#Surface Vision and Inspection Market size

Explore tagged Tumblr posts

Text

Surface Vision and Inspection Market trends growth & Analysis

https://www.researchnester.com/reports/surface-vision-and-inspection-market/5539

#Surface Vision and Inspection Market#Surface Vision and Inspection Market share#Surface Vision and Inspection Market size

0 notes

Text

#Surface Vision And Inspection Market size#Surface Vision And Inspection Market share#Surface Vision And Inspection Market price

0 notes

Text

Worley Machine Enterprises: A Leader in Large-Scale CNC Precision Machining for Global Industries

In today’s rapidly evolving industrial landscape, precision and accuracy are more critical than ever, particularly when it comes to manufacturing complex components. For companies in need of large-scale CNC machining services, Worley Machine Enterprises stands out as a leader in the field. With a reputation for delivering high-quality components that meet exact blueprint specifications, Worley Machine Enterprises serves industries worldwide, providing the expertise and technology required for even the most demanding projects.

Precision and Reliability at the Core of Worley Machine Enterprises

Worley Machine Enterprises has built its success on a foundation of precision, reliability, and customer-focused service. As a full-scale CNC (Computer Numerical Control) machine shop, the company specializes in producing custom components to meet the unique needs of each client. Whether it’s a small batch run or large-scale production, they are equipped to handle projects of varying sizes and complexities with unmatched accuracy.

Key elements of their service include:

Advanced CNC Machining Capabilities

At the heart of Worley Machine Enterprises’ operation is their state-of-the-art CNC machinery. These advanced machines can produce highly complex parts with tight tolerances, ensuring that every component matches the exact specifications outlined in client blueprints. Their capabilities include turning, milling, drilling, and grinding, allowing them to produce parts with intricate geometries and precise dimensions. This makes them a preferred choice for industries such as aerospace, automotive, oil and gas, medical, and heavy machinery.

Large-Scale Production Capacity

Worley Machine Enterprises is uniquely positioned to handle large-scale production orders, making them a valuable partner for companies that require high-volume manufacturing. Their facility is equipped with high-capacity CNC machines that can operate around the clock, meeting tight deadlines without sacrificing quality. This capability is particularly important for industries that require a consistent supply of precision components, enabling them to maintain efficient production lines and meet market demands.

Blueprint-Driven Manufacturing

One of the distinguishing factors of Worley Machine Enterprises is their meticulous approach to blueprint-driven manufacturing. They work closely with clients to fully understand the specifications and requirements of each project, ensuring that every detail is accounted for during the machining process. From initial design consultation through to final production, their team is committed to delivering parts that match the client’s vision with pinpoint accuracy.

Commitment to Quality Assurance

Quality is paramount at Worley Machine Enterprises, and their rigorous quality assurance processes ensure that each component leaving their facility meets the highest standards. They utilize advanced inspection equipment and quality control methods to verify that each part aligns with blueprint specifications, including precision measurements, surface finishes, and material integrity. This commitment to quality has earned them a reputation for delivering components that not only meet but often exceed client expectations.

Global Reach and Industry Expertise

While based in the United States, Worley Machine Enterprises has a global reach, serving clients across multiple continents. Their ability to manufacture and ship precision components worldwide makes them an ideal partner for companies looking for a reliable supplier that understands international standards and requirements. Their extensive industry knowledge allows them to adapt to the specific needs of each market, offering solutions that align with diverse regulatory environments and performance criteria.

How Worley Machine Enterprises Supports Key Industries

The expertise of Worley Machine Enterprises extends across a variety of sectors, where precision, durability, and consistency are non-negotiable. Here are some of the industries they serve and how their CNC precision machining services make a difference:

Aerospace: The aerospace industry requires components with extremely tight tolerances and complex geometries to ensure safety and performance. Worley Machine Enterprises’ CNC precision machining capabilities make them a trusted supplier for aerospace parts, including custom fittings, engine components, and structural elements that meet strict aerospace standards.

Automotive: Automotive manufacturers depend on precision machining for everything from engine parts to transmission components. Worley Machine Enterprises offers large-scale production capacity, allowing them to support automotive clients with high-volume runs of precision parts that keep vehicles running smoothly.

Medical Devices: In the medical industry, precision is critical to the function of devices and implants. Worley Machine Enterprises’ ability to produce complex components with exact specifications makes them a valuable partner in the production of medical equipment, surgical instruments, and prosthetic parts.

Oil and Gas: Components for the oil and gas industry must withstand extreme conditions and stresses. Worley Machine Enterprises provides durable, high-precision parts that are essential for equipment reliability and efficiency, such as valves, drilling components, and pipeline parts.

Heavy Machinery and Industrial Equipment: For industries that rely on heavy machinery, Worley Machine Enterprises delivers the robust components needed to ensure operational efficiency. Their ability to produce large parts with precision helps industrial clients maintain uptime and extend the lifespan of their equipment.

The Worley Machine Enterprises Advantage

Partnering with Worley Machine Enterprises offers several key advantages:

Tailored Solutions: Worley Machine Enterprises takes a collaborative approach, working closely with clients to provide tailored machining solutions that align with their specific requirements. This includes custom material selection, surface finishes, and specialized processes to meet the unique demands of each project.

State-of-the-Art Technology: Their investment in cutting-edge CNC technology allows them to stay at the forefront of the machining industry. This commitment to innovation ensures that clients benefit from the latest advancements in precision manufacturing, resulting in better quality and faster turnaround times.

Dependable Delivery: Timely delivery is crucial in today’s fast-paced industries, and Worley Machine Enterprises has built a reputation for meeting deadlines without compromising quality. Their efficient production processes and logistical expertise enable them to deliver components when and where they are needed, keeping client projects on track.

Trust Worley Machine Enterprises for Your Precision Machining Needs

Worley Machine Enterprises is more than just a CNC machine shop; they are a strategic partner for companies around the world seeking precision, reliability, and excellence in manufacturing. With a focus on delivering components that meet exact blueprint specifications, they have earned the trust of clients across a variety of industries. Their combination of advanced technology, experienced craftsmanship, and unwavering commitment to quality makes them the ideal choice for large-scale CNC precision machining.Precision CNC Machining& Contract Manufacturing in Virginia:When precision matters, choose Worley Machine Enterprises - where your vision meets unparalleled machining expertise. Contact them today to learn how they can support your next project with precision components delivered to the highest standards.

1 note

·

View note

Text

Aimtron Electronics’ Premier PCB Assembly Manufacturing Services in Vadodara

In the dynamic realm of electronics manufacturing, finding a partner that can deliver on precision, efficiency, and reliability is crucial for success. Nestled in the vibrant city of Vadodara, Aimtron Electronics emerges as a beacon of excellence in the domain of PCB assembly manufacturing services, offering comprehensive solutions tailored to meet the diverse needs of clients across industries.

Aimtron Electronics: Pioneering Excellence

Aimtron Electronics boasts a stellar reputation built on a foundation of innovation, technology, and unwavering dedication to client satisfaction. With cutting-edge facilities and a team of seasoned professionals, the company stands at the forefront of PCB assembly manufacturing, delivering superior results with every project.

State-of-the-Art Technology:

At Aimtron Electronics, technological prowess is not just a badge of honor; it’s a commitment to excellence. The company harnesses the latest advancements in machinery, automation, and software to ensure unparalleled precision and efficiency in every PCB assembly. From surface-mount technology (SMT) to through-hole assembly and beyond, Aimtron Electronics leverages state-of-the-art equipment to meet the most demanding requirements with ease.

Tailored Solutions:

Recognizing that one size does not fit all, Aimtron Electronics takes a personalized approach to each client engagement. Whether it’s a startup navigating the complexities of prototyping or a large-scale enterprise requiring high-volume production, the company offers customized solutions tailored to the unique needs of each project. With a keen focus on collaboration and communication, Aimtron Electronics works closely with clients to understand their goals, challenges, and vision, delivering results that exceed expectations.

Rigorous Quality Assurance:

Quality is the cornerstone of Aimtron Electronics’ operations. The company adheres to stringent quality control protocols at every stage of the assembly process, ensuring that every PCB meets the highest industry standards. From meticulous component inspection to rigorous testing and validation, Aimtron Electronics leaves no room for compromise when it comes to quality assurance. By prioritizing excellence and attention to detail, the company instills confidence in clients, ensuring the reliability and integrity of every product that bears its name.

Timely Delivery:

In today’s fast-paced business landscape, time is of the essence. Aimtron Electronics understands the importance of timely delivery and works diligently to meet or exceed client deadlines without sacrificing quality. Leveraging streamlined production workflows and agile manufacturing processes, the company ensures that projects are completed on schedule, allowing clients to seize market opportunities and stay ahead of the competition.

Commitment to Sustainability:

As a responsible corporate citizen, Aimtron Electronics is committed to sustainability and environmental stewardship. The company embraces eco-friendly manufacturing practices, prioritizing energy efficiency, waste reduction, and responsible sourcing to minimize its ecological footprint. By integrating sustainability into its operations, Aimtron Electronics not only reduces environmental impact but also contributes to a brighter, more sustainable future for generations to come.

Conclusion:

In the competitive landscape of electronics manufacturing, finding a reliable partner is paramount to success. With its unwavering commitment to innovation, quality, and customer satisfaction, Aimtron Electronics emerges as a trusted ally for businesses seeking superior PCB assembly manufacturing services in Vadodara and beyond. By harnessing the power of technology, customization, and a relentless pursuit of excellence, Aimtron Electronics sets the standard for excellence in the industry, empowering clients to bring their electronic innovations to life with confidence and precision.

#ElectronicsDesign#ElectronicsDesignandManufacturing#PCB Assembly#ElectronicsManufacturing#PCBAssemblyManufacturer

0 notes

Text

Elevate Your Game: Comprehensive Basketball Court Installation Service

Whether you're a school, community center, or a homeowner with a love for basketball, having a professionally installed basketball court can transform any space into a hub for athletic activity.

A well-designed court not only enhances the aesthetic of your property but also provides a safe, high-quality surface for players of all ages and skill levels.

In this article, we’ll explore the benefits, the process, and what to expect from a top-notch basketball court installation service.

Benefits of Professional Basketball Court Installation

Durability and Longevity 🏅

Professional installation ensures that the court surface is built to withstand the rigors of daily use, harsh weather, and the passage of time. High-quality materials like asphalt, concrete, or acrylic ensure the court remains in top condition for years.

Custom Design Options 🎨

Whether you want a regulation-size court, a half-court for casual play, or a custom design that fits your unique space, professional services offer a wide range of customization options. You can choose colors, logos, and even integrate additional sports lines for multi-use functionality.

Safety First 🛡️

A professionally installed court prioritizes safety, with proper leveling, drainage, and surface materials that minimize the risk of injury. Anti-slip coatings and cushioned surfaces can also be added to reduce impact and provide a safer playing environment.

Enhanced Property Value 📈

Adding a basketball court to your property not only enhances your personal enjoyment but also increases your property’s market value. A well-maintained court is an attractive feature for potential buyers. If you are looking for basketball court installation service then you may visit this website https://precision-greens.com/.

The Installation Process: Step-by-Step Guide

1. Consultation and Site Assessment 📝

The process begins with a thorough consultation where your specific needs, budget, and vision are discussed. A site assessment follows, where professionals evaluate the space to ensure it’s suitable for installation. Factors like soil condition, drainage, and available space are carefully considered.

2. Design and Planning ���️

Next, the design phase takes your ideas and turns them into a workable plan. This includes selecting materials, determining the court layout, and choosing any custom features. A detailed blueprint is created, ensuring that every aspect of the court meets your expectations.

3. Ground Preparation 🌍

Once the design is approved, the ground preparation begins. This involves clearing the area, leveling the ground, and installing a base layer of gravel or stone. Proper drainage systems are also integrated to prevent water accumulation and maintain the court's longevity.

4. Court Construction 🏗️

The court surface is then laid down according to the chosen materials—whether it's asphalt, concrete, or synthetic surfaces. This phase includes adding color coatings, game lines, and any custom logos or designs. The goal is to create a smooth, durable surface that meets regulation standards.

5. Final Touches and Inspection 🔍

After the court is constructed, the final touches are added. This may include installing basketball hoops, lighting, and fencing. A thorough inspection is conducted to ensure everything meets safety and quality standards. Once complete, the court is ready for use!

What to Look for in a Basketball Court Installation Service

Experience and Expertise 💼

Choose a company with a proven track record in basketball court installations. Experience ensures the job will be done right, with attention to detail and adherence to industry standards.

Quality of Materials 🏗️

Ensure the service uses high-quality materials that are durable, weather-resistant, and safe. Cutting corners on materials can lead to costly repairs down the line.

Customization Options 🖌️

Look for a service that offers customization, allowing you to create a court that reflects your style and meets your specific needs.

Customer Reviews and Testimonials ���

Check out customer reviews and testimonials to gauge the quality of service. Positive feedback from previous clients is a good indicator of reliability and satisfaction.

Conclusion: Invest in Your Court, Invest in Your Game

A professionally installed basketball court is more than just a playing surface—it's an investment in your property, your health, and your community. Whether for personal use, school sports, or community recreation, a custom basketball court enhances the quality of play and provides a safe, enjoyable space for everyone.

0 notes

Text

Deck Installation Lodi, NJ: Elevate Your Outdoor Living Space with Construction First Choice LLC

Are you dreaming of a stunning outdoor oasis where you can relax, entertain, and create lasting memories? Look no further than Construction First Choice LLC in Lodi, NJ. As your trusted deck installation experts, we specialize in transforming your backyard into a captivating extension of your home. With our commitment to quality craftsmanship, exceptional customer service, and a wide range of design options, we’ll create a custom deck that perfectly complements your lifestyle and enhances the value of your property.

The Importance of a Well-Designed Deck

A deck is more than just a platform; it’s an outdoor living space that offers endless possibilities. Whether you envision a cozy retreat for morning coffee or a spacious entertainment area for hosting gatherings, a well-designed deck can significantly improve your quality of life.

Enhanced Property Value: A professionally installed deck can increase your home’s curb appeal and market value.

Increased Living Space: Expand your living area outdoors and enjoy the fresh air and natural surroundings.

Lifestyle Enhancement: Create a dedicated space for relaxation, dining, and entertaining friends and family.

Outdoor Entertaining: Host unforgettable BBQs, parties, and gatherings on your stylish deck.

Our Deck Installation Process

At Construction First Choice LLC, we pride ourselves on a meticulous and customer-centric approach to deck installation. Our process involves the following steps:

Initial Consultation: We begin by scheduling a consultation to discuss your vision, preferences, and budget. Our experienced team will assess your property and provide expert guidance on design options, materials, and layout.

Design and Planning: Based on your input, we’ll create detailed plans and renderings to visualize your dream deck. We’ll consider factors such as deck size, shape, materials, and safety regulations.

Material Selection: We offer a wide variety of decking materials, including:

Wood: Classic and natural, with options like cedar, redwood, and pressure-treated pine.

Composite: Low-maintenance and durable, with various colors and finishes to choose from.

PVC: Extremely durable and weather-resistant, ideal for low-maintenance lifestyles.

Permits and Approvals: We handle all necessary permits and inspections to ensure your deck complies with local building codes.

Preparation and Excavation: Our skilled team prepares the site by removing existing structures, grading the ground, and installing footings for a solid foundation.

Framing and Construction: We build the deck frame using high-quality materials and expert craftsmanship. We pay close attention to details, ensuring structural integrity and safety.

Decking Installation: We meticulously install the decking boards, creating a beautiful and even surface. We offer various installation patterns to match your desired aesthetic.

Railings and Stairs: We install sturdy and stylish railings to ensure safety and enhance the deck’s appearance. We also construct custom stairs for easy access.

Finishing Touches: We add the finishing touches, including staining or sealing the deck, installing lighting, and incorporating any additional features you desire.

Cleanup: We leave your property clean and tidy, ensuring a seamless completion of your project.

Deck Design Ideas

To inspire your deck project, consider these design ideas:

Elevated Decks: Create a multi-level deck with different seating areas and entertainment zones.

Covered Decks: Enjoy shade and protection from the elements with a pergola or awning.

Low-Maintenance Decks: Opt for composite or PVC decking for easy care and long-lasting beauty.

Incorporate Outdoor Living Spaces: Add a grill, outdoor kitchen, or fireplace to enhance your deck’s functionality.

Create a Relaxation Oasis: Include comfortable seating, planters, and water features for a tranquil retreat.

Why Choose Construction First Choice LLC?

Expertise and Experience: Our team of skilled professionals has years of experience in deck design and installation.

Quality Craftsmanship: We use high-quality materials and employ meticulous attention to detail.

Customer Satisfaction: We prioritize your satisfaction and strive to exceed your expectations.

Competitive Pricing: We offer competitive pricing without compromising on quality.

Comprehensive Services: We handle every aspect of your deck project, from design to completion.

Contact Us Today

Ready to transform your outdoor space? Contact Construction First Choice LLC today for a free consultation. Our friendly and knowledgeable team will help you bring your deck vision to life. Let us create the perfect deck for your home and lifestyle.

0 notes

Text

The global surface vision and inspection market is driven by several key factors. The increasing demand for quality control and automation in manufacturing processes is significantly boosting the adoption of surface vision and inspection systems.

0 notes

Text

Premier Supplier of Alaska Gold Granite in India for Exquisite Interiors and Exteriors

When it comes to finding the best Alaska Gold Granite supplier in India, Tripura Stones stands out as a premier choice. Renowned for our exceptional quality and diverse range, we are dedicated to providing top-notch granite solutions not only across India but also to international markets such as Vietnam, China, Turkey, the Middle East, and Africa. Our Alaska Gold Granite is a symbol of luxury and elegance, making it a preferred choice for various architectural and interior design applications.

Why Choose Alaska Gold Granite from Tripura Stones?

Unmatched Quality and Variety

We at Tripura Stones are proud to provide Alaska Gold Granite, which is renowned for both its striking look and strength. Our granite comes in a variety of finishes, including as tumbled, polished, sandblasted, and honed, so our clients may choose the ideal texture to fit their design requirements. We offer a broad range of alternatives to meet every need, whether you're looking for slabs, tiles, or blocks.

Customization to Suit Your Needs

Recognizing that every project is different, we provide tailored solutions to satisfy particular needs. We can customise our Alaska Gold Granite to fit a variety of applications, including slab countertops, tiles, and mosaics. Our versatility enables us to accommodate a wide range of applications, ranging from large-scale commercial projects to countertops in home kitchens.

Global Reach and Export Excellence

In several nations, Tripura Stones has made a name for itself as a reliable provider. Because of our dedication to excellence and client satisfaction, we have established trusting bonds with customers in Vietnam, China, Turkey, the Middle East, and Africa. By selecting us, you can take advantage of our vast knowledge of global export and logistics, which guarantees that your granite will arrive at your location promptly and in flawless shape.

Applications of Alaska Gold Granite

Interior Design

Alaska Gold Granite is perfect for designing opulent interior spaces. Its elaborate designs and deep golden tones give living rooms, kitchens, and bathrooms a sense of refinement. Because it gives surfaces like countertops and vanity tops a polished, elegant appearance, this finish is very popular.

Exterior Projects

For exterior applications, our sandblasted and tumbled finishes offer a robust and slip-resistant surface, making them perfect for outdoor flooring, facades, and wall cladding. The natural beauty of Alaska Gold Granite enhances the aesthetic appeal of gardens, patios, and building exteriors.

Commercial Spaces

In commercial settings, Alaska Gold Granite is used to create impressive and enduring designs. From hotel lobbies to office buildings, its durability and visual appeal make it a favored choice for high-traffic areas. The versatility in sizes and finishes allows architects and designers to execute their vision with precision and style.

Commitment to Sustainability and Quality

At Tripura Stones, we are committed to sustainable practices and ensuring the highest standards of quality. Our granite is sourced from ethically managed quarries, and we employ advanced processing techniques to minimize environmental impact. Quality control is paramount, and every piece of Alaska Gold Granite undergoes rigorous inspection to meet our stringent criteria.

Partner with Tripura Stones for Your Next Project

Selecting Tripura Stones is a decision to work with a business that prioritizes quality, dependability, and client happiness. Our team of professionals is committed to offering you the best Alaska Gold Granite, going above and beyond your expectations. From the beginning to the end of your project, we are here to help, providing direction and encouragement along the way.

Contact Us Today

Discover the difference that Tripura Stones can make for your next project. Contact us today to learn more about our Alaska Gold Granite and how we can help you achieve your design goals. Whether you are an architect, designer, contractor, or homeowner, we are here to provide you with the finest granite solutions that will stand the test of time.

0 notes

Text

0 notes

Text

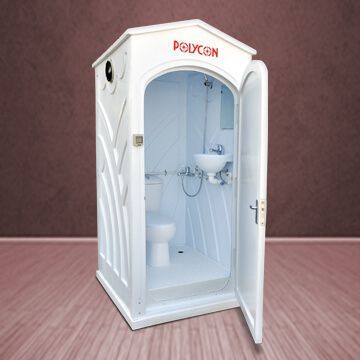

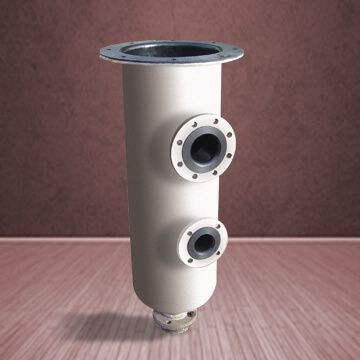

Polycon Gulf Ltd: A Leader in Quality Manufacturing for the UAE

Polycon Gulf Ltd., a subsidiary of the prestigious Al Nasser Industrial Enterprises LLC, stands as a leading manufacturer of high-quality products across various sectors. Established in 1993, Al Nasser Industrial Enterprises boasts a strong presence in the AGCC region, with manufacturing facilities spanning steel, polymers, fabrication, and industrial intermediates. Polycon Gulf Ltd. itself is a market leader in the UAE, recognized for its unwavering commitment to quality and exceptional customer service.

Polycon offers a diverse range of products, including:

- Water Tanks: Available in various sizes and configurations, Polycon's water tanks are ideal for residential, commercial, and industrial applications.

- Road Barriers: Polycon's robust track barriers ensure safety and traffic control on roadways across the UAE.

- Portable Restrooms: Polycon provides high-quality portable restrooms for events, construction sites, and other temporary needs.

- Inspection Chambers: Polycon offers durable inspection chambers for various underground applications.

- Rotolining Services: Polycon provides expert rotolining services for enhancing the interior surfaces of carbon steel pipes and tanks.

Polycon prioritizes the use of medium-density polyethylene (MDPE) in its manufacturing process. This environmentally friendly material offers exceptional resistance to both physical and chemical damage, ensuring the longevity and reliability of Polycon's products.

Driven by a clear mission to create safe, strong, and durable products through continuous innovation, Polycon consistently strives to explore new applications and push boundaries within the industry. Their vision is to solidify their position as the leading rotomolding company in the GCC, achieved through unwavering commitment to innovation, best practices, and stringent quality standards.

Polycon's dedication to quality is evident in their meticulous design process, utilizing advanced analytical methods to optimize product thickness and minimize stress and deflection. This meticulous approach ensures that Polycon products can withstand heavy hydrostatic loads, offering years of reliable service. Furthermore, Polycon adheres to strict quality control measures aligned with the requirements of DIN ISO 9001:2008, guaranteeing the highest quality standards at every stage of production.

Whether you require water storage tanks in Abu Dhabi, portable restrooms for your next event, or any other product from their extensive range, Polycon Gulf Ltd. stands as a trusted and reliable partner in the UAE.

#Good Company For Water Tank#Horizontal Tank Suppliers In Al AIN#Water Tank Sharjah#Best Water Tank Supplier In Al AIN#Road Barriers In Uae#Best Quality Water Tank In Abudhabi

0 notes

Text

The Essence of Inspection Machines in Modern Industries

In the dynamic landscape of modern industries, the role of inspection machines has become increasingly vital. As technological advancements continue to revolutionize manufacturing processes, the significance of maintaining high standards in quality control cannot be overstated. In this blog post, we delve into the world of inspection machines, understanding their purpose, types, and the pivotal role they play in ensuring precision and efficiency. Let's embark on a journey to unravel the essence of inspection machines and their impact on various sectors.

Understanding Inspection Machines :

Inspection machines are sophisticated tools designed to assess and verify the quality, accuracy, and integrity of products during the manufacturing or production process. These machines employ advanced technologies to detect defects, inconsistencies, or deviations from established standards, ensuring that only products meeting the desired criteria reach the market.

Types of Inspection Machines

1. Vision Inspection Systems:

Vision inspection systems utilize cameras and image processing software to scrutinize products for defects. These systems are highly versatile, capable of identifying irregularities in size, shape, color, and surface characteristics.

2. X-ray Inspection Machines:

X-ray inspection is particularly valuable in industries where internal defects or inconsistencies need to be identified without compromising the integrity of the product. This method is commonly used in the food, pharmaceutical, and electronics industries.

3. Ultrasonic Inspection Machines:

Ultrasonic inspection involves the use of high-frequency sound waves to detect defects or inconsistencies beneath the surface of materials. This method is frequently applied in assessing the structural integrity of components in industries such as aerospace and automotive.

4. Eddy Current Inspection:

Eddy current inspection is employed for assessing the conductivity and integrity of conductive materials. This method is extensively used in the manufacturing of metal components, including tubes and pipes

The Role of Inspection Machines in Industries :

1. Quality Assurance:

Inspection machines are instrumental in maintaining and assuring product quality. By identifying and rectifying defects early in the production process, manufacturers can prevent substandard products from reaching consumers.

2. Efficiency Improvement:

Efficient production is a key goal for any manufacturing process. Inspection machines contribute to efficiency by automating the quality control process, reducing the need for manual inspection and minimizing production delays.

3. Cost Reduction:

Detecting defects early in the production cycle helps in minimizing waste and reducing the overall cost of production. This not only benefits manufacturers but also contributes to sustainability efforts.

4. Compliance with Standards:

In industries with stringent regulations and standards, inspection machines play a crucial role in ensuring compliance. This is particularly important in sectors such as healthcare and aerospace, where adherence to specific standards is paramount.

Industries Benefiting from Inspection Machines :

1. Automotive:

Inspection machines are extensively used in the automotive industry to assess the quality of components, ensuring the safety and reliability of vehicles.

2. Pharmaceutical:

The pharmaceutical industry relies on inspection machines to guarantee the accuracy and integrity of medicinal products, from tablets to packaging.

3. Food and Beverage:

In the food and beverage sector, inspection machines are employed to identify contaminants, ensure proper packaging, and maintain quality control throughout the production process.

4. Electronics:

Precision is critical in the electronics industry, and inspection machines help in identifying defects in circuit boards, components, and final products.

Conclusion :

In conclusion, inspection machines play a pivotal role in today's industrial landscape, contributing to the enhancement of product quality, efficiency, and compliance with standards. As technology continues to advance, the capabilities of inspection machines will evolve, further solidifying their importance in various sectors. Manufacturers embracing these technologies are better positioned to deliver products that meet and exceed customer expectations, fostering trust and loyalty in an increasingly competitive market.

To explore advanced inspection solutions for your industry, visit Mitchell Industries - injection moulding machines . Stay tuned for more insights into the innovative world of manufacturing and quality control.

#injection moulding#injection moulding machines#moulding machine#blow moulding machine alphamac#recycling machine

0 notes

Text

What is AI-based Visual Inspection and its Use cases ?

Visual checks form an essential part of quality management in almost every industrial and manufacturing process. However, the task requires dedicated employees and is repetitive when conducted manually. Technological innovation now means that it is possible to improve productivity and guarantee consistency, thanks to artificial intelligence. Today's forward-thinking manufacturers are deploying AI-based visual inspection to reduce errors and detect anomalies with impressive accuracy. Automated visual inspection techniques can help save your business time, effort, and money. Read on to discover how automatic visual evaluation and a deep learning approach can save significant time and effort.

What is Visual Inspection?

Visual inspection is a process of evaluating objects, materials, or systems using human eyes to identify defects, irregularities, or specific attributes. It is a fundamental quality control technique employed across various industries to ensure the accuracy, integrity, and compliance of products or processes. Visual inspection involves careful observation and assessment of visual cues such as color, shape, size, texture, and overall appearance to make informed judgments about the condition or quality of the subject under scrutiny. While traditionally a manual process, advancements in technology have led to the integration of automation and artificial intelligence, enhancing the precision, efficiency, and scope of visual inspection tasks.

What Is AI-Based Visual Inspection?

AI-based visual inspection refers to the integration of artificial intelligence (AI) and computer vision technologies in the process of inspecting and evaluating products or components visually. This approach enhances traditional visual inspection methods by utilizing advanced algorithms, machine learning, and deep learning techniques to analyze images or videos for defects, irregularities, or specific attributes. In AI-based visual inspection, high-definition cameras capture visual data, which is then processed and analyzed by AI algorithms. These algorithms can identify patterns, anomalies, or specific features that might be difficult to detect by human eyes alone. Through training on labeled datasets, the AI system learns to recognize different characteristics and make informed decisions about the quality or condition of the items being inspected.

The benefits of AI-based visual inspection include increased accuracy, consistency, and efficiency compared to manual inspections. It can handle large volumes of data quickly and perform inspections at a much higher speed. This technology is employed in various industries, such as manufacturing, quality control, automotive, electronics, healthcare, and more, to ensure products meet predetermined specifications and standards. AI-based visual inspection represents a significant advancement in quality control processes, leveraging the power of artificial intelligence to enhance accuracy and streamline inspection tasks.

Real-world applications of AI Visual inspection

AI-based visual inspection finds wide-ranging applications across various industries due to its accuracy, speed, and ability to detect subtle nuances that might escape human eyes. Some notable real-world applications include:

Product Defect Detection: AI-driven visual inspection automates the identification of defects in manufactured products. It's used to spot cosmetic issues, misalignments, faulty welds, or assembly errors, ensuring only high-quality items reach the market.

Damage Detection: The technology is leveraged to autonomously identify damage in equipment, structures, or buildings. It can swiftly spot surface cracks, dents, structural integrity issues, or even water damage, facilitating prompt maintenance and preventing further deterioration.

Corrosion Monitoring and Detection: In industries dealing with infrastructure, pipelines, storage tanks, and vessels, AI-powered visual inspection monitors corrosion levels. It aids in identifying the early stages of corrosion, allowing for proactive maintenance and minimizing risks.

Equipment Inventory Management: AI streamlines asset management by automatically tagging and recording equipment details. Visual inspection helps read and transcribe equipment tags, thereby cataloging them efficiently into a database, and simplifying inventory tracking.

Quality Assurance in Food Production: AI visual inspection is used to scrutinize food products for quality control. It can identify size, shape, color, and defect irregularities, ensuring only safe and high-quality items reach consumers.

Pharmaceutical Inspection: In pharmaceuticals, AI-based visual inspection ensures the integrity of medications by detecting imperfections in pills, capsules, or packaging, thus upholding stringent safety standards.

Agricultural Yield Estimation: AI-driven visual inspection assists in estimating crop yields by analyzing images of fields. This aids farmers in making informed decisions about resource allocation and harvesting times.

Security and Surveillance: The technology enhances security by autonomously monitoring areas for suspicious activity. It identifies unauthorized personnel, intrusions, or unusual behaviors in real-time, improving overall safety.

Automotive Manufacturing: AI-based visual inspection verifies the quality of automotive components during production, catching issues such as paint defects, misalignments, or faulty components before they escalate.

Medical Diagnostics: In medical imaging, AI-powered visual inspection aids in diagnosing diseases by analyzing medical images, identifying anomalies, and assisting medical professionals in making accurate decisions.

Retail Inventory Management: AI visual inspection can help in stock management by automatically counting items on shelves and comparing them to inventory records, reducing human error and ensuring accurate stock levels.

Advantages Of AI-Based Visual Inspection

Below are some common reasons you should choose automated visual inspection for quality testing.

Enhanced Precision: AI-powered visual inspection offers unparalleled accuracy in identifying even the minutest defects or irregularities, surpassing human visual capabilities.

Consistent Performance: Automated systems maintain a consistent level of performance regardless of factors like fatigue or external distractions, ensuring reliable and standardized results.

High-Speed Analysis: AI-based inspection processes data rapidly, enabling quick decision-making and efficient handling of large volumes of visual data in real time.

Cost-Efficiency: Once set up, AI visual inspection systems reduce labor costs and operational expenses by streamlining the inspection process and minimizing the need for extensive human involvement.

Risk Mitigation: By deploying AI in hazardous environments or situations, organizations can protect human workers from potential dangers while maintaining quality control.

Complex Pattern Recognition: AI algorithms excel at recognizing intricate patterns, making them suitable for tasks that involve analyzing intricate details, textures, or complex shapes.

Data-Driven Insights: The data generated by AI-based inspections can offer valuable insights into production processes, allowing for continuous improvement and optimization.

Reduced Error Rates: Automated inspections minimize human error, contributing to higher accuracy levels and reducing the risk of faulty products reaching consumers.

Scalability: AI inspection can be easily scaled up or down to meet varying production demands without compromising accuracy or efficiency.

Data Annotation for Visual Inspection AI

Data annotation is a fundamental process in the realm of computer vision, specifically for tasks involving visual inspection. In this context, data annotation refers to the meticulous labeling of images or videos with specific attributes, such as object boundaries, classifications, or semantic features. The need for data annotation in visual inspection using computer vision arises from several critical factors:

Training Machine Learning Models: Computer vision models, particularly those driven by machine learning algorithms, require substantial amounts of labeled data to learn and generalize from. By annotating images with accurate labels, the models can identify patterns, make informed decisions, and perform visual inspections with high precision.

Quality Control and Defect Detection: Visual inspection is often employed in quality control and defect detection scenarios. For instance, in manufacturing industries, products are visually inspected for defects, and these defects need to be precisely labeled for the model to recognize and classify them accurately.

Semantic Understanding: Data annotation facilitates semantic understanding. It enables the model to differentiate between objects, identify their positions, and understand their relationships within an image. This is crucial for applications like object counting, locating specific features, or measuring dimensions.

Complex Task Handling: Many visual inspection tasks involve intricate or subjective criteria that cannot be solely determined by automated algorithms. Human annotators with domain expertise can label such nuanced attributes effectively, ensuring the accuracy of the model's predictions.

Diverse Scenarios: Visual inspection occurs across a broad spectrum of industries, from healthcare and automotive to agriculture and electronics. Data annotation allows models to adapt to the unique attributes and variations of each domain, making it versatile for various applications.

Model Validation: Labeled data serves as a benchmark for evaluating model performance. With annotated data, the model's predictions can be compared to ground truth, allowing for continuous refinement and improvement of the algorithm.

Human-AI Collaboration: Data annotation promotes a symbiotic relationship between humans and AI. While automation can handle large volumes of data, human annotators are vital for refining complex or ambiguous cases, enhancing the model's accuracy.

Data annotation for visual inspection using computer vision is the cornerstone upon which accurate and reliable AI models are built. It bridges the gap between raw visual data and AI understanding, empowering machines to perform complex tasks with the precision and reliability required for critical applications.

Conclusion

In a world saturated with visual data, the significance of AI-powered visual inspection cannot be overstated. The transformational impact it brings to quality control, efficiency, and accuracy is reshaping industries at their core. What was once a manual and time-consuming process has evolved into a realm where machines, armed with advanced algorithms and deep learning, can scrutinize vast volumes of visual data swiftly and precisely.

At TagX, we recognize the immense potential of AI visual inspection and stand ready to guide you on this journey. Our expertise lies in translating this potential into reality by providing tailored data solutions for various applications of AI visual inspection. Our dedicated team brings years of experience in Data collection, curation, and data annotation, enabling businesses to harness the full potential of computer vision solutions. With TagX by your side, you can unlock the true power of visual data, scale your visual technologies, and achieve unparalleled accuracy in detection and analysis.

0 notes

Text

Machine Vision And Inspection System Market Share and Demand Analysis with Size, Growth Drivers and Forecast to 2030

The latest market report published by Credence Research, Inc. “Global Machine Vision And Inspection System Market: Growth, Future Prospects, and Competitive Analysis, 2022 – 2030. Machine vision and inspection solutions have become crucial components in industrial automation. There’s a growing global demand for these systems, driven by heightened awareness of their benefits and further bolstered by ongoing technological advancements and decreasing costs.

Machine Vision and Inspection System Market is a dynamic and rapidly evolving segment of the technology and manufacturing industry. This market revolves around the development and implementation of advanced machine vision systems and inspection technologies that enable automated quality control, defect detection, and precision measurements in various industrial processes. Machine vision systems rely on cameras, sensors, artificial intelligence, and computer vision algorithms to analyze and interpret visual data, ensuring product quality and consistency across sectors such as manufacturing, automotive, electronics, healthcare, and food and beverage.

Key components of this market include 2D and 3D vision systems, smart cameras, optical character recognition (OCR), and robotic inspection systems. The adoption of machine vision and inspection systems is driven by the need for improved product quality, reduced production errors, increased efficiency, and compliance with regulatory standards. These systems find applications in tasks ranging from surface inspection, part identification, and assembly verification to barcode reading, packaging inspection, and defect sorting.

As technology continues to advance, machine vision systems are becoming more accessible, cost-effective, and capable of handling complex inspection tasks. The market's growth is propelled by Industry 4.0 and the integration of machine vision into smart factories and automation processes. Furthermore, the expanding scope of machine vision applications in areas like healthcare diagnostics, autonomous vehicles, and robotics underscores its versatility and potential for transformative impact across industries.

The dynamics of the Machine Vision and Inspection System Market are shaped by a multitude of factors that influence its growth, innovation, and adoption across various industries. These dynamics encompass trends, challenges, opportunities, and market drivers, all of which contribute to the evolving landscape of machine vision and inspection systems.

Here are the key dynamics at play:

Automation and Industry 4.0: The rise of automation and Industry 4.0 initiatives in manufacturing and industrial sectors is a primary driver. Machine vision systems play a pivotal role in automating quality control, process monitoring, and defect detection.

Quality Assurance: Ensuring product quality and consistency remains a top priority for industries. Machine vision systems provide real-time inspection and quality assurance, reducing defects and enhancing customer satisfaction.

Increasing Complexity: As products and manufacturing processes become more complex, the demand for advanced machine vision and inspection solutions grows. Systems capable of handling intricate tasks, including 3D measurements and defect classification, are in high demand.

Technological Advancements: Ongoing advancements in hardware, sensors, cameras, and machine learning algorithms improve the capabilities and accuracy of machine vision systems. Enhanced image processing and AI-driven analytics enable more sophisticated inspections.

Cost Reduction: The declining cost of machine vision hardware and components makes these systems more accessible to a broader range of industries and applications, including small and medium-sized enterprises.

Browse 245 pages report By Application (Identification, Location, Measurement, Inspection), By System Type (Pc-Based Solution, Camera), By Components (Camera, Optics, Lighting, Frame Grabber, Software), By End Use Vertical (Automotive, Electrical/Electronics, Food And Beverage, Semiconductor, Pharmaceutical, Metal, Rubber And Plastic, Printing) - Growth, Future Prospects & Competitive Analysis, 2016 – 2030) https://www.credenceresearch.com/report/machine-vision-and-inspection-system

Machine Vision And Inspection System Market Recommendations-

Invest in Advanced Technologies: Embrace the latest advancements in machine vision, including 3D imaging, deep learning, and AI-based algorithms. Staying at the forefront of technology ensures that your solutions remain competitive and capable of meeting complex inspection needs.

Offer Scalable Solutions: Provide machine vision systems that are scalable to accommodate both small businesses and large enterprises. Offer flexibility in system configurations and pricing models to cater to a broad customer base.

Focus on User-Friendliness: Develop user-friendly interfaces and software for machine vision systems. Simplify the setup, calibration, and operation of these systems to make them accessible to users with varying levels of technical expertise.

Customization Services: Offer customization services to tailor machine vision solutions to the unique needs of different industries and applications. Work closely with clients to understand their specific requirements and challenges.

Integration Expertise: Develop expertise in integrating machine vision systems seamlessly into existing production lines and automation setups. Collaborate with automation experts to ensure smooth deployments.

Training and Support: Provide comprehensive training and ongoing support to customers. This includes training on system operation, maintenance, and troubleshooting. Prompt and effective customer support enhances long-term relationships.

Data Security: Address data security concerns by implementing robust cybersecurity measures in machine vision systems. Ensure data protection and compliance with relevant regulations, especially in sensitive industries like healthcare.

The Machine Vision and Inspection System Market offers a range of key offerings that cater to the diverse needs of industries seeking automated quality control and inspection solutions. These offerings encompass hardware, software, and services, designed to enhance manufacturing efficiency, product quality, and defect detection.

Here are the primary key offerings in this market:

Machine Vision Cameras: High-resolution cameras equipped with advanced sensors and optics capture visual data from manufacturing processes, enabling precise inspection and analysis.

Machine Vision Software: Specialized software, including image processing and computer vision algorithms, processes and interprets visual data to identify defects, measure dimensions, and perform quality control tasks.

3D Vision Systems: Cutting-edge 3D vision technology allows for the three-dimensional inspection of objects, enabling the measurement of height, depth, and volume, ideal for complex tasks such as surface profiling and defect detection.

Smart Cameras: Compact, embedded smart cameras with built-in processing capabilities for real-time inspection and data analysis at the edge, reducing the need for external processing units.

Optical Character Recognition (OCR): OCR software interprets and reads text and alphanumeric characters from images, crucial for applications involving printed labels, barcodes, and product identification.

Robotic Inspection Systems: Integration with robotic systems enables automated and precise inspection, pick-and-place operations, and assembly verification in industries like automotive and electronics manufacturing.

Why to Buy This Report-

The report provides a qualitative as well as quantitative analysis of the global Machine Vision And Inspection System Market by segments, current trends, drivers, restraints, opportunities, challenges, and market dynamics with the historical period from 2016-2020, the base year- 2021, and the projection period 2022-2028.

The report includes information on the competitive landscape, such as how the market's top competitors operate at the global, regional, and country levels.

Major nations in each region with their import/export statistics

The global Machine Vision And Inspection System Market report also includes the analysis of the market at a global, regional, and country-level along with key market trends, major player analysis, market growth strategies, and key application areas.

Browse Full Report: https://www.credenceresearch.com/report/machine-vision-and-inspection-system

Visit: https://www.credenceresearch.com/

Related Report: https://www.credenceresearch.com/report/positive-displacement-pumps-market

Related Report: https://www.credenceresearch.com/report/smart-contact-lenses-market

Browse Our Blog: https://www.linkedin.com/pulse/machine-vision-inspection-system-market-future-growth-singh

About Us -

Credence Research is a viable intelligence and market research platform that provides quantitative B2B research to more than 10,000 clients worldwide and is built on the Give principle. The company is a market research and consulting firm serving governments, non-legislative associations, non-profit organizations, and various organizations worldwide. We help our clients improve their execution in a lasting way and understand their most imperative objectives. For nearly a century, we’ve built a company well-prepared for this task.

Contact Us:

Office No 3 Second Floor, Abhilasha Bhawan, Pinto Park, Gwalior [M.P] 474005 India

0 notes

Text

Surface Vision And Inspection Market Worth $4,591.6 Million By 2030

The global surface vision and inspection market size is expected to reach USD 4,591.6 million by 2030 registering a CAGR of 7.1% from 2023 to 2030, according to a new study by Grand View Research, Inc. The manufacturing sector across the globe is witnessing rapid growth, amid improved demand conditions and easing COVID-19 restrictions. This increasing production activity is responsible for the…

View On WordPress

0 notes

Text

The Complete Guide to Cleaning Your Bicycle Helmet

Cycling is a great way to get exercise and enjoy the outdoors, but it can be dangerous without proper safety gear. One of the most important pieces of gear a cyclist can have is a bicycle helmet. Helmets protect the head from impact during falls or accidents, but they can also become dirty and smelly over time. Regular cleaning of your helmet can help maintain its integrity and ensure it continues to offer the protection you need. Here's a complete guide to cleaning your bicycle helmet.

Why Cleaning Your Bicycle Helmet Is Important

Before we dive into the cleaning process, let's talk about why it's essential to clean your helmet. A dirty helmet can be a breeding ground for bacteria, sweat, and grime, which can create an unpleasant odor and potentially harm your skin. Additionally, dirt and debris on the helmet's surface can obscure the rider's vision, making it harder to see the road ahead. Finally, a dirty helmet can also reduce the lifespan of your gear and its ability to protect your head.

Cleaning Your Bicycle Helmet: The Step-by-Step Guide

Cleaning your bicycle helmet is a relatively simple process that can be completed with a few household items. Follow these steps to clean your helmet thoroughly:

Step 1: Remove Any Detachable Parts

The first step in cleaning your helmet is to remove any detachable parts, such as the padding or visor. These parts can be cleaned separately, allowing you to focus on the helmet's shell.

Step 2: Rinse Your Helmet

Rinse your helmet with warm water to remove any loose dirt or debris. Be sure to avoid using hot water, as it can damage the helmet's structure. Use a soft cloth to wipe away any remaining dirt or grime.

Step 3: Fill a Bucket With Warm Water and Soap

Fill a bucket with warm water and add a few drops of mild soap or detergent. Avoid using harsh chemicals or bleach, as they can damage the helmet's surface.

Step 4: Soak Your Helmet

Place your helmet in the bucket and let it soak for a few minutes. Use a soft-bristled brush or toothbrush to gently scrub any stubborn dirt or grime.

Step 5: Rinse and Dry Your Helmet

Rinse your helmet thoroughly with warm water to remove any soap residue. Then, use a soft cloth or towel to dry the helmet. Avoid using heat to dry the helmet, as it can damage the shell or visor.

Step 6: Reassemble Your Helmet

Once your helmet is dry, reassemble any detachable parts you removed in step one. Be sure to follow the manufacturer's instructions to ensure proper reassembly.

Tips for Maintaining Your Bicycle Helmet

Now that you know how to clean your bicycle helmet let's discuss some tips for maintaining your gear's integrity:

Tip 1: Store Your Helmet Properly

When you're not riding, store your helmet in a cool, dry place. Avoid exposing it to direct sunlight or extreme temperatures, as these can damage the helmet's structure.

Tip 2: Replace Your Helmet Every Few Years

Helmets should be replaced every few years, even if they have not been involved in an accident. Over time, the foam padding and other materials in the helmet can degrade, reducing their ability to protect your head.

Tip 3: Don't Share Your Helmet

Sharing your helmet with others can increase the risk of spreading bacteria or infections. It's best to use your helmet exclusively and avoid sharing it with friends or family members.

Tip 4: Check Your Helmet for Damage

Before each ride, inspect your helmet for any signs of damage or wear. Cracks, dents, or other damage can compromise the helmet's ability to protect your head, so it's important to replace a damaged helmet immediately.

Tip 5: Avoid Using Harsh Chemicals

When cleaning your helmet, avoid using harsh chemicals or solvents, as they can damage the helmet's surface or degrade the foam padding. Stick to mild soap and warm water for best results.

Conclusion

Regular cleaning and maintenance of your bicycle helmet are essential to ensure its longevity and effectiveness in protecting your head. Follow these simple steps to clean your helmet thoroughly, and use the tips above to maintain its integrity over time. With proper care, your helmet will continue to offer the protection you need for many rides to come.

FAQs

How often should I clean my bicycle helmet? A: It's a good idea to clean your helmet after every few rides or whenever it becomes visibly dirty or smelly.

Can I put my helmet in the dishwasher? A: No, dishwashers use hot water and harsh chemicals that can damage the helmet's structure.

Can I use bleach to clean my helmet? A: No, bleach can damage the helmet's surface and degrade the foam padding.

How do I know when to replace my helmet? A: Helmets should be replaced every few years, even if they have not been involved in an accident. Check your helmet for signs of damage or wear before each ride.

Can I share my helmet with others? A: It's best to avoid sharing your helmet with others, as it can increase the risk of spreading bacteria or infections. Use your helmet exclusively.

0 notes

Text

Surface Vision and Inspection Market Trend,Growth 2021

Surface vision and inspection systems help in waste reduction, minimizes production cost, and increases the production efficiency. These systems provide instant quantitative feedback such as types of defects and quantity. Surface vision and inspection systems are being used in several workplaces throughout manufacturing processes. Machineries at various workshops are increasingly integrating with cameras and computer systems to improve the performance of manufacturing processes. By integrating such vision and inspection systems, problems in the process are identified at the root. The use of surface vision and inspection systems reduces waste, production time, and manufacturing costs for manufacturers.

0 notes