#Stainless Steel 310 Pipe manufacturers

Explore tagged Tumblr posts

Text

Stainless Steel 310 Seamless Pipes Exporters In India

Metinox Overseas is the pioneering exporter of remarkable quality Stainless Steel 310 Pipes & Tubes in Mumbai, India. We include high-quality SS 310 Pipes and Tubes in a range of sizes and shapes, all of which are engineered to follow national and international raw material quality requirements.

Stainless Steel 310 Pipes is a chromium-nickel alloy that has the same strength as 304-grade pipes but has greater heat and corrosion resistance. Carbon, manganese, silicon, phosphate, sulphur, and a minimum of 24 percent chromium and 19 percent nickel make up the material's concentration. Welded and smooth 310 stainless steel pipes are used in a number of commercial applications. Round, rectangle, rectangular, and hydraulic types can also come with the ASTM 310 ERW Tubing. The pipes can be seamless, welded, welded for electrical fusion, and welded for electrical resistance.

In mildly oxidizing, nitriding, cementing, and thermal cycling applications, Alloy 310 can be used; however, the overall service condition must be lowered. Also known as UNS S31000, these pipes and tubes are not designed for service in wet corrosive environments. The WNR 1.4841 pipes' high carbon content, which is present to improve creep properties, has a negative influence on aqueous corrosion protection. Our SS 310 Seamless Pipe is available at market-leading rates and can be sold in customizable length sizes and forms. Our Stainless Steel 310 Welded Tubes can also be manufactured and machined to suit our customers' piping needs.

#stainlesssteel#manufacturers#industrial#suppliers#Seamless Pipes#pipesupplier#Stainless Steel 310/310S Seamless Pipes#Stainless Steel 310/310S Seamless Pipes Manufacturers#Stainless Steel 310/310S Seamless Pipes Suppliers#Stainless Steel 310/310S Seamless Pipes Stockists#Stainless Steel 310/310S Seamless Pipes Exporters

0 notes

Text

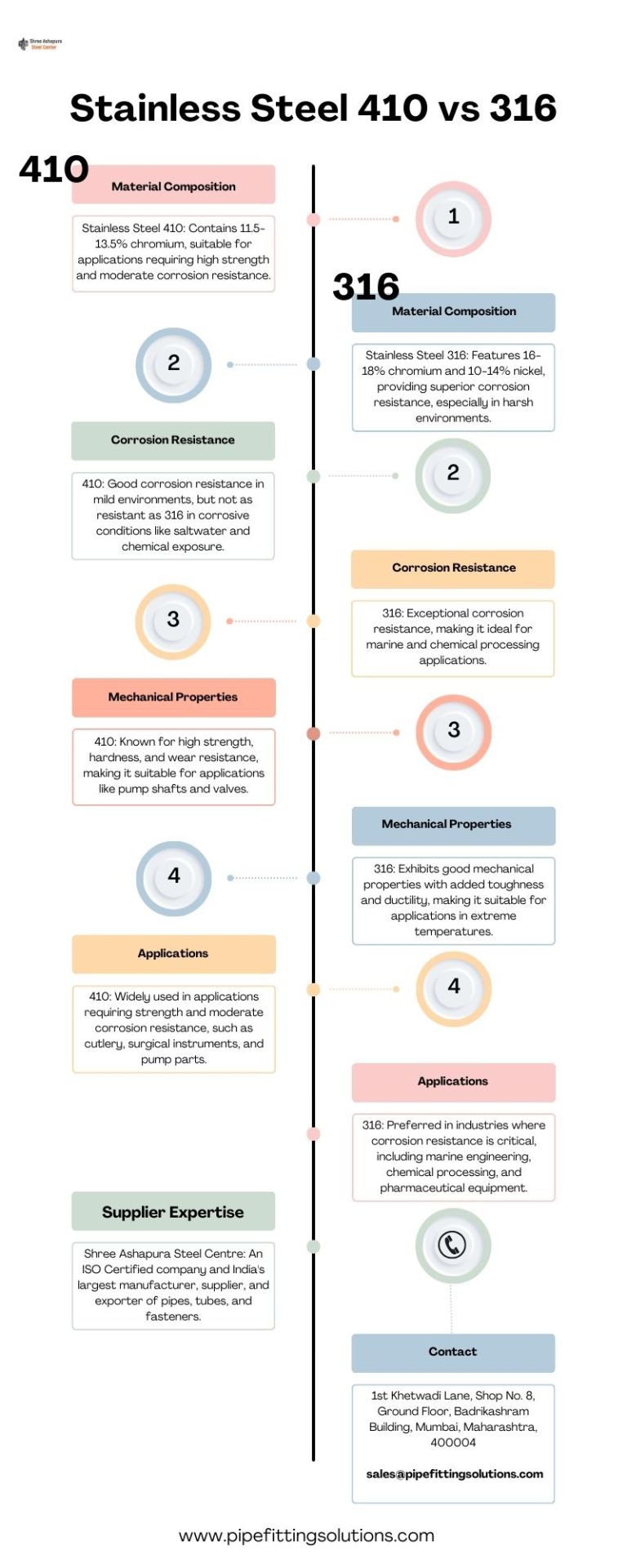

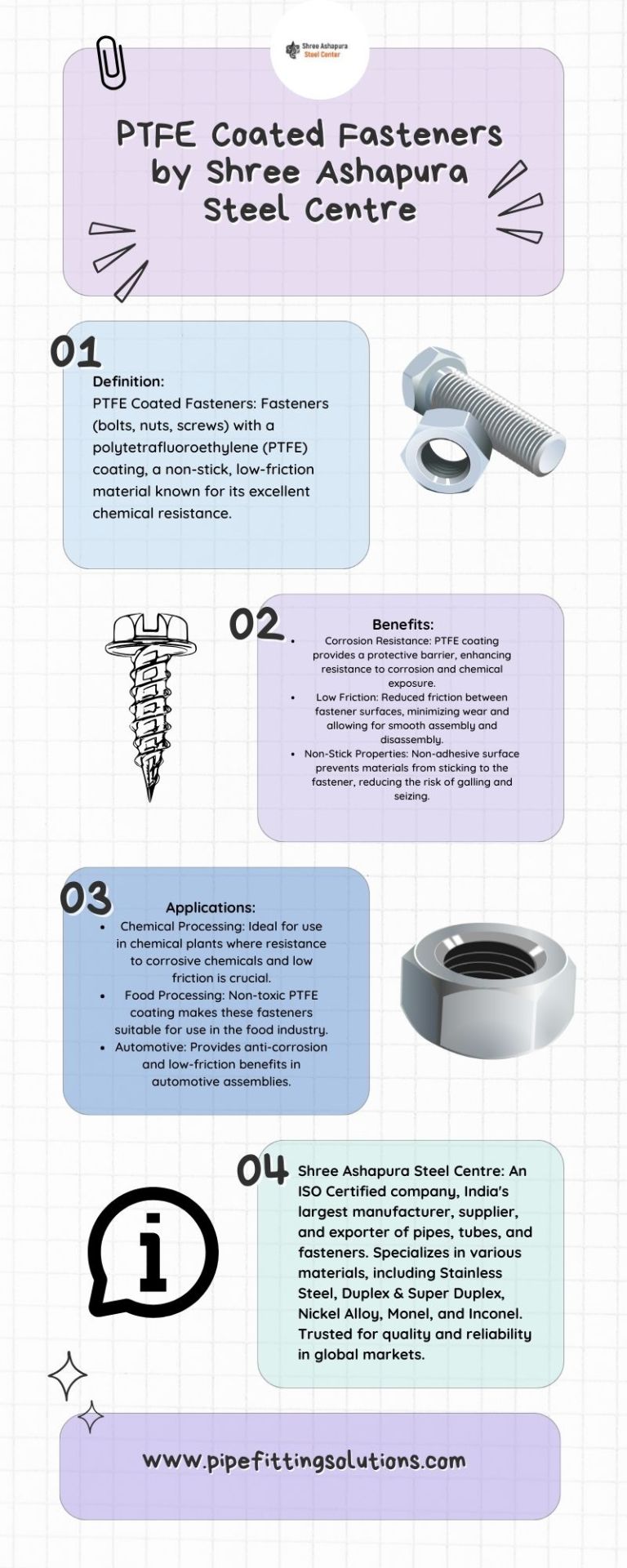

Shree Ashapura Steel Centre an ISO Certified company. We are India's largest Manufacturers, Suppliers and Exporters of Pipe & Tubes and Fasteners, etc. in a various material such as Stainless Steel, Duplex & Super Duplex, Nickel Alloy, Monel, Inconel.

#Stainless Steel 310 Seamless Pipe Manufacturer#DIN 1.4841 Seamless Tube#ASME SA312 SS 310 Polished Pipe#UNS S31000 Seamless Pipe Supplier#ASTM A312 TP310 Pipe#Stainless Steel 310 ERW pipe Stockiest#ss 310 tube#310 stainless steel square tubing#DIN 1.4539 Seamless Tube#ASME SA673 SS 904L Polished Pipe Manufacturer#UNS N08904 Seamless Pipe Supplier#ASTM A312 tp 904L Welded Pipe#DIN 1.4539 Rectangular Pipe#Stainless Steel 904L Seamless Tube Stockiest

0 notes

Text

Learn about the many kinds of seamless stainless steel pipe

What is Stainless Steel Seamless Pipe ?

Stainless steel seamless pipe is a kind of stainless steel pipe that is fabricated without any seams or welding. It is made using a method known as seamless pipe fabrication, which involves heating a solid steel billet and then piercing it to create a hollow tube. With no weld beads or seams, the seamless technique enables a smooth and homogeneous surface that is very heat- and corrosion-resistant.

Stainless steel seamless pipes are often used in sectors including oil and gas, chemical, petrochemical, pharmaceutical, food and beverage, and maritime where pipes that can survive harsh environments like high pressure, high temperature, or corrosive environments are needed.

They may be produced in a variety of stainless steel grades, including 304, 310, and 316, and come in a variety of diameters and thicknesses.Inox Steel India is the Leading Stainless Steel Seamless Pipe Manufacturers in India.

Types Of stainless steel seamless pipe

There are several types of stainless steel seamless pipes accessible, each with special qualities and traits. The following are a few of the most popular kinds of seamless stainless steel pipes:

Stainless Steel 304 Seamless Pipe

Stainless Steel 304 seamless pipe is often used in industries such as the food and beverage sector, chemical processing, and pharmaceuticals where corrosion resistance is important. Additionally, it has uses in architecture, including railings and balustrades.

Stainless Steel 310 Seamless Pipe

Stainless Steel 310 seamless pipe commonly found in high-temperature equipment including furnaces, kilns, and other heat treatment devices. It is frequently used for applications that need resistance to corrosive conditions and high-temperature gases in the chemical and petrochemical industries.

Stainless Steel 316 Seamless Pipe

Stainless Steel 316 seamless pipe is the perfect material for applications that require both corrosion resistance and structural integrity because of its high strength and outstanding weldability.It is frequently utilised in sectors including maritime, chemical processing, and pharmaceuticals because of its superior corrosion resistance, especially in chloride conditions.

Stainless Steel 317 Seamless Pipe Manufacturer in India

Stainless Steel 317 Seamless Pipe Manufacturer in India. Based on the requirements and drawings provided by the customer, we modify the stainless steel 317 seamless pipe. With accuracy and superior stainless steel materials, we manufacture ASTM A312 SS 317 Seamless Pipe.

Overall, due to their superior qualities and adaptability, seamless stainless steel pipes are a crucial component in many sectors. Moreover, we are a Stainless Steel Pipe Supplier in Australia and stainless steel pipe manufacturers in singapore.

For More Detail Visit:Seamless Pipe Manufacturers in India

0 notes

Text

Monel K500 Blind Flanges Exporters

Monel Blind Flanges are manufactured without a bore and used to blank off the ends of piping, Valves and pressure vessel openings. From the standpoint of internal pressure and bolt loading, blind flanges, particularly in the larger sizes, are the most highly stressed flange types. A Blind flange is round plate which has all of the relevant boltholes but no center hole, and because of this feature this flange is used to close off the ends of a piping systems and pressure vessel openings. It also permits easy access to the interior of a line or vessel once it has been sealed and must be reopened.

However, most of these stresses are bending types near the center, and since there is no standard inside diameter, these flanges are suitable for higher pressure temperature applications.

Monel Blind Flanges are used for testing the flow of gas or liquid through a pipeline or vessel. It helps to close the end of piping systems or vessel openings. It allows easy access to the pipeline when there is a requirement to work done inside the line. They are used in high pressure applications available in all grades, materials, size and specifications. Blind pipe flanges are typically provided with a raised face, flat face, or RTJ facing. When a raised face is necessary for blind pipe flanges, the standard height is 1/16" for blind pipe flanges under 400 ( 2.4360)#. For blind pipe flanges of 400 ( 2.4360)# and up, the standard blind pipe flange raised face height is 1/4".

B16.5 ASTM A182 Blind Flange, Fusion Bonded Epoxy Coating, EN 1092-2 PN16 Blind Flange, ASME B16.5 Dual Monel Alloy Blind Flange, ANSI B16.5 Class 150 Flat Face Blind Flange, Monel Alloy Reducing Blind Flange Stockiest.

Standards Specification:

Size : 1/2" to 48"

Specifications : ASTM A182

Rating: 150#, 300#, 600 (2.4640)#, 900#, 1500#, 2500#,

Material & Grade :

Stainless Steel :Grade: 304 (1.4301), 304L (1.4307), 304H (1.4948), 309 (1.4828), 309S, 310, 310S (1.4845) , 316 ( 1.4401), 316H, 316L( 1.4404 /1.4432) , 317, 317L (1.4438), 321 (1.4541), 321 H(1.4878), 347 (1.4550), 347H (1.4961), 904L (1.4539) Duplex Steel:Grade: 2205 (1.4507) Super Duplex Steel:Grade: 2507 (UNS S32750) (1.4410) (UNS S32750) Inconel :Grade: Inconel 600 (2.4640), Inconel 601 (2.4851), Inconel 625 (2.4856), Inconel 718(2.4668) Incoloy :Grade: Incoloy 800 (2.4958), Incoloy 800H, Incoloy 800HT Nickel :Grade: Nickel 200, Nickel 201 Titanium :Grade: Gr.1 (3.7025) , Gr.2 (3.7035) , Gr.3:(3.7055) , Gr.5(3.7164/65), Gr. 7(3.7235) , Gr. 11 (3.7225) Hastalloy :Grade: Hastalloy B2, Hastalloy B3, Hastalloy C22, Hastalloy C276, Hastalloy X.

For More Information Visit Our Website - http://www.kobsindia.in/monel-blind-flange.html Contact Us -9819523999 Email Id - [email protected]

4 notes

·

View notes

Text

Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh

Arisa Impex is a leading Manufacturer, Exporter, and Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh. Our SS Angle, Black Round Bar, Coil, Flange, Flat Bar, Hexagonal Bar, Pipe and Tube, Round Bar, and more Manufacturing units are based in Ahmedabad, Gujarat. Our SS Hexagonal Bars offer superior quality, precision, and versatility, ideal for manufacturing, construction, automotive, aerospace, and more. Features of SS Hexagonal Bar: Durability and Strength: We design our stainless steel hexagonal bars for high strength and durability, ideal for demanding applications. Corrosion Resistance: Our high-quality stainless steel hexagonal bars are corrosion-resistant, ensuring long-lasting performance and integrity in harsh environments. Versatility: Industries like construction, automotive, machinery, aerospace, and more widely use these stainless steel hexagonal bars. Precision and Quality: Arisa Impex manufactures SS hexagonal bars with precise dimensions and high-quality standards, meeting national and international specifications. Easy Machining and Fabrication: Our stainless steel bars are easy to machine, fabricate, and weld, perfect for custom applications and processes. Specification: SS Hexagonal Bar Grades: 201, 202, 301, 302, 303, 304, 304H, 304L, 316, 316H, 316L, 309, 309S, 310, 310S, 316Ti, 317, 317L, 347, 321, 321H, 410, 416, 420, 430, 430F, 431, 440C, 630, 17-4PH, F51, ASTM A276, ASTM A484 Size: 16mm to 55mm Length: 4 to 6meters, or as customer’s requirements Tolerances: K11, K10, K12, H8, H10, K9, H9, H11, H13, H12 Packing: Standard packing Specifications: EN 10272, EN 10088-3 Grade 1.4301 (304), 1.4306 (304L), 1.4401 (316), 1.4404 (316L) Finish: Black, Peeled, Polished, Smooth Turned, Rough Turned, Centreless Ground, Grinding, Cold Drawn Turned, Bright Drawn, Bright, Annealed Applications of SS Hexagonal Bars: Manufacturing Automotive Aerospace Marine Electrical Arisa Impex is a Supplier of Stainless Steel Hexagonal Bar in Andhra Pradesh including locations like Visakhapatnam, Vijayawada, Guntur, Nellore, Kurnool, Kakinada, Rajamahendravaram, Kadapa, Mangalagiri-Tadepalli, Tirupati, Anantapuram, Ongole, Vizianagaram, Eluru, Proddatur, Nandyal, Adoni, Madanapalle, Machilipatnam, Tenali, Chittoor, Hindupur, Srikakulam, Bhimavaram, Tadepalligudem, Guntakal, Dharmavaram, Gudivada, Narasaraopet, Kadiri, Tadipatri, Chilakaluripet. For more information or to place an order, contact Arisa Impex today! Read the full article

0 notes

Text

DIN 1.4835 Pipes & Tubes in Spain: Excellence in High-Temperature Applications by Vento Tubos

Due to its remarkable resistance to corrosive conditions and high temperatures, DIN 1.4835 Pipes & Tubes have attracted a lot of interest in Spain's industrial sector. Vento Tubos, one of the Major Manufacturer of DIN 1.4835 Pipes & Tubes in Spain, provides these specialty pipes and tubes with unmatched quality and longevity. These pipes, which are widely utilized in sectors including construction, energy, and petrochemicals, guarantee dependability in demanding applications. With an emphasis on Vento Tubos' proficiency in offering premium solutions, this paper examines the characteristics, uses, and advantages of DIN 1.4835 pipes.

Outstanding Material Properties

High-alloy austenitic stainless-steel DIN 1.4835, sometimes referred to as X12CrNi25-21 or AISI 310, is made to function very well in harsh environments. Important characteristics include:

Heat Resistance: Perfect for high-temperature settings, it functions flawlessly at temperatures as high as 1150°C.

Excellent resistance to oxidation and scaling: provided by corrosion resistance, even in hostile chemical conditions.

Mechanical Strength: Under heat and mechanical stress, durability is guaranteed by high tensile strength.

Because of these characteristics, DIN 1.4835 pipes and tubes are the best option for Spain's industrial infrastructure, particularly in situations where dependability and extended service life are essential.

Applications of DIN 1.4835 Pipes in Spain

For effective operations, Spain's varied sectors mostly depend on reliable pipe systems. Pipes and tubes made to DIN 1.4835 are used for:

Petrochemical Industry: Because of their resistance to sulfur compounds and thermal wear, they are utilized in gas plants and refineries.

Energy and Power Generation: Because of their resistance to high temperatures, heat exchangers, boilers, and turbine components depend on them.

Engineering and construction: Used in buildings subjected to intense heat and chemical reactions.

Vento Tubos has been in the forefront of offering solutions to various industries, making sure that every product satisfies particular customer needs as well as worldwide quality standards.

Why Choose Vento Tubos?

When it comes to providing DIN 1.4835 pipes and tubes that are suited to the ever-changing demands of contemporary businesses, Vento Tubos is a reputable Manufacturer of DIN 1.4835 Pipes & Tubes in Spain,. Customers favour Vento Tubos for the following reasons:

Extensive Selection: A large assortment of wall thicknesses, sizes, and finishes appropriate for a variety of uses.

Certified Quality: Products meet international standards such as ASTM, DIN, and EN, guaranteeing unwavering quality.

Technical know-how: A skilled group provides specialized solutions, technical advice, and dependable post-purchase assistance.

Quick Deliveries: By minimizing operational downtime, effective supply chain management guarantees on-time delivery across Spain.

Conclusion

DIN 1.4835 under Spain's industrial environment, pipes and tubes are essential because they provide unparalleled performance under demanding circumstances. Vento Tubos is a dependable partner for businesses looking for high-temperature, long-lasting plumbing solutions. Vento Tubos has established itself as a leader in the industry by focusing on quality, innovation, and client happiness. When you choose Vento Tubos for all of your DIN 1.4835 pipe and tube needs, you can be sure that every product will be of unmatched quality. For More Details CLICK HERE

0 notes

Text

Meghmani Metal Industries is a Manufacturer and Supplier of SS Pipe and Fittings in Rajasthan, India. Meghmani Metal Industries offers a comprehensive range of high-quality Stainless Steel (SS) Pipes and Fittings that cater to various industrial applications. We take pride in producing an extensive variety of SS pipes, tubes, and fittings, available in seamless, welded, threaded, and fabricated forms. We offer SS pipes and fittings in various grades, including 304, 316, and 310, ensuring compatibility with different environmental conditions and operational demands. Why Choose Meghmani Metal Industries' SS Pipe and Fittings? Superior Quality: Manufactured using high-grade stainless steel, these pipes and fittings are designed for long-lasting performance in harsh industrial environments. Corrosion Resistance: Stainless steel's natural resistance to rust and corrosion ensures the longevity of the pipes, making them ideal for both indoor and outdoor applications. Precision Engineering: Meghmani Metal Industries' SS Pipes and Fittings are precisely engineered to meet stringent industry standards and specifications. Versatility: Suitable for a wide range of applications, including fluid and gas transportation, structural support, and pressure systems. Applications: Pharmaceutical Industry Chemical Processing Food and Beverage Oil & Gas Water Treatment Pulp and Paper FAQs: What makes SS pipes and fittings better than other materials? Stainless steel is more durable, resistant to corrosion, and has a longer lifespan compared to other materials like carbon steel or plastic. It also maintains its strength at high temperatures. How do I maintain SS pipes and fittings? Stainless steel requires minimal maintenance. Regular cleaning and ensuring there is no accumulation of debris or corrosive substances will help maintain their performance and appearance. Are these pipes customizable for specific needs? Yes, Meghmani Metal Industries offers customizable SS pipes and fittings, with options for different sizes, grades, and finishes to meet specific operational requirements. Meghmani Metal Industries is Supplier of SS Pipe and Fittings in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes

Text

How To Select A Good Stainless Steel Round Bar Using Weight Chart

Stainless steel round bars are commonly used in the industrial sector in conditions involving high as well as low pressure work. They are either made seamless or in welded nature. The material used in manufacturing these pipes has to go through different procedures like melting, casting and hot rolling. Following is a detailed explanation of this procedure:

Melting: the stainless steel material is composed of iron, chromium, nickel, etc and it is melted in Electric Arc Furnace (EAF) for further steps.

Casting: the molten steel is then emptied into a cast to form billets or large slabs which will be used to make the round bars.

Hot rolling: this process involves passing the billets obtained in the casting process through rollers to achieve round bars. The diameter and the thickness of the bars is also decided in this stage.

After this, the bars are given cold drawing or heat treatment to provide enhanced strength or to relieve stress.

These bars are either seamless or welded. The seamless round bars are made by piercing a heated billet, thereby leaving no weak areas on the surface, while welded round bars are made by joining two ends of a steel plate by performing welding on it.

There are at least 5 different grades of stainless steel round bar namely austenitic, ferritic, martensitic, duplex and Precipitation-Hardening grades.

It becomes very hard for someone to select a good stainless steel round bar which fit into their specific preference and requirement due to availability of so many grades.

Hence following are some pointers one should remember while selecting a round bar using a weight chart:

Knowing the specification requirement:

Stainless steel round bars have a variety of grades like austenitic, ferritic, duplex, etc while contain more standard specifications like 304, 316, 310, etc, which are used in demanding environments. Hence, before selecting a material, one should know the requirements of the machinery like corrosion resistance, durability, weldability, etc. this helps in proper functioning of the machinery.

Selecting based on requirement:

One should be familiar with the conditions of the working environment, this helps in selection process regarding the material grade. many factories have extreme heat zones, high pressure work, high exposure to corrosion or low temperature zone as well. Hence because of this, there are different standard specified grades available in the market and one should carefully examine them as per the need before selecting.

Use of weight chart:

The weight chart contains very valuable information of the material related to its size, dimensions and weight.

The size of rod is an important variable as the rod should be able to cover the required area without falling short.

The dimensions are an important aspect as well because the diameter or thickness of different materials should be compatible otherwise it may lead to accident.

The weight of the material is directly proportional to its capability to handle pressure while maintaining its stability hence, one should calculate the weight requirement of the project and select the bar accordingly.

0 notes

Text

Stainless Steel 310 Pipes & Tubes Exporters

Stainless Steel 310 Pipe & Tubes, composed of a chromium-nickel alloy, boasts similar strength to 304 grade pipes but offers superior corrosion and oxidation resistance. Jaiman Metalloys LLP is a prominent supplier and manufacturer of Stainless Steel 310 Pipe & Tubes, offering various products in various dimensions and types. The material composition includes carbon, manganese, silicon, phosphorus, and sulfur, with a minimum of 24% chromium and 19% nickel. These pipes adhere to ASTM A312 and A358 specifications, with dimensions specified by ASTM, ASME, and API standards.

0 notes

Text

What are the different grades of SS (stainless) pipes & tubes? How do they differ in terms of properties such as tensile strength and hardness?

Different Grades of Stainless Steel Pipes and Tubes

Stainless steel (SS) is a versatile material known for its corrosion resistance and durability. It's widely used in various industries, including construction, manufacturing, and food processing. The different grades of SS pipes and tubes are categorized based on their chemical composition, which affects their properties like tensile strength, hardness, and corrosion resistance.

Common Grades and Their Properties

Austenitic Stainless Steel: Grades: 304, 316, 316L, 309, 310 Properties: Excellent formability, good weldability, high corrosion resistance, moderate strength. Applications: Food processing, chemical processing, architectural applications.

Ferritic Stainless Steel: Grades: 430, 440A, 440C Properties: Good corrosion resistance, moderate strength, magnetic. Applications: Automotive components, cutlery, surgical instruments.

Martensitic Stainless Steel: Grades: 410, 420, 440A, 440C Properties: High hardness and strength, good wear resistance, magnetic. Applications: Cutlery, surgical instruments, bearings.

Duplex Stainless Steel: Grades: 2205, 2209Properties: Excellent corrosion resistance, high strength, good weldability. Applications: Oil and gas industry, marine applications, chemical processing.

0 notes

Text

Different types and grades of Seamless Pipe explained

Since there are no welds or connections in a seamless pipe, it is more durable and dependable than a welded pipe. They find widespread use in a variety of businesses, including the oil and gas industry, the petrochemical industry, the power generating industry, and others. There are different types and grades of seamless pipes available in the market, and here are some of them:

Carbon Steel Seamless Pipes: These pipes are made of carbon steel and are commonly used in industries such as oil and gas, refineries, and petrochemicals. They are available in different grades, such as ASTM A106 Grade B, ASTM A53 Grade B, and API 5L Grade B.

Alloy Steel Seamless Pipes: These pipes are made of alloy steel and are used in industries such as power generation, chemical processing, and oil and gas. They have high strength, corrosion resistance, and are available in different grades, such as ASTM A335 P5, ASTM A335 P11, and ASTM A335 P22.

Stainless Steel Seamless Pipes: These pipes are composed of stainless steel, and they are often used in a variety of sectors, including those dealing with the processing of food, medicines, and chemicals. They are offered in a variety of grades, some examples of which include the Stainless Steel 304 Pipe, the Stainless Steel 310 Pipe, and the Stainless Steel 316 Pipe.

Duplex Steel Seamless Pipes: These pipes are made of duplex steel, which is a combination of austenitic and ferritic stainless steel. They find widespread use in a variety of fields, including the processing of chemicals, the oil and gas industry, and naval applications. They have high strength, corrosion resistance, and are available in different grades, such as ASTM A790 UNS S31803 and ASTM A790 UNS S32750.

Nickel Alloy Seamless Pipes: These pipes are made of nickel alloys and are commonly used in industries such as aerospace, chemical processing, and oil and gas. They have high strength, corrosion resistance, and are available in different grades, such as Inconel 600, Inconel 625, and Incoloy 800.

In addition to the type of material used, seamless pipes are also classified based on their pressure rating, size, and thickness. The grades and specifications of seamless pipes are set by standards organizations such as ASTM International and API (American Petroleum Institute). It's important to consult with a reputable supplier to determine which type and grade of seamless pipe is best suited for your specific application.

#stainless Steel 304 pipe#stainless steel 310 pipe#stainless steel#pipes#supplier#manufacturer#industrial#steel#shree ashapura steel center#mumbai#maharashtra#india

0 notes

Text

Stainless Steel Pipe Manufacturer in India

Inox Steel India is the Leading Stainless Steel Pipe Manufacturers in India. Steel is stainless Applications that call for great strength and high pressure, such those in the oil and gas sector, chemical processing facilities, and construction, frequently use seamless pipe.Additionally, we create a wide range of Stainless Steel 304 Large Diameter Pipe and Stainless Steel Pipe Singapore.

Stainless steel seamless pipes are available in a variety of diameters, from tiny pipes used in medical equipment to large diameter pipes applied in industrial settings. Depending on the particular needs of the application, they are also offered in a variety of wall thicknesses. Moreover, we are the Leading Steel Pipe Supplier Singapore, Pipe Supplier in Saudi Arabia, and Large Diameter Steel Pipe Suppliers.

Product Source: Stainless Steel Seamless Pipe Manufacturer in India and Large Diameter Steel Pipe Manufacturer in India

Also Visit: Stainless Steel Pipe Supplier in Australia

#StainlessSteelPipe#stainless steel pipe singapore#stainless steel seamless pipe suppliers#steel pipe supplier singapore#SS Seamless Pipe Manufacturer#stainless steel pipe supplier#Stainless Steel 310 Large Diameter Pipe

0 notes

Text

Stainless Steel 316 Flanges Exporters in India

Introduction

Stainless Steel 316 Flanges, renowned for their exceptional resistance to corrosion and high temperatures, are a cornerstone in various industrial applications. These flanges are particularly favored in environments where superior resistance to chlorides and acids is required, making them indispensable in industries such as chemical processing, petrochemical, and marine engineering. At Universe Metal & Alloys, we pride ourselves on being leading Manufacturers, Suppliers, Stockists, and Exporters of top-quality Stainless Steel 316L Flanges, ensuring that our clients receive only the best in durability and performance.

Description

Universe Metal & Alloys specializes in manufacturing stainless steel 316 flanges, designed to meet the rigorous demands of industries such as petrochemical, oil and gas, power generation, and more. Stainless steel 316 is a highly sought-after material due to its superior corrosion resistance, strength, and durability. These flanges are produced using state-of-the-art technology and adhere to stringent international standards to ensure optimal performance and reliability.

The flanges are available in various types, including slip-on, weld neck, blind, socket weld, and threaded, catering to the diverse needs of different applications. Each flange is meticulously crafted to ensure a perfect fit and seal, providing long-lasting and leak-free connections in piping systems.

Benefits

Choosing stainless steel 316 flanges from Universe Metal & Alloys comes with a multitude of benefits:

Excellent Corrosion Resistance: Stainless steel 316 flanges offer superior resistance to corrosion, especially in harsh environments and chemical exposure, ensuring longevity and reliability.

High Strength and Durability: The mechanical properties of stainless steel 316 make these flanges exceptionally strong and durable, capable of withstanding high pressure and temperature conditions.

Versatility: Available in various types and sizes, these flanges can be used in a wide range of applications, from industrial piping systems to specialized equipment.

Hygiene and Cleanliness: The smooth surface finish of stainless steel 316 ensures easy cleaning and maintenance, making these flanges ideal for applications in the food and pharmaceutical industries.

Compliance with Standards: Universe Metal & Alloys ensures that all its products meet international standards and certifications, providing customers with confidence in the quality and safety of their products.

Specification

Stainless Steel 316L Flanges Specification:

Stainless Steel 316 Flange Specification

ASTM A182 / ASME SA182

Stainless Steel 316 Flange Manufacturing Process

Hot Forging / Rolling / Machining

Stainless Steel 316 Flange Other Grades

202 / 304 / 304L / 304H / 309S / 310S / 316 / 316L / 316Ti / 317L / 321 / 321H / 347 / 347H / 904L etc. UNS No. - UNS S30400, UNS S30403, UNS S31008, UNS S31620, UNS S31603, UNS S31603, UNS S31635, UNS S31703, UNS S32100, UNS S34700, UNS S34709, UNS S8904 EN No. - 1.4301, 1.4307, 1.4845, 1.4401, 1.4404, 1.4571, 1.4438, 1.4541, 1.4550, 1.4551, 1.4539

Stainless Steel 316 Flange and Flanges Pipe Fittings Outer Diameter

1/2" NB TO 64" NB

Stainless Steel 316 Flange Pressure Class

Class 150#, Class 300#, Class 400#, Class 600#, Class 900#, Class 1500#, Class 2500# or As Per Custom Requirement PN 6, PN 10, PN 16, PN 25 and PN 40 etc

Stainless Steel 316 Flange Schedule

Sch 10s TO Sch XXS or As Per Custom Requirement

Stainless Steel 316 Flange Facing

Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ)

Stainless Steel 316 Flange Dimension

ASME B16.5, ASME B16.47 SERIES A, ASME B16.47 SERIES B, ASME B16.36, BS10, EN1092-1:2013, MSS SP44, ASA, API-605, ISO 7005, ISO 15590-3, DIN 2631--2638, DIN 2573-2576, DIN 2527, DIn 2641-2642, DIN 2565-2566, DIN2502, AWWA, AS2129 TABLE C, D, E, F, J etc..

Stainless Steel 316 Flange Other Testing

NACE MR0175, Ultrasoung TEST, IGC TEST, Intergranular Corrrosion Test as per ASTM A262 Practice E, Charpy Impact Test, Macro, Grain Size, Hardness, HIC, SSC, Sour Service etc.

Stainless Steel 316 Flange Value Added Services

Rolling, Drill, Punch, CNC Machining, Sand Blasting, Shot Blasting, Heat Treatment, Anti-rust Paint, Oil Black Paint, Yellow Transparent, Zinc Plated, Cold and Hot Dip Galvanized

Stainless Steel 316 Flange Packaging

Loose / Carrate / Wooden Pallet / Wooden Box / Plastic Cloth Wraps

Stainless Steel 316 Flange Shipment & Transportation

By Road - Truck / Train Partial Load, Full Load, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes

Stainless Steel 316 Flange Material Test Certificate

Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS, Bureau of Indian Standards BIS Approved ETC

Conclusion

Universe Metal & Alloys has established itself as a leading manufacturer of stainless steel 316 flanges in India, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. Their products are trusted by industries worldwide for their superior performance, durability, and compliance with stringent standards.

For more information or to place an order, contact Universe Metal & Alloys at [email protected] or call +91-22-66363360 / 66393788. Experience the excellence of working with a premier manufacturer of stainless steel 316 flanges.

0 notes

Text

Supplier of Stainless Steel Flange in Karnataka

Arisa Impex is a trusted Manufacturer, Exporter, and Supplier of Stainless Steel Flange in Karnataka.

Our Manufacturer Unit is in Ahmedabad, Gujarat, India.

We offer stainless steel flanges made from top-grade materials that ensure exceptional strength and resistance to corrosion.

Arisa Impex flanges are manufactured to meet international quality standards, ensuring they perform reliably in even the most challenging environments.

We supply a diverse range of stainless steel flanges, including slip-on, blind, weld neck, threaded, and socket weld flanges, available in various sizes and specifications.

We believe in offering premium-quality stainless steel flanges at competitive prices.

Our efficient sourcing, manufacturing, and delivery processes allow us to pass on cost savings to our customers, providing excellent value for money without compromising on quality.

Types of Stainless Steel Flanges Offered by Arisa Impex Weld Neck Flanges Slip-On Flanges Blind Flanges Threaded Flanges Socket Weld Flanges

Why Stainless Steel Flanges are Essential for Your Business: Stainless steel flanges are critical components in piping systems, providing secure connections between pipes, valves, pumps, and other equipment.

They ensure leak-proof seals, high strength, and the ability to withstand extreme temperatures, pressures, and corrosive environments.

By choosing Arisa Impex, you ensure that your piping systems operate safely and efficiently, minimizing downtime and costly repairs.

Specifications: Material Standards: ASTM A182 / ASME SA182 Size Range: 1/2″ (15 NB) to 48″ (1200 NB) Dimensions: ANSI/ASME B16.5, B16.47 Series A & B, B16.48, BS4504, BS10, EN-1092, DIN, and other industry standards. Standard: ANSI Flanges, ASME Flanges, BS Flanges, DIN Flanges, EN Flanges. Class / Pressure Ratings: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6, PN10, PN16, PN25, PN40, PN64, etc. Flange Face Types: Flate Face (FF), Raised Face (RF), Ring Type Joint (RTJ). Stainless Steel Flanges Grades: 304, 304L, 304H, 310, 310S, 310H, 316, 316L, 316H, 316Ti, 317, 317L, 321, 321H, 347, 347H, 446, 904L Flanges are produced in size ranges: ½” to 40″

Applications of SS Flanges: Oil and Gas Chemical and Petrochemical Industries Water Treatment Power Generation Food and Beverage Pharmaceutical

Arisa Impex is a Supplier of Stainless Steel Flange in Karnataka including locations like Bangalore, Mysore, Hubballi-Dharwad, Kalaburagi, Mangalore, Belagavi, Davanagere, Bellary, Vijayapura, Shimoga, Tumkur, Raichur, Bidar, Udupi, Hospet, Gadag-Betageri, Robertsonpet, Hassan, Bhadravati, Chitradurga, Kolar, Mandya, Chikmagalur, Gangavati, Bagalkot, Ranebennuru, Arsikere.

For more information, inquiries, or to place an order, feel free to contact us today!

https://arisaimpex.com/supplier-of-stainless-steel-flange-in-karnataka/

0 notes

Text

Stainless Steel 316/316L/316Ti Pipes & Tubes Manufacturers In India

Navneet Metal Corporation, based in Mumbai, India, is a prominent manufacturer, supplier, and exporter of stainless steel pipes and tubes. The company offers a comprehensive range of stainless steel products that cater to various industrial applications due to their durability, corrosion resistance, and high strength.

Key Features of Navneet Metal Corporation's Stainless Steel Pipes & Tubes

High-Quality Materials:Navneet Metal Corporation ensures the use of premium quality stainless steel materials, including grades like 304, 304L, 316, 316L, 321, and 310. These materials are known for their excellent corrosion resistance, mechanical properties, and ease of fabrication.

Product Range:Types: The company offers both seamless and welded stainless steel pipes and tubes. They provide options for different forms including round, square, rectangular, and oval pipes and tubes. Sizes: Their products range from 1/8" NB to 24" NB in seamless and 1/8" NB to 36" NB in ERW (Electric Resistance Welded) and welded pipes and tubes (Rajkrupa Metal) .

Applications:These stainless steel pipes and tubes are used across a variety of sectors such as chemical processing, petrochemical, oil & gas, power generation, and marine industries. They are ideal for applications requiring high temperature and corrosion resistance.

Specifications:Products adhere to international standards such as ASTM A213, ASTM A312, and ASTM A269, ensuring compliance with rigorous quality requirements. This makes them suitable for global markets and diverse applications.

Customization:Navneet Metal Corporation offers customization to meet specific project requirements, including various lengths, wall thicknesses, and finishes. They also provide tailored solutions for special applications.

Advantages of Choosing Navneet Metal Corporation

Comprehensive Quality Control:The company implements stringent quality control measures including chemical and mechanical testing, hydrostatic testing, and non-destructive testing to ensure that products meet the highest standards .

Timely Delivery:They are known for their commitment to timely delivery, making sure that clients receive their products within the agreed time frame.

Competitive Pricing:Navneet Metal Corporation offers competitive pricing, providing high-quality stainless steel products at cost-effective rates.

Global Reach:The company exports its products worldwide, maintaining a robust presence in international markets which speaks to the reliability and trust in their products and services.

Contact Information

For detailed product inquiries or to request a quote, you can contact Navneet Metal Corporation via their official website or reach out directly to their customer service.

Additional Manufacturers

If you are exploring other manufacturers for stainless steel pipes and tubes in India, here are a few reputable options:

Ratnamani Metals & Tubes Ltd: Known for their extensive range of stainless steel and alloy products .

Suraj Limited: Specializes in stainless steel seamless pipes and tubes for various industrial applications .

Apex Tubes Pvt Ltd: Offers a wide range of stainless steel tubes and pipes, particularly for the automotive and instrumentation sectors .

These companies, along with Navneet Metal Corporation, provide reliable solutions for your stainless steel needs, ensuring high quality and dependable service.

For more information

Visit our website: https://www.navneetcorp.com/

Call us on: 8369128023

Email us: [email protected]

0 notes

Text

Meghmani Metal Industries is a Manufacturer and Supplier of SS Pipe and Fittings in Rajasthan, India. Meghmani Metal Industries offers a comprehensive range of high-quality Stainless Steel (SS) Pipes and Fittings that cater to various industrial applications. We take pride in producing an extensive variety of SS pipes, tubes, and fittings, available in seamless, welded, threaded, and fabricated forms. We offer SS pipes and fittings in various grades, including 304, 316, and 310, ensuring compatibility with different environmental conditions and operational demands. Why Choose Meghmani Metal Industries' SS Pipe and Fittings? Superior Quality: Manufactured using high-grade stainless steel, these pipes and fittings are designed for long-lasting performance in harsh industrial environments. Corrosion Resistance: Stainless steel's natural resistance to rust and corrosion ensures the longevity of the pipes, making them ideal for both indoor and outdoor applications. Precision Engineering: Meghmani Metal Industries' SS Pipes and Fittings are precisely engineered to meet stringent industry standards and specifications. Versatility: Suitable for a wide range of applications, including fluid and gas transportation, structural support, and pressure systems. Applications: Pharmaceutical Industry Chemical Processing Food and Beverage Oil & Gas Water Treatment Pulp and Paper FAQs: What makes SS pipes and fittings better than other materials? Stainless steel is more durable, resistant to corrosion, and has a longer lifespan compared to other materials like carbon steel or plastic. It also maintains its strength at high temperatures. How do I maintain SS pipes and fittings? Stainless steel requires minimal maintenance. Regular cleaning and ensuring there is no accumulation of debris or corrosive substances will help maintain their performance and appearance. Are these pipes customizable for specific needs? Yes, Meghmani Metal Industries offers customizable SS pipes and fittings, with options for different sizes, grades, and finishes to meet specific operational requirements. Meghmani Metal Industries is Supplier of SS Pipe and Fittings in Rajasthan, India Including Ajmer, Alwar, Anupgarh, Balotra, Banswara, Baran, Barmer, Beaware, Bharatpur, Bhilwara, Bikaner, Bundi, Chittorgarh, Churu, Dausa, Deeg, Dholpur, Didwalna-Kuchaman, Dudu, Dungarpur, Ganganagar, Gangapur City, Hanumangarh, Jaipur, Jaipur, Jaisalmer, Jalore, Jhalawa, Jhunjhunu, Jodhpur, Karauli, Kekri, Kherthal-Tijara, Kota, Kotputli-Behror, Nagaur, Pali, Phalodi, Pratapgarh, Rajsamand, Salumbar, Sanchore, Sawai Madhopur, Shahpura, Sikar, Sirohi, Tonk, Udaipur. For more information and inquiries, feel free to contact us. View Product: Click Here Read the full article

0 notes