GR 7: Similar to GR 2, this alloy is a commercially natural titanium alloy however with the addition of palladium. GR 7 gives superior corrosion resistance, mainly in acidic environments, making it appropriate for chemical processing and oil and fuel industries.

The Role of Malaysia in Titanium Alloy Manufacturing

Malaysia has positioned itself as a huge participant in the worldwide titanium market, way to its superior manufacturing competencies and proximity to key markets in Asia and beyond. Boasts a whole lot of manufacturers specializing in the production of titanium round bars, catering to each characteristic and international demand.

Manufacturing Process of Titanium Alloys in Malaysia

The approach to producing titanium alloy round bars in Malaysia includes several vital steps:

Raw Material Sourcing: Quality raw titanium is sourced from trusted providers to ensure that the very last merchandise meets company requirements.

Melting and Alloying: The titanium is melted in vacuum arc furnaces, which gives a managed environment to prevent infection. This is critical for maintaining the integrity of the alloy.

Forming: Once melted, the titanium is solid into billets or right away solid into round bars. This technique may also contain heat running techniques to reap the favored dimensions and mechanical features.

Heat Treatment: To beautify the electricity and longevity of the titanium alloys, warmness remedy techniques that incorporate annealing are hired.

Finishing: The round bars go through ground completing techniques, which might also additionally encompass machining, grinding, or sprucing, to attain the desired specifications and ground excellent.

Quality Control: Rigorous checking out is carried out to ensure that the round bars meet international satisfactory standards, which includes mechanical attempting out and corrosion resistance critiques.

Jay Steel Corporation: Your Trusted Partner

As one of the prominent Titanium Alloy GR 5 round bar exporters in Malaysia, Jay Steel Corporation has set up a recognition for turning in great titanium products. The employer’s dedication to excellence is pondered in its big kind of titanium round bars, such as GR 2, GR 5, and GR 7. With a focus on purchaser delight, Jay Steel Corporation ensures that each product is artificial to meet the unique necessities of clients throughout numerous industries.

Key Advantages of Sourcing from Jay Steel Corporation

Quality Assurance: All titanium round bars go through strict satisfactory control techniques to ensure that they meet or exceed employer requirements.

Diverse Product Range: Jay Steel Corporation gives an extensive form of titanium alloys to cater to specific packages, ensuring that customers locate the right material for their goals.

Timely Delivery: The business enterprise prides itself on its efficient delivery chain management, supplying properly timed delivery to customers in Malaysia and around the arena.

Expertise and Support: With years of revel in in the titanium industry, Jay Steel Corporation gives precious insights and aid to customers, assisting them make informed choices.

Conclusion

In summary, the decision for titanium alloy round bars, mainly GR 2, GR 5, and GR 7 keeps to develop in diverse industries because of their first-rate features. Malaysia stands out as a key participant in this marketplace, with manufacturers like Jay Steel Corporation's main manner as reliance on suppliers and exporters. By specializing in best, purchaser satisfaction, and innovation, Jay Steel Corporation is well-placed to meet the growing worldwide wishes for titanium alloys. Whether you're seeking out a Titanium Alloy GR 2 round bar provider in Malaysia or looking for a reliable Titanium Alloy GR 7 round bar manufacturer in Malaysia, Jay Steel Corporation is your flow-to accomplice for all your titanium needs.

0 notes

Text

#Titanium Gr 5 Pipes & Tubes#Titanium Gr 5 Pipes & Tubes Manufacturers#Titanium Gr 5 Pipes & Tubes Suppliers#Titanium Gr 5 Pipes & Tubes Stockists#Titanium Gr 5 Pipes & Tubes Exporters#ASTM B337 Grade 5 Titanium Pipes#Titanium Alloy Grade 5 Pipes#Grade 5 Titanium Alloy Pipes#IS 14836 Grade 5 Titanium Pipes#Aerospace Grade Titanium Pipes#Grade 5 Ti-6Al-4V Pipes#Marine-Grade Titanium Grade 5 Pipes#Titanium Gr 5 Pipes & Tubes In India#Titanium Gr 5 Pipes & Tubes Manufacturers In India#Titanium Gr 5 Pipes & Tubes Suppliers In India#Titanium Gr 5 Pipes & Tubes Stockists In India#Titanium Gr 5 Pipes & Tubes Exporters In India#BS EN 10204 Titanium Grade 5 Tubes#Aircraft Grade Titanium Tubes#Surgical Grade Titanium Tubes#Medical Grade 5 Titanium Tubes#UNS R56400 Tubes#ASTM B861 Gr 5 Tubes#ISO 5832-3 titanium Tubes#Titanium Gr 5 Pipes & Tubes in Mumbai#Titanium Gr 5 Pipes & Tubes Manufacturers in Mumbai#Titanium Gr 5 Pipes & Tubes Suppliers in Mumbai#Titanium Gr 5 Pipes & Tubes Stockists in Mumbai#Titanium Gr 5 Pipes & Tubes Exporters in Mumbai#DIN 3.7165 Pipes & Tubes

1 note

·

View note

Text

Titanium Alloy Gr 5 Sheets & Plates Exporters in India

We stay aware of the transcendent idea of Titanium Gr 5 Sheets & Plates at Sankalp Alloys Overseas. This is among the most notable and regularly used titanium grade. This thing range has incomprehensible strength with the extra combinations of aluminum. They are light weighted and against disastrous nature. Thusly, these Steel have been truly troublesome applications.

It has the best strength and warm as well as electrical conductivity properties. This thing is moreover good to go with heat treatment works. They display wonderful properties of transparency, weldability, flexibility, and versatility. They have an unassuming extent of yield as well as inflexible characteristics. Also, the protracting range goes up to the 15 % generally outrageous.

Titanium Alloy Gr 5 Sheets & Plates Manufacturers, Titanium Alloy Gr 5 Sheets & Plates Suppliers, Titanium Alloy Gr 5 Sheets & Plates Stockists, Titanium Alloy Gr 5 Sheets & Plates Exporters

ASTM B265 Titanium Grade 5 Curls Provider, ASTM B265 Titanium Gr 5 Sheets Exporter, Gr 5 Titanium Checkered Plates Stockists, Titanium Gr 5 Punctured Sheets, Titanium Gr 5 CR Sheets, Titanium Gr 5 #4 Completion Plates, Titanium Gr 5 Shim Sheets, Titanium Compound Gr 5 Hot Moved Plates, Titanium ASTM B265 Gr 5 Plates, Titanium Grade 5 Sheets & Plates Producer in India.

Grade 5 sheets of steel are available in variety tempers to work with cold-moved too. This thing is well off in a very unprecedented compound part named as vanadium. In this way, it has such astonishing hardening and stress fixing credits. Other than this, they are moreover elaborate the parts like titanium, aluminum, hydrogen, nitrogen, carbon, and iron. This compound make-up has lovely temperature opposition. The condensing point by and large reaches to 1660 degrees Celsius (or 3020 degrees Fahrenheit). Also, they moreover have exceptional amounts of warm turn of events and modulus of flexibility.

Considering its cost reasonability and quick store, they are by and large applied in the gathering of bicycle body parts and bolts. Similarly, they have been on a very basic level liked in the plane organizations for their high-temperature general fundamental applications. Other than this, their pure and rich engineered development let them go into the biomedical inserting purposes.

The general speculation for the detail and properties of Titanium Gr 5 Sheets & Plates is referred to in the ASTM B265 and ASME SB265 standards. They can be benefitted in variety hardness ranges like fragile, hard, half-hard, quarter-hard, spring-hard, etc.

Furthermore, grade 5 comes in different fulfillment works like hot-rolled, cold-rolled, 2B, 2D, BA, Silk (with plastic covering, etc it is dependent upon the specifics given by the clients.

Titanium Gr 5 Sheets & Plates expected to complete a piece of the evaluations for validity and quality affirmation. Some of them are PMI, pariah assessment, positive material tests, engineered and mechanical examination, IGC tests, etc.

Specification of Titanium Gr 5 Sheets & Plates

Titanium Sheets & Plates Specification : ASTM B265 / ASME SB265 Dimension Standard : JIS, AISI, ASTM, GB, DIN, EN, etc Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc Thickness : 0.3 mm to 120 mm Form : Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Perforated Sheet, Chequered Plate, Strip, Flats, Blank (Circle), Ring (Flange) etc. Surface Finishing : Hot rolled plate (HR), Cold rolled sheet (CR),2B, 2D, BA, NO.1, NO.4, NO.8, 8K, mirror, Chequered, embossed, hair line, sand blast, Brush, etching, SATIN (Met with Plastic Coated) etc.

0 notes

Text

Titanium Gr2 Sheet Plate and Titanium Gr5 Sheet Manufacturers

2 notes

·

View notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539) Duplex Steel:Grade: 2205 (1.4507) Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750) Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668) Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT Nickel :Grade: Nickel 200, Nickel 201 Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225) Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html Contact Us -9819523999 Email Id - [email protected]

4 notes

·

View notes

Text

Titanium Gr 2, Gr 5, and Gr 7 Sheet/Plates/Coils Manufacturers in Kuwait | Bhagya Laxmi Industrial

When it consists of sourcing Titanium Gr 2 Sheet/Plates/Coils, Titanium Gr 5 Sheet/Plates/Coils, or Titanium Gr 7 Sheet/Plates/Coils, Bhagyalaxmi Industrial is a relied-on name in Kuwait. With years of records, we offer first-rate titanium products for numerous industries, which consist of aerospace, chemical, and marine sectors. In this weblog, we’ll look at the precise features and programs of numerous titanium grades to help you choose the right product for your dreams.

What Is Titanium?

Titanium is a flexible, sturdy, and moderate-weight steel for its corrosion resistance, making it terrific for disturbing environments. It is extensively carried out in aerospace, chemical processing, medical, and marine industries because of its functionality to upwardly push up to excessive temperatures, harsh chemical materials, and mechanical stresses.

Titanium Gr 2 Sheet/Plates/Coils: Versatile and Reliable

Use: Titanium Gr 2 is the purest form of titanium with fantastic corrosion resistance.

Titanium Gr 2 sheets/plates/coils are famous in industries in which excessive corrosion resistance is crucial, which incorporates chemical processing and marine programs. Due to its extraordinary weldability and formability, Titanium Gr 2 is proper for manufacturing warmth exchangers, pressure vessels, and pharmaceutical tools.

Titanium Gr 2 is usually applied in:

Marine Hardware

Power generation

Heat exchangers

Pharmaceutical device

We ensure our Titanium Gr 2 products meet stringent enterprise requirements, providing you with long-lasting and dependable solutions.

Titanium Gr 5 Sheet/Plates/Coils: Strength and Lightweight Properties

Use: Titanium Gr five (Ti-6Al-4V) is the most substantially used titanium alloy, imparting immoderate strength and corrosion resistance.

Titanium Gr 5 sheets/plates/coils are top-notch for applications that require energy and weight reduction. This alloy, which incorporates aluminium and vanadium, is substantially more potent than Titanium Gr 2 without sacrificing corrosion resistance. It is used in aerospace, cars, and clinical industries.

Titanium Gr 5 gives:

Excellent fatigue resistance

High electricity-to-weight ratio

Resistance to oxidation and corrosion

Applications encompass:

Aircraft additives

Medical implants

Power plants

Structural applications

Whether you need titanium Gr 5 sheets, plates, or coils for aerospace or clinical programs, we offer tremendous products that meet specific specs.

Titanium Gr 7 Sheet/Plates/Coils: Superior Corrosion Resistance

Use: Titanium Gr 7 is an alloy that includes small quantities of palladium to enhance corrosion resistance.

Titanium Gr 7 sheets/plates/coils are extremely good for environments that contain aggressive chemical substances, acids, or chlorides. Its superior corrosion resistance makes it a first-rate desire for programs in chemical processing, marine environments, and energy generation.

Titanium Gr 7 is believed to be:

Exceptional resistance to acids and chlorides

Superior weldability and formability

Increased resistance to corrosion in the assessment of natural titanium

Applications encompass:

Chemical processing device

Marine applications

Heat exchangers and condensers

For industries requiring brilliant levels of corrosion resistance, Titanium Gr 7 is the proper product. We offers one's products in several sizes and finishes to meet your needs.

Why Choose Bhagyalaxmi Industrial?

We prioritize turning out very first-rate satisfactory titanium products to our clients in Kuwait. Our titanium sheets, plates, and coils undergo strict, fantastic control strategies to ensure they meet the demands of industries like aerospace, clinical, and chemical processing.

Advantages of strolling with us include:

High-brilliant titanium products

A large shape of grades and sizes

Customization alternatives for unique requirements

Reliable shipping and excellent customer service

We are a relied-on partner for industries that require titanium solutions, and we make certain that every product meets or exceeds your expectations.

Conclusion

Finally, deciding on the right titanium product is crucial to the achievement of your demands. Whether you require Titanium Gr 2 Sheet/Plates/Coils for corrosion resistance, Titanium Gr 5 Sheet/Plates/Coils for power, or Titanium Gr 7 Sheet/Plates/Coils for advanced corrosion resistance, Bhagyalaxmi Industrial in Kuwait has the right solutions for you. Contact us in recent times to talk about your titanium needs and permit us to offer you brilliant products on your programs.

#Titanium Gr 2 Sheet/Plates/Coils#Titanium Gr 5 Sheet/Plates/Coils#Titanium Gr 7 Sheet/Plates/Coils#Bhagya Laxmi Industrial

0 notes

Text

Top quality Titanium Grade 5 flanges manufacturer in India | Mehta Metals

Mehta Metals offers top-quality Titanium Grade 5 flanges known for their exceptional strength, lightweight properties, and corrosion resistance. Titanium Grade 5, also called Ti-6Al-4V, is an alloy that combines titanium with aluminum and vanadium, making it ideal for demanding applications like aerospace, marine, chemical processing, and power generation. Our Titanium Gr 5 Flanges are designed to handle extreme temperatures and harsh environments while providing excellent durability and longevity. if you’re looking for reliable and cost-effective solutions for Titanium Grade 5 flanges, Mehta Metals has you covered!.

0 notes

Text

Ganpat Metal Industries an extensive variety of Titanium Alloy Gr 5 Flanges, where these items is being presented by us are fabricated utilizing top notch metal. Titanium Gr 5 Slip On Flanges (UNS R50400) is a strong arrangement Alloy that must be solidified by cool working. Welding strategies including gas - circular segment welding, metal - bend welding, gas - metal - curve welding and lowered - circular segment welding are suggested on these Titanium Gr 5 Strung Flanges. Uncompromising machining hardware and tooling ought to be utilized in Titanium Gr 5 Weld Neck Flanges to limit prattle or work - solidifying of the amalgam in front of the cutting.

#carbon steel socketweld fittings manufacturers#carbon steel socketweld fittings suppliers#high nickel alloy socketweld fittings suppliers#high nickel alloy socketweld fittings stockists

0 notes

Text

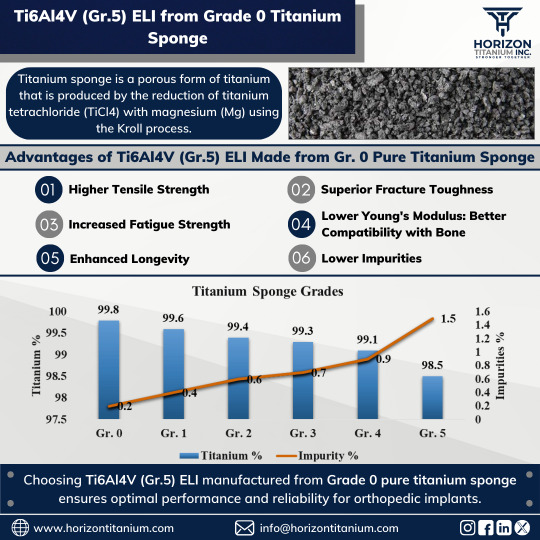

Titanium is vital in the medical field due to its biocompatibility, strength, and corrosion resistance. However, the quality of medical-grade titanium depends on the grade of titanium sponge used in production. Let's explore how titanium sponge impact the quality of titanium for medical devices and implants.

What is Titanium Sponge? Titanium sponge, made through the Kroll process, is a porous, brittle form of titanium. It needs further processing and alloying with elements like aluminum and vanadium (Ti6Al4V (Gr.5) ELI) to be used in manufacturing medical devices. Its quality and purity are critical for the final titanium properties.

Importance of Choosing the Right Grade The grade of titanium sponge used to manufacture titanium material for medical applications has a profound impact on the quality and performance of the final product. By selecting the right grade, manufacturers can ensure that medical devices made from high-purity Sponge Gr. 0 material will meet the stringent standards required for medical use, providing safe and effective solutions for patients.

If you need any further information, reach out at [email protected]

#KnowYourTitanium#Titanium#TitaniumSponge#TitaniumSpongeGrade0#TitaniumManufacturing#KrollProcess#Ti6Al4VELI#Grade5ELI#HigherTensileStrength#SuperiorFractureToughness#IncreasedFatigueStrength#LowerYoungModulus#EnhancedLongevity#LowerImpurities#MaterialScience#TitaniumQuality#MedicalGradeTitanium#TitaniumImplants#OrthopaedicImplants#MedicalDevices#HorizonTitanium#StrongerTogether

0 notes

Text

What industries use fasteners?

Fasteners play a critical role in construction, manufacturing, and engineering. As a leading force in the industry, Bullion Pipes & Tubes LLP stands out as the premier fasteners manufacturer, supplier, stockist, and exporter worldwide. With an extensive range that includes Bolts, Nuts, Screws, Washers, Studs, Rivets, Self-Clinching Fasteners, and more, our commitment is to provide top-notch solutions that cater to diverse project requirements.

This blog post aims to shed light on the diverse industries that heavily rely on fasteners, emphasizing the broad spectrum of applications our products cater to.

Types of Fasteners We Offer

With us, we offer fasteners with a variety of Types and Features, including the following;

Bolts: These threaded fasteners require corresponding nuts for secure connections. Choose from an array of head styles, including hex head, socket head, and round head.

Nuts: Complementing bolts, nuts secure connections. Opt for hex nuts, lock nuts, or wing nuts based on specific application requirements.

Screws: Known for versatility, screws find use in diverse applications. Choose from different head styles like Phillips, flat, or hex, and opt for self-tapping or machine screws.

Washers: Flat and disk-shaped, washers play a pivotal role in distributing fastener loads and protecting surfaces. Types include flat, lock, and spring washers.

Studs: Characterized by threaded rods without heads on one end, studs are ideal for dual-threaded connections and situations where nuts are impractical.

Rivets: Permanent fasteners with a cylindrical shaft and deformed head create a secure connection.

Pins: Cylindrical fasteners for alignment, securing, or support, including types like dowel, cotter, and clevis pins.

Anchors: These fasteners affix objects to hard surfaces, such as concrete. Common types involve wedge, sleeve, and drop-in anchors.

Clips and Clamps: Secure items like hoses and cables using clips and clamps, such as hose clamps, spring clips, and wire rope clamps.

Threaded Rods: Lengthy straight rods with continuous threading, frequently used for hanging and providing support.

U-Bolts: Featuring a U-shaped design with threads on both ends, they secure round objects to surfaces.

Eye Bolts: Equipped with a loop or "eye," these bolts are designed for lifting and securing heavy loads.

Stud Bolts: Threaded at both ends with an unthreaded portion in the middle, commonly used in flange connections.

Self-Clinching Fasteners: Specifically designed for sheet metal and thin materials, including self-clinching nuts, studs, and standoffs.

Hinges and Latches: Serving as fasteners for attaching doors, gates, and panels, they include hinges, hasps, and latches.

Materials Wise Grade We Offer – Fasteners

At, Bullion Pipes & Tubes LLP, provides a wide variety of fasteners, including;

Copper – CDA 102, CDA 101, CDA 110

Titanium – Titanium Alloy Gr 2 & Titanium Alloy Gr 5

Monel – Monel K500 & Monel 400

Carbon Steel – ASTM A193/194 & ASME SA193/194 Carbon Steel

Brass – Alloy 260, Alloy C48200 – C48500, Alloy 385, Alloy 360, Alloy 353, Alloy 330, Alloy 272, Alloy 464

Tantalum – RO5200, RO5400, RO5252(Ta2.5W), RO5255(Ta10W)

Inconel – Inconel 718, Inconel 600, Inconel 601, Inconel 625

Aluminum – he 20 65032 6061, he 30 64430, ASTM 6061, 6063, 6351

Nickel – Nickel Alloy 200/201

SMO 254 – ASTM A 479 ASME SA 479

Duplex Steel – Duplex Steel UNS S32205, Duplex Steel UNS S31803

Hastelloy – Hastelloy C22 & Hastelloy B2, Hastelloy C276

Super Duplex Steel – Super Duplex Steel UNS S32750, Super Duplex Steel UNS S32760

Incoloy – Incoloy 800/800H/800HT, Incoloy 825

Alloy 20 – DIN 2.4460 Alloy Hexagonal Nut, Alloy 20 Bolts, UNS N08020 Alloy 20 Screws, Alloy 20 Washers

Industries Uses Fasteners

Here are some industries where fasteners are used extensively:

Construction: Fasteners such as bolts, nuts, screws, and anchors are widely used in the construction industry for connecting structural elements like beams, columns, and panels.

Automotive: The automotive industry relies heavily on fasteners for assembling vehicles. A variety of screws, bolts, nuts, and clips are used in the manufacturing of cars, trucks, motorcycles, and other vehicles.

Aerospace: Aerospace applications require precision and reliability. Fasteners play a critical role in assembling aircraft and spacecraft components, ensuring safety and structural integrity.

Manufacturing: In general manufacturing processes, fasteners are used to assemble a wide range of products across different industries, including appliances, electronics, and consumer goods.

Energy: Fasteners are used in the energy sector for assembling components in power plants, wind turbines, solar panels, and other energy infrastructure.

Shipbuilding: The shipbuilding industry relies on fasteners for assembling the various components of ships, including the hull, decks, and internal structures.

Railway: They are crucial in the railway industry for connecting rail tracks, assembling train components, and maintaining the structural integrity of railway infrastructure.

Oil and Gas: In the oil and gas industry, fasteners are used in the construction and maintenance of pipelines, platforms, and other infrastructure.

Electronics: Fasteners play a role in the assembly of electronic devices and equipment. They are used to secure components on circuit boards and in the housing of electronic products.

Medical Devices: Fasteners are used to ensure that components are held together in a precise manner in medical devices and equipment.

Furniture: In the furniture industry, fasteners such as screws, bolts, and nuts are used to assemble various types of furniture, from simple household items to complex office furniture.

Final Words! As a global Fasteners Supplier, Manufacturer Stockist, and Exporter, Bullion Pipes & Tubes LLP takes pride in contributing to the success of diverse industries. Our fasteners, available in an array of sizes, specifications, standards, grades, materials, and types, offer versatility and reliability. Whether it's bolts, nuts, screws, washers, studs, rivets, or self-clinching fasteners, our commitment to quality ensures that our customers can confidently choose the perfect solution for their project requirements. Contact us today at [email protected] or [email protected] to explore how our fasteners can enhance the strength and durability of your applications.

0 notes

Text

Advantages of Titanium GR 5 Fittings in High-Performance Industries

In the sector of excessive-common normal overall performance substances, titanium stands out as a frontrunner because of its precise properties, which encompass extremely good power, low weight, and brilliant corrosion resistance. Among its various grades, Titanium GR 5 is especially authentic for its versatility and reliability. As a leading Titanium Alloy GR 5 fittings supplier, Jay Steel Corporation is dedicated to offering pinnacle-first-rate products that cater to the annoying dreams of immoderate-performance industries.

Understanding Titanium GR 5 and Its Significance

Titanium GR 5, additionally known as Ti-6Al-4V, is an alloy composed of 90% titanium, 6% aluminum, and 4% vanadium. This precise mixture presents the alloy with its super mechanical houses, making it a high-quality desire for severa programs, mainly in the aerospace, marine, and clinical industries. With an excessive energy-to-weight ratio, Titanium GR 5 fittings have become critical additives in environments in which widespread ordinary overall performance and durability are critical.

Key Advantages of Titanium GR 5 Fittings

1. Exceptional Strength-to-Weight Ratio

One of the maximum substantial blessings of Titanium GR 5 fittings is their splendid electricity-to-weight ratio. This technique that additives crafted from Titanium GR 5 can go through excessive stress on equal time as the final slight weight. In aerospace and car industries, where weight reduction is important for reinforcing performance and everyday overall performance, these belongings can reason for widespread gasoline savings and advanced speed.

2. Corrosion Resistance

Titanium is evidence closer to corrosion, which could be an essential characteristic in industries that deal with harsh environments. Titanium GR 5 fittings can withstand publicity to saltwater, acids, and exceptional corrosive substances, making them best for products in marine environments, chemical processing, and oil and gasoline sectors. This corrosion resistance not high-quality extends the lifespan of the fittings however moreover minimizes upkeep expenses over time.

3. High Fatigue Resistance

In high-regular performance applications, substances are frequently subjected to cyclical loading, which might result in fatigue failure. Titanium GR 5 has wonderful fatigue resistance, permitting it to perform reliably beneath repetitive strain conditions. This is mainly vital in industries that encompass aerospace, in which components need to bear non-prevent vibrations and load changes.

4. Biocompatibility

In the medical area, the biocompatibility of substances is critical for ensuring affected man or woman protection. Titanium GR 5 fittings are recognized for their biocompatibility, making them appropriate for severa medical implants and gadgets. This asset allows the alloy for use in surgical devices, dental implants, and orthopedic gadgets, in which durability and protection are paramount.

5. Versatility in Applications

Titanium GR 5 fittings are flexible and may be artificial into numerous paperwork, together with bolts, nuts, flanges, and extra. This adaptability permits engineers and designers to make use of Titanium GR 5 in a full-size form of applications, from aerospace additives to chemical processing equipment. The ability to personalize fittings ensures that they meet the right necessities of every assignment.

6. Weldability and Machinability

While titanium has been recognized for being difficult to work with, Titanium GR 5 has pretty proper weldability and machinability. This makes it less complex to produce complicated components and ensures that fittings can be included seamlessly into massive assemblies. The capacity to weld and machine Titanium GR 5 without compromising its structural integrity is a large benefit in high-conventional universal performance products.

7. Heat Resistance

Titanium GR 5 continues its strength and balance at stepped-forward temperatures, making it suitable for applications that contain excessively warm temperatures. This belonging is especially treasured in industries together with aerospace and power technology, wherein components have to be carried out reliably underneath immoderate-temperature situations.

We are Your Reliable Supplier

At Jay Steel Corporation, we understand the important significance of great materials in excessive-ordinary universal overall performance industries. As an amazing Titanium Alloy GR 5 plates supplier, we provide an in-depth sort of products designed to fulfill the various wishes of our customers. Our commitment to first-rate, mixed with our enterprise knowledge, guarantees that you get keep of the high-quality titanium fittings and plates available.

Our group of specialists is dedicated to offering tailor-made solutions to fulfill your specific requirements. Whether you need Titanium Alloy GR 7 fittings manufactured or specialized plates, we've been given the assets and information to aid your initiatives from beginning to completion.

Conclusion

The benefits of Titanium GR 5 fittings in immoderate-overall average performance industries are easy. Their fantastic energy-to-weight ratio, corrosion resistance, excessive fatigue resistance, and versatility make them a brilliant choice for a big form of application. Whether in aerospace, medical, or chemical processing, these fittings play an essential characteristic in improving average performance and reliability.

As your relied-on Titanium Alloy GR 5 fittings supplier, Jay Steel Corporation is here to offer the very best amazing substances that meet global requirements. With our willpower to excellence and purchaser delight, we're organized to useful resource your needs and assist to procure your assignment dreams.

Explore the ability of Titanium GR 5 fittings these days, and enjoy the difference that top-notch materials could make to your products. Contact us to investigate more approximately our services and the way we will permit you to your subsequent mission.

0 notes

Text

Hastelloy C2000 Pipe Fittings Exporters In India

Pipe fittings are utilised in different industries for various present-day and business applications. One of the most remarkable sorts of pipe fittings is Hastelloy C2000 pipe fittings, which have been getting notoriety because of their unmatched strength and deterioration impediment. Hastelloy C2000 pipe fittings are made using a nickel-based alloy anticipated for normal use in terms of obstruction and strength. This alloy has grand protection from an impressive number of heartbreaking media, including oxidising acids, diminishing acids, hot, dirtied seawater, and cruel water plans. Its phenomenal mechanical properties make it the ideal choice for applications involving high temperatures or strains. Hastelloy C2000 pipe fittings are generally utilised in chemical handling, thermal energy stations, oil and gas creation, food handling, and different industries where deterioration deterrents are major.

Hastelloy C2000 pipe fittings show up in several obvious shapes and sizes, including elbows, tees, reducers, couplings, and affiliations. They also come in different wall thicknesses ranging from Schedule 5 to Schedule XXS. This makes them reasonable for certain errands. Hastelloy C2000 pipe fittings can be utilised in applications including high temperatures and strains. They are commonly used in oil and gas production working environments, petrochemical plants, power plants, chemical handling plants, drug manufacturing working environments, water treatment frameworks, food handling plants, cooling designs, and more. Hastelloy B3 pipe fittings, Hastelloy C2000 pipe fittings, and essentially more grades are similarly accessible.

The fundamental advantage of using C-2000 hastelloy pipe fittings is that they are incredibly invulnerable to breaking down from different chemicals, including sulfuric disastrous, hydrochloric horrendous, and nitric damaging. In this way, they have astounding mechanical strength, which makes them reasonable for use in high-pressure structures. Moreover, they are not difficult to introduce and require less upkeep than different sorts of pipe-fitting materials, like treated steel or metal. Various types of things are accessible, such as mind-blowing bars, SMO 254 UNS S31254 pipe fittings, and so forth. UNS N06200 Nickel Alloy Pipe Fitting is a remarkable decision for applications that require huge, strong regions for a breaking-down-safe material. Its best opposition over harming media makes it reasonable for countless industries, including chemical handling, thermal energy stations, oil and gas creation, food processing, and more. Its phenomenal mechanical properties make it ideal for applications including high temperatures or tensions.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

#Hastelloy C276 Pipe Fittings Exporters In India#Hastelloy C2000 Pipe Fittings Exporters In India#Alloy 20 Pipe Fittings Exporters In India#Titanium Gr 1 Pipe Fittings Exporters In India#Titanium Gr 2 Pipe Fittings Exporters In India#Titanium Gr 5 Pipe Fittings Exporters In India

0 notes

Text

Titanium Gr 5 Flanges Suppliers

Introduction:

Titanium Grade 5 (Ti-6Al-4V) flanges are a dependable and high-performing option in the realm of industrial applications, where strength, durability, and corrosion resistance are critical factors. These flanges are perfect for a variety of critical applications since they are made of a titanium alloy that has low density and outstanding mechanical qualities. We shall examine the features, advantages, and uses of Titanium Grade 5 flanges in this blog post.

Understanding Titanium Grade 5:

The composition of Titanium Grade 5 alloy is 90% titanium, 6% aluminium, and 4% vanadium. This particular mixture results in a material that is remarkably strong, resistant to heat, and corrosion. Due to the combination of these elements, titanium grade 5, which includes flanges, is a preferred choice for a variety of industrial components.

Key Features of Titanium Grade 5 Flanges:

Exceptional Strength: The strength-to-weight ratio of titanium Grade 5 flanges is high, outperforming that of several other materials that are frequently used in flange fabrication. Because of this, they can be used in situations where strength is essential but overall weight is not a concern.

Corrosion Resistance: Titanium Grade 5 is distinguished by its remarkable resistance to corrosion. These flanges exhibit exceptional resistance against corrosion in a range of harsh settings, such as seawater and chemical processing applications. This feature lowers maintenance expenses and increases the flanges' lifespan.

High Temperature Performance: Even at high temperatures, Grade 5 titanium flanges keep their strength and integrity. This qualifies them for use in sectors where exposure to high temperatures is frequent, like power generating, chemical processing, and aircraft.

Biocompatibility: Titanium Grade 5 is appropriate for use in medical applications, such as implanted devices, due to its biocompatibility. Even if flanges might not be directly utilised in medical implants, this characteristic increases the material's overall adaptability.

Applications of Titanium Grade 5 Flanges:

Aerospace Industry: The aerospace industry uses a lot of titanium Grade 5 flanges for structural, landing gear, and exhaust system components. In this industry, the combination of low weight and great strength is especially advantageous.

Chemical Processing: Titanium Grade 5 flanges offer a dependable option in chemical processing industries where exposure to corrosive chemicals is frequent. They are long-lasting and corrosion-resistant in abrasive chemical conditions.

Power Generation: Titanium Grade 5 is suitable for use in power generation applications, such as gas and steam turbines, where components are exposed to high temperatures due to its strong temperature resistance.

Oil and Gas Industry: Because titanium Grade 5 flanges don't corrode in hostile environments or seawater, they are used in both onshore and offshore oil and gas exploration.

Conclusion:

To sum up, Grade 5 titanium flanges are evidence of the exceptional performance of titanium alloys in severe industrial applications. They are the material of choice in a variety of industries, including chemical processing and aerospace, due to their strength, resistance to corrosion, and high temperature performance. Titanium Grade 5 will likely continue to be essential in improving the dependability and performance of vital components across a range of industries as technology develops.

For more Information Visit website: https://www.deepsteelalloys.com/titanium-alloys-gr-5-seamless-welded-flanges-manufacturer-exporter.html Email: [email protected] Contact: 9930466755

0 notes

Text

Titanium Gr 5 Flanges Suppliers

Introduction:

Titanium Grade 5 (Ti-6Al-4V) flanges are a dependable and high-performing option in the realm of industrial applications, where strength, durability, and corrosion resistance are critical factors. These flanges are perfect for a variety of critical applications since they are made of a titanium alloy that has low density and outstanding mechanical qualities. We shall examine the features, advantages, and uses of Titanium Grade 5 flanges in this blog post.

Understanding Titanium Grade 5:

The composition of Titanium Grade 5 alloy is 90% titanium, 6% aluminium, and 4% vanadium. This particular mixture results in a material that is remarkably strong, resistant to heat, and corrosion. Due to the combination of these elements, titanium grade 5, which includes flanges, is a preferred choice for a variety of industrial components.

Key Features of Titanium Grade 5 Flanges:

Exceptional Strength: The strength-to-weight ratio of titanium Grade 5 flanges is high, outperforming that of several other materials that are frequently used in flange fabrication. Because of this, they can be used in situations where strength is essential but overall weight is not a concern.

Corrosion Resistance: Titanium Grade 5 is distinguished by its remarkable resistance to corrosion. These flanges exhibit exceptional resistance against corrosion in a range of harsh settings, such as seawater and chemical processing applications. This feature lowers maintenance expenses and increases the flanges' lifespan.

High Temperature Performance: Even at high temperatures, Grade 5 titanium flanges keep their strength and integrity. This qualifies them for use in sectors where exposure to high temperatures is frequent, like power generating, chemical processing, and aircraft.

Biocompatibility: Titanium Grade 5 is appropriate for use in medical applications, such as implanted devices, due to its biocompatibility. Even if flanges might not be directly utilised in medical implants, this characteristic increases the material's overall adaptability.

Applications of Titanium Grade 5 Flanges:

Aerospace Industry: The aerospace industry uses a lot of titanium Grade 5 flanges for structural, landing gear, and exhaust system components. In this industry, the combination of low weight and great strength is especially advantageous.

Chemical Processing: Titanium Grade 5 flanges offer a dependable option in chemical processing industries where exposure to corrosive chemicals is frequent. They are long-lasting and corrosion-resistant in abrasive chemical conditions.

Power Generation: Titanium Grade 5 is suitable for use in power generation applications, such as gas and steam turbines, where components are exposed to high temperatures due to its strong temperature resistance.

Oil and Gas Industry: Because titanium Grade 5 flanges don't corrode in hostile environments or seawater, they are used in both onshore and offshore oil and gas exploration.

Conclusion:

To sum up, Grade 5 titanium flanges are evidence of the exceptional performance of titanium alloys in severe industrial applications. They are the material of choice in a variety of industries, including chemical processing and aerospace, due to their strength, resistance to corrosion, and high temperature performance. Titanium Grade 5 will likely continue to be essential in improving the dependability and performance of vital components across a range of industries as technology develops.

For more Information Visit website: https://www.deepsteelalloys.com/titanium-alloys-gr-5-seamless-welded-flanges-manufacturer-exporter.html Email: [email protected] Contact: 9930466755

0 notes

Text

Duplex Steel High Tensile Fasteners

CHHAJED STEEL & ALLOYS MANUFACTURES AND EXPORTS STAINLESS AND SUPER ALLOY BOLTING MATERIALS WHICH INCLUDES: HEX BOLT, HEX NUTS, STUD BOLTS, THREADED BARS, WASHERS, ETC. AS PER STANDARDS ASTM, ASME, DIN AND UNI, OUR MOST COMMON MATERIAL ARE IN STOCK AS WELL AS IN PRODUCTION ARE OF STAINLESS STEEL GRADE 304, 316, 321, 347, 310, 410, A453 660A/B/C, AISI 904L, ALLOY 20, DUPLEX UNS S32750 & UNS S32760, INCONEL 600, INCONEL 625, INCONEL 800, INCONEL 825, INCONEL 925, HATELLOY C-276, HASTELLOY C-22, TITANIUM GR 2 & GR 5 & ALUMINIUM BRONZE. BESIDE THIS WE ALSO SUPPLIES ALL KIND OF RAW MATERIAL IN STAINLESS STEEL, DUPLEX STEEL AND EXOTIC MATERIALS IN THE FORM OF PIPES, PLATES, ROUND BAR, WIRES, ELECTRODES, FLANGES AND PIPE FITTINGS.

#alloy 20 bolts exporters#astm a 479 duplex flat washer#alloy 20 fastners#alloy 20 bolts suppliers#alloy 20 bolts manufacturers#duplex steel bolts manufacturers#monel 400 bolts#duplex steel round washer#monel 400 fasteners

0 notes

Text

Titanium Grade 5 Coils Suppliers In Mumbai

Titanium coils are best offered and exchanged by Padmavati Steel. They are the remarkable alliance giving the sheets, plates, and coils from the titanium grade 5 coils. It is the best blend in the class of the tempered steel as this is considered as the most premium quality harsh material. The mix utilized genuinely working out as expected of these plates is having fine structure and Provides fine zenith in the wake of machining. The plates as such are giving the Hard-wearing limit, despite how these plates are much lightweight.

These plates, sheets, and circles are having Soaring moldable quality as they can be extended and compacted up to much degree with no breakage or distortion. This thing is having higher quality and hardness and subsequently addresses progressively undeniable durability. They are set up in the fortified condition and as necessities be accomplish progressively recognizable adaptability at high temperature and weight. This composite is Ductile in nature and accordingly the plates, sheets, and winds can be shown in various estimations and shapes.

We at Padmavati Steel are additionally appearing custom structure things for the utilization of the client's needs. This amalgam is in like way having Good deficiency and break confinement and the plates and sheets encompassed don't confront any part and setting, this is likewise by prudence of turns and different things.

The Padmavati Steel are passing on the things with fine quality and logically basic capacity. We are in this business of progress for a long time and are giving our clients the delight in utilizing the finely assembled mechanical thing with much dependence and trust. We are giving the Titanium Alloy Gr 5 Sheets, Plates, Coils at truly sensible costs which are completely palatable to our clients. You can control us through our site or the contact support. We give the 24x7 contact sponsorship to the request of our clients.

TITANIUM GRADE 5 COILS SPECIFICATIONS

Specifications: ASTM / ASME SB265 Size: 1000 mm x 2000 mm, 1220 mm x 2440 mm, 1500 mm x 3000 mm, 2000 mm x 2000 mm, 2000 mm x 4000 mm Thickness: 0.1mm to 12 mm Thk Form: Coils, Foils, Rolls, Plain Sheet, Shim Sheet, Strip, Flats, Blank (Circle), Ring (Flange) Finish: Hot rolled plate (HR), Cold rolled sheet (CR), 2B, 2D, BA NO(8), SATIN (Met with Plastic Coated) Hardness: Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

0 notes