#Solid Rocket Motor Cases

Link

The missile defense market is observing rising investment across hypersonic missile capabilities, and this is driving the investments across comparable defensive capabilities. Focus on End User, Subsystem, Material, Manufacturing Process and Country 2022-2032.

Get Now | The Sample Report of High-Speed Aircraft and Missiles Composite Materials Study at: https://bit.ly/3JsIeRd

#High-Speed Aircraft#High-Speed#High-Speed Aircraft and Missiles Composite Material#Commercial#Commercial Hypersonic#Commercial Hypersonic and Supersonic Aircraft#Defense#Hypersonic and Supersonic Missile#Defense Hypersonic and Supersonic Aircraft#Aircraft Subsystem#Airframe#Engine#Landing Gear System#Weapon System#Solid Rocket Motor Cases#Propulsion System#Radomes#Airframes#Fiber Types#Carbon Fiber#Glass Fiber#Resin Types#Thermoset#Thermoplastic#Ceramic Matrix Composite#Automated Fiber Placement#Compression Molding#Additive Manufacturing

0 notes

Text

The Imperial bolter shell is a rocket-propelled, armour-piercing, spin-stabilised, high-explosive, delay-fused grenade designed to penetrate light armour and then explode behind it. The vast majority are approximately 19mm in diameter, manufactured for the relative frailty of human constitutions, with a select number produced in the 25mm size exclusively for Astartes organisations. The Imperium is so incomprehensibly vast that even these hand-crafted icons of righteous death are made by the millions each day.

Each round is fired from a brass casing using a small "kicker" charge, large enough to ensure each explosive round exits the barrel safely. Once the projectile is clear, an internal fuse ignites a solid rocket motor which more properly propels the round towards the target. The four nozzles on the rear are angled to provide spin-stabilisation during flight, with the rocket motor lasting for approximately one second before expending itself completely.

Upon impact the diamantine tip pierces the target, allowing the high-explosive charge to enter behind it. A mass-reactive fuse detonates the charge once it detects sufficient penetration depth, ensuring maximum effect on the target. Many other payloads also exist, exploiting the large volume of the bolt shell to deliver anything from powerful toxins to psychically-active materials. "Inferno" variants are relatively popular, adding a promethium-based incendiary gel to the explosive to set targets on fire.

67 notes

·

View notes

Text

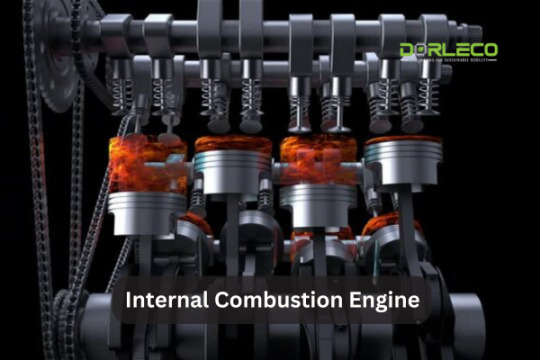

Internal Combustion Engine

March 5, 2024

by dorleco

with no comment

Autonomous Vehicle Technology

Edit

Introduction

In the United States, internal combustion engines power almost 250 million highway vehicles due to their exceptional longevity and drivability. They can run on renewable or alternative fuels in addition to gasoline or diesel (e.g., natural gas, propane, biodiesel, or ethanol). Additionally, they can be paired with plug-in hybrid electric systems to increase the range of hybrid electric vehicles or with hybrid electric powertrains to improve fuel efficiency.

Internal combustion engines are divided into two groups:

Continuous combustion:

Engines with both intermittent and continuous combustion. Fuel and oxidizer enter the engine steadily, which is the hallmark of a continuous-combustion engine. An engine (such as a jet engine) maintains a steady flame.

Intermittent-combustion engines:

The air and fuel in an intermittent combustion engine ignite periodically, giving rise to the term “reciprocating engine.” A cycle is used to process discrete amounts of fuel and air. Examples of this second type are diesel engines and gasoline piston engines.

A sequence of thermodynamic events can be used to describe internal combustion engines. Thermodynamic processes take place concurrently in a continuous-combustion engine as the fuel, oxidizer, and combustion products move through the engine in a steady flow.

In contrast, all of the events in an intermittent combustion engine happen one after the other and are repeated throughout each cycle.

Internal combustion engines consume air, compress it, and either introduce fuel into the air or compress the air-fuel combination. Rockets are an exception to this rule, as they use both liquid-propellant and solid rocket motors.

The air-fuel mixture is then burned, work is obtained from the expansion of the hot gaseous combustion products, and finally, the combustion products are discharged through the exhaust system, as is the case with all internal combustion engines.

Their functioning can be compared to that of external combustion engines (such as steam engines), where energy is obtained exclusively by heat transfer to the working fluid via a heat exchanger and no chemical reaction occurs in the working fluid.

The four-stroke, gasoline-powered, homogeneous-charge, spark-ignition engine is the most widely used internal combustion engine. This might be attributed to its exceptional performance as a leading player in the ground transportation sector.

The aeronautics industry uses spark-ignition engines as well, but because of its focus on range, speed, and passenger comfort, aircraft gas turbines have emerged as the industry’s main players.

Exotic systems including advanced rocket engines and motors, like those found on U.S. space shuttles and other spacecraft, and supersonic combustion ramjet engines (scramjets), like those envisioned for hypersonic aircraft, are also included in the category of internal combustion engines.

How Does An Internal Combustion Engine Work?

The fundamental chemical process of releasing energy from a fuel and air mixture is called combustion, or burning. The process of fuel ignition and combustion in an internal combustion engine (ICE) takes place inside the engine. After that, the engine uses a portion of the energy produced by combustion to power itself. A stationary cylinder and a moving piston make up the engine. The crankshaft rotates as a result of the piston being pushed by the expanding combustion gasses. In the end, this action turns the wheels of the car through a set of gears in the powertrain.

The spark-ignition gasoline engine and the compression-ignition diesel engine are the two types of internal combustion engines that are currently in production. The majority of these are four-stroke engines, which require four piston strokes to complete a cycle. The intake, compression, combustion, power stroke, and exhaust are the four independent operations that make up the cycle.

The methods used by compression ignition diesel engines and spark ignition gasoline engines to feed and ignite fuel are different. During the intake phase in a spark ignition engine, fuel and air are combined and then forced into the cylinder. The fuel-air mixture is compressed by the piston and then ignited by the spark, leading to combustion. During the power stroke, the piston is pushed by the combustion gasses’ expansion. Only air is introduced and subsequently compressed into an engine in a diesel. The fuel then ignites when diesel engines spray it into the hot compressed air at a proper, controlled rate.

In essence, an internal combustion engine converts the air-fuel mixture’s heat energy into mechanical energy. The reason it is named Four Strokes is that a full combustion cycle in the piston requires four strokes to complete. An internal combustion engine, sometimes known as an ICE (internal combustion engine), is a four-stroke piston engine that powers a passenger car.

Let’s now investigate which constitutes an ICE’s principal parts.

The camshaft(s), valves, valve buckets, valve return springs, spark/glow plugs, and injectors (for direct injection engines) are typically located in the cylinder head. The engine’s cooling liquid passes via the cylinder head.

We can locate the piston, connecting rod, and crankshaft inside the engine block. Regarding the cylinder head, coolant passes through the engine block to assist in regulating the engine’s temperature.

From BDC to TDC, the piston travels inside the cylinder. When the piston is near TDC, a volume is formed between the cylinder head, engine block, and piston. This space is known as the combustion chamber.

An ICE with four strokes has the following phases (strokes) in a complete engine cycle:

Intake power (expansion) exhaust compression intake The piston’s movement between the bottom and top dead centers is referred to as a stroke.

Now that we are aware of an ICE’s constituent parts, we can investigate the actions that take place throughout each engine cycle stroke. The position of the piston at the start of each stroke and the specifics of what happens inside the cylinder are displayed in the table below.

Stroke 1 – INTAKE

Stroke 2 – COMPRESSION

After the intake stroke is complete, the piston begins the compression stroke at BDC. The intake and exhaust valves close during the compression stroke, and the piston travels toward TDC. The air/mixture is compressed when both valves are closed, and when the piston approaches TDC, the pressure reaches its maximum.

During the compression stroke, just before the piston reaches TDC (but not quite there),

Stroke 3 – POWER

Stroke 4 – EXHAUST

After the power stroke is over, the exhaust stroke begins with the piston at the BDC. There is an open exhaust valve during this stroke. Most of the exhaust gasses are forced out of the cylinder and into the exhaust pipes by the piston’s movement from the BDC to the TDC.

The engine uses energy during the exhaust stroke because the components’ inertia causes the crankshaft to rotate.

As you can see, the piston needs to make four strokes to complete a combustion (engine) cycle. This indicates that two full crankshaft revolutions (720°) are required for one engine cycle.

Advantages of internal combustion engines

Engine size is extremely small in comparison to external combustion engines.

The power-to-weight ratio is elevated.

Excellent for applications with low power requirements

Typically, more transportable than external combustion engines of the same kind

safer to use with a much shorter start time

Higher efficiency compared to an external combustion engine

There is no possibility of working fluid leaks

minimal upkeep is necessary

Compared to external combustion engines, there is a reduction in lubricant use.

Because the peak temperature is only achieved briefly (during the fuel’s explosion), the overall working temperature in the case of reciprocating internal combustion is modest.

Disadvantages of internal combustion engines

The range of fuels available for utilization is restricted to extremely high-quality gaseous and liquid fuels.

Fuel utilized, such as gasoline or diesel, is quite expensive.

In general, engine emissions are higher than those of an external combustion engine.

Unsuitable for producing significant amounts of power

When there is reciprocating internal combustion, fuel detonation produces noise.

Types and applications of internal combustion engine:

Gasoline engines are utilized in automobiles, boats, and airplanes.

Gas engines are employed to provide industrial power.

Diesel engines are utilized in the automotive, railroad, power, and marine industries.

Gas turbines: They are employed in the maritime, industrial, and aircraft industries.

Conclusion:

To sum up, for more than a century, internal combustion engines have been essential in powering a variety of industry and transportation options. They are essential to contemporary industrialization and mobility because of their effectiveness, dependability, and flexibility. However, the desire to switch to greener, more sustainable options is growing as worries about the effects on the environment and the depletion of resources increase.

Internal combustion engines’ dependence on fossil fuels is still a severe disadvantage, despite notable improvements in efficiency and emissions reduction. Research and development efforts are being directed toward alternative fuels like biofuels and hydrogen, as well as electrification technologies like electric and hybrid powertrains, in an attempt to address these problems.

Moreover, the use of sophisticated engine management systems, lightweight materials, and enhanced aerodynamics keeps improving internal combustion engine performance and fuel efficiency. To combat climate change and lessen reliance on limited resources, a thorough transition to greener transportation options is required.

In conclusion, even though internal combustion engines have proved essential to contemporary transportation and industry, there are growing concerns about their long-term viability. The key to the future is adopting cutting-edge technologies that balance environmental protection with the changing demands of society for dependable and efficient power sources.

Also Read: Things to know about Hybrid Powertrains

#InternalCombustionEngine#VCU#Powertrains#EVEMS#EVCharging#Dorleco#ADAS#Electricmotor#EVs#Hybridelectricvehicles#Electrigenerator

0 notes

Text

hold on. forgive me for going on a gun rant unprovoked but i just realized something

so, bit of context. normal firearms use bullets inserted into a brass/steel/polymer (rarely) case full of propellant, the bullet has no way of accelerating itself. it's purely a projectile. gyrojet rounds have no case, the bullet contains angled solid rocket motors that both propel and spin-stabilize it.

as such, gyrojet firearms do not require case ejection ports except for clearing a jam, and the rounds gain kinetic energy up to the point where the motors burn out long after leaving the barrel. this means they are not particularly effective at close range.

so why is it that the only properly manufactured gyrojet cartridge is a 13mm caliber pistol round??? you're hardly gonna get more out of that than .45 ACP!!! all the ballistic advantages, rendered pointless because it would never be used at long enough range for it to matter!!! agh!!!

#toaster thoughts#firearms#guns#only guns made to fire these rounds were a self-loading pistol a single-shot bolt-action rifle and a pistol-caliber carbine#caseless and/or rocket-propelled small arms ammo has merit but pistol-caliber gyrojets were just a technological dead-end

1 note

·

View note

Text

Aerojet Rocketdyne Poised to Accelerate GMLRS Motor Production Under New Contract

Aerojet Rocketdyne, an L3Harris Technologies company, will leverage ongoing upgrades to its solid rocket motor manufacturing facilities to fulfill a new contract from Lockheed Martin to continue providing propulsion systems for the U.S. Army’s Guided Multiple Launch Rocket System (GMLRS) program. Last year, the Army awarded Lockheed Martin a contract modification to increase GMLRS production to meet increased domestic and international demand. Aerojet Rocketdyne, which has delivered more than 35,000 steel- and composite-cased GMLRS motors to date, announced last year it had been purchasing new equipment, automating processes, and incorporating improved X-ray technology to increase production efficiency.

Aerojet Rocketdyne, an L3Harris Technologies company, will leverage ongoing upgrades to its solid rocket motor manufacturing facilities to fulfill a new contract from Lockheed Martin to continue providing propulsion systems for the U.S. Army’s Guided Multiple Launch Rocket System (GMLRS) program. Last year, the Army awarded Lockheed Martin a contract modification to increase GMLRS production to…

View On WordPress

0 notes

Link

Blue Origin’s New Shepard rocket is planned to return to flight on Dec. 18, 2023, with a launch window that opens at 8:30 AM CST (14:30 UTC) from Blue Origin’s Launch Site One in West Texas. This mission follows a failure during the last New Shepard mission, NS-23, on Sept. 12, 2023. The NS-24 mission will lift off from Launch Site One carrying 33 science and research payloads as well as 38,000 postcards for the company’s Club for the Future foundation. NS-23 Failure and Investigation During the uncrewed flight of NS-23, New Shepard’s BE-3PM engine nozzle suffered a thermo-structural failure which led to the capsule firing its launch abort system shortly after Max-Q. The New Shepard capsule safely escaped the booster as intended and made a soft landing under its three main parachutes nearby. The booster, known as Tail 3, was lost when it commanded the engine to be shut down as part of the response to the Crew Capsule escape. It then impacted the ground one kilometer east of the launch pad. This was the first failure of a New Shepard booster since the first mission in 2015 where Tail 1 crashed during descent after losing hydraulic pressure. Following the failure, Blue Origin formed a Mishap Investigation Team (MIT) led by members of Blue Origin’s Safety & Mission Assurance organization. In the days following the launch, the MIT recovered all critical flight hardware from the area surrounding the launch site. A nozzle fragment on the ground at Launch Site One following the failure. (Source: Blue Origin) Blue Origin began testing BE-3PM engines immediately following the incident to assist in the investigation. During the investigation, the MIT was able to determine that the cause of the failure was structural fatigue on the BE-3PM nozzle during flight. The fatigue was found to be caused by thermal damage and hot streaks from increased operating temperatures. A change made to the boundary layer cooling system of the engine led to an increase in nozzle heating and the present hot streaks. Since the investigation, Blue Origin has been working to implement corrective actions to the BE-3PM’s combustion chamber and operating parameters, as well as design changes to improve the structure performance of the nozzle under dynamic and thermal loads. A BE-3 engine going through testing at Corn Ranch. (Credit: Blue Origin) New Shepard Mission Overview See AlsoNS-24Blue Origin Forum SectionL2 Future Vehicles SectionClick here to Join L2 Named in honor of the first American to fly into space, astronaut Alan Shepard, New Shepard is Blue Origin’s reusable suborbital rocket system which was designed to carry both humans and research payloads past 100 kilometers in altitude, and safely return them to Earth during a 10-minute flight. The New Shepard vehicle consists of a Propulsion Module and a Crew Capsule. When stacked, the vehicle stands approximately 18 meters tall and 3.6 meters in diameter. The Crew Capsule can be configured to support dedicated crewed missions, dedicated payload missions, as well as human-tended payload missions. The capsule is equipped with a solid rocket motor which can be used in the case of an in-flight abort to safely push the Crew Capsule away from the Propulsion Module. On the morning of launch, New Shepard will be rolled out of the Vehicle Processing Facility in a horizontal configuration and take a 2.9-kilometer journey to the launch pad. Once at the launch pad, the rocket will be erected vertically on the launch stand where the vehicle will be prepared for flight. A New Shepard Crew Capsule and Propulsion Module on display. (Credit: Jack Beyer for NSF) At T-500 seconds, the payloads onboard New Shepard will be powered on and prepared for flight. At T-0, the ignition of the BE-3PM engine, which runs on liquid hydrogen (LH2) and liquid oxygen (LOX), is commanded. The vehicle will then sit on the launch pad while the engine starts up until T+7 seconds when New Shepard will lift off from the launch stand. Around 128 seconds into the flight, New Shepard will experience Max-Q. During this period, the BE-3PM engine will throttle down to help reduce the g-load which will peak around 2.8 g. At T+146 seconds, New Shepard’s BE-3PM engine will cut off as the vehicle passes 60 kilometers in altitude. This is followed by the separation of the Crew Capsule around 15 seconds later. The capsule will fire its reaction control system (RCS) after separation to ensure it’s stabilized. Just over four minutes into the mission, the capsule will continue to coast up to an apogee of over 100 kilometers. During this time the payloads onboard the vehicle will get to experience microgravity for roughly three minutes. After reaching apogee, both the New Shepard booster and capsule begin their return to Earth and reenter the atmosphere. At around five and a half minutes into the flight, the propulsion module will deploy four wedge fins from the ring fin that is located on the forward end of the booster. These help provide extra stability through the atmosphere. About a minute later, four drag brakes will deploy from the ring fin and assist in cutting the speed of the booster in half. Four actuating fins on the aft end of the booster also assist in guiding the booster through the atmosphere. New Shepard Tail 4 landing during the NS-19 million, Dec. 11, 2021. (Credit: Blue Origin) Seven minutes into the flight, the Propulsion Module will begin its landing burn by relighting its BE-3PM engine. This is then followed by the deployment of four landing legs and a soft touchdown on the landing pad 3.2 kilometers north of the launch pad. Roughly a minute after the Propulsion Module touches down, the Crew Capsule will deploy its drogue chutes which help slow down the vehicle, and are then followed by the deployment of the three main parachutes at around one kilometer in altitude. The Crew Capsule will then gently descend under the main parachutes for about three minutes. Just before the capsule touches down in the designated primary landing area, it will fire a retro-thrust system which provides a cushion of air under the capsule to ensure a soft touchdown. Following the successful mission, Blue Origin will recover both the Propulsion Module and the Crew Capsule before returning the payloads to customers. (Lead image: New Shepard on the launch pad ahead of the NS-16 mission in July 2021. Credit: Blue Origin) The post Blue Origin’s New Shepard to return to flight appeared first on NASASpaceFlight.com.

0 notes

Text

L3Harris’ acquisition of Aerojet Rocketdyne nears completion

Aerojet Rocketdyne is the only company that produces both composite-case and steel-case solid rocket motors for the GMLRS. Credit: U.S. Army

WASHINGTON — L3Harris told investors July 26 that federal regulators will not challenge the company’s acquisition of Aerojet Rocketdyne, clearing the way for the deal to close as early as July 28.

“We were advised today that the Federal Trade Commission…

View On WordPress

0 notes

Link

[ad_1] Scientists are closer to identifying a large mystery object that has attracted worldwide attention after it appeared on a Western Australian beach. The Australian Space Agency has narrowed down on what the object is, determining that the object is “most likely a solid rocket motor casing”.The piece of space debris was found on Sunday by beachgoers near Green Head, about 250km north of Perth. This type of case would surround a solid-motor rocket and serves as both a propellant tanks and combustion chamber for the rocket. “We’re continuing the process of identifying the type of rocket and its origin through ongoing engagement with our global counterparts,” the agency said on social media. The 2m high metal cylinder was initially treated as hazardous by police as they and state and federal agencies raced to determine if it was a risk to the community.However, analysis by the Department of Fire and Emergency Service and Chemistry Centre of Western Australia determined that the object was safe and there was no risk to the community because of it.The ASA has urged anyone who finds further suspected debris to report it to local police and notify the agency.“The object could be from a foreign space launch vehicle and we are liaising with global counterparts who may be able to provide more information,” a spokesman said.WA Police have now removed the object and put it in storage but officers have been guarding it all week to ensure the safety of the public. This comes three weeks after another mysterious device was found floating offshore close to North Beach in Perth.According to The West Australian newspaper, Australian Defence Force personnel detonated the device that was later found to be a marker marine flare. [ad_2]

0 notes

Text

Why Are High-Temperature Resins Important?

High-temperature resins are thermosetting polymer substances frequently employed in adhesives, sealants, and composite resins for purposes that include exposure to high temperatures. They are mostly utilized in the aerospace sector in gaskets, adhesives, sealants, missile castings, and spacecraft.

Their many qualities, including strong impact resistance, adhesion, chemical resistance, radiation resistance, flexibility, etc., might be attributed to this. High-temperature resins may function in situations with extremely high temperatures, from 232°C to 427°C. They come in solid, liquid, solution, blended, and multipurpose forms.

High-temperature resins are employed in many applications, including jet engines, ducting, heat shields, heat safety systems, rocket motor nozzles, thrusters, and power plants. Moreover, those specifically related to the military include turbine brush seals, capacitors, integrated circuit housing, and high-temperature composite tooling.

The global high-temperature resin market will reach $5,031.7 million by 2030. The capacity of such materials to survive exceptionally high temperatures and extreme environmental conditions is principally responsible for the industry expansion.

The expanding aerospace and military industries worldwide are driving the need for high-temperature composite resins. These resins are used in a variety of aircraft components, including engines, stators, ducting, and heat shields.

Why Demand for High-Temperature Resin Is High

The demand for high-temperature composite resin is projected to rise as a result of the booming aviation sector and rising need for commercial aircraft, particularly in emerging countries, due to rising air traffic and cheap fuel prices.

High-temperature composite resins are being used more often in a variety of space usages, including rocket booster casings, payload doors and fairings for launching a rocket, as well as solar arrays and buss for commercial and military satellites.

The need for high-temperature composite resins is likely to increase due to the burgeoning aerospace and defense industries and the rising military spending by governments in countries like the US, Germany, China, and India.

Need for High-Temperature Resin Is Highest in APAC

Globally, APAC currently offers the most promising market outlook. Construction industry advancements have been consistent, and quick urbanization in fast-growing nations like China, India, and Japan are two significant drivers of this expansion.

Over the next few years, the Chinese government wants to relocate approximately a quarter of a billion local citizens to recently built cities and towns. The goal is for 850 million people, or more than 65% of the country's population, to reside in cities by 2025.

Due to the enormous need for hospitals, schools, office buildings, and residential complexes that would result from this, more paint and coatings will be applied, increasing the need for high-temperature resins.

1 note

·

View note

Text

Not an Egg, a Frog Statue

1 minute 30 seconds to read.

Saturday morning, 16 November 1974. (Reviewed Sunday morning, 28 August 2022.)

Not an Egg, a Frog Statue

Dream # 2,889-02.

I float upward to the nest of a flycatcher in the late evening. There is enough light to see vivid details. (This type of scenario was most common around this age as a post-hypnagogic stage 5 event, which usually involves the illusory perception of floating, as well as associations with birds and bird nests or other associations with flight, both in a natural and manufactured context, such as airplanes or rockets, though this intriguing narrative occurs in the "dream state proper.")

The bird seems aware of my presence but does not move much or fly away. I push my hand down into the deep nest. I am aware of my spontaneous and predictable integration into the somatosensory phasing response of this mode of dreaming. Summoning eggs is a common factor because of how a chicken egg fits into the palm of my hand. This event is ambiguous because a flycatcher's eggs are much smaller.

My right hand seems to reach an undefined space instead of the anticipated bottom of the nest. However, I eventually perceive solidity regarding what I mistakenly believe should be a chicken egg (instead of one from a small bird).

The vivid definition of the egg's surface over the palm of my right hand feels extraordinarily realistic, bringing me a deep sense of peace as this type of phasing response usually does.

When I pull the "egg" from the nest, it is not an egg but a small grayish-green "valuable" frog sculpture in the shape of an egg. I feel cheerful.

Frog statues specifically occur with myoclonic anticipation (not necessarily perceptually correct because of the lack of viable consciousness) during or after dream-based vestibular-motor phasing (though corresponding simultaneously with intuitive or lucid REM atonia awareness), but typically without sleep myoclonus in its outcome. That is, the frog statue signifies the probable lack of the myoclonic event in most cases despite occurring after vestibular-motor phasing (floating up to the bird's nest). In contrast, the sculpture of a standing or sitting man is simply REM atonia (without myoclonic anticipation) - as waking up does not necessarily coincide with myoclonus in every case.

0 notes

Link

The high-speed aircraft and missiles composite material market has seen major development by key players operating in the market, such as business expansion, contracts, mergers, partnerships, collaborations, and joint ventures. The favored strategy for the companies has been contracts to strengthen their position in the high-speed aircraft and missiles composite material market.

Get the FREE ToC of this Upcoming Report: https://bit.ly/3xzmOxx

#High-Speed Aircraft & Missiles Composite Material Market#High-Speed Aircraft Composite Material Market#High-Speed Missiles Composite Material Market#High-Speed Aircraft Market#High-Speed Missiles Market#Additive Manufacturing#Compression Molding#Automated Fiber Placement#Thermoplastic#Resin Types#Fiber Types#Carbon Fiber#Glass Fiber#Airframe#Radomes#Propulsion System#Solid rocket motor cases#Weapon System#Landing Gear System#Engine#Commercial#Defense#Defense Hypersonic and Supersonic Aircraft#Hypersonic and Supersonic Missiles#Commercial Hypersonic and Supersonic Aircraft

0 notes

Note

A point you made the other day about ballistic vs laser/plasma/pulse got me really thinking.

In all honesty, ballistic tech has really kinda reached its apex unless we move into CT ammo, caseless ammo or railguns.

I mean, obviously it holds its merits. But other-than solid munitions imo have one massive advantage. Sound or Recoil. There should be virtually none, theres no explosion, just energy.

Playing the devils advocate, I could see there being key, unique issues. Like laser not doing well against hard targets and vice versa with pulse/plasma.

That last bit is mostly me theorizing, but I'm sure you have some more grounded opinions.

Yeah, solid munitions have advantages in ease and cost of manufacture (particularly in a future scenario where 3D-printing, automated sintering/fabrication, or automatic forging/molding technologies are ubiquitous) and they're of all foreseeable options the best at penetrating rain, dust, and vegetation on a battlefield. Futuristic options are likely either going to be electrically/magnetically propelled, or possibly use caseless or polymer-cased ammunition; depends on the military in question's preference of more power demands vs. chemical processing demands. It'll retain a niche but not a universal monopoly.

Rocket-assisted munitions (I envision something like a gyrojet with a two-stage motor to alleviate the problems the historical gyrojet ran into) have advantages in very low recoil relative to energy-on-target, along with the capability delivering specialized payloads easily (largely AP, HE and incendiary). The complexity and cost/ time-to-fabricate of ammunition would largely consign them to smaller-scale uses ranging from SF to private security groups, despite the weapons themselves being theoretically quite cheap due to low stress on components and minimal moving parts required.

Energy weapons come in two main flavors; both predicated on the conceit that we'll solve the power storage demands enough to make them field-expedient:

Lasers (along with masers and other focused radiation/ directed energy weapons) are of course extremely accurate, with functionally nonexistent recoil and an effective range of the literal horizon. Downsides include high vulnerability to atmospheric conditions and debris refracting or attenuating the ray, along with a laser powerful enough that a pulse is effective on target also ionizing the atmosphere it passes through, pinpointing the shooter's location and posing a hazard to eyesight of the shooter themselves. Power demands are also extremely inefficient in comparison to effect on target; while this is alleviated by notional futuristic generators/field reactors, it's still a factor. Even so, lasers are logistically extremely friendly as they require power and no material save any replacement/maintenance components for the weapon itself. Armor poses a problem, but effect on a softer target would be extreme and grizzly, so how widespread these would be is largely dependent on how widespread ammo is

Plasma (specifically, magnetically self-contained plasmoid projectiles) is actually no longer a pure sci-fi concept, but the lab-tested ones thus far have a range measured in fractions of an inch. For the sake of discussion, we'll work under the conceit that this can and will be extended to combat-effective ranges. Even so, you're left with the problem that a plasma weapon would have a short effective range, with its effect on target inversely proportional to distance from the shooter, as it's hemorrhaging energy the entire time it's in flight--hemorrhaging so much energy, in fact, that the shooter likely requires protective gear to prevent permanent blindness and serious flash-burns, as even our notional improved magnetic containment tricks aren't likely to change the properties of plasma itself. That said, these weapons would have extreme effect on anything it hits, threatening even armored vehicles and fortified positions--and, unfortunately, virtually no effect on anything more than a few inches behind what it hits, as once the magnetic containment is broken, the plasma disperses rapidly. Armored infantry and armored vehicles are severely damaged, an unarmored infantryman who happened to have a stray branch 2 meters in front of him is all but untouched. So it would take careful planning and positioning, but the ability of what we'll assume to be an infantry carbine-sized repeating firearm to threaten armored vehicles and risk mobility kills on conventional tanks would still rattle the cages of both doctrine and tactical planning

14 notes

·

View notes

Photo

Although Henry Thomas Sampson has often been cited for the invention of the cell phone, he was more so involved in producing the core technology (Gamma-Electric Cell) which makes cell phones and other advanced wireless technologies possible. Jesse Eugene Russell builded upon Sampson’s ingenious invention to fully materialize the vision of modern mobile wireless devices. According to Purdue University, “On July 6, 1971, Sampson was awarded a patent with George H. Miley for the invention of the gamma-electric cell, a direct-conversion energy device that converts the energy generated from the radiation of high-energy gamma rays into electricity. Other patents include a binder system for rocket propellants and explosives and a case-bonding system for cast-composite rocket propellants, both related to the manufacturing and production of solid-propellant rocket motors.” Libertywritersafrica reports, “Jesse Eugene Russell created the concept for the wireless digital phone and communication, while he was working as an engineer at AT&T-Bell Laboratories in 1988. He developed the world’s first digital cellular base station and holds the patent to the digital services which many companies of the world use today. Before Russell invented the wireless mobile device, the mobile devices available were mainly used in cars or in other vehicles. This was mainly because the mobile devices needed the power to be able to transmit signals to a cell tower. And that point the power needed to drive a mobile phone was too much to fit into a wireless movable device. It was Russell’s ingenuity and creation of the mobile device that made it possible for mobile phones to be handy and affordable today. His innovation made it possible for mobile devices to transmit signals between the handsets we use today, and the cell phone towers.” Sources: Trudreadz, Libertywritersafrica, WonderWombman, Wikipedia, https://www.instagram.com/p/Ca5NTfBu_9W/?utm_medium=tumblr

14 notes

·

View notes

Video

youtube

I post this to honor the brave crew of Challenger - not to dis honor them

The Space Shuttle Challenger disaster was a fatal incident in the United States' space program that occurred on January 28, 1986, when the Space Shuttle Challenger (OV-099) broke apart 73 seconds into its flight, killing all seven crew members aboard. The crew consisted of five NASA astronauts, and two payload specialists. The mission carried the designation STS-51-L and was the tenth flight for the Challenger orbiter.

The spacecraft disintegrated over the Atlantic Ocean, off the coast of Cape Canaveral, Florida, at 11:39 a.m. EST (16:39 UTC). The disintegration of the vehicle began after a joint in its right solid rocket booster (SRB) failed at liftoff. The failure was caused by the failure of O-ring seals used in the joint that were not designed to handle the unusually cold conditions that existed at this launch. The seals' failure caused a breach in the SRB joint, allowing pressurized burning gas from within the solid rocket motor to reach the outside and impinge upon the adjacent SRB aft field joint attachment hardware and external fuel tank. This led to the separation of the right-hand SRB's aft field joint attachment and the structural failure of the external tank. Aerodynamic forces broke up the orbiter.

The crew compartment and many other vehicle fragments were eventually recovered from the ocean floor after a lengthy search and recovery operation. The exact timing of the death of the crew is unknown; several crew members are known to have survived the initial breakup of the spacecraft. The shuttle had no escape system, and the impact of the crew compartment at terminal velocity with the ocean surface was too violent to be survivable.

The disaster resulted in a 32-month hiatus in the Space Shuttle program and the formation of the Rogers Commission, a special commission appointed by United States President Ronald Reagan to investigate the accident. The Rogers Commission found that NASA's organizational culture and decision-making processes had been key contributing factors to the accident, with the agency violating its own safety rules. NASA managers had known since 1977 that contractor Morton-Thiokol's design of the SRBs contained a potentially catastrophic flaw in the O-rings, but they had failed to address this problem properly. NASA managers also disregarded warnings from engineers about the dangers of launching posed by the low temperatures of that morning, and failed to adequately report these technical concerns to their superiors.

Approximately 17 percent of the US population witnessed the launch on live television broadcast because of the presence of high school teacher Christa McAuliffe, who would have been the first teacher in space. Media coverage of the accident was extensive; one study reported that 85 percent of Americans surveyed had heard the news within an hour of the accident. The Challenger disaster has been used as a case study in many discussions of engineering safety and workplace ethics

7 notes

·

View notes

Photo

Final hot firing proves P120C booster for Ariane 6 The qualification model of the P120C motor configured for Ariane 6, has been static fired on the test stand at Europe’s Spaceport in French Guiana in a final test to prove its readiness for flight. Advanced features make this new motor a pivotal achievement of European industry. It is an example of innovative thinking and optimisation that allows Europe to equip two very different launch vehicles with the same solid rocket motor. Depending on the configuration, two or four P120C boosters will be strapped onto the sides of the future Ariane 6 heavy-lift rocket, the P120C will also serve as the first stage of the smaller Vega-C launch vehicle. This huge P120C motor was filled with 142 tonnes of solid propellant inside its 13.5 m long and 3.4 m diameter casing and was moved from the integration building to the dedicated stand used for testing solid propulsion stages. After ignition it burned for 130 seconds, delivering a maximum thrust of about 4500 kN simulating liftoff and the first phase of flight. No anomalies were seen and, according to initial recorded data, the performance met expectations. A full analysis of these test results and inspection of all components will confirm readiness of this motor for the debut launch of Ariane 6. “This firing of the P120C motor paves the way for its use on Ariane 6. It is proof of the hard work and dedication of all the teams involved who have made this test possible despite the COVID-19 crisis. This accomplishes an important milestone towards flight,” commented Stefano Bianchi, Head of Space Transportation Development at ESA. Avio in Italy built this motor case in one piece by winding carbon-fibre composite for a strong and rigid lightweight shell casing. ArianeGroup in France developed the advanced P120C nozzle, while Nammo in Norway provided the igniter. The propellant was cast by Regulus in French Guiana. Advanced manufacturing techniques have been incorporated by Europropulsion in horizontal robotic integration of the nozzle too. Efficient production methods have shortened production cycles and optimised costs. Europropulsion built three models of the P120C for testing: a development model (DM) configured for Vega-C; a first qualification model (QM1) also configured for Vega-C; and a second qualification model (QM2) configured for Ariane 6. This hot firing of QM2 is the third and final test of the P120C. It follows the test of the development model in July 2018 and the first qualification model in January 2019. The test stand was modified with some specific mechanical and avionics adaptations for the Ariane 6 configuration. This test aimed to observe increased performance characterised by a higher burning rate in a shorter combustion time than in the DM and QM1 motors. The environmental impacts of every P120C test are measured in a similar way to any launch. Air quality and water pollution are checked in real time around the test bench, in the cities of Kourou and Sinnamary, and at launch observation sites. The measurements are then analysed by the Institut Pasteur. All measurements on this test so far, indicate an extremely low impact on the ecosystem. This is also thanks to the strict meteorological constraints on wind speed at sea level and at certain altitudes, and the required absence of rain. Completion of this test is an important achievement and maintains the development schedule for Ariane 6 and Vega-C. The ‘Ground Qualification Review 2’ of all the data collected will finally confirm this motor is qualified for use on Ariane 6. Ariane 6 will extend Europe’s capabilities to independently access space and offer more opportunities for the commercial and institutional market worldwide while reducing costs. ESA, France’s CNES space agency, and Europropulsion which is jointly owned by Avio and ArianeGroup, collaborated on this test. TOP IMAGE....The second qualification model of the P120C solid rocket motor, configured for Ariane 6, completed its hot firing on 7 October 2020 in a final test to prove its readiness for flight. Depending on the configuration, two or four P120C motors, developed in Europe, will be strapped onto the sides of the future Ariane 6 launch vehicle as boosters for liftoff. The P120C will also be used as the first stage of Vega-C. After it was fully loaded with 142 tonnes of fuel, the 13.5 m long and 3.4 m diameter motor was ignited to simulate liftoff and the first phase of flight. The motor burned for 130 seconds and delivered a maximum thrust of about 4500 kN. The test was performed at Europe’s Spaceport in French Guiana, and was completed with no anomalies. ESA, France’s CNES space agency, and Europropulsion which is jointly owned by Avio and ArianeGroup, collaborated on this test. ESA/CNES/Arianespace/Optique vidéo du CSG - JM Guillon LOWER IMAGE....The second qualification model (QM2) of the solid rocket booster P120C configured for Ariane 6, was transferred from the booster integration building to the test stand to prepare for its hot firing at Europe’s Spaceport in Kourou, French Guiana. The P120C is 13.5 m long and 3.4 m in diameter, and contains 142 tonnes of solid propellant. Depending on the configuration, two or four P120C motors will be strapped onto the sides of the future Ariane 6 launch vehicle as boosters for liftoff, it will also be used as the first stage for Vega-C. ESA, France’s CNES space agency, and Europropulsion which is jointly owned by Avio and ArianeGroup, collaborated on this test. • ESA

4 notes

·

View notes

Text

Raytheon to challenge Lockheed Martin’s acquisition of Aerojet Rocketdyne

https://sciencespies.com/space/raytheon-to-challenge-lockheed-martins-acquisition-of-aerojet-rocketdyne/

Raytheon to challenge Lockheed Martin’s acquisition of Aerojet Rocketdyne

Raytheon CEO Gregory Hayes: “We obviously have some concerns.”

WASHINGTON — Raytheon Technologies plans to formally oppose Lockheed Martin’s proposed $4.4 billion acquisition of rocket engine manufacturer Aerojet Rocketdyne, Raytheon’s CEO Gregory Hayes said Feb. 17.

Aerojet Rocketdyne’s engines are used by both Raytheon and Lockheed Martin in tactical and strategic missiles the companies make for the U.S. Defense Department.

“We obviously have some concerns” about Aerojet being acquired by a competitor, Hayes said at the Barclays Industrial Select Conference.

“They are a huge supplier to us,” Hayes said of Aerojet. If Lockheed Martin is allowed to buy the company, “you don’t have an independent supplier on the solid rocket motor side. It gives us pause as we think about the competitive landscape going forward.”

Hayes said Raytheon will make its case to regulatory agencies, including the Federal Trade Commission and the Department of Defense. “We will see how this whole thing plays out,” he said.

Since Lockheed Martin’s Dec. 20 announcement of its intent to acquire Aerojet, analysts have anticipated a challenge from Raytheon on grounds that the acquisition would give Lockheed too much power over military missile programs. The consolidation of Aerojet under Lockheed Martin, for example, would put Raytheon in the position of having to buy about 70 percent of its missiles’ propulsion systems from its primary competitor.

Lockheed Martin’s chief financial officer Ken Possenriede said the company would “play fair” as an engine supplier to defense primes. “Aerojet Rocketdyne is going to be a more reliable supplier as part of Lockheed Martin than it would be as an independent supplier,” he said at the Barclay’s conference a few hours after Hayes’ remarks.

Lockheed Martin’s CEO Jim Taiclet said Dec. 21 he expects the regulatory review of the acquisition to follow the model of Northrop Grumman’s takeover of solid rocket motor supplier Orbital ATK. Regulators approved the deal in 2018 on condition that Northrop agreed to supply motors to its competitors.

Possenriede argued that vertically integrating Lockheed Martin’s missile manufacturing business with the propulsion supplier would improve the engineering process and reduce the fees that are charged to the government when products are bought from subcontractors.

Raytheon is expected to make the case to regulators that Northrop Grumman’s purchase of Orbital ATK should be viewed as a cautionary tale of what happens when competitors are removed from the marketplace.

Orbital ATK was the dominant supplier of solid rocket motors and acquiring the company helped Northrop Grumman gain an overwhelming advantage in the competition for the Air Force’s next-generation intercontinental ballistic missile. Because that advantage was hard to compete against, Boeing bowed out of the missile program and Northrop won by default.

The FTC required Northrop to make Orbital ATK motors available to competitors on a non-discriminatory basis.But Boeing pointed out that such agreements are hard to enforce.

Raytheon also contends that ownership of Aerojet would give Lockheed Martin a huge advantage in future DoD procurements of ballistic and hypersonic missiles.

Aerojet is the sole U.S. supplier of a key technology — the Divert and Attitude Control System — used in interceptor missiles acquired by the Missile Defense Agency to defend the United States against incoming intercontinental ballistic missiles. Both Raytheon and Lockheed Martin use DACS in missiles they make for the MDA.

On hypersonic missiles, whether it’s boost glide vehicles or air breathing missiles powered by ramjet engines, Aerojet would be the primary propulsion supplier.

Biden administration’s views still unknown

A big unknown is whether the Biden administration will view industry consolidation with a different lens than its predecessors.

Deputy Defense Secretary Kathleen Hicks would play a central role in reviewing industry mergers. During her confirmation hearing Feb. 2, she said “some consolidation is probably inevitable” because the defense market can only sustain a certain number of suppliers. “But extreme consolidation does create challenges for innovation,” Hicks said. “That’s our comparative advantage over authoritarian states like China and Russia … If we move all competition out, obviously that’s a challenge both for the taxpayer, but it’s also a challenge in terms of the innovation piece.”

The Pentagon in the past has maintained that the defense industry is made up of private companies and it prefers to not interfere with market forces except in cases of mergers between top prime contractors. Aerojet executives have made no secret that they want to be acquired by a large prime contractor like Lockheed Martin to bolster its financial stability. If the FTC sued to oppose the deal, analysts said, Lockheed Martin could walk away but sooner or later somebody would end up buying Aerojet.

Industry consultant Loren Thompson, who works with both Aerojet and Lockheed Martin, said Aerojet is a “fragile enterprise that won’t survive as a stand-alone player in the marketplace.” Aerojet would benefit from being part of a larger conglomerate because currently it is overly dependent on military and civil space programs that “can be derailed by an election outcome,” he said.

Thompson said blocking this merger would raise questions about why the FTC let Northrop Grumman acquire Orbital ATK and now suddenly decided that this transaction raises “too many competitive concerns.”

#Space

1 note

·

View note