#Steel Pipe Manufacturer in Texas

Explore tagged Tumblr posts

Text

High-Quality Steel Pipe Manufacturer in Texas - PipingProjects.us

One of the top Steel Pipe Manufacturer in Texas is Piping Projects.us. With ODs ranging from 12.7mm to 906mm and wall thicknesses up to 40mm, our seamless and welded pipes provide unparalleled versatility. Brass, copper, stainless steel (304/304L, 316L), Duplex, titanium, alloy 600, alloy 400, alloy 625, alloy 825, and alloy C276 are used to produce our steel pipes.

Being a reputable Steel Pipe Supplier in Texas, we provide precise pipes that meet your requirements. For durable, excellent steel pipes that work well in any project, you can rely on Pipingprojects.us.In order to keep our standing as Texas' leading steel pipe manufacturer, we are extending our services to new areas and pledging to provide premium steel pipes on schedule. If you're looking for premium steel pipes in Texas, go as far as our company.

Our expertise is in producing seamless and welded steel pipes in compliance with strict quality control procedures and guidelines that guarantee precise dimensional tolerances and a high degree of surface polish. We are a top global provider of carbon steel, alloy steel, and stainless steel pipe solutions and a Texas-based supplier. We also supply in many other cities, like Steel Pipe Manufacturer in California.

Product: Steel Pipe Manufacturers

Website: pipingprojects.us

#Steel Pipe Manufacturer in Texas#Steel Pipe Manufacturers#Steel Pipe Supplier in Texas#steel pipes in Texas#steel pipes

0 notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

16 - 17 October 2024, Houston, Texas USA

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#16 - 17 October 2024#Houston#Texas#USA#HEAT EXCHANGER WORLD AMERICAS - 2024#Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024#Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions#Duplex#Super Duplex#Nickel Alloy#and Exotic-Grade Material Tubes#Pipes#and U-Tubes.#Event Details:#•#Date: 16 – 17 October 2024#Venue: Houston#Booth Number: Stand 2110#Event Hours: 10:00 AM – 5:00 PM#Event Link: https://heat-exchanger-world-americas.com#KRYSTAL X HEAT EXCHANGER#2024#Manufacturer and Exporter of Seamless Stainless Steel#Nickel Alloy Tubes#Pipes & U Tubes.#At the trendsetting#ultimate networking event for the process industry#you will have an opportunity to connect with Krystal experts#tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics in#the latest decarbonization innovations

0 notes

Text

Best Quality Flanges Manufacturer in USA

Pipingprojects.us is an respected Flanges Manufacturer in USA. We produce and offer a wide variety of flanges, including lap joint, weld neck, orifice, slip-on, and more. We manufacture high-quality flanges using a range of materials. Nickel, molybdenum, and chromium are among the most common alloy steel flange materials. Chrome moly flanges are well known for their superior corrosion and oxidation resistance. We are one of the main Flange supplier in USA.

We are the top flange manufacturer. These flanges can be made by forging or casting. TThese components, available from renowned stainless steel flange manufacturers, are used to strengthen or connect beams and columns. When installing stainless steel pipe flanges, a certain flange type is necessary to provide a precise and secure fit and seamless integration into the piping system. We provide Flanges in a number of cities like Flanges Supplier in Texas, Flanges Supplier in California and Flanges Supplier in Florida.

#Flanges Manufacturer in USA#Flanges Supplier in USA#Flanges Manufacturer#Flanges Supplier in Texas#Flanges Supplier in California#Flanges Supplier in Florida

0 notes

Text

Choosing the Right Tubing Fittings for High-Pressure Applications

In high-pressure environments, selecting the right tubing fittings is essential to ensure the safety, reliability, and efficiency of your system. Tubing fittings are used to connect pipes and tubes, facilitating the smooth flow of fluids, gases, or steam under intense conditions. Whether you’re dealing with industrial machinery, chemical processing, or hydraulic systems, using high-quality tubing fittings can prevent leaks, maintain pressure, and extend the lifespan of your system. This guest blog will guide you through the factors to consider when choosing tubing fittings for high-pressure applications and the benefits of working with reliable suppliers in Texas.

Why the Right Tubing Fittings Matter in High-Pressure Applications

High-pressure systems demand tubing fittings that can withstand extreme pressure without compromising on performance or safety. Inadequate fittings can lead to leaks, reduced efficiency, or even catastrophic failure. Choosing fittings made from durable materials like stainless steel and selecting designs that meet the requirements of your application ensures that the system functions optimally.

In industries such as oil and gas, petrochemicals, and manufacturing, the importance of reliable stainless steel tube fittings in Texas cannot be overstated. These fittings are designed to withstand the corrosive environments and high pressures that are often found in these applications.

Key Factors to Consider When Choosing Tubing Fittings

Material Compatibility

The material of the fitting must be compatible with the tubing and the fluid or gas passing through the system. For high-pressure environments, stainless steel tube fittings in Texas are the preferred choice due to their corrosion resistance, strength, and durability. Stainless steel can endure the harsh conditions of high-pressure applications without deforming or corroding.

Pressure Rating

One of the most critical factors to consider is the pressure rating of the tubing fittings. The fittings must be able to handle the maximum pressure of the system without failing. Always choose fittings with a pressure rating that exceeds the operational pressure of your system to ensure safety.

Temperature Resistance

In high-pressure applications, the temperature of the fluid or gas can fluctuate significantly. Make sure the tubing fittings are designed to withstand extreme temperatures without losing integrity. Tubing fittings in Texas suppliers can provide fittings that are specifically engineered for both high-pressure and high-temperature environments.

Fitting Type

There are various types of tubing fittings, including compression, flare, and push-to-connect. Each fitting type has its own benefits, depending on the application. Compression fittings, for instance, offer excellent leak-tight connections and are commonly used in high-pressure systems. Steel tube connectors in Texas are another popular choice for their strength and ability to secure a robust connection in demanding conditions.

Size and Compatibility

Ensure that the tubing fittings you choose are compatible with the tubing size and diameter. Mismatched fittings can lead to poor connections, leaks, or even system failure. Consult with your tubing fittings in Texas supplier to find the right size and type for your application.

Ease of Installation and Maintenance

The ease of installation and maintenance is another factor to consider. Fittings that are difficult to install or maintain may increase downtime, which can be costly in high-pressure environments. Look for fittings that provide a secure, leak-proof connection and are easy to install, even in tight spaces.

Benefits of Working with Reliable Tubing Fittings Suppliers in Texas

High-Quality Products: Reputable suppliers provide fittings made from high-grade materials, ensuring durability and performance in high-pressure environments.

Expert Guidance: Experienced suppliers can help you select the right fittings based on your application’s pressure, temperature, and material requirements.

Customization: Some suppliers offer custom solutions to meet the unique needs of your system, ensuring the best fit for your high-pressure application.

Compliance with Industry Standards: Reliable suppliers provide fittings that comply with industry standards, ensuring safety and reliability in your operations.

Selecting the right tubing fittings for high-pressure applications is critical to ensuring the safety and efficiency of your system. By considering factors such as material compatibility, pressure rating, temperature resistance, and ease of installation, you can choose fittings that meet the demands of your specific application. Working with reputable tubing fittings in Texas suppliers, like Arek Solutions, can provide you with the guidance and high-quality products needed for optimal performance. Arek Solutions offers a wide range of steel tube connectors in Texas and stainless steel tube fittings in Texas designed to withstand the rigors of high-pressure environments. Learn more about their offerings at Arek Solutions.

0 notes

Text

Friedman Industries, Incorporated Announces Cash Dividend

LONGVIEW, Texas, June 26, 2024 (GLOBE NEWSWIRE) — The Board of Directors (the “Board”) of Friedman Industries, Incorporated, (NYSE American: FRD) a Texas-based company engaged in steel processing, pipe manufacturing, and steel and pipe distribution, declared on June 26, 2024, a cash dividend of $0.04 per share on the Common Stock of the Company. The Company will pay the cash dividend on August…

View On WordPress

0 notes

Text

Who are the Top Flange Manufacturers in Usa ?

In the elaborate world of business pipelines, endless components work collectively to make certain safe and efficient fluid glides. Among these vital elements are flange, the unsung heroes that join pipes, valves, and different devices. Arcellor Controls, a dependent on companion in industrial automation solutions arcellor manipulate ON Arcellor Controls, recognizes the importance of superb flanges. But with several producers in the USA, how do you identify the top contenders?

Flanges: The Cornerstones of Secure Connections

A flange is a ring-shaped steel element with holes drilled around its circumference. It is connected to the ends of pipes, valves, or other equipment the usage of bolts and gaskets to create a stable and leak-evidence connection. Flanges are an essential part of flange couplings, which might be assemblies that are a part of pipes or tubes together completely. Flanges are available in diverse sorts, each suited for precise applications and pressure requirements:

Weld Neck Flange: Considered the strongest and most flexible flange kind, proposing an extended neck that is welded to the pipe for top-quality strain dealing with. This is a famous choice for high-strain packages.

Slip-On Flange: A price-effective option that slips over the pipe quit and is welded at the backside for a good stress score. This is suitable for lower strain packages where ease of meeting is vital.

Threaded Flange: Ideal for low-stress applications wherein frequent disassembly is needed, providing internal threads that screw onto the pipe. This is a superb option for clean renovation.

Socket Weld Flange: Similar to a slip-on flange however with a smaller internal socket for welding, supplying right strength in smaller diameter pipes. This is a space-saving option for programs with confined rooms.

Blind Flange: A stable disc-formed flange used to seal off the stop of a pipeline. This is useful for separating sections of a pipeline for upkeep or destiny growth.

The Advantages of Using Flanges

Flanges offer several benefits in business piping structures:

Leak-Proof Connections: The combination of bolts and gaskets ensures a tight seal, stopping leaks and safeguarding towards environmental contamination.

Easy Assembly and Disassembly: Flanges permit for easy connection and disconnection of pipes and systems, facilitating preservation and repair techniques.

High-Pressure Rating: Different flange sorts are designed to resist various pressure degrees, accommodating diverse business programs. Flange selection is vital for the safe operation of flange couplings in excessive-strain structures.

Versatility: The extensive form of flange kinds and substances guarantees compatibility with various pipe sizes, pressures, and fluids. This permits flexibility in designing and constructing exclusive sections of a pipeline.

Top Flange Manufacturers in the USA

While a definitive rating can be subjective and rely on unique desires, a number of the top flange producers within the USA are renowned for their best, reliability, and numerous product services:

Shaw Stainless and Alloy: A main manufacturer of incredible flanges in diverse grades of stainless-steel, alloy metal, and carbon metallic.

Texas Flange: Specializes in a comprehensive range of ASME and non-code flanges, catering to numerous industries like petrochemical, system, and waterworks.

SWEP International AB: A global dealer of flanges and different piping components, recognized for his or her commitment to international requirements and nice management.

Conclusion

Flanges are the silent workhorses of business pipelines, the crucial components forming the inspiration of secure and reliable flange couplings. Understanding special flange types, their benefits, and legitimate manufacturers inside the USA empowers you to make knowledgeable selections on your specific wishes. When it comes to industrial automation solutions, Arcellor Controls is your one-prevent shop for tremendous flanges and different essential components. We associate with leading manufacturers to offer you with the excellent possible products in your commercial initiatives.

0 notes

Text

Friedman Industries Inc as of the shareholder record 2024-03-28 $FRD #FriedmanIndustriesIncasoftheshareholderrecord2024-03-28

Friedman Industries, Incorporated Increases Cash Dividend for 207th Consecutive Quarter LONGVIEW, Texas, March 21, 2024 - Friedman Industries, Incorporated (NYSE-American: FRD), a Texas-based company engaged in pipe manufacturing, steel processing, and steel and pipe distribution, announced on March 20, 2024, that the Board of Directors has declared a cash dividend of $0.04 per share on the Common Stock of the Company. This marks the 207th consecutive quarterly cash dividend for the company. The decision to increase the cash dividend reflects Friedman Industries* commitment to rewarding its shareholders and distributing profits. The steady quarterly dividends showcase the company*s strong financial performance over the years. https://csimarket.com/stocks/FRD-Dividend-Comparisons.html?utm_source=dlvr.it&utm_medium=tumblr

0 notes

Text

Everything About Compression Tube Fittings

Safe and leak-free tubing connections are crucial in the fluid systems industry. Compression tube fittings are crucial components that strongly join pipes or tubes without the need for intricate welding or soldering. They are invaluable in various industries, including plumbing, automotive, hydraulic, pneumatic, and aerospace applications, due to their unique form, simplicity of installation, and capacity to prevent leaks. They are affordable options that guarantee consistent and effective fluid transfer in various applications due to their simplicity of installation and reusability. Below, you can see the compression tube fittings:

What are compression tube fittings?

Compression tube fittings are designed to form a waterproof barrier between two distinct lines by compressing one of the fitting's components into another, usually tubing. With the introduction of quick-connect type fittings, compression fittings have become less common in the water treatment sector, and yet, compression fittings are still great, withstand high pressure, and offer a consistent, tight seal. A compression fitting is made up of three components such as the fitting body itself, a nut, and a sleeve.

You may see a variety of materials available when purchasing compression tube fittings Texas. Brass is the most popular material for compression fittings and however, you need to ensure that the fittings are lead-free because using lead-containing fittings is prohibited. They are often composed of plastic and stainless steel. The material of your fitting will determine how much pressure or temperature it can withstand.

How do tube compression fittings work?

In a hydraulic or pneumatic system, two tubing sections are connected using tube compression fittings. When the nut is tightened after the tube has been placed into the fitting, the tube is compressed, and a secure connection is made. Additionally, they work effectively in applications where a prompt separation is required. Stainless steel compression fittings offer a dependable, leak-proof connection that can tolerate high pressure when placed correctly.

Components of compression tube fittings

Typically, compression tube fittings are made up of multiple parts:

Ferrule

The ferrule, which fits over the end of the tube, is a tiny, cylindrical component referred to as the compression ring or olive. The ferrule creates a tight seal by compressing against the fitting's body to stop fluid leaks.

Nut

A secure connection is made by compressing the ferrule onto the tube by threading the nut into the fitting's body and tightening it. To buy stainless steel compression fittings Texas, choose the best manufacturers.

Insert

An insert or compression sleeve may be used in certain fittings to give the tubing more support and reinforcement, particularly in situations involving softer materials or bigger tube diameters.

Ferrule

When compressed against the body of the fitting, the ferrule forms a tight seal, preventing fluid leakage. To buy the tubing fittings Texas, choose a high-quality shop.

Thus, the above details are about the compression tube fittings. Visit Arek Solutions if you are looking to buy stainless steel tube fittings Texas. They provide premium products that satisfy your specific needs because they consider quality as the foundation of their business.

0 notes

Text

Flanges Forecast to 2031 with Key Companies Profile, Supply, Demand and SWOT Analysis

Flanges Market Research, 2031

The global flanges market size was valued at $4.50 billion in 2021, and is projected to reach $7.39 billion by 2031, growing at a CAGR of 5% from 2022 to 2031. Flange is a protruding ridge/rim that is used to improve strength or distribute load. Flanges are used to connect valves, pumps, pipes & other equipment to form a piping system. It also allows for simple washing, inspection, and alteration. Flanges are welded or screwed together. Flanged joints are created by bolting two Flanges together and placing a gasket between them to form a seal.

The development of control technology in the flanges provides monitoring of the fluids that helps in reducing the energy consumption along with wastage of fluids. In addition, the oil & gas industry is the largest consumer of the flanges globally. The energy sector in North American countries such as U.S. and Canada is largely privately operated, financed, and owned. Owing to this, the investment over the development of oil & gas sector has grown, which boosts the demand of flanges in order to connect the components of equipment. Moreover, the demand for food from developing countries such as India, Brazil and others have boosted the agriculture industry. This led to establishment of new food & beverage processing units in the country. The food & beverage processing industry is the largest consumer of the flanges. This in turn has driven flanges market growth.

However, different countries such as the U.S. has increased the tariffs on steel and aluminum imports that has affected the manufacturing sector of the country. Thus, this led to cause a hike over the price of the raw materials from which flanges are made, thereby, restraining the flanges market share.

Furthermore, during the outbreak of the COVID-19 pandemic, construction, manufacturing, hotel, and tourism industries were majorly affected. Manufacturing activities were halted or restricted. Construction and transportation activities, along with their supply chains, were hampered on a global level. This led to decline in manufacturing of various construction materials as well as their demand in the market, thereby restraining the growth of the flanges market. Conversely, industries are gradually resuming their regular manufacturing and services. This is expected to lead to re-initiation of flanges companies at their full-scale capacities, that helped the market to recover by end of 2021.

On the contrary, addition of new technologies, such as fluid monitoring technology along with the further R&D for the development of new technologies for flanges that help in finding out new processes while inserting the flanges in order to reduce the amount of time, which is expected to offer new flanges market outlook.

COMPETITION ANALYSIS

The major players profiled in the global flanges market include, AFG Holdings, Inc., Coastal Flange, Inc., Flanschenwerk Bebitz GmbH, General Flange & Forge LLC, Hitachi, Kerkau Manufacturing, Kohler Corporation, Mass Global Group, METALFAR Prodotti Industriali S.P.A., Outokumpu Armetal Stainless Pipe Co. Ltd (OASP), Pro-Flange, Qontrol Devices, Inc., Saini Flange (p) ltd., Sandvik AB, Simtech Process Systems, SSI Technologies, Inc. and Texas Flange. Major companies in the market have adopted product launch, partnership, business expansion, and acquisition as their key developmental strategies to offer better products and services to customers in the market.

Full Report With TOC:-https://www.alliedmarketresearch.com/flanges-market-A10713

0 notes

Text

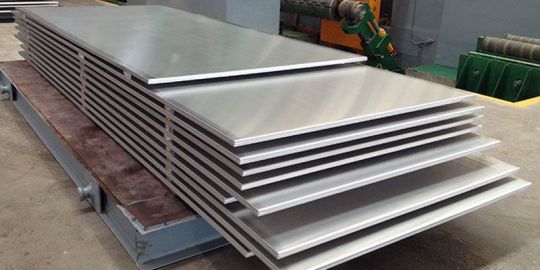

The Lifeline of Industrial Sector: Unveiling the Secrets of Steel Plate Manufacturing

Piping Projects is one of the most trusted Steel Plate Manufacturers in USA. Steel plates function efficiently in various environments and have good corrosion resistance. The most skilled workers are hard at work, ensuring that all quality standards satisfy the customer's demands. In addition to producing the best-quality steel plates, we are an official Jindal and ISMT dealer for providing carbon and alloy steel plates.

Steel Plate Manufacturers metal plates using steel that can be formed into more intricate products through cutting and fabrication. Steel plates come in a range of thicknesses and may be made to any desired width or length. The alloy steel plate acquires particular constraints and qualities by adding these components. Also, We lead Welding Electrode Manufacturers in USA.

We are also a market-leading provider of carbon steel, alloy steel, and Stainless Steel Plate with ASME Quality and ISO 9001:2015 Certifications. The AS plate is alloyed with 1% to 50% elements. Steel Plates production is necessary for a structure to be dependable and long-lasting. Because of their extreme robustness and durability, these plates are crucial for manufacturing, shipbuilding, and construction. Also, Check Our Steel Plate Weight Chart

The Significance of Steel Plate Manufacturing

The production of steel plates is essential to many different sectors. Its importance is seen in some ways:

Infrastructure Development: Steel Plate Suppliers, which are frequently used in the construction of buildings, bridges, and roads, provide the framework for the development of infrastructure. Steel plates' durability and adaptability guarantee the lifetime and safety of these kinds of constructions.

Automotive Industry: The transportation sector uses steel plates extensively because they give transport structure and body parts the strength and crash resistance they need. Steel plates' low weight and strength combination helps improve passenger safety and fuel economy.

Shipbuilding: Steel plates are a significant component of ships built in the marine industry. Because of their superior structural integrity and immunity to corrosion, these plates are perfect for withstanding opposing marine conditions and preserving sailors' safety.

Energy Sector: In the energy industry, steel plates are crucial, especially for offshore oil rigs, pipelines, and power plants. Their great tensile strength and tolerance to high temperatures and pressure make energy production efficient and dependable.

Cities We Supply Steel Plate

Steel Plate Manufacturer in Texas

These plates are thicker than foils but thinner than ordinary steel plates. Stainless steel plates are widely known for their strong resistance to corrosion and work very well in various challenging conditions. Texas's top steel plate supplier, PipingProjects.us, offers premium plates for various commercial and construction applications.

Steel Plate Manufacturer in California

Our experts are dedicated to maintaining the highest quality standards, making us a leading Steel Plate Supplier in California. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. The welding process used to join these plates is standard.

Steel Plate Manufacturer in Florida

We produce seamless and welded steel plates under stringent quality control guidelines and standards that provide good surface and near-dimensional tolerances. We are a market-leading Steel Plate Manufacturer in Florida, offering solutions on a worldwide scale, with ASME Quality and ISO 9001:2015 Certifications.

Steel Plate Manufacturer in New York

As among the best Steel Plate Suppliers in New York, we have experienced staff members dedicated to maintaining the best calibre requirements. The components in the steel plates are carefully alloyed, ranging from 1% to 50%. The alloy steel plate gains distinct qualities and tolerances from adding various components. These plates are welded using standard welding techniques.

Common Uses For Stainless Steel Plate

The planning and constructing a building's external features, such as the exterior, roof, railings, doors, and windows, is called architecture.

Equipment for meal preparation, sinks, and appliances are all part of the food service setup.

Oil and gas, chemical processing, medical, and shipping equipment.

Application, Energy Management, and Manufacturing Automation.

Producing steel plates is a multi-step, specialised procedure to provide high-quality plates appropriate for various industrial uses. Identifying the best raw materials determines the quality of Steel Plate Supplier in USA. Based on the intended use, manufacturers carefully evaluate strength, durability, and corrosion resistance when selecting the steel alloy.

To Know More, Visit us,

Product: Steel Plate Manufacturers USA

Website: pipingprojects.us

#Steel Plate Manufacturers in USA#Steel Plate Manufacturers#Welding Electrode Manufacturers in USA#Stainless Steel Plate#Steel Plate Weight Chart#Steel Plate Suppliers#Steel Plate Manufacturer in Texas#Steel Plate Manufacturer in California#Steel Plate Manufacturer in Florida#Steel Plate Manufacturer in New York#Steel Plate Supplier in USA

0 notes

Text

KRYSTAL GLOBAL ENGINEERING LIMITED AT HEAT EXCHANGER WORLD AMERICAS - 2024

HEAT EXCHANGER WORLD AMERICAS - 2024

Krystal Global Engineering Limited at HEAT EXCHANGER WORLD AMERICAS - 2024

Welcome to Krystal Global Engineering Limited’s official event page for Heat Exchanger World Americas 2024! Discover our leading solutions in high-performance Stainless Steel, Duplex, Super Duplex, Nickel Alloy, and Exotic-Grade Material Tubes, Pipes, and U-Tubes.

Event Details:

Date: 16 – 17 October 2024

Venue: Houston, Texas, USA

Booth Number: Stand 2110

Event Hours: 10:00 AM – 5:00 PM

Event Link: https://heat-exchanger-world-americas.com

KRYSTAL X HEAT EXCHANGER

2024

Manufacturer and Exporter of Seamless Stainless Steel, Duplex, Super Duplex, Nickel Alloy Tubes, Pipes & U Tubes.

At the trendsetting, ultimate networking event for the process industry, you will have an opportunity to connect with Krystal experts, tune into our thought-provoking presentations on an hourly basis and experience our virtual reality training demo live. Highlight topics include the path beyond blue to green hydrogen, the latest decarbonization innovations, advances in electrolyser technologies with ITM Power and the role of services in future-proofing your plant.

About Krystal Global Engineering Limited:

Krystal Global Engineering Limited is your premier destination for top-quality tubes and pipes, serving industries worldwide including petrochemical, oil and gas, chemical processing, and power generation. We prioritize excellence and innovation, delivering superior products tailored to global standards.

What to Expect:

Extensive Product Showcase: Explore our comprehensive range of high-performance tubes, pipes, and U-tubes designed to endure extreme temperatures, corrosive environments, and high-pressure conditions.

Expert Consultation: Meet our team of industry specialists available to discuss your specific needs and provide tailored solutions.

Networking Opportunities: Connect with professionals, engineers, and industry leaders to exchange ideas, insights, and business opportunities.

Live Demonstrations: Witness live demonstrations highlighting the durability, reliability, and performance of our products in real-world applications.

Why Visit Us?

Quality Assurance: Our products undergo stringent quality control measures, ensuring compliance with international standards and specifications.

Customization: Benefit from our flexible manufacturing capabilities, allowing for customized solutions to meet your unique project requirements.

Global Reach: With a vast network of distributors and partners, we offer prompt delivery and comprehensive support worldwide.

Innovation: Stay ahead with our continuous investment in research and development, delivering cutting-edge solutions to address evolving industry challenges.

#heat exchanger#exhibition 2024#krystalgeltd#Krystal Global Engineering Limited#steels#tubes#pipes#metals#mining#worldwide 2024#bright annealed tubes#buy seamless tubes and pipes#capillary tubes#heat exchanger tubes manufacturers#inconel alloy#instrumentation tubes#seamless tube suppliers#seamless heat exchanger tubes#hydraulic tube manufacturer#manufacturer of instrumentation tubes

0 notes

Text

Flanges: Types, Applications, and Advantages

Pipingprojects.us is an independent Flanges Manufacturer in USA. We manufacture and sell a broad range of flanges, such as lap joint, weld neck, orifice, slip-on, and more. We create high-quality flanges from a variety of materials. Nickel, molybdenum, and chromium are some of the most prevalent alloy steel flange materials. Chrome moly flanges are widely recognized for their high corrosion and oxidation resistance. We are one of the major Flange supplier in USA.

What is a Flange?

A flange is a mechanical component that connects two pieces of equipment or pipe sections. It provides strength and allows for easy maintenance, inspection, and repair. Flanges are commonly found in industries such as oil and gas, water treatment, chemical plants, and power generation.

The basic structure of a flange includes a circular or rectangular plate with holes around its perimeter. These holes are designed for bolts, which help fasten the flange to another piece of equipment or pipe. The sealed connection often uses a gasket to prevent leaks under pressure.

Types of Flanges

There are various types of flanges, each designed to cater to specific requirements and working conditions. Below are the most common types:

Slip-On Flanges

These are the most popular and cost-effective flanges. They slip over the pipe end and are welded in place, ensuring a secure connection.

Applications: Water lines, low-pressure systems.

Weld Neck Flanges

Recognized for their long tapered neck, weld neck flanges are ideal for high-pressure systems. The neck provides reinforcement and reduces stress concentration at the base.

Applications: Oil refineries, chemical industries.

Blind Flanges

These flanges close the ends of piping systems, preventing flow. Blind flanges are essential for isolating systems or performing maintenance.

Applications: End of pipelines, testing pressure points.

Socket Weld Flanges

Designed for small-diameter pipes, socket weld flanges provide strong connections using fillet welds.

Applications: High-pressure and non-corrosive environments.

Threaded Flanges

These flanges have internal threads and are suitable for pipes with matching external threads. Threaded flanges require no welding, making installation easier.

Applications: Low-pressure systems, non-critical connections.

Lap Joint Flanges

These flanges are used with stub-end fittings and are ideal for systems requiring frequent dismantling.

Applications: Systems prone to corrosion, where cost savings on materials are essential.

Orifice Flanges

Designed to measure the flow rate of fluids in pipelines, orifice flanges come with orifice plates and pressure taps.

Applications: Flow metering systems.

We are Flanges Supplier In:

Flanges Supplier in Texas

Flanges Supplier in California

Flanges Supplier in Florida

Flanges Supplier in New York

Flanges Supplier in Los Angeles

Applications of Flanges

Flanges are indispensable in modern industries for their versatility and ease of use. Some prominent applications include:

Oil and Gas Industry: Flanges connect pipelines that transport crude oil, natural gas, and refined products across vast distances.

Water and Wastewater Management: Flanges secure pipes and valves in water treatment facilities, ensuring leak-proof connections.

Chemical and Petrochemical Plants: Corrosion-resistant flanges handle harsh chemicals under high pressure and temperature conditions.

Power Generation: Flanges are critical for maintaining steam flow and fluid systems in thermal, nuclear, and renewable energy plants.

HVAC Systems: Flanges ensure air ducts and piping systems are properly joined for efficient climate control.

Benefits of Using Flanges

Flanges provide numerous benefits that make them an indispensable part of piping systems:

Ease of Installation and Maintenance

Flanges allow easy dismantling for cleaning, repairs, and inspections.

Leak-Proof Connections

With the use of gaskets, flanges ensure tight, leak-resistant seals under pressure.

Versatility

Available in various materials (e.g., carbon steel, stainless steel, and alloy), flanges can withstand extreme environments and working conditions.

Structural Strength

Welded and bolted flanges add strength and durability to pipelines, preventing failures under load.

Customization

Flanges can be customized to specific standards (e.g., ASME, ANSI, DIN) and sizes to meet unique project requirements.

Flanges Manufacturer In USA

We are the leading flange manufacturer. These flanges can be made by forging or casting. These components, available from reputable stainless steel flange manufacturers, are used to reinforce or connect beams and columns. When installing stainless steel pipe flanges, a certain flange type is required to provide a precise and secure fit and seamless integration into the piping system.

#Flanges Manufacturer in USA#Flanges Supplier in USA#Flanges Manufacturer#Flanges Supplier in Texas#Flanges Supplier in California#Flanges Supplier in Florida

0 notes

Text

How to Eradicate Rodent and Termite in Residential Areas - iPestpros

Eradicating rodents and termites in residential areas can be a difficult one, As these are the common pests, they can live in any situation. So, we can look back few tips that can be taken to minimize or eliminate their presence completely:

Find a Source: The primary step is to identify the source of the rodent or termite invasion. Look at signs of damage, urination, droppings, gnaw marks, and tracks. This will help you assess where to focus your efforts.

Seal off Entry Points: Rodents and termites can enter through small openings in the home's foundation, walls, and roof. Seal any gaps and cracks with caulk, expanding foam, or steel wool to prevent entry.

Remove food items and water sources: Rodents and termites attract food and water sources, such as open garbage cans, pet food left outside, and standing water around the building. Ensure confirm food and garbage in sealed containers or boxes, and fix any leaks or standing water sources.

Utilize Rodent traps: Use traps which is an effective way to capture rodents without using poison, which can be dangerous to pets and children. Using Live traps to capture and release rodents away from the house, snap traps can be used to kill them quickly.

Install bait stations: Bait stations are an effective way to destroy termites. It contains a slow-acting poison that the termites come back to their colony, finally killing them all. And It is a very must thing to follow the manufacturer's instructions carefully while using bait stations.

Home-based tips for Termite Control:

Remove unwanted wood debris and cellulose things: Termites feed on cellulose material, such as wood, cardboard, paper, and other wooden things. Remove any wood debris or cellulose material near your home to make it less attractive to termites.

Fixing leakages and moisture problems: Termites are attracted to moisture, so If we will fix any leaks and moisture issues around your home can help prevent them from entering. Repair any leaky pipes or faucets, and ensure that there is proper ventilation in areas such as the attic and crawl space.

Take assistance from Pest control professionals: If you are facing a severe infestation, it would be better to hire a professional pest control company or service to eradicate rodents or termites without infections. Because they have the expertise and equipment necessary to locate and eliminate the infestation

Dont hesitate to contact iPestpros pest control company, offering a wide range of pest control and solutions to various pests Termites, Bedbugs, Mosquitoes, Ticks, Rodents, and Wildlife animals, services are available in San Antonio, Austin, and Waco Texas.

0 notes

Text

There are a few notable exceptions

As occurred in PVC siding and windows a decade ago, fence profiles are now seeing explosive growth and rapid plant expansions, including conversions of entire plants from pipe, siding, and other construction profiles. While demand for all types of fencing typically grows 5-7% a year, the PVC sector has been surging ahead by 20-30% annually, and this year’s growth could hit 50%, according to David Lawrence of Outdoor Advantage in Snohomish, Wash. “The only China wholesale plastic barrier mesh limiting factor may be the shortage of PVC,” adds the president of this two-year-old start-up, which operates PVC fence-profile plants in Florida and Texas. Unlike windows and siding, fence makers such as temporary fence,wire mesh,fence manufacturers,steel fence post,wire fence,portable fence face few hurdles in the form of building codes or ASTM standards.

There are a few notable exceptions. Acoustical fence must meet stringent performance tests. Pool fences and deck rails have to withstand specified lateral loadings. Ranch fence needs to be robust enough to keep horses in. And any fence in Dade County, Fla., must stand up to 120-mph hurricanes. But otherwise, fence requirements are mostly aesthetic, which has helped PVC profiles to become a mainstream product in just a few years. Forty-six percent of the current PVC fence market is in residential fencing, 36% in ranch (post and rail), 12% in encapsulated-metal railings, 4% in decking, and 2% in lawn and garden. “Fences are at critical mass now, where a lot of processors are doing well and expanding rapidly,” says Harlan Doering, v.p. of Kansas American Tooling, McPherson, Kan., a maker of dies and calibrators for fence profiles. From a standing start in the early 1980s, PVC fence sales grew to about $350 million last year, industry sources say. “The larger market of wood fences is $2 billion a year, so there’s still a lot of replacement potential out there,” says the sales director of one big vinyl fence company.

In the past year alone, Krauss-Maffei Corp., Florence, Ky., says it has delivered 16 conical twin-screw extrusion lines to three PVC fence processors, all of which are running dual strands for maximum output. “Usually with that kind of growth, you’d expect the product to be cheaper than the alternative, but PVC fences are more expensive,” says Michael Riese, product manager at Lawrence McCoy in Worcester, Mass., a distributor of vinyl, wood, and aluminum fences. Even a 10-15% price increase early this year hasn’t dampened sales, he notes. What triggered this year’s explosive growth is sudden, broad customer acceptance of PVC fences, especially among smaller contractors and buildings-supply houses. They offer PVC as a high-end choice to customers.

0 notes

Link

CASTINGS

We provide cast iron, white cast iron, wear resistance, SG iron, Stainless Steel, Alloy steel, High alloy steel, Heat resistance steel, High chrome steel casting for various industries. Our engineers have a combined experience of more than 25 years. We manufacture castings by No bake Molding and Co2 Process depending on the requirements of the customer and job; with the capacity to manufacture 2400 MT of casting per annum. Anaya Enterprises is the best company for steel casting in Canada, Sand mould casting in Canada, metal casting in Canada & USA, Ontario, Quebec, Toronto, Ottawa, Newyork, California, Texas, Pennsylvania, Ohio

SAND MOULD CASTING

We have been servicing customers spread out in various industries. Our products are widely used in Oil & Gas, Pharma, Tractors, Agricultural Diesel Engine, Heavy Earth Moving, Insulators, Compressors, Pipe Fittings, Valves, Pumps, Cranes, Gears, Textile Machinery, Marine, Railway and other Engineering Sectors.

1 note

·

View note

Text

An Indepth Guide to Compression Tube Fittings

Compression tube fittings emerge as unsung heroes in the complicated network of fluid systems, orchestrating smooth couplings with no fuss or fanfare. These subtle parts, consisting of a body, ferrule, and nut combination, can resist leaks and guarantee fluid containment.

They provide safe seals in the industrial, HVAC, and plumbing sectors due to their adaptability to various materials and industries. Compression tube fittings are essential components that silently maintain the fluid world in different industrial and residential settings. They are simple to install with tubing fittings Texas and robust against pressures and vibrations.

Compression Tube Fittings Explained

Compression tube fittings create leak-proof joints in fluid systems without welding. They are composed of a body, a ferrule, and a nut. The ferrule is compressed onto tubing and pressed against the fit body. These fittings can be used to join various materials and are simple to remove for reuse. They are widely used in industrial, HVAC, and plumbing applications and are vibration-resistant and pressure-tolerant. They play a crucial role in creating safe and effective connections in fluid systems, and proper installation, upkeep, and frequent inspections guarantee their dependability. You can get the assistance of compression tube fittings in Texas to make the installation process easier.

The Advantages of Compression Tube Fittings

Compression tube fittings offer flexible, leak-proof couplings without the need for welding or soldering. Their flexibility to be easily disassembled and reassembled for reuse across various materials, including plastic, stainless steel, and copper, makes them perfect for maintenance or temporary setups.

These fittings are widely used in different sectors because of their strong pressure and vibration resistance. Their easy installation without heat application and seal integrity further highlights their advantages. Compression tube fittings are indispensable in fluid-based applications throughout sectors, offering variety, dependability, and ease of use. They are a dependable option for fluid systems.

Installation Guidelines and Best Practices

Ensuring the tubing ends are square-cut and deburred prior to assembly is a necessary step in correctly installing compression tube fittings. Use a wrench to tighten the nut after hand-tightening it onto the fitting.

A leak could result from overtightening, which could harm the components. After installation, check the integrity of the seal with a pressure test. Compression tube fitting performance in fluid systems is maximized by adhering to these best practices, and a safe and leak-proof connection is guaranteed.

Applications in Various Industries

Plumbing, HVAC, manufacturing, and the automotive industries are just a few of the many industries that use compression tube fittings extensively. These fittings are essential for instruments, hydraulic systems, pneumatic applications, and gas and water supply.

Their resistance to leaks makes them perfect for home plumbing systems, but their adaptability in connecting different tubing materials makes them suitable for industrial machinery.

Their broad application in various contexts results from their adaptability to various fluids, pressure ranges, and conditions, highlighting their significance as dependable connectors in fluid systems in both industrial and domestic domains. The oil and gas and chemical processing industries are just two of the many uses for stainless steel tube fittings Texas.

Bottom Line:

Compression tube fittings provide a dependable, adaptable, and leak-resistant solution for fluid system connections in various sectors. To have a safe and secured pipe fitting, you can opt for tube fittings suppliers from Arek Solutions.

0 notes