#Suction Pumps manufacturer

Explore tagged Tumblr posts

Text

Find Local Suction Pumps Manufacturer, Supplier at Indian Trade Bird?

Best Suction Pumps manufacturer, Supplier and Exporter from Ahmedabad, Coimbatore, Ghaziabad, Karnal, New Delhi.

Finding Local Suction Pumps Suppliers

When searching for local Suction Pumps suppliers, proximity becomes a significant advantage, offering various benefits such as shorter lead times, reduced shipping costs, and easier access to technical support and spare parts. Additionally, We have local suppliers facilitate closer collaboration and relationship building, which can be invaluable in ensuring seamless operations. Business directories, trade associations, and online platforms serve as valuable resources for identifying nearby Suction Pumps manufacturers. Furthermore, attending networking events, and industry trade shows, seeking referrals from colleagues and peers can aid in the search for local suppliers. Collaborating with local vacuum pump suppliers fosters a sense of partnership and mutual support. This partnership allows for greater flexibility in customization, faster response times to urgent requirements, and a deeper understanding of local market dynamics and regulations, ultimately enhancing efficiency and reliability.

Suction Pumps manufacturers play a crucial role in providing essential equipment for a wide range of applications across various industries. By understanding the different types of Suction Pumpss, their applications, and key considerations when selecting manufacturers, businesses can make informed decisions to ensure optimal performance, reliability, and efficiency.

For More Details Click here: https://www.indiantradebird.com

0 notes

Text

End Suction Pumps are a versatile and efficient choice for fluid handling across a wide range of industries. Known for their compact design and reliable performance, these pumps are ideal for applications in water supply, irrigation, industrial processing, and HVAC systems.

Designed with precision, End Suction Pumps offer high efficiency and reduced energy consumption, making them a cost-effective solution for your pumping needs. Their robust construction ensures durability and long-term reliability, even in demanding operating conditions.

One of the key advantages of End Suction Pumps is their ease of maintenance. The back pull-out design allows quick servicing without dismantling the entire system, minimizing downtime and ensuring uninterrupted operations. These pumps are compatible with a variety of fluids, including water, light chemicals, and mild slurries, making them a versatile option for diverse industries. Available in various sizes and configurations, End Suction Pumps can be customized to meet specific application requirements.

0 notes

Text

Best Suction Irrigation Pump Manufacturer in India

Started in the year 1995 at Ahmedabad, Gujarat. We at Nidhi Meditech Systems are manufacturing and exporting of best quality suction irrigation pump. We are one of the best suction irrigation pump manufacturer in India. Suction irrigation pump to be used in different types of procedure like hysteroscopy, urology and all laparoscopy procedures. Our devices are fully automatic and multifunctional with high accuracy which can use in different types of surgeries.

0 notes

Text

End Suction Centrifugal Pump Manufacturers, Suppliers India Pune

We are End Suction Centrifugal Pumps Manufacturers,Suppliers,Exporters & Dealers in Pune, Mumbai, Nashik, Goa, Aurangabad, Kolhapur, MH From India.End Suction Centrifugal Pumps at Best Price

0 notes

Text

Air Separator - What You Need to Know

An Air Separator is a device used to separate air from a fluid, such as water, oil or gas. It is a type of centrifugal pump that uses centrifugal force to separate the fluid from the air.

An Air Separator Manufacturers is a device used to remove air from a fluid, gas, or liquid. It is used to improve the quality of the fluid by removing impurities or to increase the density of the fluid. An air separator can help improve your process efficiency and product quality. By removing entrained air from your process, you can avoid problems such as material segregation, poor product quality, and reduced production rates. An air separator can also help minimize fines production, and improve the overall efficiency of your process. Air separators are devices that are used to remove air from a fluid. There are several different types of air separators that are used in various industries. Some of the most common types of air separators are cyclone separators, vortex separators, and plate separators.

Cyclone separators are devices that use centrifugal force to remove air from a fluid. They are often used in industries such as petrochemicals, power generation, and food processing. Vortex separators are similar to cyclone separators, but they use a whirling motion to remove air from a fluid. They are often used in industries such as pharmaceuticals and biotechnology. Plate separators are devices that use a series of plates to remove air from a fluid. They are often used in industries such as water treatment and metal processing. Air separators work by using air pressure to separate the lightest particles from the heaviest. The lightest particles are blown away by the air pressure, while the heaviest particles are left behind. This process can be used to separate different types of particles, such as dust, dirt, and gravel. When choosing an air separator, there are a few main factors to consider: the type of material being separated, the particle size of the material, and the airflow rate.

The type of material being separated will determine the type of air separator needed. If the material is a solid, a gravity air separator will work best. If the material is a liquid, an aerosol or centrifugal air separator will work best.

The particle size of the material will also determine the type of air separator needed. If the particles are small, a gravity air separator will work best. If the particles are large, a centrifugal air separator will work best.

The airflow rate is also important when choosing an air separator. The higher the airflow rate, the faster the material will be separated.

Installing an air separator is a relatively easy process that can be completed in a few hours. The first step is to identify the location of the air separator. The air separator should be installed as close to the fan as possible. The next step is to determine the size of the air separator. The size of the air separator will depend on the size of the fan. Once the size of the air separator has been determined, the installation process can begin.

The first step is to remove the old air separator, if one is already installed. The next step is to install the new air separator. The air separator should be installed in the same location as the old air separator. The next step is to connect the air separator to the fan. The air separator should be connected to the fan using the provided screws. The last step is to connect the power supply to the air separator. The power supply should be connected to the air separator using the provided screws. Once the installation is complete, the air separator should be tested. Air separators are important pieces of equipment in many industrial settings, and proper maintenance is critical to keeping them running smoothly. The requirements for air separator maintenance vary depending on the specific separator model, but some general guidelines include regular filter cleaning and replacement, oil changes, and inspections for damage or wear. It is also important to keep an eye on the condition of the separator's housing and seals, and to address any issues promptly. By following the appropriate maintenance procedures, air separators can provide many years of reliable service. An air separator can cost a lot of money, but it is worth the investment. The separator can improve the quality of the air in your home or office, and it can help to keep your family or employees healthy. There are many benefits of using an air separator. One of the main benefits is that it can help to improve the quality of the product. It also helps to improve the efficiency of the production process. Additionally, it can help to reduce the amount of waste that is produced. An air separator is a necessary piece of equipment for any facility that deals with fluids. It is important to understand the function and operation of an air separator in order to ensure that it is running properly and to prevent any potential problems.

#air separator manufacturers#duplex strainer manufacturers#pot strainer manufacturers#suction guide manufacturers#pressurization pump unit manufacturers#industrial strainer manufacturers#simplex strainer manufacturers#air vessel tank manufacturers#expansion tank manufacturers#t strainers manufacturers

0 notes

Text

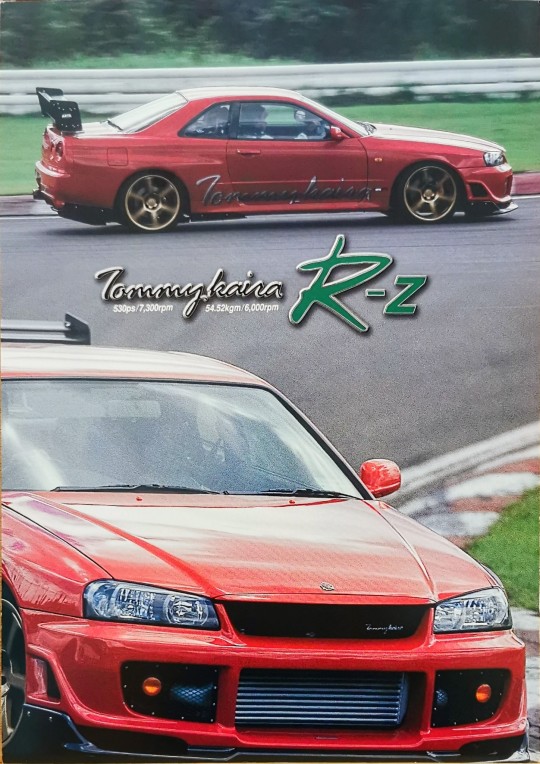

Tommykaira R-z brochure translation.

The wonders of Tommykaira Magic that you can experience while driving. R

Total balance with a high degree of perfection commensurate with 530ps.

The displacement has been increased to 2700cc, achieving a maximum output of 530 horsepower and a maximum torque of 54.52kgm. To achieve this, various types of tuning have been applied. For example, the crankshaft, which is the most important element for bringing out the best performance of the engine, is an original crankshaft manufactured by Fandon in the UK. Highly rigid full counter type provides excellent balance performance. Furthermore, the R-z uses an H-section connecting rod and forged aluminum piston, making it both highly rigid and lightweight. What's more, it achieves well-balanced tuning. In addition, the R-z uses metal head gaskets, high-lift camshafts, valve springs, and racing plugs to bring out the best in the pistons, connecting rods, and crankshafts that are the main moving parts. Composite Radiator Improves cooling effect by using NI water pump.

I got it.

Changes to the intake and exhaust system have resulted in a significant increase in efficiency through the use of a stainless steel exhaust system with suction from the front pipe and a racing type intercooler. By increasing the size of the fuel system parts and strengthening the drive system, you can enjoy ample torque even when driving at low rpm around town. What's more, the sense of power, extension, and revving at high rpm will captivate anyone sitting in the driver's seat.

suspension tuning is

"High ride comfort and handling"

Balance in Dimensions.” During normal driving

Passenger-friendly ride

While realizing the taste, wine day

It is sharp and has excellent turning performance when turning.

Tomita has achieved this goal and has received rave reviews from many quarters.

It's a magic called Kaira Magic.

The front brake has been strengthened to control the 530 horsepower. Uses AP 6-pot calipers, AP brake rotors, and PFC brake pads. This is a highly reliable braking system that responds precisely to the driver's wishes.

[mechanism]

engine body

・Cylinder head/port polishing

・Cylinder block/boring, internal polishing

・Original crankshaft made in UK Fandon

・Special H section connecting rod

・Special forged piston

・Titanium coated piston ring

・Metal head gasket

・High lift camshaft

・Reinforced valve spring, valve guide

・Racing plug

computer unit

・R-z dedicated computer unit

cooling system

・Large capacity water-cooled oil cooler

Water pump for high speed N1

Intake and exhaust system

・All exhaust system

・Large capacity intercooler

・Special turbine

fuel system

Large capacity air flow meter

large capacity injector

・Large capacity fuel pump

drive system

・Twin plate clutch

Reinforcement parts

・Strut tower bar (with master cylinder stopper)

・Reinforced engine mount

・Enhanced mission mount

[Suspension]

Brake system

・AP 6-pot caliper & rotor (F)

・PFC brake pad

suspension

・Bilstein original shock absorber

・Original spring (F)

Original double spring (R)

tires/wheels

・Forged magnesium cut wheel “PRO R” 9.5×19+22

・DUNLOP FORMULA FM901 275/30ZR19

Reinforcement parts

・Stainless mesh brake hose

・Front tension rod (pillow ball)

* [Exterior] and [Interior] are the same specifications as R-s.

Tommykaira R-Z SPECIFICATION

PRICE ¥10,500,000-

PERFORMANCE

Max Output 530ps/7300rpm

Max Torque 54.52kgm/6000rpm

ENGINE

RB26DETT STRAIGHT-6 DOHC Turbo with multi-cup Intercooler

Piston Displacement: 2700cc

Bore x Stroke: 87.0mm x 75.7mm

BODY

Length: 4620mm

Width: 1785mm

Height: 1335mm

Wheelbase: 2665mm

Tread: Front 1496mm

Rear 1496mm

LAYOUT

4 Wheels Drive

Transmission: 6MT

Brakes:(F) 6 Piston Opposed Type Caliper + Ventilated Disc

Brakes:(R) 2 Piston Opposed Type Caliper + Ventilated Disc

Wheels: 9.5JJX 19 (Front&Rear)

Tire: 275/30ZR19 (Front&Rear)

Suspension : Original Shock absorber + Original Coil Spring

Steering: Rack & Pinion < SUPER HICAS >

*Price is vehicle price delivered at Kyoto store, registration fees and consumption tax not included US specifications, data, etc. are subject to change without notice. *Detailed options, equipment, body color, etc. are based on genuine Nissan. Catalog photos may look different from the actual products as they are printed materials. For inquiries and requests..

TOMITA

dream factory

http://www.tommykaira.com

18 notes

·

View notes

Text

Find The Best Commercial RO Plant Manufacturer In Noida ?

Netsol Water with Commercial RO Plant is currently treated as one of the top Commercial RO Plant Manufacturer in Noida with advanced evaluation systems for commercial water treatment. Technically skilled chairpersons having professional knowledge have helped establish Netsol Water & then Commercial RO Plant in Noida, whose base headquarted is located in Gr.Noida. The main intent involves employing technologies such as UF (Ultrafiltration) as well as modern, creative ion-exchange membranes for sterilization & purification of natural raw water before distributing it to different commercial & residential water suppliers.

Furthermore, wastewater is treated by the treatment plant's systems or equipment to remove impurities & convert it fit for human consumption. Because of its ISO recognition or certification, the company's quality standards comply with worldwide standards or laws.

By utilizing their dedicated workforce plus vast technology capabilities, they have expanded their turnkey projects to include contract maintenance along with extra services. They support or assist in the development, construction, design, & special architecture of their numerous water treatment plant facilities, as well as their mounting or installation, suitable upgrading, correction, including any modification.

Their dedicated team of support representatives around the company adopts their technological know-how to satisfy the organization's needs & its various clients. As a result, they have been successfully able to raise awareness of some of the biggest & most significant commercial businesses in the country, which has expanded their client. Though Commercial RO Plant Manufacturer in Noida such as both Netsol Water & Commercial RO Plant operates in every corners of Noida, it has branches all over the country to purify water to the extreme purity level that could be easily available to every person in the population during the need.

Various processes & mechanism involved in Reverse Osmosis

Reverse osmosis is the process of physically removing minerals & dissolved solids from water. This water purification plant with RO technology is based on the osmosis idea, which lowers the hazardous mineral content in raw water by causing osmosis to occur at high pressure via a partially permeable membrane.

RO technology has the greatest adaptability to meet a range of needs in many industrial commerces & residential applications. By adopting our exclusive software-based approach, our clients may maximize their RO benefits.

When entering water standards & your capacity requirements are taken into consideration, the software-driven device or equipment provides you with the optimal combination. This choice is influenced by a number of factors, including different flow rates, pump versions based on annual upgrades, membrane kinds, as well as intake water quality. Appropriate responses cause fewer problems.

The benefits of establishing a strong commercial RO plant manufacturer in Noida are as follows:

Compact as well as adaptable RO segments or partitions;

Simple setup alongside installation with routine maintenance along with operation;

The liberty to opt from a variety of available options among the line;

Wider scope for more RO Advantage since plants are powered by software-based devices

Shorter pipe length greatly reduces system loss;

Highly automated, highly developed & controlled, modern digital tracking & gauging system aids in diagnosis & repair.

Assessing the water quality of products remotely or online;

Electric run Pumps & thin membranes' safety features, as well as a stainless steel multiple-phase centrifugal pump with integrated supply along with suction for ease of operation & maintenance-servicing;

Commercial RO Plant System for best Purification of Raw Water

Make sure clients receive prompt along with automated water contamination removal when running a commercial RO plant for the thorough purification of raw water by applying RO technology. The biggest challenge of Netsol Water & its partner branch Commercial RO Plant is to offer the most leading-edge RO water filtration technology, together with full installation & maintenance services. To ensure your RO plant runs reliably, we also manage a large range of commercial RO plant-equipped components. Our products are appropriate for your specific requirements at work or home, such as:

The company efficiently & successfully implements a variety of interconnected water treatment plant systems adopting RO techniques. Professionals with extensive wide knowledge & specialization supervise as well as manage the assembly or installation process.

Updated instructions led to modifications in installation techniques.

Application of the newest along with the most popular technology.

Most workers closely monitor every aspect of industrial processes. They also supervise while keeping a regular check on customer duties, such as RO installation. This ensures a faultless installation in addition to outstanding quality. With the assistance of the Commercial RO Plant Branch, Netsol Water has assembled teams of specialists to offer suitable solutions that adhere to industrial, commercial, along with home regulations.

Conclusion

Netsol Water & Commercial RO Plant takes the implementation or installation of commercial RO plant units very seriously. As consequently, we help to provide complete support during the fitting along with the installation procedure. Additionally, we offer up-to-date maintenance options that guarantee the plant's durability & longevity.

They both also guarantee to offer world-class advanced technology equipped post-purchase assistance. Here at Netsol Water & Commercial RO Plant, every staff believe that without the value of providing additional after-sales support & assistance, it is not that easy to achieve the maximum customer satisfaction. We have lifted the bar above our competition due to our dedication to providing & achieving client satisfaction to the utmost extent possible along with our desire for contemporary, modern technologies.

Both of These Companies have nearly multiplied several folds in its market share through installing the finest & high-performing Commercial RO Plant Manufacturer In Noida & consistently providing its clients with excellent products and services. As an industrial water treatment company, they currently control a large portion of the market.

#commercial ro plant#commercial ro plant manufacturer in noida#netsol water#save water#water is life#water treatment plant

0 notes

Text

Exploring the Fundamentals of Hydraulic Filter Elements

In today’s world of advanced machinery and industrial applications, hydraulic systems play a crucial role in powering heavy equipment, manufacturing processes, and various other operations. At the heart of these systems lies a vital component: the hydraulic filter element. Understanding its importance, function, and types can help ensure the longevity and efficiency of hydraulic systems.

What is a Hydraulic Filter Element?

A hydraulic filter element is a replaceable component within a hydraulic filtration system. Its primary function is to remove contaminants such as dirt, debris, and metal particles from hydraulic fluids. These contaminants can originate from internal wear, environmental exposure, or system breaches, posing risks to the system’s performance and reliability.

Why is it Important?

Hydraulic systems are designed with precision to perform high-pressure operations. Even minute contaminants can lead to:

System Downtime: Clogged or damaged components can halt operations, leading to costly delays.

Wear and Tear: Abrasive particles accelerate the degradation of system components.

Reduced Efficiency: Contaminants impede the smooth flow of hydraulic fluids, impacting performance.

Catastrophic Failures: Over time, unchecked contamination can result in critical system failures.

Installing and maintaining high-quality hydraulic filter elements is crucial to prevent these issues and ensure smooth operation.

Types of Hydraulic Filter Elements

Hydraulic filter elements come in various types, each tailored for specific applications and filtration needs:

Suction Filters: Installed at the pump’s intake, they prevent large particles from entering the hydraulic system.

Pressure Filters: Positioned downstream of the pump, they handle high-pressure filtration to protect sensitive components.

Return Line Filters: Located in the return line, these filters clean the hydraulic fluid before it re-enters the reservoir.

Off-Line Filters (Kidney Loop Systems): These operate independently of the main system to provide continuous filtration.

Key Features to Look For

When selecting a hydraulic filter element, consider the following features:

Filtration Efficiency: Measured in microns, this indicates the filter’s ability to capture particles of varying sizes.

Dirt-Holding Capacity: Determines how much contamination the filter can hold before requiring replacement.

Material Composition: Filter media can be made from cellulose, synthetic fibers, or wire mesh, each offering distinct benefits.

Compatibility: Ensure the filter matches the hydraulic system’s specifications, including pressure and flow rate.

Bypass Valve: A built-in safety mechanism that allows fluid to bypass the filter in case of clogging, preventing system damage.

Maintenance and Replacement

Proper maintenance of hydraulic filter elements is essential for optimal performance. Regularly inspect and replace filters according to the manufacturer’s guidelines or when pressure drop indicators signal a need for change. Neglecting this routine can compromise the entire hydraulic system.

Conclusion

The hydraulic filter element is a small yet indispensable component of any hydraulic system. By effectively removing contaminants, it safeguards the system’s efficiency, extends the life of components, and minimizes operational disruptions. Understanding its role and selecting the right type for your application can make a significant difference in maintaining a reliable and efficient hydraulic system.

Investing in high-quality hydraulic filter elements and adhering to regular maintenance schedules is not just a best practice—it’s a necessity for the smooth functioning of modern machinery and industrial operations.

Source URL:https://shorturl.at/DmkPZ

0 notes

Text

Peristaltic Pump Drive Classifications

Peristaltic pump drives can be categorized based on the type of control required. Most pump manufacturers have considered the interchangeability of the pump head with the drive to some extent. This is especially important in the early stages of peristaltic pump testing and various research. Peristaltic pump drives can be divided into the following two categories:

Constant Speed Drive It represents a simple method of fluid transfer. The pump system can maintain a constant operating speed throughout the entire operation. Sometimes, the flow rate can also be changed by changing the size of the pump tube.

Variable Speed Drive For applications requiring a wide range of flow rate adjustment, a variable speed drive can be considered for the peristaltic pump. Pumping the correct flow rate at the right time requires skill. Variable speed peristaltic pump drives typically offer stepless speed variation between low and high speeds. Motor speed, gear ratio, and percentage speed adjustment are three key factors to consider when selecting a peristaltic pump drive. The reverse function of the peristaltic pump drive helps to clean the suction line before replacing the pump tube.

0 notes

Text

Auger Dredges and Wetland Restoration: A Perfect Match

Auger dredges have emerged as an innovative solution for wetland restoration, offering precision and minimal environmental impact. These specialized dredging machines use a rotating auger to remove sediment in a controlled and efficient manner, making them ideal for delicate ecosystems like wetlands. By carefully excavating silt and debris, auger dredges help restore natural water flow, improve habitat conditions, and support biodiversity. Unlike traditional dredging methods, they minimize turbidity and disruption to aquatic life, preserving the integrity of the wetland environment. Their versatility and eco-friendly operation make them a preferred choice for conservation projects. Auger dredges not only rejuvenate degraded wetlands but also ensure long-term ecological balance, highlighting their vital role in sustainable restoration practices.

What Is an Auger Dredge? A Comprehensive Overview

An auger dredge is a specialized type of dredging equipment used for precise sediment removal in shallow water bodies. Unlike traditional dredgers, an auger dredge employs a rotating screw-like mechanism that loosens and transfers material for easy extraction. This equipment is popular in industries like mining, agriculture, and wastewater management due to its ability to provide accurate dredging solutions.

Key Features and Advantages of Auger Dredges

Auger dredges are designed for efficiency, accuracy, and environmental sustainability. Some of their key features include advanced propulsion systems, adjustable auger heads for varying depths, and minimal turbidity generation. They excel in removing fine sediments without disturbing the surrounding ecosystem, making them a preferred choice for eco-sensitive dredging projects.

Applications of Auger Dredges Across Industries

Auger dredges find extensive use across various industries. In agriculture, they help clean irrigation canals for improved water flow. In mining, auger dredges are used to extract valuable minerals from riverbeds and lakes. Wastewater treatment plants rely on them to remove sludge from ponds, while environmental projects use these dredgers to restore wetlands and clean contaminated water bodies.

How Does an Auger Dredge Work? The Process Explained

The working mechanism of an auger dredge involves a rotating auger head attached to the suction pipe. This head breaks up sediments, which are then pumped through the suction system to a discharge site. The process ensures minimal sediment resuspension, reducing water turbidity and protecting aquatic habitats. This efficiency makes auger dredges a reliable tool for targeted dredging operations.

Choosing the Right Auger Dredge for Your Project

When selecting an auger dredge, factors like project size, sediment type, and water depth play a crucial role. For small-scale projects, portable auger dredges offer convenience, while larger dredges are better suited for extensive operations. Consulting with experts and manufacturers ensures you choose the right dredge tailored to your specific needs and environmental considerations.

Environmental Impact of Auger Dredging

One of the key benefits of auger dredges is their eco-friendliness. The precise operation minimizes disruption to aquatic life and prevents excessive sediment dispersion. They are particularly effective in environmental cleanup projects, such as removing toxic sludge or restoring natural habitats. With proper usage, auger dredging can promote sustainable waterway management.

Top Manufacturers of Auger Dredges and Their Innovations

Several leading manufacturers specialize in producing high-quality auger dredges. Companies like IMS Dredges and Ellicott Dredges have introduced innovative designs, incorporating advanced control systems, GPS-guided dredging, and enhanced energy efficiency. These advancements improve productivity and reduce operational costs, making auger dredges an increasingly popular choice for modern dredging projects.

Conclusion

Auger dredges have transformed dredging operations by combining precision, efficiency, and environmental consciousness. Their versatility makes them ideal for applications ranging from agriculture to environmental restoration. By investing in the right auger dredge and following sustainable practices, industries can achieve their dredging goals while preserving aquatic ecosystems. As innovations continue to improve their capabilities, auger dredges are poised to play an even greater role in maintaining waterway health worldwide.

0 notes

Text

Find The Best Commercial RO Plant Manufacturer In Noida ?

Netsol Water is one of the top Commercial RO Plant Manufacturer in Noida with advanced evaluation systems for commercial water treatment. A collective squad of technically skilled professionals established Netsol Water in Noida, whose base headquarter is located in Gr.Noida. The aim is to implement technologies like UF (Ultra Filtration) & various other advanced innovative ion-exchange membranes to purify & sterilize natural occurring water for distribution in various commercial & residential water supplies.

Additionally, the equipment or systems of the treatment plant aid in the treatment of wastewater to reduce contaminants while making it edible or consumable. The company's quality standards adhere to international standards or regulations due to its ISO recognition or certification.

They have added contract maintenance & additional services to their turnkey projects by leveraging their committed staff along with extensive technological capabilities. Their various Water Treating Plant facilities are developed, built, designed & specially architected, mounted or installed, transformed with proper upgradation, corrected, & modified with their support or assistance.

Their nationwide team of committed support representatives applies their technological expertise to meet every demand of the business doing company & various other clients . Because of this, they have been able to draw attention around some of the most important & big companies in the nation, which has increased their customer base. Though Commercial RO Plant Manufacturer in Noida such as Netsol Water operates in every corner of Noida, it has branches all over the country to make purified water accessible to every individual in need.

Overview of the RO Process

The method of physically extracting minerals plus dissolved solid particles from water is called reverse osmosis. The osmosis concept, which occurs at high pressure through a membrane that is partially permeable to lower harmful mineral content in raw water, is the basis of this water purification plant included with RO technology.

When it comes to industrial & residential domesticated applications, RO technology provides the most flexibility to satisfy a variety of needs. Our clients may optimize their RO Benefits of applying our exclusive software-based solution.

The software-driven equipment or gadget gives you the best combination when your capacity requirements along with entering water standards are taken into account. Various levels of flow, pump versions according to yearly upgrade, membrane types, & intake water quality all have an impact on this decision. There are fewer issues with appropriate answers.

The benefits of installing a commercial RO plant manufacturer in Noida are as follows:

Small alongside versatile RO segments or partitions;

Easy Setup & Installation with regular operation, & maintenance;

The flexibility to select a desired option from a wide range;

Greater RO Advantage since plants run through software-based devices

System loss is significantly decreased by providing minimum pipe length;

A computerized digital monitoring system with a high degree of plant mechanization assists in diagnosis & repair.

Online or Remote monitoring of product water quality;

Safety characteristics of pumps & membranes, & also, a multi-stage centrifugal pump made of stainless steel with inline supply & suction for convenience of utilization as well as maintenance;

Commercial RO Plant System for Purification of Water

When operating a commercial RO Plant for the complete purification of raw water with RO technology make sure customers get quick & automated removal of contaminants from water. The mission we have at Netsol Water is to provide the most advanced RO water purification technology with its complete installation & maintenance. In addition, we oversee a wide variety of commercial RO plant equipped components to guarantee your RO plant operates consistently. Our goods are suitable for your particular needs at home or at work, including:

We efficiently & quickly install a range of various RO technique integrated water purification plant systems.

The mounting or installation procedure is handled & supervised by professionals with continuous rigorous training & experience.

Modified installation methods in response to updated guidelines.

putting the most new & widely adopted technologies into practice.

The majority of employees keep a careful eye on all industrial operations. Additionally, they oversee while maintaining an eye on customer tasks like RO installation. This guarantees both excellent quality as well as a flawless installation. Teams of experts have been brought in by Netsol Water to provide appropriate solutions that comply to domestic, commercial, & industrial laws.

Conclusion

Implementing & Installing a commercial RO plant unit is something that Netsol Water does very seriously. And accordingly, we contribute towards offering full assistance all through the whole fitting & installation process. Furthermore, we provide modern world maintenance alternatives that ensure the plant's longevity & endurance.

Netsol Water also guarantee to offer world-class advanced technology equipped post-purchase assistance. Here at Netsol Water, every staff believe that without the value of providing additional after-sales support & assistance, it is not that easy to achieve the maximum customer satisfaction. Because of our commitment to provide & achieve client happiness to the fullest & our desire for high-tech modern technology, we have raised the bar of standards above the competitors.

The Netsol Water Company has nearly multiplied several folds in its market share through installing the finest & high-performing Commercial RO Plant Manufacturer in Noida & consistently providing its clients with excellent products and services. These days, they dominate the market as an industrial firm for water treatment.

0 notes

Text

Suction Pumps — Suction Pump Manufacturer, Supplier And Exporter In India

We are leading manufacturer, supplier, exporter and retailer of Suction Pumps. Our manufactured Suction Pumps is highly demanded in the market due to our maximum efficiency, effectiveness, and long working life. Suction pumps, also known as suction lift pumps, are a type of pump that moves fluid from a lower level to a higher level by creating a pressure difference.

Suction pumps are versatile and efficient devices used in a variety of applications to move fluids from lower to higher levels by creating a pressure differential. Buy best Suction Pumps in Ahmedabad, Coimbatore, Ghaziabad, Karnal, New Delhi at Indian Trade Bird B2B Portal.

For more details Click here : https://www.indiantradebird.com/product/suction-pumps

0 notes

Text

A wide variety of commercial and industrial applications can benefit from end suction water pumps. They have multiple uses and are primarily employed for transporting water. There is typically just one impeller in end suction pumps. As the liquid passes through the impellers, its velocity is increased. The liquid travels from the impeller to the casing at high velocities, and its pressure is increased through diffusion. The mainstream end suction pumps are powered by an irregular current motor. They are also capable of running on steam turbines and diesel and gasoline engines. It also includes air motors, hydraulic motors and direct current electric motors.

This type of pump is vital to many developments due to its many useful features

The ease of installation and operation is a major benefit of End Suction Pump. They are low-maintenance In addition to lasting for a long time without needing replacement. They are a budget-friendly choice Because of this. It is for companies and groups who transfer water or other fluids frequently.

The fact that these pumps are adaptable to many different situations is yet another plus. They find widespread application in water treatment plants, equipment cooling systems, and agricultural irrigation systems. Because of their speed and efficiency in moving water, they are used in many different types of industry. The aptitude of transferring huge amounts of water is a major advantage of end suction pumps. When time is of the essence this becomes very crucial. It is like during a flood or other emergency.

#end suction pump manufacturers#End Suction Pump#End Suction Pumps#End Suction Pumps manufacturers India

0 notes

Text

Understanding the Working Principles of Suction Irrigation Pumps

#Urology Equipment Manufacturer#Uroflowmetry Manufacturer#PC Based Wireless Uroflowmetry Manufacturer#Intracorporeal Pneumatic Lithotripter Manufacturer#Suction Irrigation Pump#Suction Irrigation Pump Manufacturer#Double Pigtail Urology Stent Manufacturer#Cystoscope Accessories Manufacturer#Resectoscope Accessories#Ureteroscopy Nephoscopy Accessories Manufacturer#Laparoscopy LED Light Source Manufacturer#Urology Disposable Basket Manufacturer

0 notes

Text

Air Separator - JSR Global Sales Company

Air separators are an important part of any business. They help to keep the air clean and free of dust and dirt. This is important for the safety of the employees and for the quality of the products. Air separators are devices used to separate air from a fluid. They can be used to remove air from a liquid or to remove gas from a liquid. Air separators are often used in the dairy industry to remove air from milk. This helps to prevent the milk from souring.

Air Separators Manufacturers can help businesses by removing dust, dirt, and other pollutants from the air. This can improve the air quality in the workplace and help to protect the employees from the harmful effects of these pollutants. Air separators can also help to reduce the amount of dust and dirt that builds up on the machinery and equipment in the workplace.

Air separators offer a variety of benefits for businesses. By removing impurities from the air, businesses can improve the quality of the air in their facilities. This can help to improve the comfort and safety of employees, and can also help to reduce the likelihood of equipment failures. Additionally, air separators can help to improve the efficiency of heating and cooling systems.

If you are in the market for an air separator, it is important to understand the different types available and how to choose the right one for your business. There are four basic types of air separators: gravity separators, centrifugal separators, cyclone separators, and baghouse filters.

Gravity separators are the simplest type of air separator and use the force of gravity to separate the air from the particles. Centrifugal separators use the centrifugal force of a rotating disk to separate the air from the particles. Cyclone separators use a vortex to separate the air from the particles. Baghouse filters use a filter bag to separate the air from the particles.

The type of air separator you choose will depend on the type of particles you are trying to separate and the amount of air you need to separate them. Gravity separators are good for separating large particles from a small amount of air. Centrifugal separators are good for separating small particles from a large amount of air. Cyclone separators are good for separating particles from a medium amount of air. Baghouse filters are good for separating particles from a small amount of air.

Air separators are an important part of any dust collection system, but they require regular maintenance to maintain their efficiency. If the air separators are not properly maintained, the dust collector will not work as well as it should, and could even cause a fire.

The best way to maintain your air separators is to schedule regular inspections and cleanings. You should also check the filters and other parts of the separator to make sure they are in good condition. If any parts are worn or damaged, they should be replaced as soon as possible.

By keeping your air separators well-maintained, you can ensure that your dust collector works properly and keeps your workplace safe.

Air separators are an important part of any business. They help to keep the air clean and free of dust and dirt. This is important for the safety of the employees and for the quality of the products. Air separators are a necessary piece of equipment for any business that wants to stay safe and productive.

#Suction Guide manufacturers#Pressurization Pump Unit manufacturers#Expansion Tank manufacturers#Air Separator manufacturers#Pot Strainer manufacturers#T Strainers manufacturers#Air Vessel Tank manufacturers#Duplex Strainer manufacturers#Industrial Strainer manufacturers#Simplex Strainer manufacturers

0 notes

Text

Understanding Hydraulic Filtration Systems and the Uses of Filter Elements

Hydraulic systems are integral to a wide range of industries, including manufacturing, construction, aerospace, and automotive. These systems rely on hydraulic fluid to transfer power and perform various mechanical tasks. However, the efficiency and longevity of hydraulic systems heavily depend on maintaining clean hydraulic fluid, which is where hydraulic filtration systems and filter elements come into play.

What is a Hydraulic Filtration System?

A hydraulic filtration system is designed to remove contaminants from hydraulic fluid. These contaminants can include dirt, metal particles, water, and other debris that can accumulate during operation. If left unchecked, these impurities can lead to component wear, reduced system efficiency, and even catastrophic failure.

The filtration system typically consists of the following components:

Filter Elements: The core component of the system, responsible for capturing and holding contaminants.

Filter Housing: Encloses the filter element and directs fluid flow through the filtration medium.

Bypass Valves: Allows fluid to bypass the filter element if it becomes clogged, ensuring uninterrupted system operation.

Indicators: Alerts operators when the filter needs replacement.

How Do Hydraulic Filtration Systems Work?

Hydraulic filtration systems operate by forcing the hydraulic fluid through filter elements. These elements are made from specialized materials designed to trap contaminants. The filtration process can be classified based on the location within the system:

Suction Filters: Positioned before the pump, these filters protect the pump from larger contaminants.

Pressure Filters: Installed after the pump, they remove fine particles to protect downstream components.

Return Line Filters: Located before the reservoir, these filters capture contaminants that have entered during operation.

Off-Line Filters: Operate independently to continuously clean hydraulic fluid.

Types of Filter Elements

Filter elements are the heart of hydraulic filtration systems. They are made from various materials to suit different applications:

Cellulose Filters: Made from natural fibers, these filters are cost-effective and suitable for low-pressure systems.

Synthetic Filters: Composed of man-made fibers, they offer superior filtration efficiency and durability.

Metal Mesh Filters: Reusable and designed for high-pressure systems, these filters are ideal for capturing large particles.

Water Absorbing Filters: Specifically engineered to remove water from hydraulic fluid, preventing corrosion and degradation.

Uses of Filter Elements

Filter elements are crucial for ensuring the proper functioning of hydraulic systems. Their primary uses include:

Protecting System Components: By removing contaminants, filter elements prevent wear and tear on pumps, valves, and actuators.

Improving Efficiency: Clean hydraulic fluid reduces friction and energy losses, enhancing overall system performance.

Extending Equipment Life: Regular filtration minimizes the risk of breakdowns and prolongs the lifespan of hydraulic components.

Maintaining System Reliability: Consistent filtration ensures that hydraulic systems operate smoothly, even in demanding environments.

Choosing the Right Filter Elements

Selecting the appropriate filter element is essential for optimal system performance. Consider the following factors:

Filtration Rating: Measured in microns, this indicates the size of particles the filter can capture.

Compatibility: Ensure the filter material is compatible with the hydraulic fluid used.

Pressure Rating: Choose a filter that can withstand the system’s operating pressure.

Environmental Conditions: Consider factors like temperature, moisture, and potential contamination sources.

Conclusion

Hydraulic filter elements and filtration systems play a critical role in maintaining the performance, reliability, and longevity of hydraulic systems. By understanding how these systems work and selecting the right components, operators can ensure their hydraulic equipment runs efficiently and experiences minimal downtime. Investing in quality filter elements not only protects your equipment but also reduces maintenance costs and enhances operational productivity.

Source URL: https://shorturl.at/W4ben

0 notes