#Super Ammonia Valves

Explore tagged Tumblr posts

Text

Chilled Water Systems

Chilled water systems are used not only in big industries but also in small ones. In fact, they are used in almost all households in Air Conditionersto provided controlled cooling mechanisms. With such a wide variety of uses, they are not only necessary for running the machinery, but also for keeping up with the working of the machinery. This is why it is important to buy the best quality…

View On WordPress

#Ammonia air-cooling units#ammonia chiller manufacturer#ammonia receiver manufacturer#ammonia stop valves#refrigeration compressor India#screw chiller manufacturer India#shell and tube condensers manufacturer India#Shell and tube heat exchanger manufacturer India#Super Ammonia Valves

0 notes

Text

HouseQuest 2019 (5/?)

Ok, it’s been a while, I forgot most of what happened in the meantime, so I’m just going to recap as much as I can and some of it will be duplicates of preexisting material. We’ve been making quick progress on the house, and I get moved in next week (this doesn’t mean it’s done yet, though, it’s still in construction) So here’s some of what’s been going on since last time: Out front, there were three trees which were leaning over against the neighbor’s house. We hired some tree removal guys to chainsaw them down. Tree removal guys were super-competent, doing cool things like tying a rope to parts of the tree so when it fell it’d fall in a certain way, and wielding a chainsaw in scary ways. But the trees are gone now. We thought the showers weren’t working and that it was a plumbing issue. So we pour water down the drain... and it propagates down to the sewer as usual and works, so it isn’t a blockage issue. And we turn on the water... and nothing happens. We go into the crawlspace under the house to see if there’s some valve or something. Nope. (although the crawlspace was very neat and tidy, a first for the house). We go to the outside water shutoff spot, mess around with that, and it’s on (we’re getting very confused now). We pop the handle off the shower and start messing around with the piping internals of the shower. Still no water. What it turned out to be was that the showers required pulling the lever out to turn on the water and although we rotated the lever every direction we never pulled it out. So good to get that mystery solved. Since we were cleaning out the upstairs by throwing everything off the balcony, we had to haul away trash. It turned out to be 9 truckloads hauled away by this guy who stacked up the trash so high in his truck that it looked like something from the streets of Mumbai. It was a huge pile of rubble, but is gone now. All the flooring is ripped out, and it wasn’t easy to do so, they sunk giant nails in every three inches. New drywall installed around the fireplace. Also, while cleaning out the stove area, we pulled about six dead birds out from behind the wall. Apparently there was a nest in the chimney and one day the stove was turned on and they all asphyxiated. It was gross. The kitchen has been ripped apart, we got some new flooring in, and it’s been partially painted. There’s grapevines growing up the side of the house, giving it the cool “covered in ivy” look. Except that grapevines growing up inside the walls and ripping them apart is actually super-bad, despite how aesthetic it looks. So we cut that off at the base and they’re dying right now. The abandoned swimming pool out back has been drained of water. Still chock-full of two decades of rubble, everything from an old TV to rusty paint cans to thorny branches to floorboards to six inches of mulch on the bottom. Also, for the about two decades in which it was a swamp, it has been (and still is) infested with huge mosquitos which terrorize the surrounding neighborhood and the Public Health people would have a heart attack if they knew about it. So we just have to kill a bunch of mosquitos now that we drained their swamp, I’m thinking of a UV bug zapper. Two windows downstairs have been drywalled over, also there’s a nice little nook under the stairs that’d be perfect for people who like curling up in enclosed areas. All three bedrooms have been painted and fully dismantled, along with several other areas. Current color is beige, old colors varied between bright blue, forest green, puke green, mustard yellow, and bloodstain red. Looks much better. Lots of painting, though. One of the bedrooms had a cat living in it for many years. An un-litterbox-trained cat. And there was a patch of carpet in that room. Past posts detail the process of removing that, but then there was a big area of pee-soaked plywood that we had to figure out what to do with. We hit it with enzymatic pet stain cleaner. Takes down a lot of the smell, still smells funny. We hit it with bleach (the astute among you will notice that this is the legendary and infamous bleach+ammonia reaction). After I flee the room with my eyes burning and everything upstairs smelling like public swimming pool... takes down some of the smell, still sorta smells like pee. We throw down a layer of Kilz on the floor, a sort of sealing paint that I have been assured should just lock everything in the wood, never to emerge. Still smells like pee (which other house-repair people said sounds impossible). So eventually we just saw out that area of the floor completely and put in new plywood. Apparently that part of the floor was directly above the plenum for part of the air vents of the house, and the pee managed to soak through a half-inch of plywood to be exposed to the air system duct, so every time the old owner turned on the heat, he was dispersing piss-infused air into the bedrooms. Fortunately it’s finally gone now, the bedroom finally doesn’t smell like anything. And then there’s the tale of the fucking roof. So, there were skylights, and they had leaked quite a bit, but we were assured that they were recently fixed. We poke around a bit, the drywall is all wet, so we rip it out. The insulation is all moldy, so we rip it out. And... it looks like the roof is still leaking. So we decide to just remove the skylights and do a standard roof. Step 1 is to get on the roof and saw out the skylights. This requires climbing a two-story-tall ladder. That is wiggly. Anyways, we can now access the roof... and apparently whatever dumbass fixed the roof the last three times had a problem solving strategy composed entirely of the steps “needs moar nails” and “dump gallons of tar everywhere”. Alright, time to just rip out the skylights and tarblob and put in some roof tiles... so we hit up a roofing company and the salesman is like “we don’t stock this stuff, you’ve gotta drive several hours to Stockton to pick up a half-pallet of roofing tiles and it’ll weigh a literal ton”. We think for a while and decide that this is bad, and we’re going to exploit the fact that there’s no homeowner’s association in the area. So we decide to do a standard black shingle roof over where the skylights used to be. Note that the rest of the roof is red tile, so there’s just going to be a random rectangular patch of a different type and color of roof in the middle of our roof. We can do this because there’s no HOA to throw a fit. Rip out the tarblob (not easy), have a foot accidentally go through the roof because some of the boards are so rotted, screw in the wood replacements for the skylight holes (so now we’re locked on the roof and have to descend a 2-story ladder to get back down), nail down the waterproof paper, nail down all the shingles, apply tar to a bunch of places (tar is super-sticky and gets everywhere and can’t be removed by anything short of lacquer thinner or gasoline, I wound up ripping out a bunch of arm hair), realize that due to being unprotected on a roof for several hours I have gotten a truly magnificent sunburn, descend ladder, have sinking feeling that I’m gonna have to go back up to the roof one day and fix some other problem with it. Then, go back up, realize that due to a math error we got seven huge bundles of fresh insulation when we only needed two, wrestle huge unwieldy drywall sheets up the narrow stairs, screw huge unwieldy drywall sheets to the ceiling where the skylights used to be, and... done?? Oh, also put in flooring. There was a bunch of other stuff too that I’m forgetting.

1 note

·

View note

Text

These 3 energy storage technologies can help solve the challenge of moving to 100% renewable electricity

Kerry Rippy, National Renewable Energy Laboratory

In recent decades the cost of wind and solar power generation has dropped dramatically. This is one reason that the U.S. Dept. of Energy projects that renewable energy will be the fastest-growing U.S. energy source through 2050.

However, it’s still relatively expensive to store energy. And since renewable energy generation isn’t available all the time – it happens when the wind blows or the sun shines – storage is essential.

As a researcher at the National Renewable Energy Laboratory, I work with the federal government and private industry to develop renewable energy storage technologies. In a recent report, researchers at NREL estimated that the potential exists to increase U.S. renewable energy storage capacity by as much as 3,000% percent by 2050.

Here are three emerging technologies that could help make this happen.

Longer charges

From alkaline batteries for small electronics to lithium-ion batteries for cars and laptops, most people already use batteries in many aspects of their daily lives. But there is still lots of room for growth.

For example, high-capacity batteries with long discharge times – up to 10 hours – could be valuable for storing solar power at night or increasing the range of electric vehicles. Right now there are very few such batteries in use. However, according to recent projections, upwards of 100 gigawatts worth of these batteries will likely be installed by 2050. For comparison, that’s 50 times the generating capacity of Hoover Dam. This could have a major impact on the viability of renewable energy. Batteries work by creating a chemical reaction that produces a flow of electrical current.

One of the biggest obstacles is limited supplies of lithium and cobalt, which currently are essential for making lightweight, powerful batteries. According to some estimates, around 10% of the world’s lithium and nearly all of the world’s cobalt reserves will be depleted by 2050.

Furthermore, nearly 70% of the world’s cobalt is mined in the Congo, under conditions that have long been documented as inhumane.

Scientists are working to develop techniques for recycling lithium and cobalt batteries, and to design batteries based on other materials. Tesla plans to produce cobalt-free batteries within the next few years. Others aim to replace lithium with sodium, which has properties very similar to lithium’s but is much more abundant.

Safer batteries

Another priority is to make batteries safer. One area for improvement is electrolytes – the medium, often liquid, that allows an electric charge to flow from the battery’s anode, or negative terminal, to the cathode, or positive terminal.

When a battery is in use, charged particles in the electrolyte move around to balance out the charge of the electricity flowing out of the battery. Electrolytes often contain flammable materials. If they leak, the battery can overheat and catch fire or melt.

Scientists are developing solid electrolytes, which would make batteries more robust. It is much harder for particles to move around through solids than through liquids, but encouraging lab-scale results suggest that these batteries could be ready for use in electric vehicles in the coming years, with target dates for commercialization as early as 2026.

While solid-state batteries would be well suited for consumer electronics and electric vehicles, for large-scale energy storage, scientists are pursuing all-liquid designs called flow batteries.

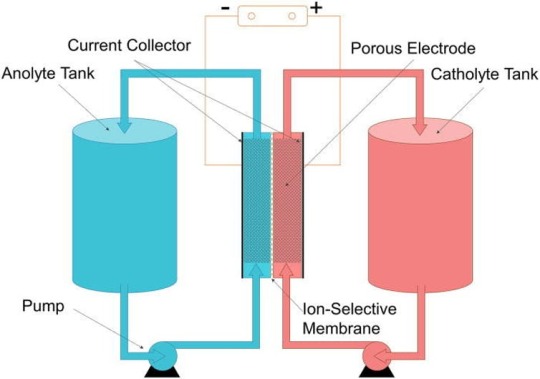

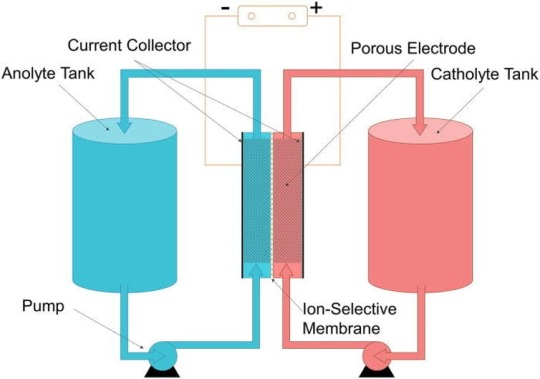

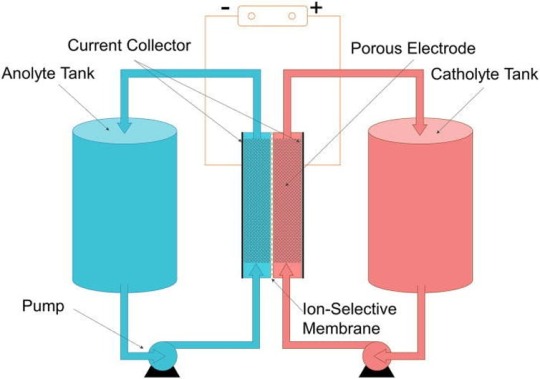

A typical flow battery consists of two tanks of liquids that are pumped past a membrane held between two electrodes. Qi and Koenig, 2017, CC BY

In these devices both the electrolyte and the electrodes are liquids. This allows for super-fast charging and makes it easy to make really big batteries. Currently these systems are very expensive, but research continues to bring down the price.

Storing sunlight as heat

Other renewable energy storage solutions cost less than batteries in some cases. For example, concentrated solar power plants use mirrors to concentrate sunlight, which heats up hundreds or thousands of tons of salt until it melts. This molten salt then is used to drive an electric generator, much as coal or nuclear power is used to heat steam and drive a generator in traditional plants.

These heated materials can also be stored to produce electricity when it is cloudy, or even at night. This approach allows concentrated solar power to work around the clock.

Checking a molten salt valve for corrosion at Sandia’s Molten Salt Test Loop. Randy Montoya, Sandia Labs/Flickr, CC BY-NC-ND

This idea could be adapted for use with nonsolar power generation technologies. For example, electricity made with wind power could be used to heat salt for use later when it isn’t windy.

Concentrating solar power is still relatively expensive. To compete with other forms of energy generation and storage, it needs to become more efficient. One way to achieve this is to increase the temperature the salt is heated to, enabling more efficient electricity production. Unfortunately, the salts currently in use aren’t stable at high temperatures. Researchers are working to develop new salts or other materials that can withstand temperatures as high as 1,300 degrees Fahrenheit (705 C).

One leading idea for how to reach higher temperature involves heating up sand instead of salt, which can withstand the higher temperature. The sand would then be moved with conveyor belts from the heating point to storage. The Department of Energy recently announced funding for a pilot concentrated solar power plant based on this concept.

Advanced renewable fuels

Batteries are useful for short-term energy storage, and concentrated solar power plants could help stabilize the electric grid. However, utilities also need to store a lot of energy for indefinite amounts of time. This is a role for renewable fuels like hydrogen and ammonia. Utilities would store energy in these fuels by producing them with surplus power, when wind turbines and solar panels are generating more electricity than the utilities’ customers need.

Hydrogen and ammonia contain more energy per pound than batteries, so they work where batteries don’t. For example, they could be used for shipping heavy loads and running heavy equipment, and for rocket fuel.

Today these fuels are mostly made from natural gas or other nonrenewable fossil fuels via extremely inefficient reactions. While we think of it as a green fuel, most hydrogen gas today is made from natural gas.

Scientists are looking for ways to produce hydrogen and other fuels using renewable electricity. For example, it is possible to make hydrogen fuel by splitting water molecules using electricity. The key challenge is optimizing the process to make it efficient and economical. The potential payoff is enormous: inexhaustible, completely renewable energy.

[Understand new developments in science, health and technology, each week. Subscribe to The Conversation’s science newsletter.]

Kerry Rippy, Researcher, National Renewable Energy Laboratory

This article is republished from The Conversation under a Creative Commons license. Read the original article.

from https://ift.tt/3yqN7mH

0 notes

Text

These 3 energy storage technologies can help solve the challenge of moving to 100% renewable electricity

Kerry Rippy, National Renewable Energy Laboratory

In recent decades the cost of wind and solar power generation has dropped dramatically. This is one reason that the U.S. Dept. of Energy projects that renewable energy will be the fastest-growing U.S. energy source through 2050.

However, it’s still relatively expensive to store energy. And since renewable energy generation isn’t available all the time – it happens when the wind blows or the sun shines – storage is essential.

As a researcher at the National Renewable Energy Laboratory, I work with the federal government and private industry to develop renewable energy storage technologies. In a recent report, researchers at NREL estimated that the potential exists to increase U.S. renewable energy storage capacity by as much as 3,000% percent by 2050.

Here are three emerging technologies that could help make this happen.

Longer charges

From alkaline batteries for small electronics to lithium-ion batteries for cars and laptops, most people already use batteries in many aspects of their daily lives. But there is still lots of room for growth.

For example, high-capacity batteries with long discharge times – up to 10 hours – could be valuable for storing solar power at night or increasing the range of electric vehicles. Right now there are very few such batteries in use. However, according to recent projections, upwards of 100 gigawatts worth of these batteries will likely be installed by 2050. For comparison, that’s 50 times the generating capacity of Hoover Dam. This could have a major impact on the viability of renewable energy. Batteries work by creating a chemical reaction that produces a flow of electrical current.

One of the biggest obstacles is limited supplies of lithium and cobalt, which currently are essential for making lightweight, powerful batteries. According to some estimates, around 10% of the world’s lithium and nearly all of the world’s cobalt reserves will be depleted by 2050.

Furthermore, nearly 70% of the world’s cobalt is mined in the Congo, under conditions that have long been documented as inhumane.

Scientists are working to develop techniques for recycling lithium and cobalt batteries, and to design batteries based on other materials. Tesla plans to produce cobalt-free batteries within the next few years. Others aim to replace lithium with sodium, which has properties very similar to lithium’s but is much more abundant.

Safer batteries

Another priority is to make batteries safer. One area for improvement is electrolytes – the medium, often liquid, that allows an electric charge to flow from the battery’s anode, or negative terminal, to the cathode, or positive terminal.

When a battery is in use, charged particles in the electrolyte move around to balance out the charge of the electricity flowing out of the battery. Electrolytes often contain flammable materials. If they leak, the battery can overheat and catch fire or melt.

Scientists are developing solid electrolytes, which would make batteries more robust. It is much harder for particles to move around through solids than through liquids, but encouraging lab-scale results suggest that these batteries could be ready for use in electric vehicles in the coming years, with target dates for commercialization as early as 2026.

While solid-state batteries would be well suited for consumer electronics and electric vehicles, for large-scale energy storage, scientists are pursuing all-liquid designs called flow batteries.

A typical flow battery consists of two tanks of liquids that are pumped past a membrane held between two electrodes. Qi and Koenig, 2017, CC BY

In these devices both the electrolyte and the electrodes are liquids. This allows for super-fast charging and makes it easy to make really big batteries. Currently these systems are very expensive, but research continues to bring down the price.

Storing sunlight as heat

Other renewable energy storage solutions cost less than batteries in some cases. For example, concentrated solar power plants use mirrors to concentrate sunlight, which heats up hundreds or thousands of tons of salt until it melts. This molten salt then is used to drive an electric generator, much as coal or nuclear power is used to heat steam and drive a generator in traditional plants.

These heated materials can also be stored to produce electricity when it is cloudy, or even at night. This approach allows concentrated solar power to work around the clock.

Checking a molten salt valve for corrosion at Sandia’s Molten Salt Test Loop. Randy Montoya, Sandia Labs/Flickr, CC BY-NC-ND

This idea could be adapted for use with nonsolar power generation technologies. For example, electricity made with wind power could be used to heat salt for use later when it isn’t windy.

Concentrating solar power is still relatively expensive. To compete with other forms of energy generation and storage, it needs to become more efficient. One way to achieve this is to increase the temperature the salt is heated to, enabling more efficient electricity production. Unfortunately, the salts currently in use aren’t stable at high temperatures. Researchers are working to develop new salts or other materials that can withstand temperatures as high as 1,300 degrees Fahrenheit (705 C).

One leading idea for how to reach higher temperature involves heating up sand instead of salt, which can withstand the higher temperature. The sand would then be moved with conveyor belts from the heating point to storage. The Department of Energy recently announced funding for a pilot concentrated solar power plant based on this concept.

Advanced renewable fuels

Batteries are useful for short-term energy storage, and concentrated solar power plants could help stabilize the electric grid. However, utilities also need to store a lot of energy for indefinite amounts of time. This is a role for renewable fuels like hydrogen and ammonia. Utilities would store energy in these fuels by producing them with surplus power, when wind turbines and solar panels are generating more electricity than the utilities’ customers need.

Hydrogen and ammonia contain more energy per pound than batteries, so they work where batteries don’t. For example, they could be used for shipping heavy loads and running heavy equipment, and for rocket fuel.

Today these fuels are mostly made from natural gas or other nonrenewable fossil fuels via extremely inefficient reactions. While we think of it as a green fuel, most hydrogen gas today is made from natural gas.

Scientists are looking for ways to produce hydrogen and other fuels using renewable electricity. For example, it is possible to make hydrogen fuel by splitting water molecules using electricity. The key challenge is optimizing the process to make it efficient and economical. The potential payoff is enormous: inexhaustible, completely renewable energy.

[Understand new developments in science, health and technology, each week. Subscribe to The Conversation’s science newsletter.]

Kerry Rippy, Researcher, National Renewable Energy Laboratory

This article is republished from The Conversation under a Creative Commons license. Read the original article.

from https://ift.tt/3yqN7mH

0 notes

Text

These 3 energy storage technologies can help solve the challenge of moving to 100% renewable electricity

Kerry Rippy, National Renewable Energy Laboratory

In recent decades the cost of wind and solar power generation has dropped dramatically. This is one reason that the U.S. Dept. of Energy projects that renewable energy will be the fastest-growing U.S. energy source through 2050.

However, it’s still relatively expensive to store energy. And since renewable energy generation isn’t available all the time – it happens when the wind blows or the sun shines – storage is essential.

As a researcher at the National Renewable Energy Laboratory, I work with the federal government and private industry to develop renewable energy storage technologies. In a recent report, researchers at NREL estimated that the potential exists to increase U.S. renewable energy storage capacity by as much as 3,000% percent by 2050.

Here are three emerging technologies that could help make this happen.

Longer charges

From alkaline batteries for small electronics to lithium-ion batteries for cars and laptops, most people already use batteries in many aspects of their daily lives. But there is still lots of room for growth.

For example, high-capacity batteries with long discharge times – up to 10 hours – could be valuable for storing solar power at night or increasing the range of electric vehicles. Right now there are very few such batteries in use. However, according to recent projections, upwards of 100 gigawatts worth of these batteries will likely be installed by 2050. For comparison, that’s 50 times the generating capacity of Hoover Dam. This could have a major impact on the viability of renewable energy. Batteries work by creating a chemical reaction that produces a flow of electrical current.

One of the biggest obstacles is limited supplies of lithium and cobalt, which currently are essential for making lightweight, powerful batteries. According to some estimates, around 10% of the world’s lithium and nearly all of the world’s cobalt reserves will be depleted by 2050.

Furthermore, nearly 70% of the world’s cobalt is mined in the Congo, under conditions that have long been documented as inhumane.

Scientists are working to develop techniques for recycling lithium and cobalt batteries, and to design batteries based on other materials. Tesla plans to produce cobalt-free batteries within the next few years. Others aim to replace lithium with sodium, which has properties very similar to lithium’s but is much more abundant.

Safer batteries

Another priority is to make batteries safer. One area for improvement is electrolytes – the medium, often liquid, that allows an electric charge to flow from the battery’s anode, or negative terminal, to the cathode, or positive terminal.

When a battery is in use, charged particles in the electrolyte move around to balance out the charge of the electricity flowing out of the battery. Electrolytes often contain flammable materials. If they leak, the battery can overheat and catch fire or melt.

Scientists are developing solid electrolytes, which would make batteries more robust. It is much harder for particles to move around through solids than through liquids, but encouraging lab-scale results suggest that these batteries could be ready for use in electric vehicles in the coming years, with target dates for commercialization as early as 2026.

While solid-state batteries would be well suited for consumer electronics and electric vehicles, for large-scale energy storage, scientists are pursuing all-liquid designs called flow batteries.

A typical flow battery consists of two tanks of liquids that are pumped past a membrane held between two electrodes. Qi and Koenig, 2017, CC BY

In these devices both the electrolyte and the electrodes are liquids. This allows for super-fast charging and makes it easy to make really big batteries. Currently these systems are very expensive, but research continues to bring down the price.

Storing sunlight as heat

Other renewable energy storage solutions cost less than batteries in some cases. For example, concentrated solar power plants use mirrors to concentrate sunlight, which heats up hundreds or thousands of tons of salt until it melts. This molten salt then is used to drive an electric generator, much as coal or nuclear power is used to heat steam and drive a generator in traditional plants.

These heated materials can also be stored to produce electricity when it is cloudy, or even at night. This approach allows concentrated solar power to work around the clock.

Checking a molten salt valve for corrosion at Sandia’s Molten Salt Test Loop. Randy Montoya, Sandia Labs/Flickr, CC BY-NC-ND

This idea could be adapted for use with nonsolar power generation technologies. For example, electricity made with wind power could be used to heat salt for use later when it isn’t windy.

Concentrating solar power is still relatively expensive. To compete with other forms of energy generation and storage, it needs to become more efficient. One way to achieve this is to increase the temperature the salt is heated to, enabling more efficient electricity production. Unfortunately, the salts currently in use aren’t stable at high temperatures. Researchers are working to develop new salts or other materials that can withstand temperatures as high as 1,300 degrees Fahrenheit (705 C).

One leading idea for how to reach higher temperature involves heating up sand instead of salt, which can withstand the higher temperature. The sand would then be moved with conveyor belts from the heating point to storage. The Department of Energy recently announced funding for a pilot concentrated solar power plant based on this concept.

Advanced renewable fuels

Batteries are useful for short-term energy storage, and concentrated solar power plants could help stabilize the electric grid. However, utilities also need to store a lot of energy for indefinite amounts of time. This is a role for renewable fuels like hydrogen and ammonia. Utilities would store energy in these fuels by producing them with surplus power, when wind turbines and solar panels are generating more electricity than the utilities’ customers need.

Hydrogen and ammonia contain more energy per pound than batteries, so they work where batteries don’t. For example, they could be used for shipping heavy loads and running heavy equipment, and for rocket fuel.

Today these fuels are mostly made from natural gas or other nonrenewable fossil fuels via extremely inefficient reactions. While we think of it as a green fuel, most hydrogen gas today is made from natural gas.

Scientists are looking for ways to produce hydrogen and other fuels using renewable electricity. For example, it is possible to make hydrogen fuel by splitting water molecules using electricity. The key challenge is optimizing the process to make it efficient and economical. The potential payoff is enormous: inexhaustible, completely renewable energy.

[Understand new developments in science, health and technology, each week. Subscribe to The Conversation’s science newsletter.]

Kerry Rippy, Researcher, National Renewable Energy Laboratory

This article is republished from The Conversation under a Creative Commons license. Read the original article.

from Renewable Energy World https://ift.tt/3yqN7mH via Solar Energy Marketing Blog

0 notes

Text

These 3 energy storage technologies can help solve the challenge of moving to 100% renewable electricity

Kerry Rippy, National Renewable Energy Laboratory

In recent decades the cost of wind and solar power generation has dropped dramatically. This is one reason that the U.S. Dept. of Energy projects that renewable energy will be the fastest-growing U.S. energy source through 2050.

However, it’s still relatively expensive to store energy. And since renewable energy generation isn’t available all the time – it happens when the wind blows or the sun shines – storage is essential.

As a researcher at the National Renewable Energy Laboratory, I work with the federal government and private industry to develop renewable energy storage technologies. In a recent report, researchers at NREL estimated that the potential exists to increase U.S. renewable energy storage capacity by as much as 3,000% percent by 2050.

Here are three emerging technologies that could help make this happen.

Longer charges

From alkaline batteries for small electronics to lithium-ion batteries for cars and laptops, most people already use batteries in many aspects of their daily lives. But there is still lots of room for growth.

For example, high-capacity batteries with long discharge times – up to 10 hours – could be valuable for storing solar power at night or increasing the range of electric vehicles. Right now there are very few such batteries in use. However, according to recent projections, upwards of 100 gigawatts worth of these batteries will likely be installed by 2050. For comparison, that’s 50 times the generating capacity of Hoover Dam. This could have a major impact on the viability of renewable energy. Batteries work by creating a chemical reaction that produces a flow of electrical current.

One of the biggest obstacles is limited supplies of lithium and cobalt, which currently are essential for making lightweight, powerful batteries. According to some estimates, around 10% of the world’s lithium and nearly all of the world’s cobalt reserves will be depleted by 2050.

Furthermore, nearly 70% of the world’s cobalt is mined in the Congo, under conditions that have long been documented as inhumane.

Scientists are working to develop techniques for recycling lithium and cobalt batteries, and to design batteries based on other materials. Tesla plans to produce cobalt-free batteries within the next few years. Others aim to replace lithium with sodium, which has properties very similar to lithium’s but is much more abundant.

Safer batteries

Another priority is to make batteries safer. One area for improvement is electrolytes – the medium, often liquid, that allows an electric charge to flow from the battery’s anode, or negative terminal, to the cathode, or positive terminal.

When a battery is in use, charged particles in the electrolyte move around to balance out the charge of the electricity flowing out of the battery. Electrolytes often contain flammable materials. If they leak, the battery can overheat and catch fire or melt.

Scientists are developing solid electrolytes, which would make batteries more robust. It is much harder for particles to move around through solids than through liquids, but encouraging lab-scale results suggest that these batteries could be ready for use in electric vehicles in the coming years, with target dates for commercialization as early as 2026.

While solid-state batteries would be well suited for consumer electronics and electric vehicles, for large-scale energy storage, scientists are pursuing all-liquid designs called flow batteries.

A typical flow battery consists of two tanks of liquids that are pumped past a membrane held between two electrodes. Qi and Koenig, 2017, CC BY

In these devices both the electrolyte and the electrodes are liquids. This allows for super-fast charging and makes it easy to make really big batteries. Currently these systems are very expensive, but research continues to bring down the price.

Storing sunlight as heat

Other renewable energy storage solutions cost less than batteries in some cases. For example, concentrated solar power plants use mirrors to concentrate sunlight, which heats up hundreds or thousands of tons of salt until it melts. This molten salt then is used to drive an electric generator, much as coal or nuclear power is used to heat steam and drive a generator in traditional plants.

These heated materials can also be stored to produce electricity when it is cloudy, or even at night. This approach allows concentrated solar power to work around the clock.

Checking a molten salt valve for corrosion at Sandia’s Molten Salt Test Loop. Randy Montoya, Sandia Labs/Flickr, CC BY-NC-ND

This idea could be adapted for use with nonsolar power generation technologies. For example, electricity made with wind power could be used to heat salt for use later when it isn’t windy.

Concentrating solar power is still relatively expensive. To compete with other forms of energy generation and storage, it needs to become more efficient. One way to achieve this is to increase the temperature the salt is heated to, enabling more efficient electricity production. Unfortunately, the salts currently in use aren’t stable at high temperatures. Researchers are working to develop new salts or other materials that can withstand temperatures as high as 1,300 degrees Fahrenheit (705 C).

One leading idea for how to reach higher temperature involves heating up sand instead of salt, which can withstand the higher temperature. The sand would then be moved with conveyor belts from the heating point to storage. The Department of Energy recently announced funding for a pilot concentrated solar power plant based on this concept.

Advanced renewable fuels

Batteries are useful for short-term energy storage, and concentrated solar power plants could help stabilize the electric grid. However, utilities also need to store a lot of energy for indefinite amounts of time. This is a role for renewable fuels like hydrogen and ammonia. Utilities would store energy in these fuels by producing them with surplus power, when wind turbines and solar panels are generating more electricity than the utilities’ customers need.

Hydrogen and ammonia contain more energy per pound than batteries, so they work where batteries don’t. For example, they could be used for shipping heavy loads and running heavy equipment, and for rocket fuel.

Today these fuels are mostly made from natural gas or other nonrenewable fossil fuels via extremely inefficient reactions. While we think of it as a green fuel, most hydrogen gas today is made from natural gas.

Scientists are looking for ways to produce hydrogen and other fuels using renewable electricity. For example, it is possible to make hydrogen fuel by splitting water molecules using electricity. The key challenge is optimizing the process to make it efficient and economical. The potential payoff is enormous: inexhaustible, completely renewable energy.

[Understand new developments in science, health and technology, each week. Subscribe to The Conversation’s science newsletter.]

Kerry Rippy, Researcher, National Renewable Energy Laboratory

This article is republished from The Conversation under a Creative Commons license. Read the original article.

from Renewable Energy World https://ift.tt/3yqN7mH

0 notes

Text

New Axial Check Valve in Size Ranging from 1/2 to 6 Inch

Available with flanged, butt weld, hub, lens ring or custom connections Features B16.34 design, integral gland wrench for concentric 360° packing load and in-line renewability Available in 316L urea grade, ferralium 255, 310 MoLN, duplex F51, super duplex F53, 25-22-2 SS, Zeron 100 and titanium allolys This story is related to the following: Fluid & Gas Flow Equipment Search for suppliers of: Ammonia Valves | Check Valves | In-Line Valves from Air Conditioning /fullstory/new-axial-check-valve-in-size-ranging-from-1-2-to-6-inch-40045270 via http://www.rssmix.com/

0 notes

Text

Different type of vales and their features

Ball Control Valve was first developed in 1967, and since then thousands of valves have been installed in:

Pulp and paper mills

Cement and steel companies

Coal and mining processing plants

Slip plants

Hardened water treatment plants

Chemical and pharmaceutical industry

Refining, gas and thermal power plants

Due to its self-draining, excellent regulation behavior, very good resistance to abrasion, easy to automate and install inline and its high tightness in critical conditions, SS 316 Bolts is recommended for:

Cellulose and paper pulp

Suspensions with abrasive liquids such as iron ore, slip, whitewash, ash, sand, etc.

Acidic and caustic solutions

Air, oxygen, methane, nitrogen, ammonia.

Oils and hard waters

Regulation of high flow rates and abrasive fluids

Different types of valves

Ball and butterfly valves from SS Ball Valve manufacturer in India are popular because of their relatively low cost, long service life, and reliability. However, there are some differences to help determine which one to choose from.

Ball valves

A valve is (in simple terms) a ball with a hole through it. The valve from SS fasteners manufacturers in india must be rotated to different positions to either completely block, partially or fully open it to the flow line through the valve.

Advantages of the ball valve include a good seal, or do not leak when fully closed. A ball valve will rotate regardless of the pressure on the inlet side. If the diameter of the hole through the device is as large or larger than the internal diameter of the pipe it supplies, the ball valve will not exhibit a pressure drop or limiting when fully open.

Butterfly valves

A butterfly valve is a disc mounted on a rotating shaft. When fully closed, the disc totally blocks the line. When fully open, the disc is parallel to the flow of gas or liquid.

One of the benefits of using this type of valves is that they are comparatively reasonably priced to build and maintain. They are the most common valve for systems with large volumes of water such as municipal water service. They can be used for dirty water applications such as drainage or controlling river water.

This type of valve disc remains in the flow line when completely open, so there will for all time be a pressure drop all across the butterfly valve. Also, if the pressure difference across the butterfly valve is greater, it may be not easy to open it. Some applications require a bypass valve to equalize the pressure difference before the butterfly valve can operate.

Differences

Butterfly valves are less expensive and generally lighter than other types of valves. A large diameter pipeline butterfly valve is much smaller than its equivalent ball valve.

Butterfly valves do not seal completely like ball valves and are rarely used in gas flow control. Ball valves provide a reliable seal.

At high pressures, the ball valve will provide superior shear characteristics since they have no trouble turning or do not need a pressure balancing scheme.

Read more Super Duplex Bolts

0 notes

Text

The big idea

We’re planning a basement remodel and that gives me an opportunity to make sure there’s a spot for a tank and a strong floor (concrete slab). Now, I’m not made of money, and I have other priorities for my time and my money, so this isn’t some giant tank. But I really want it to be 6ft long so I can have a few bigger fish.

I’m currently angling toward a 6x2x2, or a 180 gallon. I might decide to go 30″ deep as a 210 so I can see it sitting down (make stand 6″ shorter) and kids can see it better. The spot I want to put it backs up to the new laundry room, which will double as a ‘fish room’.

The Plan

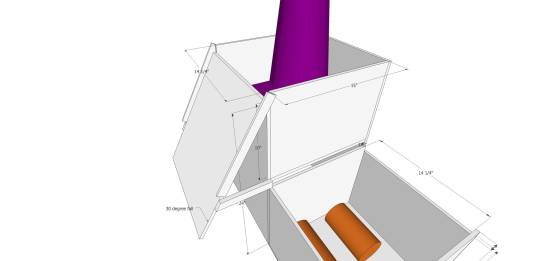

Display tank

6ft long 180g or 210g, starphire on two sides (front and one side)

super-long internal glass weir, around 6″ tall, 1-2″ deep, around 66″ long

holes in back wall to an external overflow box about 36″x6″x6″ with an oversized bean animal overflow (except the ‘open’ tube’s airline will be below the emergency)

An acrylic box down one back corner for the fuge’s drain into the tank, more on this later

Probably start with two Radeon G4 XR30 pro, add a 3rd or even 4th later?

Start with two Neptune WAV pumps, add more flow later?

Start with 900gph from the sump and 150gph from the fuge (plus surge...keep reading)

Here’s the idea, the fuge/surge is top-left, sump is behind and below. Note the placement of those is TBD, but they’ll be basically in the room right behind/next to the display.

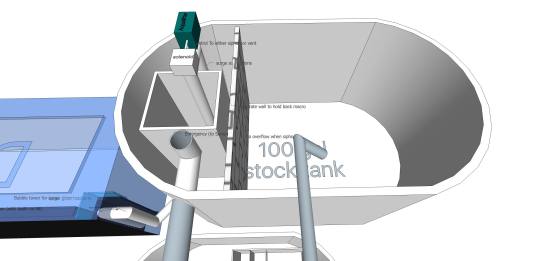

Sump

a 150 gallon (maybe?) stock tank from Rubbermaid

An acrylic skimmer stand that has a wateright box for the skimmer to sit in. Sump is 25″ deep, skimmer stand will be 25″ tall with a platform 8″ down for the skimmer to sit in, maybe 10″ and I can prop the skimmer higher if needed.Stand will sit in the middle of the sump with the display tank’s siphon pipe running straight here for consistent water level.

Skimmer stand will overflow into the main sump area that will normally run around half full. Yes, this is a large drop, I may add an angled piece to one short side so the overflow from the skimmer stand falls gently into the rest of the sump.

Another acrylic box to house the two neptune Cor-20 pumps and the ATO. One pump is the return (900gph to display, 150gph to fuge, each with a valve). One pump is the manifold (for any reactors I end up running), but may also provide extra flow to the fuge and/or sump circulation, and will serve as the backup for the return pump.

I’ll probably start with the one little reactor I have for occassional carbon, and buy other reactors as I decide I need to run GFO or biopellets or calcium, etc.

Apex controller with two extra PMUPs and optical sensors to do auto water changes, though I’ll wait to actually do these until I either need to for the system’s chemistry and/or need the quarantine/hospital tank (see below)

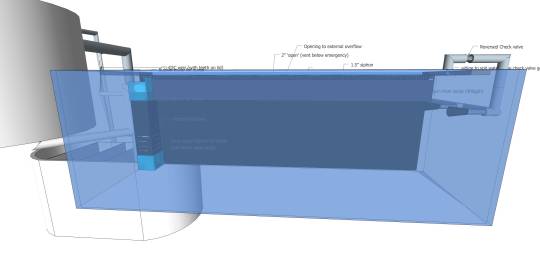

Here���s the idea for that skimmer stand/return section, remember this is sitting in a stock tank:

I do want to make sure I can put a 7″ sock in the skimmer section...I’ll need to look at that

Refugium

another 150g rubbermaid stock tank (I think) on a tall stand. black walls are convenient for blocking the low-kelvin light from the rest of things.

Receives 1x turnover from the return (150gph) that then drains into an overly-elaborate overflow box (see ‘surge below) and to the display. This should give some copepods and such a little ride into the display for my fish to snack on.

Stack the not-pretty rocks to make a nearly-complete wall across the tank so about 2/3s is on the lighted refugium side of the rocks, probably put some egg crate on one side to help hold all the macroaglae away from the overflow. Return flows into the macroalgae, so the water is consistently flowing through this ‘wall’

I may stick another circulation pump in here to have the apex kick on occasionally to shake a few pods loose and down to the display.

I’ll build a five-sided box, probably something like 8″x8″x23″ with one 2″ drain a few inches from its bottom, through its bottom, through the floor of the fuge (extra o-ring on the bulkhead) and it can easily carry the 150gph silently as a ‘durso’ drain.

I’ll put a giant (3″?) emergency drain outside the overflow box about an inch below the stock tank’s rim. Only making it giant to make sure it doesn’t get clogged. a 1/2″ pipe could probably carry the 150gph that will be flowing in. This will probably just go into the sump, I’m not worried about feeding the fish if I’m in an emergency situation and some will get swept up to the display anyways.

The basic idea of the fuge here

Left to right: overflow box with u-tube, emergency drain. then egg crate, then an un-pictured rock wall, then the return from sump in the area with the macroalgae

Surge

That ‘durso’ drain is also my surge drain. I want to have a surge feature, it’s just too cool to see all that flow, it seems good for the livestock, and does a nice job of shaking detritus into the sump (if the surge enters low in the display). But, they have a reputation for being noisy and bubbly, so despite some effort I’ll make to minimize this, I need to be able to just surge when I feel like it, and/or have the Apex surge at specific times of the day.

I plan to build a PVC u-tube out of 3″ PVC that goes 8″ down outside the overflow box (far from the rock wall to avoid sucking macro in) and almost to the bottom inside the overflow box (maybe 2 inches up, and around 2″ below the overflow box’s water level, which is set via the durso plumbing).

In the top-most (horizontal) piece of this u-tube, I’ll put a fitting for 1/4″ airline, which I’ll Tee to an aqualifter and a normally-open solenoid. When not powered, the aqualifter is off, the solenoid allows air in, and the u-tube doesn’t do anything. When they are powered, the solenoid stops letting air in, and the aqualifter removes the air so a siphon starts, just like some designs of the HOB overflow box. When there’s a siphon, the water will rush very fast from the refugium into the overflow, quickly swamping the durso, which will switch to siphon the mass of water above it, then dropping (I hope) about 50gpm into the display tank, which then washes through the DT’s overflow into the sump (note I plan to have about 75g of unused capacity in the sump for the surge+pipes to drain in a worst-case power outage)

I’ll set the maximum surge to be about 50 gallons, based on how low the plumbing reaches into the fuge (8″ below water level should be about right), but I can set the apex to break the siphon (and therefore surge) early by turning off the outlet that controls the aqualifter and solenoid. In normal use, I’ll probably turn on the outlet for about 2 minutes while the siphon builds and the 50g drains, then open it up. Otherwise, the siphon will try to keep starting as the aqualifter keeps trying.

The drain into the display I want to go down low in the tank so the surge pushes water up the water column and into the overflow. No sense in having all this water just rush across the top and into the overflow box, plus I want the ‘pods to feed the fish. I’ll poke a small hole in the pipe right at the display’s water level to make the siphon start easier (to airlock), but have the pipe dive down into the acrylic box in the display’s corner. Cut a bunch of holes in the acrylic walls (down low), and make the top of the tower about 1/2″ above the water level (still below the eurobracing). When just acting as a fuge, the water and a few pods will fall into the tower and tend to come out the holes near the bottom. When surging, most things will be forced down through those holes and any excess flow that doesn’t fit will fall over the top into the tank. This should provide a nice updraft of about 50 gallons (or about 1/3 of the DT’s water volume) pretty quickly, giving everything a good rinsing and pushing pods into the water column.

I’m thinking I’ll probably set it up initially to run once an hour during lights on and put the feedings a few minutes after a surge. If it doesn’t bother me, I could set it to surge around the clock every 20-30 minutes (150gph return, remember?). I may also just do it once a day in the evening after I feed, or maybe when I’m dosing alkalinity, or maybe only when I want to watch it :)

One more piece: I’m expecting the DT’s weir to be long enough to only raise the tank level about 1/4″ during the surge. The siphon of its Bean Animal shouldn’t change much (doing about 800gph, probably). the open will turn to a siphon quickly (and be 2″ to carry all the surge) and this will skip the skimmer section of the sump so the skimmer has a constant water level. The emergency might carry a trickly, but the DT’s open will have a straighter fall and a higher fall, so I expect it won’t have trouble carrying the normal trickle plus the surge. I might put a valve on the surge from the fuge so I can slow it down just a touch.

Oh, and the ATO will be unaffected because it will be set for a full fuge (lowest sump level), but it could kick on a touch when the surge’s u-tube is filling, so I’ll probably turn off the ATO while the u-tube’s electronics are powered.

Quarantine/Frag/Hospital

I plan to stick my existing 29g somewhere after I drill a little hole in its side with a simple bulkhead (and strainer) that literally goes to a floor drain. I’ll run my existing 29g with the return pump and probably a power head, stick some PVC pipes in there, etc.

The auto-water change in the display will drain its old water into here, which will raise the water level and cause a drain to the floor drain. Obviously top-off is a problem, so when I actually have something in quarantine, I’ll have to monitor salinity carefully, but if it gets a 1 gallon AWC every day in a 29g tank, it should stay free of things like ammonia. Big point: the water from the quarantine never enters the main system, and the quarantine doesn’t have much toxicity to worry about with regular water changes.

I may add a level sensor (at the drain height) in the quarantine and let the apex top-off the quarantine right before it does an AWC in the display, then this is a non-issue.

I figure this is best as a quarantine or hospital tank (as long as I want normal salinity). If I need a hyposalinic hospital tank, I’ll have to do that separately. I might want it as a frag system, but the salinity is a bigger issue, and I would need to be more thoughtful if I ever am treating a fish (eg, with copper). I may just put a little light and frag rack in the sump so I can temporarily keep frags I’m waiting to get rid of, we’ll see.

Other things

I’m planning to have 2-3 barrels, one for RODI, 1-2 for saltwater. Each with a float valve and solenoid on the incoming waterline and an optical or float sensor down low. When the Apex seems the RODI is empty, open the solenoid and let it fill. I’ll figure out how long it takes to fill and just program a time for the solenoid to be open that’s about that time, but the float valve should stop it on time. I can turn off the solenoid on my phone if I want.

When I need to make saltwater, I make sure the RODI is full, then drain it into the other barrel and add salt mix. Good time to clean out both barrels, but probably not every time.

PMUP in both barrels so the Apex can run topoff in the sump and can run AWC from the salt barrel. I plan to put a ball valve in the wall of the sump’s return section so I can do a pump-driven large-volume water change when I choose to. I’ll probably run a line from the manifold to the drain so I can dump a lot of water in a hurry, then let the PMUP fill it up from the barrel.

Planning for the apex to run everything. I’ll probably put one of my two heaters in the fuge, mostly as a backup (maybe set to 74). I’ll put a new one (maybe 200w?) in the display as a backup (maybe set to 76?) and put two 200w heaters in the sump as the main heat source.

0 notes

Photo

Super Refrigeration LNT Industrial Engineering Exporter of Refrigeration Valves, Refrigeration Controllers Refrigeration And Air Conditioning Compressors from Pune India. Visit http://www.lntindustries.in/ammonia-valves.php

0 notes

Text

Corrosion resistance and applications of super alloys at high temperatures

Ammonia and Nitrogen

Various metals and alloys are inert against molecular nitrogen at high temperature. Although, atomic nitrogen interacts with and penetrates various steels, developing hard, brittle nitride surface layers. The main source of atomic nitrogen is dissociation of ammonia in ammonia converters and nitriding furnaces that serve in the temperature limit of 700oF to 1100oF at pressure values ranging from atmospheric to 15,000 psi. In these conditions low-chromium steels may fail. When chromium concentration goes beyond 12%, these problems can be prevented. Stainless steels are safely used for high temperature service in hot ammonia conditions. The function of stainless steels in ammonia environments is based on temperature, pressure, gas concentration and concentrations of chromium and nickel. Outcomes from different service tests have shown that corrosion rates for chromium stainless steels are more than chromium-nickel alloys.

Halogens

Austenitic stainless steels are vigorously corroded by halogen gases at high temperatures. Fluorine is more corrosive as compare to chlorine and the upper temperature limits for dry gases are approx 480oF and 600oF respectively, for high chromium-nickel alloys. Wet chlorine gas comprising 0.4% water is more corrosive as compare to dry chlorine up to 700oF.

Liquid Metals

Liquid metal corrosion differs from aqueous and gaseous corrosion as it is mainly based on the dissolution of the solid metal in liquid metal unlike to electro-chemical forces. However chemical reactions have an essential role in liquid-metal corrosion, mass flow mechanisms are highly important. Major mass transfer and chemical corrosion by liquid metals are:

Alloying or simple solution, temperature based mass transfer, concentration gradient, impurity reactions.

High temperature applications of Nickel alloys

The elevated temperature applications of super alloys are wide, such as components for aircraft, chemical plant systems and petrochemical equipments. For example F119 engine, that is the latest in a series of military engines to power high performance aircraft. The gas temperatures in these engines in the hot regions can go up to 1093oC. Cooling methods decrease the real component metal temperatures to lower levels and super alloys that can serve at these temperatures are the main components of the hot regions of these engines.

The importance of super alloys in modern commercial sector is signified by the fact that whilst in 1950 only around 10% of the whole weight of an aircraft gas turbine engine was made from super alloys, in 1985, this magnitude was about 50%. It will be stated that not all applications demand high temperature strength, there are also high strength paired with corrosion resistance have made specific super alloys essential such as in biomedical equipments and cryogenic applications.

Common applications of Inconel 625 in aerospace engineering include disks, bolts, shafts, cases, blades, vanes, combustors, afterburners and thrust reversers, steam turbine include bolts, blades, and stack gas reheaters and specific automotive components include turbochargers and exhaust valves.

0 notes

Text

Refrigeration Chiller Manufacturer

Ammonia Valves. Such valves are specifically designed for the suction of hot gas lines with ammonia. They are designed to work in the super aggressive environments where there is extreme high humidity along with high fluctuations in the temperatures that occurs mostly in all types of industries get more info :- http://www.coltfreeze.com/ammonia-chiller-manufacturer.php

#Refrigeration compressor India#Ammonia Piston Compressor#Ammonia chiller manufacturer#Ammonia Valves

0 notes

Text

Screw refrigeration compressor

Colt has been practicing fast working parts organization to supply the necessary spare parts throughout the world. We dispatch the required spare parts as soon as possible and in most cases the parts can be delivered within 24 hours after order for more info :- http://www.coltfreeze.com/spare-parts.php

#Super Ammonia Valves#Ammonia chiller manufacturer#Refrigeration compressor India#Ammonia Refrigeration compressor#ammonia Receiver manufacturer

0 notes

Text

Ammonia Piston Compressor

The liquid recirculation system is the most advanced and energy efficient technique in ammonia refrigeration terminology.The ammonia liquid from surge drum (accumulator) is forced circulated in the evaporators of cold storages, or freezer get more info :- http://www.coltfreeze.com/lpr.php

#Ammonia Refrigeration compressor#Super Ammonia Valves#Valves for Cold Storage#Ammonia chiller manufacturer#Ammonia Stop valves#Refrigeration compressor India

0 notes

Text

Shell and tube heat exchanger manufacturer India

Refrigeration is required for preserving any substance for a longer duration of time. There are firms today that are into the business of delivering excellent refrigeration units and cold storages for meeting the above requirement get more info :- https://coltfreeze.wordpress.com/2017/11/20/cooling-and-refrigeration-units-at-saarthak/

#Ammonia Refrigeration compressor#Super Ammonia Valves#Valves for Cold Storage#Ammonia chiller manufacturer#Refrigeration compressor India#Ammonia Stop valves

0 notes

Text

Ammonia air cooling units

An evaporative condenser is a condenser integrated into a cooling tower which rejects the latent heat of condensation of refrigerant (Ammonia/Freon) through a coil to the surroundings by means of evaporation. any more info :- http://www.coltfreeze.com/evaporative-condensors.php

#Ammonia Refrigeration compressor#Super Ammonia Valves#Valves for Cold Storage#Ammonia chiller manufacturer#Ammonia Stop valves#ammonia Receiver manufacturer

0 notes