#Construction Material

Explore tagged Tumblr posts

Text

Due to concerns over children consuming pieces of drywall containing potentially toxic products, all modern drywall recipes are non toxic and in theory edible.

30 notes

·

View notes

Text

10 (More) Random Entries from the Dictionary of Islamic Architecture

The following entries were pulled from the Dictionary of Islamic Architecture (1995).

Iznik tilework (architectural facet)

Fatimids (people)

Gujarat (region)

Susa (city)

Yasavi (shrine of Ahmed Yasavi) (building)

Ukhaidhir (building complex)

Machicolation (architectural facet)

Kharana (building)

Bedestan (structure type)

Anjar ('Ayn Jar) (city)

(Previously: 10 Random Entries from the Dictionary of Islamic Architecture)

----------------------------------------------------------------------------

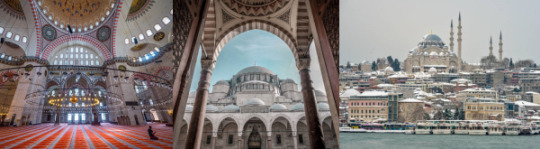

❯ ❯ Iznik tilework (architectural facet)

Ottoman tiles produced from the mid-sixteenth century will have a distinctive under-glaze blue color and design.

Iznik is a town in north-west Anatolia famed for its pottery production. during the Ottoman period. Under the Byzantines the town was known as Nicea and enclosed within a large circuit wall which still survives. The city was one of the first towns to be conquered by the Ottoman Turks and contains the earliest dated Ottoman mosque known as the Haci Ozbek Cami.

Before 1550 the kilns of Iznik seem to have been mostly concerned with making pottery rather than tiles. Sometime around 1550 there was a change to tile production which was induced by the tiling of three great monuments, the Dome of the Rock in Jerusalem, the Suleymaniye Mosque in Damascus and the Suleymaniye complex in Istanbul. Before 1550 Ottoman tiles were hexagonal with bold cuerda sec designs, the new Iznik tiles were square and carried underglaze designs. The new shape and use of underglaze painting enabled large multi-tile compositions to be made. Another innovation of this period was the use of thick red slip as an underglaze color which gave Iznik pottery its distinctive appearance.

See also: Istanbul; Ottomans; Suleymaniye.

❯ Further reading ❯ (1) J. Raby, 'A seventeenth-century description of IznikNicea', Istanbuler Mitteilungen, 149-188, 1976; (2) J. Raby and N. Atasoy, lznik: The Pottery of Ottoman Turkey, London 1989. ❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 130. ❯ Photos ❯ (1) SOPA Images/Contributor; (2) Ayhan Altun; (3) Ayhan Altun.

----------------------------------------------------------------------------

❯ ❯ Fatimids (people)

Caliphs who ruled North Africa, Egypt and Palestine from the tenth to the twelfth century.

The Fatimids were a religious dynasty who claimed descent from the prophet's daughter Fatima. In historical terms the Fatimids belonged to an extreme sect of Shi'a known as Ismailis who emerged as rivals to both the Umayyads of Spain and the Abbasid caliphate in Baghdad. The Fatimids' first successes were amongst the Berber tribes of North Africa who adopted the Fatimids as leaders. Their first conquest destroyed the Aghlabid rulers of Ifriqiyya (Tunisia) in 909 and replaced them with the Fatimid caliph the Mahdi Ubaid Allah. In the following years the Fatimids pursued an aggressive expansionist policy, conquering Tripoli and making raids on the French and Italian coasts. During the reign of the Caliph al-Mu'iz the empire was expanded westwards to include the whole of North Africa to the Atlantic Ocean and eastwards to Egypt and Palestine in 969. The conquest of Egypt began a new phase in Fatimid history with the foundation of Cairo as the imperial capital.

The architecture of the Fatimids can be divided into two periods, the North African period from 909 to 969 and the Egyptian period from 969 to 1171. The North African period was a time of expansion and religious extremism which can be seen in the architecture of the mosques. Examples of early Fatimid mosques are at Ajdabiya in Libiya and Mahdiya in Tunisia. The first of these was the mosque of Mahdiya, which was built like a fortress with two square comer towers flanking a single projecting monumental entrance. The mosque at Ajdabiya had a similar plan but lacks the monumental entrance facade. For ideological reasons, neither of these mosques had a minaret, a feature which remained absent until the last years of Fatimid rule in Egypt.

See also: Ajdabiya; Cairo (The Fatimid Period); Libiya; Mahdiya; Tunisia.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, pages 86-87. ❯ Photos ❯ (1) J.M. Bloom; (2) Wikimedia Commons.

----------------------------------------------------------------------------

❯ ❯ Gujarat (region)

Predominantly Hindu coastal region of western India with distinctive Islamic architecture. Gujarat is a fertile low-lying region located between Pakistan, Rajasthan and the Indian Ocean. The position of the region on the Indian Ocean has meant that it has always had extensive trading contacts particularly with the Arabian peninsula. It is likely that the first Muslims in Gujarat arrived sometime in the eighth century although there is little published archaeological evidence of this. The oldest standing mosques in the area are located at the old seaport of Bhadresvar in western Gujarat and have been dated to the mid-twelfth century although they may stand on older foundations.

The first Muslim conquest of the area took place at the end of the thirteenth century under the Ala al-Din the Khaliji sultan of Delhi. The earliest monument from this period is the Jami Masjid at Cambay which includes columns taken from ruined Hindu and Jain temples. The form of the mosque resembles that of the Quwwat al-Islam Mosque in Delhi with a rectangular courtyard with gateways on three sides and an arched screen in front of the sanctuary on the west side. Other early mosques built in a similar style include those of Dholka Patan and Broach all of which are located close to the coast. During the fifteenth century many mosques, tombs and other monuments were built in the regional capital Ahmadabad, the most significant of which are the Jami Masjid and the tomb of Ahmad Shah. These buildings incorporate many features from Hindu temple architecture including projecting balconies, perforated jali screens and square decorated columns. Monuments of the sixteenth century contain the same Hindu and Islamic elements combined in a more developed fashion as can be seen in the Jami Masjid of Champaner built in 1550. The Mughal conquest in the mid-sixteenth century brought Gujarat into the mainstream of architectural development. However, the architecture of the region exerted a considerable influence on the Mughal emperor Akbar, who built the city of Fatehpur Sikri in Gujarati style.

The secular architecture of Gujarat is mostly built of wood and characterized by elaborately carved screens and overhanging balconies. Another characteristic feature of the region is the use of step wells, or vavs, which consist of deep vertical shafts, approached via recessed chambers and steps. Sometimes these were very elaborate structures with multiple tiers of steps.

See also: Ahmadabad; India; Mughals; Qutb Minar.

❯ Further Reading ❯ (1) Z. A. Desai, 'Some Mughal inscriptions from Gujarat', Epigraphica Indica: Arabic and Persian Supplement, 1970, 63-92; (2) J. Jain-Neubauer, The Stepwells of Gujarat in Art Historical Perspective, New Delhi 1981; (3) E. Koch, '[The] Influence [of Gujarat] on Mughal architecture', in Ahmadabad, ed. G. Michell and S. Shah, Bombay 1988, 168-185; (4) M. Shokooy, M. Bayani-Wolpert and N. H. Shokooy, Bhadresvar: The Oldest Islamic Monuments in India, part of Studies in Islamic Art and Architecture, Supplements to Muqamas, vol. 2, Leiden 1988. ❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, pages 102-103. ❯ Photos ❯ (1) Gujarat Tourism; (2) C. Krishna Gairola/University of Washington Libraries, Special Collections; (3) Booksfact.

----------------------------------------------------------------------------

❯ ❯ Susa / Soussa / Sousse (city)

Tunisian coastal city noted for its ninth-century Aghlabid buildings. Under the Byzantines the city was known as Justinianopolis in honor of Justinian who rebuilt it after the Vandal destruction. In 689 CE, it was captured by the Arabs and became one of the principal ports for the Aghlabid conquest of Sicily. In 827, the city was refortified with ramparts and walls built in the Byzantine style. Important Aghlabid buildings within the city include the ribat built or restored by Ziyadat Allah in 821, the Bu Fatata Mosque built in 840 and the Great Mosque established in 859.

See also: Aghlabids; Tunisia.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 271. ❯ Photos ❯ TravelFeed.

----------------------------------------------------------------------------

❯ ❯ Yasavi (shrine of Ahmed Yasavi) / mausoleum of Khoja Ahmed Yasawi) (building)

Shrine built by Timur for his son Jahangir between 1397 and 1399.

The shrine is located in the city of Turkestan (modern Yasi) in the Republic of Kazakhstan. The building is oriented north-south on a rectangular ground plan (65.5m by 46.5m) with portals at the south and north ends. The main doorway is the magnificent south portal which is flanked by huge cylindrical corner towers or minarets over 20m high. Behind the portal is the dome of the prayer hall rising to a height of over 37m. At the other end of the structure is the north facade in the center of which is the entrance to the mausoleum. The mausoleum is capped by a tall 'melon-shaped' ribbed dome set on a high cylindrical drum. Externally the building is well articulated with its two entrance facades, domes and an extensive covering of tilework. Internally, however, there is less feeling of unity beyond the principal rooms: leading off from the prayer hall and mausoleum are many smaller rooms with different vaulting systems which do not seem integrated in an overall design.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 310. ❯ Photos ❯ (1) Yevgeniy Volkov/Shutterstock; (2) leszczem/Shutterstock; (3) AlexelA/Shutterstock.

----------------------------------------------------------------------------

❯ ❯ Ukhaidhir / al-Ukhaidir Fortress (building complex)

Early Abbasid palace in the desert of south-western Iraq.

The palace stands in the desert west of the city of Kerbala and east of the oasis of Shithatha. The building is made out of rough-hewn limestone blocks and mud plaster with baked brick used for roofing vaults, resembling earlier Sassanian structures (cf. Kharana in Jordan). The palace may be divided into two structural phases, a central palace core and an outer enclosure wall added slightly later. The exterior curtain wall is composed of tall blind niches alternating with solid semi-circular buttress towers. On top of the wall there was a parapet which was cantilevered over the niches allowing a continuous series of slits (machicolation) which could protect the lower parts of the wall from attack. The main gateway is set between two quarter-round towers and contains a slot for a portcullis. To the right of the entrance on the outside there is a large stable block. The central core of the palace contains a mosque, a bath house and a main reception hall. The upper floor is reached by ramps running up at right angles to the axis of the main gateway. There are small tunnels running over the main vaults which provided cooling and ventilation.

Recent survey work in the vicinity of Ukhaidhir has demonstrated the development of the area during the early Islamic period, starting with the small palace at Tulul Ukhaidhir several kilometers to the north of the main palace. In addition there is an outer mud-brick enclosure containing a variety of mud-brick buildings which are now only visible as humps.

See also: Abbasids: Atshan, Khan; Iraq; Sassanians.

❯ Further reading ❯ (1) G. Bell, Palace and Mosque at Ukhaidhir: A Study in Early Muhammadan Architecture, Oxford 1914; (2) B. Finnster and J. Schmidt, Sasaidische und fruhislamische Ruinem im Iraq, Baghdader Miffeilungen 8, Berlin 1976. ❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 294. ❯ Photos ❯ (1) Taisir Mahdi; (2) Mustafa Hamzah Almosawy.

----------------------------------------------------------------------------

❯ ❯ Machicolation (architectural facet)

Downward openings or slits used defending a castle or fortification.

There are three types of machicolation, a box machicolation, concealed machicolation and continuous machicolation. A box machicolation resembles a projecting window or gallery and may also be used for this purpose. There are usually one or more slits in the floor and the box is normally located over a gate or doorway. Box machicolations were used in Roman times and their first use in Islamic structures is at Qasr al-Hayr (East and West).

Concealed machicolations are usually set into the roof above a vaulted passage leading from a gateway and are often used in conjunction with a portcullis. The first example in Islamic architecture comes from the eighth-century palace of Ukhaidhir in Iraq. These were frequently used in medieval Islamic fortifications.

Continuous machicolation consists of a parapet which is cantilevered over the front face of a wall with a series of downward openings. The earliest example of this is also at Ukhaidhir although it is not used later on in Islamic architecture.

See also: Fortification.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 167. ❯ Photos ❯ (1) Bernard Gagnon; (2) Vyacheslav Argenberg/Getty.

----------------------------------------------------------------------------

❯ ❯ Kharana / Qasr al-Kharana (building)

Early Islamic or Sassanian building in the Jordanian desert 60km east of Amman.

Kharana is a remarkably preserved square two-story structure with solid semi-circular and circular buttress towers. The building is made out of roughly-hewn stone blocks laid in courses covered with successive layers of plaster. There are three rows of vertical slits in the walls which have been interpreted as arrow slits, although. their height above the inside floor level makes this unlikely. The gateway is set between two quarter-round towers which lead into an entrance passage flanked with two long vaulted rooms that functioned as stables. Inside the building is a square courtyard with a series of undecorated rooms (for storage?) whilst on the upper floor the rooms are decorated with plaster/stucco designs similar to those at Ukhaidhir in Iraq. These include engaged pilasters, blind niches and decorative bosses. Two of the upper rooms have semi-domes resting on wide squinches at the end.

Although it was built before 710 (according to an inscription) and is Sassanian in style, the building is now generally believed to be early Islamic.

See also: Tunisia.

❯ Further reading ❯ S. Urice, Qasr Kharana in the Transjordan, Durham, NC: AASDR, 1987. ❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 147. ❯ Photos ❯ Haupt & Binder.

----------------------------------------------------------------------------

❯ ❯ Bedestan (structure type)

Special closed form of Turkish market where goods of high value were traded. The usual form of bedestan is a long domed or vaulted hall two storeys high with external shop units.

Originally, bedestan referred to the area of a market where cloth was sold or traded from the bezzaz han (cloth market). The earliest bedestans were probably specific areas of a general bazar or market. The earliest known bedestan is the Beysehir Bedestan built in 1297 according to an inscription above the gateway. The building consists of a closed rectangular courtyard covered by six domes supported on two central piers. There are doorways on three sides and on the outside there are small open shop units, six on the east and west sides and nine on the north and south sides.

During the Ottoman period bedestans developed as a specific building type and became the center of economic life in a city. Because they could be locked, they were often used for jewelry or money transactions and came to be regarded as signs of prosperity in a city. Ottoman bedestans were built in a variety of forms and may include features such as external shops, internal cell units and arastas (arcades). The simplest plan consists of a square domed hall with one or two entrances like those at Amasya or Trabzon. More complicated structures like the Rustem Pasha Bedestan in Erzerum consist of a central enclosed courtyard surrounded by a closed vaulted corridor containing shop units.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 33. ❯ Photos ❯ (1) Mustafa Cambaz; (2) GarySandyWales; (3) selimaksan.

----------------------------------------------------------------------------

❯ ❯ Anjar ('Ayn Jar) (city)

Umayyad city in Lebanon.

Anjar was built by the Umayyad caliph al-Walid in 714-715 CE. The city is contained within a rectangular enclosure (370m north-south and 310m east-west) supported by a series of solid semi-circular buttress towers and four hollow corner towers. There are four principal gateways and the walls were originally crowned with stepped merlons (crenellation). Internally the city is built to a regular plan recalling earlier Byzantine and Roman cities. There are four principal colonnaded streets which meet at the center in a tetrapylon. Many of the buildings are built of alternating courses of ashlar blocks and layers of baked brick. There is a series of shop units (3.5m wide and 5m deep) lining the main streets behind the colonnades. In the south-east quadrant of the city is a palace within a rectangular enclosure (about 70 by 60 m). The interior of the palace is divided into four units arranged symmetrically; at the south end there is a building with a triple aisles and an apse resembling a basilical hall, this is duplicated at the north end. To the north of the palace is the mosque which is entered from the west street. The mosque is a rectangular structure (47m by 30m) with a small central courtyard surrounded by two aisles on the west, east and qibla (south) sides whilst there is one aisle on the north side. On either side of the mihrab are two entrances which lead into a narrow lane that connects with the palace. There is a small bath house next to the north gate which comprises a square vaulted hall, leading via two intermediate rooms into a hot room.

❯ Text ❯ Peterson (1995) Dictionary of Islamic Architecture, page 20. ❯ Photos ❯ (1) Malcolm P. Chapman; (2) Henryk Sadura; (3) Eric Lafforgue/Art in All of Us/Contributor.

----------------------------------------------------------------------------

Current article: 10 (More) Random Entries from the Dictionary of Islamic Architecture

Previous article: 10 Random Entries from the Dictionary of Islamic Architecture

#islamic architecture#writeblr#writing research#masterpost#writing#writing tips#writing advice#culture#novel writing#fiction writing#worldbuilding#writing stuff#architecture research#construction material#fatimids#gujarat#susa#sousse#yasavi#ahmed yasavi#ukhaidhir#machicolation#kharana#iznik tiles#izkik#bedestan#anjar#architecture#spelling and pronunciation may differ#exact dates may differ

7 notes

·

View notes

Text

T U A T H - t h e v i s i t o r - a n c u a i r t e o i r

An Gailearai, Dún na nGall, 2023

Making Visible the Visceral and Personal connections between the body and place

Installation at An Gailearaí consists of an assemblage of disregarded construction material, small geometric sculptures, floor text, infra-red photographs, sound and two video projections.

Is machnamh lom, fileata agus meafarach é an taispeántas suiteáin seo ar an ngaol idir an daonnacht, an miotas agus an talamh.

Working with Performance Artist Hollie Miller, Composer Seán Ó Dálaigh and Camera Person Siobhán Dempsey, we created a multi layered work which draws inspiration from three dominant sources: the story of a banished Monk who returns to his land to settle a dispute blindfolded and on blocks of wood, a 1514 allegorical drawing by Hans Baldung Grien of a naked female figure walking with small spheres attached to her feet and the Myth of Tiresias, the blind prophet of Apollo and Thebes, famous for clairvoyance and for being transformed into a woman for seven years.

Here in this installation the ‘blind seer’ brings us, somewhat unsettlingly, through a built and natural landscape, there a sense of impending tragedy or traces of a previously traumatic event.

#art#artists on tumblr#andrew duggan#hans baldung grien#blind seer#county donegal#gaeltacht#an Gailearai#hollie miller#art performance#sean o dalaigh#banished#monk#colm cille#myth#Myth of Tiresias#tiresias#blind#blind prophet#Apollo and Thebes#Apollo#Thebes#sex change#transformed into a woman#construction material#infrared#photography#installation#video art#gothic

3 notes

·

View notes

Text

Achieving Optimal Performance with High-Quality IBR Fitting and Flanges What You Need to Know

In the complex world of industrial operations, achieving optimal performance is paramount. When it comes to steam and power generation systems, the choice of components plays a crucial role. IBR (Indian Boiler Regulations) Fittings and Flanges are integral parts of these systems, ensuring efficiency and safety. As a leading IBR Fitting and Flanges distributor in Vadodara and a trusted IBR Fitting and Flanges dealer in Gujarat, Tube Trading Co. recognizes the importance of these components. In this blog post, we will delve into the key aspects of IBR fittings and flanges, shedding light on how the right choice can contribute to achieving peak performance in industrial settings.

Understanding IBR Fittings and Flanges

What is IBR?

The Indian Boiler Regulations (IBR) are a set of regulations governing the design, fabrication, and inspection of boilers and related components in India. IBR compliance is mandatory for manufacturers and users of boilers and associated equipment to ensure safety and quality standards.

IBR Fittings

IBR fittings are components designed to connect and control the flow of fluids within a steam or power generation system. These fittings must adhere to IBR standards to guarantee their reliability and safety in high-pressure environments. Examples of IBR fittings include bends, elbows, tees, reducers, and valves.

IBR Flanges

Flanges are essential components that connect pipes, valves, and other equipment in a steam or power system. IBR flanges, compliant with IBR regulations, are designed to withstand high pressure and temperature conditions. They provide a secure and leak-proof connection between different sections of a piping system.

Importance of High-Quality IBR Fittings and Flanges

Safety Compliance

In industries where steam and power generation are critical processes, safety is non-negotiable. IBR regulations are in place to ensure that the components used in these systems meet stringent safety standards. Choosing high-quality IBR fittings and flanges from a reputable distributor in Gujarat is essential for compliance and to mitigate the risk of accidents.

Reliability and Durability

The harsh conditions of industrial operations demand components that can withstand high temperatures, pressures, and corrosive environments. High-quality IBR fittings and flanges are constructed from materials that offer exceptional durability, ensuring a longer lifespan and minimal downtime for maintenance.

Efficient Performance

The efficiency of a steam or power generation system depends on the seamless operation of its components. Inferior fittings and flanges can lead to inefficiencies, including leaks and pressure drops, resulting in decreased system performance. By choosing top-notch IBR fittings and flanges from a reliable distributor in Vadodara, industrial operators can optimize the performance of their systems.

Applications of IBR Fittings and Flanges

Power Plants

In power plants, where steam is a primary component in electricity generation, IBR fittings and flanges are extensively used. These components help regulate the flow of steam and ensure the integrity of the entire system.

Chemical and Petrochemical Industries

Industries dealing with chemicals and petrochemicals operate in demanding environments. IBR fittings and flanges play a crucial role in maintaining the integrity of piping systems that transport hazardous substances.

Refineries

Refineries, involved in processing crude oil into various products, rely on high-pressure steam for many processes. IBR fittings and flanges are vital in ensuring the safe and efficient operation of these steam systems.

Textile and Food Processing Units

In textile and food processing, where steam is used for various purposes, IBR fittings and flanges are employed to guarantee the reliability and safety of steam transport.

Choosing the Right IBR Fitting and Flanges Distributor

Selecting the right distributor is as crucial as choosing the right components for your industrial applications. As a reputable IBR Fitting and Flanges distributor in Vadodara, Tube Trading Co. stands out for several reasons:

Extensive Product Range

We offer an extensive range of IBR fittings and flanges, catering to diverse industrial needs. Our products are sourced from trusted manufacturers, ensuring quality and reliability.

Compliance with Standards

All our IBR fittings and flanges comply with Indian Boiler Regulations and other relevant industry standards. We prioritize safety and performance in every product we offer.

Technical Expertise

Our team of experts possesses in-depth technical knowledge about IBR fittings and flanges. We provide valuable insights and guidance to help our clients make informed decisions.

Timely Delivery

At Tube Trading Co., we understand the importance of timely delivery in industrial settings. We ensure that our clients receive their orders promptly, minimizing downtime and disruptions.

Conclusion

In the intricate tapestry of industrial operations, the choice of IBR fittings and flanges can significantly impact the efficiency, safety, and reliability of steam and power systems. Tube Trading Co., as a trusted IBR Fitting and Flanges distributor in Vadodara and a reputable IBR Fitting and Flanges dealer in Gujarat, takes pride in being a reliable partner for industries across the region. Our commitment to quality, safety, and customer satisfaction sets us apart in the competitive landscape.

If you are in search of high-quality IBR fittings and flanges to enhance the performance of your industrial processes, look no further than Tube Trading Co. Contact us today for all your IBR fitting and flange requirements, and let us contribute to the success and efficiency of your operations.

#IBR Fitting and Flanges distributor in Gujarat#IBR Fitting and Flanges distributor in Vadodara#IBR Fitting and Flanges dealer in Gujarat#Steel Companies#Steel Industry#Construction Material#Stainless Steel#business#India#Gujarat#Vadodara

6 notes

·

View notes

Text

Case Study - The Engineering Behind Skyscraper Foundations – An In-Depth Analysis

Introduction – The Hidden Strength Beneath Skyscrapers When we look at the world’s tallest buildings, we admire their height, design, and structural brilliance. But the true engineering marvel lies underground—in the foundations that keep these skyscrapers standing against gravity, wind, earthquakes, and soil movement. Have you ever wondered how a 100-story building remains stable in storms,…

#Case study#Civil Engineering#Climate change#Construction material#Environmental Engineering#The Engineering Behind Skyscraper

0 notes

Text

Why choose ABCO as supplier for your construction project in Saudi Arabia?

A successful construction project requires the right materials, timely delivery, and expert support. ABCO Saudi provides all three, ensuring that your project is completed on time, within budget, and to the highest quality standards.

With ABCO Saudi, you can:

✅ Get high-quality construction materials ✅ Ensure timely deliveries anywhere in Saudi Arabia ✅ Save money with competitive pricing and bulk discounts ✅ Receive expert support for material selection and project planning

No matter the size of your construction project, ABCO Saudi is the perfect partner to help you achieve success. Get in touch with them today and experience hassle-free procurement, cost-effective solutions, and top-notch quality for all your building needs!

#construction#building material supplier#buildings#saudi arabia#riyadh#construction material#hardware dealers in saudi#construction material supplier

0 notes

Text

Remarkable NOVA Plastic Formwork - Designed To Meet All Construction Requirements

To meet a variety of construction needs, Nova Formworks offers high-performance plastic formwork solutions that are made to be strong, effective, and reusable.

#nova plastic formwork#formwork construction#plastic formwork#construction formwork#formwork in construction#construction industry#construction material

0 notes

Text

Explore the beauty and durability of cobblestone. Learn about its types, uses, and history in our complete guide to this classic paving material.

0 notes

Text

Build The Impossible With Nova Formworks

From big buildings to challenging structures, our strong plastic formworks help you take construction to the next level. Here’s how we make it happen:- ➢ Durable plastic formworks. ➢ Precision engineering. ➢ Built for your toughest projects. ➢ Faster delivery ➢ Smoother finish

#construction#construction sector#construction material#construction materials#low cost construction#formwork#plastic formwork in india#plastic formworks

0 notes

Video

youtube

💃A corner of the production workshop of the wedge anchor through bolt fa...

#wedge anchor factory#wedge anchor manufacturing#wedge anchor fixing#wedge concrete anchors#using a wedge anchor#concrete wedge anchor bolts#expansion bolts for concrete#wedge anchor in concrete#wedge anchor test#through bolt manufacturer#through bolt#bolts and fasteners#bolt manufacturer#bolts and nuts suppliers#fasteners factory#fixdex fastener factory from china#free sample#building material#construction material#concrete construction#goodfix fixdex

0 notes

Text

10 Random Entries from the Dictionary of Islamic Architecture

The following entries were pulled from the Dictionary of Islamic Architecture (1995).

Funduq (structure type)

Coral (construction material)

Kufa (city)

Songhay (people)

Süleymaniye (named building complex)

Squinch (architectural facet)

Aghlabid (people, lineage)

al-Aqsa Mosque (building)

Arasta (structure type)

Hassan Fathy (person, architect)

❯ ❯ Funduq (structure type)

North African term for a small, urban shop complex. A typical funduq is a square two-story structure built around a central courtyard with shops on one floor and store rooms on the other. Equivalent to a khan in the Middle East.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 91.

Photo source: (1) Barbara J. Anello-Adnani; (2) Islamic Architectural Heritage

❯ ❯ Coral (construction material)

Coral is used as a building material for coastal settlements throughout the Indian Ocean, Arabian/Persian Gulf and the Red Sea.

Two main types of coral stone are used for construction: fossil coral quarried from the coastal foreshore, and reef coral which is cut live from the sea bed. Fossil corals are more suitable for loadbearing walls whilst reef corals such as porites are more suitable for architectural features such as door-jambs or mihrab niches. Fossil corals are mostly from an order of coral known as Rugosa, which is now extinct. When quarried this coral forms rough uneven blocks known as coral rag. Although this can be cut into rough blocks, it cannot be dressed to a smooth finish and therefore has to be used in conjunction with another material to produce an even surface.

Living coral from the reef is easier to cut and dress to a smooth finish, although it does require hardening by exposure to the air. The preferred type of reef coral for building is porites because of its compact vascular structure which means it is both strong and easy to carve. However, this is not the only type used and, at the eleventh-century site of Ras al-Hadd in Oman, at least seven different types were noted. In the Maldives and Bahrain, platy corals such as oxypora and montipora are used for partitions.

The origins of coral-building are not well understood although it is generally believed that the technique originated on the coasts of the Red Sea. The earliest example was discovered at the site of al-Rih, in the Sudan, where a Hellenistic cornice made of coral was found reused in an Islamic tomb. From the Red Sea, the technique spread to the East African coast of the Indian Ocean where it was established as the primary building material for monumental buildings. In the Arabian/Persian Gulf, there is another tradition of coral stone construction although the antiquity of this tradition is in doubt as suitable coral has only grown in the area within the last 1,000 years. At the present time, the use of coral stone extends over large areas of the Indian Ocean and includes the coastline of India (Gujarat), the Maldives and Sri Lanka. The origins of coral-building in these areas has not been investigated, although it generally seems to be associated with Islamic traders.

See also: Bahrain; East Africa; Maldives; Qatar; Saudi Arabia; Sudan; United Arab Emirates.

Text source: Peterson (1995) Dictionary of Islamic Architecture, pages 54-55.

Photo source: Getty

❯ ❯ Kufa (city)

Southern Iraqi city founded in the early Islamic period.

Kufa is located on the west bank of the Eurphrates near the Shi'a shrine city of Najaf. Like Baghdad, Kufa was a purely Islamic foundation, although it stood close to the Lakhimid capital of al-Hira.

After the battle of Ctesiphon and the capture of al-Mad'ain (Ctesiphon and Seleucia) the Arab armies settled in the old Sassanian capital. Soon afterwards, the armies moved to Kufa because of its pleasanter climate and strategic location on the west bank of the Euphrates (i.e., easy access to Syria and the Hijaz). In 645, Ali transferred the seat of government to Kufa. The assassination of Ali in the Great Mosque of the city in 645 brought an end to the city's role as capital.

The original city had no walls and was simply surrounded by a ditch. The principal monuments in Kufa are the Great Mosque and the Dar al-Imara, or Governor's Palace. The Great Mosque consists of a number of different phases from the early Islamic period to the present day. The first mosque on the site was laid out by a man who threw spears to each of the cardinal points to delineate a square two-spear throws long. The area was enclosed by a ditch and the only permanent architectural feature was a marble colonnade 20m long. The columns were taken from the nearby city of al-Hira. In 670 CE, the mosque was expanded and covered with a flat roof resting on stone columns. The mosque visible today has a beautiful golden dome and contains the tombs of the two saints Muslim ibn Aqeel and Hani ibn Arwa. The golden dome and tilework date to the Saffavid period (seventeenth and eighteenth centuries), although the outer wall of the mosque which is supported by twenty-eight semi-circular buttress towers probably originates in the early Islamic period.

To the south of the Great Mosque is the Dar al-Imara, which was excavated by the Iraqi Antiquities Authority. The palace is enclosed by a square enclosure 170m per side with walls 4m wide supported by twenty semi-circular buttress towers and four round corner buttresses. In the center of the palace there is a square (domed?) chamber approached by a vaulted hall which was probably the throne room.

See also: Dar al-Imara; Iraq.

Further reading: (1) S. Ahmad, 'Survey of the Kufa area' (in Arabic), Sumer 21:229-252, 1965. (2) M. A. Mustafa, 'Dar al Imara at Kufa', Sumer 21:229-252, 1965. (3) M. A. Mustafa, 'Preliminary report on the excavations in Kufa during the third season', Sumer 19:36-65, 1963.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 156.

Photo source: (1) Taghrib News; (2) Narjes Ahmed/Wikimedia Commons.

❯ ❯ Songhay (people)

The people who inhabit the banks of the Niger river between Gao and Dendi in West Africa. The Songhay people were the ruling population of the empire of Gao during the fifteenth and sixteenth centuries. Some of them were Muslim before the eleventh century but some have remained pagan to the present day. Little is known of early Songhay architecture, although ancestor-worship seems to have been expressed through earthen burial mounds. Elements of this tradition seem to have been incorporated in Islamic monuments where prominent people are buried within solid earth pyramid-like constructions, the most famous of which is the tomb of Askiya Muhammad at Gao.

See also: Gao; West Africa.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 262.

Photo source: (1) Reuters/Joe Penney; (2) Reuters/Joe Penney; (3) Islamic Architectural Heritage.

❯ ❯ Süleymaniye (named building complex)

Ottoman mosque complex in Istanbul built for Suleyman the Magnificent between 1550 and 1557.

The complex consisted of a hospital, medical school, hospice, soup kitchen, primary school, four madrassas (colleges), shops and coffee houses in addition to the mosque itself. The complex is built on an artificial platform on top of a hill that overlooks the Bosphorus; to the east the ground slopes away rapidly. The mosque precinct contains three main areas, the mosque itself in the center, a courtyard to the north and a tomb garden to the south which contains the tomb of Suleyman and his wife. The mosque is covered with a large central dome (25m diameter) with two large semidomes of equal radius, one above the north entrance and one above the mihrab. The central area is flanked by side aisles covered by small domes of alternating size. Like that of its predecessor, the Sehzade Cami, the central dome rests on four huge central piers placed in a square. The whole building is illuminated with more than a hundred windows and grilles, many of which are filled with stained glass made by the celebrated Ottoman glass-maker Ibrahim Sarhos. Outside at each corner of the courtyard are four minarets with balconies supported on muqarnas corbels. This is the first Ottoman building in Istanbul to have four minarets, although previously the Üc Serefeli in Edirne also had four. The sides of the building are enlivened with several entrances (three on each side), approached by steps and two-tier arcaded galleries placed between the outer corner buttresses.

The tomb garden behind the mosque contains a large cemetery which has grown up around the tombs of Suleyman and Roxelane. Both tombs are octagonal structures in the traditional Ottoman fashion, although Suleyman's tomb unusually faces east instead of north. Roxelane's tomb is smaller and placed to one side of Suleyman's tomb which stands in the middle of the garden. The interiors of both tombs are decorated with Iznik tiles, although Roxelane's tomb is significantly less grand. Suleyman's tomb is surrounded by a colonnaded veranda with a porch on the east side. This arrangement is echoed internally where Suleyman's sarcophagus is surrounded by a circular colonnade.

The arrangement of the complex outside the mosque precinct consists of an L-shaped arrangement of buildings on the north-west side and a smaller group to the east. The eastern complex is built on a steep hill so the madrassas are stepped into the hillside. On the north-west corner of the complex is the tomb of the architect Sinan.

See also: Istanbul; Ottomans; Sinan.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 268-269.

Photo source: (1) CamelKW/Flicker; (2) Kevser Salih/Getty; (3) Izzet Keribar/Getty.

❯ ❯ Squinch (architectural facet)

Small arch in the corner of a building that converts a square space to an octagonal area, which may then be covered with a dome.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 267.

Photo source: (1) Dig Magazine; (2) José Carlos Palacios Gonzalo/Rana Munir Alkadi; (3) José Carlos Palacios Gonzalo/Rana Munir Alkadi.

❯ ❯ Aghlabid (people, lineage)

Dynasty which ruled the north African province of Ilfriqiyya during the ninth century.

Although nominally under Abbasid control, the Aghlabids were able to exercise a great deal of independence. Militarily their great achievement was the conquest of Byzantine Sicily.

The Aghlabids were great patrons of architecture, and much of their work has survived. Their work demonstrates a mixture of Byzantine and Abbasid building styles. One of the most important projects was the rebuilding of the Great Mosque of Qairawan and the addition of the huge three-tiered minaret/tower. The Aghlabids were also responsible for major irrigation and water supply systems, the most famous example of which are the huge circular cisterns of Qairawan. Much of their effort was also directed towards the development of the coastal towns as bases from which to launch the conquest of Sicily. The military nature of Aghlabid rule is further reflected in the large number of ribats, or fortified monasteries, which they constructed.

See also: Tunisia.

Further reading: A. Lezine, Architecture de L'Ilfriqiyya: Recherche sur les monuments aghlabides, Paris 1966.

Text source: Peterson (1995) Dictionary of Islamic Architecture, pages 6-7.

Photo source: (1) Richard Mortel/Flicker; (2) Alberto Biscaro/Masterfile.

❯ ❯ al-Aqsa Mosque (building)

The principal mosque of Jerusalem which forms part of the sacred enclosure (haram) with the Dome of the Rock at the center.

The Aqsa Mosque is located on the southern part of the Haram al-Sharif on an axis with the south door of the Dome of the Rock. In the time of Umar, a mosque is known to have been built on the site although it appears to have been a semipermanent structure made out of re-used material, hastily put together to form a covered prayer area with a shed roof. During the reign of al-Walid the mosque was rebuilt with its present alignment.

Only a small part of al-Walid's mosque survives, but this indicates that the aisles all ran perpendicular to the qibla wall (as they do today). This arrangement is unusual and recalls the arrangement of Byzantine churches, such as the Church of the Nativity in Bethlehem.

The earthquake of 748 severely damaged the mosque, which was subsequently rebuilt by the Abbasid caliphs al-Mansur (759) and al-Mahdi (775). The mosque of al-Mahdi had a raised central aisle leading to the mihrab in front of which he built a wooden dome; either side of the central aisle were seven side-aisles. An earthquake of 1033 destroyed the mosque and it was once again rebuilt by the Fatimid caliph al-Zahir in 1035. This mosque had a total of seven aisles, a central aisle with three aisles on either side.

See also: Damascus Great Mosque; Dome of the Rock; Jerusalem; Medina; Palestine; Umayyads.

Further reading: R. W. Hamilton, The Structural History of the Aqsa Mosque. A Record of Archaeological Gleanings from the Repairs of 1938-42, Government of Palestine, Jerusalem 1949.

Text source: Peterson (1995) Dictionary of Islamic Architecture, pages 22-24.

Photo source: (1) Niels M. Knudsen/Flicker; (2) Sam Rohn/Flicker.

❯ ❯ Arasta (structure type)

Turkish term for a street or row of shops whose income is devoted to a charitable endowment or waqf (equivalent to a European shopping arcade).

Arastas are found in most of the regions of the former Ottoman Empire and usually form part of a commercial or religious complex which may include a han (or khan), a mosque and bath house. Many arastas were probably made of wood but these have largely disappeared leaving only those made of more permanent materials. Arastas are often covered over with a barrel vault and have a row of shops either side of a central street, but they can also be open to the sky. Important examples of arastas include the Misir Carsi in Istanbul, the arasta associated with the Selimiye mosque in Edirne and the arastas at the Sokollu complex· at Luleburgaz and the Selim I complex at Payas both designed by Sinan.

See also: Ottomans.

Further reading: M. Cezar, Typical Commercial Buildings of the Ottoman Classical Period and the Ottoman Construction System, Istanbul 1983.

Text source: Peterson (1995) Dictionary of Islamic Architecture, page 24.

Photo source: (1) Banu/Flicker; (2) Alda Cravo Al-Saude/Flicker.

❯ ❯ Hassan Fathy (person, architect)

Egyptian architect noted for his use of traditional materials to build modern Islamic structures.

Born in 1900, the son of a wealthy landowner, Hassan Fathy was brought up in Cairo, Alexandria and Europe. He studied architecture at the University of Cairo whence he graduated in 1926. In 1927, on his first visit to one of the family estates, he was shocked by the terrible living conditions of the poor and resolved to find a way to house the poor reasonably. He also conceived a love for the Egyptian countryside, which was to motivate him for the rest of his life. He realized that imported western material and technology was too expensive and inappropriate for rural housing in Egypt. Instead, Fathy thought that mud brick, the traditional building material of Egypt, should be used in modem constructions. Although he realized that traditional designs were sometimes too cramped and dark for modern housing, Fathy argued that this was not the fault of the material.

In 1937 Fathy held exhibitions of his work at Mansoura and Cairo, which resulted in several commissions from wealthy patrons. However, these buildings were quite expensive and relied on timber for their flat roofs. With the outbreak of the Second World War and the resulting shortage of timber, he had to find a new method of roofing his houses. On a visit to Upper Egypt, Fathy noticed that the Nubian villages were roofed with mud brick vaults produced without wooden centering. The method used was to lean the bricks against an end wall so that all the bricks leant against each other. Fathy employed the local Nubian builders and undertook several projects using these workers. The most important of these projects was the Nasr House in Fayyum and the tourist rest-house at Safaga.

In 1946 Fathy was approached by the Department of Antiquities who wanted to move the people of Gurna in western Luxor out of the ruins of ancient Thebes where they had been living. The Gurnis had been living in the ancient Necropolis for several generations and some lived in the tombs themselves. Nevertheless, the Department of Antiquities issued a decree stating that they wanted the 7,000 people moved to a new settlement, which was to be designed by Fathy. The settlement was to contain homes for 1,000 families and include public buildings like a mosque, a covered market, schools and a theatre. The houses were built around courtyards and arranged in neighborhood groups which had access to the main streets. Although built with traditional materials, Fathy made use of earth scientists and structural and mechanical engineers to improve his designs and ensure that they worked. Part of the project was to involve the future inhabitants in the construction, both as a cost-saving measure and so that they were not alienated from their new housing.

However, the project faced considerable difficulties in implementation through the opposition of some of the Gurni Sheikhs and the slow-moving bureaucracy of the Egyptian Antiquities Department.

In addition there was general suspicion of a project, which involved traditional materials at a time when Modernism was seen as the only way to build. In the end, only one-fifth of the project was completed and some parts of the village like the khan and the craft center remain unused. Nevertheless, the mosque is well used and maintained and the Department of Antiquities has restored the theatre, belatedly realizing the value of Fathy's work. Despite the difficulties New Gurna showed the potential of mud-brick architecture and the value of training people in traditional techniques.

Other important projects carried out by Fathy in the 1950s were at Lu'luat aI-Sahara in the Nile Delta and the village schools project. At Lu'lat al-Sahara, houses were built in pairs, together with a mosque and a school. The village schools project involved Fathy in designing a school, which was to be the prototype for village schools throughout Egypt. The design consisted of domed rooms opening onto courtyards with ventilation shafts to cool the interior during the summer. Unfortunately, only two of the schools were built, one at Fares and the other at Edfu.

In 1957, Fathy left Egypt for several years to work for an architectural firm in Athens, specializing in the Middle East, and during this time he designed a traditional housing scheme in Iraq. In the early 1960s, Fathy returned to Egypt where he undertook two further major projects, a training center in the Nile Valley and a new town in the Kharga oasis. Unfortunately the training center was subsequently destroyed because of its bad location and the town known as New Bariz was abandoned because of the 1967 war.

In the 1970, Fathy began writing books about his work, which were highly successful in universities throughout the world where the appeal of Modernism was wearing off. He showed that it was possible to design and build desirable residences and functional buildings, which respected the traditional values of a culture and were also cheap. Since the 1970s, Fathy's work in Egypt was concentrated on private houses and commissions. These buildings were constructed with increasingly sophisticated designs based on harmonic units of measurement derived from the dimensions of the human body. Probably the most important recent commission was for a Muslim community in New Mexico known as Dar al-Salam and built in 1981.

Further reading: (1) H. Fathy, The Arab House in the Urban Setting: Past, Present and Future, Fourth Arab Carreras Lecture, University of Essex, November 1970. London 1972. (2) H. Fathy, Architecture for the Poor, Chicago and London 1973. (3) H. Fathy, Natural Energy and Vernacular Architecture, Chicago 1985. (4) G. Leick, 'Hassan Fathy, architect for the poor', Egyptian Bulletin May 1988: 4-8. (5) J. M Richards, I. Serageldin and D. Rastorfer, Hassan Fathy, London 1985. (6) A. Schkifer, 'Hassan Fathy: A voyage to New Mexico', Arts and the Islamic World 1(1): 1982/3.

Text source: Peterson (1995) Dictionary of Islamic Architecture, pages 84-86.

Photo source: (1) Green Prophet; (2) Green Prophet; (3) Marc Rykaert/Wikimedia Commons.

#islamic architecture#writeblr#writing research#masterpost#writing#writing tips#writing advice#architecture research#novel writing#funduq#construction material#songhai#songhay#kufa#suleymaniye mosque#fiction writing#squinch#aghlabid#alaqsa mosque#arasta#hassan fathy#architect#structure#turkey#morocco#north africa#iraq#istanbul#tomb garden#ottoman empire

15 notes

·

View notes

Text

Understanding Time and Materials Contracts: A Flexible Approach for Project Management in Bangalore-AcreOk

Time and materials (T&M) contracts provide flexibility when working on projects such as software development and product development, especially when the entire project is not known up front giving the client exactly the time and resources needed for the completion of the project, rather than a comparable up -front fixed fee.

In this type of arrangement, the client covers labor and material costs on an hourly or daily basis. The ultimate cost will depend on what is actually used; the builder can give an estimate of how long it will take and what materials are needed. This flexibility allows both the client and contractor to adjust as the project moves forward, especially if unexpected changes or challenges come up. T&M contracts are particularly useful when the project is likely to evolve or when technical details aren’t fully known from the start.

Visibility is one of the key benefits of a T&M contract. The user can monitor costs as they arise and make adjustments to the project as needed. Consequently, the process is highly collaborative, with both individuals working together completing the task on time and to the highest standards.

But T&M contracts aren’t without their challenges. Clients need to stay on top of the project and monitor expenses closely, which can take time and effort. Without careful management, costs can rise if the amount of time or materials is underestimated. To avoid these issues, it’s important to communicate well, set up regular check-ins, and possibly agree on a budget cap to keep things under control.

In Bangalore, T&M contracts are a good fit for the city's fast-paced tech environment and its large pool of skilled professionals. This contract type matches well with the agile work methods many companies are using today, offering the flexibility needed for fast-changing projects. At AcreOK, we know how important it is to have flexibility and clear communication in project management. With our experience in handling T&M contracts, we make sure your projects are completed smoothly, giving you full visibility and control throughout the process.

0 notes

Text

Your Trusted Partner for Building Materials in South Carolina

When it comes to sourcing high-quality construction materials and building supplies, Palmetto Building Materials is your go-to provider in South Carolina. We are dedicated to serving both professional contractors and DIY enthusiasts with a comprehensive selection of products that meet the diverse needs of any construction project. Whether you are searching for building supplies near me, specific construction materials, or specialized electrical supplies in Charleston, SC, we have everything you need under one roof. Our commitment to quality, competitive pricing, and exceptional customer service makes us the preferred choice for all your construction supply needs in South Carolina.

A Comprehensive Range of Construction Materials

At Palmetto Building Materials, we understand that the success of any construction project hinges on the quality of the materials used. That’s why we offer an extensive range of construction materials to cater to every phase of your project, from the foundation to the finishing touches. Our inventory includes top-grade lumber, concrete, drywall, insulation, roofing materials, and much more. We work closely with reputable manufacturers to ensure that all our products meet the highest standards of durability, performance, and safety. Whether you are constructing a new home, renovating an existing structure, or undertaking a commercial project, you can count on us to provide the materials you need to get the job done right.

Building Supplies Near Me: Convenience and Accessibility

One of the most common concerns for contractors and homeowners alike is finding reliable building supplies near me. At Palmetto Building Materials, we prioritize convenience by ensuring that our products are easily accessible to customers throughout South Carolina. Our strategically located store in Charleston, SC, makes it easy for you to pick up the materials you need without the hassle of long drives or extensive searches. We also offer delivery services to bring your supplies directly to your job site, saving you time and effort. With us, you can enjoy the convenience of having a trusted supplier right in your neighborhood.

Electrical Supplies Charleston, SC: Powering Your Projects

Electrical systems are the backbone of any building, and having the right electrical supplies is crucial for ensuring the safety and functionality of your construction projects. At Palmetto Building Materials, we stock a wide range of electrical supplies in Charleston, SC, including wiring, switches, outlets, circuit breakers, lighting fixtures, and more. Our products are sourced from leading manufacturers, ensuring that you receive only the best in terms of quality and performance. Whether you are working on a residential, commercial, or industrial project, our team is here to help you find the right electrical components to meet your specific needs.

Plumbing Supplies Charleston, SC: Comprehensive Solutions

In addition to electrical supplies, Palmetto Building Materials also offers a full selection of plumbing supplies in Charleston, SC. Plumbing systems are essential to the functionality of any building, and having access to high-quality plumbing materials is vital for both new installations and repairs. Our inventory includes pipes, fittings, valves, faucets, fixtures, and all the accessories needed to ensure a reliable and efficient plumbing system. We cater to both professional plumbers and DIY enthusiasts, offering expert advice and guidance to help you select the right products for your project. Whether you are working on a simple repair or a complex plumbing installation, we have the supplies you need to get the job done with confidence.

Construction Supplies South Carolina: A One-Stop Shop

Palmetto Building Materials is proud to be a one-stop shop for all your construction supplies in South Carolina. We understand the demands of the construction industry and the importance of having a reliable source for all your materials. Our extensive product range covers everything from basic building materials to specialized supplies for electrical, plumbing, roofing, and more. We are committed to providing our customers with the highest quality products at competitive prices, ensuring that your projects are completed on time, within budget, and to the highest standards.

Exceptional Customer Service and Support

At Palmetto Building Materials, we believe that our success is built on the relationships we cultivate with our customers. Our team is dedicated to providing exceptional customer service and support at every stage of your project. Whether you are a seasoned contractor or a first-time builder, we are here to assist you with expert advice, product recommendations, and personalized service. Our knowledgeable staff can help you navigate our extensive inventory, answer any questions you may have, and ensure that you find the exact materials you need. We take pride in being more than just a supplier – we are your partner in building success.

Serving South Carolina with Pride

At Palmetto Building Materials, we are proud to serve the communities of South Carolina with high-quality construction supplies and unmatched customer service. Whether you are located in Charleston, Columbia, Greenville, or anywhere in between, we are committed to providing you with the materials and support you need to complete your projects successfully. Our reputation for reliability, quality, and service has made us a trusted name in the industry, and we are dedicated to maintaining that standard with every customer we serve.

Contact Palmetto Building Materials Today

If you are in need of building supplies near me, construction materials, electrical supplies, or plumbing supplies in Charleston, SC, or anywhere else in South Carolina, look no further than Palmetto Building Materials. Contact us today to learn more about our products, services, and how we can help you achieve your construction goals. Our friendly and knowledgeable staff are ready to assist you with all your building material needs, ensuring that your projects are completed to the highest standards of quality and efficiency.

Conclusion

Palmetto Building Materials is your trusted partner for all your construction needs in South Carolina. From construction materials and building supplies to specialized electrical and plumbing supplies, we offer a comprehensive range of products to meet the demands of any project. With a commitment to quality, convenience, and exceptional customer service, we are dedicated to helping you build with confidence. Reach out to us today and discover why we are the preferred choice for contractors and homeowners alike.

0 notes

Text

Green Building Certifications: What Engineers Need to Know

Introduction Sustainable construction is no longer just a trend – it has become a necessity. With increasing climate change, rising energy costs and strict environmental regulations – green building certifications have become a must for modern construction. Green Building Certifications ensure that buildings meet high sustainability standards and reduce environmental impact and enhance the…

#Civil Engineering#Civil engineering Jobs#Construction material#Energy Efficiency#energy-efficient#Green Building#Green Building Certification#Net-Zero#Smart Building#sustainable construction

0 notes

Text

Versatile Conduction & Electric Evolution: Copper Busbar Market

According to Inkwood Research, the global copper busbar market is expected to grow at a CAGR of 6.19% from 2024 to 2032. Copper busbars are essential in electrical power distribution systems, serving as efficient conductors of electricity within various applications. These flat strips or bars, made from high-quality copper due to their excellent conductivity and corrosion resistance, are integral components in electrical panels, switchgear, and distribution boards. The superior electrical conductivity of copper ensures minimal power loss during transmission, making busbars a preferred choice for efficient energy distribution.

Additionally, copper busbars are valued for their durability and ability to withstand high currents without significant heat generation. Their versatility in busbar design and ease of installation contribute to their widespread use in diverse industries, providing a reliable and cost-effective solution for optimizing electrical power systems.

Request a FREE sample of the Copper Busbar Market: https://www.inkwoodresearch.com/reports/copper-busbar-market/#request-free-sample

Power Distribution & Energy Integration: Copper Busbar Market Applications

- Copper busbars are effective for the uninterrupted integration of renewable energy sources, such as solar and wind, into power grids.

- Beyond linking high-voltage equipment in electrical switchyards and low-voltage equipment in battery banks, copper busbars are important in the automotive and defense industries.

- Their application spans diverse environments, including factories, data centers, retail facilities, laboratories, and technology settings.

- Additionally, specific variants, like laminated busbars, are prevalent in cellular communication systems, telephone exchanges, military equipment, and power generation systems.

- Flexible busbars, on the other hand, find utility in electric, hybrid, and fuel cell vehicles, charging stations, switching cabinets, and power links for generators and transformers.

Extrusion & Rolling Phases in Copper Busbar Market

The copper busbar production cycle comprises several key steps aimed at efficient and energy-saving manufacturing, including these:

1. Initially, cathode copper undergoes melting in a preheated and dried melting device. The copper solution's surface is coated with charcoal and graphite scales, and a copper rod is drawn through a tractor using a separation and reunion approach.

2. In the subsequent phase, an oxygen-free copper rod, a byproduct of the initial process, serves as the raw material. It undergoes straightening on a dedicated device before entering a continuous extruding device for extrusion. The resulting blank is promptly cooled to 40–60°C post-extrusion at high temperatures.

3. Following this, the cooled copper busbar blank is directly fed into two rolling mills for the rolling process.

4. Ultimately, a slitting tool is employed to cut the copper busbar. This production method distinguishes itself with its coordinated procedure, efficiency, and energy-saving attributes.

5. Compared to conventional processes, it eliminates head and tail cutting in the drawing procedure, improves material utilization rates, reduces energy consumption by over 20%, and achieves a rolling yield of 90% or more.

Stay Up-to-Date with What’s Trending in the Global Copper Busbar Market: https://www.inkwoodresearch.com/global-copper-busbar-market/

Operational Resilience & Heat Management with Copper Busbar Types

Flat Busbars: Widely recognized for their excellent current-carrying capacity and ease of fabrication. Available in a range of widths and thicknesses, they can be selected based on the desired current rating.

Round Busbars: With increased surface area and enhanced heat dissipation capabilities, round busbars are ideal for high-current applications. They also exhibit greater mechanical robustness compared to flat bars.

Hollow Busbars: Similar to round busbars, those with a hollow core offer a reduction in weight without sacrificing strength or current-carrying capacity.

Shaped Busbars: Custom-designed for specific applications, these busbars feature distinct shapes. Examples include rectangular variants with rounded corners for enhanced current distribution and complex profiles made to seamlessly integrate with specific equipment.

Various copper busbar manufacturers, including ABB Ltd, Aurubis AG, Eaton Corporation Plc, Rittal, and Luvata, produce and offer a variety of busbar types, including flat busbars, round busbars, hollow busbars, and custom-shaped busbars.

Functional Aspects and Electrical Role of Copper Busbar Market

Functionally, busbars serve as conductive components, typically appearing as single or multiple copper bars, whether exposed or enclosed. These systems incorporate joints to achieve the required length and configuration, featuring multiple take-off points connected to designated equipment.

Electrically, copper busbars function as conductors or groups of conductors that gather electric power from incoming feeders and distribute it to outgoing feeders. Essentially, they serve as electrical junctions where all incoming and outgoing electrical currents converge.

Moreover, the busbar system, equipped with isolators and circuit breakers, ensures safety during faults. In the event of a short circuit, the circuit breaker promptly activates, disconnecting the faulty section of the busbar from the circuit.

Copper Busbar Market: Powering Future of EV Charging Infrastructure

The growing prevalence of electric vehicles (EVs) on a global scale reflects the essential need for a reliable EV charging infrastructure. Meeting this demand, copper busbars emerge as a solution, offering both robustness and high conductivity to manage the elevated currents associated with EV charging stations.

Effective EV charging stations rely on a dependable power distribution system in response to the increasing requirement for electric mobility. Copper busbars, capable of handling diverse loads and conducting high currents, are integral in ensuring the swift and competent charging of electric vehicles.

As the global demand for resourceful solutions in electrical infrastructure rises, copper busbars are gaining prominence. Recognized for their exceptional conductivity, durability, and energy efficiency in modern power distribution systems, they are expected to promote the copper busbar market's growth over the forecast period.

In conclusion, the copper busbar industry presents numerous opportunities for busbar manufacturers. The demand for busbars in energy distribution, particularly for high power applications, is increasing. Copper busbar sales are projected to rise, driven by the need for efficient, durable, and high-conductivity metallic bars in diverse applications. The ongoing advancements in busbar technology, including the development of laminated and flexible busbars, further highlight the potential for innovation and growth within the industry.

Frequently Asked Questions (FAQs) –

What is the significance of copper busbar plates in electrical applications?

A: Copper busbar plates are integral in establishing a resilient and reliable electricity infrastructure, thereby enhancing the efficiency of power distribution.

Which companies are prominent in the manufacturing of copper busbars?

A: ABB Ltd, Eaton Corporation PLC, Oriental Copper Ltd, Schneider Electric SE, and Siemens AG are major global manufacturers of copper busbars, ensuring the delivery of reliable and high-quality products.

0 notes

Text

Top 5 Benefits Of Using Nova Plastic Formwork In Construction

The Nova formwork is revolutionizing the construction industry. Remarkable due to its homogeneity and heat isolation features, this innovation is a breakthrough for construction. Traditional formwork in construction involves wood or metal, but plastic formworks now offer a modern alternative. The following are the highlights of the advantages of using Nova plastic formwork.

Lightweight and Easy to Handle

Nova plastic formwork is far lighter than metal and wood formwork. This makes it easy for workers to handle and install without using bulky and large equipment. Because the structure is so lightweight, it reduces labor expenses and the time required for project completion. This is a significant benefit in construction formwork, where quick installations make a big difference.

Durable and Long-lasting

Concerning the features of its application, special attention should be paid to the high durability of Nova plastic formwork. It is also resistant to relatively high loads and various unfavorable weather conditions. In this regard, as does wooden material, metal does not bend and twist once in contact with moisture.

Its high resistance to cracking makes it perfect for large-scale formwork in construction projects. When used and installed by builders and construction crews, they can be used several times, effectively saving costs and preventing wastage.

Environmentally Friendly

Sustainability is crucial nowadays. Nova plastic formwork has the advantage of minimizing waste, earning it a place in green buildings. Being reusable up to 100 times, it is eco-friendly compared to wood and metal. Its use aids in saving natural resources and demotion of forest lands. Contractors who prioritize sustainability choose Nova plastic construction formwork.

Cost-effective Solution

Nova plastic formwork allows builders to save their money. As it is reusable, it will lead to reduced costs in the future. With this formwork, builders are also denied the pricey costs of labor and replacement of materials. In addition, it has a low transport cost because it is manufactured from light materials. This makes Nova plastic formwork an economical choice for construction.

Excellent Surface Finish

Another advantage of using Nova plastic formwork is that it produces a highly smooth surface finish for the structural members. It is nonabrasive and perfect for giving a polished finish on concrete surfaces. Builders do this without additional plastering or surface finishing, saving time and money. This advantage gives Nova plastic construction formwork an edge over traditional options.

Why Choose Nova Plastic Formwork?

Nova plastic formwork is of special value for construction projects. It is assertive because it saves weight, is inexpensive, and uses a durable material. It is widely appreciated by habitat builders because of its environmentally friendly nature as well as its appealing finishing.

In the current rapidly growing construction industry, the element of simplicity and recyclability of the Nova plastic formwork makes it suitable for modern construction formwork.

Nova plastic construction formwork sets a new standard for efficient building. Its benefits promote optimality in the use of resources in construction as a career path and pro-environmentalism as well.

Each of the five benefits mentioned above makes it the number-one choice for builders all over the world. This new plastic formwork enables civil construction solutions that are faster, safer and more environmentally friendly for builders.

#nova plastic formwork#formwork construction#construction formwork#plastic formwork in india#formwork in construction#construction material#civil engineering

0 notes