#Stainless Steel 316 Seamless Tubes Exporters

Explore tagged Tumblr posts

Text

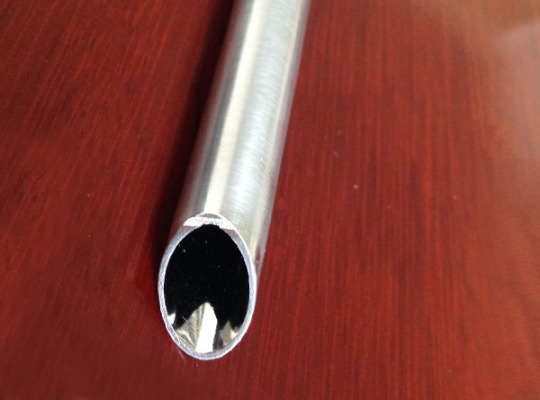

Stainless Steel 316 Seamless Tubes Manufacturers

Metinox Overseas is a renowned manufacturer, supplier, stockist, and exporter of Stainless Steel 316/316L Seamless Tubing in Mumbai, India. Our Stainless Steel 316 Seamless Tubes are meticulously tested and examined by industrial experts to ensure high standard quality, free from any crease or damages, before supplying them to our esteemed clients.

#Stainless Steel 316 Seamless Tubes Stockists#Stainless Steel 316 Seamless Tubes Exporters#Stainless Steel 316 Seamless Tubes Manufacturers In India#Stainless Steel 316 Seamless Tubes Suppliers In India#Stainless Steel 316 Seamless Tubes Stockists In India#Stainless Steel 316 Seamless Tubes Exporters In India#Stainless Steel 316 Seamless Tubes Manufacturers In Mumbai#Stainless Steel 316 Seamless Tubes Suppliers In Mumbai

0 notes

Text

316 stainless steel tubes are made from an alloy that contains 16-18% chromium, 10-14% nickel, and 2-3% molybdenum. The addition of molybdenum enhances the material's resistance to pitting and crevice corrosion, especially in chloride environments, making 316 stainless steel highly suitable for marine, chemical, and other harsh environments.

0 notes

Text

Pipe Elbow Manufacturer and Exporter

What is Pipe Elbow?

A piping system for changing the fluid flow direction is called a steel elbow. It is an important part of plumbing pipeline systems and is used to change the fluid direction. It ranges in different types as per body material; there are stainless steel elbows, carbon steel elbows, and alloy steel. As per fluid directions, there are 45 degree , 90 degree elbows, and 180 elbows; as per elbow length and radius, there are short radius elbows and long radius elbows. As per connection types, there are butt weld elbows, socket weld elbows, and threaded steel piping elbows.

Use of the Product

Pipe elbows suppliers have assorted applications in different industries, like plumbing, power plants, chemical plants, and oil and gas refineries. One of its primary uses is as a connector to distribute water supplies. Also, it is used to deal with the gas or liquid transportation process, which prioritizes diverting or redirecting the fluid flow direction. The elbow is also utilized in situations where pipes must fit confined areas, including walls and ceilings. Most commonly, 90-degree and 45 degree turns are also used to connect two pipes with the same or different nominal diameters and to make the pipe turn at a specific angle, such as 45° or 90°.

Grades in Pipe Elbow

Stainless Steel Elbow

⇒ ASTM A403 WP Gr. 304

⇒ASTM A403 WP Gr 304H

⇒ASTM A403 WP Gr 309

⇒ASTM A403 WP Gr 310

⇒ASTM A403 WP Gr 316

⇒ASTM A403 WP Gr 316L

⇒ASTM A403 WP Gr 317L

⇒ASTM A403 WP Gr 321

⇒ASTM A403 WP Gr 347

⇒ASTM A403 WP Gr 904L

Carbon Steel Elbow

Low Temperature Carbon Steel Elbow

Alloy Steel Elbow

Duplex Steel Elbow

Nickel Alloy Elbow

Manufacturing Standards

With the rapid expansion of global trade, standardization of various products has become an essential requirement. The standards given to various products significantly contribute towards expanding worldwide exchange, which in turn bridges the quality gap between the manufacturers, producers, and buyers of various countries. In pipe fittings too, norms assume a crucial role. The manufacture and establishment of pipe fittings are solidly coordinated by different standards and codes. The trustworthiness of pipe fittings and flanges in the piping system depends upon different principles used in the design, construction, and maintenance of the entire system. The components of pipe fittings are made of different materials in different sorts and sizes, and they should be built in accordance with the manufacturers’ instructions or common national standards. proprietary things. Some manufacturers also use their own internal piping standards based on national and industry sector standards. Types of pipe fitting standards: ANSI B16.9, ANSI B16.28, MSS-SP-43, ASME B16.25,ASTM-A403-ASMESA403.

Pipe Elbow Material Grades

When it comes to selecting the right material for pipe elbows supplier, a comprehensive understanding of various grades is essential to ensuring optimal performance and longevity in diverse applications. Stainless steel elbows, including ASTM A403 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, and 904L, offer exceptional corrosion resistance and durability, making them ideal for industries requiring stringent hygiene standards or exposure to harsh environments. Carbon steel elbows, available in ASTM A 234 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65, & WPHY 70, provide robust strength and reliability for general-purpose applications, offering cost-effectiveness without compromising on performance. For low-temperature applications, ASTM A420 WPL3 and A420 WPL6 offer superior toughness and impact resistance, ensuring dependable operation even in extreme conditions. Alloy steel elbows, encompassing ASTM / ASME A/SA 234 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, and WP 91, deliver enhanced mechanical properties and resistance to high temperatures, making them suitable for demanding industrial environments. Additionally, duplex steel elbows, such as ASTM A 815 and ASME SA 815 UNS NO S31803, S32205, provide a combination of strength, corrosion resistance, and cost-efficiency, making them a preferred choice for applications requiring exceptional performance in aggressive environments. Nickel alloy elbows, which include ASTM / ASME SB 336 UNS 2200 (NICKEL 200), UNS 2201 (NICKEL 201), UNS 4400 (MONEL 400), UNS 8020 (ALLOY 20 / 20 CB 3), UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600), UNS 6601 (INCONEL 601), UNS 6625 (INCONEL 625), and UNS 10276 (HASTELLOY C 276), offer unparalleled resistance to corrosion, oxidation, and high temperatures, making them indispensable for applications demanding exceptional performance in corrosive or high-temperature environments. With a wide range of material grades available, selecting the appropriate pipe elbow ensures optimal performance, longevity, and cost-effectiveness in various industrial applications.

LONG RADIUS ELBOWS, SHORT RADIUS ELBOW, CARBON STEEL ELBOWS, STAINLESS STEEL ELBOW MANUFACTURER A234 WPB, A420 WPL6, A234 WP11, A234 WP5, A403 WP304L, A403 WP316L | ASME/ANSI B16.9, ANSI B16.28, MSS-SP-43 LONG/SHORT RADIUS ELBOWS – 90° ELBOW, 45° ELBOW, 180° ELBOW, 1D, 2D, 3D, 4D, 5D, 10D, CUSTOM RADIUS ELBOWS

Pipe Elbow Carbon Steel Elbows, Stainless Steel Elbows, Alloy Steel Elbows, Long Radius Elbows, Short Radius Elbows. 3D Elbows, 5D Elbows, Custom Radius Elbow Supplier in India, 316 Elbow, A234 WPB Elbows Manufacturer, A420 WPL6 Elbow, A234 WP11 Elbow, A234 WP5 Elbow, A403 WP304 Elbow, A403 WP304L Elbow, A403-WP316 Elbow, A403-WP316L Elbow, Seamless Elbows, Large Diameter Fabricated Elbows, 20″ NB Elbow,36″ NB Elbow Supplier, Buttweld Elbows Manufacturer, Duplex 2205 Pipe Elbow, 100% X-Ray Welded Elbows.

0 notes

Text

Stainless Steel 316/316L/316Ti Pipes & Tubes Manufacturers In India

Navneet Metal Corporation, based in Mumbai, India, is a prominent manufacturer, supplier, and exporter of stainless steel pipes and tubes. The company offers a comprehensive range of stainless steel products that cater to various industrial applications due to their durability, corrosion resistance, and high strength.

Key Features of Navneet Metal Corporation's Stainless Steel Pipes & Tubes

High-Quality Materials:Navneet Metal Corporation ensures the use of premium quality stainless steel materials, including grades like 304, 304L, 316, 316L, 321, and 310. These materials are known for their excellent corrosion resistance, mechanical properties, and ease of fabrication.

Product Range:Types: The company offers both seamless and welded stainless steel pipes and tubes. They provide options for different forms including round, square, rectangular, and oval pipes and tubes. Sizes: Their products range from 1/8" NB to 24" NB in seamless and 1/8" NB to 36" NB in ERW (Electric Resistance Welded) and welded pipes and tubes (Rajkrupa Metal) .

Applications:These stainless steel pipes and tubes are used across a variety of sectors such as chemical processing, petrochemical, oil & gas, power generation, and marine industries. They are ideal for applications requiring high temperature and corrosion resistance.

Specifications:Products adhere to international standards such as ASTM A213, ASTM A312, and ASTM A269, ensuring compliance with rigorous quality requirements. This makes them suitable for global markets and diverse applications.

Customization:Navneet Metal Corporation offers customization to meet specific project requirements, including various lengths, wall thicknesses, and finishes. They also provide tailored solutions for special applications.

Advantages of Choosing Navneet Metal Corporation

Comprehensive Quality Control:The company implements stringent quality control measures including chemical and mechanical testing, hydrostatic testing, and non-destructive testing to ensure that products meet the highest standards .

Timely Delivery:They are known for their commitment to timely delivery, making sure that clients receive their products within the agreed time frame.

Competitive Pricing:Navneet Metal Corporation offers competitive pricing, providing high-quality stainless steel products at cost-effective rates.

Global Reach:The company exports its products worldwide, maintaining a robust presence in international markets which speaks to the reliability and trust in their products and services.

Contact Information

For detailed product inquiries or to request a quote, you can contact Navneet Metal Corporation via their official website or reach out directly to their customer service.

Additional Manufacturers

If you are exploring other manufacturers for stainless steel pipes and tubes in India, here are a few reputable options:

Ratnamani Metals & Tubes Ltd: Known for their extensive range of stainless steel and alloy products .

Suraj Limited: Specializes in stainless steel seamless pipes and tubes for various industrial applications .

Apex Tubes Pvt Ltd: Offers a wide range of stainless steel tubes and pipes, particularly for the automotive and instrumentation sectors .

These companies, along with Navneet Metal Corporation, provide reliable solutions for your stainless steel needs, ensuring high quality and dependable service.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

0 notes

Text

Stainless Steel 316 Seamless Tubes Stockists In Mumbai

Metinox Overseas: Premier Stainless Steel 316/316L Seamless Tubing Manufacturer, Supplier, Stockist, and Exporter in Mumbai, India

Metinox Overseas stands out as a leading manufacturer, supplier, stockist, and exporter of Stainless Steel 316/316L Seamless Tubing in Mumbai, India. Our commitment to excellence ensures that each tube is meticulously tested and inspected by industrial experts, guaranteeing the highest quality standards, free from creases or damages, before reaching our esteemed clients.

Comprehensive Testing for Superior Quality

At Metinox Overseas, we prioritize quality through rigorous testing procedures for our Stainless Steel 316L Seamless Tubes. Our comprehensive array of tests includes:

Eddy Current Testing

Hydrostatic Testing or Ultrasonic Examination

Non-Destructive Testing (NDT)

Chemical and Physical Property Inspections

Additionally, we perform:

Chemical Analysis

Mechanical Tests

Rockwell Hardness Tests

Intergranular Corrosion Tests

Positive Material Identification (PMI)

Flattening and Flaring Tests

Third-Party Inspections

Exceptional Features and Applications

The inclusion of molybdenum in our alloys enhances corrosion resistance, making our Stainless Steel 316 Seamless Tubes ideal for various demanding applications. The austenitic structure of these tubes ensures exceptional toughness, while nickel and molybdenum significantly improve their strength and resistance to corrosion. These grades also exhibit excellent weldability, both with and without filler metal, offering versatility and ease of use in numerous applications.

Versatility of Stainless Steel 316/316L Grades

Stainless Steel 316/316L grades are highly sought after for their superior mechanical and corrosion properties. The straight 316 grade is suitable for pressure or structural applications, while the 316L grade, with its lower maximum carbon limit, is ideal for projects requiring long-term durability and sustainability. Notably, 316L is 100% recyclable, underscoring its environmental benefits. Our SS 316L Seamless Tubing is extensively used in process engineering, control lines, and heat exchangers, especially in aggressive environments where corrosion resistance is crucial.

Commitment to Excellence

At Metinox Overseas, our dedication to excellence goes beyond manufacturing top-quality products. We strive to provide our customers with informative, engaging, and optimized content for search engines. This ensures that when you choose Metinox Overseas, you're receiving not only premium-grade Stainless Steel 316 Seamless Tubes but also a wealth of valuable information.

Specifications of Stainless Steel 316 Tubes

Specifications: ASTM A213 / ASME SA213

Outside Diameter: 1/8″ OD to 2″OD, 3mm OD to 38mm OD

Thickness: 1mm to 3mm, 0.028 to 0.156 inches, SCH 5, SCH 10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS

Size: 1/2″ NB – 24″ NB

Type: Seamless / Capillary Tubes

Form: Round Tubes, Square Tubes, Rectangular Tubes

Length: Single Random, Double Random & Required Length

End: Plain End, Beveled End, Threaded

Finish: Annealed and Pickled, Polished, Bright Annealed, Cold Drawn

Equivalent Grades of Stainless Steel 316 Tubes

STANDARD: UNS S30403, WERKSTOFF NR. 1.4301, AFNOR Z7CN18‐09, EN X5CrNi18-10, JIS SUS 304, BS 304S31, GOST 08Х18Н10

Chemical Composition and Mechanical Properties

Chemical Composition: C: 0.08, Mn: 2.0, Si: 0.75, P: 0.045, S: 0.030, Cr: 18.0-20.0, Mo: –, Ni: 8.0-10.5, N: 0.10

Mechanical Properties: Tensile Strength (MPa) min 515, Yield Strength 0.2% Proof (MPa) min 205, Elongation (% in 50mm) min 40, Hardness Rockwell B (HR B) max 92, Brinell (HB) max 201

Contact Us

For the best in Stainless Steel 316 Seamless Tubes, trust Metinox Overseas for quality and reliability. Contact us at:

Phone: +91-98199 80997 / +91-70212 61928

Metinox Overseas is dedicated to maintaining its reputation for excellence in manufacturing, supplying, stocking, and exporting top-quality stainless steel seamless tubing. Trust Metinox Overseas for all your stainless steel tubing needs, where quality and reliability are guaranteed.

0 notes

Text

Stainless Steel Coil Tubes Manufacturer

https://ziontubes.com/stainless-steel-coil-tubes-manufacturer-india.php :

Stainless Steel Coil Tubes Manufacturer, Supplier & Stockist in India - Zion Tubes & Alloys

Zion Tubes & Alloys is a top Stainless Steel Coil Tube Manufacturer in India. We offer a wide range of products, including SS 304, 316, 202, and 321 Coil Tubes. As a leading ASTM SS Coil Tube Supplier In India, we ensure high-quality products and competitive pricing. We offer a variety of diameters and custom cutting and polishing services to meet your specific requirements. ASTM A231 Stainless Steel 304 Seamless Coiled Tube is widely used in industries such as Petrochemical & Natural Gas Plant. We are a popular Supplier of ASTM A249 Stainless Steel 304 Welded Coiled Tube Exporter in India.

As a leading Stainless Steel Coil Tube Manufacturer In India, we offer a wide range of Stainless Steel Coiled Tube options, including length stainless steel coil tubing, seamless coil tubing, and welded coil tubing.

Zion Tubes & Alloys offers top-quality Stainless Steel Coil Tubes Manufacturer in India, in various grades, sizes, and specifications. Our products are made from high-quality raw materials using advanced technology. We are one of the largest SS 304 Coil Tube Supplier & 316L Stainless Steel Coil Tubing Manufacturer, which is used in a variety of industries.

Zion Tubes & Alloys is a top Stainless Steel 304 Coiled Tube Supplier, offers SS UNS S30400 Coiled Tubing tailored to meet the client's specifications for dimensions, wall thickness, and heat treatment. Our 1 inch Stainless Steel Tubing Coil Manufacturer complies with API, ASTM, and ASME standards. We also provide large diameter 3/8 Stainless Steel Tubing Coils for unique applications.

Contact Number : 98195 64323

Email Id : [email protected]

Headoffice - Shop No- 3 Minty House, Panjrapole Main Road ,

Mumbai - 400004.

0 notes

Text

Stainless Steel Tubes & Pipes Manufacturer near me

Stainless Steel Tubes & Pipes Manufacturer near me

Krystal Global Engineering Limited (formerly known as Krystal Steel Manufacturing Private Limited) stands as a prominent figure in the stainless steel industry, aiming to establish itself as the foremost authority in Stainless and Nickel Alloy Tubes originating from India. Our triumphs are built on our dedication to Operational Excellence and the provision of outstanding services.

We are devoted to equipping our customers with a competitive advantage through a wide range of offerings, encompassing Tubes & Pipes, stainless steel tube and pipe Manufacturer near me, and Manufacturer of Stainless Steel Welded and Seamless Pipes. As a distinguished Producer of SS Tube Suppliers In India & Stainless Steel Tubes Manufacturer in India, Stainless Steel 316 Pipe Manufacturer, Supplier in India, Stainless Steel Pipes Tubes in Mumbai, Stainless Steel Pipes/Tubes suppliers in India, Stainless Steel Pipes & Tubes Manufacturers, Supplier, Stainless Steel Pipes & Tubes, Stainless Steel Tubes And Pipes Manufacturers in India, we take pride in delivering top-quality products to fulfill the diverse requirements of our clientele.

Krystal features cutting-edge facilities committed to continuous enhancement in both product excellence and service provision, with the aim of meeting the varied demands of our global customer base. Whether you require a Stainless Steel Pipes/Tubes Manufacturers in India, Stainless steel pipes and tubes manufacturers in India, Stainless Steel Pipe and Tube Manufacturing Process, Stainless Steel Tubes & Pipes | Stainless Steel Price, Stainless Steel (SS) Pipe & Tube Dealers, Stainless Steel Pipes | S.S. Tubes Supplier, Exporter, Steel Tubes and Pipes - Steel Pipes Manufacturer from Mumbai, Steel Tubes & Pipes Manufacturer, Stainless Steel Pipes & Tubes Suppliers & Exporters, ensures comprehensive coverage with our extensive array of products and services.

Our esteemed clientele represents a broad spectrum of sectors, including Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textiles, Railways, Defense, Automobiles, Desalination, and many others. Our products are utilized in various engineering applications such as Pressure Vessels, Heat Exchangers, Condensers, Heat Recovery Systems, among others. Our global footprint ensures that customers worldwide can rely on our products, technology, and services with utmost assurance. Count on Krystal as your dependable ally for all your hydraulic component requirements in Mumbai and beyond.

Tap here to know more about:

#BrightAnnealedTubes#BuySeamlessTubesandPipes#SSCapillaryTubes#HeatExchangerTubesManufacturer#Inconelalloy#InstrumentationTube#SeamlessTubeSuppliers#SeamlessHeatExchangerTube#HydraulicTubesManufacturer#ManufacturerofInstrumentationTubes#ManufacturerofSeamlesstubesandPipes#ManufacturerHeatExchangerTubes#ManufacturerofStainlessSteelPipe#ManufacturerofStainlessSteelTubeandPipe#ManufacturerofStainlessSteelTubes#MonelAlloy#NickelAlloyTubes#SeamlessPipeManufacturer#StainlessSteelBrightAnnealedTubesManufacturers#StainlessSteelManufacturerinIndia#StainlessSteelPipeManufacturersinIndia#StainlessSteelPipeManufacturingCompanyInVadodara#StainlessSteelSeamlessPipes#StainlessSteelSeamlessTubes

0 notes

Text

The Art of Integration: Stainless Steel Tube & Pipe in Modern Architectural Design

In the dynamic realm of current structure, the seamless integration of materials is the cornerstone for undertaking modern designs that encourage awe. At Jay Steel Corporation, we pleasure ourselves on being the first-class stainless steel tube stockist and number one stainless-steel pipe exporter, focusing on offering top-quality substances to form cutting-edge and the next day's architectural wonders. Our whole range consists of SS 17-4 PH, SS 17-7 PH, SS 304/304L/304H, SS 310/310S, SS 316/316L/316Ti, SS 321, SS 347, SS 904L, and SMO 254, catering to severa challenge requirements. Moreover, we excel in 304 Stainless Steel Wire Mesh Manufacture and characteristic a reliable 316 stainless steel cord mesh provider, making sure the maximum top notch and sturdiness. Join us in exploring the paintings of integration, wherein stainless-steel tube and pipe, along side twine mesh, redefine the possibilities of contemporary shape.

Why Stainless Steel Tube & Pipe?

Stainless metallic tubing and pipes provide a totally specific aggregate of durability, versatility, and aesthetic enchantment that lead them to necessary in current architectural designs. Here’s why they're preferred by manner of architects and designers alike:

Versatility in Design:

Stainless metallic tube and pipe provide architects and designers outstanding versatility of their innovative endeavors. Available in some of shapes, sizes, and finishes, the ones materials can be seamlessly incorporated right into a extensive sort of architectural styles and ideas. Whether it is the smooth traces of a minimalist facade or the complex curves of a contemporary sculpture, chrome steel tube and pipe provide the potential to hold honestly any design imaginative and prescient to existence.

Durability and Longevity:

One of the standout features of stainless-steel tube and pipe is their exquisite sturdiness and toughness. Engineered to stand as much as the maximum harsh environmental conditions, collectively with corrosion, extreme temperatures, and UV exposure, stainless steel remains certainly safety-loose within the path of its lifespan. This inherent resilience makes it a amazing choice for architectural applications where sturdiness and reliability are paramount, making sure that systems preserve their aesthetic attraction for many years to come.

Structural Integrity:

Beyond its aesthetic attraction, chrome steel tube and pipe additionally provide superior structural integrity, making them critical additives in cutting-edge architectural layout. Whether used as help columns, handrails, or structural frames, stainless steel presents the power and balance necessary to face as much as the rigors of every day use on the equal time as maintaining its glossy appearance.

Sustainability and Eco-friendliness:

In an era increasingly more described through environmental consciousness, chrome steel tubes and pipe end up sustainable alternatives for architectural duties. Manufactured from recycled substances and definitely recyclable on the quit of their lifecycle, chrome steel embodies the ideas of round economic gadget and useful useful resource overall performance. Additionally, improvements in fabrication strategies have made it feasible to gain complex geometries and seamless connections, in addition enhancing the structural overall performance of chrome steel in architectural packages.

Aesthetic Impact:

Last but genuinely no longer least, stainless steel tube and pipe make a bold aesthetic assertion in contemporary structure. Whether used as glossy cladding on a excessive-upward thrust constructing, putting sculptures in public areas, or elegant balustrades in indoors design, chrome steel affords a touch of class and contemporary aptitude to any setting. Its reflective surface captures and presentations mild, developing dynamic visible outcomes and enhancing the overall atmosphere of the space.

Grades We Offer Stainless Steel Tubes & Pipes

SS 17-4 PH

SS 17-7 PH

SS 304/304L/304H

SS 310/310S

SS 316/316L/316Ti

SS 321

SS 347

SS 904L

SMO 254

Specifications of Stainless Steel Tube & Pipe

Specifications: ASTM A213, A269, A249, A312, A358 / ASME SA213, SA269, SA249, SA312, SA358

Seamless Pipes & Tubes Size: 1 / eight" NB - 24" NB

ERW Pipes & Tubes Size: 1 / eight" NB - 36" NB

EFW Pipes & Tubes Size: 6" NB - one hundred" NB

Standard: ASTM, ASME, and API

Length: Single Random, Double Random & Required Length

Outer Diameter:6.00 mm OD as much as 914.4 mm OD, Sizes up to 24” NB

Thickness:0.3mm – 50 mm, SCH five, SCH10, SCH 40, SCH eighty, SCH 80S, SCH a hundred and sixty, SCH XXS, SCH XS

Schedule :SCH20, SCH30, SCH40, STD, SCH80, XS, SCH60, SCH80, SCH120, SCH140, SCH160, XXS

Types: Seamless / ERW / EFW / Welded / Fabricated / LSAW Pipes

Form: Round Pipes/Tubes, Square Pipes/Tubes, Rectangular Pipe/Tubes, Coiled Tubes, “U” Shape, Pan Cake Coils, Hydraulic Tubes

End: Plain End, Beveled End, Treaded

Applications in Modern Architecture: Stainless Steel Tube & Pipes

The versatility and aesthetic appeal of chrome steel tube and pipe from Jay Steel Corporation cause them to vital in numerous architectural programs, consisting of but no longer limited to:

Exterior Facades: Our stainless steel tube and pipe lend themselves perfectly to outside facades, providing super corrosion resistance and a graceful, modern-day appearance that enhances the visible enchantment of houses and structures.

Interior Design Elements: From stair railings and balustrades to ornamental furniture and furnishings, our stainless steel tube and pipe add a hint of beauty and class to interior areas, elevating the overall environment of residential, commercial enterprise, and institutional environments.

Structural Support Systems: With their immoderate strength-to-weight ratio, our chrome steel tube and pipe offer reliable structural help for canopies, awnings, pergolas, and different architectural elements, making sure structural integrity with out compromising format aesthetics.

Final Words!

The real essence of the paintings of integration comes alive via stainless steel tube and pipe offerings from Jay Steel Corporation, a renowned chrome steel tube stockist and leading stainless steel pipe exporter. As industry pioneers, we relentlessly push the limits of innovation, fantastic, and sustainability to empower architects and architects globally. Our willpower extends to shaping iconic skylines, reworking public areas, and knowing residential dreams with our chrome steel answers. With offerings inclusive of SS 17-four PH, SS 17-7 PH, SS 304/304L/304H, SS 310/310S, SS 316/316L/316Ti, SS 321, SS 347, SS 904L, and SMO 254, we stand as a beacon of excellence in modern-day-day shape. Partner with Jay Steel Corporation, the relied on 304 Stainless Steel Tube Exporter, and embark on a journey of limitless opportunities, wherein creativeness knows no bounds.

Resorch Link: https://jaysteelcorporation.co.in/blog/the-art-of-integration-stainless-steel-tube-pipe-in-modern-architectural-design/

#304 Stainless Steel Tube Exporter#stainless steel 904l round bar#stainless steel 304/304l/304h round bar

0 notes

Text

Stainless Steel 316 Boiler Tubes Exporters In India

Metinox Overseas is a renowned manufacturers, exporters, stockists, stockholders, and suppliers of a qualitative range of Stainless Steel 316 Boiler Tubes. SS 316 Boiler Tubes are molybdenum-alloyed steel and are the second most common austenite stainless steel, making them highly suitable for various applications. UNS S31600 Boiler Tubes are preferred in marine environments due to their greater resistance to pitting corrosion compared to other grades of steel.

Product Overview:

One of the significant advantages of WNR 1.4401 Boiler Tubes is their negligible responsiveness to magnetic fields, allowing them to be used in applications where a non-magnetic metal is required. Designed to meet national and international standards for quality raw materials, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Stainless Steel 316 Boiler Tubes Specification :

Specifications : ASTM A / ASME SA213 / A312

Range : 6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness.

Form : Round, Square, Rectangular, Coil, U Tube, Pan Cake.

Wall Thickness : 0.50 mm TO 6.0 mm

End : Plain End, Bevelled End

Length : Single Random, Double Random & Required Lengt

Types : Seamless / ERW / Welded

Application of Stainless Steel 316 Boiler Tubes :

1. Chemical Processing: Ideal for transporting corrosive fluids, including acids and chemicals, in refineries and petrochemical plants.

2. Marine Applications: Utilized in shipbuilding and offshore platforms due to their resistance to saltwater corrosion.

3. Food and Beverage Industry: Employed in processing equipment where hygiene and resistance to corrosion are critical.

4. Pharmaceuticals: Used in sterilization and manufacturing processes requiring high cleanliness standards.

Conclusion :

Stainless Steel 316 boiler tubes offer a robust solution for industries that demand high performance under extreme conditions. Their resistance to corrosion, ability to withstand high temperatures, and structural integrity make them an ideal choice for applications involving steam and heat transfer.

#Stainless Steel 316 Boiler Tubes Manufacturers#Stainless Steel 316 Boiler Tubes Suppliers#Stainless Steel 316 Boiler Tubes Stockists#Stainless Steel 316 Boiler Tubes Exporters#Stainless Steel 316 Boiler Tubes Manufacturers In India#Stainless Steel 316 Boiler Tubes Suppliers In India

0 notes

Text

What are stainless steel fittings used for?

Stainless steel fittings, where precision meets durability. Bullion Pipes & Tubes LLP is your premier destination for top-quality SS fittings. Our stainless steel buttweld fittings embody the perfect fusion of precision and durability. Renowned as a leading manufacturer, supplier, stockist, and exporter of SS fittings, we take pride in offering a diverse range that is meticulously tailored to meet the unique project requirements of our esteemed global clientele. Explore the excellence of Stainless Steel Buttweld Fittings with us – where precision meets durability in every weld.

Stainless Steel Fittings

Stainless steel fittings play a crucial role in ensuring the seamless flow of liquids and gases in diverse industries. These fittings are meticulously crafted from high-quality stainless steel, offering exceptional corrosion resistance, longevity, and low maintenance.

Specification of Stainless Steel Fittings

Standard

ANSI B16.5, ANSI B16.47 Series A & B, MSS SP44, ASA, API-605, AWWA, Custom Drawings

Size

1/2″ NB TO 48″ NB

Designation

A 182 / A 240, SA 182 / SA 240

Class

150#, 300#, 400#, 600#, 900#, 1500# & 2500#.

Grades

ASTM A182 F304, 304L, 304H, 316, 316Ti, 316H, 316L, 316LN, 309S, 309H, 310S, 310H,317, 317L, 321, 321H, 347, 347H, 201, 202, 904L ETC.

Type

Socket Weld Fittings, Screwed-Threaded Fittings, Stainless Steel Buttweld Fittings

Diverse Range of Stainless Steel Fittings:

Bullion Pipes & Tubes LLP provides an extensive array of Stainless Steel Fittings & Stainless Steel Buttweld Fittings ensuring that clients have a wide selection to meet their specific project needs. The range includes:

Elbows (90 degrees, 180 degrees, 45 degrees): These fittings facilitate changes in the direction of the pipeline, allowing for smooth flow transitions around corners.

Tee Fittings: Tees are used to create branch connections in a pipeline, providing a way to channel fluids or gases in different directions.

Cross Fittings: Cross fittings offer a four-way connection in pipelines, allowing for the seamless distribution of fluids or gases in multiple directions.

Reducers: Reducers are crucial for connecting pipes of different sizes, ensuring a smooth transition and efficient flow within the system.

Stub End Fittings: Stub ends are used for connecting flanges to pipes, offering versatility in various applications.

Pipe Bend Fittings: These fittings are designed to redirect the pipeline around obstacles or corners, maintaining the integrity of the system.

Bushing and Plug Fittings: Bushings and plugs play a role in sealing or closing off pipes, ensuring the integrity of the pipeline.

Uses of Stainless Steel Fittings

Stainless steel fittings are a critical component in various industries, offering a multitude of uses that guarantee exceptional performance and durability. With their unique chemical composition, these fittings possess outstanding corrosion resistance, making them highly reliable for applications exposed to high moisture or harsh environments. One prominent use of stainless steel fittings can be found in the construction industry. These fittings are extensively employed in plumbing and pipework systems, connecting different components and ensuring leak-proof connections. Their corrosion resistance ensures the longevity and integrity of the plumbing infrastructure, reducing the need for costly repairs and replacements in the long run. Here are some common applications of stainless steel fittings:

Plumbing and Water Systems

Chemical and Petrochemical Industries

Food and Beverage Industry

Pharmaceutical Industry

Oil and Gas Industry

Agricultural Equipment

Automotive Industry

Construction and Architecture

Marine Applications

Power Generation

Mining Industry

Other Applications

Final Words! Stainless Steel Fittings from Bullion Pipes & Tubes LLP stand as a testament to quality, durability, and versatility. With a comprehensive range of SS Fittings & Stainless Steel Buttweld Fittings that caters to various applications and a commitment to global standards, the company continues to be a trusted partner in providing top-notch stainless steel fittings for projects worldwide in various countries Asia, Saudi Arabia, Singapore, Oman, Maldives, Vietnam, United Arab Emirates, Turkey, Qatar, Europe, Italy, Romania, Chile, Australia, Brazil, Russia and other region. Contact us today at [email protected] or [email protected] for fittings that go beyond expectations, ensuring the seamless flow and success of your industrial endeavors.

0 notes

Text

Stainless Steel Electropolished Tubes Exporters In India

Stainless Steel Electropolished Tubes Supplier In India, SS Electropolished Tubes Exporter Electropolished Stainless Steel Tubing, Electropolished Tubes, Electropolished Tube Fittings 304/304l Electropolished Pipes, 316/316l Electropolished Pipes, Seamless/Welded EP Pipes

Stainless Steel Electropolished Pipes Manufacturer, Electropolished Tubes Exporter, High Purity Stainless Steel Tubing, Electropolished Stainless Steel Tubes, EP Tubes Processor in Mumbai, SS Electropolished Tubes in India, SS 304L Electropolished Tubes, SS 316L Electropolished Pipes, SS 904L Electropolished Tubing Suppliers, Electropolished Tubes Suppliers in India, Dairy Tubes, Tubes for Pharma Industry, Electropolished Tubes for Food Processing Industry, Best Quality EP Tubes in India, Mumbai

Kobs India is a leading processor and supplier of high quality electropolished or mechanically polished stainless steel pipes, electropolished tubes in all major stainless steel grades including 304/304L and 316/316L. Electropolishing is also commonly known as electrochemical polishing or electrolytic polishing. EP stainless steel tubes are generally made by carrying out the electropolishing process on high quality seamless and welded stainless steel tubes.

Standards Specification:

Size : ½”Inch and 24”Inch

Specifications : ASTM A249, A269, A270

Grades: : 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Length: : Up to 6 meters, custom cut lengths

Thickness: 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish:BA Finish inside and outside, Electropolished finish inside and outside

Specifications : ASTM A312 / ASTM SA312

Material & Grade :

Stainless Steel : Grade: 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Product Features:

Durability

High strength

Effective functionality

Sturdy construction

Corrosion resistance

Dimensional accuracy

Electropolished Tubes Manufacturer, Electropolished Tubes Manufacturers, Electropolished Tubes Suppliers, Electropolished Tubes Exporters, Electropolished Tubes Stockists.

Electropolished Tubes in Mumbai, Electropolished Tubes Manufacturers in Mumbai, Electropolished Tubes Suppliers in Mumbai, Electropolished Tubes Exporters in Mumbai, Electropolished Tubes Stockists in Mumbai.

Electropolished Tubes in India, Electropolished Tubes Manufacturers in India, Electropolished Tubes Suppliers in India, Electropolished Tubes Exporters in India, Electropolished Tubes Stockists in India.

Manufacturing Process :

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Product Usage & Application :

Useful in Paper & Pulp Companies

Useful in High Pressure Applications

Useful in Oil and Gas Industry

Useful in Chemical Refinery

Useful in Pipeline

Useful in High Temperature Application

Useful in Water Pipe Line

Useful in Nuclear Power Plants

Useful in Food Processing and Dairy Industries

Useful in Boiler & Heat Exchangers

Packing :

Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Shrink-wrapped

Carton boxes

Wooden pallets

Wooden boxes

Wooden crates

Why Choose Us :

You can get the perfect material according to your requirement at the least possible price.

We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

e guarantee to give a response within 24hours(usually in the same hour)

You can get stock alternatives, mill deliveries with minimizing manufacturing time.

We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Tests we carry out (including both Destructive and Non-Destructive) :

Positive material recognition

Mechanical examining like tensile, Elongation and reduction of area.

Large-scale test

Chemical examination-Spectro analysis

Firmness test

Pitting protection test

Small tests

X-ray test

Impact analysis

Eddy current examining

Hydrostatic analysis

Prompt test

For more details: Website - http://kobsindia.in/ Phone No. - 9819523999 Email - [email protected]

#Electropolished Tubes in India#Electropolished Tubes Manufacturers in India#Electropolished Tubes Suppliers in India#Electropolished Tubes Exporters in India#Electropolished Tubes Stockists in India.

0 notes

Text

Stainless Steel 316 Boiler Tubes Suppliers In India

Introduction

Metinox Overseas is a renowned manufacturer, exporter, stockist, stockholder, and supplier of a qualitative range of Stainless Steel 316 Boiler Tubes. With a commitment to quality and customer satisfaction, Metinox Overseas stands as a leader in the industry, delivering products that meet the highest standards.

Description

Stainless Steel 316 Boiler Tubes, also known as UNS S31600 Boiler Tubes, are molybdenum-alloyed steel and the second most common austenite stainless steel. These tubes are highly suitable for various applications, particularly in marine environments due to their superior resistance to pitting corrosion compared to other grades of steel. One of the significant advantages of WNR 1.4401 Boiler Tubes is their negligible responsiveness to magnetic fields, making them ideal for applications requiring non-magnetic metals.

Designed to meet both national and international standards, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Benefits

Stainless Steel 316 Boiler Tubes offer numerous advantages:

Corrosion Resistance: Enhanced resistance to pitting and crevice corrosion in chloride environments.

Non-Magnetic Properties: Negligible responsiveness to magnetic fields, suitable for specific applications.

Versatility: Suitable for a wide range of industries, including marine, chemical processing, and more.

Durability: High strength and excellent durability ensure long-term performance.

Customization: Available in various sizes and customizable to meet specific requirements.

Specifications

The Stainless Steel 316 Boiler Tubing comes with the following specifications:

Standards: ASTM A / ASME SA213 / A312

Range: 6.35 mm OD up to 152.4 mm OD in 0.6 to 10 mm thickness

Form: Round, Square, Rectangular, Coil, U Tube, Pan Cake

Wall Thickness: 0.50 mm to 6.0 mm

End: Plain End, Bevelled End

Length: Single Random, Double Random & Required Length

Types: Seamless / ERW / Welded

Product Overview

As leading manufacturers, suppliers, stockists, and exporters, Metinox Overseas is committed to providing top-quality Stainless Steel 316 Boiler Tubes. Our products undergo rigorous quality checks to meet industry standards and exceed customer expectations.

We offer excellent customer service and support, with a dedicated team available to assist clients with inquiries and ensure satisfaction with every purchase. Metinox Overseas prioritizes sustainability and environmental responsibility in all aspects of our operations, adhering to strict environmental regulations and minimizing our environmental impact through responsible practices.

Conclusion

Choose Metinox Overseas for all your Stainless Steel 316 Boiler Tube needs. Experience the difference in quality, reliability, and service that sets us apart as an industry leader.

For inquiries and more information, please contact us at:

Phone: +91-98199 80997 / +91-70212 61928

Explore our extensive range of Stainless Steel 316 Boiler Tubes and experience unparalleled quality and service with Metinox Overseas.

0 notes

Text

Stainless Steel Coil Tubing

Zion Tubes & Alloys is a top Stainless Steel Coil Tube Manufacturer in India. We offer a wide range of products, including SS 304, 316, 202, and 321 Coil Tubes. As a leading ASTM SS Coil Tube Supplier In India, we ensure high-quality products and competitive pricing. We offer a variety of diameters and custom cutting and polishing services to meet your specific requirements. ASTM A231 Stainless Steel 304 Seamless Coiled Tube is widely used in industries such as Petrochemical & Natural Gas Plant. We are a popular Supplier of ASTM A249 Stainless Steel 304 Welded Coiled Tube Exporter in India .

It sounds like Zion Tubes & Alloys offers a wide range of stainless steel coil tubing options to cater to various industry needs. With a focus on quality and customization, they seem equipped to meet specific client requirements. It's essential to ensure that the products meet industry standards and specifications, which they claim to comply with. Customers seeking stainless steel coil tubing solutions might find their offerings suitable for their applications.

https://ziontubes.com/stainless-steel-coil-tubes-manufacturer-india.php

Product: Zion Tubes & Alloys

contact: - 98699 95231

Mail:- [email protected]

0 notes

Text

Manufacturer of Stainless Steel Pipe near me

Manufacturer of Stainless Steel Pipe near me

Krystal Global Engineering Limited (formerly known as Krystal Steel Manufacturing Private Limited) stands as a prominent figure in the stainless steel industry, aiming to establish itself as the foremost authority in Stainless and Nickel Alloy Tubes originating from India. Our triumphs are built on our dedication to Operational Excellence and the provision of outstanding services.

We are devoted to equipping our customers with a competitive advantage through a wide range of offerings, encompassing Pipes, stainless steel pipe suppliers near me, and Stainless Steel Pipes in Mumbai. As a distinguished Producer of 304/304L Stainless Steel Pipe Manufacturers & Suppliers in Mumbai, Stainless Steel 316 Pipe Manufacturer, Supplier in India, Lowest Prices for Stainless Steel Pipes In India, Seamless Pipe, Stainless Steel Pipe, Stainless Steel Pipes in Mumbai, Stainless Steel Pipes Manufacturer In India, Stainless Steel Seamless Pipe manufacturer in India, Stainless Steel Pipes Manufacturers & Suppliers in India, Stainless Steel Pipes Manufacturers, Suppliers in India, Stainless Steel 304 Pipe Manufacturer, Exporter in Mumbai, Leading Stainless Steel Pipe Manufacturers & Suppliers, Stainless Steel Pipe Suppliers and Stainless Steel Seamless Pipe manufacturer in India, we take pride in delivering top-quality products to fulfill the diverse requirements of our clientele.

Krystal features cutting-edge facilities committed to continuous enhancement in both product excellence and service provision, with the aim of meeting the varied demands of our global customer base. Whether you require a Stainless Steel Pipes & Tubes Manufacturer, ASTM A312 TP304 Stainless Steel Pipe, Stainless Steel Pipe 304 Manufacturers in India, Stainless Steel Seamless Pipes & Tubes ensures comprehensive coverage with our extensive array of products and services.

Our esteemed clientele represents a broad spectrum of sectors, including Power Plants, Oil & Gas, Chemical Plants, Fertilizers, Pharmaceuticals, Textiles, Railways, Defense, Automobiles, Desalination, and many others. Our products are utilized in various engineering applications such as Pressure Vessels, Heat Exchangers, Condensers, Heat Recovery Systems, among others. Our global footprint ensures that customers worldwide can rely on our products, technology, and services with utmost assurance. Count on Krystal as your dependable ally for all your hydraulic component requirements in Mumbai and beyond.

Tap here to know more about:

#BrightAnnealedTubes#BuySeamlessTubesandPipes#SSCapillaryTubes#HeatExchangerTubesManufacturer#Inconelalloy#InstrumentationTube#SeamlessTubeSuppliers#SeamlessHeatExchangerTube#HydraulicTubesManufacturer#ManufacturerofInstrumentationTubes#ManufacturerofSeamlesstubesandPipes#ManufacturerHeatExchangerTubes#ManufacturerofStainlessSteelPipe#ManufacturerofStainlessSteelTubeandPipe#ManufacturerofStainlessSteelTubes#MonelAlloy#NickelAlloyTubes#SeamlessPipeManufacturer#StainlessSteelBrightAnnealedTubesManufacturers#StainlessSteelManufacturerinIndia#StainlessSteelPipeManufacturersinIndia#StainlessSteelPipeManufacturingCompanyInVadodara#StainlessSteelSeamlessPipes#StainlessSteelSeamlessTubes

0 notes

Text

Stainless Steel 316 Pipes Exporters In India

316 alloy is a standard molybdenum-bearing grade. The Stainless Steel 316 Pipe/ Tube is designed with excellent corrosion resistance. These grade has better crevice corrosion and pitting resistance compared to the 304 alloys. The Stainless Steel 316 Tube is designed with a minimum tensile strength of 515Mpa and minimum yield strength of 200Mpa. They also possess a good density of 8000kg/m3. The standard wall thickness of these tubes ranges from 0.5mm to 6.35mm. The SS 316 Seamless Pipe is made without a fillet or welds. These pipes range from ½ inches to 16 inches in outer diameter. They are widely used in marine systems, pulp, and paper, chemical industries, etc. This Marine grade Stainless Steel 316 Tubing doesn't corrode or rust in these harsh marine environments. It is also referred to in many cases as marine stainless steel. We are the leading stockiest of Stainless Steel 316 Pipe/ Tube.

The 316 SS Welded Pipe has a range up to 24 inches and above. They have a melting point of up to 1400 degrees C. These pipes also have 35% of elongation properties. The Stainless Steel 316 Seamless Tubing can suffice in chloride-rich environments. These tubes can be available up to 24 inches. Seamless tubes are strong compared to welded tubes as they are made from a single sheet of steel. The ASTM A312 TP 316 ERW Pipe is designed with the help of dies by passing a current. This makes the pipes highly versatile and durable. These fusion-welded pipes are available in sizes up to 100 inches. We are a leading supplier who can customize all our products including, the SA 312 TP 316 Schedule 40 Pipe in different shapes and sizes as per your requirements

#Stainless Steel 316 Pipes Manufacturers in Mumbai#Stainless Steel 316 Pipes Suppliers in Mumbai#Stainless Steel 316 Pipes Exporters in Mumbai

0 notes

Text

Stainless Steel 317/317L Boiler Tubes Exporters In India

Metinox Overseas is a renowned manufacturer, exporter, stockist, stockholder, and supplier of a qualitative range of Stainless Steel 317/317L Boiler Tubes. SS 317 Boiler Tubes (also known as UNS S31700 and WNR 1.4449) find typical applications in various industries, including boat fittings, structural members, architectural components in marine, polluted or industrial environments, food and beverage processing equipment, hot water systems, and plants for chemical, petrochemical, mineral processing, photographic, and other industries.

Product Overview :

Stainless Steel 317L Boiler Tubes (also referred to as UNS S31703 and WNR 1.4438) are similar to SS 316 Boiler Tubes but offer improved resistance to atmospheric corrosion, many organic and inorganic chemicals, and food and beverages. Designed to meet both national and international standard quality of raw materials, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Stainless Steel 317/317L Boiler Tubing Specification:

Specifications : ASTM A / ASME SA213 A312

Range : 6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness.

Form : Round, Square, Rectangular, Coil, U Tube, Pan Cake.

Wall Thickness : 0.50 mm TO 6.0 mm

End : Plain End, Bevelled End

Length : Single Random, Double Random & Required Length

Types : Seamless / ERW / Welded

Application of Stainless Steel 317/317L Boiler Tubes :

1. High-Temperature Boilers: Stainless Steel 317 and 317L are commonly used in power plants and other high-temperature boiler systems that require materials resistant to corrosion and oxidation at elevated temperatures. These alloys maintain their strength and integrity under thermal cycling, making them ideal for industrial boilers that operate at high pressures and temperatures.

2. Heat Exchangers: Due to their excellent thermal conductivity and resistance to scaling and corrosion, Stainless Steel 317/317L tubes are employed in heat exchangers in various industries, including power generation, petrochemical, and chemical processing.

3. Fossil Fuel Power Plants: The superior resistance to sulfuric acid and chloride stress corrosion cracking makes 317/317L stainless steel ideal for applications in fossil fuel power plants, where acidic gases or harsh conditions are present.

4.Superheaters and Reheaters: Due to their heat-resistance and ability to withstand high pressure, these stainless steel grades are often used in the construction of superheaters and reheaters in steam generation systems.

Conclusion :

Stainless Steel 317 and 317L boiler tubes are highly advantageous materials for applications in industries that require resistance to high temperatures, pressure, and corrosive environments. Their excellent resistance to corrosion, oxidation, and scaling, combined with good weldability and formability, makes them ideal for use in critical applications such as boilers, heat exchangers, superheaters, and reheaters in power generation, petrochemical, and chemical industries.

#Stainless Steel 317/317L Boiler Tubes Manufacturers#Stainless Steel 317/317L Boiler Tubes Suppliers#Stainless Steel 317/317L Boiler Tubes Stockists#Stainless Steel 317/317L Boiler Tubes Exporters#Stainless Steel 317/317L Boiler Tubes Manufacturers In India#Stainless Steel 317/317L Boiler Tubes Suppliers In India#Stainless Steel 317/317L Boiler Tubes Stockists In India#Stainless Steel 317/317L Boiler Tubes Exporters In India

0 notes