#Stainless Steel Wire Mesh Manufacturer in India

Explore tagged Tumblr posts

Text

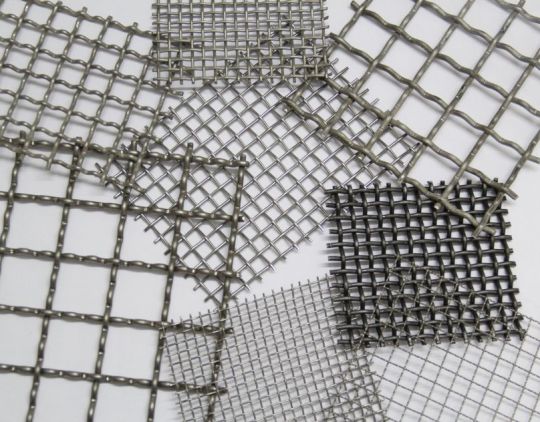

Stainless Steel Wire Mesh Manufacturer in India - Bhansali Wire Mesh

Bhansali Wire Mesh is one of the leading Stainless Steel Wire Mesh Manufacturers in India. SS Wire Mesh Manufacturers in India have established themselves as key players in the global wire industry. We are commonly considered as industry experts and consistently meet the needs and requests of our clients for all types of wire mesh.

Because of its corrosion resistance and strength, stainless steel wire mesh is a popular choice for many industrial and commercial applications. Stainless Steel Wire Mesh Suppliers in India work with various manufacturers to ensure that they have a vast inventory of wires available for immediate delivery to their customers.

Bhansali Wire Mesh is one of the leading SS Wire Mesh Manufacturers in Saudi Arabia. In order to help our clients' work be simpler and more effective, we provide the highest quality goods at a fair price. It is also among the top exporters of steel wire mesh, concentrating on top-notch goods.

We are also a SS Wire Mesh in such countries:

SS Wire Mesh Manufacturers in Oman

SS Wire Mesh Manufacturers in Kuwait

SS Wire Mesh Manufacturers in Iran

SS Wire Mesh Manufacturers in Qatar

SS Wire Mesh Manufacturers in Uae

For More Detail

Website: bhansaliwiremesh.com

Product: Stainless Steel Wire Mesh Manufacturer in India

Other Product: Double Crimped Wire Mesh Manufacturer in India

#Stainless Steel Wire Mesh Manufacturer in India#Stainless Steel Wire Mesh Manufacturer#Stainless Steel Wire Mesh

0 notes

Text

best stainless steel wire mesh manufacturer in India- meshtech (India)

0 notes

Photo

"Stainless Steel Wires."

304 wires is the most widely used stainless steel, and like 302, it has good mechanical properties and corrosion resistance. This alloy can withstand attack in a range of corrosive media, and its durability makes it easy to sanitise, meaning it is ideal for kitchen and food applications. SS 309/309L Wires , which is associated in nursing solid solution heat resistant alloy with wonderful resistance to oxidation underneath gently cyclic conditions through 2000 Degree F. Stainless Steel 309/309L Wires is quickly fancied by commonplace industrial procedures compared to steel, unsullied steels are harder and have a tendency to figure harden speedily. Bhansali Enterprise is a well-known distributor and stockiest of Stainless Steel 316 Wires , which is essentially a standard carbon 316 type with titanium stabilization. It is similar in principle to the titanium stabilization of the 304. Grade 316 Wires is a titanium-stabilized version of Type 316 molybdenum-bearing austenitic stainless steel. This Stainless Steel 321 Wires must be absolutely clean and free from all oil, paint, grease, and shop soil when charged into the furnace. The furnace atmosphere for forging or open annealing in our Stainless Steel 321 Wire should be slightly reducing, containing at least 2 % of carbon monoxide.

#stainless steel wire#stainless steel wire mesh#stainless steel wire manufacturers in india#stainless steel 304#wire manufacturers#stainless steel 201 cu wire manufactures in mumbai#steel companies of india#steel industries in india#steel price today per kg#top steel company in india#steel manufacturer#steel manufacturers in india#steel distributor#polished stainless steel#stainless steel manufacturers in india#stainless steel mesh wire

0 notes

Text

Welded Wire Mesh Supplier in Rajasthan

Meghmani Metal is a prominent Manufacturer, and Supplier of Welded Wire Mesh in Rajasthan, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. Meghmani Metal supplies high-quality welded wire mesh, trusted for a wide range of industrial, commercial, and residential applications. We make our welded wire mesh from high-tensile steel wire welded at every intersection, ensuring exceptional strength, durability, and uniformity. People widely use it in construction, fencing, reinforcement, and other applications where strength and security are paramount. Types of Welded Wire Mesh: Stainless Steel Welded Wire Galvanized Welded Wire Mesh PVC Coated Welded Wire Mild Steel Welded Wire Mesh Heavy-Duty Welded Wire Mesh Features: Offers excellent load-bearing capacity, making it ideal for reinforcement and fencing. Uniformly spaced intersections ensure consistent strength across the entire sheet. Galvanized or PVC coatings provide enhanced protection against rust and environmental wear. Resistant to deformation, ensuring long-lasting performance in both indoor and outdoor settings. Available in various sizes, coatings, and wire gauges to meet diverse needs. Made from recyclable materials, supporting sustainable practices in construction and manufacturing. Applications: Construction Industry Fencing & Security Agriculture & Animal Enclosures Industrial & Manufacturing Infrastructure Development Architectural & Decorative Use FAQS: Can welded wire mesh be customized? We can customize welded wire mesh in terms of size, wire gauge, coating, and mesh opening to meet your project’s specific needs. How durable is welded wire mesh? Welded wire mesh is highly durable, especially when galvanized or PVC-coated, offering long-term performance even in harsh environmental conditions. Meghmani Metal is Welded Wire Mesh Supplier in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

Trusted Wire Mesh Exporter – Fine Perforators Offering Superior Mesh Solutions

Fine Perforators is a trusted wire mesh exporter in India, providing an extensive range of high-quality wire mesh solutions for industrial, commercial, and decorative applications. Our wire meshes, manufactured from premium stainless steel, galvanized steel, brass, and copper, offer exceptional durability, strength, and versatility. Serving sectors like filtration, construction, mining, and food processing, we deliver customized mesh products designed to meet the highest industry standards. With decades of experience and advanced production techniques, Fine Perforators ensures reliable service, precision engineering, and competitive pricing.

0 notes

Text

Best Fin Tube Suppliers in India

Timex Metals is one of India's largest fin tube suppliers. We provide high-quality stainless steel fin tubes to a variety of industries worldwide. Fin Tube Manufacturer in India ensures that they understand their customers' needs in order to produce high-quality products that match industry standards.

Our business is among India's biggest producers and suppliers of fin tubes. At our unique manufacturing plant, we create and manufacture Fin Tubes of the highest quality in a variety of sizes and grades. Our brand is well-known worldwide, and people

all over the world are very intrigued in our high-quality fin tubes. Fin Tube Supplier in India is highly competitive and dynamic with quality and customer satisfaction.

We create Fin Tube using precision and cutting-edge equipment. New technologically advanced production equipment assists us in processing and producing the greatest quality Fin Tube. We are also a wire mesh manufacturers in India.

For More Details:

Website: timexmetals.com

Product: Fin Tube Manufacturers

Other Product: Electropolished Pipe Manufacturers in India.

0 notes

Text

Stone Gabions Manufacturer in India

Stone gabions are revolutionizing modern construction and landscaping with their unique combination of functionality and aesthetic appeal. As a leading stone gabions manufacturer in India, Gurukrupa provides high-quality gabion solutions that are durable, versatile, and eco-friendly. Whether for infrastructure projects, landscaping, or erosion control, our stone gabions are designed to meet the demands of diverse applications with superior efficiency and style.

What Are Stone Gabions?

Stone gabions are wire mesh containers filled with stones or other durable materials, creating robust structural elements for various uses. Their strength, flexibility, and natural look make them an excellent choice for construction and landscaping projects.

Key Features:

Strength and Stability: Reinforced to withstand heavy loads and pressure.

Environmentally Friendly: Utilize natural materials, blending seamlessly with the surroundings.

Versatility: Suitable for retaining walls, decorative fences, and erosion control.

Durability: Highly resistant to environmental factors like water, wind, and temperature changes.

Types of Stone Gabions We Manufacture

1. Welded Mesh Gabions

Welded gabions are made from rigid wire mesh panels, providing a sleek and contemporary look.

Applications:

Retaining walls for gardens and terraces.

Decorative partitions in landscaping projects.

Soundproof barriers for urban areas.

Material: Galvanized steel for corrosion resistance and longevity.

2. Woven Wire Gabions

These gabions use flexible wire mesh, making them ideal for uneven terrain and dynamic loads.

Applications:

Riverbank protection to prevent erosion.

Slope stabilization in hilly areas.

Roadside and railway embankments.

Material: Hot-dipped galvanized or PVC-coated wire for added durability.

3. Gabion Mattresses

Gabion mattresses are flat, wide structures primarily used for erosion control.

Applications:

Protecting riverbeds and channels.

Preventing soil erosion in coastal areas.

Stabilizing slopes and drainage systems.

Material: Heavily galvanized mesh with PVC coating for water resistance.

4. Decorative Gabions

Designed for aesthetic purposes, these gabions enhance the visual appeal of outdoor spaces.

Applications:

Garden sculptures and features.

Stone benches and seating areas.

Fencing with a modern, rustic charm.

Material: Stainless steel or weather-resistant coatings for prolonged lifespan.

Advantages of Our Stone Gabions

1. High Durability

We manufacture Stone Gabions Manufacturer in India using premium-grade materials like galvanized or stainless steel, ensuring they stand the test of time even under extreme conditions.

2. Customization

Our gabions are available in various sizes, shapes, and finishes to cater to your specific needs, whether functional or decorative.

3. Easy Installation

Stone gabions are simple to assemble and install, reducing construction time and labor costs.

4. Cost-Effective

Compared to traditional construction methods, gabions offer an economical alternative without compromising quality or performance.

5. Eco-Friendly

Using natural stones and recyclable materials, gabions support sustainable development practices.

Applications of Stone Gabions

1. Retaining Walls

Stone gabions provide a strong and visually appealing solution for creating retaining walls in gardens, roadsides, and commercial properties.

2. Erosion Control

Used in riverbanks, canals, and coastal areas, gabions prevent soil erosion by stabilizing the terrain.

3. Landscaping

Gabions add an artistic touch to landscaping designs, doubling as functional and decorative elements.

4. Noise Barriers

Their dense structure helps in sound insulation, making them suitable for highways and urban areas.

5. Flood Protection

Gabions act as barriers against flooding, protecting infrastructure and natural environments.

Why Choose Us as Your Stone Gabions Manufacturer?

At Gurukrupa, we are committed to delivering top-notch gabion solutions that exceed expectations. Here’s why we stand out:

1. Expertise

With [X years] of experience, we have mastered the art of manufacturing gabions that meet global standards.

2. Quality Assurance

Our products undergo rigorous quality checks to ensure durability, reliability, and aesthetic excellence.

3. Advanced Technology

We use state-of-the-art manufacturing techniques to create gabions that are strong, precise, and long-lasting.

4. Sustainable Practices

Our processes are designed to minimize environmental impact, aligning with the principles of green construction.

5. Nationwide Delivery

We provide timely delivery across India, ensuring your projects are completed without delays.

How to Select the Right Gabion Solution

Step 1: Identify Your Project Requirements

Determine the purpose of the gabion, whether it’s for structural support, landscaping, or erosion control.

Step 2: Choose the Material

Select a wire mesh type (galvanized, PVC-coated, or stainless steel) based on environmental conditions.

Step 3: Decide on the Design

Pick the size and shape that aligns with your project’s aesthetic and functional needs.

Step 4: Consult Experts

Our team of professionals can guide you in selecting the best gabion system for your specific application.

Maintenance Tips for Stone Gabions

1. Regular Inspection

Check for signs of wear, corrosion, or displacement, especially in high-moisture environments.

2. Clean the Gabions

Remove debris or vegetation that may compromise the structure over time.

3. Refill Stones if Needed

In case of settling or loss of stones, refill the gabions to maintain their effectiveness and appearance.

4. Apply Protective Coatings

Ensure long-term durability by applying anti-corrosion coatings when required.

Conclusion

Stone gabions are a versatile and sustainable solution for modern construction and landscaping. As a trusted stone gabions manufacturer in India, Gurukrupa delivers innovative products that blend strength, functionality, and elegance. Whether for large-scale infrastructure projects or decorative landscaping, our gabion systems are built to last and impress.

#Stone Gabions Manufacturer in India#Fence System And Accessories Manufacturer#Wire Mesh For Garden Manufacturer India#Turnkey Fence Solutions Manufacturer

0 notes

Text

Leading Mesh Wire Manufacturer, Supplier, and Exporter in India - Mcneil Instruments Inc.

Mcneil Instruments Inc. is a topa manufacturer, supplier, and exporter of high-quality mesh wire in India. Our mesh wire, made from materials like stainless steel and galvanized steel, is crafted with precision for durability and strength. Available in various patterns and sizes, including Wire Mesh, Perforated Sheet, Expanded Metal, and Spring Mesh, our products meet diverse industrial and construction needs. With advanced machinery and skilled expertise, Mcneil Instruments ensures reliable performance and quality in every product, making us a trusted name in the wire mesh industry.

0 notes

Text

JB Engineering is a dominant perforated sheets manufacturer in Baddi, who trades in various shapes and sizes in all over India.

#road#rockbolt#RebarCouplers#Coupler#JB#selfdrilling#anchorbolts#hollowbar#rod#threadedrods#threadedbars#tierods#coilrods#SDABars#Bridge#tunnel#construction#pumps

0 notes

Text

Top Stainless Steel Wire Mesh Manufacturer in India

Bhansali Wire Mesh is a major Stainless Steel Wire Mesh Manufacturer in India. Stainless Steel Wire Mesh Manufacturers in India have emerged as major players in the worldwide wire market. We are commonly considered as industry experts, and we consistently meet our clients' needs and specifications for all types of wire mesh.

SS Wire Mesh is a popular choice for many industrial and commercial applications due to its corrosion resistance and strength. Stainless Steel Wire Mesh Supplier in India collaborates with a variety of manufacturers to ensure that they have a large inventory of wires ready for fast delivery to their customers.

Our organisation is one of India's leading manufacturers of stainless steel wire mesh. At our one-of-a-kind manufacturing facility, we produce and supply high-quality stainless steel wire mesh in a variety of sizes and grades. The stainless steel wire mesh manufacturer in India is highly competitive and dynamic in terms of quality and customer satisfaction.

#Stainless Steel Wire Mesh Manufacturers in India#Stainless Steel Wire Mesh Suppliers in India#Stainless Steel Wire Mesh#SS Wire Mesh

0 notes

Text

Premium Stainless steel wire mesh By Meshtech (India), best wire mesh manufacturer in india

#Premium Stainless Steel wire mesh#best wire mesh manufacturers in India#steel wire mesh#steel mesh#mesh

0 notes

Text

Cable Tray Supplier in Maharashtra

Meghmani Metal is a prominent Manufacturer, and Supplier of Cable Tray in Maharashtra, India. Our Manufacturer Unit is in Ahmedabad, Gujarat, India. At Meghmani Metal, we provide high-quality cable trays designed to meet the rigorous demands of industrial and commercial applications. Our cable trays provide an effective solution for cable management, ensuring safe, organized routing of electrical wires in various environments. A cable tray is an essential component in electrical systems used to support and route wires and cables in buildings and industrial facilities. It provides a structured pathway for electrical cables, allowing for easier maintenance, installation, and management. Cable trays, made from steel, aluminum, or fiberglass, come in various designs to suit different cable types and system needs. Types of Cable Trays: Ladder Type Cable Trays Perforated Cable Trays Solid Bottom Cable Trays Wire Mesh Cable Trays Trunking Cable Trays Channel Type Cable Trays Specifications: Material Options: Stainless steel, mild steel, galvanized steel, aluminum. Width: Ranges from 50mm to 1200mm depending on your cable management needs. Height: Typically ranges from 50mm to 150mm. Length: Custom lengths available based on your project specifications. Thickness: Varies from 1mm to 3mm based on the tray material and load requirements. Finish: Powder-coated, galvanized, or stainless steel finish. FAQS: Are your cable trays corrosion-resistant? Yes, our cable trays are available with galvanization and powder coating to ensure they are resistant to corrosion and can withstand harsh environmental conditions. How easy is it to install cable trays? Our cable trays are designed for easy installation with pre-drilled holes, adjustable fittings, and lightweight materials that reduce labor and installation time. Meghmani Metal Industries is a Cable Tray Supplier in Maharashtra, India Including Mumbai, Pune, Nagpur, Thane, Pimpri-Chinchwad, Nashik, Kalyan-Dombivli, Vasai-Virar, Aurangabad, Navi Mumbai, Solapur, Mira-Bhayandar, Bhiwandi-Nizampur, Jalgaon, Amravati, Nanded-Waghala, Kolhapur, Ulhasnagar, Sangli-Miraj-Kupwad, Malegaon, Akola, Latur, Dhule, Ahmednagar, Chandrapur, Parbhani, Ichalkaranji, Jalna, Ambarnath, Bhusawal, Panvel, Badlapur, Beed, Gondia, Satara, Barshi, Yavatmal, Achalpur, Osmanabad, Nandurbar, Wardha, Udgir, Hinganghat. For further inquiries or customized solutions, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

A manufacturing line that includes a variety of equipment for cleaning, filling, capping, and labeling syrup bottles is known as a pharmaceutical syrup filling line. It’s interesting that it also has an automated syrup production facility. We are a well-known manufacturer of syrup filling lines with uses in the culinary, pharmaceutical, nutraceutical, and herbal industries. Our syrup suspension filling line, which has an elegant appearance, is furnished with state-of-the-art components for production, cleaning, filling, capping, and labeling tasks. The entire suspension fill line functions as a single, integrated system, streamlining the production process.

As one of the top exporters of oral suspension filling lines from India, Adinath has developed both fully automatic and semi-automated oral liquid filling lines. The manufacturing capacity of our filling lines ranges from 500 to 50,000 liters per day.

Let’s have a look on some of the key equipments of our syrup filling line:

Syrup Manufacturing Plant

The pharmaceutical business uses oral liquid manufacturing plants as the best instruments for producing oral liquids. It is specifically made to address two important issues that have a direct impact on the liquids’ quality. Minimal liquid handling by hand and efficient cleanliness throughout production.

youtube

Automatic Bottle Washing Machine

Our bottle washing machine, sometimes called a linear bottle washer, is widely utilized in the pharmaceutical business. It has an all-automatic setup that guarantees hassle-free vial loading on the stainless steel wire mesh conveyor. You can also push them manually from the feed table if you’re comfortable doing things that way. Use this automated machine to save a lot of labor, and you can even opt to have an automatic emptying mechanism when needed. The latter is not required.

youtube

Automatic Bottle Filling Machine

The pharmaceutical business frequently uses bottle filling machines, also referred to as bottle fillers, to pack various liquids into various bottle types. This adaptable device can be used to fill bottles, jars, and containers made of glass, plastic, aluminum, steel, copper, and PET, among other materials. It can also fill aqueous solutions, foamy liquid, and semi-viscous solutions. The machine’s essential components include feeding needles, a piston pump, a quality stainless steel slat conveyor belt, and a robust foundation structure.

youtube

Automatic Bottle Capping Machine

We provide bottle stoppers that are used to cap bottles in a variety of industries, including the manufacturing of chemicals, pharmaceuticals, food and beverage products, pesticides, and alcoholic beverages. Our bottle capping machine is constructed with an M.S. frame and stainless steel enclosures or cladding. An orientation-style cap feeder is included with our ROPP bottle cap sealing machine to ensure smooth cap feeding.

youtube

Bottle Visual Inspection Machine

Adinath International produces and exports a cGMP certified bottle inspection machine with a three track conveyor and hooded lighting configuration. Aside from an inspection table with an SS construction, there is a background that alternates between black and white for a perfect visual inspection. A slat chain made of stainless steel is also a part of it. This machine will last for many years because of its sturdy adjustable bolt support and stainless steel square pipes.

youtube

Automatic Bottle Sticker Labeling Machine

This machine is widely used for labeling PET, aluminum, glass, plastic, and copper bottles, cans, jars, and other containers. With the most advanced microprocessor control label dispensing mechanism available, this linear design machine can detect labels and items with maximum efficiency. Additionally, it features a specially created mechanical and electronic technology that is useful for quickly applying transparent labels on bottles. For the labeling of different bottle types, there are no sections that need to be changed.

youtube

#syrup suspension filling line#oral suspension filling lines#semi-automated oral liquid filling lines#oral liquid manufacturing plants#Automatic Bottle Washing Machine#Automatic Bottle Filling Machine#Automatic Bottle Capping Machine#Bottle Visual Inspection Machine#Automatic Bottle Sticker Labeling Machine#Youtube

0 notes

Text

Wire Mesh | Fin Tube | Electropolished Pipe - Timex Metals

Timex Metals is known as one of the biggest Fin Tube Manufacturers in India. We offer one of the finest quality Stainless Steel Fin Tube to various industries around the globe.

Wire Mesh: https://timexmetals.com/wire-mesh-manufacturer-supplier-india.php

Fin Tube: https://timexmetals.com/fin-tube-manufacturer-india.php

Electropolished Pipe: https://timexmetals.com/electropolished-pipe-manufacturer-supplier-india.php

For More Detail

Website: timexmetals.com.

0 notes

Text

SS Wires in Chhattisgarh

Company Overview: Keshar Bhawani Metal & Tubes Pvt. Ltd is a leading Manufacturer, Stockiest and Supplier of SS Wires in Chhattisgarh, India. Manufacturers make thin, flexible strands of stainless steel wire for various industrial, commercial, and residential applications. They are known for their exceptional mechanical properties, including high tensile strength, flexibility, and resistance to rust and corrosion. Types of Stainless Steel Wire: Round Wire: The most common type, used in various applications, including cables, springs, and reinforcement. Flat Wire: The material, with a rectangular cross-section, is used in applications like springs and bands that require flat, uniform wire. Strip Wire: Available in flat, wide strips, used in applications requiring a larger surface area, like in metal mesh and screens. Spring Wire: Engineers specifically design it for making springs, providing high tensile strength and flexibility. Braided Wire: Composed of multiple strands woven together, used in flexible cables and hoses. Technical Specification: Grade: Common grades include 304, 316, and 316L, each offering specific properties for different applications. Diameter: Available in various diameters, depending on the requirements of the application. Finish: Options include polished, matte, and coated finishes to meet aesthetic and functional needs. Keshar Bhawani Metal & Tubes Pvt. Ltd is a Stainless Steel Wire in Chhattisgarh, India Including Raipur, Bilaspur, Kanker, Raigarh, Rajnandgaon, Bemetara, Baikunthpur, Ambikapur, Jagdalpur, Chirimiri, Kondagaon, Manendragarh, Bhatapara, Baloda Bazar, Sakti, Takhatpur, Ambagarh Chowki, Sarangarh, Khairagarh, Dharamjaigarh, Bilha, Arang, Simga, Katghora, Saraipali, Bijapur, Kharsia, Pandariya, Pithora, Kurud, Pathalgaon, Akaltara, Ramanujganj, Bagbahara, Gharghoda, Jashpur Nagar, Bishrampur, Mahasamund, Mungeli, Korba, Dhamtari. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Akaltara#AmbagarhChowki#Ambikapur#Arang#Bagbahara#Baikunthpur#BalodaBazar#Bemetara#Bhatapara#Bijapur#Bilaspur#Bilha#Bishrampur#Chhattisgarh#Chirimiri#Dhamtari#Dharamjaigarh#Gharghoda#India#Jagdalpur#JashpurNagar#Kanker#Katghora#Khairagarh#Kharsia#Kondagaon#Korba#Kurud#Mahasamund#Manendragarh

0 notes

Text

No 1 Wire Mesh Manufacturers in India

Wire Mesh Manufacturers

For over six decades, Wire Mesh Manufacturers, Sulesh Wooven Wire Mesh has established itself as a frontrunner in the Indian wire mesh industry. Their reputation hinges on a commitment to quality, innovation, and exceeding customer expectations. Sulesh Wooven Wire Mesh isn't just another manufacturer; they're artisans of woven metal. Their expertise lies in crafting high-precision woven wire mesh, meticulously designed to meet the diverse needs of various industries. From construction and agriculture to manufacturing and filtration, their products are instrumental in countless applications.

Wire Mesh

Sulesh doesn't believe in a one-size-fits-all approach. They offer a vast array of mesh types, including square, rectangular, and hexagonal weaves. Their materials range from robust stainless steel and galvanized steel to lightweight aluminum, catering to various requirements. But that's not all - they understand the need for customization.

Wiremesh

Their team of experts collaborates with clients to design and manufacture bespoke mesh solutions that perfectly fit specific project needs. Wire Mesh Manufacturers, Sulesh Wooven Wire Mesh is not content with simply maintaining the status quo. They actively explore advancements in weaving techniques and material science to constantly improve their product offerings. This dedication to innovation ensures their clients have access to the latest and most effective mesh solutions.

Wire Mesh

Wire Mesh Manufacturers, Sulesh Wooven Wire Mesh's success story isn't just about their products; it's about their commitment to exceeding customer expectations. Their focus on building strong relationships, prompt deliveries, and exceptional after-sales support has garnered them a loyal clientele across the country. So, the next time your project demands high-quality, reliable wire mesh, look beyond the ordinary. Choose Sulesh Wooven Wire Mesh, the trusted name in woven excellence.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit :- https://www.wiremeshdelhi.com/welded-wire-mesh.html

Address : H.O:K-245, Pushta Road, Karawal Nagar, Shahdara, Delhi-94 K-46, Sector-5, Bhawana, Delhi-39

Twitter :- https://twitter.com/mesh_wire28439

0 notes