#Thermal Insulation Solutions

Explore tagged Tumblr posts

Text

#Fire Safety#Fire Protection#Fireproofing#Thermal Insulation#GRP Lining#Acoustics#Fire-Stopping#Saudi Arabia#Vision 2030#Fire and Safety Solutions#RNSKSA#Safety Services#Industrial Solutions#Business Continuity#Innovation#Sustainable Future

2 notes

·

View notes

Text

Why Tikidan? Excellence in Waterproofing & Insulation

In the world of construction and infrastructure, durability and protection are non-negotiable. At Tikidan, we understand that the longevity of a structure depends heavily on two critical factors: waterproofing and insulation. That’s why we’ve made it our mission to be India’s leading experts in these specialized fields, offering innovative solutions that safeguard buildings from moisture, temperature fluctuations, and environmental damage.

A Legacy of Innovation

Tikidan is not just a brand — it is a benchmark of quality, innovation, and reliability. Backed by global expertise and cutting-edge technology, we bring decades of international experience to the Indian market. Our advanced product portfolio, including high-performance membranes and insulation systems, is engineered to meet the evolving demands of modern construction.

Comprehensive Solutions, Tailored to You

Whether it’s a residential high-rise, a commercial complex, an industrial facility, or an infrastructure megaproject, Tikidan offers end-to-end solutions that are customized to your needs. From design consultation and technical support to installation and post-project assistance, we ensure that every phase of waterproofing and insulation is executed with precision.

Sustainable Performance

At Tikidan, sustainability is more than a goal — it’s a responsibility. Our materials are designed to enhance energy efficiency, reduce environmental impact, and promote long-term cost savings. By preventing water ingress and minimizing thermal loss, our systems help clients meet green building standards and contribute to a more sustainable future.

Proven Track Record

We take pride in our portfolio of successful projects across India, from metro stations and highways to commercial buildings and luxury apartments. Our solutions have stood the test of time, delivering reliable performance in diverse climates and challenging conditions. Clients choose Tikidan because they trust in our commitment to quality, consistency, and compliance with global standards.

A Partner You Can Count On

Choosing Tikidan means choosing peace of mind. With a dedicated team of engineers, technical experts, and customer support professionals, we’re with you at every step — from blueprint to completion. Our goal is simple: to protect your investment, enhance your building’s performance, and exceed your expectations.

Committed to Expertise Driven Sustainable Solutions For a Better Tomorrow!

Website | Facebook | Instagram | Blog | Quora | Medium | Tumblr

1 note

·

View note

Text

#PUF Panels#Polyurethane Foam Panels#PUF Sandwich Panels#Thermal Insulation#Fire Retardant PUF Panels#Durable PUF Panels#PUR/PIR Panels#Cold Storage Solutions#Modern Building Materials

1 note

·

View note

Text

Top 5 Uses of Mica Paper: A Comprehensive Guide for Engineers and Designers | OmkarPaper

Discover the top 5 uses of mica paper in engineering and design with our comprehensive guide. Learn how mica paper enhances electrical insulation, thermal management, and structural applications. Perfect for engineers and designers seeking innovative solutions. Explore OmkarPaper's offerings today!

#Mica Paper Uses#Mica Paper for Engineers#Mica Paper for Designers#Electrical Insulation Mica Paper#Thermal Management Mica Paper#Structural Mica Paper Applications#Fireproof Mica Paper#Decorative Mica Paper Laminates#OmkarPaper Mica Solutions#Mica Paper Provider Service

0 notes

Text

Insulation Kings

Website: https://www.lasvegasinsulationkings.com

Address: 410 S. Rampart Blvd. Suite #390, Las Vegas, Nevada 89145, USA

Insulation Kings, a veteran-owned and locally operated company, has been a trusted name in insulation services for over 20 years. Based in Las Vegas, Nevada, they offer a wide range of residential, commercial, and industrial insulation solutions. Known for their professionalism and guaranteed satisfaction, Insulation Kings provides services including garage insulation, wall insulation, soundproofing, foam sealing, attic insulation, and more. They are recognized for their 24/7 availability and commitment to excellence in every project.

Yelp: https://www.yelp.com/biz/insulation-kings-las-vegas-2

Keywords:

Insulation contractors near me

Attic insulation near me

Soundproofing insulation

Attic insulation installation

Insulation services near me

Insulation removal near me

Soundproofing near me

Thermal imaging near me

Attic insulation Las Vegas

Thermal imaging services

Commercial insulation near me

Residential energy efficiency

Home insulation solutions

Professional insulation contractors

Residential insulation services

Superior insulation services

Sustainable insulation options

Energy-efficient insulation

Thermal imaging Las Vegas

Casita insulation

Energy-efficient home solutions

Pool house insulation

Top insulation contractors

commercial insulation solutions

foam sealing experts

energy efficient insulation

insulation removal specialists

24 hour insulation services

las vegas insulation company

veteran owned insulation business

emergency insulation services

custom home insulation

guest house insulation

lakefront house insulation

bpi certified insulation

investment savings insulation

quality attic insulation

commercial property insulation

effective soundproofing solutions

expert foam sealing services

advanced insulation removal

insulation emergency response

professional thermal imaging

reliable insulation specialists

trusted las vegas contractors

veteran owned insulation services

rapid emergency insulation

personalized home insulation

pool house energy solutions

guest house comfort insulation

lakefront property insulation

casita energy efficient insulation

certified home insulation

customized insulation solutions

leading insulation experts

proven soundproofing techniques

cutting edge foam sealing

attic insulation excellence

energy efficient home solutions

las vegas insulation specialists

sustainable insulation practices

insulation services in las vegas

las vegas commercial insulation

insulation contractors in nevada

soundproofing in las vegas

energy efficient insulation nevada

insulation removal nevada

24 hour insulation las vegas

veteran owned insulation nevada

emergency insulation las vegas

custom home insulation nevada

pool house insulation las vegas

guest house insulation nevada

lakefront house insulation las vegas

casita insulation nevada

bpi certified insulation las vegas

investment savings insulation nevada

insulation experts in las vegas

best insulation services nevada

energy efficient insulation near me

24 hour insulation near me

veteran owned insulation near me

emergency insulation near me

custom home insulation near me

pool house insulation near me

guest house insulation near me

lakefront house insulation near me

#Insulation contractors near me#Attic insulation near me#Soundproofing insulation#Attic insulation installation#Insulation services near me#Insulation removal near me#Soundproofing near me#Thermal imaging near me#Attic insulation Las Vegas#Thermal imaging services#Commercial insulation near me#Residential energy efficiency#Home insulation solutions#Professional insulation contractors#Residential insulation services#Superior insulation services#Sustainable insulation options#Energy-efficient insulation#Thermal imaging Las Vegas#Casita insulation#Energy-efficient home solutions#Pool house insulation#Top insulation contractors#commercial insulation solutions#foam sealing experts#energy efficient insulation#insulation removal specialists#24 hour insulation services#las vegas insulation company#veteran owned insulation business

1 note

·

View note

Text

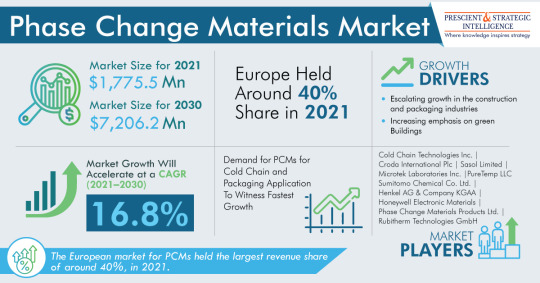

Transforming Industries: Phase Change Materials Market Insights

As stated by P&S Intelligence, the total revenue generated by the phase change materials market was USD 1,775.5 million in 2021, which will power at a rate of 16.8% by the end of this decade, to reach USD 7,206.2 million by 2030.

This has a lot to do with the increasing growth in the construction and packaging sectors and increasing importance on green buildings.

Cold chain and packaging category will grow at the highest rate, of above 17%, in the years to come. This can be mostly because of the surge in PCM requirement to sustain precise temperatures through the supply chain while lowering the emissions of carbon dioxide. Using ACs and electric fans to stay cool contributes to approximately 20% of the total electricity employed in buildings globally. The increasing requirement for space cooling is straining quite a few countries' power infrastructure, along with bringing about increased emissions.

With the enormous increase in the requirement for energy-efficient ACs, the requirement for PCMs will soar, as the electrical consumption of modified ACs with PCMs could be brought down by 3.09 kWh every day.

Europe dominated the industry with a share, of about 40%, in the recent past. The predisposition toward the acceptance of eco-friendly materials will power the PCM industry in the region. European regulatory associations, such as the SCANVAC, took more than a few initiatives for developing and promoting and effective building mechanical solutions and increase awareness pertaining to PCM applications.

The convenience of paraffin at a wide range of temperatures is a major reason for its appropriateness as an energy storage medium. Likewise, paraffin-based PCM is called a waxy solid paraffin, safe, dependable, noncorrosive, and economical material.

HVAC systems had the second-largest share, of about 30%, in phase change materials market in the recent past. This has a lot to do with the fact that PCM installation decreases fluctuations of temperature. HVAC with PCM supports in maintaining a steadier temperature and eliminating thermal uneasiness caused by alterations in temperature. It is because of the emphasis on green buildings, the demand for phase change materials will continue to rise considerably in the years to come.

#Phase Change Material Market#Phase Change Material Market Size#Phase Change Material Market Share#Phase Change Material Market Growth#Phase change materials (PCMs)#Thermal energy storage#Energy efficiency solutions#Heat management technology#Sustainable materials#Building insulation#HVAC systems#Thermal regulation#Cold chain logistics#Renewable energy storage#Temperature-sensitive packaging

0 notes

Text

The technology involves assembling heat-absorbing bricks in an insulated container, where they can store heat generated by solar or wind power for later use at the temperatures required for industrial processes. The heat can then be released when needed by passing air through channels in the stacks of "firebricks," thus allowing cement, steel, glass, and paper factories to run on renewable energy even when wind and sunshine are unavailable.

These systems, which several companies have recently begun to commercialize for industrial heat storage, are a form of thermal energy storage. The bricks are made from the same materials as the insulating bricks that lined primitive kilns and iron-making furnaces thousands of years ago. To optimize for heat storage instead of insulation, the materials are combined in different amounts.

Batteries can store electricity from renewable sources and provide electricity to generate heat on demand. "The difference between firebrick storage and battery storage is that the firebricks store heat rather than electricity and are one-tenth the cost of batteries," said lead study author Mark Z. Jacobson, a professor of civil and environmental engineering in the Stanford Doerr School of Sustainability and School of Engineering. "The materials are much simpler too. They are basically just the components of dirt."

#good news#environmentalism#science#environment#nature#energy efficiency#energy storage#bronze age#green technology#technology#batteries#geothermal power#firebricks#climate crisis#climate change

28 notes

·

View notes

Text

How Does Residential Metal Roofing Compare to Clay Tiles?

The choices when selecting a roofing material for your home can be overwhelming. You might be pondering various options, but two popular choices stand out: residential metal roofing and clay tiles. Both options have unique advantages and aesthetic appeal, but which is right for you? In this article, we'll explore how residential metal roofing compares to clay tiles, helping you make an informed decision that suits your style and needs.

Understanding Residential Metal Roofing

What is Residential Metal Roofing?

Residential metal roofing is a durable system made from metal materials such as steel, aluminum, or copper. Known for its longevity and resistance to weather conditions, metal roofing has gained popularity among homeowners looking for a reliable, energy-efficient solution. Available in many colors and finishes, residential metal roofing can complement any architectural style, from modern to traditional.

Pros of Residential Metal Roofing

Durability: Metal roofs can last 40 to 70 years, significantly longer than traditional roofing materials. This longevity often offsets the initial investment.

Energy Efficiency: Metal roofing reflects solar radiant heat, which can help reduce cooling costs in warmer climates. Some metal roofs even have special coatings to improve energy efficiency.

Low Maintenance: Unlike clay tiles, which may require regular maintenance and repairs, metal roofs are relatively low maintenance. They’re also resistant to mold, mildew, and insects, making them hassle-free.

Lightweight: Metal roofing is lighter than clay tiles, which can reduce the structural load on your home. This may allow for easier installation and lower labor costs.

Variety of Styles: From sleek modern designs to traditional barn styles, residential metal roofing comes in various colors and finishes, including matte and glossy options.

The Case for Clay Tiles

What are Clay Tiles?

Clay tiles are made from natural clay and are known for their classic aesthetic and durability. Often associated with Mediterranean and Spanish-style architecture, these tiles have been used for centuries and are cherished for their elegance and longevity.

Pros of Clay Tiles

Aesthetic Appeal: Clay tiles have a unique charm and character that many homeowners love. Their natural earth tones and textures add warmth to any home.

Longevity: When maintained properly, clay tiles can last over 100 years. Their durability means they can withstand harsh weather conditions, including extreme heat and cold.

Fire Resistance: Clay tiles are non-combustible, making them a safe choice in fire-prone areas. This characteristic can contribute to lower insurance premiums.

Eco-Friendly Option: Made from natural materials, clay tiles are recyclable and often considered an environmentally friendly roofing choice.

Insulation Properties: Clay tiles can provide excellent thermal insulation, helping to keep your home cool in summer and warm in winter.

Comparing Residential Metal Roofing and Clay Tiles

Cost Considerations

Cost is a significant factor when evaluating residential metal roofing versus clay tiles. Metal roofing typically has a lower initial cost than clay tiles, but installation might require specialized labor, which can add to the overall expense. Conversely, while clay tiles have a higher upfront investment, their longevity may justify the cost over time.

Weight and Structural Requirements

Clay tiles are heavier than metal roofing, so your home's structural framework supports the additional weight. This requirement can lead to higher construction costs. Metal roofing, being lightweight, offers more flexibility in design and may not necessitate structural reinforcements.

Installation Process

The installation process for each roofing type varies. Residential metal roofing can generally be installed more quickly than clay tiles, requiring careful placement to ensure longevity and effectiveness. The complexity of the installation may also influence labor costs.

Maintenance Needs

While both roofing materials are durable, their maintenance needs differ. Metal roofs require less maintenance than clay tiles, which may need regular inspections and repairs to address issues like cracked tiles or leaks. Homeowners looking for a low-maintenance option may lean toward residential metal roofing.

Weather Resistance

Both roofing types perform well under various weather conditions. However, clay tiles can crack under extreme impacts (like hail), while metal roofs are more resistant to dents and damage. Metal roofing excels in areas prone to heavy rain and snow, as its design allows for effective water drainage.

Making the Right Choice for Your Home

When choosing between residential metal roofing and clay tiles, consider your home’s architectural style, budget, and long-term plans. Residential metal roofing might be your best bet if you prefer a modern, sleek look with minimal maintenance. Alternatively, if you’re drawn to the timeless beauty of clay tiles and are willing to invest in maintenance, clay tiles may be the perfect choice.

Ultimately, the right choice will depend on your preferences and your home's needs. Assess the advantages of each option and consult with professionals to find the best solution for your roofing project.

Find the Perfect Roof for Your Home

In summary, residential metal roofing and clay tiles have advantages and drawbacks. Residential metal roofing offers durability, energy efficiency, and low maintenance, while clay tiles provide aesthetic appeal and longevity. By weighing the pros and cons of each option, you can make an informed decision that enhances your home’s beauty and functionality.

Are you ready to explore energy-efficient roofing solutions for your home? Visit Lastime Exteriors to learn more about your options, including residential metal roofing. Our expert team is here to guide you through the choices and help you find the perfect solution for your home's unique needs!

7 notes

·

View notes

Text

In everyday life, materials that conduct electricity well, like metals, also tend to conduct heat. For instance, a metal spoon left in a hot cup of tea will get hot, while the ceramic mug remains cool. This is because good electrical conductors are usually good heat conductors too. However, researchers at Drexel University and Université catholique de Louvain (UCLouvain) in Belgium have discovered that MXenes, a type of material known for its excellent electrical conductivity, actually have very low thermal conductivity. This finding challenges the usual link between electrical and heat conduction. And the discovery could lead to new developments in building materials, performance apparel and energy storage solutions. Recently published in the journal ACS Nanothe research reports that MXenes, a class of two-dimensional materials, originally discovered at Drexel in 2011, demonstrate the rare combination of high electrical conductivity and low thermal conductivity. While MXene materials have proven exceptional among two-dimensional materials in a number of ways -- including their strength, ability to selectively block and trap radiation and filter chemicals -- their performance as an ultrathin thermal insulator could be their most promising trait for future applications, according to the research team.

Read more.

#Materials Science#Science#Conductivity#MXenes#Thermal conductivity#Electronic conductivity#2D materials#Insulators#Drexel University

8 notes

·

View notes

Text

Unlocking Energy Efficiency: The Importance of Thermal Insulation in Saudi Arabia

In the heart of Saudi Arabia, where soaring temperatures can lead to soaring energy bills, the need for effective thermal insulation has never been more critical. As energy costs rise and the demand for sustainable living grows, homeowners and businesses alike are turning to innovative solutions to enhance their buildings’ efficiency. This is where RNS KSA comes into play, offering premier insulation services that ensure comfort without compromising on energy savings.

Why Thermal Insulation Matters

Thermal insulation is essential for maintaining comfortable indoor temperatures, especially in the extreme climates of Saudi Arabia. By reducing heat transfer between the outside and inside of a building, insulation helps keep interiors cool during the blistering summer months. This not only enhances comfort but also significantly lowers energy consumption, making it a win-win for both the environment and your wallet.

The construction industry in Saudi Arabia is rapidly evolving, and energy efficiency is now at the forefront of this transformation. High-quality building materials that feature advanced insulation properties are becoming standard in new developments. Investing in effective thermal insulation can lead to substantial savings on air conditioning costs, which are a significant portion of monthly energy bills.

RNS KSA: Your Partner in Energy Efficiency

RNS KSA specializes in providing top-tier thermal insulation solutions that cater to the unique demands of the Saudi Arabian climate. Our commitment to eco-friendly solutions ensures that our products not only enhance energy efficiency but also contribute to a sustainable future. We understand that every building has distinct needs, which is why we offer tailored insulation services that are designed to meet specific requirements.

Our expert team is dedicated to helping you choose the right insulation materials for your project. From spray foam to fiberglass, RNS KSA utilizes only the best products that comply with international standards. By focusing on HVAC efficiency, we help reduce the load on your heating and cooling systems, leading to longer lifespan and lower operational costs.

The Benefits of Investing in Thermal Insulation

Cost Savings: With rising energy prices, investing in thermal insulation can dramatically reduce your energy bills. The initial cost of installation is often offset by the long-term savings achieved through lower energy consumption.

Enhanced Comfort: Proper insulation keeps your indoor environment stable and comfortable. Say goodbye to hot spots and drafty rooms!

Environmental Impact: By improving energy efficiency, thermal insulation helps reduce your carbon footprint. This aligns with Saudi Arabia’s vision for a more sustainable future.

Increased Property Value: Homes and buildings with quality insulation tend to have higher market values. Potential buyers are increasingly aware of energy efficiency, making insulated properties more attractive.

Noise Reduction: Quality thermal insulation not only manages temperature but also absorbs sound, making your indoor spaces quieter and more peaceful.

Choosing the Right Insulation

When it comes to selecting the best thermal insulation for your building project, it’s important to consider factors such as climate, building design, and intended use. RNS KSA’s team of professionals is here to guide you through the selection process, ensuring you choose the right product that suits your needs and budget.

We also provide comprehensive installation services, ensuring that your insulation is applied correctly for maximum effectiveness. Our commitment to excellence means that we stay updated with the latest techniques and materials in the industry, guaranteeing that you receive the best service possible.

Conclusion

In a country like Saudi Arabia, where energy efficiency is not just a choice but a necessity, RNS KSA stands out as a trusted partner in thermal insulation solutions. By investing in quality insulation, you can achieve significant cost savings, enhance indoor comfort, and contribute to a more sustainable future.

Make the smart choice today. Contact RNS KSA to learn more about our thermal insulation services and how we can help you maximize your building’s energy efficiency. Together, let’s create a cooler, more comfortable environment while being kind to our planet.

#thermal insulation#insulation services#energy efficiency#RNSKSA#building insulation#HVAC insulation#industrial insulation#thermal protection#insulation solutions#heat resistance

0 notes

Text

Enhance Energy Efficiency with Lamatherm Insulation from RNS Qatar

Discover the benefits of Lamatherm insulation at RNS Qatar! Our high-quality insulation solutions are designed to enhance energy efficiency in residential and commercial buildings. Lamatherm products provide superior thermal performance, reducing energy consumption and creating comfortable indoor environments. Whether you're involved in new construction or retrofitting existing buildings, our insulation solutions meet your needs. Trust RNS Qatar for innovative building materials that promote sustainability and reduce operational costs. Explore our range of Lamatherm insulation products today and take the first step towards a more energy-efficient future!

Website: https://rnsqatar.com/lamatherm-insulation/

#Insulation#Energy Efficiency#Lamatherm#Construction Solutions#Building Materials#Thermal Insulation#Qatar

0 notes

Text

Protecting Your Home Investment with Durable Roofs During Storm Season

Introduction

When it comes to safeguarding your home, few things are as critical as a sturdy roof. Protecting your home investment with durable roofs during storm season isn’t just a good idea; it’s essential for maintaining the safety and integrity of your property. Storms can wreak havoc, and if your roofing materials aren’t up to par, you may find yourself facing costly repairs or worse. In this article, we’ll delve into the world of roofing—specifically focusing on roofing materials in Cork, durable roofs in Cork, and the various types of weather-resistant solutions available.

So grab a cup of coffee, sit back, and let’s explore how to keep your home safe from the elements.

Understanding Weather-Resistant Roofing What is Weather-Resistant Roofing?

Weather-resistant roofing refers to materials designed to withstand adverse weather conditions such as heavy rain, strong winds, hail, and even snow. These roofing types are engineered to prevent leaks and damage during storms, ensuring that your home remains dry https://about.me/rooferscorkcity/ and comfortable.

Why Choose Weather-Resistant Roofing in Cork?

In Cork, we’re no strangers to unpredictable weather. The right roofing material can mean the difference between a cozy home and a leaky nightmare. Choosing durable roofs in Cork can save you time, money, and stress down the line.

Types of Durable Roofs for Storm Season Asphalt Shingles: The Popular Choice

Asphalt shingles are one of the most common roofing types due to their affordability and durability. They come in various styles and colors but primarily offer decent resistance against wind and water.

Metal Roofing: A Tough Contender

Metal roofs have gained popularity for their longevity and ability to withstand extreme weather conditions. With proper installation, they can last over 50 years!

Slate Roofs: Timeless Elegance

Slate is not only stunning but also incredibly durable against storm damage. It's fire-resistant too! However, it tends to be pricier than other options.

Tile Roofs: A Mediterranean Look

Tile roofs are aesthetically pleasing while offering great durability against severe weather elements. They’re made from clay or concrete and can last for decades if maintained well.

youtube

Choosing Roofing Materials in Cork Factors to Consider When Selecting Roofing Materials Climate: Are you in an area prone to heavy rains or high winds? Budget: How much are you willing to invest? Longevity: Do you want something that lasts decades or something more temporary?

These factors will significantly influence your choice of roofing materials.

Roof Insulation in Cork Why is Roof Insulation Important?

Insulating your roof is vital for energy efficiency. Proper insulation keeps heat inside during winter months while preventing excess heat during summer—making it a smart investment.

Types of Roof Insulation Available

Cork insulation is gaining traction due to its eco-friendliness and excellent thermal performance. Other options include fiberglass batts and spray foam insulation.

Maintaining Your Durable Roof

2 notes

·

View notes

Text

Latest Innovations in Railway Bushings for High-Speed Rail Networks

Enhancing High-Speed Rail Efficiency with Advanced Railway Bushings

The rapid development of high-speed rail systems has revolutionized global transportation, necessitating more efficient, durable, and high-performance components. Among these, railway bushings play a crucial role in ensuring seamless power transmission, insulation, and vibration mitigation within electrical railway systems.

Radiant Enterprises, a leading high-current bushing manufacturer in India, is at the forefront of innovation, providing advanced solutions tailored for modern railway infrastructure. This blog explores recent advancements in railway bushings and their impact on the efficiency and safety of high-speed rail networks.

The Role of Railway Bushings in High-Speed Rail Systems

Railway bushings serve as a critical interface between electrical and mechanical components in high-speed rail networks. They are responsible for insulating high-voltage currents, reducing electrical interference, and minimizing vibrations that could impact railway system efficiency.

The expansion of high-speed rail has driven a surge in demand for customized epoxy bushings. These bushings provide superior insulation and withstand extreme weather conditions, making them an ideal choice for contemporary railway applications.

Innovations Shaping the Future of Railway Bushings

1. Advanced Custom Epoxy Bushings

To meet the growing demand for durability and efficiency, epoxy bushings have undergone significant advancements. Modern epoxy formulations enhance mechanical strength and thermal resistance, ensuring long-term reliability in high-speed rail networks.

Key Features:

Superior dielectric strength for exceptional electrical insulation

Enhanced mechanical properties to withstand high-speed vibrations

Resistance to environmental factors such as humidity, temperature fluctuations, and pollutants

Radiant Enterprises specializes in manufacturing custom epoxy bushings tailored to the specific needs of railway systems, ensuring top-tier performance and longevity.

2. Lightweight, High-Strength Materials

Traditional bushings were primarily made from porcelain and other dense materials. However, recent advancements have introduced lightweight composite materials that maintain durability and insulation while reducing overall system weight.

These high-strength materials enhance energy efficiency and improve the overall performance of high-speed rail systems.

3. Advanced Thermal Management Systems

High-speed rail networks generate significant heat due to elevated power transmission. To address this, epoxy bushings now incorporate advanced thermal-resistant coatings and cooling mechanisms that prevent overheating and extend operational lifespan.

By integrating heat-dissipating properties, these bushings ensure consistent performance and reduce the risk of electrical failures caused by excessive heat buildup.

4. Sustainable and Eco-Friendly Manufacturing

Sustainability is a growing priority across industries, including railway infrastructure. Modern railway bushings are now manufactured using environmentally friendly epoxy materials that lower carbon emissions and waste production.

Radiant Enterprises is committed to sustainable manufacturing practices, ensuring our epoxy bushings comply with industry standards while promoting environmental responsibility.

5. Smart Sensor-Integrated Bushings

The integration of IoT (Internet of Things) technology into railway bushings marks a new era of intelligent monitoring and predictive maintenance. Sensor-equipped bushings provide real-time performance data, including:

Temperature variations

Electrical resistance fluctuations

Mechanical stress levels

These insights allow railway operators to conduct proactive maintenance, reducing downtime and enhancing the efficiency of high-speed rail networks.

The Future of Railway Bushings

Ongoing research and technological advancements will continue to drive innovation in railway bushings. Key trends shaping the industry include:

3D Printing for Bushing Manufacturing: Utilizing additive manufacturing for precise and customized bushing production.

Nano-Coated Epoxy Bushings: Enhancing resistance to moisture, corrosion, and electrical failures.

High-Frequency Performance Bushings: Engineered for next-generation high-speed rail systems operating at ultra-high frequencies.

Radiant Enterprises remains dedicated to pioneering bushing innovations, ensuring continuous progress in railway infrastructure with state-of-the-art solutions.

Why Choose Radiant Enterprises for Railway Bushing Solutions?

Radiant Enterprises is a leader in bushing technology, specializing in customized epoxy bushings designed for high-speed rail applications worldwide.

Key Benefits of Our Railway Bushings:

Superior dielectric strength and electrical insulation

Enhanced thermal and mechanical resilience

Tailored solutions to meet specific railway requirements

Smart sensor integration for real-time performance monitoring

Environmentally sustainable manufacturing processes

We work closely with railway authorities, engineers, and system integrators to deliver epoxy bushings that enhance the safety, efficiency, and reliability of high-speed train networks.

Conclusion

The evolution of railway bushings has been instrumental in the advancement of high-speed rail networks worldwide. From custom epoxy bushings with superior insulation to smart sensor-integrated solutions for predictive maintenance, continuous innovation is driving progress in the railway sector.

As one of India's leading high-current bushing manufacturers, Radiant Enterprises is committed to delivering cutting-edge bushing solutions that meet the ever-evolving demands of modern railway infrastructure. By leveraging advanced materials, intelligent technology, and sustainable manufacturing, we are shaping the future of high-speed rail networks.

For premium railway bushing solutions, contact Radiant Enterprises today.

#Texas#Russia#railway bushings#railway insulator#India#customised epoxy bushings#cutomised epoxy insulator#pantograph#locomotive#third rail

4 notes

·

View notes

Text

Sectional Doors Manufacturers | NIHVA Technologies

Sectional Door, is a gateway solution for exterior application, suitable for both industrial and commercial building. Sectional doors perform the desired role with top performance and also have a very pleasing aesthetic appearance. High flexibility makes it possible to install this door in almost every type of building. The door slides up under the roof when opened, allowing free space around the door opening and leaving the door opening completely free. The door is made of insulated panels/Glazed Panel. These panels are designed without a thermal bridge to provide minimal thermal transmittance, which reduces energy cost.

The Overhead Sectional Doors are made of PUF panels, with external aluminum or GI panels. The doors can also be provided with vision panels in the form of glazing. The vision panel size is customizable. Fully glazed sectional doors are also available, which have very high aesthetic value. They are used as exterior doors for showrooms and industries.

In the manufacturing sector, NIHVA Technologies is emerging as the leading Sectional Door Manufacturer. We provide customized solutions for Insulated sectional doors and fully glazed sectional doors. Get in touch with us today to get the best quote and price for the sectional door.

Features of Sectional Doors

Used for functional and aesthetic needs

Protects against rough weather

External use

Used at loading bay or main entrances

Pass door – optional

Button / remote operated

Radar based automatic operation

Acts as therVision panels and full glazing availablemal barrier

Unlocking the Benefits of Sectional Doors: A Comprehensive Guide

Sectional doors have revolutionized the way we perceive garage and industrial access. As the world evolves, so do our needs for efficient, secure, and aesthetically pleasing entry points. In this guide, we delve into the realm of sectional doors, exploring their advantages, applications, and why NIHVA Technologies stands at the forefront of this innovative industry.

Unlocking the Benefits of Sectional Doors: A Comprehensive Guide

Sectional doors, unlike traditional overhead garage doors, consist of separate panel sections connected by hinges. This design allows for smooth vertical opening, maximizing space both inside and outside the garage or industrial facility. With their vertical operation, sectional doors are ideal for spaces with limited headroom, providing optimal clearance for vehicles and machinery.

2 notes

·

View notes

Text

The Power Of Polymer: Unfolding The Magic Of Polyurethane Foam Production

INTRODUCTION:

In the dynamic and evolving world of polymer science, one name specifically stands out due to its versatility and vast applicability – Polyurethane. A byproduct of the mind-boggling chemical reaction between two liquid materials, polyurethane is a unique type of polymer that effectively transforms into a foam. This article endeavors to offer you a detailed look into the exciting world of polyurethane foam production

THE DYNAMIC DUO:

Polyurethane foam is produced when two chemically distinct liquid materials – commonly referred to as the “”A”” component and “”B”” component – are combined under specifically controlled conditions.

The “”A”” component, or Polymeric MDI (methylene diphenyl diisocyanate), is a reactive isocyanate that boasts a relatively low viscosity level, enabling it to mix flawlessly with the “”B”” component. It has a brownish coloration and often exudes a slightly sweet smell.

Meanwhile, the “”B”” component, also known as Polyol, is a polyether compound that is generally less reactive than its “”A”” counterpart. It is characterized by a pale, almost transparent color and presents a tasteless, odorless profile.

POLYURETHANE PRODUCTION:

Let’s delve into the fascinating process through which these two distinct liquids join forces to produce the mighty polyurethane foam.

When combined, the polyether polyol and the polymeric MDI kickstart an exothermic chemical reaction that generates a considerable amount of heat. During this process, tiny gas bubbles are formed, which get trapped within the polymer structure, eventually giving rise to what we commonly recognize as foam. This intriguing process is commonly referred to as “”foaming.””

The reaction’s speed and the cell structure’s quality are heavily dependent on the specific quantities and properties of the A and B components. Manipulating these parameters allows for the production of a wide variety of foam types from rigid and semi-rigid to flexible. Additionally, various catalysts and surfactants can be added to control the cell structure’s size and distribution, as well as the reaction speed.

The transformation process from a liquid state to a solid, foamed state is surprisingly quick – often taking less than a few minutes. However, it’s noteworthy to mention that the foam continues to cure and reach its complete strength over the course of a few hours or even days.

APPLICATIONS OF POLYURETHANE FOAM:

The versatility of polyurethane foam is extraordinary. From furniture and bedding to automotive applications, thermal insulation in construction, and even in the footwear industry, polyurethane foam has spread its roots far and wide.

UNDERSTANDING THE SCIENCE:

The combination of a polyether polyol and a polymeric MDI generates not just heat but also a new product – urethane. Urethane forms strong, resilient bonds that contribute to the flexible, durable nature of the resultant foam. This is what makes polyurethane an excellent choice for various applications that require durability, flexibility, and excellent thermal and acoustic insulation properties.

In conclusion, the creation of polyurethane foam from two liquid materials is a mesmerizing example of polymer formation, which encapsulates the dexterity and capability of synthetic chemistry. By manipulating the compounds’ properties and the conditions under which the reaction occurs, scientists and engineers have managed to expand the realms of possibility, thereby furthering the boundaries of modern industrial applications. Thus, polyurethane foam not only offers an excellent material for various purposes but also profoundly echoes the power and potential of polymer science.

Tagged Foundation Solutions, Polymer, Power Of Polymer

#Foundation Solutions#Power Of Polymer#Foundation Repair#Foundation#Polymer#foundation contractor#foundation experts#foundation services#foundation repair near me

6 notes

·

View notes

Text

Do Roofing Contractors Offer Green Roofing Solutions?

As the world increasingly embraces eco-friendly practices, homeowners are becoming more conscious of the environmental impact of their choices, including roofing options. If you're considering a new roof, you may wonder whether roofing contractors like Lastime Exteriors offer sustainable solutions. This article will explore the concept of green roofing, the benefits of eco-friendly materials, and how Lastime Exteriors can help you make informed decisions for your home.

Understanding Green Roofing

Green roofing is more than just a trend; it's a practical approach that promotes sustainability and environmental stewardship. This innovative roofing solution typically involves two main types:

Vegetative Green Roofs: These roofs feature soil and vegetation layers that create a living ecosystem. They improve air quality, reduce stormwater runoff, and provide insulation, which can lead to lower energy costs.

Built-Up Green Roofs: These roofs incorporate multiple layers, including waterproof membranes and drainage systems, to support vegetation while protecting the underlying structure.

Both types offer many benefits, from improved energy efficiency to enhanced aesthetics. However, do roofing contractors like Lastime Exteriors have experience with these solutions?

Roofing Contractors and Green Solutions

Yes, many roofing contractors, including Lastime Exteriors, are stepping up to meet the demand for green roofing solutions. They understand the importance of sustainable building practices and have the expertise to design and install eco-friendly roofs that suit your home’s needs.

Why Choose a Roofing Contractor for Green Roofing?

Expert Guidance: Professional roofing contractors can provide valuable insights into the various green roofing options. They can help you select materials that align with your sustainability goals and budget.

Quality Installation: Proper installation is crucial for the performance of green roofs. Experienced contractors like Lastime Exteriors ensure your roof is installed correctly, maximizing its lifespan and effectiveness.

Maintenance Services: Green roofs require specific maintenance to thrive. Roofing contractors can offer ongoing support and maintenance services to keep your roof in excellent condition.

Benefits of Green Roofing Solutions

Choosing green roofing solutions can offer myriad advantages for homeowners:

Energy Efficiency: Many green roofs, like those made from recycled materials, excel in thermal performance. They keep your home cooler in the summer, which can reduce energy consumption and lower utility bills.

Stormwater Management: Green roofs absorb rainwater, reducing runoff and alleviating pressure on local drainage systems. This can help mitigate flooding and protect water quality.

Enhanced Property Value: Homes with eco-friendly roofing solutions are often more attractive to buyers. A green roof can improve your home's aesthetics and increase its resale value.

Environmental Impact: By choosing sustainable materials, you're contributing to a reduction in waste and pollution. Many green roofing options are recyclable, further minimizing environmental impact.

Regulatory Support: Cities are increasingly implementing policies that encourage green roofing practices. By opting for these solutions, you may benefit from incentives or rebates.

How Lastime Exteriors Can Assist You

At Lastime Exteriors, we pride ourselves on providing eco-friendly roofing solutions. Our team is skilled in various sustainable roofing practices, ensuring you receive the best service tailored to your needs. Here’s how we can help:

Customized Roofing Solutions

Every home is unique, and so are its roofing needs. Our team will work closely with you to assess your property and provide customized recommendations for green roofing solutions that align with your vision.

Expertise in Installation and Maintenance

Whether you choose a vegetative green roof or another eco-friendly option, our experienced contractors will install it with precision. We also offer maintenance services to ensure your roof remains healthy and effective over time.

Education and Resources

We believe in empowering our clients through knowledge. Our team will provide the information you need to decide your roofing options, including financial incentives and installation best practices.

Factors to Consider When Choosing Green Roofing

When selecting a roofing contractor for green roofing solutions, consider the following factors:

Experience: Look for contractors who have experience with green roofing practices. Ask for examples of previous projects they have completed.

Materials Used: Inquire about the types of materials they recommend and their sustainability credentials. The more recycled content, the better for the environment.

Warranty and Support: Ensure the contractor offers warranties on materials and workmanship. A good warranty can provide peace of mind.

Customer Reviews: Check testimonials and reviews from previous clients to gauge the contractor's reputation and reliability.

Communication: Choose a contractor who communicates openly and transparently. Good communication is essential for a successful project.

Build a Greener Future with Lastime Exteriors

Green roofing solutions are an excellent way to enhance your home’s sustainability, energy efficiency, and aesthetic appeal. Roofing contractors like Lastime Exteriors are well-equipped to guide you through the process, from selecting the right materials to ensuring proper installation and maintenance.

If you’re ready to explore eco-friendly roofing options for your home, look no further than Lastime Exteriors. We can create a greener future, one roof at a time.

2 notes

·

View notes