#Rubber Timing Belt Manufacturers

Explore tagged Tumblr posts

Text

Anti-Aging Polyurethane Timing Belt

Boost your machinery's efficiency with high-quality rubber timing belts from our leading manufacturers! These belts are engineered for precision and durability, ensuring smooth operations in various industrial applications.

0 notes

Text

Leading Rubber Timing Belt Manufacturers - The Phoenix Industry

As par, the Rubber Timing Belt Manufacturers, The Phoenix Industry sets the industry standard with precision-engineered belts for diverse applications. With a decade of expertise, we ensure durability and optimal performance, delivering solutions that meet the highest standards of quality and reliability. Trust The Phoenix Industry for your timing belt needs.

Image reference:- https://ekcochat.com/post/269303_https-www-tpindustrialbelts-com-rubber-timing-belt-manufacturers.html

0 notes

Text

To ensure that your equipment runs effectively and efficiently, it is crucial to select the best Rubber Timing Belt Manufacturers in India that offer high-quality timing belts.

0 notes

Text

Chastity (Strade/MC)

day 12: chastity second person. same mc as this fic. cw for genital mutilation aftermath.

"There we go!"

You flinched as the metal belt clicked into place around your hips, the harsh edges pressing into your skin and threatening to slice if you moved incorrectly.

Had it been manufactured, made with care and some kind of love you didn't understand, you guessed that the metal would have been shaved down, or perhaps lined with a soft material like rubber or leather, but he wouldn't have allowed such a privilege, you knew that much.

A second belt of metal was already positioned, tightly, between your legs and locked to a loop at your tailbone, reinforced by a thick, metal locking system that turned off and on at the touch of a button, much like the collar hanging around your neck.

He had full control of each of your body, in short.

"And it's a perfect fit!" He smiled, golden eyes tracing the cold metal that now hugged your body, a little too close for comfort, his hands resting on your hips as he observed your heated expression in the mirror. "How does it feel? Are you comfortable?"

"Mm,"

Your own eyes went down to his hands, staring at the 'cage'.

You supposed you should have been grateful.

He had been good enough to stop the bleeding, after all, to seal the wound, and even cover the mess he'd made of your mangled crotch with something he'd built just for you. As far as horror stories went, he could have done much worse by now.

"It's...certainly something." You murmured.

"Something? Don't be shy to tell me, now. Does it hurt?" He stepped closer, pressing you against the mirror, the glass cool against your bare flesh, as his hand raised to your chin, forcing you to look up at him.

Into him.

"Be honest now. How do you feel?"

"Honest? You want me honest?" You murmured with a little grunt, your speech fogging up the glass as your hips jerked, metal clattering. "I feel...well, I feel pretty damn emasculated. Satisfied?"

"HA!" Strade let out a laugh, genuinely amused as opposed to anything cruel or harsh (though it was still enough to make you flinch). "Ah, I'm sorry about that, bud, but there isn't much I can do there."

It wasn't a statement of remorse, but even the sympathetic words were enough to make your stomach turn, your eyes going down to the metal bands belting up your crotch.

"Mm, I'm sure you'll get used to your new belt in time, mein herr. And hey, it matches your collar!" He teased, taking hold of the back of the belt and pulling on it, forcing your backside against his hips. "Now come on, cheer up a little bit; you're breathing, you're alive. Not many people get as far as you have!"

"NGH!" You grunted weakly at the unexpected pull (feeling the initial swellings of arousal in his khakis, too, he just loved fucking with you like this), bracing yourself with your palms against the glass. "Easy, fuck-!"

"Sorry, sorry." He chuckled apologetically as he let go of the belt, his hands running up your bristling sides to grab the underside of your collar, jerking your head up and forcing your body against his own, his other hand reaching around the front of your body and pressing against the metal cup that guarded your mutilated cock. "Can't help it, though." He muttered, his voice lowering. "You look good like this."

"S-Stop," You breathed out, your naked body trembling. "Hurts, hurts-"

"The human body is amazing, isn't it?" Strade ignored you and breathed against your neck, pressing more pressure against the metal cupping your crotch, cold and agonisingly painful as it irritated the bandaged flesh. "Here you are, standing on your two feet after I cut off your cock...mm, maybe I'm not giving you enough credit, hm?"

"Strade, I'm sorry, I'm sorry I talked back, please stop-" You babbled through grit teeth, trying to keep your whimpers and cries at the back of your throat, trying not to cry and give him what he wanted.

"Are you gonna cry?" He asked, his voice taking on a condescending lilt (though he moved his hand down to your thigh), pushing your hips back even more. "Hah, and you blame me for feeling so emasculated!"

Your expression trembled a little, your eyes squeezed shut, unable to take the curling, twisting shame settling in your gut as he taunted you.

"God, you're adorable when you're like this. So small and fragile. I really can't help but fuck with you when you react so well to it." He huffed out a chuckle, his lips trailing along the side of your neck, just above the collar, his grip on you never once loosening. "Like a porcelain doll. Hmph."

You felt a smirk grow against your neck and your eyes opened, burning with unshed tears.

"That's pretty, ah, on the nose, right? Dolls don't have any use for genitals, after all."

You tried to pull away from him, tried to hide your mutilated body (and what he'd done to cover it up) and suffer through it, suffer through the pain and burning humiliation, without his taunts to make you feel worse.

But he wouldn't let you, just holding onto you tighter as you felt the warmth of his arousal burn into your bare skin.

"What, you don't like me calling you a doll? I'm trying to give you compliments here, mein lieber." He crooned, the condescension replaced with a mocking version of sympathy, his tone akin to a parent scolding a child.

Strade then pushed you, more forcefully, against the mirror, his thick legs caging your own and forcing your chest against the cold glass, your panicked breathing fogging it up again as you were forced to stare at yourself, stare at the thing he had created from you.

Your skin was sallow and almost grey, your eyes dull and dead, your body littered with healing scars and bruises.

A fucked up kind of doll, that was for sure.

"And after I went so far out of my way to help you get presentable again." He continued, the hand not clutching your collar roaming downwards to palm your backside, groping hungrily. "Mm, shame I covered up your ass with my first prototype. though. Maybe the next one. I'll just bolt straight onto your new boy-cunt-"

"Oh god," You moaned miserably, your head tipping forward, your sweating forehead cold against the glass. "Please, no-"

"So you're all covered up for as long as I need you to be." He smirked, resting his chin on your shaking shoulder. "Good idea, eh?"

"Kill me," You pleaded softly, looking up so you could stare into his eyes through the mirror, so he could see how dead inside you already were. "Please, just kill me..."

"Kill you?" He repeated, his voice a murmur of amusement. "Mm...I'd rather not, no."

He leaned forward until his breath puffed against your ear.

"You didn't think you'd get off the hook that easily, did you?"

32 notes

·

View notes

Text

Gaetano Pesce (8 November 1939 – 3 April 2024)

Moving against the stream of rational, functional modernism in the 1960s and early 70s, Mr. Pesce experimented with materials and production methods to create furniture pieces imbued with political or religious meaning for brands from Cassina to B&B Italia.

Many would go on to become icons of Italian design including the Up5 chair – an innovative vacuum-packed chair designed to resemble a female prisoner – which he designed for B&B Italia precursor C&B.

Pesce moved to New York in 1983 and began to move away from mass production to create "standardised series" in everyday materials like resin, adapting conventional production techniques to create varied and imperfect outcomes.

The result are pieces such as the 1884 Pratt chair, which toe the line between functional design and decorative art, helping to create a new category that would later become collectible design.

Mr. Pesce was born in the Italian city of La Spezia in November 1939, only two months after the start of world war two.

As was common at the time, he trained in both architecture and design, studying first at the University of Venice and later at the Venice Institute of Industrial Design.

Among his architecture projects is the Organic Building in Osaka from 1993, with its plant-covered facade made of orange fiberglass that served as a precursor to today's vegetation-covered green walls.

But Mr. Pesce's most pioneering and well-known work happened in the world of design. In the late 1960s, he became one of the leaders of Italy's Radical Design movement, rejecting modernism's rigid focus on forms dictated by function.

Instead, Pesce focused on the idea that functional objects, much like art, could carry a deeper message.

One of the most famous examples is the controversial Up5 chair from 1969, which manufacturer B&B Italia describes as "the first product of Italian design with a political meaning".

Rest In Power !

"Up 5 & 6" Dressed Up Chair & Ottoman, 1969 – 2014, Polyurethane foam, fabric, Height: 40.5 in (102.87 cm)Width: 47 in (119.38 cm)Depth: 51 in (129.54 cm)Seat Height: 16 in (40.64 cm),

“Square Airport Lamp” (1986/1994). Photography by Elizabeth Carababas/The Future Perfect. Light sculpture consisting of a flexible rubber membrane studded with small light bulbs. Although made from a mold, no two lamps are alike, due to the imperfections that arise from the hand-mixing and pouring of colored urethane. H 92 - W 65 Cm,

"Feltri" Armchair for Cassina, 1980 -1989, Felt, Fabric, Resin, Width: 156 cm, Depth: 80 cm, Height: 129 cm, Seat height:42 cm, Courtesy: Oldera,

"Pratt Chair #7," 1984 2018 (purple), 2018, Transparent polyurethane, :93 x 53 x 53 cm. (36.6 x 20.9 x 20.9 in.),

"The Cabinet of The Tired Man," 2018, Photo: Courtesy of Salon 94 Design and Gaetano Pesce,

"Tramonto a New York" three-door screen, for Cassina, Made of coloured resin, hinges and feet in burnished brass, Width: 221, Height: 199,

"Organic" Building, Osaka, Japan, Completed in 1993 to embody the corporate ideal of Oguraya Yamamoto Co., Ltd,

"La In-Portante" Modular Bookshelf from the "Abbraccio" Series, 2010. Comprising 57 adjustable polyurethane resin shelves. Produced by Le Fablier, Italy. Polyurethane resin, painted wood, lacquered metal, 86½ x 118¾ x 16⅞ in. (219.7 x 301.6 x 42.6 cm) Courtesy of Sotheby's,

La Michetta Modular Sofa,Compostion of 8 by Meritalia, Structure in Lacquered Wood Seat with Elastic Belts, Flexible Polyurethane & Fiberfill Padding, Dimensions: W370 x D245cm,

Unique 'Ireland' table, Made of polyurethane and metal. The table was made and exhibited in 1996 by Gallery Mourmans, Knokke-Zoute, Belgium. It was part of a series of 'EU tables', where all 15 member countries were represented as a table, in this case Ireland. The top of the table has the shape of the outlines of the country and it stands on legs in the shape of question marks. W.80.71 in;H.28.74 in;D.57.09 in; (W.205 cm;H.73 cm;D.145 cm), Courtesy: Incollect.

#art#design#sculpture#furniture#seat#chair#forms#cassina#B&B#polyurethane#incollect#ireland#modular#bookshelf#table#fiberglass#sofa#gaetano pesce#rip#rip gaetano pesce#screen#iconic#up5#UP6#political#pratt chair#feltri#tramonto#new york

57 notes

·

View notes

Text

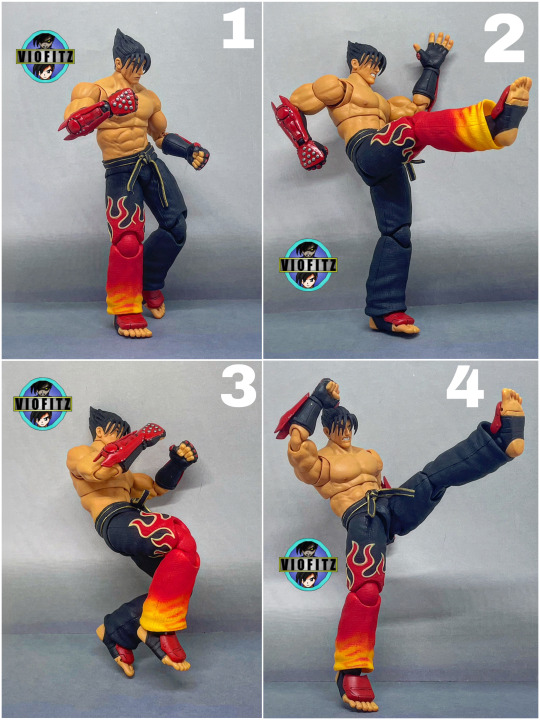

Storm Collectibles TEKKEN 7: Jin Kazama (Review)

Introduction:

Storm Collectibles is a Hong Kong based designer and manufacturer of action figures. They are known for making officially licensed, high quality collectible action figures, primary from fighting game series and iconic figures. They also have the license to make TEKKEN action figures. These figures were made into 1/12 scale with feature numerous points of articulation, interchangeable head sculpts and pairs of hands, and special fighting effect parts. This time, the review is going to focus on Jin Kazama, he was given with a standard boxart like Blue Mary. With the visible large window plastic, we can almost see the whole contents. The front part was printed with "TEKKEN 7" logo with Jin name in both japanese and romaji, his TEKKEN 7 render artwork portrait, there is age 17+ that this figure was meant for those 17 years old or above. And Bandai Namco entertainment inc logo prints. While the back part is mostly shown the figure's promotional photos showing how the figure works.

Contents:

Jin comes with his main figure, he's included with 3 interchangeable head sculpts in total, 4 pair of hands in total and an electric punch effect for his Rage Art Finisher. His background paper inside the box is a diorama stage of G Corp Helipad.

Jin is a muscular young man of Japanese ethnicity. He has black hair that spikes at the back of his head like his father Kazuya Mishima. He also sports a fringe like his mother, Jun Kazama. Jin's face also strongly resembles his mother's. One of Jin's most prominent aspects is the black tattoo-like mark on his left shoulder, a mark that Devil branded onto him. Jin is shirtless and wears black trousers with a red, orange and yellow flame design on the right pant leg and red and black footpads. He wears Mishima style red gauntlets with a triangular pattern of metallic studs on the back of the hands, resembling his father's gloves. His outfit is an updated design of his TEKKEN 6 getup which the red flame on his pants is now larger with an orange and yellow tint. He wears an black with gold trim karate belt and red and black footpads. His gauntlets now extend down his entire forearm and come to a set of spikes at the end. I gotta say, in terms of design and physical appearance Storm really nails Jin but, my only complain is only his face, I'll show the pictures below.

His articulation points consisted movable head, torso, arms with bicep cut, double jointed elbow, wrists, legs with thigh, double jointed knee, ankles and tiptoe part. Another movable part is his tied belt which you can rotate it to create his move lists with more motions. His gauntlets are movable and also removable since it's separate pieces so, we can see his bare lower arms but, removing the gauntlets is useless since there is no bare hand part for Jin and his wrist joints are black colored which they're meant to connect Jin's gauntlet gloves with his wrist parts.

Jin was included with 3 head sculpts (HS) in total, first would be his standard serious expression. Second HS is his angry expression with a heavy grit and third is even angrier with open mouth. Well, you can already tell the purpose of these expressions. His hair are not removable nor swappable so, most of his head sculpts uses the same hair mold. His hairs are mostly made from hard materials including his fringe... So, his fringe may break if I'm careless. Honestly, he looks nothing like how Jin was portrayed in the game... Despite Jin's brutal fighting style but, he got better looks than his father since he also inherits his mother's face. But, this one, he's looking like a grunt man. Although, they still captured his calm demeanor nicely....

Jin comes with 4 pair of hands in total, that would be: fisted hands which was already attached to his main figure, 2 finger gesture hands. Open splayed and open palm hands for his necessary battle poses. His hands were also made from semi flexible rubber material but, thicker. These hands are more than enough to recreate Jin's iconic poses and even his move lists.

Jin is given with punch effect since he is iconic with his punching moves so, it's kinda obvious if he comes with this. Unlike Mary's stomping effect, Jin's effect was made from a semi hard rubber material and it's a little tricky inserting Jin's arms on it. The effect was made from a semi transparent materials that is mainly red with yellow gradation to the edge. Despite the little flexibility, I kinda reluctant to use it again since several part feels breakable yet, his effect got seamlines like it was separate 2 pieces glued.

His diorama stage was a printed of the G Corporation's Helipad background which, kinda ironic since G Corp leadership is his father Kazuya. Jin was never a part of G Corp except his war involvements during his ownership in Mishima Zaibatsu.

Yes, we can make tons of his move lists even some of his classic TEKKEN 3 moves that he nolonger use in his later appearances. In TEKKEN 3, most of Jin's move lists were mixture between Heihachi, Kazuya and Jun. However, I recreated this because I grew up by playing TEKKEN 3 as my very first TEKKEN game I played and Jin was my main character, although I'm not a good player myself but, I really enjoyed that old times.

Thoughts:

Jin is my very first Storm figure collection but, his mobility is as good as Mary since Jin was designed with newer body format since Storm had been releasing many male action figures prior Jin and that includes Jin's father Kazuya Mishima and grandfather Heihachi Mishima so, I could still make tons of his iconic move lists from his game easily.

Thank youu for reading!😁🙏🏻

#action figures#toys#collectibles#storm#storm collectibles#tekken#tekken 7#jin kazama#samurai spirits#samurai shodown#bandai namco#namco#bandai#fighting games#snk#snk playmore#nakoruru#review#toy review

2 notes

·

View notes

Text

Top-Rated Cigarette Machine Parts for Long-Lasting Performance

Cigarette machines are a great investment for smokers who prefer to roll their own cigarettes, offering convenience, cost savings, and customization. However, like any machine, they require regular maintenance and occasional part replacements to ensure smooth operation and longevity.

In this guide, we’ll explore the top-rated cigarette machine parts, how they impact performance, and where to find the best quality replacements to keep your machine running efficiently.

Why High-Quality Cigarette Machine Parts Matter

Your cigarette rolling machine is designed tofill tubes quickly and evenly, providing a seamless smoking experience. But over time, frequent use can lead to wear and tear on critical components such as the injector, motor, and gears.

Here’s why using high-quality replacement parts is essential:

✔ Longer Machine Lifespan – Durable parts help prevent breakdowns and extend the machine’s usability. ✔ Better Cigarette Packing – Worn-out parts can lead to loose or unevenly packed cigarettes. ✔ Smoother Operation – Faulty components can cause jamming or inconsistent performance. ✔ Cost Savings – Replacing parts is more affordable than buying a new machine.

Now, let’s dive into the most important cigarette machine parts and what to look for when buying replacements.

Essential Cigarette Machine Parts for Optimal Performance

1. Injector Tube & Nozzle

The injector tube (or nozzle) is one of the most crucial parts of a cigarette rolling machine. It’s responsible for pushing tobacco into the cigarette tube, ensuring a firm and even pack.

Signs You Need a New Injector Tube:

Tobacco is not filling the tube evenly.

The machine jams frequently.

Cigarettes come out too loose or too tight.

💡 Pro Tip: Choose a stainless steel or high-durability plastic injector for longevity and precision.

2. Electric Motor (For Automatic Machines)

If you have an electric cigarette machine, the motoris its powerhouse. A failing motor can result in slow operation, overheating, or total machine failure.

Common Motor Issues:

The machine struggles to push tobacco into the tube.

Unusual noises or overheating.

The device stops working mid-operation.

💡 Pro Tip: Look for OEM (Original Equipment Manufacturer) motors that match your machine’s specifications to ensure compatibility.

3. Gears & Drive Belts

Gears and belts work together to rotate and push the tobacco through the machine. If these wear out, your machine may become sluggish or fail to function entirely.

Symptoms of Worn Gears & Belts:

Machine makes grinding noises.

The tobacco does not move smoothly.

Belts appear frayed or cracked.

💡 Pro Tip: Metal gears last longer than plastic ones, and reinforced rubber belts provide better durability.

4. Spring Mechanism

For manual cigarette machines, the spring mechanism ensures smooth movement and precise compression of tobacco. If the spring loses tension, the machine may become harder to operate.

When to Replace the Spring Mechanism:

The handle feels loose or does not return smoothly.

Cigarettes are unevenly packed.

The machine requires extra force to function.

💡 Pro Tip: Opt for stainless steel replacement springs for longevity and reliability.

5. Tobacco Hopper & Chamber

The tobacco hopper (or chamber) holds and distributes tobacco before it enters the rolling mechanism. Over time, residue build up and wear can reduce its efficiency.

Issues Caused by a Worn Tobacco Chamber:

Uneven tobacco distribution.

Frequent clogging or jamming.

Excess tobacco spilling from the machine.

💡 Pro Tip: Regularly clean your hopper and consider a replacement if you notice cracks or worn edges.

How to Choose the Best Cigarette Machine Parts

Now that you know which parts to look for, here are some key factors to consider when buying replacements:

✔ Material Quality – Look for stainless steel, reinforced plastic, or durable rubber components. ✔ Compatibility – Ensure the part is designed for your specific machine model. ✔ User Reviews – Check for customer feedback to gauge performance and durability. ✔ Warranty & Return Policy – Opt for brands that offer warranties for added peace of mind.

Where to Buy High-Quality Cigarette Machine Parts

Finding reliable replacement parts is crucial for keeping your machine in top shape. Here are the best places to shop:

1. Official Manufacturer Websites

Most brands offer OEM parts directly on their website, ensuring the perfect fit and top performance.

2. Online Marketplaces (Amazon, eBay, etc.)

These platforms provide a wide range of aftermarket and OEM parts, but be sure to check reviews and seller ratings before purchasing.

3. Specialty Smoke Shops

Some local and online smoke shops carry replacement parts, especially for popular machine brands.

4. Repair & Service Centers

If your machine requires more than a simple part replacement, acertified repair center can help diagnose and fix the issue.

Tips for Maintaining Your Cigarette Machine for Long-Lasting Performance

To reduce wear and tear and keep your cigarette machine running smoothly, follow these maintenance tips:

🛠 Clean your machine regularly – Remove tobacco build up to prevent clogging and ensure smooth operation. 🛠 Use high-quality tobacco – Dry, low-quality tobacco can cause jamming and increase wear on parts. 🛠 Replace worn-out parts immediately – Don’t wait until the machine breaks down completely. 🛠 Store in a dry place – Keep your machine away from moisture to prevent rust and damage.

Final Thoughts

Investing in top-rated cigarette machine parts is essential for keeping your machine efficient, reliable, and long-lasting. Whether it’s a new injector tube, motor, gears, or spring mechanism, choosing high-quality replacements will help maintain smooth performance and ensure your cigarettes are evenly packed every time.

By following proper maintenance routines and knowing where to buy durable, compatible parts, you can extend the life of your cigarette machine and enjoy a seamless rolling experience for years to come.

🚀 Need the best cigarette machine parts? Explore top-rated replacements today and keep your machine running at peak performance!

0 notes

Text

What is rubber conveyor belt splicing and what advantages does it offer?

What do heavy loads and high tensions do to your conveyor belts? The belt will show immediate signs of damage like uneven wearing or tearing. This will lead to industrial downtime. If you are tight on budget, how can you replace the belts? Instead, you can go for rubber conveyor belt splicing.

What do you mean by rubber conveyor belt splicing?

Splicing in rubber belting is the method that joins two parts of conveyor belts together. This process helps extend the conveyor belt. Besides, it can also repair damaged portions of the rubber belt conveyor. Splicing ensures that the conveyor belts are functional and efficient.

Exploring the different methods of rubber conveyor belt splicing:

Different methods join the conveyor belts together. The methods are as follows:

Mechanical splicing:

In this method, the technicians use mechanical fasteners to join the rubber belting. It allows easy assembly and disassembly of the rubber conveyor belt pieces. Thus, mechanical splicing does not consume much time.

Vulcanized splicing:

The next method is the vulcanized splicing method. In this method, they join the pieces of the rubber belting with heating and chemical bonding. Nevertheless, it is a much more complex process.

Cold bond splicing:

In this process, the technicians join the parts of the belt conveyor rubber with adhesives or chemicals. This process does not use heat.

Overlap splicing:

The overlap splicing method overlaps the ends of the rubber belting pieces and joins them. As a result, it makes the joint areas thicker.

Fabric splicing:

In this method, they join the fabric layers of the rubber belt conveyor pieces. Stitches or glue help join these layers.

Finger splicing:

The technicians cut the ends of the belts in a zigzag pattern. The patterns or "fingers" are interlocked together.

Hot melt splicing:

This splicing method uses heat and pressure to conduct the splicing. However, you should be careful and apply appropriate heat without melting the belt.

What are the advantages of a good rubber conveyor belt splicing?

High-load capacity:

Splicing the rubber conveyor belt pieces strengthens the joints. As a result, it can withstand high stress and tension without breaking down. Thus, splicing boosts the load capacity of the belts.

Enhances durability:

It helps create strong joints of the rubber belting. It does not easily damage or degrade in abrasive environments. Thus, it increases the durability of the belt.

Increases the lifespan:

Owing to the high durability due to splicing, the belts will not easily break down under stress. Hence, it will offer a long service life even in demanding industries.

Repair damaged parts:

Instead of buying a new belt, you can splice your belts. It can repair the worn-out parts of your belts.

Cost-effective:

With the help of rubber conveyor belt splicing, you do not have to replace the belt. Thus, you do not have to spend money on a new belt and its installation.

Minimize downtime:

Splicing is not time-consuming. As a result, you do not have to face downtime like regular maintenance. Your industrial processes remain uninterrupted and run smoothly.

To conclude,

Rubber conveyor belt splicing is an effective way to increase the lifespan of your belts. It will increase the durability and load-bearing capacity of the belts. Besides, it will prevent downtime in the industries. Splicing of rubber belting minimizes frequent replacements. As a result, it is a cost-effective way of dealing with your damaged belts.

Read to check some interesting FAQs!

Is the rubber conveyor belt material sustainable?

Ans: Yes, a belt rubber conveyor is sustainable. Reputed manufacturers conduct sustainable practices during manufacturing. Besides, you can recycle it to make other rubber products like rubber mats. This is an energy-efficient method of making rubber products. They may take more time to decompose, but they are biodegradable.

How do you maintain a rubber conveyor belting?

Ans: You should make sure to keep your conveyor belts clean. Regularly brush and clean your belts to avoid accumulation of dust and dirt. In addition, you should regularly check if your belts show signs of damage. Immediately repair or replace your belts if you see any damage. Avoiding this can cause operational failure and unnecessary downtime.

How do you find reliable rubber belting suppliers?

Ans: You should thoroughly check different suppliers and compare them. Quality and price are the two most important aspects to look into. The rubber belt company should have a reputation in the market. In addition, they should have quality-assured belts at a competitive price. You should check if they are providing test and warranty certificates.

#rubber belting#rubber conveyor belt#rubber belt conveyor#belt conveyor rubber#rubber belting suppliers#Rubber conveyor belting#rubber conveyor belt material#rubber belt company#6 ply rubber belt

0 notes

Text

The Phoenix Industry is a reputable rubber timing belt manufacturers in Noida, India. We offer a wide range of products designed to meet the diverse needs of businesses across various sectors, our rubber timing belts are known for their durability, reliability, and efficiency. We have resources to satisfy your particular needs, whether or not you are looking for normal timing belts.

0 notes

Text

The Ultimate Guide to Water Hose Pipe: Heavy-Duty Solutions for Industrial Applications

Industrial water hose pipes play a crucial role in various sectors, providing efficient and durable solutions for water suction, discharge, and other fluid management operations. Whether it’s a construction site, mining operation, or wastewater treatment facility, having the right water hose pipe ensures seamless performance and enhanced safety.

At Rubber Hose India LLP, we specialize in offering heavy-duty water hose pipes that are built to last. Since our establishment in 1993, we have been committed to delivering high-quality hose pipes tailored for demanding industrial applications.

Key Applications of Water Hose Pipe

Our water hose pipes are engineered for versatility and resilience, making them indispensable across multiple industries:

Water Extraction and Distribution in Drilling Projects Efficient water management is critical for large-scale construction and excavation projects. Our hose pipes enable smooth drainage and effective water separation operations.

Mining Operations Mining environments demand robust and reliable pipe solutions. Our water hose pipes are designed to handle the transfer of water and other liquids in harsh conditions, ensuring uninterrupted operations.

Sewage and Wastewater Management Our pipes excel in managing wastewater and sewage diversion, ensuring reliable performance even in challenging environments laden with muck and sludge.

Construction Projects Construction sites rely on water hose pipes for tasks such as water suction, drainage, and liquid transfer. Our products are crafted to withstand the rigors of these operations.

Superior Construction for Enhanced Durability

To meet the demands of heavy-duty applications, our water hose pipe is manufactured with premium materials and advanced engineering:

Rubber Material: A blend of natural and synthetic rubber ensures flexibility, durability, and resistance to corrosion.

Reinforcement: The hose pipes are reinforced with rubber-coated woven fabric and spiral galvanized steel wire, providing exceptional strength and flexibility.

Ends and Fittings: Available in bare or flanged ends, our hose pipes are easy to assemble and integrate seamlessly into any industrial system.

Available Sizes and Specifications

At Rubber Hose India LLP, we offer water hose pipes in a variety of sizes to cater to diverse industrial needs. Our product range includes sizes from 2 inches to 12 inches internal diameter (ID), ensuring a perfect fit for any application.

All our hose pipes adhere to IS 3549–1983 Type I, II, III specifications, guaranteeing superior durability, performance, and safety.

Why Choose Rubber Hose India LLP for Your Water Hose Pipe Needs?

As a trusted name in the industry, we bring unparalleled expertise and a commitment to excellence:

Unmatched Expertise: With over 30 years of experience, we have an in-depth understanding of industrial requirements and provide tailored solutions.

High-Quality Products: Our hose pipes are manufactured to meet the highest standards, ensuring peak performance in the toughest conditions.

Wide Product Range: From hydraulic hoses to industrial fittings and assemblies, we are your one-stop solution for all fluid handling needs.

Timely Delivery: We prioritize efficiency and ensure prompt delivery of products to keep your operations running smoothly.

Industry-Leading Brand: As one of India’s leading distributors of Gates Hoses, a globally trusted name in hoses, belts, and hydraulic systems, we uphold a legacy of quality and reliability.

Conclusion

Water hose pipe is indispensable for numerous industrial applications, ranging from construction and mining to wastewater management. At Rubber Hose India LLP, we offer high-performance water hose pipes designed to withstand the harshest conditions while delivering unmatched durability and reliability.

With a wide range of sizes and a steadfast commitment to quality, Rubber Hose India LLP is your trusted partner for all industrial fluid handling needs. Let us provide you with solutions that set the benchmark for performance and dependability.

0 notes

Text

In this blog post, we will discuss why using Rubber Timing Belts is better than using leather ones. Additionally, you will understand why rubber timing belts were a better option. We recommend reading this blog to gain a better insight.

0 notes

Text

The market for rubber timing belt manufacturers is anticipated to continue expanding in the future. The demand for dependable and effective machinery will only grow as sectors like automotive, industrial production, and printing continues to develop.

#Rubber Timing Belt Manufacturers#Rubber Timing Belt Manufacturers in India#Treadmill Belt Manufacturers#PVC and PU Conveyor Belt Manufacturers

0 notes

Text

Why Cogged Belts Are Ideal for Industrial Applications

Cogged belts, also called notched or toothed belts, have become a preferred choice for industrial applications due to their remarkable advantages over traditional rubber timing belts. Their superior performance, durability, and efficiency make them indispensable for modern machinery. Let’s explore the reasons why cogged belts are ideal for industrial use and how they enhance operations across various sectors.

Superior Power Transmission

Cogged belts feature a toothed design that engages seamlessly with pulley grooves. This secure engagement minimizes slippage and ensures efficient power transmission, making them perfect for high-torque applications. Industries like automotive, manufacturing, and heavy equipment operations benefit from the enhanced grip and energy efficiency cogged belts provide.

Resistance to Stretching

One significant issue with traditional rubber timing belts is their tendency to stretch, which can lead to timing errors and equipment failures. Cogged belts solve this problem with their precise design, ensuring minimal stretch and reliable performance even under heavy loads and high-speed operations.

Precision and Accuracy

In applications requiring exact timing, such as automated production lines and synchronized machinery, cogged belts excel. Their positive engagement with pulley grooves reduces vibration and noise, enabling smooth and stable machine operations. This precision is critical for ensuring efficiency in industrial settings.

Durability and Longevity

Made from robust materials such as neoprene and polyurethane, cogged belts are highly resistant to wear, abrasion, and chemical exposure. Their toothed design evenly distributes stress, preventing premature wear and extending their lifespan. With fewer replacements and repairs needed, industries benefit from reduced downtime and maintenance costs.

Versatility Across Industries

Cogged belts are versatile and adaptable to various industrial uses, including powering conveyors, compressors, and other machinery. Their ability to perform under extreme conditions, such as high speeds or heavy loads, makes them a reliable choice for diverse sectors like agriculture, HVAC, and manufacturing.

Energy Efficiency and Cost Savings

By eliminating slippage and maximizing power transfer, cogged belts reduce energy loss, resulting in lower operational costs. Their long service life further enhances cost efficiency, making them a wise investment for industrial facilities aiming to optimize performance.

Sustainability

Cogged belts also align with sustainability goals. Their durability reduces waste from frequent replacements, and their energy-efficient operation supports eco-friendly practices. Manufacturers are increasingly using sustainable materials to produce these belts, further contributing to environmental conservation.

Conclusion

Cogged belts are the ultimate solution for industrial applications, offering unmatched power transmission, precision, and durability. Their resistance to wear, energy efficiency, and ability to handle demanding conditions make them an excellent choice for improving machinery performance.

For high-quality cogged belts that deliver exceptional results, trust Jigna sales, a leading provider of industrial belt solutions designed to meet diverse operational needs. Explore their range today to enhance the efficiency and reliability of your industrial equipment.

0 notes

Text

V Belt Suppliers in Australia

In countless industries across Australia, from agriculture to manufacturing, the humble V belt plays a crucial role in powering machinery. These flexible, power-transmitting belts are essential for efficient operation, making reliable V belt suppliers a vital link in the supply chain. If you're searching for a V belt for sale or exploring options to buy V belt online, understanding the landscape of Australian suppliers can save you time and resources.

The Importance of Reliable V Belt Suppliers

A broken or worn-out V belt can bring operations to a standstill, resulting in costly downtime. This underscores the importance of sourcing quality belts from reputable V belt suppliers. A dependable supplier not only offers a wide range of belts but also provides expertise and support to help customers select the right product for their specific needs. This includes considerations like:

Belt Material: Different materials, such as rubber, polyurethane, and neoprene, offer varying degrees of resistance to heat, chemicals, and abrasion.

Belt Profile: The shape and dimensions of the belt (e.g., classical, narrow, banded) determine its compatibility with specific pulley systems.

Belt Length: Accurate measurement is crucial for proper tension and efficient power transmission.

Choosing the right V belt and supplier can significantly impact the performance and longevity of your machinery.

Navigating the Australian Market for V Belts

Australia has a diverse network of V belt suppliers, ranging from large national distributors to smaller, specialized businesses. When searching for a V belt for sale, consider the following avenues:

Industrial Supply Companies: These companies typically offer a wide range of industrial products, including V belts, bearings, and other power transmission components. They often cater to a broad customer base across various industries.

Specialized Belt Suppliers: Some suppliers focus specifically on belts and related products. They often possess in-depth knowledge and can provide expert advice on belt selection and application.

Online Retailers: The convenience of V belt online purchasing has become increasingly popular. Online platforms offer a vast selection of belts from various manufacturers, often at competitive prices.

Key Considerations When Choosing a V Belt Supplier

Selecting the right V belt suppliers can be a strategic decision that impacts the efficiency and reliability of your operations. Here are some key factors to consider:

Product Range: Does the supplier offer a comprehensive selection of V belts in various sizes, profiles, and materials?

Product Quality: Are the belts sourced from reputable manufacturers known for their quality and durability?

Technical Expertise: Can the supplier provide technical support and advice on belt selection, installation, and maintenance?

Pricing and Availability: Are the prices competitive, and are the belts readily available or subject to long lead times?

Customer Service: Does the supplier offer prompt and responsive customer service?

The Rise of Online V Belt Purchasing

The digital age has transformed how businesses source industrial products, and V belt online purchasing has become increasingly common. Online platforms offer several advantages:

Convenience: Browse and compare products from multiple suppliers from the comfort of your office or workshop.

Wide Selection: Access a vast inventory of V belts from various manufacturers, often exceeding the stock of local suppliers.

Competitive Pricing: Compare prices from different vendors and potentially find better deals online.

Fast Shipping: Many online retailers offer fast and reliable shipping across Australia.

However, when opting to buy V belt online, it's crucial to ensure you're dealing with a reputable vendor and that you accurately identify the required belt specifications.

Making the Right Choice

Finding the right V belt suppliers in Australia is essential for maintaining efficient and reliable operations. By considering the factors outlined above and exploring the available options, you can secure a reliable source of quality V belts and minimize downtime. Whether you choose to work with a local supplier or buy V belt online, prioritizing quality, expertise, and reliable service will ensure you get the right fit for your needs.

1 note

·

View note

Text

Automotive Engine Belt & Hose Market To Witness the Highest Growth Globally in Coming Years

The report begins with an overview of the Automotive Engine Belt & Hose Market 2025 Size and presents throughout its development. It provides a comprehensive analysis of all regional and key player segments providing closer insights into current market conditions and future market opportunities, along with drivers, trend segments, consumer behavior, price factors, and market performance and estimates. Forecast market information, SWOT analysis, Automotive Engine Belt & Hose Market scenario, and feasibility study are the important aspects analyzed in this report.

The Automotive Engine Belt & Hose Market is experiencing robust growth driven by the expanding globally. The Automotive Engine Belt & Hose Market is poised for substantial growth as manufacturers across various industries embrace automation to enhance productivity, quality, and agility in their production processes. Automotive Engine Belt & Hose Market leverage robotics, machine vision, and advanced control technologies to streamline assembly tasks, reduce labor costs, and minimize errors. With increasing demand for customized products, shorter product lifecycles, and labor shortages, there is a growing need for flexible and scalable automation solutions. As technology advances and automation becomes more accessible, the adoption of automated assembly systems is expected to accelerate, driving market growth and innovation in manufacturing. Automotive Engine Belt & Hose Market Size, Share & Industry Analysis, By Belt Type (Timing Belt, Drive Belt), By Hose Type (Turbocharger, Heating/Cooling, Fuel Delivery, Steering, Braking), By Vehicle Type (Passenger Car, LCV, HCV) Others and Regional Forecast, 2021-2028

Get Sample PDF Report: https://www.fortunebusinessinsights.com/enquiry/request-sample-pdf/101975

Key Strategies

Key strategies in the Automotive Engine Belt & Hose Market revolve around optimizing production efficiency, quality, and flexibility. Integration of advanced robotics and machine vision technologies streamlines assembly processes, reducing cycle times and error rates. Customization options cater to diverse product requirements and manufacturing environments, ensuring solution scalability and adaptability. Collaboration with industry partners and automation experts fosters innovation and addresses evolving customer needs and market trends. Moreover, investment in employee training and skill development facilitates seamless integration and operation of Automotive Engine Belt & Hose Market. By prioritizing these strategies, manufacturers can enhance competitiveness, accelerate time-to-market, and drive sustainable growth in the Automotive Engine Belt & Hose Market.

Major Automotive Engine Belt & Hose Market Manufacturers covered in the market report include:

Some of the major companies that are present in the automotive engine belt & hose market include Toyoda Gosei Co. Ltd., Continental AG, Yokohama Rubber Co. Ltd., Sumitomo Riko Co. Ltd., Pinafore Holdings B.V., Schaeffler AG, Cooper Standard Holdings Inc., Bando Chemical Industries Ltd., Hutchinson SA. and Nichirin Co. Ltd. among the other players.

Hoses are made up of various materials depending on their application inside the vehicle. In recent years serpentine belts are used to deliver power to the cooling fan, air conditioning compressor, power steering pump, and air injector pump.

Trends Analysis

The Automotive Engine Belt & Hose Market is experiencing rapid expansion fueled by the manufacturing industry's pursuit of efficiency and productivity gains. Key trends include the adoption of collaborative robotics and advanced automation technologies to streamline assembly processes and reduce labor costs. With the rise of Industry 4.0 initiatives, manufacturers are investing in flexible and scalable Automotive Engine Belt & Hose Market capable of handling diverse product portfolios. Moreover, advancements in machine vision and AI-driven quality control are enhancing production throughput and ensuring product consistency. The emphasis on sustainability and lean manufacturing principles is driving innovation in energy-efficient and eco-friendly Automotive Engine Belt & Hose Market Solutions.

Regions Included in this Automotive Engine Belt & Hose Market Report are as follows:

North America [U.S., Canada, Mexico]

Europe [Germany, UK, France, Italy, Rest of Europe]

Asia-Pacific [China, India, Japan, South Korea, Southeast Asia, Australia, Rest of Asia Pacific]

South America [Brazil, Argentina, Rest of Latin America]

Middle East & Africa [GCC, North Africa, South Africa, Rest of the Middle East and Africa]

Significant Features that are under offering and key highlights of the reports:

- Detailed overview of the Automotive Engine Belt & Hose Market.

- Changing the Automotive Engine Belt & Hose Market dynamics of the industry.

- In-depth market segmentation by Type, Application, etc.

- Historical, current, and projected Automotive Engine Belt & Hose Market size in terms of volume and value.

- Recent industry trends and developments.

- Competitive landscape of the Automotive Engine Belt & Hose Market.

- Strategies of key players and product offerings.

- Potential and niche segments/regions exhibiting promising growth.

Frequently Asked Questions (FAQs):

► What is the current market scenario?

► What was the historical demand scenario, and forecast outlook from 2025 to 2032?

► What are the key market dynamics influencing growth in the Global Automotive Engine Belt & Hose Market?

► Who are the prominent players in the Global Automotive Engine Belt & Hose Market?

► What is the consumer perspective in the Global Automotive Engine Belt & Hose Market?

► What are the key demand-side and supply-side trends in the Global Automotive Engine Belt & Hose Market?

► What are the largest and the fastest-growing geographies?

► Which segment dominated and which segment is expected to grow fastest?

► What was the COVID-19 impact on the Global Automotive Engine Belt & Hose Market?

Table Of Contents:

1 Market Overview

1.1 Automotive Engine Belt & Hose Market Introduction

1.2 Market Analysis by Type

1.3 Market Analysis by Applications

1.4 Market Analysis by Regions

1.4.1 North America (United States, Canada and Mexico)

1.4.1.1 United States Market States and Outlook

1.4.1.2 Canada Market States and Outlook

1.4.1.3 Mexico Market States and Outlook

1.4.2 Europe (Germany, France, UK, Russia and Italy)

1.4.2.1 Germany Market States and Outlook

1.4.2.2 France Market States and Outlook

1.4.2.3 UK Market States and Outlook

1.4.2.4 Russia Market States and Outlook

1.4.2.5 Italy Market States and Outlook

1.4.3 Asia-Pacific (China, Japan, Korea, India and Southeast Asia)

1.4.3.1 China Market States and Outlook

1.4.3.2 Japan Market States and Outlook

1.4.3.3 Korea Market States and Outlook

1.4.3.4 India Market States and Outlook

1.4.3.5 Southeast Asia Market States and Outlook

1.4.4 South America, Middle East and Africa

1.4.4.1 Brazil Market States and Outlook

1.4.4.2 Egypt Market States and Outlook

1.4.4.3 Saudi Arabia Market States and Outlook

1.4.4.4 South Africa Market States and Outlook

1.5 Market Dynamics

1.5.1 Market Opportunities

1.5.2 Market Risk

1.5.3 Market Driving Force

2 Manufacturers Profiles

Continued…

About Us:

Fortune Business Insights™ delivers accurate data and innovative corporate analysis, helping organizations of all sizes make appropriate decisions. We tailor novel solutions for our clients, assisting them to address various challenges distinct to their businesses. Our aim is to empower them with holistic market intelligence, providing a granular overview of the market they are operating in.

Contact Us:

Fortune Business Insights™ Pvt. Ltd.

US:+18339092966

UK: +448085020280

APAC: +91 744 740 1245

#Automotive Engine Belt & Hose Market#Automotive Engine Belt & Hose Market Share#Automotive Engine Belt & Hose Market Size#Automotive Engine Belt & Hose Market Trends#Automotive Engine Belt & Hose Market Insights

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] From the manufacturer Pull Up Training Using Resistance Bands, pull-ups are highly beneficial if you're trying to build muscular strength and endurance to progress to bodyweight pull-ups. Perform Yoga Resistance Bands Help Us Stabilize Joint Activity Through Isometrics also Helps To Control Our Movements By Moving Against An External Force. Stretch & Strength Resistance Bands help activate and tone the muscles, building strength along the way. If you have about as much flexibility as a wooden board, resistance bands are going to be your BFF for stretching. Attach With Equipments Just Attach the Band with Your Favourite Gym Equipement To Enhance the Stabilty & Strength Of The Workout. FitBox Sports Resistance bands can assist you with your mobility training. Stretch the hamstrings, arms, shoulder muscles and back. FitBox Sports Resistance Bands Not only can you train at home or at the gym, you can also go outside and train for fresh air. Made with 100% Natural Rubber. The sturdy band combines the best of elasticity, weight-resistant strength, and reliable support for optimal results and long-lasting performance. Natural and Solid: Resistance band is created from 100% natural rubber and the thick working out band furthermore features a strong tear resistance, which does presently not wreck without issues can make certain your assurance at the same time as working out. Multi-Functional Resistance Bands: Resistance bands can used for multiple exercises, such as strength training, assisted pull-ups, basketball tension training, warm-ups etc. Compact and portable: exercise belts take up little space. You can use the exercise band for training anytime and anywhere, be it in the gym, at home or even while traveling. It's perfect for casual sports enthusiasts. [ad_2]

0 notes