#Thermocouples

Explore tagged Tumblr posts

Text

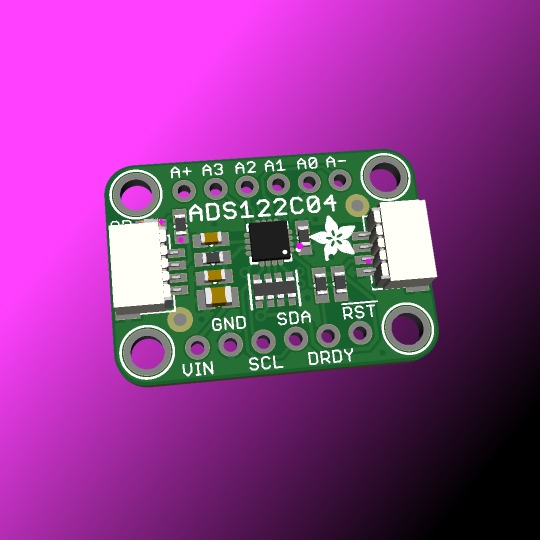

We stock and use a couple of different I2C ADCs, such as the NAU7802

and the HX711

Both of these are kinda designed specifically for load cells. This is a more general-purpose 24-bit ADC using the ADS122C04

with adjustable 1x to 128x gain, up to 2ksps and an internal reference. It can be single or differential input. Good for sensitive things like RTDs, thermocouples, or resistive bridges like load cells! Coming soon.

#adafruit#ADS112C04#24bit#4channel#i2c#adc#NAU7802#loadcells#ti#texasinstruments#rtd#thermocouples#24bitadc#analogtodigital#electronicsdesign#sensormeasurement#embeddedhardware#differentialinput#internalreference#gaincontrol#highresolution#texasinstrumentsadc#sensorinterface#loadcellapplications#precisionelectronics#thermocouplesupport#rtddesign#adcdesign#i2cinterface#resistivebridges

12 notes

·

View notes

Text

Temperature Measurement Manufacturing Companies in India

Trusted thermocouple manufacturers in India. Hi-Tech Transducers offers durable, high-precision thermocouples for industrial needs. Visit: hitechtransducers.com

#Temperature Sensors#Thermocouples#Industrial Measurement#Precision Monitoring#Temperature Measurement#Manufacturing Solutions

0 notes

Text

Thermocouples for Bakers Pride Catering Equipment

We stock a massive inventory of commercial catering equipment parts, from industry-leading manufacturers. Whether your ice machine needs a new evaporator coil, your convection oven requires a fresh heating element, or your grill is missing a grate, CateringSparesOnline has the exact replacement part you need to get things humming again. Find reliable Bakers Pride thermocouples for precise temperature monitoring in your catering equipment. Ideal for pizza ovens and other high-performance appliances.

https://www.cateringsparesonline.co.uk/m/bakers-pride/thermocouples

#cateringequipmentparts#cateringparts#restaurantequipmentparts#cateringpartsuk#cateringsparesonline#BakersPride#Thermocouples

0 notes

Text

High Temperature Heater Accessories enhance performance and reliability in extreme conditions. These components include thermostats, thermal sensors, and insulation materials designed to withstand and optimize high heat levels. Ideal for industrial applications, they ensure precise temperature control, safety, and efficiency, contributing to the longevity and effectiveness of your heating systems.

#HighTemperatureHeaters#HeatingAccessories#IndustrialHeating#Thermocouples#HeaterInsulation#EnergyEfficiency#HeatingElements#HeatManagement#ThermalInsulation#HomeHeating#HeatDistribution SustainableHeating#HeaterMaintenance

0 notes

Text

Thermocouples vs. RTDs: Which Is the Ideal One for Your Industrial Application?

In the context of temperature measurements, choosing an ideal sensor could considerably impact the accuracy & reliability of your industrial data. The 2 most commonly used sensors in this regard happen to be thermocouples & RTDs or resistance-temperature-detectors. What more?

Read our article to know more.

Looking to purchase different types of Heating Sensors ?

Call Heatcon Sensors on 098442 33244 to start a discussion and place your order. Heatcon Sensors have been manufacturing reliable, accurate and long lasting thermocouples, RTD & Cartridge Heaters with customizations to suit a particular business' needs for more than 35 years.

#heatconsensorspvtltd#calibration#thermocouples#RTD#Accuracy#pharmaceutical#foodindustry#precise#heatingsensors

1 note

·

View note

Link

Radiant Heating Technologies is a top-notch Industrial Heaters Manufacturers in Coimbatore. The company offers a wide range of industrial heaters, Thermocouples, Controllers, Sensors, ovens, hot air generators, furnace spares and related products to cater to the needs of different industries. With a strong reputation for quality and reliability, we are dedicated to serving our customers with the best industrial heating solutions.

#Industrial Heaters Manufacturers in Coimbatore#Industrial Heaters Manufacturers in Coimbator#industrial heating solutions..#Thermocouples

0 notes

Text

An Overview of Thermocouples and Their Applications in India

Thermocouples are critical devices used in various industries for temperature measurement, and their applications in India are vast and diverse. In this article, we will provide an overview of thermocouples and their applications in India.

What are Thermocouples? A thermocouple is a temperature measurement device that consists of two dissimilar metals connected at one end. When the connected end of the thermocouple is exposed to a temperature gradient, a voltage is generated, which can be measured and converted into a temperature reading. Thermocouples are widely used in various industries, including petrochemicals, manufacturing, automotive, aerospace, and more.

Types of Thermocouples There are several types of thermocouples, each with its own unique characteristics, including:

Type K: Type K thermocouples are the most commonly used thermocouples and are suitable for use in high-temperature applications.

Type J: Type J thermocouples are suitable for use in low-temperature applications and offer high accuracy.

Type T: Type T thermocouples are suitable for use in low-temperature applications and offer excellent accuracy.

Type E: Type E thermocouples are suitable for use in moderate temperature applications and offer high accuracy.

Type N: Type N thermocouples are suitable for use in high-temperature applications and offer excellent accuracy.

Applications of Thermocouples in India Thermocouples have numerous applications in various industries in India, including:

Petrochemical Industry: In the petrochemical industry, thermocouples are used to measure the temperature of gases, liquids, and solids in various processes, including distillation, cracking, and polymerization.

Manufacturing Industry: In the manufacturing industry, thermocouples are used to measure the temperature of machines, equipment, and processes, including welding, forging, and casting.

Automotive Industry: In the automotive industry, thermocouples are used to measure the temperature of engines, exhaust systems, and other components.

Aerospace Industry: In the aerospace industry, thermocouples are used to measure the temperature of engines, turbines, and other components.

Medical Industry: In the medical industry, thermocouples are used to measure the temperature of medical devices, laboratory equipment, and biological samples.

Choosing the Right Thermocouples for Your Application Choosing the right thermocouples for your application is crucial for ensuring accuracy, reliability, and safety. When selecting thermocouples, it is essential to consider factors such as temperature range, material, accuracy, and environment.

Conclusion Thermocouples are critical devices used in various industries in India for temperature measurement. With numerous types of thermocouples available, it is crucial to choose the right one for your application to ensure accuracy, reliability, and safety. In industries such as petrochemicals, manufacturing, automotive, aerospace, and medical, thermocouples are essential for measuring temperatures and maintaining optimal performance.

#Thermocouples in India#Thermocouples manufacturer in India#Thermocouples manufacturer#Thermocouples

0 notes

Text

fr though how much free energy could you squeeze out of an undying human? for simplicity call it a sphere that stays 100F no matter what but which can't be put in too cold an environment or it'll be sad

#im tempted to say you can't beat a thermocouple to absolute 0#but idk maybe there's some way to leverage this for arbitrary amounts of work

13 notes

·

View notes

Note

understand that the kiln is a hungry and jealous thing; to earn its fiery blessings you must feed it in turn; do not deprive her of offerings of shattered earth as she demands

maybe to u, to me she is like an annoying sister that promises she wont take my clothes and then i see her wearing my favorite shirt like 2 days later

#she just made me change the thermocouple#not her fault but i dont love it when she doesn't tell me anything is wrong until mid fire

8 notes

·

View notes

Text

lookin for replacement tips for a 40 year old soldering iron should i end my lyfe instead

#if any1 knows surplus suppliers w/ weller wtl24 tips PLEASE#tip is fine but its not gonna last forever and this is a hella fuckin nice soldering station#should prob figure out if the thermocouple is in the tip or the other thang if its in the tip mounty thingy i might could use a new one if#they fit

2 notes

·

View notes

Text

Gravebarr: Yeah I just got this sinking feeling at 1:30 in the morning that something was wrong with the furnace so I went to check on it but my key didn’t work so I just got absolutely no sleep last night because I was so worried that something bad was going to happen. Is this what anxiety feels like? IS THIS WHAT YOU FEEL LIKE EVERY DAY?!

Jonah: Yes.

#source: my laid back friend randomly worried that his hot plate’s thermocouple shorted and might set the lab on fire#of swamp and sea#osas#incorrectosas#incorrect of swamp and sea#webtoon#he really biked all the way to lab only to discover his access card was still glitching

4 notes

·

View notes

Text

A Thermocouple Accessories Manufacturer specializes in producing a wide range of components and accessories that support the functionality and performance of thermocouples. These manufacturers provide essential products such as connectors, extension wires, probes, and mounting hardware that are critical for accurate temperature measurement and control in various industrial applications.

#Thermocouples#ThermoCoupleManufacturer#TemperatureMeasurement#IndustrialSensors#ThermocoupleAccessories#ManufacturingExcellence#QualityControl#IndustrialSafety#TemperatureSensors#CustomThermocouples#IndustryStandards#ThermocoupleProbes#TechManufacturing#ReliabilityInIndustry

0 notes

Text

good morning mewtchies (mutuals) happy fucked up Friday I hope u all are having a good day when u see this. I've been in the lab since 3 am and now it's 8 🫡

#petchyposting#i got crickets to freeze. u kniw how it is. took me so long to get those guys set up and the thermocouples (wires that read their temp)#are so sensitive it took forever to get them workinf

11 notes

·

View notes

Text

R-tek RT 939 K-type/ J-type Thermocouple Thermometer Buy : https://vegabazaar.com/product/top-thermoelectric-thermometer-rtek-rt-939-ktype-jtype-thermocouple-thermometer/

0 notes

Text

https://mangofy.in/products/client/index?search=OSTW-K-M

The OSTW-K-M thermocouple connector is a dependable solution for K-type thermocouples, designed to ensure accurate temperature measurements in various applications. Its rugged construction and compact design make it ideal for demanding industrial environments. Featuring color-coded terminals for easy identification and secure connections, this connector is perfect for HVAC, manufacturing, and research setups. Available in Noida, the OSTW-K-M in Noida connector offers durability, precision, and ease of use, making it a trusted choice for professionals seeking reliable temperature sensing solutions.

0 notes