#Rock Drill

Explore tagged Tumblr posts

Text

Jacob Epstein’s “Rock Drill” 1913-15

Much has been written about the figure, its symbolism at a time of war (the machine gun like rock drill itself), its gender (the drill is obviously a huge phallus and yet, on close examination, the figure shields a foetus of the species between its ribs)

Torso in Metal from the Rock Drill

“Torso” is thought by many to reflect Epstein’s revulsion at the maiming and butchery of soldiers in this new and deadly form of mechanised warfare. The white plaster figure straddling the rock drill has lost both legs, one arm and a lower arm, but the foetus remains safe.

Vorticists exploring questions of embodiment, transformation and the fusion of human & machine over a century ago.

Y'all are acting like the giant robot fandom invented the eroticism of the machine when I've literally met self-taught mechanics who talk about working on their shitty cars in exactly the same way. When you've heard somebody wax rhapsodic about the transformational power of being shoulder-deep in a 1993 Ford Taurus, seeing folks on Tumblr shitpost about roboticising their genders just ain't that unusual.

#Mecha#The Eroticism of the Machine#Mecha as Embodiment#Human/Machine Fusion#Rock Drill#Torso in Metal from the Rock Drill#Jacob Epstein

5K notes

·

View notes

Text

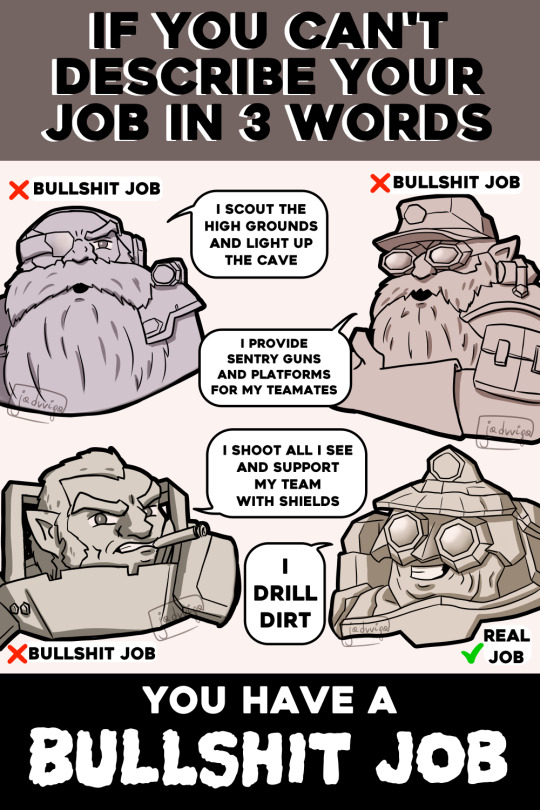

the classes of all time ⛏️

#deep rock galactic#deep rock#drg#drg engineer#drg scout#drg gunner#drg driller#video game#video game memes#was gonna do full color but then went with friends advise#to leave it sepia-low-saturated like#and ngl i really#*dig* the final result heehee#you know the drill#ok i stop now#rock and stone

753 notes

·

View notes

Text

Day 13!

A short little animation thing of Rock using Quake Drills, which is Tempo’s Special Tool/Weapon. If he uses it for too long, he’ll start behaving like Tempo as well due to the fact that his processor has a tendency to download extra Data when copying.

This was maybe a bit of a stretch but I had very few ideas on what to do here lol

#sibling shuffle au#mega man au#mega man classic#megaman#my art#rock light#Quake drills#Edit:#flashing light#I FORGOT TO TAG THAT HOLY FRICK#THANK YOU FOR REMINDING ME @DARKWOLF13#Rocktober#rocktober 2024

63 notes

·

View notes

Text

kuwabara suffering during ep 89 for 10 minutes gay thumbnail + alt that was too complicated for the youtube

#i am once again making niche yyh content for like 4 ppl on youtube#been meaning to make this one for a while phew. anyway it's got captions and everything (all my videos do actually) so. ow my wrist basical#ly. anyway yeah wahoo rock on#yyh#yu yu hakusho#kuwameshi#kazuma kuwabara#yusuke urameshi#etc etc you know the drill#this one is profoundly self indulgent but that's what it's for babeyy#if you don't have this scene playing in your head all the time here's a fun fact: all 27 or so of the images in the tv on the right#are from ep 89 because like i said he is suffering. he is in agony etc

73 notes

·

View notes

Text

#mega man#megaman#rock man#mm#rockman#mega man classic#elec man#fire man#heat man#bright man#block man#quick man#flash man#bubble man#crystal man#drill man#crash man

55 notes

·

View notes

Text

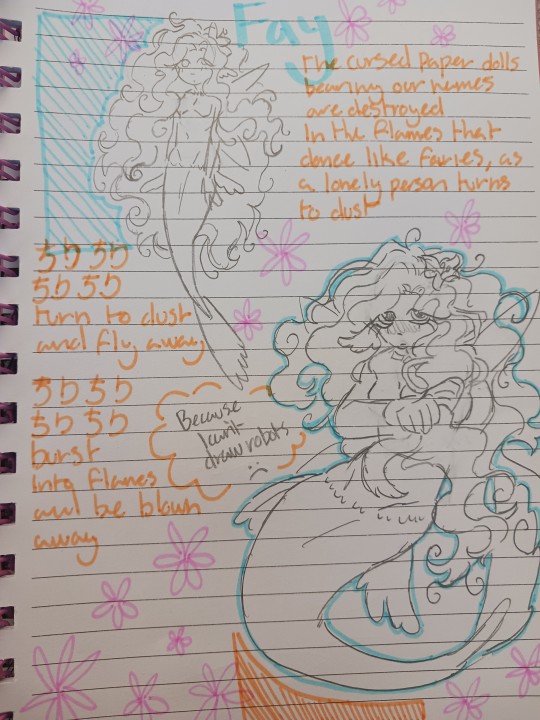

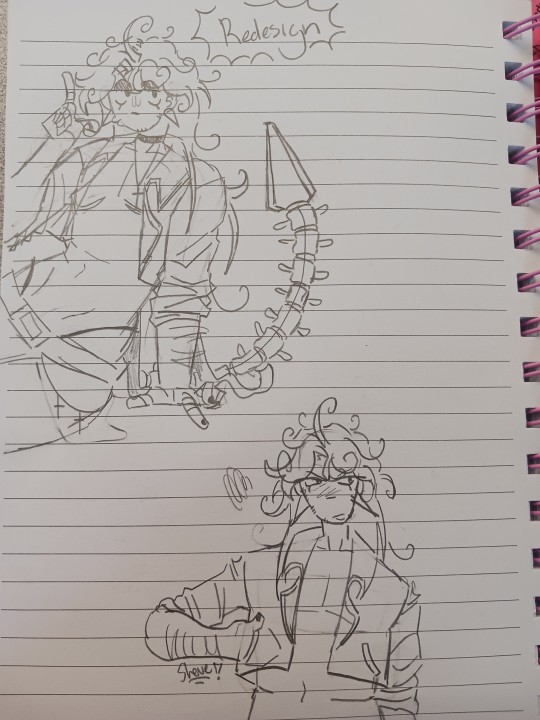

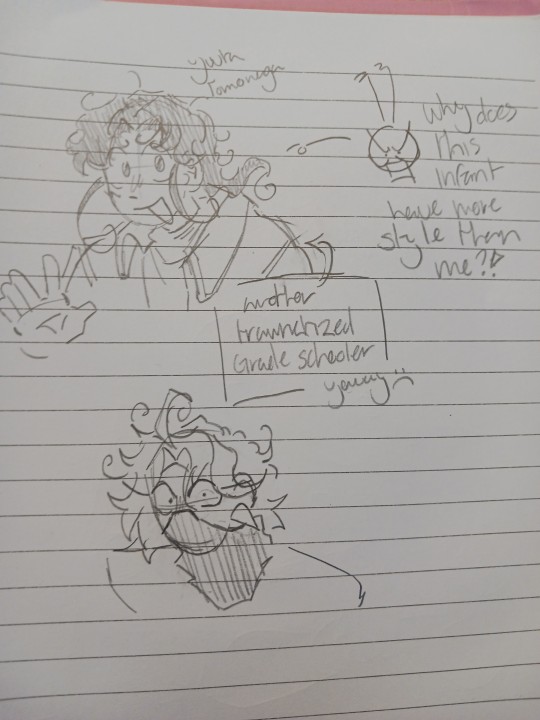

Roll concept art and some other doodles, everything for this Megaman AU

#mechanical drawings#robot art#artists on tumblr#art#traditional art#alternate universe#taking commissions#megaman#megaman art#mega man#rock man#rockman#roll#roll megaman#megaman roll#protoman#bass#dr. wily#dr. light#turboman#dust man#woodman#drill man#metal man

53 notes

·

View notes

Text

No undo button, we die like the kings of hyrule

#they die a lot#ok small rant but do you know how hard it is for me to understand the undo button?#I carve eggs. EGGS.#my primary form of art for years has been on something that's very breakable- but also every stroke I make is completely irreversible#I can't erase a layer of eggshell I carved and I can't cover it up or like. add more eggshell on top of it fhcjdhxudjd#same with etching glass- I can't undo anything there#the closest I've gotten to an erase button before is carving rocks- which you can't take back a stroke but won't really be visible#unless it's really deep and intentional#and I can erase pencils if I sketch it out on an egg first#but other than that it's just. if I make a stroke in art in my mind it's there permanently because there's no going back#If my drill skids across an eggshell while I'm doing it I change the entire design to accommodate that and make the mark look intentional#so this undo button thing makes no sense to me!! If I make a mistake should I not just keep going??? and find ways to work around it#because that's what I have to do with eggs#Also there's layers- and doing layers in digital art is actually easy for me to grasp because I've carved emu eggs#(emu eggs have different tiny layers of colour I can carve through)#but the undo button can die by my blade#like the kings of hyrule to gavondoofies. yes.#personal#lol????

28 notes

·

View notes

Text

#I know too much about seed drills and agriculture inventions#and there’s one person to blame#funnily enough not Ian this time#but the guy that was studying history and gave them the name#jethro tull#ian anderson#prog rock

25 notes

·

View notes

Text

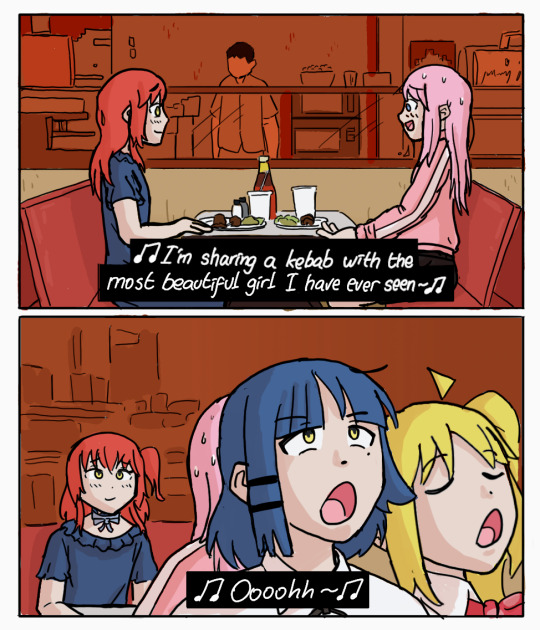

Some old Bocchi arts before I went back to this site

#bocchi the rock#bocchi the rock!#contains references of:#flight of the conchords#barbie#itysl#marc rebillet#planet of the bass#the drill version of adele's hello

207 notes

·

View notes

Text

Best holiday wishes from Tennessee ~ Happy New Year ❤️

#donald trump#trump#president trump#elvis presley#elvis the king#elvis history#elvis fans#2a#nra#happy new year#happy new month#tennessee#memphis#nye#usa#america#graceland#mississippi#punk rock#rock n roll#hip hop#street style#gangsta rap#gangster#rap#pooh shiesty#memphis rap#death row#snoop dogg#drill rap

18 notes

·

View notes

Note

Rock Crush definitely seems like an orphan that Glober took in.

Honestly what I love about Rock Crush and Glober is that they knew eachother before Machina blew up. They left together, albeit in different pods, and I’ve always assumed that Glober had been taking care of Rock Crush for a while.

I wouldn’t be surprised that Rock Crush was a scared and lonely kid who Glober picked up off the streets and said ‘yeah you’re coming home with me’. He has an affinity for bonding with misfits and outcasts given that he is one. I love it so much.

But yeah i definitely think Glober took it upon himself to take care of this kid when he had no one else , it’s a very Glober thing to do. Get adopted, loser.

#je sees the little mole all scared and cold and he’s like I have room for one more#every day I think of when Rock Crush crashed on earth and drilled into the underground cable he screamed for Glober#I cry every time#my poor baby#:(( my baby#Glober takes one look at a weird little guy and decides to bond with them#did that to Deep Bite too#I bet he wouldn’t leave the guy alone until he let him be friends with him#love them so much your honor#mars blurbs#Metal cardbot#Metal cardbot S#메탈카드봇#메탈카드봇S

14 notes

·

View notes

Text

The 90s MV Melee - round 1 match 63

youtube

youtube

TW for flashing imagery in the Aphex Twin video; also it is quite scary so be forewarned!

Voter-submitted propaganda:

Man-Size -

"LOVE HER LOVE HER LOVE HER LOVE HER LOVEEEEE HERRRRRRRRRR best music video of hers i think i love the black and white and when her earring falls off and the look on her face yay pj harvey :D"

Come To Daddy -

"It’s the scariest video ever!"

"SCARY!!! WHAT THE FUCK"

#the 90s mv melee#round 1#poll#polls#music poll#90s music#90s#aphex twin#90s electronic#electronic music#drill and bass#breakbeat#pj harvey#polly jean harvey#alternative rock#indie rock#music video#Youtube

36 notes

·

View notes

Text

Oh to be a baby elf dreaming of a 2025 Dewalt 60v cordless drill for Christmas to make the best rocking horse you've ever seen.

#art#doodle#drawing#ratatheart#rat at heart#elf#baby#baby elf#dream#dewalt#cordless drill#rocking horse#toy maker#toys

11 notes

·

View notes

Text

Welcome to the stupidest rescue bots au.

They stick megs on rescue force sigma-17 instead of exiling him

Arguably, this is worse than exile.

#rescue bots#tfp#megatron#bonus optimus for the prime enjoyers#he has a drill instead of the fusion cannon bc the rb megstron toy that exists for some reason has one#i think its a good replacement tbh#still a big scary weapon but at least he could use ut for rescue work#given the amount of cave ins on griffin rock#maccadam

54 notes

·

View notes

Text

Do you guys think Ingo had a gliscor because it vaguely reminded him chandelure? They both more or less have the same color palette…

#pokemon#submas#pokemon submas#submas ingo#subway boss nobori#subway boss#subway boss ingo#subway master ingo#warden ingo#chandelure#gliscor#i was fish-smacked with the idea just now#HOLY SHIT MAGNEZONE = KLINKLANG?? SAME DUAL TYPE..#tangrowth = garbodor(size and general body shape)#machamp = haxorus(height)#alakazam = excadrill(spoons are drills??)#probopass = crustle(rock types..)#holy shit his entire hisuian team are all vaguely reminiscent of his unovan team…#im not crying you are

51 notes

·

View notes

Text

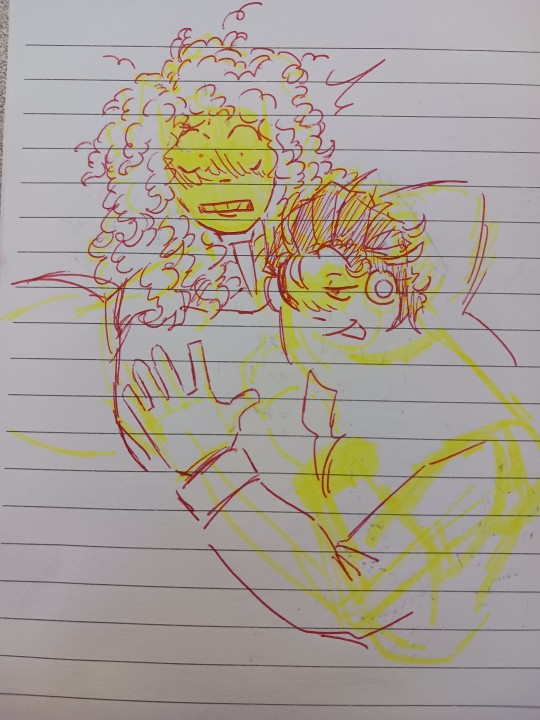

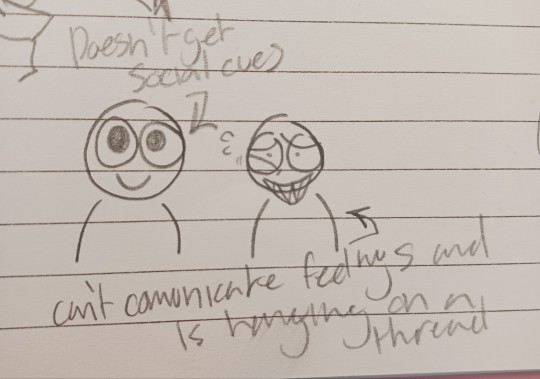

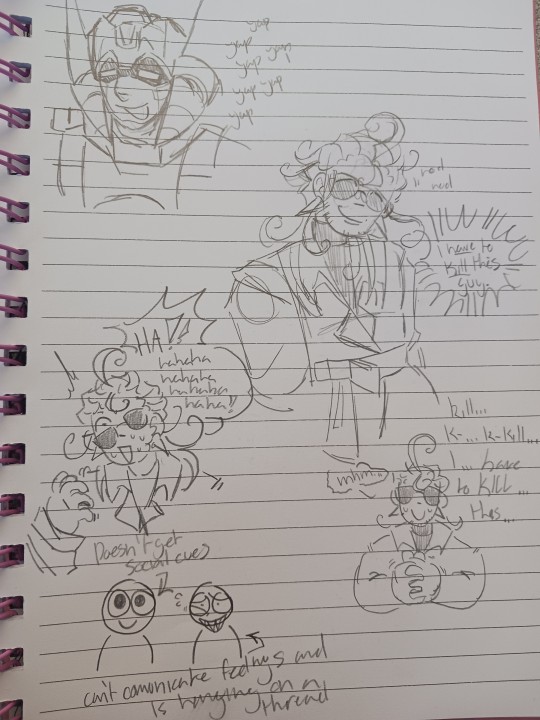

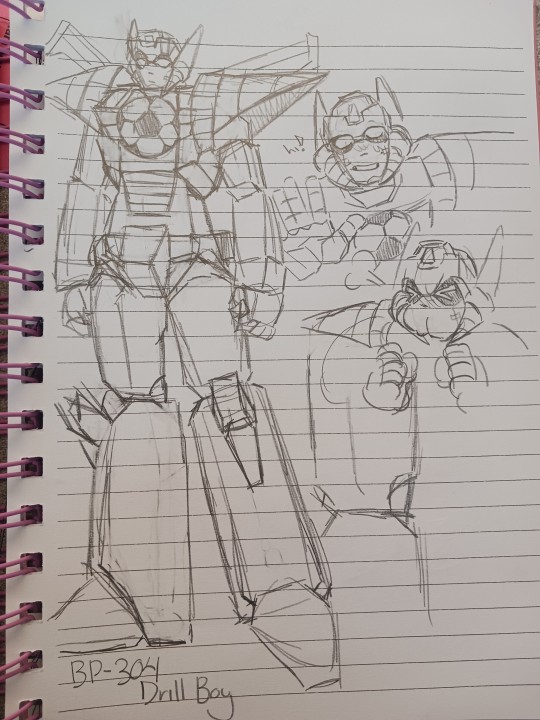

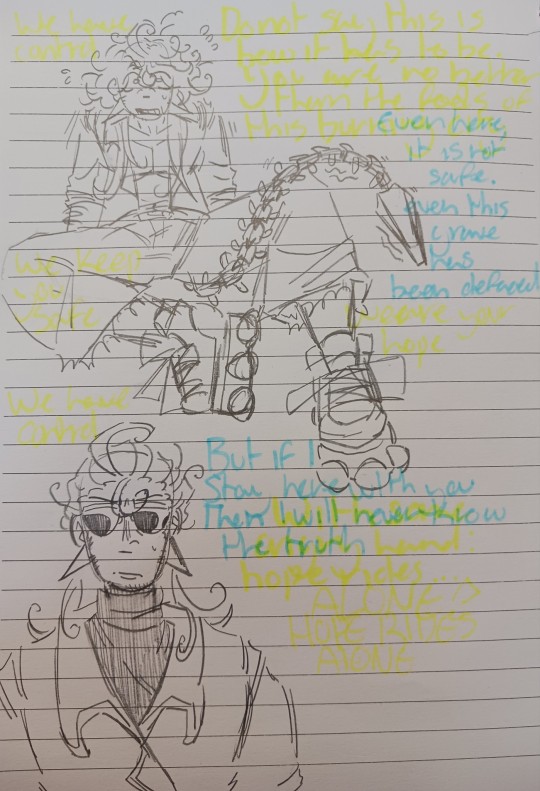

I'm tweaking, guys... These robots, guys......

#art dump#doodles#just...... everything from this week ig#mega man#megaman#rock man#rockman#mm#mega man classic#brave police j decker#bpjd#bpjd drill boy#drill boy#bpjd yuuta#yuuta tomonaga#bpjd fay#fay#protoman#protoman megaman#blues light#blues megaman#fire man#fireman#elecman#elec man#fireelec#oc#oc doodles#IDK

49 notes

·

View notes