#Stainless Steel 316 Boiler Tubes Manufacturers

Explore tagged Tumblr posts

Text

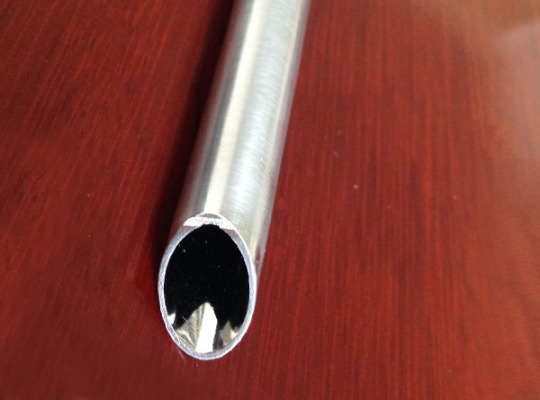

Stainless Steel 316 Boiler Tubes Exporters In India

Metinox Overseas is a renowned manufacturers, exporters, stockists, stockholders, and suppliers of a qualitative range of Stainless Steel 316 Boiler Tubes. SS 316 Boiler Tubes are molybdenum-alloyed steel and are the second most common austenite stainless steel, making them highly suitable for various applications. UNS S31600 Boiler Tubes are preferred in marine environments due to their greater resistance to pitting corrosion compared to other grades of steel.

Product Overview:

One of the significant advantages of WNR 1.4401 Boiler Tubes is their negligible responsiveness to magnetic fields, allowing them to be used in applications where a non-magnetic metal is required. Designed to meet national and international standards for quality raw materials, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Stainless Steel 316 Boiler Tubes Specification :

Specifications : ASTM A / ASME SA213 / A312

Range : 6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness.

Form : Round, Square, Rectangular, Coil, U Tube, Pan Cake.

Wall Thickness : 0.50 mm TO 6.0 mm

End : Plain End, Bevelled End

Length : Single Random, Double Random & Required Lengt

Types : Seamless / ERW / Welded

Application of Stainless Steel 316 Boiler Tubes :

1. Chemical Processing: Ideal for transporting corrosive fluids, including acids and chemicals, in refineries and petrochemical plants.

2. Marine Applications: Utilized in shipbuilding and offshore platforms due to their resistance to saltwater corrosion.

3. Food and Beverage Industry: Employed in processing equipment where hygiene and resistance to corrosion are critical.

4. Pharmaceuticals: Used in sterilization and manufacturing processes requiring high cleanliness standards.

Conclusion :

Stainless Steel 316 boiler tubes offer a robust solution for industries that demand high performance under extreme conditions. Their resistance to corrosion, ability to withstand high temperatures, and structural integrity make them an ideal choice for applications involving steam and heat transfer.

#Stainless Steel 316 Boiler Tubes Manufacturers#Stainless Steel 316 Boiler Tubes Suppliers#Stainless Steel 316 Boiler Tubes Stockists#Stainless Steel 316 Boiler Tubes Exporters#Stainless Steel 316 Boiler Tubes Manufacturers In India#Stainless Steel 316 Boiler Tubes Suppliers In India

0 notes

Text

Grade 321 Fasteners: Properties, Applications, and Benefits

Introduction to Grade 321 Fasteners

Grade 321 is a titanium-stabilized austenitic stainless steel alloy known for its excellent resistance to intergranular corrosion, high-temperature strength, and good mechanical properties. It is widely used in environments requiring superior oxidation resistance and strength retention at elevated temperatures.

Grade 321 fasteners, including bolts, nuts, washers, and screws, are highly sought after in industries such as aerospace, chemical processing, power generation, and automotive manufacturing. These fasteners offer exceptional performance in high-temperature environments, making them an ideal choice for heat exchangers, exhaust systems, and other demanding applications.

Chemical Composition of Grade 321 Stainless Steel

Grade 321 stainless steel fasteners are composed of various elements that contribute to their strength, durability, and corrosion resistance. The chemical composition of Grade 321 is as follows:

Chromium (Cr): 17.0 – 19.0%

Nickel (Ni): 9.0 – 12.0%

Manganese (Mn): ≤ 2.0%

Silicon (Si): ≤ 0.75%

Carbon (C): ≤ 0.08%

Phosphorus (P): ≤ 0.045%

Sulfur (S): ≤ 0.030%

Titanium (Ti): 5x(C%+N%) min - 0.70%

Iron (Fe): Balance

The addition of titanium in Grade 321 enhances its ability to resist carbide precipitation, which prevents intergranular corrosion at high temperatures.

Mechanical Properties of Grade 321 Fasteners

Grade 321 stainless steel fasteners exhibit excellent mechanical properties, making them suitable for use in various high-stress applications. Below are the key mechanical properties:

Tensile Strength: 515 MPa (75,000 psi) min

Yield Strength (0.2% Offset): 205 MPa (30,000 psi) min

Elongation: 40% min

Hardness: 217 HB max

These properties enable Grade 321 fasteners to maintain strength and integrity even in extreme temperature conditions.

Key Features and Benefits of Grade 321 Fasteners

Grade 321 fasteners provide numerous advantages in critical applications. The key benefits include:

High-Temperature Resistance:

Withstands temperatures up to 900°C (1652°F), making it ideal for heat-intensive applications.

Excellent Corrosion Resistance:

Resistant to oxidation and intergranular corrosion, especially in environments exposed to heat cycling.

Improved Weldability:

Can be easily welded without post-weld heat treatment.

Good Mechanical Strength:

Retains high strength and durability under extreme conditions.

Resistance to Scaling:

Ideal for applications requiring repeated exposure to heating and cooling cycles.

Applications of Grade 321 Fasteners

Due to their high resistance to corrosion and heat, Grade 321 fasteners are extensively used in various industries, including:

Aerospace Industry:

Used in aircraft exhaust systems, jet engine components, and thermal barriers.

Automotive Industry:

Applied in exhaust manifolds, catalytic converters, and turbochargers.

Chemical Processing Plants:

Used in reactors, heat exchangers, and pressure vessels where high corrosion resistance is required.

Power Generation:

Employed in boiler tubes, heat exchangers, and turbine components.

Food Processing Equipment:

Resistant to organic and inorganic acids, making it suitable for hygienic processing environments.

Comparison Between Grade 321 and Other Stainless Steels

When selecting stainless steel fasteners, it is essential to compare Grade 321 with other common grades.

Grade 321 vs. Grade 304:

Grade 321 has superior high-temperature performance due to its titanium stabilization.

Grade 304 is more cost-effective but less resistant to intergranular corrosion.

Grade 321 vs. Grade 316:

Grade 316 offers better overall corrosion resistance, especially in chloride environments.

Grade 321 is preferred for high-temperature applications.

Grade 321 vs. Grade 347:

Both grades offer similar high-temperature properties, but Grade 347 contains niobium instead of titanium for stabilization.

Grade 321 is widely used in welding applications due to its lower susceptibility to sensitization.

Why Choose Grade 321 Fasteners?

Grade 321 stainless steel fasteners are the preferred choice for applications requiring excellent corrosion resistance, high-temperature strength, and long-lasting durability. Their superior performance makes them ideal for aerospace, automotive, chemical processing, and industrial applications.

Ananka Group is a leading manufacturer and supplier of high-quality Grade 321 fasteners. With a commitment to excellence, we provide reliable and precision-engineered fasteners that meet international standards and customer requirements.

Conclusion

Grade 321 fasteners are an essential component in various industries due to their excellent corrosion resistance, high-temperature capabilities, and mechanical strength. Their ability to withstand extreme conditions makes them highly reliable for demanding applications.

Frequently Asked Questions (FAQs)

1. What makes Grade 321 fasteners better for high-temperature applications?

Grade 321 contains titanium, which stabilizes the alloy and prevents carbide precipitation at high temperatures, making it ideal for applications above 500°C.

2. Are Grade 321 fasteners suitable for marine environments?

While Grade 321 offers good corrosion resistance, it is not the best choice for marine environments. Grade 316 is a better option for exposure to saltwater.

3. Can Grade 321 stainless steel fasteners be welded?

Yes, Grade 321 fasteners can be welded without post-weld heat treatment, making them suitable for various fabrication processes.

4. Where can I buy high-quality Grade 321 fasteners?

Ananka Group is a trusted manufacturer and supplier of premium Grade 321 fasteners, offering high-quality products that meet global standards.

5. How does Grade 321 compare to Grade 347 in high-temperature applications?

Both grades perform well under high temperatures, but Grade 347, stabilized with niobium, provides slightly better performance in prolonged high-temperature environments.

For the best Grade 321 fasteners, contact Ananka Group today!

#Ananka#Fasteners#grade321#grade#gradematerial#material#fastenersmanufacturer#Anankafasteners#Article#Blog#manufacturer#supplier#mumbai#hex#bolt#tumblr#tumblr blog#usa#uk

0 notes

Text

0 notes

Text

Grades Of Stainless Steel Flanges And SA 210 Gr A1 Tubes

These stainless steel flanges are known extremely as the back bones of piping systems attached with pipes, valves, pumps, and other apparatus. Comparatively, stainless steel flanges offer high security and easier assembling/disassembling/maintenance capabilities compared to other materials. Grades of stainless steel flanges are totally different from each other but according to every special feature they will be used for different industrial purposes.

1. 304 and 304L Stainless Steel Flanges

Composition:304 Stainless Steel Flanges Manufacturers are highly alloyed with chromium and nickel to provide excellent corrosion resistance in addition to superior formability.

304 vs. 304L : The low-carbon variant of 304 is thought of as 304L, that means, the carbides fall out slowly on welding. This makes it an excellent choice for applications wherein welded could be a problem of corrosion resistance.

Applications: Both grades are employed in food processing, chemical, and water treatment plants wherein corrosion resistance is relatively mild.

2. 316 and 316L Austenitic Stainless Steel Flanges

Stainless Steel Composition: Presence of higher level of molybdenum content makes 316 stainless steel better corrosion resistance compared to 304 toward acids and chlorides.

316 vs. 316L: Like 304L, 316L contains very low carbon content which reduces its tendency to case of sensitization thus is an excellent weldability property.

Applications: These flanges are reportedly applied in marine environments, manufacturing of pharmaceutical agents, chemical processes amongst many places where the environment requires severe resistance to corrosion strength.

321 Stainless Steel Flanges

321 Grade: It is titanium-doped 321 stainless steel, with high oxidation as well as intergranular corrosion resistance.

Applications: it has used in applied application at the high temperature for aerospace as well as the heat exchangers and is used in the production of boilers, thus 321 stainless steel flanges are worthy of all those applications that require durability.

SA 210 Gr A1 Seamless Tubes contains tubes of that kind which are basically of medium carbon steel. The tubes are prepared for usage in high pressure services inside heat exchangers and boilers as well as equipment of that type which can carry higher strength and tolerate heat to a significant extent.

The American Society for Testing and Materials calls the product specification as SA 210 Gr A1.

These features are associated with A1-grade tubes, rolled and specifically prepared to be used in the supply of seamless carbon steel tubes for services which face high pressure. Such SA 210 Gr A1 Tubes hold advanced hardness as well as heat resistivity and a high capacity of carrying pressure. Such characteristics of the tubes have gained its popularity in industrial boilers as well as heat exchangers in which rigors as well as reliable conditions do exist.

Properties SA 210 Gr A1 Tubes:

Chemical Composition: SA 210 Gr A1

This grade provides good weldability with strength. This grade high Manganese for toughness to raise

Strength and Heat Resistance: This is because tensile and yield strength is good, thus it has been found usage in service at elevated temperature without modifying its general structure.

Seamless Weld: The SA 210 Gr A1 seamless Tubes also do not have any weld or weak point because they are in seamless, thus giving them more tensile strength and elasticity. Therefore, they use in high-pressure operations. Applications of SA 210 Gr A1 Tubes

Industrial application of Boiler Tubes: SA 210 Gr A1 tubes are industrially applied by the industrial boilers, as the tubes can resist the extreme requirements concerning temperature and pressure for the process of steam production.

The stability of stresses in the tube SA 210 Gr A1 is a significant principal major factor for its efficiency in heat transfer. This feature has a crucial necessity for tubular heat exchangers.

On the other hand, if the SA 210 Gr A1 tube or stainless steel flange is to be used depends upon other requirements such as strength level, which is required, exposure of the environment, and corrosion resistance required.

Environmental Conditions

Some of the chemical process plants might face the following environmental conditions in a chemical process plant:

Some of the general guidelines amongst others are as follows:

Corrosion-Resisting Requirements: High-Extreme Corrosion Resistance; one investment is to be anticipated to be incurred when a choice of Super Duplex 2507 is made for an application whose conditions happen to align with those environments that exist with offshore and aggressive chemical environments.

These tubes are more suitable in boilers along with the operation of the heat exchanger under the working conditions of smooth unreliability in high-pressure operation with higher temperature. With high-temperature and high-pressure operation, stainless steel and SA 210 Gr A1 tubes have been developed for providing the already existing industrial system through their flanges.

#stainless steel flanges manufacturers#SA 210 gr a1 tubes#Rishabh steel industries#Nitron alloys overseas

0 notes

Text

Krystal Global Engineering Limited: A Leader in Manufacturing Premium Tubes and Pipes

Krystal Global Engineering Limited, a leading steel product manufacturer, is renowned for delivering high-quality industrial solutions, specializing in high finned tubes, finned tubes, low finned tubes, and other critical steel products. As a trusted name in the industry, we cater to diverse sectors, including the power, petrochemical, oil & gas, and mechanical engineering industries. Our offerings range from seamless pipes and seamless tubes to complex heat transfer systems and air cooler heat exchangers, making us a preferred partner for industries globally.

Diverse Range of Tubes and Pipes

Our extensive portfolio includes a wide array of tubes and pipes, designed to meet the rigorous demands of industrial applications. These include:

- High Finned Tubes: These are ideal for efficient heat transfer in boilers and heat exchangers.

- Low Finned Tubes: Suitable for air coolers and condensers, these tubes increase the surface area for enhanced heat transfer.

- Mechanical Tubes: These versatile tubes are engineered for mechanical and structural applications.

- Seamless Pipes & Tubes: Our seamless pipes and tubes ensure reliability and strength in high-pressure environments, widely used in oil & gas, petrochemical, and power generation industries.

Advanced Alloy Offerings

At Krystal Global Engineering, we offer tubes and pipes manufactured from advanced alloys like Nickel and Nickel Alloy Tubes. These alloys provide exceptional corrosion resistance and high-temperature strength, making them suitable for harsh environments like chemical processing plants and marine applications. Our range includes:

- Nickel 2200 and Nickel 2201: Known for excellent corrosion resistance and thermal stability.

- Monel 4400: An alloy known for high strength and resistance to corrosion in a variety of environments.

- Inconel 6600, 6601, 6622, 6625: These nickel-chromium alloys offer outstanding resistance to oxidation and high-temperature strength, ideal for heat exchanger tubes and gas turbines.

- Incoloy 8800, 8810, 8811, 8020, 8825: With remarkable resistance to oxidation, carburization, and sulfidation, Incoloy alloys are perfect for applications in petrochemical and refinery industries.

Expertise in Heat Exchangers and Boiler Tubes

One of our specialties is manufacturing boiler tubes and heat exchanger tubes. Our products ensure efficient thermal conductivity and durability in demanding environments, such as power plants and chemical industries. With our state-of-the-art U-Bend Tubes, we provide solutions that ensure high-performance and energy-efficient systems.

Additionally, our shell and tube heat exchangers are designed for optimal heat transfer performance. They are engineered with precise tolerances, ensuring longevity and minimal maintenance requirements, even under extreme conditions.

Premium Stainless Steel Products

We pride ourselves on manufacturing and supplying stainless steel tubes and pipes that are compliant with global standards. Our Super Austenitic Steel products, such as TP 304, TP 316, and TP 321, are known for their corrosion resistance, strength, and durability. These products are commonly used in chemical processing, marine, and food industries, where materials must withstand corrosive environments.

Krystal Global Engineering offers a wide range of ferritic steel and super duplex stainless steel options as well. Our Super Duplex UNS S31803, Super Duplex UNS S32205, and Super Duplex UNS S32750 provide superior resistance to stress corrosion cracking, pitting, and crevice corrosion, making them ideal for offshore and subsea applications.

Cutting-Edge Manufacturing Processes

At Krystal Global Engineering, our commitment to quality and innovation is demonstrated by our advanced manufacturing techniques. We follow stringent industry standards like ASTM Pipes and EN Tubes in all our products, ensuring precision and consistency. Our bright annealed tubes are manufactured using a process that creates a smooth, polished surface, minimizing the risk of corrosion and contamination, making them perfect for industries like food processing, pharmaceuticals, and high-purity applications.

We are also leaders in the production of coil-formed tubes, providing flexible and reliable solutions for applications that require precision and performance. With our cutting-edge technology, we ensure that our coil-formed tubes meet the strictest industry standards, from production to quality control.

Specialized Offerings: Monel, Inconel, and Hastelloy Alloys

We manufacture tubes and pipes using high-performance alloys like Monel, Inconel, and Hastelloy, ensuring superior durability and corrosion resistance in extreme environments. These alloys are particularly valued in industries such as aerospace, marine, and chemical processing due to their ability to maintain strength and integrity under high pressure and temperature conditions.

- Monel alloy: Monel alloys, such as Monel 4400, offer excellent corrosion resistance in seawater and various acidic environments.

- Inconel alloys: Inconel 6600, 6625, and 7718 are renowned for their resistance to oxidation and carburization at high temperatures, making them suitable for gas turbine components and heat exchanger applications.

- Hastelloy C-22 and C-276: Known for their exceptional corrosion resistance in chemical processing and nuclear industries, these alloys are ideal for applications that involve aggressive chemicals.

Solutions for Every Industry

As a leading manufacturer of seamless tubes and pipes, Krystal Global Engineering serves industries across the globe, providing custom solutions that meet the unique requirements of each sector. Our products are designed to offer superior performance, durability, and cost-effectiveness in even the most challenging environments.

- Air Cooler Heat Exchanger: Our air cooler heat exchangers ensure optimal cooling performance, energy efficiency, and extended service life, making them ideal for petrochemical plants and power generation facilities.

- Hydraulic Tubes: We manufacture high-precision hydraulic tubes for applications in heavy machinery, construction, and automotive industries, where reliability and precision are paramount.

- Instrumentation Tubes: Our instrumentation tubes are critical for process control and monitoring systems, ensuring accuracy and reliability in industries such as oil & gas, pharmaceuticals, and chemical processing.

Quality Assurance and Global Standards

Krystal Global Engineering adheres to international standards such as ASTM, EN, and ASME for all its products, ensuring that they meet or exceed global benchmarks for quality and safety. We employ rigorous quality control measures at every stage of the manufacturing process, from raw material selection to final inspection. Our in-house testing facilities allow us to guarantee that our products meet the highest standards of precision, strength, and durability.

Global Reach

As a globally recognized manufacturer, Krystal Global Engineering is dedicated to providing high-quality seamless tubes and pipes to clients worldwide. Our products are sought after by companies in Vadodara, India, and across the globe. With our extensive distribution network, we ensure that our customers have access to premium stainless steel pipes and tubes, no matter where they are located.

Our products are trusted by major industries for their durability, efficiency, and superior performance. Whether you are looking for seamless heat exchanger tubes, U-bend tubes, or specialized nickel alloy tubes, Krystal Global Engineering delivers excellence in every product.

Why Choose Krystal Global Engineering?

At Krystal Global Engineering, we are committed to delivering not just products but solutions. Our team of experienced engineers and industry experts work closely with clients to understand their needs and deliver tailored solutions. Our state-of-the-art manufacturing facilities, combined with our focus on quality and innovation, make us a trusted partner in the global steel industry.

By choosing Krystal Global Engineering, you benefit from:

- Superior product quality and adherence to international standards.

- Custom solutions tailored to your specific industry needs.

- A wide range of materials, including stainless steel, nickel alloys, and duplex stainless steel.

- Cutting-edge technology and advanced manufacturing processes.

- A commitment to sustainability and environmentally responsible practices. Krystal Global Engineering Limited continues to set the benchmark in the manufacturing of seamless tubes, pipes, heat exchangers, and related steel products. Our focus on quality, innovation, and customer satisfaction ensures that we remain at the forefront of the industry, delivering products that exceed expectations in performance, durability, and efficiency.

#metals#steels#tubes#pipes#mining#krystalgeltd#inconelalloy#seamlessheatexchangertube#instrumentationtube#monelalloy

0 notes

Text

Stainless Steel 316 Pipes & Tubes Exporters In India

At Nascent Pipe and Tubes, we take pride in offering top-quality stainless steel products that cater to diverse industrial needs. Among our wide range of offerings, Stainless Steel 316 Pipes & Tubes stand out for their exceptional performance and versatility. Let's delve into what makes these products a preferred choice across various sectors.

Unmatched Corrosion Resistance

Stainless Steel 316 is renowned for its superior resistance to corrosion, making it ideal for environments exposed to harsh chemicals and saline solutions. This remarkable property is attributed to the addition of molybdenum, which enhances its ability to withstand chlorides and acidic conditions. Industries such as petrochemical, marine, and pharmaceutical rely heavily on Stainless Steel 316 Pipes & Tubes for their durability and longevity.

High-Temperature Strength

In applications where high-temperature performance is crucial, Stainless Steel 316 Pipes & Tubes excel. They maintain their structural integrity and mechanical properties even in extreme heat, making them suitable for use in boilers, heat exchangers, and exhaust systems. This resilience ensures safety and efficiency in demanding settings.

Versatility in Applications

The adaptability of Stainless Steel 316 extends beyond industrial use. Its aesthetic appeal and ease of fabrication make it a popular choice in architectural and decorative applications. From modern kitchen appliances to elegant railings, the possibilities are endless with Stainless Steel 316. Nascent Pipe and Tubes provide custom solutions to meet the unique needs of each project.

Commitment to Quality

At Nascent Pipe and Tubes, we understand that quality is paramount. Our Stainless Steel 316 Pipes & Tubes undergo rigorous testing and quality assurance processes to meet international standards. We ensure that every product delivers the performance and reliability our clients expect.

Why Choose Nascent Pipe and Tubes?

Expertise and Experience: With years of experience in the industry, we have honed our expertise in providing stainless steel solutions that excel in performance and value.

Customer-Centric Approach: We prioritize our clients' needs, offering personalized solutions and excellent customer service.

Sustainability: We are committed to sustainable practices, ensuring that our manufacturing processes are environmentally friendly.

In conclusion, Stainless Steel 316 Pipes & Tubes from Nascent Pipe and Tubes offer unparalleled advantages for various applications. Whether you're looking for robust industrial components or stylish architectural elements, our products deliver quality and excellence.

For more information or to discuss your specific requirements, contact Nascent Pipe and Tubes today. Experience the difference in quality and service with a trusted leader in stainless steel solutions.

0 notes

Text

Key Advantages of Stainless Steel 316 Boiler Tubes in Boiler Systems

Introduction Metinox Overseas is a renowned manufacturers, exporters, stockists, stockholders, and suppliers of a qualitative range of Stainless Steel 316 Boiler Tubes. SS 316 Boiler Tubes are molybdenum-alloyed steel and are the second most common austenite stainless steel, making them highly suitable for various applications. UNS S31600 Boiler Tubes are preferred in marine environments due to their greater resistance to pitting corrosion compared to other grades of steel.

Understanding Stainless Steel 316 Stainless Steel 316 is a chromium-nickel stainless steel alloy containing molybdenum, which enhances its ability to resist corrosion, particularly in environments with chloride ions (e.g., seawater, chemicals). The addition of molybdenum also improves its resistance to pitting and crevice corrosion, making it more robust compared to standard 304 stainless steel. This makes Stainless Steel 316 a preferred material for applications that require greater durability under harsh chemical and environmental conditions.

Unique Advantages of Stainless Steel 316 Boiler Tubes 1. Superior Resistance to Corrosion in Harsh Environments Stainless Steel 316 Boiler Tubes are known for their excellent resistance to corrosion, particularly in environments where chemicals, saltwater, and acidic substances are present. Industries such as petrochemical processing, chemical plants, and offshore oil rigs favor 316-grade stainless steel due to its ability to withstand corrosive substances that could degrade other materials. This corrosion resistance ensures that boiler tubes maintain their integrity over time, reducing the risk of leaks or failures in critical systems. 2. Enhanced Performance in High-Temperature Applications Boilers often operate under extreme heat, and the ability of Stainless Steel 316 to maintain its strength and stability at elevated temperatures is a major advantage. With excellent oxidation resistance and thermal stability, 316-grade stainless steel is well-suited for high-temperature environments where sustained heat exposure could otherwise compromise material performance. Its superior heat resistance makes it an ideal choice for power generation plants and other industries that rely on boilers to operate continuously under heat-intensive conditions. 3. Resistance to Chemical Attack and Chloride Stress Cracking One of the key reasons why Stainless Steel 316 Boiler Tubes are favored in chemical processing and marine industries is their exceptional resistance to chloride-induced stress corrosion cracking. This type of corrosion can severely weaken materials, particularly in environments where chloride salts or harsh chemicals are present. The molybdenum content in Stainless Steel 316 enhances its ability to resist this type of degradation, making it a more reliable option for boilers that are exposed to corrosive substances on a regular basis. 4. Long-Term Durability and Cost Efficiency Stainless Steel 316 Boiler Tubes offer excellent durability, allowing them to endure years of operation without significant wear or damage. This durability reduces the frequency of replacements and repairs, ultimately resulting in lower maintenance costs. While the initial investment in Stainless Steel 316 may be higher than some alternatives, its long lifespan and minimal maintenance needs make it a cost-effective solution over the long term. 5. High Resistance to Scaling and Fouling Another key advantage of Stainless Steel 316 Boiler Tubes is their ability to resist scaling and fouling, which can occur in boiler systems over time due to the buildup of mineral deposits, rust, or other contaminants. These deposits can impede heat transfer efficiency, leading to reduced boiler performance and higher energy consumption. The smooth surface of Stainless Steel 316 tubes helps to minimize the accumulation of scale and other materials, ensuring that the boiler operates at optimal efficiency for a longer period. Stainless Steel 316 Boiler Tubing Specification Specifications ASTM A / ASME SA213 / A312 Range 6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness. Form Round, Square, Rectangular, Coil, U Tube, Pan Cake. Wall Thickness 0.50 mm TO 6.0 mm End Plain End, Bevelled End Length Single Random, Double Random & Required Length Types Seamless / ERW / Welded Applications of Stainless Steel 316 Boiler Tubes Stainless Steel 316 Boiler Tubes are widely used across a range of industries due to their unique properties:

Power Generation: In power plants, 316-grade stainless steel is used in high-pressure boilers, steam systems, and heat exchangers, where its heat resistance and corrosion protection ensure consistent performance.

Marine and Offshore Industries: Offshore platforms and marine vessels rely on Stainless Steel 316 Boiler Tubes to resist corrosion from saltwater and harsh marine environments, ensuring the safety and longevity of their boiler systems.

Chemical Processing: In chemical plants, where exposure to corrosive substances is frequent, Stainless Steel 316 Boiler Tubes are ideal for transporting fluids and gases under pressure without the risk of degradation or leakage.

Pharmaceutical and Food Processing: In industries where hygiene and cleanliness are paramount, Stainless Steel 316 is chosen for its resistance to contamination and ease of sterilization, making it an excellent choice for boilers used in these sectors. Conclusion Stainless Steel 316 Boiler Tubes stand out for their remarkable resistance to corrosion, heat, and chemical exposure, making them a superior choice for industries that demand durability and reliability under extreme conditions. Their ability to perform consistently over time, coupled with their resistance to stress corrosion cracking and scaling, makes them the material of choice for a wide range of applications—from power generation to marine and chemical processing. If your industry requires high-performance boiler tubes that can withstand the most challenging environments, Stainless Steel 316 is an excellent option. To learn more about how Stainless Steel 316 Boiler Tubes can benefit your operations, contact Metinox Piping. Our team is ready to help you find the right solution for your specific needs. For more details Email: [email protected] Contact: 70212 61928 If any enquiries please contact us our support team will connect you as soon as possible

0 notes

Text

Building the Future: India’s Top Stainless Steel Tubing and Piping Manufacturers.

India has hooked itself up as a first-rate player within the stainless-steel region, producing great tubes and pipes for a worldwide marketplace. With a diverse variety of producers specialising in various goods, the use of a support sector that requires accuracy, sturdiness, and dependability. Kamal Steels is a key player among these producers, offering a diverse variety of stainless steel tubing and pipe solutions adapted to specific industrial requirements.

Seamless Steel Tubing: Unmatched Quality

India's seamless metallic tubing manufacturers, including Kamal Steels, are known for producing tubes with splendid strength and best ability. These seamless tubes are critical in sectors like oil and gasoline, cars, and construction, where high-strain conditions require robust materials. Seamless tubes provide better dependability and lifespan in essential packages due to the fact that they take away welds.

Complete Stainless Steel Pipe Solutions

India's stainless-steel pipe producers provide a huge range of pipes to meet a number of commercial desires. SS 304 pipes, with their remarkable corrosion resistance, are a bendy choice for an extensive variety of applications. SS 316 and SS 316L pipes, which are extra proof against chlorides and acids, are acceptable for marine and chemical processing programs. Manufacturers assure that these pipes satisfy excessive specs, making them a dependable solution for tough packages.

Specialised Tubing for Precision Applications

Kamal Steels and other outstanding producers in India excel at making specialised chrome steel tubes for unique programs. Stainless steel condenser tubes and warmth exchanger tubes are crucial in thermal management structures because they offer powerful heat transmission while also being long-lasting. Power generation and business heating rely heavily on stainless-steel boiler tubes, which could endure excessive temperatures and pressures.

Expansive Product Range

India's stainless steel tube and pipe producers produce a huge range of objects, such as:

Stainless Steel Square Pipe: These adaptable pipes are ideal for structural and architectural applications, as they offer both strength and aesthetic appeal.

Stainless metallic perforated pipes: used in filtering and screening programs, combine sturdiness with powerful overall performance.

Stainless Steel Sanitary Tube: Used inside the meals and beverage sectors. These have applications in the pharmaceutical, and dairy sectors, these tubes provide sanitary and easy-to-use answers.

Stainless Steel Coil Tubes: These flexible tubes are perfect for instrumentation and warmth in alternate packages.

Stainless Steel Mechanical Tubes: These tubes are ideal for a variety of mechanical programs due to their extra strength and dimensional correctness.

Stainless metallic capillary tubes, recognised for their accuracy and tiny diameter, are essential in scientific and scientific equipment.

Stainless Steel Rectangular Tubes: These tubes are perfect for structural and architectural programs, supplying power and a sleek appearance.

Stainless Steel Corrugated Tubes: These tubes, which enhance flexibility and power, are best for fluid transportation and business applications.

Stainless Steel Precision Tubing: These tubes are made with high precision and tight tolerances to meet the needs of particular programs.

Stainless metallic U tubes are used in heat exchangers and condensers to enhance thermal switch performance.

Stainless Steel Instrumentation Tube: These tubes are critical additives for instrumentation and management structures, supplying reliable overall performance in critical packages.

Keeping up with International Standards

Top producers, such as Kamal Steels, respect strict international standards, including ASTM A213 for seamless stainless steel tubes. This devotion assures that their goods satisfy the highest quality standards, offering consumers dependable and high-performing solutions. Detailed information about SS pipe weight and other characteristics enables clients to make educated selections, ensuring they receive the finest product for their requirements.

Building the Future: India’s Top Stainless Steel Tubing and Piping Manufacturers.

India's stainless steel tubing and piping producers, driven by industry leaders such as Kamal Steels, continue to develop and offer high-quality products to fulfil the changing demands of diverse sectors. Their dedication to quality and diverse product offerings cement their position as worldwide leaders in stainless steel manufacturing. Whether you want conventional or specialised stainless steel products, these suppliers provide the dependability and performance needed for industrial success.

0 notes

Text

Unveiling the Excellence of Indian Pipe Manufacturers:

Pipe production has advanced dramatically over the years, with Indian firms leading the way. The varied selection of pipes produced in India meets a variety of industrial applications while maintaining quality and dependability. This article investigates the vast range of Indian pipe producers, focusing on essential items and their uses.

Seamless metallic pipe manufacturers in India

Seamless metal pipes are vital for sectors that demand strong and lengthy-lasting pipeline solutions. India’s seamless metal pipe producers are famous for developing high-quality pipes that shape global necessities. The absence of seams in these pipes increases their energy and strain resistance, making them top-notch for disturbing programs within the oil and gasoline, petrochemical, and strength-producing industries.

Stainless Steel Pipe: Versatile and Strong

Steel sheet channels are vital in businesses that require erosion and electricity. The Indian manufacturer offers a wide range of steel plates, steel 304, and steel pipe 316. This form of pipe is generally used within the meals, pharmaceutical, and pharmaceutical industries due to its potential to resist harsh situations and excessive temperatures Furthermore, SS 317L pipe is known to withstand chemical assault, making it perfect for regions with heavy particles.

Carbon steel pipes are used due to the fact they’re both long-lasting and value-effective. Carbon steel pipe producers in India make excellent pipes, together with API 5L Grade B Pipe and ASTM A53 Grade B, to fulfill traumatic industry standards. Because of their exceptional tensile strength and dependability, these pipes are used in infrastructure tasks, water transportation, and construction.

Alloy metal pipe manufacturers offer excessive-performance solutions.

Alloy metal pipes, with their superior mechanical qualities, are crucial for excessive-pressure environments. Indian alloy metallic pipe manufacturers create pipes including ASTM A335 P11 and ASTM A335 P22, which can be mentioned for their potential to resist harsh situations. These pipes are extensively utilized in strength vegetation, refineries, and petrochemical sectors that require wonderful temperature and pressure resistance.

Specialized products include heat exchanger tubes and duplex pipes.

Heat exchanger tubes are important for powerful warmness transmission in quite a few sectors. Indian producers provide chrome steel heat exchanger tubes with excessive thermal conductivity and corrosion resistance. Furthermore, Duplex Pipe Suppliers in India provide excessive-electricity duplex and notable duplex pipes. These pipes are extremely protective against strain corrosion cracking and are widely used inside the oil and gasoline region due to their lengthy-time period overall performance and value effectiveness.

Advanced grades include A106 Grade B, API 5L X52, and API 5L X65 PSL2.

The A106 Grade B Pipe is wanted for high-stress programs including boilers and warmth exchangers. Indian producers guarantee that these pipes meet high-quality requirements, making them suitable for essential applications. Similarly, API 5L X52 Pipe and API 5L X65 PSL2 are endorsed due to their power and appropriateness for excessive-strain settings inclusive of the herbal gasoline and petroleum sectors. These pipes are intended to endure extreme environments, ensuring operating safety and efficiency.

ASTM Standards and Specialised Piping Solutions.

Pipes that meet ASTM necessities, which include ASTM A333 Grade 6, are crucial for programs that want durability at low temperatures. Indian manufacturers specialize in generating low-temperature carbon steel pipes, which are vital for sectors working at sub-0 temperatures. The varied preference of chrome steel pipes to be had from Indian producers, along with Stainless Steel 304 Pipe and Stainless Steel 316 Pipe, demonstrates their adaptability and electricity.

The Indian pipe manufacturing commercial enterprise is prominent because of its creativity, best, and adherence to global requirements. From consistent and carbon steel channels to cutting-edge amalgam and duplex arrangements, Indian makers meet a wide run of mechanical necessities. Their dedication to perfection guarantees that businesses worldwide rely on Indian pipes for vital applications. As the sector advances, Indian pipe makers’ contributions remain critical to the global supply chain, cementing their position as industry leaders.

0 notes

Text

Looking for the best steel pipes? Rising Steel Industries is your destination.

Steel pipes are required by every other Industry today. And the best pipes will get you the best results. Thus, Rising Steel Industries is a leading piping solutions supplier in India. Along with supply they manufacture a wide range of piping products too since 2022. Their high-quality materials reach various industries, from oil and gas and petrochemicals to power and energy and boilers.

Stainless steel specialists:

Rising Steel Industries is a specialist in stainless steel pipes. These pipes have wide applications in various different industries. Rising Steel Industries is a reliable manufacturer of stainless steel pipes in India. The variety of options they offer to suit your project requirements is given below.

Giving you variety, they are stainless steel welded pipe manufacturers in India. These stainless steel welded pipes are for various industrial uses. These are especially designed to promise the best performance.

They offer 316 stainless steel pipe, which is known for its high performance. The high performance is due to the excellent high-temperature and corrosion resistance properties.

316L stainless steel pipe is ideal for applications requiring corrosion resistance in low-temperature environments.

One of the particular varieties of steel pipes is the 304 stainless steel pipe. With its great mechanical properties, it is quite versatile and thus widely used.

Another such particular variety is stainless steel 304L pipe. This is an improved version of 304 with better resistance to corrosion.

Beyond Stainless Steel:

Not only stainless steel, they manufacture and supply other types of pipes too, which are listed below.

The leading Duplex Pipe suppliers and Super Duplex Pipe suppliers in the Indian market. For harsh environments and high pressure, there are some high-strength options.

They are the rising seamless steel pipe manufacturers in India. Such pipes are manufactured through a hot-rolling process. This process is the reason for its exceptional strength and uniformity.

Carbon steel pipe is a hybrid steel pipe. The combination of carbon and steel is durable and cost-effective. Thus, it finds application in a wide range of industrial uses, including the transportation of oil and gas.

ASTM A106 Grade B Pipe is manufactured here too. This is commonly used in high-temperature service applications. The boilers and superheater tubes used in industries.

They also offer:

Another variety is the ASTM A53 Grade B ERW Pipe. This pipe is a versatile option for low-pressure and non-critical uses.

API 5L Gr. B Pipe is also manufactured by them. This pipe is designed for use in the transportation of liquids and gases. Thus, it has a high application in the oil and gas industry.

They even supply ASTM A333 Gr. 6 pipe. This is a seamless steel pipe for high-temperature service applications. Thus used where steam, water, and other fluids are involved.

Another kind of hybrid is alloy steel pipe. This pipe is a great combination of strength, toughness, and corrosion resistance.

Reliable and Certified:

Rising Steel Industries is an ISO 14001, IOHSAS 18001, and even ISO 9001-certified company. These certifications point to the commitments given below.

The best quality management out there on the market. They make sure that the products meet the highest quality standards.

They focus on environmental responsibility too while manufacturing. They use sustainable practices to minimize their environmental impact.

They understand that it's always an effort and hence prioritize the well-being of our employees.

Rising Steel Industries is your destination!

With the best prices in the market, they get you the best deal. They have a strategic location and access to raw materials, so they have the best prices and quality. The main reason to choose them could be their fast and efficient delivery throughout India.

So get in touch and contact them right away to save money and get the best quality.

0 notes

Text

Stainless Steel 316 Boiler Tubes Exporters In India

Introduction :

Metinox Overseas is a renowned manufacturers, exporters, stockists, stockholders, and suppliers of a qualitative range of Stainless Steel 316 Boiler Tubes. SS 316 Boiler Tubes are molybdenum-alloyed steel and are the second most common austenite stainless steel, making them highly suitable for various applications. UNS S31600 Boiler Tubes are preferred in marine environments due to their greater resistance to pitting corrosion compared to other grades of steel.

Product Overview:

One of the significant advantages of WNR 1.4401 Boiler Tubes is their negligible responsiveness to magnetic fields, allowing them to be used in applications where a non-magnetic metal is required. Designed to meet national and international standards for quality raw materials, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Stainless Steel 316 Boiler Tubes Specification :

Specifications

ASTM A / ASME SA213 / A312

Range

6.35 mm OD upto 152.4 mm OD in 0.6 TO 10 mm thickness.

Form

Round, Square, Rectangular, Coil, U Tube, Pan Cake.

Wall Thickness

0.50 mm TO 6.0 mm

End

Plain End, Bevelled End

Length

Single Random, Double Random & Required Lengt

Types

Seamless / ERW / Welded

Application of Stainless Steel 316 Boiler Tubes

Applications for Stainless Steel 316 Boiler Tubes :

1. Chemical Processing: Ideal for transporting corrosive fluids, including acids and chemicals, in refineries and petrochemical plants.

2. Marine Applications: Utilized in shipbuilding and offshore platforms due to their resistance to saltwater corrosion.

3. Food and Beverage Industry: Employed in processing equipment where hygiene and resistance to corrosion are critical.

4. Pharmaceuticals: Used in sterilization and manufacturing processes requiring high cleanliness standards.

Conclusion :

Stainless Steel 316 boiler tubes offer a robust solution for industries that demand high performance under extreme conditions. Their resistance to corrosion, ability to withstand high temperatures, and structural integrity make them an ideal choice for applications involving steam and heat transfer. With ongoing advancements in manufacturing techniques, the reliability and efficiency of these tubes continue to enhance operational safety and reduce maintenance costs across various sectors. As industries evolve, the demand for high-quality materials like Stainless Steel 316 will remain pivotal in driving innovation and efficiency.

#Stainless Steel 316 Boiler Tubes#Stainless Steel 316 Boiler Tubes Manufacturers#Stainless Steel 316 Boiler Tubes Suppliers#Stainless Steel 316 Boiler Tubes Stockists#Stainless Steel 316 Boiler Tubes Exporters#Stainless Steel 316 Boiler Tubes Manufacturers In India#Stainless Steel 316 Boiler Tubes Suppliers In India#Stainless Steel 316 Boiler Tubes Stockists In India#Stainless Steel 316 Boiler Tubes Exporters In India#Stainless Steel 316 Boiler Tubes Manufacturers In Mumbai#Stainless Steel 316 Boiler Tubes Suppliers In Mumbai#Stainless Steel 316 Boiler Tubes Stockists In Mumbai#Stainless Steel 316 Boiler Tubes Exporters In Mumbai

1 note

·

View note

Text

Stainless Steel Electropolished Tubes Exporters In India

Stainless Steel Electropolished Tubes Supplier In India, SS Electropolished Tubes Exporter Electropolished Stainless Steel Tubing, Electropolished Tubes, Electropolished Tube Fittings 304/304l Electropolished Pipes, 316/316l Electropolished Pipes, Seamless/Welded EP Pipes

Stainless Steel Electropolished Pipes Manufacturer, Electropolished Tubes Exporter, High Purity Stainless Steel Tubing, Electropolished Stainless Steel Tubes, EP Tubes Processor in Mumbai, SS Electropolished Tubes in India, SS 304L Electropolished Tubes, SS 316L Electropolished Pipes, SS 904L Electropolished Tubing Suppliers, Electropolished Tubes Suppliers in India, Dairy Tubes, Tubes for Pharma Industry, Electropolished Tubes for Food Processing Industry, Best Quality EP Tubes in India, Mumbai

Kobs India is a leading processor and supplier of high quality electropolished or mechanically polished stainless steel pipes, electropolished tubes in all major stainless steel grades including 304/304L and 316/316L. Electropolishing is also commonly known as electrochemical polishing or electrolytic polishing. EP stainless steel tubes are generally made by carrying out the electropolishing process on high quality seamless and welded stainless steel tubes.

Standards Specification:

Size : ½”Inch and 24”Inch

Specifications : ASTM A249, A269, A270

Grades: : 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Length: : Up to 6 meters, custom cut lengths

Thickness: 1mm to 20mm, SCH 5/5S, 10/10S, 20/20S, 40/40S, 80/80S, 120/120S, 160/160S as per ANSI B36.19/36.10

Finish:BA Finish inside and outside, Electropolished finish inside and outside

Specifications : ASTM A312 / ASTM SA312

Material & Grade :

Stainless Steel : Grade: 304, 304L, 304H, 321H, 321, 316, 316L, 316Ti, 310S, 347, 347H, UNS31803 Duplex

Product Features:

Durability

High strength

Effective functionality

Sturdy construction

Corrosion resistance

Dimensional accuracy

Electropolished Tubes Manufacturer, Electropolished Tubes Manufacturers, Electropolished Tubes Suppliers, Electropolished Tubes Exporters, Electropolished Tubes Stockists.

Electropolished Tubes in Mumbai, Electropolished Tubes Manufacturers in Mumbai, Electropolished Tubes Suppliers in Mumbai, Electropolished Tubes Exporters in Mumbai, Electropolished Tubes Stockists in Mumbai.

Electropolished Tubes in India, Electropolished Tubes Manufacturers in India, Electropolished Tubes Suppliers in India, Electropolished Tubes Exporters in India, Electropolished Tubes Stockists in India.

Manufacturing Process :

The process commences with the formation of welded mother tube on the tube mill from imported and tested prime quality stainless steel strips. The latest TIG multi electrode welding technique is employed for superior weld quality and 100% Fusion, with argon purging, No filler metal added.

Product Usage & Application :

Useful in Paper & Pulp Companies

Useful in High Pressure Applications

Useful in Oil and Gas Industry

Useful in Chemical Refinery

Useful in Pipeline

Useful in High Temperature Application

Useful in Water Pipe Line

Useful in Nuclear Power Plants

Useful in Food Processing and Dairy Industries

Useful in Boiler & Heat Exchangers

Packing :

Packing is quite important especially in a case of international shipments in which consignment pass through various channels to reach the ultimate destination, so we put special concern regarding packaging.

We pack our goods in numerous ways based on the products. We pack our products in multiple ways, such as,

Shrink-wrapped

Carton boxes

Wooden pallets

Wooden boxes

Wooden crates

Why Choose Us :

You can get the perfect material according to your requirement at the least possible price.

We also offer Reworks, FOB, CFR, CIF, and door to door delivery prices. We suggest you to do deal for shipping which will be quite economical.

The materials we provide are completely verifiable, right from raw material test certificate to the final dimensional statement.(Reports will show on requirement)

e guarantee to give a response within 24hours(usually in the same hour)

You can get stock alternatives, mill deliveries with minimizing manufacturing time.

We are fully dedicated to our customers. If it will not possible to meet your requirements after examining all options, we will not mislead you by making false promises which will create good customer relations.

Tests we carry out (including both Destructive and Non-Destructive) :

Positive material recognition

Mechanical examining like tensile, Elongation and reduction of area.

Large-scale test

Chemical examination-Spectro analysis

Firmness test

Pitting protection test

Small tests

X-ray test

Impact analysis

Eddy current examining

Hydrostatic analysis

Prompt test

For more details: Website - http://kobsindia.in/ Phone No. - 9819523999 Email - [email protected]

#Electropolished Tubes in India#Electropolished Tubes Manufacturers in India#Electropolished Tubes Suppliers in India#Electropolished Tubes Exporters in India#Electropolished Tubes Stockists in India.

0 notes

Text

Steel Pipes and Tubes Industries (SPTI)

An ISO 9001:2008 Certified Company, Steel Pipes & Tubes Industries is India’s most trusted manufacturer, exporter and supplier of stainless steel tubes (ASTM A 312 304/304L, 316/316L), carbon steel pipes (ASTM A A106, A53, API 5L), alloy steel seamless pipes (ASTM A335 P11, P22), mild steel pipes, industrial steel tubes, galvanized steel pipes and black steel pipes.

We can manufacture and supply steel pipes which can be fabricated to customers design and specification in a variety of length and thickness requirements. We can also offer cold drawn seamless steel tubes to meet the custom design and specifications of our customers. We specialise in the manufacture and supply of cold drawn seamless steel tubes, and large diameter stainless steel welded pipes (100% X-Ray Tested). ISO 9001:2008 Certification ensures consistency in our operations and testing procedures.

Steel Pipes and Steel Tubes supplied by Metline Pipes & Tubes are used across wide range of industries including food processing, power generation, oil and gas, petrochemicals, petroleum pipelines, medical equipment, biopharma, pharmaceuticals, electrical engineering, fertilizer industry, dairy processing, boiler manufacturing and nuclear energy among others.

METLINE has been proudly servicing the steel pipe industry for over 40 years, as a major supplier and manufacturer of custom size steel pipes and steel tubes. We are the exclusive suppliers of stainless steel welded pipes, stainless steel seamless tubes, stainless steel tubing, alloy steel seamless pipes, boiler steel tubes, heat exchanger tubes, capillary tubes, coiled tubing, and galvanized steel pipes. We are serving all major cities and countries in their needs for steel pipes and steel tubes.

Our products are supplied to all major Industrial areas and cities in India such as Mumbai, Delhi, Bangalore, Hyderabad, Ahmedabad, Chennai, Kolkata, Surat, Pune, Nagpur, Indore, Thane, Bhopal, Visakhapatnam, Vadodra, Nashik, Faridabad, Rajkot, Aurangabad, Ranchi, Coimbatore, Raipur, Mysore, Bhubaneswar, Salem, Bhilai, Bhiwandi, Bikaner, Mangalore, Kochi (Cochin), Bhavnagar, Tirupur, Ankleshwar, Assam, Siliguri, Jamshedpur, Warangal, Nellore, Agartala and Thoothukudi.

Our high quality steel pipes, good customer service, and in house pipes and tubes processing capabilities have made us one of the emerging suppliers for steel pipes and tubes in Middle East countries including Bahrain, Cyprus, Egypt, Iran, Iraq, Israel, Jordan, Kuwait, Lebanon, Oman, Palestine, Qatar, Saudi Arabia, Syria, Turkey, United Arab Emirates and Yemen.

India’s #1 Supplier of Stainless Steel Pipes/Tubes, Chrome Moly Pipes,Black Pipes, Galvanised Pipes, Carbon Steel Pipes

Stainless Steel Pipes, Carbon Steel Tubes, Alloy Steel Tubes, MS Pipes Production and Stock Range

Outside Diameter: 6.00 mm OD up to 914.4 mm OD, Sizes up to 24” NB available Ex-stock, OD Size Steel Tubes available Ex-stock

Thickness Range: 0.3mm – 50 mm, SCH 5, SCH10, SCH 40, SCH 80, SCH 80S, SCH 160, SCH XXS, SCH XS

Type: Seamless / ERW / Welded / Fabricated / CDW

Key Steel Pipes & Tubes Products & Grades

1. Stainless Steel Seamless Pipes & Tubes – 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

2. Stainless Steel Welded Pipes & Tubes - 304, 304/L, 316/L, 904L, 310S, 321H, 347H, 446

3. Square Stainless Steel Pipes, Round Stainless Steel Tubes,Rectangular Stainless Steel Pipes & Tubes

4. Carbon Steel Seamless Pipes as per ASTM A 106 Grade B/API 5L Grade B/ASTM A 53 Grade B

5. Carbon Steel Seamless Tubes as per BS 3059, ASTM A 179, ASTM A 192, ASTM A 210 GR.A1

6. Alloy Steel Seamless Pipes as per ASTM A335 Grade P1/ P5/ P9 / P11/ P12 / P22 / P91

7. LTCS Pipe - Low Temperature Carbon Steel Pipes as per ASTM A 333 Grade 6

8. Alloy Steel Seamless Tubes as per ASTM A213 Grade T5/T9/T11/T12/T22/T91

9. ERW Black Pipes as per IS:1239/I, IS: 3589 Grade 330 or Grade 410

10. Galvanised Pipes as per IS:1239/I

11. Square and Rectangular Steel Pipes as per IS: 4923

12. ERW Boiler Tubes: BS 3059, ASTM A 214

13. Air Pre Heater Tubes to BS: 6323 PART V

14. Hydraulic Tubes to DIN 2391 ST. 35, ST. 45 & ST. 52

15. Seamless Heat Exchanger Tubes ASTM A 179

16. CDW TUBES IS: 3074 or BS 980

17. CRCA ERW Tubes to IS 3601 OR IS 3074

18. Stainless Steel Electropolished Pipes Manufacturer/Supplier

19. Alloy Steel Fittings Manufacturer- ASTM A234 WP5, P11, P22, P91

1 note

·

View note

Text

Titanium Sekrup dan bolt

jual titanium batangan: https://www.titanium.co.id

TITANIUM BATANGAN / BARS / RODS

Kami menjual Round Titanium Batangan produk sesuai ASTM B348/ASME SB348 tersedia di Grades 1, 2, 3, 4, Gr5 (Ti6AL4V) dan nilai titanium lainnya in round bars sizes up to 500 diameter, rectangular and square sizes are also available. Kami menyediakan AMS 4928, AMS 4911, AMS 2631, AMS 4901, AMS 4907, AMS 4919, AMS 6931, AMS T 9046, AMS T 9047, ASTM B 337, ASTM B 338, ASTM B 381, ASTM F 67, ASTM F 136, ASTM B 348, ASTM B265 dan pipa, fittings & flanges with NORSOK M630 Rev 2 MDS T01 specifications for North sea petroleum industry developments dan operations dengan sangat harga murah.

pipa titanium https://titanium.co.id/2016/09/15/titanium-tubes-pipes-fittings/

TUBE PIPA TITANIUM DAN SPECIAL METALS

Tabung Titanium, Pipa dan fiting tersedia dalam tipe Seamless maupun Welded, diproduksi dengan spesifikasi ASTM / ASME dalam berbagai ukuran. Flange types like weld-neck, slip-on, blind, lap joint, threaded and socket weld are available in ASME B16.5 specifications. We supply titanium tubes to leading Oil & Gas industry fabricators to build heat exchangers, air-coolers and other process equipments. Depending upon the requirement of your projects we can supply with ASTM/ASME or NORSOK M630 specifications. For detailed information for Titanium Tubing, please contact your Special Metals Indonesia sales representative.

titanium batangan https://titanium.co.id/2016/09/15/titanium-bars-rods/

Grade 5, also known as Ti6Al4V, Ti-6Al-4V, Ti 6-4 or R56400 adalah paduan titanium yang paling umum digunakan. Ini memiliki komposisi kimia 6% aluminium, 4% vanadium, 0.25% (maximum) iron, 0.2% (maximum) oxygen, and the remainder titanium. Grade 5 is used extensively in Aerospace, Medical, Marine, and Chemical Processing. It is significantly stronger than commercially pure titanium while having the same stiffness and thermal properties. Among its many advantages, it is heat treatable. This grade has an excellent combination of strength, corrosion resistance, weld and fabricability. In consequence, its uses are numerous such as for military aircraft or turbines. It is also used in surgical implants. Generally, it is used in applications up to 400 degrees Celsius. Its properties are very similar to those of the 300 stainless steel series, especially 316. Ti-6Al-4V is a two phase alpha + beta grade of titanium and is the most widely used of all the titanium grades. USA membuat logam AMS4928 dan AMS4911 ada stok.

harga titanium batangan https://www.titanium.co.id

PT Special Metals Indonesia adalah stokis terkemuka dan penyalur global untuk berbagai bahan titanium seperti Titanium Batang, Balok, Lempengan, Lembaran, Tabung pemindah panas, Pipa, Penyambung dan siku, Baut Titanium, Sekrup, Tabung Bersisik dan Inconel (pelapisan logam) kepada semua pelanggan baik dari industri dirgantara, otomotif, elektronik, presisi manufaktur, persenjataan, kelautan, galangan kapal, minyak & gas, sampai pembangkit tenaga listrik dan konstruksi.Kami menyediakan stok dan variasi yang luas dari titanium batangan, lempengan, balok dan gulungan atau yang ditempa datar. Bila anda membutuhkan produk titanium dalam bentuk khusus, kami menggunakan jasa mitra global kami yang akan menyediakan proses konversi secara independen seperti penempaan, penggulungan dan kurasi di suhu tinggi..

jual plat titanium https://titanium.co.id/2016/09/15/titanium-sheets-and-plates/

Kami menjual Plat Titanium / Lembar sesuai ASTM B265 / ASTM SB265 tersedia dalam gred CP dan Alloy. Ketebalan stok kami mulai dari 0,5mm hingga 100 mm. Plat Titanium tersedia dalam ukuran lebar dan panjang berdasarkan kebutuhan pelanggan, kami dapat memotong sesuai kebutuhan anda. Pelanggan hanya dapat membeli ukuran yang mereka butuhkan dan tidak seprei penuh. Kami menyediakan Lembar dan Pelat Titanium dengan harga yang sangat kompetitif dengan kualitas yang baik, dibuat oleh pabrik papan atas.

• Sheets 0.5 ~ 4.0 tk x <1000 Width x <3000 Length

• Plates 4.1 ~ 60.0 tk x <3000 Width x <4000 Length

Kami memasok titanium ke Jakarta, Surabaya, Bandung, Medan, Semarang, Bekasi, Tangerang, Depok, Palembang – Indonesia.

Hastelloy https://titanium.co.id/2016/09/26/nickel-alloys-inconel-monel-hastelloy-incoloy/

PT Special Metals Indonesia distributes high temperature, corrosion resistant grades of Nickel and Cobalt alloy metals. Materials are supplied in sheet, plate and bar forms. Our long standing relationship with the premier mills as well as US, Europe and Japan principals allows us fast deliveries for hard to find metals for the aerospace, petrochemical and electronic industries. Supplied in Annealed condition or Solution Treated & Aged-STA condition.

Inconel, Incoloy Flanges https://titanium.co.id/2020/03/01/titanium-flange/

TITANIUM & NICKEL ALLOY FLANGE

PT Special Metals Indonesia supplies Titanium, Nickel Alloys and exotic metal flanges in sizes ranging from 1/2” to 24”. All flat face flanges are supplied with serrated spiral finish per ASME/ASTM B16.5

Alloy name, UNS Number and flange type are the three requirements for manufacture of flangesand forged items to industry standards such as ASME B16.5 or non-standard dimensions.

These alloys are primarily selected for use in high temperature and/or corrosive environments.

Incoloy® alloys 800H and 800HT are utilized in high temperature services where resistance to creep and rupture is required.

Special Steel 316Ti, SS317L, 904L

904L is an austenitic stainless steel. In comparison to 316L, its molybdenum addition gives it superior resistance to localized attack (pitting and crevice corrosion) by chlorides and greater resistance reducing acids and in particular its copper addition gives it useful corrosion resistance to all concentrations of sulphuric acid. Its high alloying content also gives it greater resistance to chloride stress corrosion cracking, but it is still susceptible. Its low carbon content makes it resistant to sensitization by welding and which prevents intergranular corrosion https://titanium.co.id/2016/09/26/special_stainless_steel/

https://titanium.co.id/2016/09/26/special_stainless_steel/

Alloy 317L is a molybdenum containing, low carbon austenitic stainless steel with increased additions of chromium, nickel, and molybdenum for better corrosion resistance and increased resistance to chemical attack for sulfurous, acetic, formic, citric, and tartaric acids. Due to its low carbon content, 317L also provides resistance to sensitization when welded and higher creep, stress to rupture, and tensile strength at elevated temperatures. It is non-magnetic in the annealed condition but may become slightly magnetic after welding.

Heat Exchanger Tubes - Seamless & Welded

https://titanium.co.id/2016/09/26/heat-exchanger-tubes-seamless-welded/

Special Metals Indonesia is a distributor of high quality seamless & welded tubing certified to SA-178 Grade A and SA-214. Specializing in boiler tubes, condenser tubes, heat exchanger tubes, ferrules, and boiler tube plugs. Our customers include mechanical contractors, original equipment manufacturers, fabricators, fertilizer plants, petro-chemical plants, Rayon mills, Paper and Pulp mills, utility power plants, Oil & Gas refineries and other distributors located throughout the South East Asia region. We highly specialize in supplying titanium Gr2 SMLS & welded tubes and special grade alloy materials.

Titanium Sekrup dan bolt

PT Special Metals Indonesia menyediakan beragam pengencang, seperti baut Titanium, mur hex, sekrup, kancing berulir, dan ring. Our titanium fasteners are available in a variety of sizes in stock, as well as additional sizes upon request. Titan Titanium products meet aerospace and industrial specificationsare available in commercially pure grade 2 as well as Grade 5 Ti6Al4V.

• Standards: All DIN specifications & ANSI B18.2.3.4M. • Size: M3 ~ M36 and All Inch sizes. • Ukuran / spesifikasi khusus dibuat sesuai kebutuhan pelanggan.

https://titanium.co.id/2016/09/26/titanium-screws-nuts-and-bolts/

1 note

·

View note

Text

Stainless Steel 316 Boiler Tubes Suppliers In India

Introduction

Metinox Overseas is a renowned manufacturer, exporter, stockist, stockholder, and supplier of a qualitative range of Stainless Steel 316 Boiler Tubes. With a commitment to quality and customer satisfaction, Metinox Overseas stands as a leader in the industry, delivering products that meet the highest standards.

Description

Stainless Steel 316 Boiler Tubes, also known as UNS S31600 Boiler Tubes, are molybdenum-alloyed steel and the second most common austenite stainless steel. These tubes are highly suitable for various applications, particularly in marine environments due to their superior resistance to pitting corrosion compared to other grades of steel. One of the significant advantages of WNR 1.4401 Boiler Tubes is their negligible responsiveness to magnetic fields, making them ideal for applications requiring non-magnetic metals.

Designed to meet both national and international standards, our SS Boiler Tubes are available in various sizes and can be customized to meet specific requirements at affordable rates for our esteemed clients.

Benefits

Stainless Steel 316 Boiler Tubes offer numerous advantages:

Corrosion Resistance: Enhanced resistance to pitting and crevice corrosion in chloride environments.

Non-Magnetic Properties: Negligible responsiveness to magnetic fields, suitable for specific applications.

Versatility: Suitable for a wide range of industries, including marine, chemical processing, and more.

Durability: High strength and excellent durability ensure long-term performance.

Customization: Available in various sizes and customizable to meet specific requirements.

Specifications

The Stainless Steel 316 Boiler Tubing comes with the following specifications:

Standards: ASTM A / ASME SA213 / A312

Range: 6.35 mm OD up to 152.4 mm OD in 0.6 to 10 mm thickness

Form: Round, Square, Rectangular, Coil, U Tube, Pan Cake

Wall Thickness: 0.50 mm to 6.0 mm

End: Plain End, Bevelled End

Length: Single Random, Double Random & Required Length

Types: Seamless / ERW / Welded

Product Overview

As leading manufacturers, suppliers, stockists, and exporters, Metinox Overseas is committed to providing top-quality Stainless Steel 316 Boiler Tubes. Our products undergo rigorous quality checks to meet industry standards and exceed customer expectations.

We offer excellent customer service and support, with a dedicated team available to assist clients with inquiries and ensure satisfaction with every purchase. Metinox Overseas prioritizes sustainability and environmental responsibility in all aspects of our operations, adhering to strict environmental regulations and minimizing our environmental impact through responsible practices.

Conclusion

Choose Metinox Overseas for all your Stainless Steel 316 Boiler Tube needs. Experience the difference in quality, reliability, and service that sets us apart as an industry leader.

For inquiries and more information, please contact us at:

Phone: +91-98199 80997 / +91-70212 61928

Explore our extensive range of Stainless Steel 316 Boiler Tubes and experience unparalleled quality and service with Metinox Overseas.

0 notes

Text

Advantages of using stainless steel materials

Stainless steel pipes, as well as copper pipes, have proven themselves in heating and water supply systems. They are ideal for strapping boilers and boiler room equipment. They look perfect do not require painting because they do not oxidize and do not rust.

Stainless steel is a durable metal, alloy steel, characterized by the quality of high resistance to corrosion. Resistance to corrosion in the atmosphere and aggressive environments, exposure to various temperatures provide alloying elements that make up this metal.

Advantages of stainless steel materials

Strength

Unlike copper pipes, stainless steel is a more durable material that does not much but allocates stainless steel for the installation of plumbing and heating systems.

Durability

Just like copper pipe, 304 stainless steel pipe can stand for centuries and does not require replacement on the walls of stainless steel pipes; there are no rust outgrowths which, like a sponge, absorb alkali, which contributes to blockages in ferrous metal pipes.

Not oxidized

Stainless steel sheets are not only not susceptible to corrosion but also not oxidized. Therefore they do not require additional attention in the form of painting or varnishing because the 304 stainless steel sheet will always look perfect - like new. Although stainless steel does not have an antiseptic and disinfecting property like copper, it does not cost much acid and various aggressive chemical influences.

Installation

The installation of a tube with 316 stainless steel tube is slightly inferior to copper tubes because it cannot be soldered with tin as easy as copper. However, this installation method is not the only one, and it is possible to assemble pipelines on a press-fitting which is also widely used in the installation of copper pipes and also has the advantage over polypropylene in that it is carried out in a non-linear way

Low expansion coefficient

It is also worth saying that stainless steel pipes have a very low expansion coefficient, like all metals, so you can safely mount long pipelines without fear that when expanding, they will lead and distort due to heating.

Thermal

conductivity The thermal conductivity of stainless steel pipes is inferior to copper pipes. However, still, it is metal, which is quite suitable for use as a material for the manufacture of heat exchangers. And its heat resistance is widely used in high-temperature furnaces.

Heat resistance

The melting point of 316 stainless steel sheet is about 1800 ° C; therefore, stainless steel sheets can tie boiler rooms of any power into flesh up to an industrial scale. And the strength of stainless tubes is in no way inferior to a steel tube.

Disadvantages of using stainless steel materials are:

There are almost no shortcomings in stainless steel pipes, except that they can burst when water freezes in them. But this is rather not a drawback, but a property of any metal related to a low ductility coefficient.

At a cost, stainless steel pipes will cost less than copper pipes, but slightly more expensive than steel pipes.

1 note

·

View note