#Solid waste treatment technologies

Explore tagged Tumblr posts

Text

#Solid waste digester plants#Organic waste management#Anaerobic digestion in Hyderabad#Biogas production#Renewable energy generation#Sustainable waste management#Waste-to-energy plants#Environmental sustainability in Hyderabad#Solid waste treatment technologies#Waste management solutions in Hyderabad.

0 notes

Text

How Technology Plays a Role in Solid Waste Management

Introduction

The Role of Technology in Solid Waste Management and Effluent Treatment explores the transformative power of technology in addressing the complex challenges of waste management. In this blog, we delve into how innovative technologies are revolutionizing the way we handle, process, and dispose of solid waste, paving the way for a more sustainable future. Discover the latest advancements in waste management technology, from smart waste collection systems and IoT-enabled sensors to advanced sorting and recycling technologies. We explore how these technologies optimize waste collection routes, minimize collection costs, and improve overall operational efficiency.

Categories of Solid Waste Disposal Management Services:

The following are the different sources of solid waste management services

Residential Waste: It consists of various types of waste produced by individuals or families in their daily lives. Residential waste can be categorised into different types based on its composition, such as organic waste, recyclable waste.

Commercial: Commercial waste refers to the waste generated by businesses, commercial establishments, and institutions. It includes a wide range of waste materials resulting from various commercial activities

Industrial: Commercial waste refers to the waste materials generated by businesses, industries, institutions, and other non-residential sources. It encompasses a wide range of waste types and can vary in composition depending on the nature of the business or industry. Commercial waste includes both non-hazardous and hazardous waste materials.

Agriculture: Agriculture is the practice of cultivating plants, raising animals, and producing food, fiber, and other products used for human consumption or industrial purposes. In agriculture, farmers and agricultural workers engage in various practices to grow crops and raise livestock, with the goal of maximizing yield, quality, and profitability.

Cities: Cities are densely populated human settlements that serve as centers of social, economic, and cultural activities. They are characterized by a concentration of buildings, infrastructure, and people. Cities play a crucial role in shaping society, fostering innovation, and driving economic growth.

Benefits of Solid Waste Management

Many people may not be aware of this, but solid waste Management has many benefits for our health and our environment.

An important benefit of proper Solid Waste Management is that it improves air and water quality throughout the country, which keeps us healthier by removing less harmful particles from the air and water. Technology in Solid Waste Management: A Role for Solid Waste Management

Another benefit is that it ensures the safe disposal of any residual or wet waste through proper waste segregation. Direct handling of solid waste could result in many types of infectious diseases for collectors if the waste is not properly secured. Exposure to this hazardous waste can affect health and could cause long-term illness.

Proper solid waste management also protects citizens from biohazards and physical harm, fosters community health, promotes sanitation, and provides opportunities to earn money from recycling.

This is where the local government unit and barangay will step in to help educate residents on how to properly separate waste according to the correct bins and areas to ensure the well-being of other residents and people in this line of work.

Conclusion:

In conclusion, solid waste management plays a crucial role in creating a sustainable and healthier future for our planet and communities. Through effective waste management practices, we can reap a multitude of benefits that extend far beyond simply getting rid of our trash. Proper waste management minimizes environmental pollution, protecting ecosystems, wildlife, and human health. By reducing the amount of waste sent to landfills, we conserve valuable land resources and extend their lifespan, ensuring their availability for future generations.

#Waste Management Technologies#Role of Technology in Solid Waste Management#Technological innovation in solid waste management#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

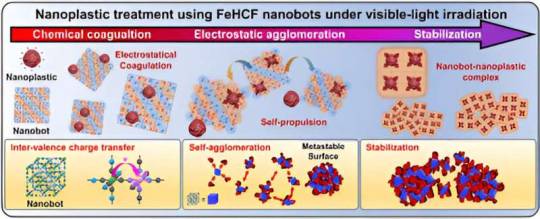

Plastic waste breaks down over time into nanoplastics (<0.1 μm). Microplastics smaller than 20 μm cannot be removed in currently operating water treatment plants and must be agglomerated to a larger size and then removed. Iron (Fe) or aluminum (Al) based flocculants are used for this purpose, but they are not the ultimate solution as they remain in the water and cause severe toxicity to humans, requiring a separate treatment process. Dr. Jae-Woo Choi of the Center for Water Cycle Research at the Korea Institute of Science and Technology (KIST) has developed an eco-friendly metal-organic skeleton-based solid flocculant that can effectively aggregate nanoplastics under visible light irradiation. The research was published in Water Research. Prussian blue, a metal-organic frameworks-based substance made by adding iron (III) chloride to a potassium ferrocyanide solution, is the first synthetic pigment used to dye jeans a deep blue color and has recently been used to adsorb cesium, a radioactive element, from Japanese nuclear plant wastewater.

Continue Reading.

191 notes

·

View notes

Text

Safely removing nanoplastics from water using 'Prussian blue', a pigment used to dye jeans

Plastic waste breaks down over time into nanoplastics (<0.1 μm). Microplastics smaller than 20 μm cannot be removed in currently operating water treatment plants and must be agglomerated to a larger size and then removed. Iron (Fe) or aluminum (Al) based flocculants are used for this purpose, but they are not the ultimate solution as they remain in the water and cause severe toxicity to humans, requiring a separate treatment process. Dr. Jae-Woo Choi of the Center for Water Cycle Research at the Korea Institute of Science and Technology (KIST) has developed an eco-friendly metal-organic skeleton-based solid flocculant that can effectively aggregate nanoplastics under visible light irradiation. The research was published in Water Research. Prussian blue, a metal-organic frameworks-based substance made by adding iron (III) chloride to a potassium ferrocyanide solution, is the first synthetic pigment used to dye jeans a deep blue color and has recently been used to adsorb cesium, a radioactive element, from Japanese nuclear plant wastewater.

Read more.

38 notes

·

View notes

Text

Netsol Water: Leader in Sewage Treatment Plant Manufacturers in Delhi

Water pollution is turning into a global crisis, as industries and urban centers produce massive amounts of wastewater each day. In populous areas like Delhi, the challenge of an effective sewage treatment has never come at such a crucial juncture. Netsol Water is one of the best Sewage Treatment Plant Manufacturers in Delhi, providing best solutions for waste waste management.

Untreated water is one of the major threats to public health, ecosystems, and the environment. It ruins the freshness of fresh-water sources, poses a threat to aquatic life and may unleash a waterborne diseases upsurge. And so comes companies like Netsol Water, breathing hope and practical solutions.

Netsol Water: A Brief Overview

With a mission to come out strongly with this vision in solving the needs of India pertaining to water treatment, Netsol Water has picked up the pace in this multiple-choice game-like environment of Delhi. The firm offers systems for designing, manufacturing, and installing the most sewage treatment plants (STPs) specifically designed according to the diversified needs of various industries.

What's special about Netsol Water?

Customized Solutions: Netsol Water knows that no two places are alike when it comes to sewage treatment. They thus ensure that solutions put in place specifically target the problem at hand and also meet the local regulatory compliances, based on their work with clients.

Latest Technology: By being on the forefront of water treatment technology, Netsol Water ensures efficiency, cost-effectiveness, and environmental friendliness of plants.

Comprehensive Services: Netsol Water offers complete services right from consultancy to installation and then next-line maintenance, thus making it a one-stop shop for all types of sewage treatment requirements.

Commitment towards Sustainability: Netsol Water doesn't treat water; it does water management sustainably with industries.

Science behind Netsol Water's Sewage Treatment Plants

Need of the Multistage Process Netsol Water STPs efficiently employ a multi-stage process so that polluted wastewater becomes usable clean water. A basic description of how such plants function would include the following:

Preliminary Treatment: It removes big debris and waste by screening and grit removal.

Primary Treatment: Sedimentation tanks allow suspended solids to settle, thereby reducing the overall pollutant load.

Secondary Treatment: Organic matter is broken down through biological processes that work through activated sludge or other microorganisms.

Tertiary Treatment: Final filtration and disinfection take away any remaining impurities and pathogens.

Sludge Management: Byproducts from the treatment process are managed safely and are frequently reused for beneficial purposes.

This multi-stage approach ensures that the water leaving Netsol Water's STPs meets or exceeds regulation standards; such water can be safely discharged or reused.

Netsol Water Changing Industries

Netsol Water caters to the diversified sectors, so its versatility can be seen in the diversified sectors that it caters to. Some of these sectors are as follows:

Textile and Dye Industries: Wastewater produced by this section of industries is heavily polluted. So they easily require the specialist treatment solutions of Netsol Water.

Pharmaceutical Companies: Sewage produced from drug manufacturing should be handled with care. To this, Netsol Water provides precision.

Food and Beverage Producers: From dairy plants to breweries, Netsol Water helps these businesses handle their organic-rich wastewater effectively.

Chemical Sector: Netsol Water's advanced technologies overcome the intricate chemical Sewages.

Automotive Industry: Netsol Water provides the automotive manufacturing and servicing industries with overall wastewater treatment solutions.

Environmental Impact of Netsol Water Delhi

Being one of the top Sewage Treatment Plant Manufacturer in Delhi, Netsol Water has been significantly contributing towards Delhi's environment. With effective wastewater treatment solutions, Netsol Water is assisting in all the ways:

Clean up pollution in the Yamuna River, which is Delhi's primary source of water

Reduce contamination and consequently boost the quality of groundwater

Improve public health by reducing probable waterborne diseases

Support the sustainable goals for the development of Delhi

Innovations and Future Outlook

Netsol Water does not boast of resting on its oars. The company keeps abreast of emerging challenges in water treatment with continuous innovations. A few areas of focus are:

Energy Efficiency: Developing treatment processes that consume less energy, thereby reducing the carbon footprint of STPs.

Water Reuse Technologies: Enhanced techniques to make treated water suitable for various industrial and agriculture applications.

Smart Monitoring Systems: Implementing IoT-based solutions for real-time monitoring and optimization of treatment plants.

Modular Designs: Creating scalable modular designs of STPs which can easily expand or change as and when the need arises.

Why Netsol Water?

For the sewage treatment requirements of any business firm at Delhi, Netsol Water offers:

Specialized Consultation: Professional experts to calculate exact requirements.

Tailor-made Design: Space-suitable, budget-suitable, and requirement-suitable STPs.

Installation Process: No Disruption in Its Services.

Comprehensive Training: Your manpower operates and maintains the STP

Ongoing Support: Maintenance and Troubleshooting services are provided to ensure the continuity of the plant.

Conclusion: A Greener Future with Netsol Water

In the middle of the ongoing rapid growth phase of the city, Delhi cannot afford to have anything short of industry-level wastewater management. Netsol Water stands at the forefront of this critical industry: With innovative, reliable, and sustainable solutions for sewage treatment. Netsol Water is top on Sewage Treatment Plant Manufacturer in Delhi, offering solutions for waste waster.

Therefore, by opting for Netsol Water, a Delhi based company would be abiding by the rules of the land while creating an environment for the generations to come that will be cleaner and healthier. And with such companies like Netsol Water, we do have hope for the future because the right technology combined with the right commitment can significantly assist in conquering the obstacles presented in front of us by water pollution and creating a more sustainable world.

Whether a small businessman or industrial giant, if you are based in Delhi and battling against wastewater issues, there is hope for you, perhaps in the form of Netsol Water, transforming those battles into opportunities for environmental stewardship.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#sewage#stp#stps#delhi

3 notes

·

View notes

Text

Essential Auxiliary Machinery on Ship

1. Generators

Generators are the heartbeat of a ship’s electrical system. They provide electrical power for various onboard systems, such as lighting, navigation equipment, communication systems, and HVAC (Heating, Ventilation, and Air Conditioning). Depending on the ship’s size and power requirements, multiple generators may be installed to ensure redundancy and continuous power supply during extended voyages.

2. Boilers

Boilers are essential for producing steam, which is utilized for various purposes on board. Steam is used for heating fuel oil and other fluids, running steam turbines for power generation, and operating various machinery and auxiliary machinery equipment, such as steam-driven pumps and winches.

3. Air Compressors

Air compressors generate compressed air used to power pneumatic tools, such as wrenches and chipping hammers, and operate pneumatic control systems. They also provide compressed air for starting main engines and auxiliary engines.

4. Purifiers

Fuel and lube oil purifiers play a critical role in maintaining the quality of fuels and lubricants used onboard. These machines remove impurities, water, and solids from fuel and oil, ensuring smooth engine operation and prolonging the life of critical machinery.

5. Refrigeration and Air Conditioning Systems

Refrigeration and air conditioning systems are vital for maintaining the temperature of provisions, perishable cargo, and living spaces. These systems use refrigerants and cooling coils to control temperature, humidity, and air quality throughout the ship.

6. Ballast Water Treatment Systems

To maintain stability and maneuverability, ships require ballast water to be pumped in or out as cargo is loaded or unloaded. Ballast water treatment systems are responsible for purifying and treating the ballast water to prevent the spread of invasive species and maintain marine ecosystem health.

7. Sewage Treatment Plants

Sewage treatment plants are responsible for processing and treating wastewater generated onboard. They help ensure that treated effluent meets international environmental standards before it is discharged into the sea.

8. Bilge Water Separators

Bilge water separators remove oil and other contaminants from the bilge water, a mix of seawater and oil that collects in the lower parts of the ship. The clean water is then discharged, while the separated oil is collected for proper disposal.

9. Incinerators

Incinerators are used to burn solid waste generated onboard, such as paper, cardboard, and non-recyclable plastics. Proper incineration reduces waste volume and ensures compliance with environmental regulations.

10. Water Makers

Water makers use reverse osmosis or distillation processes to convert seawater into potable water for drinking, cooking, and various onboard applications. They are especially vital for long voyages where access to freshwater sources may be limited.

Conclusion

The auxiliary machinery found on ships plays a crucial role in maintaining the vessel’s efficiency, safety, and comfort during journeys at sea. From power generation to waste management and water purification, each system contributes to the smooth operation and sustainability of modern ships. The continuous advancement of auxiliary machinery technology further enhances the capabilities and environmental performance of ships, making them safer, greener, and more reliable for maritime transportation across the globe.

#generator parts#ship machinery parts#navigation equipment#Auxiliary Machinery Equipment#Ship Machinery Parts#Auxiliary Machinery#Generator Parts#Automation#Navigation#pumps#automation systems

2 notes

·

View notes

Text

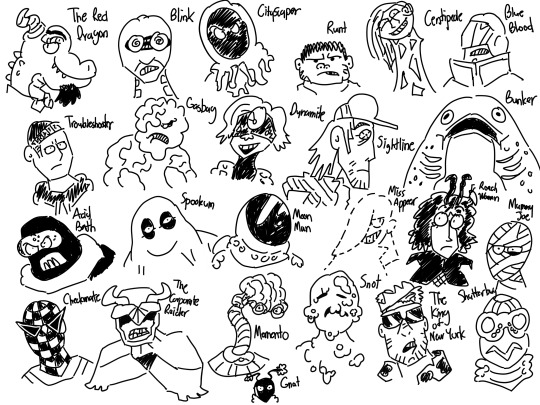

Spider-Man keeps fighting the same one or two dozen guys, so I came up with a bunch of new villains - info under the cut!

The Red Dragon - human-reptile hybrid from the same technology as the Lizard, albeit retaining his full intelligence and sadism. Mob boss, breathes fire

Blink - failed attempt at recreating the Spot, short-range unstable teleportation ("blink of an eye") and quantum duplication

Cityscaper - guerilla artist who has fallen out of touch with the common people and into madness, constructing elaborate death-traps and bizarre and hazardous pieces

Runt - diminutive mob enforcer with an absurd level of strength and durability, mostly limited by his lack of ambition and preference to dick around

Centipede - genetic engineer betrayed by her employers and made into a guinea pig, turning her into a stretchy, boneless mutant with nothing to lose. Fluctuates between anti-hero and anti-villain

Blue Blood - police officer mad about Spidey being "soft on crime" and uncooperative to cops, turned himself into a human tank with advanced SWAT gear. NYPD refuses to condone his vigilante massacres

Troubleshooter - an "invisible man", specializes in doing tasks for supervillains quickly, quietly, and efficiently. Frequently the only sane man amongst a cast of colorful criminals

Gasbag - a "gas" addition to the solid-liquid-plasma triad of Sandman, Hydro Man, and Molten Man. Transformed into a permanent vapor state by particle shenanigans

Dynamite - mad bomber, does bombings for hire or because she likes it. Cyclops goggle helps magnify for fine construction

Sightline - sniper hit-man with bionic eyes that enhance his vision in every practical way. Deeply disrupts Spidey's typical pattern of fighting in open-air

Bunker - giant fishman created by chemical waste poured into the East River and mutating wildlife. Probably eats people

Acid Bath - mercenary for hire specialized in chemical warfare. Acid sprays, flamethrowers, nitroglycerin explosives, etc

Spookum - looks like a big burly guy in a bedsheet ghost costume. Definitely something much worse. Shows up during lunar eclipses, blue moons, and other nights when the world is a little less real

Moon Man - astronaut given a corrupted neutral training implant filled to the brim with science-fiction. Believes himself to be stranded on an alien planet and with only his advanced spacesuit for protection

Miss Appear - paparazzi reporter with the ability to turn invisible. Technically not doing anything illegal, more of a nuisance for Peter Parker the reporter

Roach Woman - a woman who is also a cockroach. Keeps trying to take over the city with elaborate roach plots, really needs more human friends

Mummy Joe - bonded with a super-adhesive medical tape, able to lash it out and manipulate like a collection of tentacles.

Checkmate - up-and-coming criminal with the ambition of becoming Spidey's new arch-enemy for the fame. Fleet of chess-themed androids

The Corporate Raider - anarcho-capitalist and self-proclaimed defender of the rich and wealthy everywhere. Terrorizes unions, strikes, and whistleblowers with extreme prejudice

Memento - psychologist assigned to work with alien technology wound up a little too close. Now essentially a nervous system with legs, fond of psychically manipulating Spidey and other characters

Gnat - all the proportional abilities of a gnat, at the scale of a gnat. Scarily competent in espionage and heist assistance

Snot - artificial human created to experiment with disease symptoms and treatment, now turned into a walking super-spreader. Can also shoot globs and webs of mucus

The King of New York - fuckboy, self-proclaimed king of New York, and with a set of Superman-like powers only matched in intensity by his stupidity.

Shutterbug - at first a photographer paying supervillains to commit crimes to create exclusive reports for him, later becoming a professional spy for hire.

3 notes

·

View notes

Text

Why is ESG Intelligence Important to Companies?

Human activities burden Earth’s biosphere, but ESG criteria can ensure that industries optimize their operations to reduce their adverse impact on ecological and socio-economic integrity. Investors have utilized the related business intelligence to screen stocks of ethical enterprises. Consumers want to avoid brands that employ child labor. This post will elaborate on why ESG intelligence has become important to companies.

What is ESG Intelligence?

ESG, or environmental, social, and governance, is an investment guidance and business performance auditing approach. It assesses how a commercial organization treats its stakeholders and consumes natural resources. At its core, you will discover statistical metrics from a sustainability perspective. So, ESG data providers gather and process data for compliance ratings and reports.

Managers, investors, and government officers can understand a company’s impact on its workers, regional community, and biosphere before engaging in stock buying or business mergers. Since attracting investors and complying with regulatory guidelines is vital for modern corporations, ESG intelligence professionals have witnessed a rise in year-on-year demand.

Simultaneously, high-net-worth individuals (HNWI) and financial institutions expect a business to work toward accomplishing the United Nations’ sustainable development goals. Given these dynamics, leaders require data-driven insights to enhance their compliance ratings.

Components of ESG Intelligence

The environmental considerations rate a firm based on waste disposal, plastic reduction, carbon emissions risks, pollution control, and biodiversity preservation. Other metrics include renewable energy adoption, green technology, and water consumption.

Likewise, the social impact assessments check whether a company has an adequate diversity, equity, and inclusion (DEI) policy. Preventing workplace toxicity and eradicating child labor practices are often integral to the social reporting head of ESG services.

Corporate governance concerns discouraging bribes and similar corruptive activities. Moreover, an organization must implement solid cybersecurity measures to mitigate corporate espionage and ransomware threats. Accounting transparency matters too.

Why is ESG Intelligence Important to Companies?

Reason 1 – Risk Management

All three pillars of ESG reports, environmental, social, and governance, enable business owners to reduce their company’s exposure to the following risks.

High greenhouse (GHG) emissions will attract regulatory penalties under pollution reduction directives. Besides, a commercial project can take longer if vital resources like water become polluted. Thankfully, the environmental pillar helps companies comply with the laws governing these situations.

A toxic and discriminatory workplace environment often harms employees’ productivity, collaboration, creativity, and leadership skill development. Therefore, inefficiencies like reporting delays or emotional exhaustion can slow a project’s progress. ESG’s social metrics will mitigate the highlighted risks resulting from human behavior and multi-generational presumptions.

Insurance fraud, money laundering, tax evasion, preferential treatment, hiding conflicts of interest, and corporate espionage are the governance risks you must address as soon as possible. These problems introduce accounting inconsistencies and data theft issues. You will also receive penalties according to your regional laws if data leaks or insider trading happens.

Reason 2 – Investor Relations (IR)

Transparent disclosures can make or break the relationship between corporate leaders and investors. With the help of ESG intelligence, it becomes easier to make qualitative and manipulation-free “financial materiality” reports. Therefore, managers can successfully execute the deal negotiations with little to no resistance.

You want to retain the present investors and attract more patrons to raise funds. These resources will help you to augment your company’s expansion and market penetration. However, nourishing mutually beneficial investor relations is easier said than done.

For example, some sustainability investors will prioritize enterprises with an ESG score of above 80. Others will refuse to engage with your brand if one of the suppliers has documented records of employing child labor. Instead of being unaware of these issues, you can identify them and mitigate the associated risks using ESG intelligence and insights.

Reason 3 – Consumer Demand

Consider the following cases.

Customers wanted plastic-free product packaging, and e-commerce platforms listened to their demand. And today’s direct home deliveries contribute to public awareness of how petroleum-derived synthetic coating materials threaten the environment.

The availability of recharging facilities and rising gas prices have made electric vehicles (EVs) more attractive to consumers. Previously, the demand for EVs had existed only in the metropolitan areas. However, the EV industry expects continuous growth as electricity reaches more semi-urban and rural regions.

Businesses and investors care about consumer demand. Remember, they cannot force consumers into buying a product or service. And a healthy competitive industry has at least three players. Therefore, customers can choose which branded items they want to consume.

Consumer demand is one of the driving factors that made ESG intelligence crucial in many industries. If nobody was searching for electric vehicles on the web or everybody had demanded plastic packaging, businesses would never switch their attitudes toward the concerns discussed above.

Conclusion

Data governance has become a popular topic due to the privacy laws in the EU, the US, Brazil, and other nations. Meanwhile, child labor is still prevalent in specific developing and underdeveloped regions. Also, the climate crisis has endangered the future of agricultural occupations.

Deforestation, illiteracy, carbon emissions, identity theft, insider trading, discrimination, on-site accidents, corruption, and gender gap threaten the well-being of future generations. The world requires immediate and coordinated actions to resolve these issues.

Therefore, ESG intelligence is important to companies, consumers, investors, and governments. Properly acquiring and analyzing it is possible if these stakeholders leverage the right tools, relevant benchmarks, and expert data partners.

2 notes

·

View notes

Text

The Essential Guide to Wastewater Treatment Plants: Turning Waste into Resource

Wastewater treatment plants (WWTPs) are the unsung heroes of urban infrastructure. As they work tirelessly behind the scenes, they transform contaminated water into a clean resource that can be safely returned to the environment or even reused. In this article, we’ll explore the critical role of wastewater treatment plants, their processes, and the benefits they bring to our communities and ecosystems.

Understanding Wastewater: What Is It?

Before delving into the intricacies of treatment plants, it’s vital to understand what wastewater is. Wastewater is any water that has been adversely affected by human activity. This can include:

Domestic Wastewater: From sinks, toilets, and showers in households.

Industrial Wastewater: Generated from manufacturing processes and commercial activities.

Stormwater: Rainwater that collects pollutants as it flows over surfaces.

Proper management of these types of wastewater is crucial for public health and environmental protection.

The Importance of Wastewater Treatment Plants

Wastewater treatment plants are essential for several reasons:

Public Health: Proper treatment of wastewater prevents the spread of waterborne diseases.

Environmental Protection: Treated water reduces pollution in rivers, lakes, and oceans, preserving aquatic ecosystems.

Resource Recovery: Many plants can recover valuable resources, such as nutrients and energy, from wastewater.

Sustainable Practices: Modern WWTPs incorporate technologies that promote sustainability, reducing their carbon footprint.

The Process of Wastewater Treatment

The treatment of wastewater is a complex process that typically involves several stages. Let’s break down these stages:

1. Preliminary Treatment

In this initial stage, large debris such as sticks, leaves, and plastic are removed from the wastewater. This is usually done through screening and grit removal processes.

2. Primary Treatment

After preliminary treatment, wastewater moves to primary treatment, where solids settle to the bottom, forming sludge. This process removes about 50-70% of suspended solids and approximately 30% of biological oxygen demand (BOD).

3. Secondary Treatment

Secondary treatment is crucial for further reducing organic matter. This stage usually involves biological processes, where microorganisms break down organic pollutants. There are various methods used in secondary treatment, including:

Activated Sludge Process: In this method, air is pumped into the wastewater, allowing microorganisms to feed on the organic material.

Trickling Filters: Wastewater is distributed over media, allowing microorganisms to grow and treat the water as it trickles through.

4. Tertiary Treatment

Tertiary treatment is an advanced stage that further polishes the water. This can involve filtration, nutrient removal, and disinfection processes like chlorination or ultraviolet (UV) light treatment. The goal is to ensure that the water is safe for discharge or reuse.

5. Sludge Management

Throughout the treatment process, sludge is generated. This sludge must be treated separately to reduce its volume and make it safer. Common methods include anaerobic digestion, which produces biogas, and composting, which can create a valuable soil amendment.

Innovations in Wastewater Treatment

The landscape of wastewater treatment is evolving, thanks to technological advancements. Here are some innovations transforming the industry:

1. Membrane Bioreactors (MBRs)

MBRs combine biological treatment with membrane filtration, allowing for higher quality effluent and smaller footprint operations. This technology is ideal for areas with limited space.

2. Constructed Wetlands

These engineered ecosystems mimic natural wetlands to treat wastewater. They are cost-effective and environmentally friendly, providing additional habitats for wildlife.

3. Resource Recovery Facilities

Modern WWTPs are increasingly focusing on recovering valuable resources from wastewater. This includes extracting nutrients like nitrogen and phosphorus, which can be used as fertilizers, and capturing biogas for energy production.

The Benefits of Wastewater Treatment Plants

Investing in wastewater treatment has far-reaching benefits:

1. Economic Advantages

Efficient wastewater treatment supports local economies by ensuring clean water for industries and agriculture. It also creates jobs in engineering, operations, and maintenance.

2. Environmental Sustainability

By reducing pollution and conserving water resources, wastewater treatment plants contribute to a healthier planet. They play a critical role in combating climate change by mitigating greenhouse gas emissions from untreated wastewater.

3. Improved Public Health

Access to treated wastewater prevents health risks associated with untreated sewage. This is especially crucial in developing regions where sanitation infrastructure may be lacking.

Challenges Facing Wastewater Treatment Plants

Despite their importance, wastewater treatment plants face several challenges:

1. Aging Infrastructure

Many WWTPs are outdated and require significant investment to upgrade. Aging systems may lead to inefficiencies and increased pollution.

2. Climate Change Impacts

Extreme weather events and rising sea levels can impact the operation of wastewater treatment facilities. Adapting to these changes is crucial for future resilience.

3. Public Awareness and Engagement

Many communities are unaware of the vital role that WWTPs play. Increasing public engagement can foster support for necessary investments and improvements.

Conclusion: The Future of Wastewater Treatment

Wastewater treatment plants are more than just facilities for cleaning water; they are essential components of sustainable urban development. As technology continues to evolve, these plants will become even more efficient and capable of recovering resources, ultimately contributing to a circular economy.

By recognizing the importance of wastewater treatment and supporting innovations in the field, we can ensure that our communities remain healthy and our environment is preserved for future generations. Investing in wastewater treatment Plant is not just about managing waste; it’s about embracing a sustainable future.

2 notes

·

View notes

Text

10 Effective Strategies for Solid Waste Management: Reduce, Reuse, Recycle!

Introduction

Welcome to our blog post on effective strategies for solid waste management! In today's world, where environmental concerns are paramount, adopting proper waste management practices is crucial. By following the three R's: Reduce, Reuse, and Recycle, we can make a significant impact on minimizing waste generation and preserving our planet's resources. Let's dive into the ten strategies that can help us achieve sustainable waste management.

1. Conduct a Waste Audit

According to the Water Treatment Plant Manufacturers in India to effectively manage waste, it's essential to understand the current waste generation and disposal patterns. Conducting a waste audit will provide valuable insights into the types and quantities of waste produced, allowing for targeted interventions.

2. Embrace Source Reduction

3. Promote Reuse and Repurposing

Encouraging reuse and repurposing of items helps reduce waste and extends the lifespan of products. Consider donating or selling unwanted items, participating in local swap events, and embracing creative DIY projects to give new life to old objects.

4. Implement Recycling Programs

Setting up recycling stations and educating employees and the community about proper recycling practices is vital. Ensure clear signage, separate bins for different recyclable materials, and provide educational materials on what can and cannot be recycled.

5. Composting Organic Waste

Composting is an excellent way to manage organic waste, such as food scraps and yard trimmings. It not only reduces waste sent to landfills but also produces nutrient-rich compost that can be used for gardening and landscaping.

6. Encourage Responsible E-Waste Disposal

Electronic waste, or e-waste, requires special handling due to its hazardous components. Educate yourself and others about the proper disposal of electronic devices and consider recycling programs dedicated to e-waste management.

7. Explore Waste-to-Energy Options

Waste-to-energy technologies offer an alternative to traditional waste disposal methods by converting waste into usable energy. Consider exploring options such as incineration, anaerobic digestion, or gasification, while considering the environmental and social impacts.

8. Establish Partnerships with Waste Management Companies

Collaborating with waste management companies that specialize in recycling and waste disposal can provide valuable expertise and services. They can assist with waste collection, recycling processes, and implementing sustainable practices.

9. Educate and Engage the Community

Raising awareness about waste management is crucial for long-term success. Organize community events, workshops, and awareness campaigns to educate people about the importance of proper waste management and involve them in the process.

10. Continuous Monitoring and Improvement

Monitoring waste management practices and tracking progress is essential for identifying areas of improvement. Regularly assess your waste management strategies, analyze data, and make necessary adjustments to achieve better results.

In conclusion, by implementing these ten effective strategies for solid waste management, we can make a significant impact on reducing waste, conserving resources, and creating a cleaner and healthier environment. Let's join hands and work together to embrace the principles of reducing, reusing, and recycling for a sustainable future.

#Waste Management Strategies#10 Ways to Reduce Waste#Waste Reduction and Utilization Strategies#Waste Management Reduce Reuse Recycle#Water Treatment Plant Manufacturers in India#Sewage Treatment Plant Manufacturers in India#Operation and Maintenance of Water Treatment#Operations and Maintenance in Facility Management#Water Treatment Plant Project#Sewage Treatment Plant Project#Effluent Treatment

2 notes

·

View notes

Text

Dewatering and Drainage Pumps: Essential Tools for Construction and Industrial Projects

In the construction as well as the industrial sector, efficiency, safety, and sustainability are essential where water management acts as one of the most fundamental functions for smooth operation. Here, dewatering pump and drainage pumps are important. These products are designed for removing the additional water from construction sites, industrial infrastructure, and sewer systems so that operations are fully operational around the clock. In this blog we are going to discuss dewatering and drainage pumps in the market and their global influence in construction.

The Importance of Dewatering Pumps in Construction and Industry

Dewatering Pumps are the pumps specially designed for removing water, which can be built in construction projects, residential basements, mines, and other low-areas. While rain-water can pose problems when it gathers on work sites, workplaces, and protects structural integrity, it is the water buildup that in many instances, hinders progress and damages equipment.

Some of their key applications are:

Excavations and trenches-have become useful in managing water level.

Heavy rains, which tend to cause flooding

Soils are stabilized best for building operations.

There is a growth spurt in the demand for effective and reliable dewatering pumps in the US for projects in the US. Using the same for small projects on construction sites or big industrial operations is necessary because dewatering pumps are essential.

Drainage Pumps: Keeping Sites Dry and Functional

A drainage pump is intended for water with minimum solid particles. Such pumps are used for avoiding waterlogging at construction sites, basements, and other urban infrastructure. In regions such as the UAE, where rapid urbanization is occurring, the use of a drainage pump in UAE projects becomes indispensable for proper management of water resources and preventing destruction of structures.

Drainage pumps are also highly versatile and can be applied in:

Urban water management systems.

Irrigation projects.

Emergency flood control.

Renting vs. Buying Dewatering Pumps

For many construction and industrial companies, renting a dewatering pump in US can be a good cost-effective idea. Selecting rental dewatering pumps will avoid the need to spend large amounts of money in advance and immediately have the latest pump technology available. Rental is highly economical for projects that involve short-duration systems or for particular applications where specialized pumps have to be used.

The Role of Sewage Pump Systems in Industrial Projects

Besides water management, industrial and construction projects involve wastewater and sewage management. A pump sewage tank is an essential equipment for collecting and transferring sewage to treatment facilities or disposal systems. These tanks are used in conjunction with sewage pump systems to ensure effective and sanitary removal of waste.

Sewage pump system are designed to handle solid waste and high-viscosity fluids, which makes them appropriate for:

Industrial wastewater management.

Municipal sewage systems.

Large residential complexes.

Why Cosmos Pumps?

Cosmos Pumps offer a range of high-quality dewatering pumps, drainage pumps, and sewage pump systems tailored to meet the requirements of various projects. Whether you're looking for dewatering pumps for rent or advice on choosing the right pump sewage tank, our experts are here to help.

Our pumps are engineered to last with efficiency and reliability, keeping your construction or industrial project on schedule and budget. For US-based, UAE-based, or projects based anywhere else around the globe, Cosmos Pumps is your partner for all water management needs.

Conclusion

Water management is the core backbone of any successful construction or industrial project. Be it the use of dewatering pumps in US or a drainage pump in UAE, it has become one of the prime necessities to ensure safety, efficiency, and sustainability. Therefore, by investing in or renting the right pumps, businesses can streamline their operations and avoid costly delays or damages.

0 notes

Text

Meeting Gurgaon’s High Water Quality Standards with Netsol Water’s RO Systems

Netsol Water is a leading Commercial RO Plant Manufacturer in Gurgaon, providing advance solutions for waste water management. Netsol Water is associated with an extensive range of RO systems in different residential commercial, and industrial uses. RO systems operate through application of high pressure so as to push water through a membrane wall while excluding contaminants, dissolved solids, and suspended particles. The Netsol Water RO systems are effectively known for their efficiency, effectiveness and reliability of delivering safe water throughout the systems to meet the increasing need of High water quality in Gurgaon.

Why are high water quality standard important in Gurgaon?

Netsol Water is top on Commercial RO Plant Manufacturer in Gurgaon, offering cutting-edge solutions for waste water. Gurgaon is one of the industrial city and fast developing city of Haryana state in India. There you can find a numerous multinational corporations, start-ups, residents and living complexes that’s why it is crucial for the city to preserve high level of water balances. The primary reasons for the need for high water quality standards in Gurgaon include:

1. Health concerns: Water especially clean and safe drinking water is one of the basic needs of humanity. Drinking water containing impurities is also dangerous and can cause health complications such as diarrhea and stomach ulcers, liver and kidney ailments, and in extreme cases, fatality. The quality of water to be supplied in Gurgaon should be of high standard in order to cater for the health implication for the inhabitants of the city and the employees.

2. Industrial demand: The rapid industrial growth makes Gurgaon demanding plenty of clean water for use in production processes and for other uses such as cooling and washing. This has led to the realization that high water quality is achievable and necessary in order to support industries without degrading water quality.

3. Environmental protection: Various industries and residential areas produce wastewater that requires proper treatment before being discharged into the environment in order to protect water sources and the environment at large. High quality water in Gurgaon also plays an important role in preventing the pollution of wastewater and its effect on the environment.

How RO Systems of Netsol Water are meeting high water quality standards in Gurgaon?

Netsol Water is one of the best Commercial RO Plant Manufacturers in Gurgaon, offering waste water solutions. The RO systems provided by Netsol Water have been able to effectively address the stringent water quality requirements of Gurgaon. Some of the key reasons for their success include:

1. Advanced technology: Some features of Netsol Water’s Reverse Osmosis systems include energy saving pumps, high quality membranes and automatic control systems. Such features make certain that the system delivers hygienic and safe water with the lowest energy consumption and operating costs.

2. Customizable solutions: As for residential needs, Netsol Water provides numerous types of RO systems, which can meet the requirements of commercial and industrial customers in Gurgaon too. This way they guarantee that customer acquires the water treatment system he needs to solve his particular problem.

3. Skilled technicians: Netsol Water also has a team of highly qualified technicians who are specialized in installation, maintenance and servicing of RO systems. It also means that the RO systems in Gurgaon can guarantee residents and businesses in the city that they can get safe water all throughout.

4. Eco-friendly approach: Netsol Water is an organization with the core business of offering environmentally friendly water treatment services. The RO systems they have are engineered to be water efficient and power conscious; this will be perfect for Gurgaon’s steadily rising populace and guarantee their efforts towards the conservation of the environment.

5. Continuous monitoring and support: RO Systems of Netsol Water is often checked so that there are no problems in its proper function. The company also offers follow up services as well as maintenance so that the systems are always efficient and functional.

Conclusion

Netsol Water is a trusted Commercial RO Plant Manufacturer in Gurgaon, offering solutions for waste water management. The RO systems developed by Netsol Water can be considered ideal to deliver high quality water to Gurgaon. Their technological solutions, individualistic services, expert team of technicians, environmentally friendly methods, and ongoing monitoring and assistance render their services as the most dependable and effective in water treatment services. Therefore, if Gurgaon decides to invest in Netsol Water’s RO systems, it will be instrumental in providing clean and safe water to the people and industries, and help promote public health, protect the environment, and support the growth of industries in the city.

#environment#manufacturer#industries#water#environmental#manufacturers#industrial#netsolwater#purifier#manufacturing#industry#wastewater#filter#business#management#gurgaon

2 notes

·

View notes

Text

Leading Stainless Steel Anaerobic Digester Manufacturer in China – Center Enamel

In the rapidly evolving field of waste management and renewable energy, anaerobic digestion has emerged as a transformative solution for organic waste treatment and biogas production. As a trusted leader in the storage tank industry, Shijiazhuang Zhengzhong Technology Co., Ltd (Center Enamel) stands out as the leading stainless steel anaerobic digester manufacturer in China, offering innovative, reliable, and sustainable solutions for global customers.

As a leading storage tank manufacturer in China. At Shijiazhuang Zhengzhong Technology Co., Ltd., we excel in providing high-quality bolted steel tanks tailored for the diverse needs of fish farming. Our extensive range of bolted steel tanks includes Glass-Fused-to-Steel (GFS) tanks, fusion bonded epoxy tanks, stainless steel tanks, and galvanized steel tanks, each designed to offer exceptional durability, efficiency, and adaptability for aquaculture applications.

Configuration of Customized Storage Tanks

Storage tanks

Volume

Roofs

Application

Design Requirements

GFS Tanks

SS Tanks

Fusion Bonded Epoxy Tanks

Galvanized Steel Tanks

Welded Steel Tanks

<1000m³

1000-10000m³

10000-20000m³

20000-25000m³

>25000m³

ADR Roof

GFS Roof

Membrane Roof

FRP Roof

Trough Deck Roof

Wastewater Treatment Project

Drinking Water Project

Municipal Sewage Project

Biogas Project

Fire Water Storage Project

Oil Storage Project

Water Supply & Drainage System

Seismic Design

Wind Resistant Design

Lightning Protection Design

Tank Insulation Design

WasteWater Treatment Project Equipment Supply

Pretreatment Equipment

Resource Utilization System

Sludge Treatment System

Other Equipment

Mechanical Bar Screen

Solid-liquid Separator

Submersible Mixer

Gas Holder

Boiler System

Boost Fan

Biogas Generator

Torch System

Dehydration and Desulfurization Tank

PAM Integration Dosing Device

Screw Sludge Dewatering Machine

Slurry Separation Centrifuge

Sewage Pump

Mud Scraper

Submersible Sewage Pump

Three-phases Separator

Why Choose Stainless Steel Anaerobic Digesters?

1. Superior Durability

Stainless steel’s exceptional corrosion resistance makes it ideal for the harsh conditions within anaerobic digesters. It ensures the tank’s longevity, even in environments rich in methane, hydrogen sulfide, and other aggressive substances.

2. Excellent Hygiene and Sealing Performance

The smooth, non-porous surface of stainless steel minimizes bacterial buildup and ensures that the anaerobic digestion process occurs efficiently. Stainless steel digesters also provide excellent sealing performance, preventing leaks and optimizing biogas production.

3. Customizable Designs for Diverse Applications

At Center Enamel, we understand that every project has unique requirements. Our stainless steel anaerobic digesters are designed to meet the specific needs of industries like agriculture, food processing, wastewater treatment, and municipal waste management.

4. Sustainability and Recyclability

As a recyclable material, stainless steel aligns with the principles of a circular economy, making it an environmentally responsible choice for anaerobic digestion projects.

Center Enamel’s Stainless Steel Anaerobic Digesters

1. Advanced Manufacturing Techniques

Center Enamel employs cutting-edge production processes and precision engineering to create stainless steel digesters that meet international standards. Our products comply with ISO 9001, ISO 28765, AWWA D103-09, and other global certifications.

2. Tailored Solutions for Every Project

Whether it’s a small-scale agricultural application or a large municipal biogas plant, our team provides custom-engineered solutions to meet capacity, operational, and regulatory requirements.

3. Proven Track Record

Our stainless steel anaerobic digesters are widely used across the globe, helping clients achieve efficient waste treatment and renewable energy generation. We’ve worked on projects in over 100 countries, earning the trust of industries worldwide.

Applications of Stainless Steel Anaerobic Digesters

1. Agricultural Waste Management

Our digesters are ideal for processing animal manure and crop residues, converting waste into valuable biogas and nutrient-rich fertilizers.

2. Municipal Solid Waste Treatment

Stainless steel anaerobic digesters offer a sustainable solution for managing organic municipal waste, reducing landfill reliance while producing renewable energy.

3. Food and Beverage Industry

Anaerobic digesters help food and beverage manufacturers manage organic by-products effectively while lowering energy costs through biogas generation.

4. Wastewater Treatment

Stainless steel digesters are integral to wastewater treatment plants, processing sludge and converting it into biogas for energy recovery.

Why Center Enamel?

1. Expertise and Experience

As the first manufacturer of Glass-Fused-to-Steel tanks in China, Center Enamel has over three decades of experience in the storage tank industry. Our expertise extends seamlessly to stainless steel anaerobic digesters.

2. R&D Leadership

We invest heavily in research and development to innovate and improve our products. Our team has developed over 200 patented technologies, ensuring state-of-the-art solutions for our clients.

3. Comprehensive Support

From project design and manufacturing to installation and after-sales service, Center Enamel provides end-to-end support to ensure the success of every project.

4. Global Recognition

With installations in over 100 countries and a reputation for quality and reliability, Center Enamel is the go-to manufacturer for stainless steel anaerobic digesters.

Center Enamel is proud to lead the way as the top stainless steel anaerobic digester manufacturer in China, delivering world-class solutions for waste management and biogas production. Our commitment to quality, innovation, and sustainability ensures that our customers receive the most reliable and efficient digesters for their needs.

Contact us today to learn more about our stainless steel anaerobic digesters and discover how Center Enamel can help power your renewable energy and waste treatment projects.

0 notes

Text

Why is ESG Intelligence Important to Companies?

Human activities burden Earth’s biosphere, but ESG criteria can ensure that industries optimize their operations to reduce their adverse impact on ecological and socio-economic integrity. Investors have utilized the related business intelligence to screen stocks of ethical enterprises. Consumers want to avoid brands that employ child labor. This post will elaborate on why ESG intelligence has become important to companies.

What is ESG Intelligence?

ESG, or environmental, social, and governance, is an investment guidance and business performance auditing approach. It assesses how a commercial organization treats its stakeholders and consumes natural resources. At its core, you will discover statistical metrics from a sustainability perspective. So, ESG data providers gather and process data for compliance ratings and reports.

Managers, investors, and government officers can understand a company’s impact on its workers, regional community, and biosphere before engaging in stock buying or business mergers. Since attracting investors and complying with regulatory guidelines is vital for modern corporations, ESG intelligence professionals have witnessed a rise in year-on-year demand.

Simultaneously, high-net-worth individuals (HNWI) and financial institutions expect a business to work toward accomplishing the United Nations’ sustainable development goals. Given these dynamics, leaders require data-driven insights to enhance their compliance ratings.

Components of ESG Intelligence

The environmental considerations rate a firm based on waste disposal, plastic reduction, carbon emissions risks, pollution control, and biodiversity preservation. Other metrics include renewable energy adoption, green technology, and water consumption.

Likewise, the social impact assessments check whether a company has an adequate diversity, equity, and inclusion (DEI) policy. Preventing workplace toxicity and eradicating child labor practices are often integral to the social reporting head of ESG services.

Corporate governance concerns discouraging bribes and similar corruptive activities. Moreover, an organization must implement solid cybersecurity measures to mitigate corporate espionage and ransomware threats. Accounting transparency matters too.

Why is ESG Intelligence Important to Companies?

Reason 1 – Risk Management

All three pillars of ESG reports, environmental, social, and governance, enable business owners to reduce their company’s exposure to the following risks.

High greenhouse (GHG) emissions will attract regulatory penalties under pollution reduction directives. Besides, a commercial project can take longer if vital resources like water become polluted. Thankfully, the environmental pillar helps companies comply with the laws governing these situations.

A toxic and discriminatory workplace environment often harms employees’ productivity, collaboration, creativity, and leadership skill development. Therefore, inefficiencies like reporting delays or emotional exhaustion can slow a project’s progress. ESG’s social metrics will mitigate the highlighted risks resulting from human behavior and multi-generational presumptions.

Insurance fraud, money laundering, tax evasion, preferential treatment, hiding conflicts of interest, and corporate espionage are the governance risks you must address as soon as possible. These problems introduce accounting inconsistencies and data theft issues. You will also receive penalties according to your regional laws if data leaks or insider trading happens.

Reason 2 – Investor Relations (IR)

Transparent disclosures can make or break the relationship between corporate leaders and investors. With the help of ESG intelligence, it becomes easier to make qualitative and manipulation-free “financial materiality” reports. Therefore, managers can successfully execute the deal negotiations with little to no resistance.

You want to retain the present investors and attract more patrons to raise funds. These resources will help you to augment your company’s expansion and market penetration. However, nourishing mutually beneficial investor relations is easier said than done.

For example, some sustainability investors will prioritize enterprises with an ESG score of above 80. Others will refuse to engage with your brand if one of the suppliers has documented records of employing child labor. Instead of being unaware of these issues, you can identify them and mitigate the associated risks using ESG intelligence and insights.

Reason 3 – Consumer Demand

Consider the following cases.

Customers wanted plastic-free product packaging, and e-commerce platforms listened to their demand. And today’s direct home deliveries contribute to public awareness of how petroleum-derived synthetic coating materials threaten the environment.

The availability of recharging facilities and rising gas prices have made electric vehicles (EVs) more attractive to consumers. Previously, the demand for EVs had existed only in the metropolitan areas. However, the EV industry expects continuous growth as electricity reaches more semi-urban and rural regions.

Businesses and investors care about consumer demand. Remember, they cannot force consumers into buying a product or service. And a healthy competitive industry has at least three players. Therefore, customers can choose which branded items they want to consume.

Consumer demand is one of the driving factors that made ESG intelligence crucial in many industries. If nobody was searching for electric vehicles on the web or everybody had demanded plastic packaging, businesses would never switch their attitudes toward the concerns discussed above.

Conclusion

Data governance has become a popular topic due to the privacy laws in the EU, the US, Brazil, and other nations. Meanwhile, child labor is still prevalent in specific developing and underdeveloped regions. Also, the climate crisis has endangered the future of agricultural occupations.

Deforestation, illiteracy, carbon emissions, identity theft, insider trading, discrimination, on-site accidents, corruption, and gender gap threaten the well-being of future generations. The world requires immediate and coordinated actions to resolve these issues.

Therefore, ESG intelligence is important to companies, consumers, investors, and governments. Properly acquiring and analyzing it is possible if these stakeholders leverage the right tools, relevant benchmarks, and expert data partners.

2 notes

·

View notes

Text

Who Is The Best Commercial RO Plant Manufacturer In Noida ?

Due to the industries being established daily, water contamination is a usual but a grave matter of concern. To address the water demands in various sectors here such as residential communities, offices, farms etc., Netsol Water with the full support of its branch Commercial RO Plant has come to their rescue & has adopted the RO based water purification systems to introduce itself to be the best among the Commercial RO Plant Manufacturer In Noida.

Even with rising demands for water treatment, many companies have put their foot base in there to offer Customized Commercial RO plant systems but Netsol Water & the subsidiary Commercial RO Plant excels among them as a solid strong business enterprise.

Netsol Water when works with its subsidiary company Commercial RO Plant becomes a part among the most finest capable Commercial RO Plant Manufacturer In Noida.

Netsol Water when works with its best branch Commercial RO Plant was established with strong & firm holdings in the beginning of the decade 2010 dedicates in the designing of various water treating or processing plants integrated with the most eligible technology including Commercial RO plants. Netsol Water in alliance with its branch Commercial RO Plant already has its manufacturing unit in Gr.Noida but it has expanded its manufacturing unit as well to meet the demands there as well.

While investing in world-class equipment like bending as well as laser cutting, Netsol Water together with the additional branch Commercial RO Plant guarantees stringent in-unit service standards as well as quality control. It assumes complete responsibility for providing its clients with continuous manufacture, design, along with installation of after-sales support systems, whether they are in the retail, healthcare, or multispecialty clinic sectors.

Brief about Commercial RO Plant Manufacturer In Noida are Netsol Water who is working very effortly with its branch company Commercial RO Plant

With its completely computerized water purification system along with membrane-based technology, Netsol Water together with the subsidiary Commercial RO Plant's Commercial RO Plants are high-tech equipment that can effortlessly handle waste & raw water treatment from a several thousands to millions litres in a day.

The Units of various Commercial RO Plant Manufacturer In Noida are usually spread over around thousands of square feets & expanding which are fitted with world-class trending technology.

What kind of Features, A commercial RO Plant offers at Netsol Water collectively with Commercial RO Plant?

Some of the traits of a commercial RO plant include the following:

Intelligent Smart technology powers all of the devices, needing minimal human intervention.

The best quality components & related materials are incorporated in pumps & thin RO membranes.

More amount of minerals are dosed into the purified treated water to replenish most of the useful minerals in it.

Multi-grade or multi-level therapies are utilized in the pre-treatment.

Since the latest & the most advanced Double Staged Purification systems has been implemented globally, it is easily accessible here as well through Netsol Water.

A number of inlet-based sensing devices are set up to optimize the water quality right away.

The overall rate of water retention & recovery has increased by as much as 65-70% when compared to other manufacturers in the markets of Noida.

Corrosion occurs primarily during treatment, hence Netsol Water together with the subsidiary Commercial RO Plant adopts the highest-quality graded material for all metallic components to prevent it as much as possible.

Experts survey the regular site in response to client requests.

Annual Maintenance Contracts for routine service as well as regular water quality analysis based on various locations.

Everything is tested & functional before being given to the client or customer.

This machinery has a lower energy utilization rate as well as lower operating costs.

Conclusion

Recent history of struggling with the fear of water related ailments & illnesses, & these fear have been on the progression of complete elimination by the development of Commercial RO Plant Manufacturer In Noida such as Netsol Water together with Commercial RO Plant in the area efficiently, economically & ecologically.

With the manufacturing of such advanced RO treatment system, the cities like Noida is really working out many problems such as energy as well as water consumption, groundwater contamination, freshwater site exploitation.

Netsol Water in conjunction with the subordinate Commercial RO Plant has opened up the gate for the potential reuse, recycling along with safeguarding water for various consumptive utilizations which is going to contribute to this planet with a sustainable position in the coming years.

#commercial ro plant#commercial ro plant manufacturer in noida#netsol water#save water#water is life

0 notes

Text

The Importance of Self Priming and Sewage Pumps for UAE Industries

In the UAE, industries and commercial establishments often require efficient and reliable pumping solutions for water, sewage, and other liquid handling needs. Among the most crucial equipment are self priming pumps and sewage pumps, which offer significant advantages for a wide range of applications. Whether in construction, waste management, or water treatment, having the right pumps ensures smooth operations and prevents downtime.

Understanding Self Priming Pumps

Self priming pumps are designed to handle challenging liquid transfer tasks. These pumps are unique because they can automatically remove air from their suction line and continue pumping without needing manual priming. This feature is particularly useful in situations where the pump may lose its prime due to air entering the system or when dealing with varying water levels.

Self priming pumps are ideal for industrial applications that require continuous and reliable operation, such as water supply, irrigation, and drainage. The self-priming functionality is especially beneficial in the UAE, where the environment often presents challenges like fluctuating water sources and sediment-filled water. Whether it's for a construction site or a municipal project, these pumps provide reliability and efficiency.

For a comprehensive range of self priming pumps, check out Self Priming Pumps UAE. The multi-purpose self priming pumps offer robust performance for a variety of liquid handling tasks, ensuring that your operations remain unaffected by air or sediment issues.

The Role of Sewage Pumps

Sewage pumps are an essential part of managing waste and water systems, especially in areas with complex or large-scale sewage networks. In the UAE, where urbanization is rapid, these pumps play a vital role in ensuring that wastewater is efficiently removed from buildings and safely transported to treatment plants or sewage systems. Sewage pumps are designed to handle a variety of solids, liquids, and waste materials, making them highly reliable in managing the flow of sewage in residential, commercial, and industrial applications.

The use of sewage pumps in UAE has become even more critical due to the fast-growing infrastructure needs and the challenge of maintaining sanitary systems in high-density urban areas. Efficient pumps ensure that waste water is processed effectively, reducing the risk of flooding, contamination, or environmental hazards.

Choosing the Right Pump for Your Needs

When it comes to selecting the right pump, both self priming pumps and sewage pumps offer their unique advantages. It’s essential to consider factors such as the type of liquid to be pumped, the desired flow rate, and the system’s design. A reputable supplier like Oasis Pumps offers a wide selection of self priming pumps UAE that can be tailored to suit your specific needs, ensuring optimal performance across diverse applications.

Whether you are looking for pumps to handle clean water, wastewater, or sewage, understanding the unique needs of your system will help you make an informed decision. By investing in high-quality pumps, you can avoid costly maintenance and ensure smooth operations year-round.

Conclusion

In conclusion, both self priming pumps and sewage pumps play an essential role in various sectors within the UAE. With their advanced technology and robust features, these pumps provide reliable solutions for water and sewage management, making them indispensable for industries across the region. To learn more about self priming pumps and find the right solution for your needs, visit Oasis Pumps for more information.

0 notes