#Thermocouples in India

Explore tagged Tumblr posts

Text

An Overview of Thermocouples and Their Applications in India

Thermocouples are critical devices used in various industries for temperature measurement, and their applications in India are vast and diverse. In this article, we will provide an overview of thermocouples and their applications in India.

What are Thermocouples? A thermocouple is a temperature measurement device that consists of two dissimilar metals connected at one end. When the connected end of the thermocouple is exposed to a temperature gradient, a voltage is generated, which can be measured and converted into a temperature reading. Thermocouples are widely used in various industries, including petrochemicals, manufacturing, automotive, aerospace, and more.

Types of Thermocouples There are several types of thermocouples, each with its own unique characteristics, including:

Type K: Type K thermocouples are the most commonly used thermocouples and are suitable for use in high-temperature applications.

Type J: Type J thermocouples are suitable for use in low-temperature applications and offer high accuracy.

Type T: Type T thermocouples are suitable for use in low-temperature applications and offer excellent accuracy.

Type E: Type E thermocouples are suitable for use in moderate temperature applications and offer high accuracy.

Type N: Type N thermocouples are suitable for use in high-temperature applications and offer excellent accuracy.

Applications of Thermocouples in India Thermocouples have numerous applications in various industries in India, including:

Petrochemical Industry: In the petrochemical industry, thermocouples are used to measure the temperature of gases, liquids, and solids in various processes, including distillation, cracking, and polymerization.

Manufacturing Industry: In the manufacturing industry, thermocouples are used to measure the temperature of machines, equipment, and processes, including welding, forging, and casting.

Automotive Industry: In the automotive industry, thermocouples are used to measure the temperature of engines, exhaust systems, and other components.

Aerospace Industry: In the aerospace industry, thermocouples are used to measure the temperature of engines, turbines, and other components.

Medical Industry: In the medical industry, thermocouples are used to measure the temperature of medical devices, laboratory equipment, and biological samples.

Choosing the Right Thermocouples for Your Application Choosing the right thermocouples for your application is crucial for ensuring accuracy, reliability, and safety. When selecting thermocouples, it is essential to consider factors such as temperature range, material, accuracy, and environment.

Conclusion Thermocouples are critical devices used in various industries in India for temperature measurement. With numerous types of thermocouples available, it is crucial to choose the right one for your application to ensure accuracy, reliability, and safety. In industries such as petrochemicals, manufacturing, automotive, aerospace, and medical, thermocouples are essential for measuring temperatures and maintaining optimal performance.

#Thermocouples in India#Thermocouples manufacturer in India#Thermocouples manufacturer#Thermocouples

0 notes

Text

Thankfully, in Dubai, manufacturers of so many products are available with ease. Whether you need certified Tube Fittings Manufactures in Dubai or Level Transmitter Supplier in Dubai are all available online to provide you with the best quality products of international standards. If quality is an integral part of your product and services and customer satisfaction is key to your success then without any second thought consider dealing with the Kevit Industrial Products which is a licensed manufacturer and seller of the top-notch instrumentation and automation products. In case you are wondering what the significance is of the instrumentation and automation products then this web post is a must-read for you.

#Tube Fittings Supplier in Dubai#thermocouple manufacturers in dubai#check valves suppliers in india#level transmitter supplier in dubai

0 notes

Text

Thermocouple tips manufacturer in india

Maxwell Industrial Corporation is a prominent manufacturer of thermocouple tips based in India. They specialize in crafting high-quality tips designed for accurate temperature measurement across diverse industries. With a focus on precision engineering and product reliability, Maxwell Industrial Corporation is a trusted name known for delivering top-notch thermocouple solutions to their customers within India and globally.

0 notes

Text

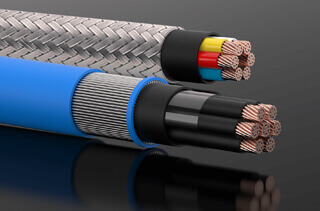

Discover India's Leading Cable Manufacturers | Top Quality Cables at Tempsens

Explore the excellence of top cable manufacturers in India at Tempsens Instruments. Elevate your connectivity with precision-engineered cables, ensuring reliability and performance. Uncover a world of trusted quality for your diverse needs.

#tempsens#cable manufacturer in india#tempsens instruments#wires and cables manufacturers in india#temperature sensor manufacturers in india#thermal solutions#tempsens india#thermocouple india

0 notes

Text

0 notes

Text

nexthermal electroheats high density cartridge heater can be considered "cartridge heating elements manufacturer" that are used to heat up many different applications

cartridge heating element.

Cartridge Heating Elements Manufacturer

cartridge heating element, cartridge heating elements manufacturer, industrial cartridge heaters, cartridge heater manufacturer, cartridge heater manufacturer in india, Cartridge Heaters, Cartridge Heater with thermocouple

#cartridge heating element#cartridge heating elements manufacturer#industrial cartridge heaters#cartridge heater manufacturer#cartridge heater manufacturer in india#Cartridge Heaters#Cartridge Heater with thermocouple

0 notes

Text

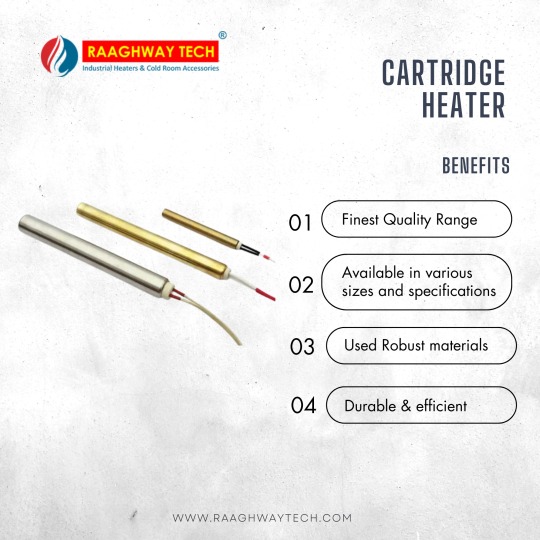

Precision Heating for Industrial Applications: Cartridge Heaters

In the realm of industrial heating, precision and reliability are paramount. Among the various heating solutions available, cartridge heaters stand out for their efficiency and adaptability. Designed for confined spaces requiring controlled and concentrated heat, these heaters are widely used across industries for their versatility and durability.

In this blog, we will explore what cartridge heaters are, their advantages, applications, and why Raghav Industries is the go-to supplier for high-quality cartridge heaters.

What is a Cartridge Heater?

A cartridge heater is a cylindrical heating element designed to provide localized and precise heating. It consists of a resistance coil wound around a ceramic core, encased in a sheath made of materials like stainless steel or Incoloy. This design ensures excellent heat transfer and durability, even under extreme conditions.

Cartridge heaters are typically inserted into drilled holes or placed in tight spaces to deliver concentrated heat, making them ideal for applications where space is limited.

How Does a Cartridge Heater Work?

Cartridge heaters operate by converting electrical energy into heat through the resistance wire inside the heating element. The heat is then transferred to the sheath and distributed evenly to the surrounding environment. Advanced designs feature high-density wattage, ensuring rapid heating and consistent temperature control.

Some cartridge heaters come with built-in thermocouples or sensors, enabling precise temperature monitoring and control.

Key Features of Cartridge Heaters

1. High-Density Wattage

Cartridge heaters are designed to deliver high watt density, ensuring rapid heating and efficient energy usage.

2. Compact and Versatile Design

The cylindrical shape and compact size allow cartridge heaters to fit into tight spaces, making them ideal for intricate applications.

3. Superior Heat Transfer

The construction ensures uniform heat distribution, minimizing energy loss and enhancing efficiency.

4. Durability

Made with high-quality materials, cartridge heaters are resistant to oxidation, corrosion, and wear, ensuring long operational life.

5. Temperature Control

Many cartridge heaters feature integrated sensors, allowing for precise temperature regulation.

Benefits of Cartridge Heaters

1. Precise Heating

Cartridge heaters provide targeted heating, making them ideal for applications requiring accurate temperature control.

2. Energy Efficiency

The high-density wattage and efficient heat transfer reduce energy consumption, lowering operational costs.

3. Versatility

These heaters can be used in a wide range of applications, from industrial machinery to laboratory equipment.

4. Longevity

Built to withstand harsh conditions, cartridge heaters offer reliable performance and require minimal maintenance.

5. Easy Installation

Cartridge heaters are designed for easy insertion and removal, simplifying installation and replacement processes.

Applications of Cartridge Heaters

Cartridge heaters are used in a variety of industries and applications, including:

1. Plastic Injection Molding

They provide precise heating for molds, ensuring consistent product quality.

2. Packaging Equipment

Cartridge heaters are used to maintain the correct temperature for sealing and cutting operations.

3. Medical Devices

They are used in medical equipment requiring precise and localized heating.

4. Food Processing

Cartridge heaters help maintain the correct temperature in machinery used for food production.

5. Aerospace

They are used in applications requiring reliable and efficient heating in extreme conditions.

6. Semiconductor Manufacturing

Cartridge heaters provide precise heating for processes like soldering and bonding.

Why Choose Raghav Industries for Cartridge Heaters?

Raghav Industries, based in Delhi, India, is a trusted name in the manufacturing and supply of cartridge heaters. Here’s why our products are the preferred choice:

1. Premium Quality

We use top-grade materials, such as stainless steel sheaths and nickel-chrome resistance wires, to ensure durability and high performance.

2. Customization Options

Our cartridge heaters are available in various sizes, wattages, and configurations to meet your specific requirements.

3. Energy Efficiency

Designed for efficient heat transfer, our heaters minimize energy consumption, helping businesses save on operational costs.

4. Advanced Features

We offer heaters with integrated sensors and thermocouples for precise temperature control.

5. Comprehensive Support

From product selection to after-sales service, we provide end-to-end support to ensure a seamless experience.

How to Choose the Right Cartridge Heater

When selecting a cartridge heater, consider the following factors:

Application Requirements: Determine the size, wattage, and temperature range needed for your application.

Material Compatibility: Ensure the sheath material is compatible with the environment and the substance being heated.

Temperature Control: Choose heaters with built-in sensors if precise temperature regulation is required.

Environmental Conditions: Consider factors like exposure to moisture, chemicals, or high pressure.

Raghav Industries offers expert guidance to help you find the ideal cartridge heater for your application.

The Importance of Reliable Heating Solutions

Cartridge heaters are a vital component in industries where precision heating is essential. Their compact design, high efficiency, and durability make them an indispensable tool for a variety of applications. Investing in high-quality cartridge heaters not only enhances operational efficiency but also reduces maintenance costs and downtime.

Conclusion

Cartridge heaters are a versatile and efficient solution for precise and localized heating in industrial applications. Their ability to deliver consistent performance in tight spaces makes them a preferred choice for industries ranging from manufacturing to medical devices.

At Raghav Industries, we are committed to providing top-quality cartridge heaters tailored to meet your unique needs. With our innovative products, you can optimize your heating processes, reduce energy consumption, and achieve reliable results every time.

Learn more about our Cartridge Heaters here.

#cartridgeheater#cartridge#heater#heatingcable#heatingsystem#industrial#industrialheater#industrialheating#manufacturing#entrepreneur

0 notes

Text

Industrial Sensors: The Core of Modern Automation Systems

In today’s highly automated industrial landscape, the role of sensors cannot be overstated. Industrial sensors are the key components that collect critical data to monitor, control, and optimize industrial processes. From manufacturing to energy production, sensors are integral in ensuring the efficiency, safety, and precision of operations. As industries advance, the demand for high-quality sensors has grown exponentially. In India, sensor manufacturers are playing a vital role in meeting this demand, providing solutions that cater to diverse industrial needs.

What Are Industrial Sensors?

Industrial sensors are devices designed to detect variations in the physical environment and translate them into signals for processing by controllers or monitoring systems. These sensors are engineered to measure various parameters, including temperature, pressure, humidity, flow, proximity, and vibration. By converting physical changes into measurable data, they provide real-time insights into machine performance, environmental conditions, and overall system functionality.

Types of Industrial Sensors

The diversity of industrial applications requires a wide range of sensors, each designed to measure specific variables:

Temperature Sensors: Temperature sensors, including thermocouples and RTDs (Resistance Temperature Detectors), are widely used in industrial environments to measure the temperature of machinery, fluids, and gases. These sensors ensure that equipment operates within safe temperature ranges, preventing overheating and failure.

Pressure Sensors: Pressure sensors are crucial in industries where fluid dynamics are involved, such as oil and gas, water treatment, and manufacturing. These sensors detect the pressure of gases or liquids, ensuring systems remain under optimal pressure levels for efficiency and safety.

Flow Sensors: Flow sensors measure the speed at which fluid or gas moves through pipelines.Industries like chemical manufacturing and pharmaceuticals rely on these sensors to maintain consistent flow rates, which is critical for maintaining quality and consistency in production.

Proximity Sensors: Proximity sensors identify the presence or absence of objects without making physical contact.These sensors are often used in automation systems to detect the position of parts on assembly lines or the proximity of tools to workpieces in robotic systems.

Vibration Sensors: Vibration sensors are essential in predictive maintenance applications. They monitor the vibrations of machinery and equipment, alerting operators to potential issues before they result in costly breakdowns.

Applications of Industrial Sensors

Industrial sensors are employed in a wide range of industries, such as manufacturing, energy, automotive, and pharmaceuticals.Their applications are broad and encompass several critical tasks, such as:

Process Monitoring and Control: Sensors ensure that industrial processes are running within designated parameters. For example, in a chemical plant, temperature and pressure sensors monitor reactors, providing real-time data for efficient control of reactions.

Predictive Maintenance: Vibration and temperature sensors help predict equipment failure by monitoring mechanical wear and tear, allowing for preventive maintenance to be performed before failure occurs.

Safety and Compliance: Industrial sensors play a crucial role in ensuring workplace safety and regulatory compliance. Gas sensors, for instance, detect dangerous leaks in industries like oil and gas, preventing hazardous situations from escalating.

Energy Management: Sensors are also used for energy management, helping industries monitor energy usage and optimize consumption to reduce costs and environmental impact.

Why Choose Sensor Manufacturers in India?

India's expanding industrial sector has led to a substantial increase in the demand for high-quality industrial sensors. As a hub for manufacturing, the country is home to several leading sensor manufacturers in India that produce sensors catering to both domestic and global markets. These manufacturers offer a variety of sensors designed to meet the unique needs of different industries, ranging from food processing to automotive and energy.

Indian sensor manufacturers are known for their competitive pricing, advanced technology, and high-quality products. With an increasing focus on industrial automation and smart factories, the demand for advanced sensors is expected to rise. Manufacturers in India are also investing in research and development to create sensors that meet the latest industry standards and technological advancements.

One of the key advantages of working with sensor manufacturers in India is their ability to provide customized solutions. Whether a company requires sensors for specific environmental conditions or bespoke designs for unique industrial applications, Indian manufacturers are adept at creating tailored solutions that meet the specific needs of their clients.

Moreover, the Indian government’s push toward 'Make in India' has helped bolster the local manufacturing industry, encouraging innovation in sensor technology. This initiative has also led to better collaboration between sensor manufacturers and industries, ensuring that sensors are specifically designed to handle the challenges faced by the industry.

The Future of Industrial Sensors

As industries move towards greater automation and digitalization, the role of sensors in industrial applications will only grow. Emerging technologies such as the Internet of Things (IoT), Industry 4.0, and artificial intelligence (AI) are driving the demand for more sophisticated sensors that can deliver high precision, reliability, and real-time data analysis.

The future of industrial sensors is closely linked to advances in wireless communication, miniaturization, and energy-efficient designs. With increasing reliance on data-driven decision-making, industrial sensors will continue to be the cornerstone of smart, connected factories that optimize processes, improve productivity, and ensure safety.

Conclusion

Industrial sensors play a vital role in maintaining the smooth functioning of industries. From monitoring temperatures and pressures to detecting vibrations and fluid flow, sensors provide the necessary data to optimize industrial processes. As a rapidly growing hub for manufacturing, sensor manufacturers in India are stepping up to meet the evolving demands of industries by providing innovative, reliable, and cost-effective sensor solutions. With advancements in technology and a growing focus on industrial automation, the role of industrial sensors in shaping the future of manufacturing and production is poised to become even more significant.

0 notes

Text

#Industrial heaters#space heaters#thermocouple sensors#tubular heaters#ceramic heaters#insulation jackets#energy-efficient heaters#high-temperature heaters#industrial heating solutions.

1 note

·

View note

Text

Temperature Measurement Manufacturing Companies in India

Trusted thermocouple manufacturers in India. Hi-Tech Transducers offers durable, high-precision thermocouples for industrial needs. Visit: hitechtransducers.com

#Temperature Sensors#Thermocouples#Industrial Measurement#Precision Monitoring#Temperature Measurement#Manufacturing Solutions

0 notes

Text

In industrial operations, measurement accuracy remains paramount; Flowmeters – the unsung heroes of accuracy – play a key role. Recognizing this importance, Kevitits, Flow Meter Suppliers in Saudi Arabia provides a wide range of such devices to meet a variety of operational needs: from monitoring fluid flows with unwavering precision; gas flow control for uninterrupted processes – their meters excel in all tasks.

#Tube Fittings Suppliers in Saudi Arabia#thermocouple manufacturers in dubai#check valves suppliers in india#mass flow meter suppliers in dubai

0 notes

Text

Thermocouple Manufacturers in India: High-Quality Temperature Measurement Solutions

As trusted Thermocouple Manufacturers in India, we provide temperature measurement solutions tailored to meet the needs of industrial processes. Our thermocouples are known for their accuracy, durability, and reliability, making them suitable for use in harsh environments such as furnaces, boilers, and chemical plants. With a wide range of models, we offer custom thermocouple solutions that meet the highest industry standards.

0 notes

Text

0 notes

Text

Best Insulation Jacket Manufacturers in India

Jackets made of insulation are essential parts of many industrial applications. They are made to keep machinery safe, cut down on energy loss, and preserve ideal operating temperatures. A Insulation jackets manufacturers should be chosen with quality, longevity, and technical know-how in mind. This blog will discuss some of the leading insulation jacket producers in India and stress the need of selecting the best partner for your particular requirements.

Insulation Jackets: Their Significant Function

There are several different industries that use insulation coats, including:

Chemical and petrochemical: Keeping equipment, valves, and pipelines safe from extremely high or low temperatures.

Power Generation: Improving power plant safety and energy efficiency.

Oil and Gas: Ensuring the processing facilities and pipelines run safely and effectively.

Pharmaceutical: Temperature control ensures product safety and quality.

These jackets' efficient insulation of equipment helps with:

Minimizing heat loss and maximizing energy use are two aspects of energy conservation.

Safety: Keeping workers safe from burns and other risks.

Protection of the environment: cutting back on heat emissions and environmental damage.

Leader in Insulation Jacket Solutions: Advance Heater

In addition to being a well-known producer of heating elements and thermocouples, Advance Heater is also a skilled maker of insulation jackets. Our dedication to meticulous engineering and material selection guarantees that our products satisfy the demanding specifications of different industries.

Jackets with advanced insulation for heaters

Important Things to Take Into Account Before Selecting an Insulation Jacket Manufacturer

Compatibility of Materials: The chemical being handled and the operational environment should be compatible with the insulating material.

Thermal Performance: In order to maintain the desired temperature, the jacket should offer sufficient insulation.

Durability: The insulation jacket needs to be long-lasting and able to endure rough use.

Installing and maintaining the jacket should be a simple task.

modification: In order to satisfy particular needs, the manufacturer ought to provide alternatives for modification.

Conclusion: The success of your operations depends on your choice of insulating jacket manufacturer. You may guarantee optimum performance, safety, and energy efficiency by carefully weighing the previously mentioned aspects and working with a respectable business like Advance Heater.

The goal of Advance Heater is to deliver dependable and cutting-edge insulating jacket solutions. Get in touch with us right now to go over your unique needs and discover how our products may help your company.

#Insulation Jackets Manufacturers#Thermocouples Manufacturers#Furnace Heater Manufacturers#Coil Heater Manufacturers

0 notes

Text

Enhancing Industrial Processes with Tubular Air Duct Heaters

In industrial settings, maintaining consistent air temperature is often a critical requirement for various processes. Tubular air duct heaters are a key component in achieving this, offering a reliable and efficient means of heating air as it passes through ductwork. The integration of temperature sensors in these systems is vital for ensuring accurate temperature control, which is essential for the quality and efficiency of many industrial processes.

tubular air duct heaters are used to monitor the air temperature within the ducts, providing real-time feedback to the control system. This data allows the system to adjust the power to the tubular air duct heater as needed, ensuring that the air is heated to the desired temperature. This level of precision is particularly important in industries such as food processing, pharmaceuticals, and electronics manufacturing, where even small variations in temperature can affect the quality of the final product.

The design of controller manufacturers in india for use with tubular air duct heaters involves selecting sensors that can withstand the specific conditions of the application. This may include high temperatures, exposure to corrosive materials, or operation in humid environments. Thermocouples, RTDs, and thermistors are common choices for these applications, each offering different advantages in terms of accuracy, durability, and response time.

In addition to temperature control, temperature sensors applications in tubular air duct heaters include safety monitoring. Overheating can pose a significant risk in industrial settings, potentially damaging equipment or causing safety hazards. By continuously monitoring the air temperature, the sensors can detect when it exceeds safe levels and trigger an automatic shutdown or other safety measures to prevent accidents.

Electrical Tubular Heaters are a versatile option for air duct heating, capable of providing consistent and controllable heat in a variety of applications. These heaters are often made from materials such as stainless steel or Incoloy, which offer excellent resistance to corrosion and high temperatures. The tubular design allows for efficient heat transfer to the air, making these heaters a popular choice in many industrial HVAC systems.

For applications requiring even greater heat transfer efficiency, Finned Tubular Heaters are often used. The addition of fins to the tubular element increases the surface area, allowing more heat to be transferred to the air as it flows over the heater. This design is particularly effective in applications where large volumes of air must be heated quickly and evenly.

In summary, tubular air duct heaters, combined with advanced temperature sensors, provide a powerful solution for maintaining precise temperature control in industrial processes. The use of industrial temperature sensors ensures that the air is heated accurately and consistently, while the incorporation of electrical tubular heaters and finned tubular heaters enhances the efficiency and performance of the system. By carefully selecting and integrating these components, engineers can design systems that meet the demanding requirements of modern industrial applications.

0 notes