#Thermocouple Temperature Sensors

Text

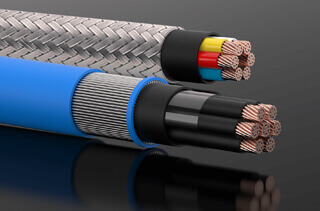

Discover India's Leading Cable Manufacturers | Top Quality Cables at Tempsens

Explore the excellence of top cable manufacturers in India at Tempsens Instruments. Elevate your connectivity with precision-engineered cables, ensuring reliability and performance. Uncover a world of trusted quality for your diverse needs.

#tempsens#cable manufacturer in india#tempsens instruments#wires and cables manufacturers in india#temperature sensor manufacturers in india#thermal solutions#tempsens india#thermocouple india

0 notes

Text

Medical Grade Thermocouple Wire Market Overview and Regional Outlook Study 2017 – 2032

The market for medical grade thermocouple wire is witnessing steady growth due to the increasing demand for accurate and reliable temperature measurement in the medical industry. Thermocouples are widely used in various medical applications, including monitoring body temperature, laboratory testing, and medical equipment calibration.

Market Overview of Medical Grade Thermocouple Wire:

Technological Advancements: Advancements in thermocouple wire technology, such as the development of high-precision sensors and miniaturization, are driving the market growth. These advancements enable accurate temperature measurements in medical devices.

Healthcare Industry Expansion: The expanding healthcare industry, including hospitals, clinics, and research laboratories, is creating a substantial demand for medical grade thermocouple wire. These wires are widely used in medical devices, such as patient monitoring systems, incubators, and surgical equipment.

Stringent Regulations: The medical industry is subject to strict regulations regarding patient safety and product quality. Medical grade thermocouple wires comply with these regulations, ensuring reliability and accuracy in temperature measurement, which is a key factor driving their adoption.

Increasing Awareness: Growing awareness among healthcare professionals and researchers about the benefits of using thermocouple wires in medical applications is boosting the market. These wires offer advantages such as high accuracy, fast response time, and compatibility with various medical devices.

Key Factors Driving the Medical Grade Thermocouple Wire Market:

Rising Focus on Patient Safety: The healthcare industry's increasing emphasis on patient safety and comfort is driving the demand for medical grade thermocouple wires. These wires help in precise temperature monitoring, ensuring optimal patient care.

Growing Demand for Minimally Invasive Procedures: The rising preference for minimally invasive procedures requires accurate temperature sensing and monitoring during surgeries. Medical grade thermocouple wires enable real-time temperature measurements, enhancing the safety and success rates of such procedures.

Advancements in Medical Device Technologies: The continuous advancements in medical device technologies, such as wearable devices and remote patient monitoring systems, are fueling the demand for medical grade thermocouple wires. These wires play a crucial role in temperature sensing within these devices.

Increasing Research and Development Activities: The ongoing research and development activities in the medical field, including the development of new drugs, medical treatments, and diagnostic techniques, rely on accurate temperature measurements. Medical grade thermocouple wires are essential components in such research activities.

Growing Geriatric Population: The global increase in the geriatric population is driving the demand for medical devices and healthcare services. Medical grade thermocouple wires find extensive applications in temperature monitoring devices used for elderly care, such as patient monitors and wearable health trackers.

COVID-19 Impact: The COVID-19 pandemic has increased the demand for medical devices and equipment, including temperature monitoring systems. Thermocouple wires are used in various COVID-19-related applications, such as vaccine storage and transport, ICU patient monitoring, and fever detection systems.

Expansion of Home Healthcare: The rising trend of home healthcare services and the need for portable medical devices have led to an increased demand for medical grade thermocouple wires. These wires enable temperature monitoring in portable devices used for home healthcare purposes.

Increasing Adoption of Wireless Thermocouple Systems: The market is witnessing a shift towards wireless thermocouple systems, which offer convenience, ease of use, and reduced clutter. Medical grade thermocouple wires are an integral part of these wireless systems, driving their demand.

Collaborations and Partnerships: Key players in the medical device industry are entering into collaborations and partnerships to develop innovative solutions. Such collaborations involving medical grade thermocouple wire manufacturers contribute to market growth.

Growing Focus on Precision Medicine: The increasing focus on precision medicine, which involves personalized treatment based on individual characteristics, requires accurate temperature monitoring in various medical procedures. Medical grade thermocouple wires play a vital role in delivering precise temperature measurements for effective treatment outcomes.

We recommend referring our Stringent datalytics firm, industry publications, and websites that specialize in providing market reports. These sources often offer comprehensive analysis, market trends, growth forecasts, competitive landscape, and other valuable insights into this market.

By visiting our website or contacting us directly, you can explore the availability of specific reports related to this market. These reports often require a purchase or subscription, but we provide comprehensive and in-depth information that can be valuable for businesses, investors, and individuals interested in this market.

“Remember to look for recent reports to ensure you have the most current and relevant information.”

Click Here, To Get Free Sample Report: https://stringentdatalytics.com/sample-request/medical-grade-thermocouple-wire-market/3577/

Market Segmentations:

Global Medical Grade Thermocouple Wire Market: By Company

• TE Wire&Cable

• Johnson Matthey

• Heraeus

• Sandvik (Kanthal)

• BASF

• OMEGA Engineering

• Belden

• Pelican Wire

• National Instruments

• Indutrade (Pentronic)

• Pyromation

• Dwyer Instruments

• Tempco

• Durex Industries

• Marlin Manufacturing Corporation

• Multi/Cable Corporation

• Ellab

• Temprel

• Thermo-Electra

• Hayashidenko

Global Medical Grade Thermocouple Wire Market: By Type

• Type T

• Type K

• Other

Global Medical Grade Thermocouple Wire Market: By Application

• Pharmaceutical Enterprise

• Hospital

• Other

Global Medical Grade Thermocouple Wire Market: Regional Analysis

All the regional segmentation has been studied based on recent and future trends, and the market is forecasted throughout the prediction period. The countries covered in the regional analysis of the Global Medical Grade Thermocouple Wire market report are U.S., Canada, and Mexico in North America, Germany, France, U.K., Russia, Italy, Spain, Turkey, Netherlands, Switzerland, Belgium, and Rest of Europe in Europe, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, China, Japan, India, South Korea, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), and Argentina, Brazil, and Rest of South America as part of South America.

Visit Report Page for More Details: https://stringentdatalytics.com/reports/medical-grade-thermocouple-wire-market/3577/

Reasons to Purchase Medical Grade Thermocouple Wire Market Report:

• To obtain insights into industry trends and dynamics, including market size, growth rates, and important factors and difficulties. This study offers insightful information on these topics.

• To identify important participants and rivals: This research studies can assist companies in identifying key participants and rivals in their sector, along with their market share, business plans, and strengths and weaknesses.

• To comprehend consumer behaviour: these research studies can offer insightful information about customer behaviour, including preferences, spending patterns, and demographics.

• To assess market opportunities: These research studies can aid companies in assessing market chances, such as prospective new goods or services, fresh markets, and new trends.

• To make well-informed business decisions: These research reports give companies data-driven insights that they may use to plan their strategy, develop new products, and devise marketing and advertising plans.

In general, market research studies offer companies and organisations useful data that can aid in making decisions and maintaining competitiveness in their industry. They can offer a strong basis for decision-making, strategy formulation, and company planning.

Medical Grade Thermocouple Wire Market Research Report Contains Answers to your following Questions

Which Manufacturing Technology is Used for Medical Grade Thermocouple Wire? What Developments Are Going On in That Technology? Which Trends Are Causing These Developments?

Who Are the Global Key Players in This Medical Grade Thermocouple Wire Market? What's Their Company Profile, Their Product Information, and Contact Information?

What Was Global Market Status of Medical Grade Thermocouple Wire Market? What Was Capacity, Production Value, Cost and PROFIT of Medical Grade Thermocouple Wire Market?

What Is Current Market Status of Medical Grade Thermocouple Wire Industry? What's Market Competition in This Industry, Both Company, and Country Wise? What's Market Analysis of Medical Grade Thermocouple Wire Market by Taking Applications and Types in Consideration?

What Are Projections of Global Medical Grade Thermocouple Wire Industry Considering Capacity, Production and Production Value? What Will Be the Estimation of Cost and Profit? What Will Be Market Share, Supply and Consumption? What about Import and Export?

What Is Medical Grade Thermocouple Wire Market Chain Analysis by Upstream Raw Materials and Downstream Industry?

What Is Economic Impact On Medical Grade Thermocouple Wire Industry?

What are Global Macroeconomic Environment Analysis Results? What Are Global Macroeconomic Environment Development Trends?

What Are Market Dynamics of Medical Grade Thermocouple Wire Market? What Are Challenges and Opportunities?

What Should Be Entry Strategies, Countermeasures to Economic Impact, Marketing Channels for Medical Grade Thermocouple Wire Industry?

Click Here, To Buy Premium Report: https://stringentdatalytics.com/purchase/medical-grade-thermocouple-wire-market/3577/?license=single

About US:

Stringent Datalytics offers both custom and syndicated market research reports. Custom market research reports are tailored to a specific client's needs and requirements. These reports provide unique insights into a particular industry or market segment and can help businesses make informed decisions about their strategies and operations.

Syndicated market research reports, on the other hand, are pre-existing reports that are available for purchase by multiple clients. These reports are often produced on a regular basis, such as annually or quarterly, and cover a broad range of industries and market segments. Syndicated reports provide clients with insights into industry trends, market sizes, and competitive landscapes. By offering both custom and syndicated reports, Stringent Datalytics can provide clients with a range of market research solutions that can be customized to their specific needs

Contact US:

Stringent Datalytics

Contact No - +1 346 666 6655

Email Id - [email protected]

Web - https://stringentdatalytics.com/

#Medical Grade Thermocouple Wire#Thermocouple Technology#Temperature Measurement#Medical Devices#Healthcare Industry#Biomedical Applications#Thermocouple Sensors#Medical Equipment#Temperature Monitoring#Diagnostic Devices#Surgical Instruments#Patient Care#Clinical Research#Temperature Sensing#Biotechnology#Laboratory Instruments#Quality Control#Regulatory Compliance#Medical Instrumentation#Patient Monitoring#Invasive Procedures#Medical Testing#Precision Measurement#Life Sciences#Remote Monitoring#Sterilization Processes#Heat Management#Data Logging#Therapeutic Devices#Research and Development.

0 notes

Link

Quick Sense(QS-TC02): Digital AC 90V 250V Digital Temperature Controller Thermostat

Switch the modes between cool and heat; Control temperature by setting the temperature set value and the different value; Temperature collaboration; Refrigerating control output delay protection; Alarm when temperature exceeded temperature limit or when sensor error.

Specification and size

Front panel size: 75(L)x34.5(W)(mm)

product size: 75(L)x34.5(W)x85(D)(mm)

Mounting size: 71(L)x29(W)(mm)

Sensor length: 2m(Include the probe)

Technical parameters

Temperature measuring range: -50°C~90°C

Resolution: 0.1°C

Accuracy: +-1°C(-50°C~70°C)

Power supply: 220VAC 50Hz/60Hz

Power consumption: <3W

Sensor: NTC sensor (1P°C)

Relay contact capacity:Cool(10A/250VAC);Heat(10A/250VAC)

Ambient temperature: 0°C~60°C

Storage temperature: -30°C~75°C

Relative humidity: 20~85%(No condensate)

1 note

·

View note

Text

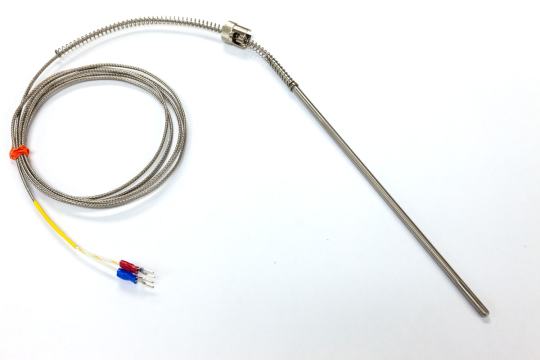

Measuring Temperature through Electrical Properties

There are three common temperature sensors that rely on the electronic properties of materials to determine temperature.

The first are thermocouples. Thermocouples measure temperature based on the Seebeck effect. When a temperature difference exists between two connected and dissimilar (electrically conductive) metals, charge will flow from the warm end to the cool end, creating a voltage that is used to calculate the temperature. There are multiple types of thermocouples, including thermocouple probes and wires, and multiple materials that are used for these sensors. Commercial thermocouples are fairly inexpensive but may not be accurate to more than a degree or so.

The term thermistors, the second type of sensor, comes from thermal resistor. These are semiconducting resistors, whereas the resistance of the material is strongly dependent on temperature. There are two general types of thermistors, negative-temperature-coefficient (NTC) thermistors and positive-temperature-coefficient (PTC) thermistors, which have either less or more resistance at higher temperatures, respectively. These sensors are typically highly accurate, but have a limited range.

Finally, resistance temperature detectors (RTDs) also use electrical resistance to measure temperature, but whereas thermistors use semiconductors, RTDs use pure metals. Platinum, copper, and nickel wires are common choices and RTDs are typically produced in 2-, 3-, or 4-wire configurations, where the 4-wire varieties have the highest accuracy.

Sources/Further Reading: (Image source - MadgeTech) Thermocouples: (Omega, Wikipedia); Thermistors: (Omega, Wikipedia); RTDs: (Electrical4U, Wikipedia)

12 notes

·

View notes

Text

When, Why and How to Change Your Transmission Fluid in Porsche

Transmission related problems have become common in most of the cars. A substance which keeps the transmission parts protected is transmission fluid. When this fluid gets older in your transmission or gearbox, it loses some of its properties and has to be replaced. In this article you will get to know why, when and how you can replace the transmission fluid in your Porsche car.

Why do you have to replace the transmission fluid?

First you need to know about the role of transmission fluid in vehicles. Transmission fluid is a transparent, red coloured fluid used in your transmission for the purpose of lubrication of moving parts, prevention of overheating and increase longevity of the gear box. It helps the gearbox to carry out its work smoothly and effortlessly. Transmission fluid is like a tonic for gear box. The transmission fluid also has validity. If it becomes too old, used or impure, then it has to be changed. As the transmission fluid flows throughout the transmission, dirt and debris may get accumulated inside it with time, also older fluids fail to carry out their work effectively. Replacing the transmission fluid makes the transmission last longer and you will not have to take your car to diagnose transmission failure. Using the same fluid for years without changing it will cause the transmission to slip, the gears will get worn out and overheat, then the transmission may fail.

When to replace the transmission fluid?

Generally in Porsche cars, the transmission fluid is to be replaced once for every 30000 miles. In some models, it is recommended to replace the fluid for every 100000 miles. But the life of the fluid also depends on how often you use your car. Here are some signs that your transmission fluid needs replacement.

The colour of the fluid becomes dark brown or light pink, opaque or becomes cloudy or dirt and debris or other residues in the fluid.

Transmission begins to slip

Unusual grinding sounds from transmission.

Transmission begins to overheat

Also note that you have to also replace the transmission fluid filter with the fluid. The filter lasts for 30000-50000 miles.

How to change your transmission fluid?

To change the fluid you need to have automatic service transmission kit for your Porsche model. This kit has all those parts that are to be installed after replacement. You must have the following tools - 240Torx, level, 17 mm hex, 10 mm socket/ratchet, torque wrench, bead thermocouple digital temperature sensor, catch tray, lint free towels, gravity oil fill. You will get these all from local auto parts stores.

Steps

1. The vehicle is raised and the under plastic shield id removed to access transmission pan

2. Level on the oil pan is placed to check if the car is level, fore and aft, side to side.

3. Then drain the fluid by opening the transmission drain plug

4. To reduce spillage and drain more fluid, pan is made to tilt down towards the drain by loosening the pan bolts.

5. Other pan bolts are also to be removed. You will see three bolts that attach filter to the valve body. You have to unbolt them to remove the filter along with seal O ring.

6. New filter is installed and bolted. Then new gasket is to be installed.

7. The transmission pan is reinstalled and use thread locker while bolting the old bolts.

8. Pour the fluid through fill hole till it drips from the fill. The fluid should be of 3-4 liters.

9. Start the engine and allow it to idle. Adding of fluid should be continued.

10. Shift the gear lever from park to D, wait for 3 seconds, then turn it to R and wait for 5 seconds.

11. Engine should idle and check the fluid temperature by the temperature sensor while adding the fluid. Pouring of fluid should continue till it drips from the hole and the temperature comes near to 40 degree C.

12. Put the hole plug with a sealing ring and torque it to 70Nm.

You should be very care full while following these steps of changing the fluid. Never work under the car if you are alone.

Conclusion

If you do not get the tools, then you can get the work done in authorized service stations for Porsche. If you take your car for transmission service then the transmission fluid change will be done in an affordable price.

2 notes

·

View notes

Text

Custom Cable Manufacturers: Tailored Solutions for Complex Needs

Custom cable manufacturers offer specialized solutions for industries requiring cables beyond standard specifications. From aerospace to medical devices, these manufacturers design and produce cables that meet exacting requirements in terms of size, material, insulation, and performance. Unlike off-the-shelf cables, custom cables are engineered to address specific challenges, such as extreme temperatures, high voltage, or unique environmental conditions.

One of the primary benefits of working with custom cable manufacturers is the ability to tailor cables to match precise technical demands. This ensures that the cable not only fits the equipment perfectly but also enhances operational efficiency and safety. Custom cables can also incorporate features such as shielding, multiple conductors, and custom jacketing to ensure optimal performance in challenging environments.

Additionally, custom cable manufacturers collaborate closely with clients to develop innovative solutions for complex projects, offering flexibility in terms of design, materials, and production timelines. This allows businesses to get a product that is perfectly suited to their needs, ensuring reliable performance and reduced downtime.

For industries looking to optimize their operations, working with custom cable manufacturers ensures access to high-quality, tailor-made cables that enhance productivity and durability.

#cable manufacturers#thermocouple wire#thermocouple wire type k#wire manufacturers#k type thermocouple wire#nichrome wire#high temperature wire#wire manufacturers in florida#heat trace cable#cable manufacturers in florida

0 notes

Text

TC Calibrator: Ensuring Precision in Temperature Measurement

In industries where accurate temperature measurement is critical, the TC calibrator (Thermocouple Calibrator) is an essential tool. Designed to test and calibrate thermocouples, which are widely used temperature sensors, the TC calibrator ensures that temperature readings are precise and reliable.

What is a TC Calibrator?

A TC calibrator is a device specifically designed for the calibration of thermocouples. Thermocouples measure temperature by generating a voltage that varies with temperature changes. The TC calibrator simulates precise temperature conditions and measures the output from thermocouples to ensure their accuracy.

Key Features

The TC calibrator comes equipped with several features that enhance its functionality:

High Accuracy: Provides precise temperature simulations, which are crucial for verifying the accuracy of thermocouples.

Wide Temperature Range: Capable of covering a broad range of temperatures, making it versatile for different calibration needs.

User-Friendly Interface: Includes a digital display and intuitive controls for easy operation and clear readouts.

Multiple Thermocouple Types: Supports various types of thermocouples, such as Type K, J, T, and others, making it adaptable to different applications.

How It Works

The TC calibrator operates through a straightforward process:

Temperature Simulation: The calibrator generates and maintains stable, known temperatures. This simulated environment is used to test the thermocouple’s response.

Measurement: The output voltage from the thermocouple is measured and compared against the expected value for the simulated temperature.

Calibration: If there are discrepancies between the thermocouple’s readings and the known values, adjustments are made to ensure accurate temperature measurement.

Applications

TC calibrators are used in various industries where precise temperature measurement is crucial:

Manufacturing: Ensures that temperature sensors in production processes are accurately calibrated to maintain product quality and process control.

Pharmaceuticals: Verifies the accuracy of temperature sensors in storage and processing environments to meet strict safety and quality standards.

Energy: Calibrates temperature sensors in power plants and other energy systems to ensure efficient and safe operation.

Benefits

Using a TC calibrator offers several significant benefits:

Enhanced Accuracy: Ensures that thermocouples provide precise temperature measurements, which is essential for maintaining accurate process control.

Reduced Downtime: Regular calibration helps prevent errors and operational issues, leading to minimized downtime and improved efficiency.

Cost Efficiency: Accurate temperature measurements contribute to process optimization and can help avoid costly mistakes or inefficiencies.

Conclusion

For industries that rely on accurate temperature measurements, the TC calibrator is an indispensable tool. By providing precise temperature simulation and measurement, it ensures that thermocouples operate reliably and accurately. Investing in a TC calibrator enhances the accuracy and efficiency of temperature-sensitive applications, making it a valuable asset for maintaining high standards in industrial operations.

0 notes

Text

0 notes

Text

A Comprehensive Guide to Data Acquisition Systems: Key Features, Applications, and Benefits

Data acquisition systems (DAQ) play a vital role in modern industries by enabling the accurate collection, analysis, and monitoring of data from various sources. Whether used in research laboratories, manufacturing facilities, or industrial automation, DAQ systems provide real-time insights that help enhance operational efficiency, improve product quality, and support data-driven decision-making.

In this blog, we’ll explore what a data acquisition system is, how it works, its key components, applications across industries, and the benefits of adopting a robust DAQ solution.

What is a Data Acquisition System?

A data acquisition system is a device or set of devices used to gather information from physical phenomena such as temperature, pressure, light, or electrical signals and convert them into digital data for processing and analysis. These systems help monitor processes, record events, and control mechanisms in various sectors, providing real-time insights into operational performance.

How Does a Data Acquisition System Work?

The process of data acquisition involves several steps:

Sensor Input: Sensors collect raw data from the physical world. These could be temperature sensors, pressure transducers, or other instruments depending on the measurement type.

Signal Conditioning: Once the sensor gathers data, it needs to be conditioned to make it suitable for processing. Signal conditioning might involve amplification, filtering, and noise reduction.

Analog-to-Digital Conversion (ADC): The conditioned signal, usually analog, is then converted into a digital format by an ADC. This makes it possible for the data to be processed by computers or control systems.

Data Processing & Storage: The digital data is processed in real-time or stored for later analysis.

Display & Analysis: The final step involves visualizing the processed data using graphical interfaces or reports for decision-making or system optimization.

Key Components of a Data Acquisition System

Sensors and Transducers: Devices used to measure physical phenomena (e.g., thermocouples for temperature).

Signal Conditioning: Enhances the signal for accurate data conversion.

Analog-to-Digital Converter (ADC): Converts analog signals into a digital format.

Data Acquisition Software: Interfaces with the hardware to control the system, process data, and present it to users.

Types of Data Acquisition Systems

Standalone DAQ Systems: These operate independently without needing a computer. They are portable and often used in field applications.

PC-based DAQ Systems: These systems require a computer for processing and are highly customizable with powerful processing capabilities.

Modular DAQ Systems: These offer flexible configurations, allowing users to mix and match components based on their specific application needs.

Applications of Data Acquisition Systems

Manufacturing & Automation

In manufacturing environments, DAQ systems are crucial for monitoring machinery performance, ensuring product quality, and automating control systems. They help detect anomalies, reduce downtime, and improve overall productivity.

Research & Development

In R&D labs, DAQ systems facilitate data collection and analysis in experiments across various disciplines such as physics, chemistry, and engineering. They provide accurate measurements to validate hypotheses and optimize product designs.

Aerospace & Defense

DAQ systems are used to collect data during testing phases of aircraft and defense systems, ensuring safety and reliability. These systems help monitor vibration, temperature, and stress factors in real-time.

Automotive Testing

In the automotive industry, DAQ systems are employed for vehicle diagnostics, performance monitoring, and testing new components. They collect data from multiple sensors placed throughout the vehicle to analyze its behavior under different conditions.

Energy and Utilities

Power plants and renewable energy facilities rely on DAQ systems to monitor energy generation and consumption, helping to optimize operations, reduce costs, and improve energy efficiency.

Benefits of Using Data Acquisition Systems

Real-time Data Monitoring: DAQ systems provide immediate insights into the performance of machines, processes, and experiments, allowing for timely intervention in case of anomalies.

Improved Decision-Making: With accurate and reliable data, organizations can make informed decisions, leading to better process optimization and productivity.

Data Accuracy and Precision: DAQ systems are designed to deliver high-quality data, reducing measurement errors and improving the accuracy of analyses.

Cost Savings: By monitoring equipment performance and preemptively identifying faults, DAQ systems can help reduce maintenance costs and prevent costly downtime.

Customization and Scalability: Modern DAQ systems offer flexible configurations that can be tailored to meet specific industry requirements, from small-scale laboratory setups to large industrial installations.

Selecting the Right Data Acquisition System

When choosing a DAQ system, consider the following factors:

Number of Channels: How many sensors or input signals does your application require?

Sample Rate: How frequently do you need to collect data? This is especially important in fast-changing environments.

Resolution: Higher resolution DAQs offer more precise data but may come at a higher cost.

Compatibility: Ensure that the DAQ system is compatible with your existing hardware and software infrastructure.

Environmental Conditions: Consider the operating environment. If the system will be used in harsh conditions, ensure it’s rugged and durable.

Conclusion

Data Acquisition Systems are invaluable tools that streamline operations, enhance product quality, and enable data-driven decision-making across industries. As technology continues to evolve, DAQ systems are becoming more accessible, customizable, and powerful, helping businesses optimize performance and stay competitive.

0 notes

Text

RTD PT-100,Bimetal thermowell

RTD PT-100 & Bimetal Thermowell: Precision & Durability in Temperature Measurement

In the world of industrial processes, accurate temperature measurement is crucial for ensuring product quality, safety, and efficiency. Among the various tools available for this purpose, RTD (Resistance Temperature Detector) RTD PT-100 sensors and bimetal thermowells stand out for their precision and durability. Understanding the roles of these components and how they work together can provide valuable insights into why they are so widely used in industries ranging from manufacturing to power generation.

What is an RTD PT-100?

An RTD PT-100 is a type of temperature sensor that uses the principle of resistance change with temperature. The "PT" in PT-100 refers to platinum, the metal used in the sensor, and "100" indicates that the sensor has a resistance of 100 ohms at 0°C. Platinum is chosen for its stable and predictable change in resistance with temperature, making it ideal for precise temperature measurements.

RTD PT-100 sensors are known for their accuracy and repeatability, often outperforming other types of temperature sensors such as thermocouples. They provide a linear relationship between temperature and resistance, which simplifies the process of converting the measured resistance into a temperature reading. This linearity, along with their wide temperature range and long-term stability, makes RTD PT-100 sensors a popular choice in industries where precise temperature control is essential.

The Role of the Bimetal Thermowell

While the RTD PT-100 is highly accurate, it is also sensitive and can be damaged by harsh environmental conditions. This is where the bimetal thermowell comes into play. A thermowell is a protective casing into which the RTD sensor is inserted. It shields the sensor from direct exposure to the process fluid, thereby preventing physical damage, corrosion, and contamination.

Bimetal thermowells are particularly valued for their ability to withstand extreme conditions. Made from two different metals fused together, they combine the strengths of each metal, offering superior durability and resistance to thermal stress. This construction allows them to perform reliably in environments with rapid temperature changes, high pressures, or corrosive substances.

The Importance of the Combination

The combination of an RTD PT-100 sensor with a bimetal thermowell creates a robust temperature measurement system that can handle the rigors of industrial environments while maintaining high accuracy. The RTD PT-100 provides precise temperature readings, while the bimetal thermowell ensures that the sensor is protected from potentially damaging conditions.

This setup is particularly useful in industries like chemical processing, oil and gas, and power generation, where temperature measurements are critical to maintaining safe and efficient operations. In these settings, any deviation from the desired temperature range can have significant consequences, making the reliability of the measurement system paramount.

Conclusion

The RTD PT-100 and bimetal thermowell combination represents the best of both worlds: precision and durability. While the RTD PT-100 offers exceptional accuracy, the bimetal thermowell provides the necessary protection to ensure the sensor’s longevity and consistent performance. Together, they form a reliable and effective solution for temperature measurement in demanding industrial environments, helping to ensure that processes run smoothly and safely.

#pressure gauge syphon#illustration#low pressure gauge#pressure gauge liquid filled gauge#pressure gauge#writers#bimetal thermometer remote reading thermometer#nonprofits#politics#nature

0 notes

Text

temperature measuring Devices

Temperature measuring devices are instruments used to measure the temperature of an object or environment, utilizing various principles such as thermal expansion, infrared radiation, and thermocouples. These devices include thermometers, thermistors, RTD sensors, and thermal imaging cameras, among others.

0 notes

Link

Quick Sense(Qs-Tc01): Digital 230V AC LED Digital Temperature Controller with Thermocouple Sensor

Measured or otherwise detected, and the passage of heat energy into or out of the space is adjusted to achieve a desired average temperature.

Specifications

Input SpecificationsThermocouple:K,J,S,R ThermalResistance:Pt100,RTD

Output SignalOptional output

Measurement Precision1.0 class (±1.0%F±1),0.5 class(±0.5%F+1)

Regulating MethodsIntelligent PID control, according to the value of P,I,D parameters,

we can get P(P=0 is on-off control),PI,PD,PID Regulating mode

Alarm function (optional function)The upper limit, Lower limit, Deviation value, Absolute value

Contact Capacity(Resistive Load): AC250V2A

Power supplyAC85-AC265V 50/60 Hz

Power Consumption≤10VA

Working Conditions Temperature:-10-50℃

Humidity: ≤85%RH non-corrosive environment

1 note

·

View note

Link

0 notes

Text

Temperature Sensors and Tubular Air Duct Heaters in HVAC Applications

In the realm of HVAC systems, particularly in industrial settings, maintaining precise air temperature is critical for both operational efficiency and product quality. Tubular air duct heaters play a crucial role in these systems, providing the necessary heat to regulate air temperature as it flows through ductwork. To achieve accurate and consistent temperature control, custom electric heating elements are integrated into these systems, ensuring that the heaters operate efficiently and effectively.

Industrial temperature sensors are essential for monitoring the air temperature within the ducts. These sensors provide real-time data that the control system uses to adjust the power output of the tubular air duct heater, maintaining the desired temperature. This precise control is vital in applications where specific temperature ranges must be maintained, such as in pharmaceutical manufacturing, food processing, and electronics production.

The selection of Hotlock Coil Heaters for use with tubular air duct heaters involves several considerations. The sensors must be capable of withstanding the operating conditions of the system, including high temperatures, humidity, and exposure to corrosive materials. Thermocouples, RTDs, and thermistors are commonly used in these applications, each offering different benefits in terms of accuracy, response time, and durability.

One of the key applications of temperature sensors in tubular air duct heaters is in energy efficiency. By accurately monitoring and controlling the air temperature, these sensors help optimize the performance of the HVAC system, reducing energy consumption and lowering operating costs. This is particularly important in large industrial facilities, where heating and cooling costs can be significant.

Electrical Tubular Heaters are commonly used in air duct heating due to their versatility and efficiency. These heaters consist of a tubular element that heats up when an electric current passes through it, transferring heat to the air as it flows over the element. The design of these heaters allows for efficient and even heat distribution, making them ideal for use in HVAC systems.

For applications that require even more efficient heat transfer, Finned Tubular Heaters are often used. The fins increase the surface area of the heater, allowing more heat to be transferred to the air as it passes through the duct. This design is particularly useful in applications where large volumes of air need to be heated quickly and evenly, such as in large industrial spaces or processing facilities.

0 notes

Text

Solar Sensors

What sensors are used in the solar system?

In the context of a solar power system, various sensors are used to monitor and optimize performance, ensure safety, and enhance efficiency. Here are some common types of sensors used in solar systems:

1. Solar Irradiance Sensors

Purpose: Measure the amount of solar energy the solar panels receive.

Examples: Pyranometers, reference cells.

2. Temperature Sensors

Purpose: Monitor the temperature of the solar panels, inverters, and batteries.

Examples: Thermocouples, RTDs (Resistance Temperature Detectors).

3. Current Sensors

Purpose: Measure the current flowing through the solar panels and into the inverter and battery.

Examples: Hall effect sensors, and shunt resistors.

4. Voltage Sensors

Purpose: Measure the voltage output of the solar panels and the voltage levels in the battery and inverter.

Examples: Voltage dividers, and voltage transducers.

5. Energy Meters

Purpose: Monitor the amount of energy produced by the solar panels and consumed by the load.

Examples: Watt-hour meters, and power meters.

6. Motion Sensors

Purpose: Detect movement around the solar installation, often used in solar street lights for security and energy-saving purposes.

Examples: Passive Infrared (PIR) sensors, and ultrasonic sensors.

7. Tilt and Position Sensors

Purpose: Ensure optimal orientation of solar panels to maximize energy capture, particularly in tracking systems.

Examples: Inclinometers, accelerometers.

8. Humidity Sensors

Purpose: Monitor the humidity levels around the solar panels to protect against moisture damage.

Examples: Hygrometers, and capacitive humidity sensors.

9. Wind Sensors

Purpose: Measure wind speed and direction to protect solar panels from damage during high winds.

Examples: Anemometers, and wind vanes.

10. Ambient Light Sensors

Purpose: Measure the ambient light levels for various applications, such as optimizing the operation of solar street lights.

Examples: Photodiodes, LDR (Light Dependent Resistors).

11. Pressure Sensors

Purpose: Monitor the pressure in solar thermal systems to ensure proper operation and safety.

Examples: Pressure transducers, and pressure gauges.

Integration and Monitoring

All these sensors are typically integrated into a central monitoring system that collects data, analyzes performance, and provides insights for maintenance and optimization. This system can be part of a larger solar power management system that includes controllers, data loggers, and software platforms for real-time monitoring and remote management.

Using these sensors effectively helps in maintaining the efficiency, reliability, and safety of solar power systems.

0 notes