#Solvent Printer

Explore tagged Tumblr posts

Text

"Eco-solvent inks in 2024: sustainability and high quality change the printing industry"

In an era where environmental concerns are at the forefront, the emergence of eco-solvent ink represents a significant milestone in the printing industry.

Unlike its counterparts, UV and water-based inks, eco-solvent ink is a composition of non-toxic solvents and natural pigments.

Please take note: a remarkable 50% of its components derive from renewable resources. With a minimal volatile organic compound (VOC) content, this ink is virtually odorless.

The Birth of Eco-Solvent Ink:

Since the advent of inkjet printers in the 1990s, the ink industry has grappled with toxicity, irritation, and high pollution.

However, through three generations of technological evolution and the relentless efforts of scientists, the printing world has been introduced to a game-changer – the non-toxic, non-irritating, and odorless eco-solvent ink. It signifies the industry's definitive break from the stigma of high pollution associated with traditional printing practices.

Cost Control and Print Quality of Eco-Solvent Ink:

The high cost of traditional inks has long been a bone of contention in the printing industry. Eco-solvent ink has opened a window of opportunity, epitomized by the phrase “a long slope with thick snow.” The substantial investment required yields a steady and stable return. Boasting excellent adhesion and vibrant color, eco-solvent ink has solidified its position in an era where print quality is a critical differentiator.

Applications of Eco-Solvent Ink:

A chasm exists between traditional inks and eco-solvent inks in the industry. The market for eco-solvent inks spans a wide range, from outdoor billboards to textile banners and car stickers, showcasing its boundless adaptability. It also defines the contours of modern printing practices:

Indoor and outdoor advertising and signage printing Automobile body stickers and wraps Industrial labeling and packaging printing Textile and eco-friendly fabric printing

Amidst the daunting challenges, from increasingly stringent regulations to technological iterations, our company, Panjet(https://www.pan-jet.com/), remains committed to the path of green and sustainable development. We stand as your provider of high-quality printing ink solutions.

3 notes

·

View notes

Text

Revolutionize Printing with Epson Eco-Solvent Printers

At K Engineering, we offer a premium range of Epson Eco-Solvent Printers designed to enhance your printing experience. With user-friendly operation, cost-effective ink consumption, and superior print quality, these printers help businesses maximize efficiency while reducing environmental impact.

1 note

·

View note

Text

Wecare Markiing and Coding Products

0 notes

Text

Epson Previews New Solvent-Based SureColor S-Series Printer

Expanding its SureColor S-Series signage printer line, Epson today previewed its next-generation SureColor S9170, which will be available in early 2025 through Authorized Epson Professional Imaging Resellers. Solvent-based printers are inkjet printers that use ink that doesn’t contain water, so that prints are waterproof when dry. It can be used on surfaces such as vinyl, metal, PVC, and…

0 notes

Text

Bluerhine offering a perfect blend of quality and sustainability of canvas for eco-solvent printers. This canvas is designed to deliver vibrant colors and sharp details, making it ideal for high-quality prints. The eco-solvent inks used with Bluerhine canvas are less harmful to the environment compared to traditional solvent inks, reducing VOC emissions and ensuring a safer printing process. Whether for indoor or outdoor applications, Bluerhine canvas provides durability and a professional finish, making it a preferred option for artists and businesses alike.

0 notes

Text

Top Printed Machine Suppliers for High-Quality Printing Solutions - Omkar Digital

At Omkar Digital, we pride ourselves on being among the top printed machine suppliers, delivering high-quality printing solutions to meet your every need. Whether you're a small business or a large enterprise, our extensive range of printing machines ensures that you get the best results every time.

#Printed machine suppliers#high-quality printing solutions#Omkar Digital#printing equipment#UV printing machines#eco-solvent printers#printing services#top printed machine suppliers#printing technology#printing maintenance services

0 notes

Text

Used Eco solvent Printing Machine in UAE:- Fortune Seven provides machiners, spare parts, inks, and materials. We are a one-stop solution for all your advertising support. Contact us today and get extensive coverage of supplies and services from us within Oman, UAE, KSA, and Qatar. We have a team of professionals who maintain everything for you. https://fortune7.ae/product-category/printers/eco-solvent-printer/

0 notes

Text

((@ghost-esc-tacy; feel free to interact when you want to/have time - just didn't want it to be forgotten in TJ's Arc 2 events or other ESC wildness <3 ))

*has prepared a lab space in an empty basement lab for the express purpose of working on the "Spice" samples*

*has performed an electrophoresis to try to make sense of the DNA, RNA, and protein make-up*

*has placed small samples into various solvents and solutions to see what reaction the samples have*

*has placed a small amount in a clear container box with printer ink; hoping they are not about to make more "Spices"; one is more than enough in their opinion*

166 notes

·

View notes

Text

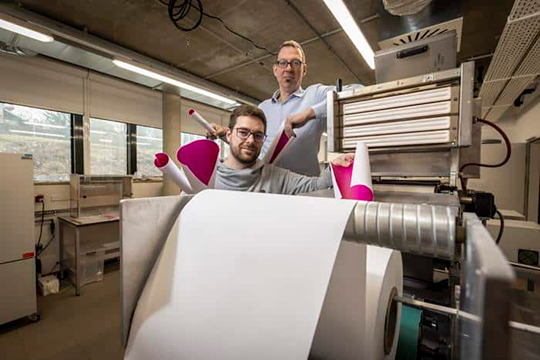

Why Inkjet Paper Curls

Printed pages from inkjet printers tends to curl up over time. Researchers found that this long-term curl correlates with the migration of glycerol -- one of the solvents used in inkjet ink -- through the paper's fiber layers toward the unprinted side. (Image credit: Lunghammer - TU Graz; research credit: A. Maass and U. Hirn; via Physics World) Read the full article

87 notes

·

View notes

Text

Dyes : The World of Colors

Colors make our world vibrant, and dyes are the magical ingredients that bring life to everything around us. Let’s explore the colorful universe of dyes, breaking down the various types and their fascinating uses in everyday life.

Understanding Dyes:

Dyes are like special paints that add color to different things. Humans have been fascinated by colors for a long time, and dyes play a huge role in making our world colorful. There are two main types of dyes: natural and synthetic. They are used to add color to items like utensils, textiles, leather products, and even food.

Types of Dyes:

Basic Dyes:

These dyes are made in labs and give really bright colors. They are great for adding color to things like acrylic fibers and synthetic materials.

Direct Dyes:

These dyes dissolve in water and are used for coloring materials like cotton. They are commonly used in the textile industry.

Natural dyes :

Natural dyes are derived from sources in nature and may include substances like indigo, turmeric, or cochineal. While these dyes have a historical and cultural significance, they often present limitations in terms of color range and fastness.

Acid Dyes:

Perfect for coloring protein fibers like wool and silk, acid dyes are highly soluble in water. They are not suitable for materials like cotton but work well for leather and medical products.

Synthetic Dyes:

Man-made and chemically produced, these dyes come in a wide range of colors. They are used in many industries due to being affordable, but they can be harmful to the environment and humans.

Reactive Dyes:

Best for cellulose, protein, and polyamide fibers, these dyes are easy to use and have good light-fastness properties. They are popular in the textile industry.

Solvent Dyes:

Modern and non-toxic, these dyes are used in upcoming textile mills. They are convenient but may be more expensive. Solvent dyes are seen as alternatives to traditional harmful dyes.

Food Dyes:

Added to food to make it look attractive, food dyes come in various forms. It’s important to use them carefully as excessive consumption can lead to health problems. They are either natural or artificial.

Application of Dyes:

Textiles: Dyes are extensively used in the textile industry to color fabrics, clothing, and other textile products. They can be applied through various methods such as dyeing, printing, or painting.

Plastics: Dyes enhance the appearance of plastic products, providing them with a wide range of colors and finishes.

Printing: Inks, whether for traditional printing or modern digital printing, often contain dyes to produce vibrant and accurate colors.

Food: Food dyes are used to add color to various food products, making them visually appealing. These dyes can be natural or synthetic.

Industrial Use: Dyes find applications in various industrial processes, including coloring materials like leather, creating inks for pens and printers, and contributing to the production of a wide array of products.

17 notes

·

View notes

Text

New solvent-free 3D printing material could enable biodegradable implants

Additive manufacturing (AM) has revolutionized many industries and holds the promise to affect many more in the not too distant future. While people are most familiar with the 3D printers that function much like inkjet printers, another type of AM offers advantages using a different approach: building objects with light one layer at a time. One such technology is digital light processing (DLP). Widely used in both industrial and dental applications, DLP works by converting a liquid resin into a solid part using light, essentially pulling solid objects out of a shallow pool of resin one layer at a time. A major challenge to using this 3D printing method, however, is that the resins need to have a low viscosity, almost like water, to function properly at high resolution. Plenty of polymers that would otherwise be useful in DLP printing are solids or too viscous, requiring solvents to dilute them to an appropriate consistency.

Read more.

8 notes

·

View notes

Text

so for anyone who isn’t on warhammer facebook, a kickstarted tabletop game called trench crusade that released recently, it just came out that a bunch of their 3d models (for people to print themselves) have voids inside them that create resin traps. what this means as far as i’ve heard is when printed with a 3d resin printer, uncured resin gets stuck inside the model and over time, emits gasses (from solvents?) which eventually turns the fun little guy into a Poisonous Frag Grenade. people are, rightly, Big Mad because these models are Paid, and STL software has safeguards against voids in models that the creators somehow dodged. also many people have already printed and lovingly painted these models and would prefer they not explode at all

5 notes

·

View notes

Text

Dan Misdea.

Editor's Note: Be sure to check out Dan's new children's book, The Light Inside, available this week!

Bio: I've been contributing cartoons to The New Yorker since 2021. My work has also appeared in Air Mail, Narrative, The Times, Weekly Humorist, The Golfer's Journal, and a few other publications. My first children's book, The Light Inside, is available now.

Find this print here!

Tools of choice: I brainstorm ideas on printer paper with a .38 Uni-ball Signo RT and sketch the roughs I submit to The New Yorker on my iPad.

For now, my finishes go on Bristol vellum (Canson) with graphic liners (Rotring), oil-based colored pencils (Lyra), and various blenders. Occasionally, I'll use a solvent to blend and fill larger areas, or an ink wash if the drawing calls for it. I used to finish all of my cartoons digitally, so there has been some trial and error in finding the right tools.

There’s no specific reason why I switched to traditional tools. It sounds corny, but it was just something I felt the urge to explore. I feel a stronger connection to my work now, and the creative process is way more enjoyable for me.

All materials are subject to change at any moment.

Tools I wish I could use better: My golf clubs.

Tricks: Allow yourself to experiment and remember to have fun.

Tools I wish existed: A magic tool that could scan my work and edit it to perfection all at once.

Misc: If you’re an aspiring cartoonist, I would suggest reading A LOT of cartoons. Try to notice how the pros compose their drawings and craft their captions. You’ll eventually gravitate towards certain styles and voices, and I think that will help shape your own values as a cartoonist.

Links:

Website: https://danmisdea.com

Instagram: @dan_misdea

The Light Inside: Buy my children's book, The Light Inside, here

Curated Cartoons: Buy my original cartoons here

-----

If you enjoy this blog, and would like to contribute to labor and maintenance costs, there is a Patreon, and if you’d like to buy me a cup of coffee, there is a Ko-Fi account as well! I do this blog for free because accessible arts education is important to me, and your support helps a lot! You can also find more posts about art supplies on Case’s Instagram and Twitter! Thank you!

26 notes

·

View notes

Text

UV printing is the latest game-changer, but can eco-solvent printing keep up? Let’s dive into the details before this discussion becomes dry.

The green factor

Eco-solvent printing has fewer emissions but still impacts the environment and needs proper disposal. Ensure good ventilation indoors

Unlike traditional methods UV printers don’t release harmful chemicals when they dry.

At the first blink

Eco-solvent and UV prints differ noticeably at first glance

1.Embossing and Gloss:

Eco-solvent prints come in matte or semi-gloss. High gloss needs extra laminates, and embossing isn't available.

Meanwhile, most UV prints are delivered directly from the printer with a high-gloss finish and embossing features.

2.Color and sharpness:

Sure, eco-solvent ink gets the job done with decent colors, but it lacks white and can't print on black items, nor does it offer laser-sharp details.

UV inks dry instantly to produce vivid colors and razor-sharp lines with the added benefit of white.

The gold standard

1.Durability:

more protective coatings may be required to improve durability for a eco solvent ink print.

The prints made by UV are very hardy, resistant to scratch, fading, and weather. The ink is more resistant to environmental factors.

2.Versatility:

Eco solvent ink printers can only support some media and have problems with some surfaces.

UV printers work with a variety of rigid and non-porous materials without the requirement for any additional coatings.

Opinion In brief, UV prints are quick, versatile, and eco-friendly, whereas eco-solvent prints are slower and still contain some polluting compounds. Next time you're ordering prints, be sure to ask if they're UV or not. Got printing questions? Our team is ready to help you find the perfect solution. Contact us today and say goodbye to confusion!Lets talk

🌐 www.burjgraphic.com

2 notes

·

View notes

Text

MWW Artwork of the Day (10/8/23) Paul Gauguin (French, 1848-1903) Eve ("The Nightmare") (c. 1899-1900) Black printer's ink, ochre ink, liquid solvent on wove paper, 64.2 x 48.9 cm. The J. Paul Getty Museum, Los Angeles

Near the end of his life in isolated French Polynesia, Gauguin invented his own technique to produce this unique, double-sided image. Both sides depict a young Tahitian woman as Eve in the Garden of Eden, surrounded by the Devil as a snake, a dark figure on horseback, and a fallen Adam. On its surface, Gauguin's experimental drawing looks primitive and casually made. However, its rough appearance belies a very sophisticated work, with nuanced mark-making and carefully aligned applications of color. The closest analogy to Gauguin's process might be the act of writing or drawing on carbon paper, which transfers marks to underlying pages.

9 notes

·

View notes

Text

30% off this item today!

Sticker.

SHOP NOW 🛒👇 https://society6.com/product/a-cosmic-tableau_rectangular-pillow?sku=s6-28352785p50a66v444

Materials and Finish

Kiss cut for more intricate cutouts.

Calendered vinyl surface with acrylic adhesive (easy to remove).

Produced with eco-solvent printer inks.

Every order is custom made just for you.

Shipping & Returns

SHIPPING: Items are made to order and typically ship within 3-4 business days.

RETURNS: Return requests can be made within 30 days of your item(s) delivery.

#fashionable#ootd#explore#streetstyle#outfitinspiration#instafashion#fashionblogger#style#fashion#fashionista

2 notes

·

View notes