#Safety Valve Manufacturer in Vadodara

Explore tagged Tumblr posts

Text

#Safety Valve Manufacturer in Mumbai#Safety Valve Manufacturer in Delhi#Safety Valve Manufacturer in Chennai#Safety Valve Manufacturer in Bangalore#Safety Valve Manufacturer in Ghaziabad#Safety Valve Manufacturer in Rajasthan#Safety Valve Manufacturer in Ahmedabad#Safety Valve Manufacturer in Vadodara#Safety Valve Manufacturer in Gujarat

1 note

·

View note

Text

Safety Valve Manufacturer in India Ensuring Industrial Safety

In the dynamic landscape of industrial manufacturing, safety remains a paramount concern. Industries spanning from oil and gas to pharmaceuticals rely heavily on high-quality safety mechanisms to protect their operations and workforce. Among the critical components ensuring operational safety are safety valves. Pedlock provides a safety valve manufacturer in Mumbai, Chennai, Ahmedabad, Gujarat, Vadodara, Rajasthan, Ghaziabad, Bangalore and Delhi in India that stands out as a trusted provider of these essential devices.

The Role of Safety Valve

Safety valves are critical components in various industrial systems. They are designed to automatically release pressure from boilers, pressure vessels, and other equipment when the pressure exceeds safe limits. This function prevents potential system failures, explosions, and catastrophic accidents, ensuring the safety of both personnel and equipment.

In industries such as chemical processing, oil and gas, power generation, and manufacturing, the reliability of safety valves can make the difference between smooth operation and disaster. Hence, choosing the right manufacturer is crucial.

Pedlock: A Trusted Name in Safety Valves Manufacturer in India

Pedlock Valves has carved a niche for itself as a leading safety valve manufacturer in Chennai, Ahmedabad, Mumbai, Vadodara, Gujarat, Delhi, Bangalore, Ghaziabad, Delhi, and Rajasthan in India. With years of expertise and a commitment to excellence, Pedlock offers a comprehensive range of safety valves that meet stringent international standards.

Commitment to Quality

At Pedlock, quality is not just a buzzword but a foundational principle. Each safety valve is meticulously engineered and rigorously tested to ensure it performs flawlessly under pressure. The company adheres to globally recognized standards such as ASME, API, and ISO, guaranteeing that every valve meets or exceeds industry benchmarks.

State of the Art Manufacturing Facilities

Pedlock’s manufacturing facilities are equipped with cutting-edge technology and modern machinery. The integration of advanced CNC machines, automated assembly lines, and precision testing equipment ensures that every safety valve produced is of the highest quality. These facilities are manned by a team of skilled engineers and technicians who bring years of experience to the table, ensuring that every product is crafted to perfection.

Diverse Product Range

Our company offers a diverse range of safety valves tailored to various industrial applications. Their product line includes:

Pressure Relief Valves: Designed to release excess pressure and protect systems from overpressure conditions.

Thermal Relief Valves: Ideal for applications where temperature-induced pressure changes are a concern.

Vacuum Relief Valves: Prevent vacuum conditions that could damage equipment or impede operations.

Each of these valves is available in various materials, sizes, and pressure ratings, ensuring that Pedlock can meet the unique needs of any industry.

Innovation and R&D

Innovation is at the heart of Pedlock’s operations. The company invests heavily in research and development to stay ahead of industry trends and technological advancements. This commitment to innovation enables Pedlock to continuously improve its product offerings, enhancing safety, reliability, and efficiency.

Global Reach with Local Expertise

While Pedlock is headquartered in India, its reach extends far beyond national borders. The company exports its high quality safety valves to various countries, catering to a global clientele. Despite its international presence, Pedlock remains deeply rooted in local expertise, understanding the unique challenges and requirements of the Indian market.

Sustainability and Compliance

Pedlock is committed to sustainable manufacturing practices. The company follows environmentally friendly processes and strives to minimize its carbon footprint. Additionally, Pedlock ensures compliance with all relevant environmental regulations, demonstrating its commitment to responsible manufacturing.

Conclusion

In an industry where safety cannot be compromised, Pedlock stands as a beacon of reliability and excellence. As a Safety valves manufacturer in Bangalore, Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Delhi, Rajasthan and Ghaziabad in India. We offer high quality, innovative solutions that ensure the safety and efficiency of industrial operations. With a commitment to quality, a customer centric approach, and a focus on innovation, Pedlock is poised to lead the safety valve manufacturing sector for years to come. Whether you are in the oil and gas, chemical, or power generation industry, Pedlock’s safety valves are your trusted partner in safeguarding your operations.

#Safety valve manufacturer in Mumbai#Safety valve manufacturer in Chennai#Safety valve manufacturer in Ahmedabad#Safety valve manufacturer in Bangalore#Safety valve manufacturer in Delhi#Safety valve manufacturer in Vadodara#Safety valve manufacturer in Gujarat#Safety valve manufacturer in Rajasthan#Safety valve manufacturer in Ghaziabad

0 notes

Text

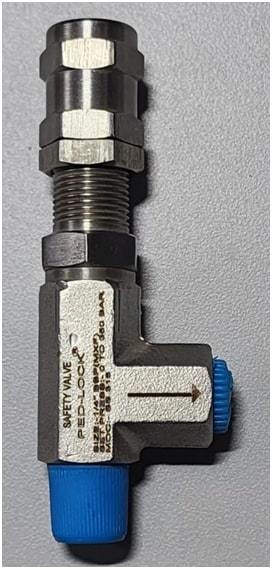

Safety valve manufacturer in India

Ped-lock In Pre-Calibrated Design the Safety Valves Manufacturer in Ahmedabad, Mumbai, Vadodara, Ghaziabad, Rajasthan, Chennai, Bengalore, Delhi, Gujarat in India. Safety Valves are calibrated as per your required set pressure. Even on continuous usage our Safety Valves opens up at the set pressure. Our high tensile spring specially fabricated ensures this. In Range Setting option we give you a lower limit and upper limit of Pressure. You can manually set at required range using the screw at the top.

Call Us: +91 99256 06950, +91 9727192468

Visit Website: https://pedlock.co.in/

#Safety Valves Manufacturer in Ahmedabad#Mumbai#Vadodara#Ghaziabad#Rajasthan#Chennai#Bengalore#Delhi#Gujarat

0 notes

Text

The Heart of Boiler Systems: Exploring the Role of IBR Fitting and Flanges

Boiler systems serve as the backbone of numerous industrial processes, powering everything from heating and hot water supply to steam generation in various manufacturing operations. Within these systems, ensuring safety, efficiency, and reliability is paramount, and this is where IBR (Indian Boiler Regulations) fitting and flanges play a pivotal role. As a trusted distributor in Vadodara and a leading dealer in Gujarat, Tubetrading is dedicated to providing top-quality IBR fitting and flanges to industries across the region. In this blog post, we'll delve into the significance of IBR fitting and flanges in boiler systems, explore their crucial functions, and highlight the expertise of Tubetrading in supplying these essential components.

Understanding IBR Fitting and Flanges

IBR fitting and flanges are integral components of boiler systems that ensure seamless operation and compliance with safety standards mandated by the Indian Boiler Regulations. These regulations are designed to safeguard the integrity of boiler components, prevent accidents, and promote efficient energy utilization. IBR fitting and flanges are manufactured according to stringent specifications outlined by the IBR to guarantee durability, reliability, and performance in demanding industrial environments.

The Role of IBR Fitting and Flanges in Boiler Systems

1. Pressure Regulation: IBR fitting and flanges are designed to withstand high-pressure environments commonly found in boiler systems. They play a crucial role in regulating and controlling the flow of fluids, gases, and steam within the system, ensuring optimal pressure levels for efficient operation.

2. Sealing and Joint Integrity: Proper sealing and joint integrity are essential to prevent leaks and maintain the integrity of boiler systems. IBR fitting and flanges are equipped with robust sealing mechanisms, such as gaskets and O-rings, to create a tight seal between interconnected components, minimizing the risk of leaks and ensuring system integrity.

3. Connection and Interoperability: IBR fitting and flanges serve as connection points between various components of boiler systems, including pipes, valves, and vessels. Their standardized dimensions and configurations enable seamless interoperability, facilitating efficient assembly, maintenance, and repair of boiler systems.

4. Compliance and Certification: Compliance with IBR regulations is mandatory for all boiler components used in India. IBR fitting and flanges undergo rigorous testing and certification processes to ensure compliance with safety standards and regulatory requirements, providing peace of mind to industries reliant on boiler systems.

Tubetrading: Your Trusted Supplier of IBR Fitting and Flanges in Gujarat

As a reputable distributor and dealer of IBR fitting and flanges in Vadodara and Gujarat, Tubetrading prides itself on delivering superior-quality products and exceptional service to its customers. Here's why industries trust Tubetrading for their IBR fitting and flanges needs:

1. Extensive Product Range: Tubetrading offers an extensive range of IBR fitting and flanges, including elbows, tees, reducers, bends, and flanges in various sizes, materials, and specifications. Whether you need standard or customized components, we have the expertise and resources to meet your requirements.

2. Quality Assurance: At Tubetrading, quality is our top priority. We partner with reputable manufacturers who adhere to strict quality control measures and comply with IBR regulations. Our products undergo thorough inspection and testing to ensure they meet the highest standards of performance, reliability, and safety.

3. Expert Guidance: With years of experience in the industry, the team at Tubetrading possesses in-depth knowledge of IBR fitting and flanges and their applications in boiler systems. We provide expert guidance and technical support to help our customers select the right components for their specific needs, ensuring optimal performance and efficiency.

4. Timely Delivery: We understand the importance of timely delivery to our customers' operations. With our efficient logistics network and inventory management systems, we strive to fulfill orders promptly and ensure on-time delivery of IBR fitting and flanges to our customers across Gujarat.

Conclusion

In conclusion, IBR fitting and flanges are the heart of boiler systems, playing a critical role in ensuring safety, efficiency, and compliance with regulatory standards. As a trusted distributor and dealer in Vadodara and Gujarat, Tubetrading is committed to supplying top-quality IBR fitting and flanges to industries across the region. With our extensive product range, quality assurance, expert guidance, and timely delivery, we are your reliable partner for all your IBR fitting and flanges needs. Contact Tubetrading today to learn more about our products and services and discover how we can support your boiler system requirements.

#IBR Fitting and Flanges distributor in Gujarat#IBR fitting and flanges distributor in Vadodara#IBR fitting and flanges dealer in Gujarat#IBR fitting and flanges#Gujarat#Maharashtra#Rajasthan#Madhya Pradesh#Daman#Uttar Pradesh

7 notes

·

View notes

Text

6000 Psi Pressure safety valves manufacturer in Rajasthan

Pedlock is Manufacturer, Exporter and Supplier of Pressure Safety Valves in Mumbai, Chennai, Ahmedabad, Vadodara, Gujarat, Rajasthan, Bengalore, Delhi and Ghaziabad in India. We provide high performance Safety Valves to our customers at affordable costs.

Safety Valves are calibrated as per your required set pressure. Even on continuous usage our Safety Valves opens up at the set pressure. Our high tensile spring specially fabricated ensures this. In Range Setting option we give you a lower limit and upper limit of Pressure. You can manually set at required range using the screw at the top.

#safety valve in Mumbai#safety valve manufacturer in Chennai#safety valve manufacturer ahmedabad#safety valve manufacturer in Gujarat#safety valve manufacturer in delhi

0 notes

Text

Supplier of Industrial Valve in Gujarat

Company Overview: Keshar Bhawani Metal & Tubes Pvt Ltd is a leading Manufacturer and Supplier of Industrial Valve in Gujarat, India. An industrial valve is a crucial component used in various industrial processes to control the flow of liquids, gases, or slurries. These valves play a pivotal role in regulating the direction, pressure, and volume of fluid flow within pipelines or systems. Industrial valves are designed to withstand high pressures, extreme temperatures, and corrosive environments, ensuring reliable performance and safety in industrial operations. Why Choose Our Industrial Valves? Precision Engineering: Engineered to exacting standards, ensuring reliability and longevity. Wide Range: Find valves for various industries including oil and gas, chemical processing, water treatment, and more. Custom Solutions: Tailored valves available to meet unique specifications and requirements. Quality Assurance: Rigorous testing procedures to guarantee performance and safety. Applications: Ideal for use in diverse industries, including: Oil and gas Chemical processing Water and wastewater treatment Power generation HVAC systems Food and beverage Manufacturing and industrial processes Keshar Bhawani Metal & Tubes Pvt Ltd is Supplier of Industrial Valve in Gujarat, India Including Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Gandhinagar, Junagadh, Gandhidham, Anand, Navsari, Morbi, Nadiad, Surendranagar, Bharuch, Mehsana, Bhuj, Porbandar, Palanpur, Valsad, Vapi, Rajkot, Veraval, Patan, Kalol, Botad, Amreli, Deesa, Jetpur. For detailed information and inquiries, please feel free to contact us. View Product: Click Here Read the full article

#Ahmedabad#Amreli#Anand#Bharuch#Bhavnagar#Bhuj#Botad#Deesa#Gandhidham#Gandhinagar#Gujarat#India#IndustrialValve#IndustrialValveinAhmedabad#IndustrialValveinGujarat#IndustrialValveinMumbai#Jamnagar#Jetpur#Junagadh#Kalol#Maharashtra#Manufacturer#Mehsana#Morbi#Nadiad#Navsari#Palanpur#Patan#Porbandar#Rajkot

0 notes

Text

#Safety Valves in Ahmedabad#Safety Valves in Mumbai#Safety Valves in Chennai#Safety Valves in Delhi#Safety Valves in Gujarat#Safety Valves in Vadodara#Safety Valves in Rajasthan#Safety Valves in Ghaziabad#Safety Valves in Bangalore

0 notes

Text

The Most Important Guide to Picking the Best Flanges Manufacturer

Trimac Piping Solutions is a prominent Flanges Manufacturers in India.

We offer our customers reliable, cost-effective, and high-quality superior Mild Steel Flanges Supplier products according to international specification ASTM and dimensional specification ANSI/ASME. Trimac Piping Solutions ASTM Flange Manufacturer are premiere value solution for all of your flanges & forged flanges needs. We are one of the premier Quality Carbon Steel Flange Manufacturer in India. Trimac Piping Solutions has been a trusted vendor as a Steel Flanges distributor & dealer in your country. To know more - Flange Weight chart and dimensions, Flanges Weight Chart in kg, mm, PDF.

Cities Where We Supply our Flanges Manufacturer

Flanges Manufacturer In Mumbai

Flanges Manufacturer In Pune

Flanges Manufacturer In Ahmedabad

Flanges Manufacturer In Vadodara

Flanges Manufacturer In Rajkot

Flanges Manufacturer In Delhi

Flanges Manufacturer In Raipur

Flanges Manufacturer In Coimbatore

Flanges Manufacturer In Kanpur

Flanges Manufacturer In Nashik

These are Some Best Types of Flanges

Flanges are essential components in various industrial and mechanical systems. They play a crucial role in connecting pipes, valves, and other equipment while providing structural support and sealing.

Weld Neck Flanges: One of the most popular forms, weld neck flanges are renowned for their high-strength construction. They are welded to the pipe and feature a long, tapered neck that offers great structural support and stress distribution. In high-pressure and high-temperature applications, such as the oil and gas industry, the flange's circular shape and smooth transition from the neck to the pipe aid decrease turbulence and erosion.

Slip-On Flanges: In low-pressure applications, slip-on flanges are frequently utilized because they are simple to install. They are made to slide over the end of the pipe and have a diameter that is just a little bit larger. After being put in position, they are kept in place by welding the perimeter. These flanges are affordable and appropriate for systems that do not need significant structural integrity.

Blind Flanges: When repair or inspection are necessary, blind flanges are utilized to close off the end of a pipe system. They are solid discs without a bore, usually fastened in place by bolts. When working on pipelines or boats, blind flanges are crucial for stopping leaks and guaranteeing worker safety.

Threaded Flanges: The internal bore of threaded flanges has threads, enabling them to be screwed into pipes having complementary external threads. In low-pressure and low-temperature applications, they are frequently utilized. For systems that need routine maintenance, threaded flanges offer a secure connection and are simple to install and disassemble.

Socket Weld Flanges: A socket or recess on socket weld flanges fits over the pipe's end. They form a solid and dependable connection since they are welded to the socket's outer edge. These flanges are perfect for use in applications involving high pressure and temperature because the socket weld joint increases structural stability.

We have Many Types of Flanges Like, Companion Flanges, Studding Outlet Flanges, ANSI B16.47 Series A Flanges, ANSI B16.47 Series B Flanges & Mild Steel Plate Flange.

The Key Factors to Consider When Choosing the Right Flanges Manufacturer

Quality Assurance and Certification: The commitment to quality and adherence to industry standards is the most important factor to take into account when choosing a flange manufacturer. Make that the manufacturer has the appropriate certifications to create flanges that adhere to international standards like ASME, ANSI, API, or ISO. Find certifications that attest to a dedication to quality management systems, such as ISO 9001:2015.

Material Selection: Carbon steel flanges, stainless steel flanges, and other materials are used to make flanges. The material you choose will depend on your application's particular needs, including temperature, pressure, and the kind of fluid or gas being conveyed. A dependable manufacturer has to offer a variety of material choices and be able to offer knowledgeable advice on material choice.

Product Range: Flanges of various varieties, including welding neck, slip-on, socket weld, and blind flanges, are needed for various tasks. To satisfy your unique requirements, confirm that the manufacturer offers a wide variety of flange types, sizes, and pressure classes. Another benefit is the ability to customize flanges to meet your specific needs.

Production Capacity: Analyze the lead times and production capacity of the firm. Take into account elements like the number of flanges you require and the project's urgency. Working with a manufacturer who can meet your manufacturing requirements and deliver on time is crucial.

Customer Reviews and References: Examine the reputation of the manufacturer by reading customer feedback. Additionally, to learn more about prior clients' opinions of the manufacturer's goods and services, get references and chat with them directly.

Conclusion

The success and safety of your projects might be affected by your choice of flange dimensions, which is a crucial decision. You can make an informed decision that protects the dependability and lifespan of your plumbing systems by carefully weighing criteria like quality, material selection, technological prowess, and customer service. When picking flanges, keep in mind that reliability and quality should always take precedence above price because the long-term effects of selecting inferior products can be expensive and dangerous.

0 notes

Text

Bronze Gate Valves, Bronze Globe Valves, Bronze Steam Valves, Manufacturer, India

Bronze Gate Valves, Bronze Globe Valves, Bronze Steam Valves, Cast Iron Steam Valves, Cast Steel Globe Valves, Cast Steel Blow Down Valves, Bronze Gauge Glass Valves, Manufacturer, Exporter, Supplier, India.

Bronze Gate Valve, Bronze Gate Valves, Bronze Globe Valve, Bronze Globe Valves, Bronze Steam Valve, Bronze Steam Valves, Cast Iron Steam Valve, Cast Iron Steam Valves, Cast Steel Globe Valve, Cast Steel Globe Valves, Cast Steel Blow Down Valve, Cast Steel Blow Down Valves, Bronze Gauge Glass Valve, Bronze Gauge Glass Valves, Protector Glass Assembly, Level Indicator, Level Indicators, Bronze Fusible Plug, Bronze Fusible Plugs, Boiler Casting, Boiler Castings, Ferrous Casting, Ferrous Castings, Non-Ferrous Casting, Non-Ferrous Castings, Manufacturers of Valves, Valves, Industrial Valve, Industrial Valves, Gate Valve, Gate Valves, Globe Valve, Globe Valves, Check Valve, Check Valves, Blow Down Valve, Blow Down Valves, Gauge Glass Valve, Gauge Glass Valves, Casting Part, Casting Parts, Graded Cast Iron Casting, Graded Cast Iron Castings, S.G Iron Casting, S.G Iron Castings, Alloy Steel Casting, Alloy Steel Castings, Stainless Steel Casting, Stainless Steel Castings, Non Ferrous Casting, Non Ferrous Castings, Steam Valve, Steam Valves, Cast Steel Valve, Cast Steel Valves, Cast Iron Casting, Cast Iron Castings, Gun Metal Casting, Gun Metal Castings, Aluminum Casting, Aluminum Castings, Traveling Grate Casting, Traveling Grate Castings, Dumping Grate Casting, Dumping Grate Castings, Pulsating Grate Casting, Pulsating Grate Castings, Boiler Mounting, Boiler Mountings, Rising Spindle Bronze Gate Valve, Rising Spindle Bronze Gate Valves, Non Rising Spindle Bronze Gate Valve, Non Rising Spindle Bronze Gate Valves, Screwed End Bronze Gate Valve, Screwed End Bronze Gate Valves, Flanged End Bronze Gate Valve, Flanged End Bronze Gate Valves, Screwed End Valve, Screwed End Valves, Flanged End Valve, Flanged End Valves, Gate Valve Non Rising Spindle, Gate Valves Non Rising Spindle, Gate Valve Rising Spindle, Gate Valves Rising Spindle, Rising Spindle Gate Valve, Rising Spindle Gate Valves, Non Rising Spindle Gate Valve, Non Rising Spindle Gate Valves, Fusible Plug, Fusible Plugs, Glass Tube Assembly, Protector Glass Assembly, Stop Valve, Stop Valves, Check Valve, Check Valves, Globe Stop Valve, Globe Stop Valves, Globe Check Valve, Globe Check Valves, Bronze Relief Safety Valve, Bronze Relief Safety Valves, Relief Safety Valve, Relief Safety Valves, Cast Iron Stop Valve, Cast Iron Stop Valves, Cast Iron Check Valve, Cast Iron Check Valves, Manufacturer, Exporter, Supplier, Ahmednagar, Maharashtra, Gujarat, Ahmedabad, Surat, Vadodara, Rajkot, Bhavnagar, Jamnagar, Junagadh, Kutch, Kheda, Gandhinagar, Anand, Morbi, Surendranagar, Bharuch, Valsad, Navsari, Gir Somnath, Porbandar, Panchmahal, Kutch, Bharuch, Botad, Palanpur, Patan, Dahod, Rajkot, Valsad, Gandhinagar, Rajkot, Amreli, Mehsana, Tamil Nadu, Chennai, Kanchipuram, Tiruvallur, Coimbatore, Madurai, Tiruchirappalli, Tiruppur, Salem, Erode, Tirunelveli, Vellore, Thoothukkudi, Thanjavur, Dindigul, Andhra Pradesh, Anantapur, Chittoor, East Godavari, Guntur, Kadapa, Krishna, Kurnool, Nellore, Prakasam, Srikakulam, Visakhapatnam, Vizianagaram, West Godavari, West Bengal, Alipurduar, Bankura, Bardhaman, Cooch Behar, Dakshin Dinajpur, Darjeeling, Hooghly, Howrah, Jalpaiguri, Kolkata, Malda, Murshidabad, Nadia, Paschim Medinipur, Purba Medinipur, Purulia, Uttar Dinajpur, India

0 notes

Text

Supplier of Industrial Valves in India

Supplier of Industrial Valves in India: Why Choose Meghmani Metal Leading supplier Meghmani Metal. Our clients receive the best metal products and exceptional service as we dedicate ourselves to delivering excellence. Our team of professionals, with a collective expertise of more than 10 years, is committed to providing the best solutions for your metal requirements. We at Meghmani Metal recognize the value of dependability and quality. Our knowledgeable team of professionals is committed to giving our customers the best metal products, prompt delivery, and affordable costs. A wide number of customization options are also available from us, allowing you to acquire exactly what you require for your project. The caliber of our goods and services reflects our dedication to excellence. Valves are incredibly important in the huge world of industrial processes because they regulate the flow of different materials like liquids, gases, and slurries. Industrial valves are crucial parts in many industries, from the oil and gas industry to manufacturing, water treatment, and power generation. This page seeks to offer a thorough overview of industrial valves, covering their kinds, uses, and importance across several industries. USES & APPLICATIONS : Oil & Gas Industries Chemical Industries Automotive Industries Fertilizer Industries Petrochemical Industries Power Industries Mechanical and Structural Industries Refinery Industries Here are some of the benefits of using industrial valves: Improved safety: Industrial valves can aid in the prevention of spills and leaks, enhancing worker safety. Increased efficiency: By controlling the flow of fluids, industrial valves can contribute to increasing the effectiveness of industrial processes. Reduced costs: In order to save money on cleanup and repairs, industrial valves can help to lower costs by preventing leaks and spills. We Provide Supplier of Industrial Valves in India Including Ankleshwar, Surat, Vadodara, Rajkot, Gandhinagar, Bhavnagar, Patan, Porbandar, Kutch, Dahod, Baruch, Amreli, Navsari, Kheda, Panchmahal, Sabarkantha, Surendranagar, Mehsana, Morbi, Gir Somnath, Palanpur, Chennai, Amritsar, Pune, Mumbai, Delhi, Faridabad, Udaipur, Nagpur, Agra, Haridwar, Dehradun, Rishikesh, Kanpur, Lucknow, Bangalore, Jaipur, Peenya Etc. Please get in touch with us. Read the full article

0 notes

Text

How to Choose the SS Check Valve Manufacturer in India for Your Industry

In the industrial world, choosing the right components is crucial for ensuring efficiency and safety. One such critical component is the SS check valve. As a leading SS check valve and check valve manufacturer in Mumbai, Ahmedabad, Delhi, Chennai, Rajasthan, Ghaziabad, Vadodara, Gujarat, and Bangalore India Padlock provides superior products designed to meet the stringent demands of various industries.

Why Choose Padlock for SS Check Valves?

Pedlock stands out as a top SS check valve manufacturer due to its commitment to quality, innovation, and customer satisfaction. Our check valves are made from high-grade stainless steel, ensuring durability, corrosion resistance, and reliable performance in harsh environments. Whether you’re in the oil and gas sector, chemical processing, or water treatment, our valves are designed to perform under the most demanding conditions.

Understanding SS Check Valves

SS check valves are essential in preventing backflow in piping systems. These valves allow fluid to flow in one direction while automatically preventing reverse flow, thereby protecting equipment from damage and maintaining process integrity. At Pedlock, we offer a variety of SS check valves, each designed to cater to specific industrial needs.

Types of SS Check Valves

Check Valves: Ideal for pipelines with low flow velocities, these valves have a disc that swings open to allow flow and swings back to block reverse flow.

Safety Valves: These are used in systems where the flow is typically unidirectional, and the flow force lifts the disc to allow passage. When the flow stops, the disc drops to prevent backflow.

SS Ball Valves: Suitable for systems where low-pressure drop and minimal backflow are crucial. The ball inside the valve moves to block or allow flow depending on the pressure differential.

Advantages of Using SS Check Valves

Corrosion Resistance: Made from high-quality stainless steel, our valves are highly resistant to corrosion, making them suitable for use in corrosive environments.

Durability: Our check valves are designed to withstand extreme temperatures and pressures, ensuring long service life and reduced maintenance costs.

Leak-Proof Design: Precision engineering ensures that our valves offer a leak-proof solution, critical for maintaining system integrity.

Customizable Solutions: Pedlock provides customized SS check valves to meet specific client requirements, ensuring optimal performance in your application.

Conclusion

When it comes to choosing an SS check valve and check valve manufacturer in Mumbai, Ahmedabad, Delhi, Chennai, Rajasthan, Ghaziabad, Vadodara, Gujarat, and Bangalore India. Pedlock is the name you can trust. Our commitment to quality, extensive product range, and customer-focused approach make us the ideal partner for all your valve needs. Contact us today to learn more about our products and how we can help you achieve your operational goals.

#SS Check valve manufacturer in mumbai#SS Check valve manufacturers in Delhi#SS Check valve manufacturers in chennai#ss check valves manufacturers in bangalore#SS Check valve manufacturers in Rajasthan#SS Check valve manufacturers in ghaziabad#ss check valves manufacturer in gujarat#SS Check valve manufacturers in Vadodara#ss check valves manufacturer ahmedabad

0 notes

Text

#Pressure Safety Valves Manufacturer in Mumbai#Pressure Safety Valves Manufacturer in Chennai#Pressure Safety Valves Manufacturer in Gujarat#Pressure Safety Valves Manufacturer in Vadodara#Pressure Safety Valves Manufacturer in Ahmedabad#Pressure Safety Valves Manufacturer in Bengalore#Pressure Safety Valves Manufacturer in Rajasthan#Pressure Safety Valves Manufacturer in Ghaziabad#Pressure Safety Valves Manufacturer in Delhi

0 notes

Text

Choosing the Best SS Check Valve Manufacturer in India

In the complex world of industrial machinery and systems, the role of small components often goes unnoticed. Yet, these components are the unsung heroes ensuring everything runs smoothly. One such crucial component is the SS check valve. Whether it’s in the oil and gas industry, water treatment plants, or even household plumbing, SS check valves are indispensable. Today, we spotlight Pedlock, a leading SS check valve manufacturer in Ahmedabad, Mumbai, Vadodara, Gujarat, Chennai, Bangalore, Ghaziabad, Rajasthan, Delhi India, and explore why they should be your go to choice for these vital components.

What is an SS Check Valve?

An SS check valve, or stainless steel check valve, is a type of valve that allows fluid to flow in one direction only. Its primary function is to prevent backflow, which can cause system failures or contamination. There are several types of SS check valves, including swing check valves, lift check valves, and dual plate check valves, each designed for specific applications and operational conditions.

Applications of SS Check Valves

SS check valves are used across various industries due to their robustness and reliability:

Industrial Uses

In industries like oil and gas, chemicals, and pharmaceuticals, SS check valves are essential for controlling the flow of liquids and gases, ensuring safety, and maintaining system integrity.

Household Uses

In residential plumbing systems, these valves prevent backflow into the water supply, protecting against contamination and maintaining water pressure.

Medical and Scientific Uses

In laboratories and medical facilities, SS check valves are used in equipment that requires precise control of fluid flow, such as in dialysis machines and analytical instruments.

Why Choose SS Check Valves?

Durability and Longevity

Stainless steel is renowned for its strength and durability making SS check valves a long-lasting choice for any application.

Corrosion Resistance

SS check valves manufacturer in Mumbai, Ahmedabad, Chennai, Vadodara, Gujarat, Bangalore, Rajasthan, Delhi, Ghaziabad India that resist corrosion, even in harsh environments, ensuring reliability and reducing maintenance costs over time.

Cost-effectiveness

While SS check valves might have a higher upfront cost compared to other materials, their longevity and low maintenance requirements make them a cost-effective solution in the long run.

Overview of Pedlock

Company History

Our company has been at the forefront of manufacturing high-quality SS check valves in India for over two decades. Founded on principles of innovation and excellence, the company has grown to become a trusted name in the industry.

Mission and Values

We are committed to delivering products that meet the highest standards of quality and reliability. Their mission is to continuously innovate and improve, ensuring customer satisfaction.

Product Range

Our company’s offers a wide range of SS check valves, including swing check valves, lift check valves, and dual plate check valves, catering to various industrial needs.

Why Pedlock Stands Out

Quality Assurance

Our company’s employs stringent quality control measures to ensure that every valve meets industry standards. Their dedication to quality has earned them numerous certifications.

Technological Advancements

By investing in cutting-edge technology, Pedlock ensures their manufacturing processes are efficient and their products are of the highest quality.

Customer Service Excellence

We pride itself on its customer centric approach, providing exceptional support and service to ensure client satisfaction.

Pedlock's Manufacturing Process

Raw Material Selection

Our company uses only the highest quality stainless steel, sourced from reputable suppliers, ensuring the durability and performance of their valves.

Precision Engineering

Advanced machinery and skilled technicians work together to create valves with precise specifications and high-performance capabilities.

Quality Control Measures

Each valve undergoes rigorous testing to ensure it can withstand the demanding conditions of industrial applications.

Certifications and Standards

Our company holds numerous national and international certifications, demonstrating their commitment to quality and compliance with industry standards. These certifications include ISO 9001, API, and CE, among others.

Comparing Pedlock with Other Manufacturers

Price Comparison

While our company’s prices are competitive, the value provided through their quality and service often surpasses that of other manufacturers.

Quality Comparison

Our company’s strict adherence to quality standards and continuous improvement efforts ensure their valves are among the best in the market.

Service Comparison

Our company’s customer service is highly responsive and supportive, ensuring a positive experience from inquiry to after-sales support.

How to Select the Right SS Check Valve

Factors to Consider

Consider the specific application, operating conditions, and material compatibility when selecting an SS check valve.

Tips for Choosing the Best Valve for Your Needs

Consult with experts, consider long-term costs, and ensure the valve meets all necessary certifications and standards.

Maintenance and Care for SS Check Valves

Cleaning and Inspection Tips

Regular cleaning and inspection are crucial to maintaining the functionality and longevity of SS check valves.

Common Issues and Troubleshooting

Understanding common issues, such as leakage or wear, can help in timely troubleshooting and repair.

Future Trends in SS Check Valve Manufacturing

Innovations in Material Science

Advancements in material science are leading to the development of even more durable and efficient SS check valves.

Technological Advancements

Technological innovations, such as automation and smart valves, are shaping the future of valve manufacturing.

Conclusion

Choosing the right SS check valve manufacturer in Chennai, Ahmedabad, Mumbai, Bangalore, Delhi, Vadodara, Rajasthan, Ghaziabad, Gujarat India, it is crucial for the efficiency and safety of your system. With us, you are assured of top-quality products, innovative solutions, and exceptional customer service. Whether for industrial use, residential plumbing, or medical equipment, Pedlock's SS check valves are designed to meet your needs and exceed your expectations.

#SS check valve manufacturer in Ahmedabad#Mumbai#Vadodara#Gujarat#Chennai#Bangalore#Ghaziabad#Rajasthan#Delhi India

0 notes

Text

Achieving Optimal Performance with High-Quality IBR Fitting and Flanges What You Need to Know

In the complex world of industrial operations, achieving optimal performance is paramount. When it comes to steam and power generation systems, the choice of components plays a crucial role. IBR (Indian Boiler Regulations) Fittings and Flanges are integral parts of these systems, ensuring efficiency and safety. As a leading IBR Fitting and Flanges distributor in Vadodara and a trusted IBR Fitting and Flanges dealer in Gujarat, Tube Trading Co. recognizes the importance of these components. In this blog post, we will delve into the key aspects of IBR fittings and flanges, shedding light on how the right choice can contribute to achieving peak performance in industrial settings.

Understanding IBR Fittings and Flanges

What is IBR?

The Indian Boiler Regulations (IBR) are a set of regulations governing the design, fabrication, and inspection of boilers and related components in India. IBR compliance is mandatory for manufacturers and users of boilers and associated equipment to ensure safety and quality standards.

IBR Fittings

IBR fittings are components designed to connect and control the flow of fluids within a steam or power generation system. These fittings must adhere to IBR standards to guarantee their reliability and safety in high-pressure environments. Examples of IBR fittings include bends, elbows, tees, reducers, and valves.

IBR Flanges

Flanges are essential components that connect pipes, valves, and other equipment in a steam or power system. IBR flanges, compliant with IBR regulations, are designed to withstand high pressure and temperature conditions. They provide a secure and leak-proof connection between different sections of a piping system.

Importance of High-Quality IBR Fittings and Flanges

Safety Compliance

In industries where steam and power generation are critical processes, safety is non-negotiable. IBR regulations are in place to ensure that the components used in these systems meet stringent safety standards. Choosing high-quality IBR fittings and flanges from a reputable distributor in Gujarat is essential for compliance and to mitigate the risk of accidents.

Reliability and Durability

The harsh conditions of industrial operations demand components that can withstand high temperatures, pressures, and corrosive environments. High-quality IBR fittings and flanges are constructed from materials that offer exceptional durability, ensuring a longer lifespan and minimal downtime for maintenance.

Efficient Performance

The efficiency of a steam or power generation system depends on the seamless operation of its components. Inferior fittings and flanges can lead to inefficiencies, including leaks and pressure drops, resulting in decreased system performance. By choosing top-notch IBR fittings and flanges from a reliable distributor in Vadodara, industrial operators can optimize the performance of their systems.

Applications of IBR Fittings and Flanges

Power Plants

In power plants, where steam is a primary component in electricity generation, IBR fittings and flanges are extensively used. These components help regulate the flow of steam and ensure the integrity of the entire system.

Chemical and Petrochemical Industries

Industries dealing with chemicals and petrochemicals operate in demanding environments. IBR fittings and flanges play a crucial role in maintaining the integrity of piping systems that transport hazardous substances.

Refineries

Refineries, involved in processing crude oil into various products, rely on high-pressure steam for many processes. IBR fittings and flanges are vital in ensuring the safe and efficient operation of these steam systems.

Textile and Food Processing Units

In textile and food processing, where steam is used for various purposes, IBR fittings and flanges are employed to guarantee the reliability and safety of steam transport.

Choosing the Right IBR Fitting and Flanges Distributor

Selecting the right distributor is as crucial as choosing the right components for your industrial applications. As a reputable IBR Fitting and Flanges distributor in Vadodara, Tube Trading Co. stands out for several reasons:

Extensive Product Range

We offer an extensive range of IBR fittings and flanges, catering to diverse industrial needs. Our products are sourced from trusted manufacturers, ensuring quality and reliability.

Compliance with Standards

All our IBR fittings and flanges comply with Indian Boiler Regulations and other relevant industry standards. We prioritize safety and performance in every product we offer.

Technical Expertise

Our team of experts possesses in-depth technical knowledge about IBR fittings and flanges. We provide valuable insights and guidance to help our clients make informed decisions.

Timely Delivery

At Tube Trading Co., we understand the importance of timely delivery in industrial settings. We ensure that our clients receive their orders promptly, minimizing downtime and disruptions.

Conclusion

In the intricate tapestry of industrial operations, the choice of IBR fittings and flanges can significantly impact the efficiency, safety, and reliability of steam and power systems. Tube Trading Co., as a trusted IBR Fitting and Flanges distributor in Vadodara and a reputable IBR Fitting and Flanges dealer in Gujarat, takes pride in being a reliable partner for industries across the region. Our commitment to quality, safety, and customer satisfaction sets us apart in the competitive landscape.

If you are in search of high-quality IBR fittings and flanges to enhance the performance of your industrial processes, look no further than Tube Trading Co. Contact us today for all your IBR fitting and flange requirements, and let us contribute to the success and efficiency of your operations.

#IBR Fitting and Flanges distributor in Gujarat#IBR Fitting and Flanges distributor in Vadodara#IBR Fitting and Flanges dealer in Gujarat#Steel Companies#Steel Industry#Construction Material#Stainless Steel#business#India#Gujarat#Vadodara

6 notes

·

View notes

Text

Leading Hydraulic Ball Valve Manufacturers in India – Pedlock.co.in

Pressure Testing: To check for leaks and ensure the valve can handle the system’s pressure requirements.

Corrosion Resistance Testing: Especially for valves used in harsh environments like offshore drilling or chemical plants.

Sustainability and Environmental Initiatives in Indian Manufacturing

Many Indian manufacturers are adopting green manufacturing practices, focusing on reducing emissions, using sustainable materials, and minimizing waste. This not only reduces their carbon footprint but also enhances their appeal to environmentally-conscious businesses.

Conclusion

Hydraulic ball valves are an essential component in various industries, and choosing the right manufacturer is crucial to ensuring efficiency, safety, and longevity. With India's manufacturing sector on the rise, the country is becoming a global hub for high-quality, cost-effective hydraulic Ball Valves manufacturer in Ahmedabad, Vadodara, Mumbai, Delhi, Chennai, Bangalore, Ghaziabad, Rajasthan, Gujarat India. Whether you are looking for standard valves or customized solutions, partnering with an Indian manufacturer is a smart, future-focused decision.

#Hydraulic Ball valves manufacturer in mumbai#Hydraulic Ball valves manufacturer in Delhi#Hydraulic Ball valve manufacturer in Chennai#Hydraulic Ball valves manufacturer in Bangalore#Hydraulic Ball valve manufacturer in Rajasthan#Hydraulic Ball valves manufacturer in ghaziabad#Hydraulic Ball valve manufacturer in Gujarat#Hydraulic Ball valves manufacturer in Vadodara#Hydraulic Ball valves manufacturer in Ahmedabad

0 notes

Text

How Many Stages of Pressure Testing are there?

Pressure safety valve testing: Pressure vessels are basically containers which hold gases or liquids at a certain pressure which is different from the outside pressure. Then, these vessels can be commonly found at industrial facilities across the globe. Furthermore, some of the common applications of pressure vessels are engine cylinders, steam boilers, storing chemicals, petroleum products, etc. However, these are just a few examples as pressure vessels have infinite utility!

Though pressure vessels have great utility and will enjoy popularity in the long run as well, they have some challenges as well. The difference between the pressure inside the vessel and outside the vessel creates a hazardous situation. Pressure vessels are known for being dangerous and causing fatal accidents. Therefore, there are specific standards for manufacturing the pressure vessels. These standards mention the need for pressure vessel testing and also have guidelines for inspection process of the pressure vessels. Our company has the best NABL accredited lab in Vadodara for the same.

What is Pressure Safety Valve Testing?

Pressure vessel inspection consists of tests which verify the integrity of the new vessel. Pressure safety valve testing can also be performed on a previously installed vessel which has been repaired. Earlier, many vessels were over-pressurized and there was a risk of explosion. As a result, many specifications were introduced for governing the way of manufacturing and maintaining pressure vessels.

Some industries have their own stringent standards for governing pressure vessels. Manufacturers need to consider the applicable standards while designing and creating pressure vessels. However, there must be a way of confirming that every pressure vessel is safe. It is here that pressure vessel inspection comes into the picture. There are different types of tests for ensuring that the vessel is safe and ready to use.

Methods of Pressure Safety Valve Testing

Visual Test

This type of testing offers a general overview of the condition of the vehicle. It is important to make sure that the surface of the vessel is well-lit and clean. The vessel is tested for any erosion, cracks, corrosion, hydrogen blistering, etc. Visual inspection can bring to light some issues but detailed inspection is required to consider a vessel fit for application.

Liquid Penetrant Test

The test looks for flaws in the pressure vessel which are open to the surface. The inspector will flow a thin liquid called penetrant into the flaw. Usually, the penetrant is sprayed and left for some time to soak. They might add a fluorescent chemical to the penetrant so that it becomes visible under UV light.

Once the penetrant dries up, the inspector will wipe off the surface and use a developer for drawing out the penetrant which has seeped in through the cracks. When the penetrant come out of the surface, it reflects the severity of the flaw. It is a commonly used testing method for welded seams. However, it can also be used for plates, pipes, bars, etc.

Read the full blog: https://trivediassociates.co.in/how-many-stages-of-pressure-testing-are-there/

#safetyandalliedservices#complianceservicesingujarat#beststatutoryandcompliancecompany#complianceservices#safetytraining#bestcomplianceservices#complianceservicesinvadodara#bestcomplianceservicesingujarat#gujaratfactoryact#skilltradevalidation

0 notes