#Structural steel detailer

Text

Engineers communicate with the fabricators and contractors through the engineering drafting. They draft large structures like bridges, buildings, highways, and sewage systems. They also develop spool drawingswhich is the pipe designing associated with the structures that are prefabricated at the workshops and later on installed in the structure. They offer complete information through these drawings for the plumber fabricators to manufacture and install the components at the right joints. Hence, approach them for your drafting needs.

1 note

·

View note

Text

ANDRADE MORETTIN ARQUITETOS ASSOCIADOS - FR HOUSE

#ANDRADE MORETTIN ARQUITETOS ASSOCIADOS#architecture#singlefamily#residential#steel details#steel#steel structure#operable shutters#metal screen#building in landscape

3 notes

·

View notes

Text

https://www.smartcadd.com/importance-of-structural-steel-detailing-in-construction-projects/

In the construction business, structural steel detailing is essential because it offers a blueprint for precise and stable building construction.

To manufacture and assemble steel framework, this procedure involves producing comprehensive drawings for steel fabricators and erectors, along with plans, reports, and other necessary paperwork.

0 notes

Text

Trustable Steel detailer- How to select?

Choosing the correct steel detailer is essential when starting any type of construction project, whether it’s an industrial facility, commercial complex, or residential building. Steel detailing is a specialized process that requires precision, expertise, and a deep understanding of engineering principles. Selecting a trustable steel detailing company can prevent costly errors, project delays, and structural issues. To ensure you make the best decision, follow this comprehensive checklist to select the right steel detailer for your project.

1. Verify Qualifications and Experience

The first step in selecting a steel detailer is to verify their qualifications and experience. A qualified detailer should have a strong background in structural engineering or related fields. When evaluating structural steel detailing companies, look for professionals who have completed relevant certifications and have a proven track record in steel detailing. Experience in similar projects is a significant advantage, as it indicates familiarity with the complexities involved in your specific type of construction.

2. Check for Software Proficiency

Steel detailing requires the use of advanced software tools like AutoCAD, SDS2, Tekla Structures, and Revit. Ensure that the detailer from a steel structure detailing company is proficient in using these tools, as they are essential for creating accurate and detailed drawings. Ask about the software they use and how up-to-date they are with the latest versions. Proficiency in 3D modeling software is particularly important, as it allows for better visualization and detection of potential issues before construction begins.

3. Review Previous Projects and References

A reputable steel detailer will have a portfolio of previous projects they’ve worked on. When considering structural steel detailing companies, examine these projects to determine the calibre of the work produced. Pay attention to the complexity of the structures they’ve detailed and how well their work aligns with your project’s requirements. Additionally, ask for references from past clients. Speaking to these clients can provide valuable insights into the detailer’s reliability, adherence to deadlines, and overall performance.

4. Evaluate Communication Skills

Effective communication is key to a successful collaboration. The steel detailer should be able to clearly convey their ideas, understand your project requirements, and provide regular updates throughout the process. When engaging with a trustable steel detailing company, assess their ability to explain technical concepts in a way that is easy to understand during initial consultations. Good communication skills will ensure that there are no misunderstandings, and any issues can be resolved promptly.

5. Assess Attention to Detail

Steel detailing is all about precision. Even the smallest mistake can lead to significant problems during construction. Evaluate the detailer’s attention to detail by reviewing their past work and asking about their quality control processes. A meticulous detailer from a steel structure detailing company will double-check their drawings and ensure that every element is accurately represented.

6. Consider Turnaround Time

Time is a crucial component of any construction project. Delays in steel detailing can push back the entire project timeline. When selecting a steel detailer, inquire about their estimated turnaround time for your project. It’s essential to choose a trustable steel detailing company that can deliver within your project’s schedule without compromising on quality.

7. Understand Pricing and Contracts

Finally, discuss pricing and contracts upfront. Request a detailed quote that breaks down the costs associated with the project. Be wary of detailers who offer significantly lower prices than others, as this could indicate a compromise in quality. Make sure the contract expressly states the conditions of payment, the extent of the task, and any provisions for changes or additional work. Structural steel detailing companies that provide transparent pricing and clear contract terms are often more reliable.

Conclusion

Selecting the right steel detailer is a critical decision that can significantly impact the success of your construction project. By following this checklist, you can ensure that you choose a trustable steel detailing company that is qualified, experienced, and capable of delivering high-quality work on time and within budget. Remember, investing in the right steel structure detailing company is an investment in the safety, durability, and overall success of your project.

#3d modeling#steel detailing services#connection design#steel fabricators#structural steel detailing services#Trustable steel detailing company#steel structure detailing company

0 notes

Text

Explore Affordable Structural Steel Detailing Services San Francisco, USA

For any complex Structural Steel Project, be it for commercial, residential, or industrial purposes, Silicon Consultants LLC stands out as the preferred choice in the United States for a comprehensive array of Structural Steel Detailing Services San Francisco at competitive rates. Our skilled Steel Detailers deliver outstanding 3D Steel Structure Models for various intricate Steel Structures, streamlining the design process and facilitating the timely execution of your Steel Detailing Project. Explore our high-quality CAD Outsourcing Services, which offer significant benefits to the United States AEC Sector through their cost-effectiveness and swift delivery.

Our Services

Steel Fabrication Drawings Services

Structural 3D Modeling Services

Erection Drawings Service

Joist Steel Detailing Services

Steel Design and Drafting Services

Steel Drawings Services

Steel Structural Detailing Services

We provide premier, cost-effective Fabrication Drawing Services that translate intricate BIM designs into precise, intelligent 3D BIM Models for clients in the Architecture, Engineering, and Construction (AEC) sector globally. Our expertise extends across numerous countries, including South Korea, Norway, Greece, Thailand, Brazil, Singapore, France, Czech Republic, Finland, Malaysia, Romania, Netherlands, Luxembourg, Australia, Taiwan, Argentina, Ireland, the United Kingdom, the Philippines, Poland, South Africa, Germany, Saudi Arabia, the United States, Japan, Denmark, Spain, China, Bulgaria, Hungary, Slovakia, Estonia, Belgium, Italy, Latvia, Sweden, Vietnam, Qatar, Lithuania, Austria, Mexico, Kuwait, United Arab Emirates, etc.

For more details click on the link below

Check out our New Blog

#Structural Steel Detailing#Steel Detailing#CAD Detailing#CAD Outsourcing Services#USA#United States of America#United States#Germany#France#Italy#Netherlands#Sweden#Singapore#Austria#Australia#South Korea#Norway#Denmark#Switzerland

0 notes

Text

Premium Rebar Detailing Outsourcing Services in Minnesota, USA

CAD Outsourcing Consultant is your go-to CAD Engineering Firm for top Rebar Detailing Outsourcing Services in Minnesota, USA. We offer a wide range of Rebar Shop Drawings Services, including detailed plans and diagrams for rebar placement, splicing, and bending. Our CAD Rebar Detailing Services cover all aspects of rebar detailing, ensuring that every element of your structure is meticulously planned and executed. Our rebar structure steel detailing services provide detailed drawings and plans for integrating rebar with structural steel elements. This integration is essential for ensuring the overall strength and stability of the structure.

Contact us today to learn more about our Rebar Detailing Outsourcing Services and how we can support your project in Minnesota, USA. Our team is ready to assist you with all your rebar detailing requirements and help you achieve your project goals with precision and efficiency

. Visit us:https://www.cadoutsourcing.net/structural-steel-detailing/rebar-detailing.html

#Rebar Detailing Outsourcing Services#Outsource Rebar Detailing Drawings Services#CAD Rebar Detailing Services#Outsource Rebar Detailing Services#Rebar Shop Drawings Outsourcing Services#Rebar Shop Drawings Services#Rebar Fabrication Services#Rebar Framing Plan Design Services#Rebar Structure Steel Detailing Services#3D Rebar Detailing Services#London#UK#Rebar Detailing Services UK#Rebar Detailing Services London

0 notes

Text

"Expert BIM Rebar Contractors | Enhance Efficiency & Quality"

"Discover top BIM rebar contractors for streamlined construction projects.

Our specialists utilize Building Information Modeling (BIM) to ensure precision, efficiency, and superior quality.

Contact us today to transform your construction process!"

BIM Rebar contractors Services

0 notes

Text

#mechcivdesignersllp#structure steel detailing service#rebar2dand3dmodelingservice#Bar Bending Schedule

0 notes

Text

#apocalyptic#industrial ruins#dystopian#surreal#Asian children#futuristic decay#desolate landscape#tangled wires#steel structures#overcast sky#mountain backdrop#floral foreground#urban decay#mechanical wreckage#dramatic scenery#outdoor#detailed textures#ai#ai generated#ai generated images#ai image#rooftop#rooftop garden#slums#chamomile

1 note

·

View note

Text

Top UK Structural Engineering Firms: Leaders in Innovative Solutions

Explore the top structural engineering firms in the UK for cutting-edge solutions. Our expert teams deliver innovative designs and robust analyses for diverse projects nationwide. From skyscrapers to bridges, trust our industry-leading expertise for superior structural engineering services tailored to your needs and aspirations.

Visit Here: https://www.cadengineeringsolutions.co.uk/

#structural engineering company#architectural design solutions#structural engineer london#structural engineering for architects#top structural engineering firms uk#structural steel detailing services

0 notes

Text

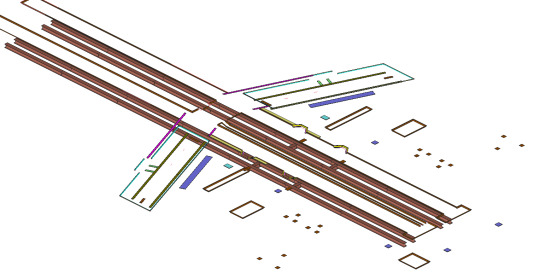

Steel shop drawings

When building and fabricating steel structures, steel shop drawings are essential. These comprehensive designs direct fabricators and contractors through the manufacturing process by giving them vital information. Shop drawings provide exact measurements, material specifications, welding details, and assembly instructions for everything from complex components to structural steel beams. Construction projects can attain increased precision, productivity, and economy by investing in expert steel shop drawings.

0 notes

Text

OLSON KUNDIG - CHARLES SMITH WINES

#OLSON KUNDIG#architecture#winery#blackened steel#gizmo#window details#adaptiveresue#brick#wood structure

0 notes

Text

Steel Detailing Insights: Turning Challenges into Opportunities

In the ever-evolving field of structural engineering, Structural steel detailing plays a crucial role in the successful execution of complex projects. It involves the creation of detailed drawings and specifications for the fabrication and erection of steel structures. As the industry faces new challenges and demands, turning these obstacles into opportunities is key to advancing the practice of structural steel design and structural detailing in steel. This article explores how embracing challenges in steel detailing can lead to innovative solutions and enhanced outcomes in construction projects.

The Essence of Structural Steel Detailing

Structural steel detailing is an intricate process that translates design concepts into actionable plans for steel fabrication and erection. It involves producing detailed drawings, specifications, and documents that guide the construction of steel structures, including buildings, bridges, and industrial facilities. Accurate detailing is essential for ensuring that steel components fit together correctly and meet structural requirements.

The role of a structural steel detailer is multifaceted, involving tasks such as:

Creating Detailed Drawings: These include plans, elevations, sections, and connections that provide clear instructions for fabricators and erectors.

Specifying Materials and Dimensions: Detailers specify the types of steel, sizes, and connections needed for each component.

Ensuring Compliance: Drawings and specifications must adhere to industry standards and building codes.

Despite its critical importance, structural steel detailing faces several challenges that can impact project outcomes. However, these challenges also present opportunities for innovation and improvement.

Common Challenges in Structural Steel Detailing

Complex Geometries and Designs: Modern architectural and engineering designs often involve complex geometries that can be challenging to detail accurately. Intricate shapes and unconventional structures require advanced detailing techniques to ensure that steel components are fabricated and assembled correctly.

Coordination with Other Disciplines: Effective structural steel design requires close coordination with other building systems, such as mechanical, electrical, and plumbing (MEP) systems. Misalignment between different disciplines can lead to conflicts and delays.

Managing Design Changes: Design changes during the project lifecycle can complicate the detailing process. Integrating modifications into existing drawings and specifications requires careful attention to avoid errors and ensure consistency.

Accuracy and Precision: Ensuring that all steel components are accurately detailed is crucial for avoiding fabrication and erection issues. Small discrepancies can lead to significant problems during construction, impacting project timelines and costs.

Compliance with Standards and Codes: Structural steel detailing must adhere to a range of industry standards and building codes. Keeping up with evolving regulations and ensuring compliance can be challenging.

Fabrication Tolerances: Managing fabrication tolerances and ensuring that detailed drawings align with the manufacturer’s capabilities is essential for successful project execution.

Turning Challenges into Opportunities

While these challenges can be daunting, they also provide opportunities for innovation and improvement in structural steel detailing. Here’s how the industry is turning these challenges into opportunities:

Leveraging Advanced Software: Modern detailing software and Building Information Modeling (BIM) tools offer advanced capabilities for managing complex geometries and designs. These tools enable detailers to create accurate 3D models, perform clash detection, and integrate various building systems, leading to more efficient and precise detailing.

Enhanced Collaboration and Coordination: Effective coordination between disciplines can be facilitated through collaborative platforms and BIM. These tools allow for real-time sharing of information and updates, helping to align structural steel detailing with other building systems and reducing the risk of conflicts.

Implementing Agile Processes: Adopting agile processes and flexible workflows can help manage design changes more effectively. By incorporating iterative reviews and updates into the detailing process, detailers can quickly adapt to changes and ensure that all modifications are accurately reflected in the drawings.

Investing in Training and Development: Continuous training and professional development are crucial for keeping up with industry advancements and evolving standards. Investing in skill development for detailers can improve accuracy, efficiency, and overall quality in structural steel detailing.

Utilizing Prefabrication and Modular Construction: Prefabrication and modular construction methods can help manage fabrication tolerances and streamline the construction process. By detailing components for prefabrication, detailers can ensure that they are manufactured to precise specifications and assembled efficiently on-site.

Embracing Automation and Robotics: Automation and robotics are transforming the steel fabrication process, offering opportunities for increased precision and efficiency. By integrating automated systems into the detailing process, detailers can enhance accuracy and reduce manual errors.

Focus on Sustainability: Sustainability is becoming an increasingly important consideration in structural steel design. Detailers can leverage sustainable practices, such as using recyclable materials and optimizing steel usage, to contribute to greener construction practices.

The Future of Structural Steel Detailing

As the construction industry continues to evolve, the role of structural steel detailing will become even more critical. Embracing challenges and turning them into opportunities will drive innovation and improve project outcomes. The integration of advanced technologies, enhanced collaboration, and a focus on sustainability will shape the future of steel detailing.

Detailers who adapt to these changes and leverage new tools and techniques will be better equipped to handle the complexities of modern construction projects. By turning challenges into opportunities, the industry can achieve greater accuracy, efficiency, and success in structural steel design and detailing.

Conclusion

Structural steel detailing is a fundamental aspect of construction that plays a vital role in translating design concepts into reality. While the field faces several challenges, these obstacles also present opportunities for innovation and improvement. By leveraging advanced technology, fostering collaboration, and focusing on continuous development, the industry can overcome these challenges and achieve excellence in structural steel design and structural detailing in steel. Embracing these opportunities will ensure that steel detailing remains at the forefront of the digital transformation in construction, driving success in future projects.

0 notes

Text

Successful Completion of Steel detailing Project-Adept engineering

Introduction

In the competitive field of structural engineering services, precision and adaptability are crucial for delivering successful projects. This case study by Adept Engineering, a leading steel structure detailing company in the USA, highlights a recent project involving miscellaneous steel components, including embed angles, embed plates, and leveling plates, totaling around 30 tons. The project centered on the basement structural steels for Airbus assembly stations, showcasing the team’s ability to overcome challenges and deliver exceptional results.

Project Scope and Initial Challenges

Adept Engineering, recognized among the best steel structure detailing companies in the USA, faced several challenges at the outset. The design drawings provided were in metric units, necessitating conversion to imperial units for modeling. Additionally, the team encountered missing coordination design drawings and discrepancies in angle lengths and assembly quantities. The initial scope of work was also not clearly defined, adding complexity to the project’s initiation.

Effective Communication and Issue Resolution

Approval Process and Strategic Modifications

After resolving initial issues, the team released the miscellaneous steels for client approval. However, during this phase, an alteration in the project numbering system and some unaddressed questions from the Engineer of Record (EOR) posed new challenges. The team quickly organized a Teams call to resolve these issues, demonstrating their commitment to maintaining project momentum.

Fabrication and Project Execution

Following the resolution of approval issues, Adept Engineering, a top steel structure detailing company, modified the model according to the customer’s requirements and released the miscellaneous steels for fabrication, specifically for Station 40. This phase was completed efficiently, reflecting the team’s dedication and adherence to the project timeline.

Expansion of Scope and Final Delivery

As the project progressed, additional tasks, including Station 41 steels and bone pit embeds, were incorporated into the scope of work. These tasks were executed promptly and without delay, further underscoring Adept Engineering’s reputation as one of the best steel structure detailing companies in the USA.

Conclusion

The successful completion of this miscellaneous steel project, despite numerous challenges, underscores Adept Engineering’s expertise in steel structure detailing and structural engineering services. The project not only met the client’s requirements but also set a high standard for future projects. This case study illustrates how meticulous planning, proactive communication, and strategic adaptability can lead to the successful delivery of complex engineering projects, solidifying Adept Engineering’s status as a leader in the industry.

#3d modeling#structural steel detailing services#connection design#steel fabricators#steel detailing services

1 note

·

View note

Text

Seattle’s First Choice for Structural Steel Detailing Services US AEC Industry

With a team of the United States' top structural steel detailers, Silicon Consultants LLC provides affordable and precise Structural Steel Detailing Services by utilizing the latest Steel Detailing software in the AEC Industry, creates precise 2D and 3D models, simulating structural behavior and optimizing design for optimal performance, and to ensure accurate and efficient fabrication-ready drawings and schedules. utilizes meticulous AutoCAD detailing strategies, including the accurate representation of complex structural forms and shapes through Parametric modeling, Topological modeling, and advanced meshing methods, to produce detailed technical drawings for fabrication. We incorporate Building Information Model (BIM) technology for enhanced teamwork and data organization and employ cutting-edge detailing approaches such as automated detailing with Tekla's Detailing module. The detailing process further encompasses comprehensive quality assurance measures to guarantee compliance with local building codes and regulations, precise fabrication tolerances, accurate assembly, precise installation, and detailed examination and simulation of the structure's performance under different loads using sophisticated industry tools.

Our Services

Steel Design and Drafting Services

Steel Structural Detailing Services

Joist Steel Detailing Services

Steel Fabrication Drawings Services

Erection Drawings Service

Steel Drawings Services

Structural 3D Modeling Services

We offer best-in-class, affordable BIM Structural Modeling Services that convert intricate BIM designs into accurate, smart 3D BIM Models for clients in the Architecture, Engineering, and Construction (AEC) Industry worldwide, in nations such as South Korea, Norway, Greece, Thailand, Brazil, Singapore, France, Czech Republic, Finland, Malaysia, Romania, Netherlands, Luxembourg, Australia, Taiwan, Argentina, Ireland, United Kingdom, Philippines, Poland, South Africa, Germany, Saudi Arabia, United States, Japan, Denmark, Spain, China, Bulgaria, Hungary, Slovakia, Estonia, Belgium, Italy, Latvia, Sweden, Vietnam, Qatar, Lithuania, Austria, Mexico, Kuwait, United Arab Emirates, etc.

For more details click on the link below

Check out our New Blog

#SteelDetailing#Structural Steel Detailing#Miscellaneous Steel Detailing#Tekla Detailing#Structural Detailing#AEC#USA#UK#Germany#France#Australia#Saudi Arabia#Qatar#Bahrain#Belgium

1 note

·

View note

Text

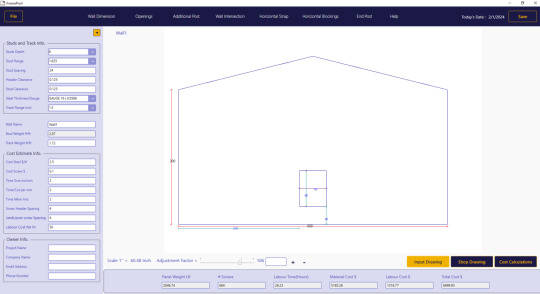

Make Use Of Light Gauge Steel Design Software Without Having 3D Modeling Skills

Did you know? Now you no longer need to have a thorough understanding of CAD design or acquire specialized 3D modeling abilities. With your basic knowledge of evaluating architectural dimensions and structural standards, you can easily enter your data into our light gauge steel design software program. After that, FrameProX instantly generates detailed shop drawings along with comprehensive cost calculation, for constructing the particular wall.

#light gauge steel design software#light gauge steel framing#3d modeling software construction#3d modeling software for buildings#3d steel detailing software#architecture 3d modeling software#building construction software#best steel detailing software#building structural analysis software

1 note

·

View note