#Recycled Polyethylene Terephthalate share

Text

Recycled Polyethylene Terephthalate Market - Forecast (2024 - 2030)

Recycled polyethylene terephthalate Market Overview

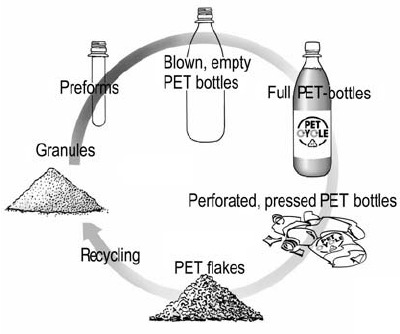

The Recycled polyethylene terephthalate market size is estimated to reach US$16.5 billion by 2030, growing at a CAGR of 6.4% from 2024 to 2030. Polyethylene terephthalate (PET) is a recyclable plastic resin and a form of polyester. PET polyester is composed of ethylene glycol (EG) and terephthalic acid (TPA), also known as purified terephthalic acid (PTA). Recycled polyethylene terephthalate is used in plastic bottles and food containers due to its protective properties. Once the original PET containers are used by consumers, they undergo a recycling program in a facility that cleans and transforms the plastic into rPET flakes and pellets. The rPET flakes and pellets can then be reused to make new products, such as plastic for food and beverage containers, fiber for clothing and carpets, and others. Recycled polyethylene terephthalate is environmentally friendly because it has a lower carbon footprint than virgin polyethylene terephthalate. According to the PET resin association (PETRA), more than 1.5 billion pounds of used PET bottles and containers including beverage bottles and containers are recovered in the United States each year for recycling. The increased demand for beverage bottles and containers made of recycled polyethylene terephthalate (rPET) will drive the recycled polyethylene terephthalate industry in the forecast period. The increase in recycling programs like the recycling and litter prevention program 2021 program by the United States environmental protection agency (EPA), will drive the recycled polyethylene terephthalate market.

COVID-19 Impact

The COVID-19 had negatively impacted the recycled polyethylene terephthalate market. This is because of the challenges faced during 2020, due to the closure of recycling centers and disruption in curbside recycling because of lockdown conditions. According to a report by National Association for PET container Resources (NAPCOR), the recycling rate for the highly recyclable plastic resin PET plastic bottles made of highly recyclable plastic resin in the U.S. stood at 26.6% in 2020, down from the rate of 27.9% in 2019. Additionally, the collection of PET bottles recorded a marginal decline of 2.3% in the U.S during 2020. With this decline in the recycling rate of polyethylene terephthalate, there was a decline in the recycled polyethylene terephthalate market.

Report Coverage

The report: “Recycled Polyethylene Terephthalate Market– Forecast (2024-2030)” by IndustryARC covers an in-depth analysis of the following segments of the Recycled polyethylene terephthalate industry.

By Product Type: Colored Recycled Polyethylene Terephthalate, Clear Recycled Polyethylene Terephthalate

By Application: Textile Fiber (Clothing, Shoes, Bags, Carpet, Others), Sheet and Films, Industrial Strapping, Food and Beverage (Food Containers, Beverage Bottles), Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium, and Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia, and New Zealand, Indonesia, Taiwan, Malaysia, and Rest of APAC), South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), Middle East (Saudi Arabia, UAE, Israel, Rest of the Middle East) and Africa (South Africa, Nigeria, Rest of Africa)

Request Sample

Key Takeaways

The increased demand for food and beverage containers and bottles made of recycled polyethylene terephthalate (rPET) will drive the recycled polyethylene terephthalate Market.

The increased use of clear recycled polyethylene terephthalate made of highly recyclable plastic resin by beverage manufacturers like Coca-Cola will increase the growth of the recycled polyethylene terephthalate market.

North America will be the fastest-growing region in the recycled polyethylene terephthalate market due to the increased demand for bottled water.

Recycled Polyethylene Terephthalate Market Segment Analysis – By Product Type

Clear recycled polyethylene terephthalate holds the largest share in the recycled polyethylene terephthalate market and is expected to grow at a CAGR of 5.9% during the forecast period. Clear rPET made by recycling plastic resin has low energy requirements and provides easy bottle-to-bottle recycling. Additionally, clear rPET is highly durable, lightweight, and non-reactive and thus food and beverage manufacturers prefer clear flakes to produce containers and bottles, compared to colored. According to a news article by Coco-Cola Company, Sprite will soon launch a 13.2-oz bottle which is a 100% rPET clear bottle in the Northeast, California, and Florida. All Sprite packaging will transition to clear packaging, which is easier to be recycled and remade into new bottles, by the end of 2022. Thus, due to the wide use of clear rPET flakes by major players in the beverage industry, there will be increased growth in the Recycled polyethylene terephthalate Market in the forecast period.

Inquiry Before Buying

Recycled Polyethylene Terephthalate Market Segment Analysis – By Application

Bottles and containers are the fastest-growing segment in the recycled polyethylene terephthalate market and is expected to grow at a CAGR of 6.9%. Recycled polyethylene terephthalate (rPET) which is made by recycling plastic resin polyethylene terephthalate, is ideally suitable for a variety of food and beverage applications including bottled water, carbonated soft drinks, juices, fruit, baked goods, and others. It is mainly used in bottles, thermoformed containers, and films, as well as other containers. This is because rPET has higher package performance because of its higher intrinsic viscosity (IV) and also has reduced CO2 emission during the manufacturing process. According to an article by Natural mineral water’s Europe organization, nestle Water is accelerating the use of recycled materials for the bottles of its natural mineral water lines to have all of its bottles contain rPET by the end of 2021. This is a major step toward Nestle Waters goal of achieving carbon neutrality in the upcoming years. Thus, the increased use of recycled polyethylene terephthalate in food and beverage containers and bottles will drive the recycled polyethylene terephthalate market in the forecast period.

Recycled Polyethylene Terephthalate Market Segment Analysis – By Geography

North America held a significant share in the recycled polyethylene terephthalate market in 2021. This is due to the rise in demand for bottled water across this region. According to the Beverage Marketing Corporation (BMC)- the US, the annual sales of bottled water increased by 4.7% in 2020 and the consumption grew by 4.2%. There are many bottled water companies like Bisleri, that have been voluntary including rPET in their containers by recycling plastic resin polyethylene terephthalate. They offer their product in containers that are made of 50, 75, or even 100 percent rPET. Thus, the growth of bottled water in the North American region will increase the growth of the recycled polyethylene terephthalate Market.

Recycled Polyethylene Terephthalate Market Drivers

Increasing growth in beverage containers in the North America region

There has been significant growth in the demand for beverage containers in the North American region. According to an article by Beverage Marketing Corporation USA, in 2020, there has been an increase in the market share of bottled water from 14.1 percent to 23.6 percent and Carbonated soft drinks share has increased by 18.3 percent. This is because rPET bottled water’s packaging has a negligible environmental footprint when compared to other packaging types including aluminum, glass, paperboard cartons, and even PET soda bottles. Owing to the demand for beverage bottles in North America, there will be increased use of Recycled polyethylene terephthalate which will drive the Recycled polyethylene terephthalate Market.

Schedule a Call

Growing recycling programs will drive the recycled polyethylene terephthalate market.

Owing to several recycling programs, there will be a growth in the supply of rPET. For instance, the United States Environmental Protection Agency (EPA) came up with EPA Recycling and Litter Prevention Program 2021 program which helps support businesses and academic institutions to initiate recycling programs, encourage sustainable practices, and support litter prevention efforts. The U.S. recycling infrastructure and programs will influence the amount of PET that is available to facilities to help them produce rPET made out of these plastic resins. According to an article by the International bottled water association, the association has approved an innovative framework for a material recovery program that helps in developing new, comprehensive solutions which to increase recycling processes throughout the United States.

Recycled Polyethylene Terephthalate Market Challenges

An increase in the amount of contamination is a major challenge for the recycled polyethylene terephthalate market

The increase in the amount of contamination is a major challenge for the recycled polyethylene terephthalate market. This is due to the rise in the proportion of inhomogeneous components in the material flow. According to an article by Food Packaging Forum, higher levels of particle contamination were found in rPET which is produced by recycling plastic resin polyethylene terephthalate, as compared to virgin PET, as well as in rPET originating from co-collection systems compared with rPET from mono-collection systems. Particle contamination is found to be directly correlated with the haziness and color parameters of PET bottles. The packaging market continues to grow at a strong pace, with a steady beat of new products using new designs and materials. This has led to greater difficulty in separating different resin types and thus increased contamination which results in loss of materials and utilization rates.

Recycled Polyethylene Terephthalate Industry Outlook

Technology launches, acquisitions, and R&D activities are key strategies that are adopted by the dominant players in this market. Recycled polyethylene terephthalate top 10 companies include:

Ulsan Chemical Co. Ltd.

OCI Materials Co.

Formosa Plastics Corporation U.S.A.

Mitsui Chemicals Inc

SK Materials Co. Ltd.

Linde plc

Central Glass Co Ltd

Shandong FeiYuan Technology Co. Ltd.

Liming Research Institute of Chemical Industry Co. Ltd.

Navin Fluorine International Limited

Buy Now

Acquisitions/Technology Launches

In August 2020, Indorama Ventures Public Company Limited (IVL), a major player in the recycled polyethylene terephthalate market, announced that it has entered into an acquisition with Industrie Maurizio Peruzzo Polowat, a PET recycling facility in Poland. This acquisition will consist of production sites having a combined capacity of 25,353 tons of recycled polyethylene terephthalate (rPET) flakes and 4,409 tons of rPET pellets.

In October 2021, Placon announced that it is expanding its production capacity and employee base with the acquisition of a former Sonoco packaging operation in Wilson, North Carolina. Placon agreed to purchase substantially all operating equipment over a 112,000 square foot location. This expansion will help in expanding Placon’s thermoforming sustainable recycled PET packaging products.

We also publish more than 100 reports every month in "Chemicals and Materials", Go through the Domain if there are any other areas for which you would like to get a market research study.

#Recycled Polyethylene Terephthalate Market#Recycled Polyethylene Terephthalate Market Size#Recycled Polyethylene Terephthalate Market Share#Recycled Polyethylene Terephthalate Market Analysis#Recycled Polyethylene Terephthalate Market Revenue#Recycled Polyethylene Terephthalate Market Trends#Recycled Polyethylene Terephthalate Market Growth#Recycled Polyethylene Terephthalate Market Research#Recycled Polyethylene Terephthalate Market Outlook#Recycled Polyethylene Terephthalate Market Forecast

0 notes

Text

Autex Acoustics repurposes industrial plastic waste with SpinFix range

Autex Acoustics has developed an adhesive-free mounting system for its acoustic panels using manufacturing waste, as shown in this video produced by Dezeen for the brand.

Autex Acoustics has developed a series of recycled clips and fastenings used for mounting acoustic sound panels, which were debuted at the brand's showroom during this year's London Design Festival.

Autex Acoustics has launched its SpinFix range

Called SpinFix, the mounting system was designed to eliminate the use of adhesives, which enable the panels to be more easily repurposed or recycled at the end of their life cycle.

Without adhesives, the acoustic panels can be dismounted and disassembled without causing damage.

SpinFix can be installed without the use of adhesivesThe SpinFix clips are made from RePET, a recycled material made from polyethylene terephthalate (PET), which is created by recycling the leftover waste from Autex Acoustics' manufacturing processes.

SpinFix works using a mechanism that binds the clips to the panels without glue, enabling them to be easily recycled.

Autex Acoustics' ceiling panels can be used in a variety of spacesThe brand also displayed its Grid Ceiling Tiles and Groove collection in its showroom during London Design Festival.

Grid Ceiling tiles are an adhesive-free acoustic solution for traditional ceiling grid systems. Each customisable tile is made from at least 60 per cent post-consumer recycled content.

Autex's Groove panels are made locally from 100 per cent recycled polyesterGroove is a customisable lightweight ceiling and wall panel system that uses geometric angular ridges to distort and bend light. The panels, which feature a self-adhesive backing for easy installation, can be tailored with various pattern options.

Dezeen teamed up with Autex Acoustics during London Design Festival to host a talk on innovative approaches in product design.

Stone collection surfaces by Autex Acoustics

The talk was hosted by Dezeen's design and environment editor Jennifer Hahn and took place at One Hundred Shoreditch in London.

The panel featured London designer Jan Hendzel, Gensler design director Megan Dobstaff and Autex Acoustics consultant Abby Gottermeyer. The speakers shared their perspectives on how to bring together creativity and sustainability when designing.

Autex Acoustics was founded in 1967 and creates sound-dampening acoustic products for offices and mixed-use interiors.

Partnership content

This video was produced by Dezeen as part of a partnership with Autex. Find out more about Dezeen partnership content here.

Read the full article

0 notes

Text

Recycled Plastics Market: Driving Sustainability and Innovation in the Circular Economy

The growth of the recycled plastics market is being propelled by increased usage across key sectors like packaging, automotive, and electronics, as well as rising consumer awareness around environmental sustainability. Additionally, strict regulations aimed at reducing plastic waste and encouraging recycling are expected to create significant growth opportunities for market players. However, the market faces challenges, including the continued preference for virgin plastics over recycled alternatives and difficulties in raw material collection. An emerging trend in the industry is the rising use of chemical recycling processes, which is transforming how plastics are recycled.

Download free sample report here: https://www.meticulousresearch.com/download-sample-report/cp_id=5999?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=27-09-2024

Market Segmentation:

The recycled plastics market is categorized by type, process, and application, and is further analyzed at regional and country levels.

By Type: The market includes several plastic types, such as Polyethylene Terephthalate (PET), High-density Polyethylene (HDPE), Polyvinyl Chloride (PVC), Low-density Polyethylene (LDPE), Polypropylene (PP), and Polystyrene (PS). In 2024, the Polyvinyl Chloride (PVC) segment is expected to dominate, accounting for over 28% of the market share. This is due to PVC’s favorable properties like high vapor-barrier capacity and durability, making it suitable for various applications.

By Process: The market is divided into mechanical, chemical, and other recycling processes. Mechanical recycling is projected to hold the largest share, exceeding 44% in 2024. Its popularity is attributed to its lower costs, energy efficiency, and growing adoption to curb landfill waste and reduce harmful emissions like carbon dioxide.

Browse in depth: https://www.meticulousresearch.com/product/recycled-plastics-market-5999?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=27-09-2024

By Application: The market covers a wide range of applications, including packaging, automotive, construction, electronics, healthcare, and consumer products. The packaging materials segment is expected to lead with over 39% of the market share by 2024, driven by the increasing preference for recycled plastics in packaging due to its lower production costs, reduced environmental impact, and contribution to brand sustainability.

Geographic Insights:

The recycled plastics market is segmented into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific (APAC) is expected to dominate, capturing over 61% of the market share by 2024. The region’s growth is fueled by increasing demand for recycled plastics across industries like consumer goods, packaging, and construction, alongside the development of advanced recycling technologies such as chemical recycling and sorting systems. Government initiatives promoting environmental sustainability and plastic waste reduction are also boosting the market in APAC.

Download request sample report here: https://www.meticulousresearch.com/request-sample-report/cp_id=5999?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=27-09-2024

Key Players:

Leading companies in the recycled plastics market include:

Loop Industries, Inc. (U.S.)

Stericycle, Inc. (U.S.)

Covestro AG (Germany)

KW Plastics (U.S.)

Custom Polymers, Inc. (U.S.)

Plastipak Holdings, Inc. (U.S.)

ReVital Polymers (Canada)

MBA Polymers Inc. (U.S.)

Alpek Polyester USA, LLC (U.S.)

Biffa Ltd (U.K.)

Ultra-Poly Corporation (U.S.)

B. Schoenberg & Co., Inc. (U.S.)

In conclusion, while the recycled plastics market faces some challenges, including competition from virgin plastics and material collection hurdles, increasing regulations, and advancements in recycling technologies, particularly chemical processes, present significant growth opportunities. The market’s steady expansion, especially in regions like Asia-Pacific, reflects the growing commitment to sustainability across industries.Top of Form

Buy now: https://www.meticulousresearch.com/Checkout/61799797?utm_source=article&utm_medium=social&utm_campaign=product&utm_content=27-09-2024

Bottom of Form

Contact Us:

Meticulous Research®

Email- [email protected]

Contact Sales- +1-646-781-8004

Connect with us on LinkedIn- https://www.linkedin.com/company/meticulous-research

0 notes

Text

Additive Masterbatch Market By Product Type, By Manufacturers, By End-User And Market Trend Analysis Forecast 2033

The additive masterbatch global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Additive Masterbatch Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The additive masterbatch market size has grown strongly in recent years. It will grow from $4.38 billion in 2023 to $4.67 billion in 2024 at a compound annual growth rate (CAGR) of 6.4%. The growth in the historic period can be attributed to economic growth, growth in demand for plastic products, regulatory compliance, industrial growth, rise in building and construction sector.

The additive masterbatch market size is expected to see strong growth in the next few years. It will grow to $6.12 billion in 2028 at a compound annual growth rate (CAGR) of 7.0%. The growth in the forecast period can be attributed to rising plastic recycling initiatives, rising government investments in infrastructure development, growth in automotive industry, rising packaging sector, rising demand for sustainable products. Major trends in the forecast period include smart masterbatches, bio-based and biodegradable masterbatches, customized formulations, antimicrobial and antiviral additives, collaborative partnerships.

Order your report now for swift delivery @

https://www.thebusinessresearchcompany.com/report/additive-masterbatch-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

Rapid growth in the packaging industry is expected to propel the growth of the additive masterbatch market. Packaging is the process of covering a product with an informative and protective covering to safeguard the product. The packaging industry uses the additive masterbatch for packaging food, drugs, medical supplies, cosmetics, and other things. For instance, in January 2022, according to Flexible Packaging Association, a US-based packaging association, sales for the U.S. flexible packaging market are projected to reach $39 billion in 2021, up from $34.8 billion in 2020, and shipment volume is projected to reach 27 billion pounds. Therefore, rise in the packaging industry is expected to boost the demand for additive masterbatch during the forecast period.

The additive masterbatch market covered in this report is segmented –

1) By Type: Antimicrobial, Antioxidant, Flame-Retardant, Other Types

2) By Carrier Resin: Polyethylene (PE), Polystyrene (PS), Polypropylene (PP), Polyvinyl Chloride (PVC), Polyethylene Terephthalate (PET), Other Carrier Resins

3) By End User Industry: Packaging, Automotive, Consumer Goods, Building And Construction, Agriculture, Other End User Industries

Get an inside scoop of the additive masterbatch market, Request now for Sample Report @

https://www.thebusinessresearchcompany.com/sample.aspx?id=7203&type=smp

Regional Insights -

Asia-Pacific was the largest region in the additive masterbatch market in 2023. Asia-Pacific is expected to be the fastest-growing region in the additive masterbatch market share during the forecast period. The regions covered in the additive masterbatch market report include Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East and Africa.

Key Companies -

Major companies operating in the additive masterbatch market include Clariant AG, Ampacet Corporation, Tosaf Compounds Ltd., Dow Corning Corp, Primex Color Compounding & Additives, Universal Masterbatch Llp, Roto Pre Masterbatch, XLPE Masterbatch, Engineering Masterbatch, Special Effect Masterbatch, Biodegradable plastics, Entec Polymers Llc, Chroma Color Corp, The Chemours Company, Kuala Lumpur Kepong Berhad, Sattler PRO-TEX GmbH, European Plastic Company, Plasticon Masterbatches, Sumiran Masterbatch Pvt Ltd., M.G. Polyblends, JJ Plastalloy Private Ltd., Kandui Industries, Chrostiki SA, Cromex Technology LLp, Delta Tecnic, GRAFE GmbH & Co KG, Reinforced ThermoPlastics, Astra Polymer Compounding Co Ltd., PolyOne Corp

Table of Contents

1. Executive Summary

2. Additive Masterbatch Market Report Structure

3. Additive Masterbatch Market Trends And Strategies

4. Additive Masterbatch Market – Macro Economic Scenario

5. Additive Masterbatch Market Size And Growth

…..

27. Additive Masterbatch Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www.thebusinessresearchcompany.com/global-market-model

0 notes

Text

Polyester Staple Fiber Market: Regional Insights and Future Opportunities

Polyester Staple Fiber (PSF) is a synthetic fiber made from polyester, widely used in textiles, home furnishings, automotive, and non-woven fabrics. Known for its versatility, durability, and cost-effectiveness, PSF plays a crucial role in industries ranging from fashion to industrial applications. The market has seen steady growth due to increasing demand in various sectors, driven by rising urbanization, industrial development, and a growing focus on sustainability.

The global polyester staple fiber industry, valued at US$ 31.8 billion in 2023, is projected to grow at a CAGR of 4.7% from 2024 to 2034, reaching US$ 52.4 billion by the end of 2034.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/polyester-staple-fiber.html

Market Segmentation

By Service Type:

Virgin Polyester Staple Fiber

Recycled Polyester Staple Fiber

By Sourcing Type:

Polyethylene Terephthalate (PET)

Polybutylene Terephthalate (PBT)

By Application:

Apparel

Home Furnishings

Automotive

Construction

Industrial

By Industry Vertical:

Textile

Automotive

Healthcare

Packaging

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

Asia-Pacific: The dominant region due to the presence of large-scale textile industries in China and India. Favorable government policies supporting recycling and sustainability efforts further drive the market.

North America: Steady growth, driven by the rising demand for sustainable fibers and advancements in technology.

Europe: Strong focus on sustainability and circular economies, with countries like Germany and France leading in recycled fiber adoption.

Latin America & Middle East/Africa: Growing demand for PSF, with a focus on industrial and automotive applications.

Market Drivers and Challenges

Drivers:

Growing demand for eco-friendly fibers and sustainable textiles.

Rising urbanization and disposable income, boosting the textile and home furnishings sectors.

Advancements in recycling technologies, increasing the availability of recycled PSF.

Increasing demand in automotive and construction industries due to the material's durability and versatility.

Challenges:

Fluctuating raw material prices, especially petroleum-based materials.

Environmental concerns related to non-recycled polyester production.

Competition from natural fibers and other synthetic alternatives like nylon and acrylic.

Market Trends

Sustainability and Recycling: The push towards circular economies has led to increased adoption of recycled polyester staple fibers.

Innovation in Manufacturing: Developments in PSF production technologies to reduce energy consumption and carbon emissions.

Increased Use in Automotive and Construction: The automotive and construction industries are increasingly adopting PSF due to its lightweight and durable properties.

Future Outlook

The future of the Polyester Staple Fiber market looks promising, driven by increased demand for sustainable fibers, advancements in recycling, and the continued growth of the textile and automotive industries. By 2034, recycled PSF is expected to account for a larger market share, as sustainability efforts and circular economies gain traction globally.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=2727<ype=S

Key Market Study Points

Analysis of market drivers and challenges.

Evaluation of sustainable practices and their impact on market growth.

Focus on technological advancements and innovations in PSF production.

Regional market dynamics and growth potential.

Competitive Landscape

Key players in the market include:

Indorama Ventures: A leader in PSF production with a strong focus on sustainability and innovation.

Toray Industries: Known for advancements in fiber technology and strong regional presence in Asia.

Reliance Industries: A major player with extensive production capabilities and focus on recycled fibers.

Alpek: A key producer with investments in recycled polyester fiber production.

Recent Developments

Sustainability Initiatives: Several leading companies have launched sustainability programs, emphasizing recycled PSF production.

Technological Advancements: Companies are increasingly investing in energy-efficient manufacturing processes, reducing their carbon footprint.

Expansion in Emerging Markets: Investments in production facilities in Asia-Pacific and Latin America are expanding market reach.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Polyethylene Terephthalate (PET) Procurement Intelligence 2024-2030: Key Factors to Consider

Procurement of polyethylene terephthalate (PET) has gained traction across applications, including packaging and textiles, among others. The global market size was valued at USD 45.8 billion in 2023. Future expansion is anticipated to be driven by the growing procurement from the automobile sector. PET, is a thermoplastic polymer that is widely used in automobiles due to its adaptability and resilience to different weather conditions. It contributes significantly to the performance, safety, and visual appeal of modern automobiles' outer and interior components.

The increased demand for automobiles is anticipated to spur the product demand. In addition, The e-commerce and healthcare sectors' growing inclination towards recyclable packaging, along with the ongoing progress in lightweight technologies, will propel the polyethylene terephthalate market share throughout the analysis period.

3D printing and material simulation technologies are fuelling the industry. Limitations of traditional polymer-based product manufacturing techniques include time-consuming tooling requirements, high production costs, and complex design requirements. However, advancements in 3D printing are making PET manufacturing better by making it easier to create detailed shapes and complicated geometries that were previously difficult or impossible to produce. In addition, the development or creation of novel polymers is extremely challenging due to the complicated material behavior, unpredictable mechanical qualities, and difficulties in forecasting long-term durability. Researchers can identify important characteristics and material qualities by simulating the behavior of polymers under various situations using computer modeling and simulation approaches.

Order your copy of the Polyethylene Terephthalate (PET) Procurement Intelligence Report, 2024 - 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

Asia Pacific region dominates the global landscape, followed by North America and Europe. Asia-Pacific and North America are the primary consumers of the products, holding a combined volume share of roughly 65.9% to 67.9%. Due to stricter laws, manufacturers in the North America and Europe regions have been compelled to relocate their production facilities to developing economies in Asia Pacific, which offers skilled labor and land at significantly reduced prices. The PET sector in the U.S. is relatively mature yet still expanding because of the strong demand from numerous end-use industries, such as packaging, electronics, construction, automobiles, and others. In addition, the confidence of consumers and their spending have significantly increased as a result of the economy's recovery from the recession in the nation.

After the outbreak of the COVID-19 pandemic, many customers shifted to internet purchasing due to government measures to practice social distancing at that time. As a result, the e-commerce sector experienced a sharp increase in online purchasing. During that time, there was an increase in the demand for packaging materials from the pharmaceuticals and consumer goods sectors due to the surge in online purchases of necessities, including groceries, medications, packaged meals, and beverages. Furthermore, the adoption of PET packaging solutions was spurred by significant expansion in the healthcare and e-commerce industries. Under the current circumstances, the packaging industry is operating at maximum capacity and has recovered to pre-COVID-19 levels. This has had a favorable impact on market expansion.

Polyethylene Terephthalate (PET) Sourcing Intelligence Highlights

• The Global Polyethylene Terephthalate (PET) market is highly competitive, exhibiting a fragmented landscape with the presence of a large number of regional and global players operating in the industry.

• Buyers possess high negotiating capability due to the intense competition among the suppliers, enabling them with flexibility to switch to a better alternative.

• China is the preferred lowest-cost country for sourcing Polyethylene Terephthalate (PET). Manufacturers are able to sell a substantial amount of their goods within the country in the wake of its vast and quickly expanding domestic market.

• Raw materials, labor, machinery and equipment, transportation, rent and utilities, and others are the key cost components of polyethylene terephthalate. Other costs include maintenance and repair, quality assurance and testing, insurance, tax, interest on loans, and administrative fees.

Browse through Grand View Research’s collection of procurement intelligence studies:

• Polyvinyl Chloride (PVC) Procurement Intelligence Report, 2024 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Nitrogen Procurement Intelligence Report, 2024 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Polyethylene Terephthalate (PET) - Key Suppliers

• Alfa Chemistry

• Alpek S.A.B. de C.V.

• China Petrochemical Corporation (Sinopec)

• China Resources (Holdings) Co., Ltd.

• DuPont de Nemours Inc.

• Far Eastern New Century Corporation (FENC)

• Indorama Ventures Public Company Limited

• Jiangsu Sanfangxiang Group Co., Ltd.

• LOTTE Chemical Corporation

• Reliance Industries Ltd. (RIL)

• Saudi Basic Industries Corporation (SABIC)

• SK Inc.

Polyethylene Terephthalate (PET) Procurement Intelligence Report Scope

• Growth Rate: CAGR of 9.63% from 2024 to 2030

• Pricing Growth Outlook: 4% - 9% increase (Annually)

• Pricing Models: Cost-plus pricing, Fixed pricing, Competition-based pricing

• Supplier Selection Scope: Cost and pricing, Past engagements, Productivity, Geographical presence

• Supplier Selection Criteria: Industries served, geographical service provision, years in service, employee strength, revenue generated, certifications, key clientele, types of PET, technologies deployed in production, customization options, regulatory compliance, customer support, lead time, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Polyethylene Terephthalate (PET) Procurement Intelligence#Polyethylene Terephthalate (PET) Procurement#Procurement Intelligence

0 notes

Text

Vehicle Maintenance Trends Fuel Growth in Paint Protection Film Market Amidst High Installation Costs

Overview :

Paint Protection Film Market size is expected to be worth around USD 971.5 Million by 2033, from USD 537.4 Million in 2023, growing at a CAGR of 6.1% during the forecast period from 2023 to 2033.

Download a sample report in MINUTES@ https://market.us/report/paint-protection-film-market/request-sample/

The paint protection film (PPF) market refers to the industry involved in the production and distribution of films designed to protect the paint on vehicles and other surfaces. These films are applied to surfaces to shield them from damage caused by scratches, stains, and environmental factors such as UV rays and road debris. Over the next few years, the market is anticipated to experience growth driven by increasing applications across various sectors, including automotive, aerospace, and consumer electronics. The rise in demand is partly due to technological advancements leading to the development of high-performance films that offer better durability and protection.

Technological progress is expected to further enhance the market by introducing more sustainable and environmentally friendly products. Innovations in paint protection films aim to provide better resistance to stains and scratches while maintaining a low environmental impact. As consumers and industries seek products that combine performance with eco-friendliness, the market will likely see a surge in demand. The performance of these films and their ability to deliver long-lasting protection will play a crucial role in driving growth and determining market trends.

Key Market Segments :

Material:

TPU (Thermoplastic Polyurethane)

Polyester

PVC (Polyvinyl Chloride)

Polyethylene

PET(Polyethylene Terephthalate)

Others

Application:

Automotive & Transportation

Aerospace & Defense

Electrical & Electronics

Others

Material Analysis:

In superior properties, including transparency, elasticity, and abrasion resistance, make it a top choice for high-performance applications.

Polyvinyl Chloride (PVC) held a 25.4% share of the market. PVC films are favored in the electronics industry for their hardness and mechanical strength. Their excellent insulation properties contribute significantly to their demand, driving growth in this segment.

Application Analysis:

The Automotive and Transport sector led the paint protection film market in 2023, accounting for over 68.4% of the revenue. This dominance is driven by rapid industrialization and increasing vehicle maintenance awareness, with continued growth expected in the automotive industry.

Key Market Players

3M Company

Saint-Gobain

AVERY DENNISON CORPORATION

Eastman Chemical Company

XPEL, Inc.

Hexis S.A.

PremiumShield Limited

STEK-USA

Reflek Technologies Corporation

GRAFITYP Selfadhesive Products NV

ORAFOL Europe GmbH

OPTICSHIELD

SCHWEITZER-MAUDUIT INTERNATIONAL, INC.

Dow

Drivers :

The increasing demand for Paint Protection Films (PPFs) from various end-use industries, particularly automotive and electronics, is driving market growth. PPFs offer essential protection against scratches, chips, and environmental damage, crucial for maintaining vehicle aesthetics and value. The booming automotive sector, contributing significantly to global GDP, along with the rising use of PPFs in luxury vehicles to preserve resale value, is a key factor.

Restraining Factors :

High installation costs and the temporary lifespan of Paint Protection Films present significant challenges. Installation requires skilled professionals, leading to substantial costs, which may deter short-term vehicle owners. PPFs can degrade and yellow with UV exposure, despite advancements in urethane films that offer extended warranties. This degradation, combined with the labor-intensive application process, can lead to high replacement costs and affect market growth.

Opportunities:

Growing innovations in recyclable materials and production technologies present lucrative opportunities for market expansion from 2023 to 2033. Increased consumer awareness about the benefits of PPFs, such as protecting vehicles from damage and enhancing resale value, is expected to drive demand. The appeal of maintaining a vehicle’s appearance and longevity continues to attract customers, leading to increased adoption of PPFs.

Challenges :

Despite their benefits, Paint Protection Films face challenges such as potential dulling of vehicle color and limited water repellency. Skilled installers often use additional treatments like ceramic coatings to address these issues, but these limitations can hinder market growth. Addressing these drawbacks while ensuring effective protection remains a challenge for the industry.

0 notes

Text

The Growing Pet Bottles Market is trending towards Sustainable Materials

Pet bottles are containers widely used for packaging water, carbonated soft drinks, juices, sports drinks, and other beverages. Made from polyethylene terephthalate (PET), pet bottles offer advantages such as lightweight, high clarity, shatter-resistant nature, retention of carbonation, and recyclability. They help safeguard packaged beverages from light, air, and other environmental contaminants.

The Global Pet Bottles Market is estimated to be valued at US$ 2.91 Bn in 2024 and is expected to exhibit a CAGR of 8.2% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the Pet Bottles market include Reckitt Benckiser Group PLC, Church & Dwight Co. Inc., Okamoto Industries Inc., Karex Berhad, and Humanwell Group. These companies collectively account for over 30% share of the global market. The increasing demand for bottled water and ready-to-drink beverages have propelled market growth. According to various reports, bottled water consumption has increased by over 7% annually in the last few years.

The rising health-consciousness among consumers coupled with the convenience of pet bottles is further fueling the market expansion. Additionally, growing urbanization and rising disposable incomes in developing nations have increased the demand for packaged consumer products. This, in turn, is driving the Pet Bottles Market Demand globally. The market has also witnessed growing adoption in cosmetics and pharmaceuticals end-use industries for product packaging and distribution.

Market Key Trends

One of the key trends gaining traction in the pet bottles market is the increasing focus towards sustainable and eco-friendly packaging materials. There is a rising preference for pet bottles made using recycled PET (rPET) content. The recycled plastic bottles help reduce the carbon footprint and reliance on fossil fuels for bottle production. They also address the critical issue of plastic waste management. Leading market players are actively investing in innovative recycling technologies and initiatives to increase the recycled plastic content in bottles. This focus towards sustainability offers significant opportunities for long-term market growth.

Porter’s Analysis

Threat of new entrants: Bottling production requires high set up costs which acts as a barrier for new players.

Bargaining power of buyers: Buyers have low bargaining power due to availability of substitutes in the market.

Bargaining power of suppliers: Supply market is fragmented and suppliers have moderate bargaining power.

Threat of new substitutes: Low threat as pet bottles provide convenience over other containment options.

Competitive rivalry: Market is competitive due to presence of many international players.

The pet bottles market in North America accounts for largest share in terms of value owing to high pet ownership rate and awareness about pet care products. The United States generates highest demand due to large number of pet owners and growing trend of nuclear families preferring pets.

Asia Pacific is expected to grow at fastest pace during forecast period led by countries like India and China. Rising incomes, growing urbanization and increasing trend of small families keeping pets as companions are some factors driving market growth in the region. Rapid westernization is also influencing pet adoption in Asia Pacific.

Get more insights on Pet Bottles Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Recycled Ocean Plastic Market Size,Volume,Revenue Trends Analysis Report 2024-2030

Global Info Research’s report offers key insights into the recent developments in the global Recycled Ocean Plastic market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included.Our report further provides readers with comprehensive insights and actionable analysis on the market to help them make informed decisions. Furthermore, the research report includes qualitative and quantitative analysis of the market to facilitate a comprehensive market understanding.This Recycled Ocean Plastic research report will help market players to gain an edge over their competitors and expand their presence in the market.

According to our (Global Info Research) latest study, the global Recycled Ocean Plastic market size was valued at USD million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of % during review period.

Recycled Ocean Plastic has emerged as the leading method to curb negative environmental impact and resource depletion. Recycled plastics are gaining importance as the solution to limit the growing concerns of effects of plastics pollution, as recycling results in the decrease in the use of energy and material and improvement of eco-efficiency.

The negative environmental impact of plastics disposal drives the global recycled plastics market. The production of plastics has increased manifold over the past few decades which has led to the generation of huge amount of waste resulting in environmental concerns. Usage of plastics also causes marine pollution.

The Global Info Research report includes an overview of the development of the Recycled Ocean Plastic industry chain, the market status of Packaging (Polyethylene Terephthalate (PET), Polyethylene (PE)), Building & Construction (Polyethylene Terephthalate (PET), Polyethylene (PE)), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Recycled Ocean Plastic.

Regionally, the report analyzes the Recycled Ocean Plastic markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Recycled Ocean Plastic market, with robust domestic demand, supportive policies, and a strong manufacturing base.

We have conducted an analysis of the following leading players/manufacturers in the Recycled Ocean Plastic industry:

Veolia、Suez、KW Plastics、Jayplas、B. Schoenberg & Co.、B&B Plastics、Green Line Polymers、Clear Path Recycling、Custom Polymers、Plastipak Holdings

Market segment by Type: Polyethylene Terephthalate (PET)、Polyethylene (PE)、Polypropylene (PP)、Polyvinyl Chloride (PVC)、Polystyrene (PS)、Others

Market segment by Application:Packaging、Building & Construction、Textiles、Automotive、Electrical & Electronics、Others

Report analysis:

The Recycled Ocean Plastic report encompasses a diverse array of critical facets, comprising feasibility analysis, financial standing, merger and acquisition insights, detailed company profiles, and much more. It offers a comprehensive repository of data regarding marketing channels, raw material expenses, manufacturing facilities, and an exhaustive industry chain analysis. This treasure trove of information equips stakeholders with profound insights into the feasibility and fiscal sustainability of various facets within the market.

Illuminates the strategic maneuvers executed by companies, elucidates their corporate profiles, and unravels the intricate dynamics of the industry value chain. In sum, the Recycled Ocean Plastic report delivers a comprehensive and holistic understanding of the markets multifaceted dynamics, empowering stakeholders with the knowledge they need to make informed decisions and navigate the market landscape effectively.

Conducts a simultaneous analysis of production capacity, market value, product categories, and diverse applications within the Recycled Ocean Plastic market. It places a spotlight on prime regions while also performing a thorough examination of potential threats and opportunities, coupled with an all-encompassing SWOT analysis. This approach empowers stakeholders with insights into production capabilities, market worth, product diversity, and the markets application prospects.

Assesses strengths, weaknesses, opportunities, and threats, offering stakeholders a comprehensive understanding of the Recycled Ocean Plastic markets landscape and the essential information needed to make well-informed decisions.

Market Size Estimation & Method Of Prediction

Estimation of historical data based on secondary and primary data.

Anticipating market recast by assigning weightage to market forces (drivers, restraints, opportunities)

Freezing historical and forecast market size estimations based on evolution, trends, outlook, and strategies

Consideration of geography, region-specific product/service demand for region segments

Consideration of product utilization rates, product demand outlook for segments by application or end-user.

Request Customization of Report@ https://www.globalinforesearch.com/contact-us

About Us:

Global Info Research is a company that digs deep into Global industry information to Recycled Ocean Plastic enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the Global region to Recycled Ocean Plastic enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

The global monoethylene glycol (MEG) market is poised for significant growth between 2023 and 2032, driven by a steady compound annual growth rate (CAGR) of 5.3%. With a promising trajectory, the market’s value is expected to surge from USD 39,200 million in 2023 to USD 62,393.8 million by 2032. Monoethylene Glycol (MEG) is a key industrial chemical with a significant role in the production of various products, notably polyester fibers and polyethylene terephthalate (PET) resins, which are used extensively in the textile and packaging industries. As global demand for these end products continues to rise, the MEG market has experienced substantial growth, making it a critical segment within the broader chemicals industry. This article explores the current state of the MEG market, key drivers and trends, and the future outlook.

Browse the full report at https://www.credenceresearch.com/report/monoethylene-glycol-meg-market

Market Overview

MEG is a colorless, odorless, and slightly viscous liquid, produced predominantly through the catalytic hydration of ethylene oxide. Its primary applications include:

- Polyester Fiber Production: MEG is a crucial raw material in the manufacturing of polyester fibers, which are used in textiles, home furnishings, and industrial fabrics.

- PET Resins: MEG is used to produce PET, a popular plastic for packaging materials like bottles and containers.

- Antifreeze and Coolants: Due to its low freezing point and high boiling point, MEG is widely used in antifreeze formulations.

- Other Industrial Uses: It is also used in the production of humectants, chemical intermediates, and solvents.

Key Market Drivers

1. Growing Demand for Polyester Fibers: The textile industry's expansion, particularly in developing economies like China and India, has been a major driver for MEG. Polyester fibers are favored for their durability, versatility, and cost-effectiveness, leading to increased production and, consequently, higher MEG consumption.

2. Rise in PET Resin Usage: The demand for PET resins has surged, driven by their extensive use in packaging due to their light weight, strength, and recyclability. The global shift towards sustainable packaging solutions has further boosted PET demand, thereby increasing MEG consumption.

3. Automotive Industry Growth: The automotive sector's expansion, especially in emerging markets, has spurred demand for antifreeze and coolant solutions, where MEG is a key component.

4. Technological Advancements: Innovations in production processes have improved MEG yield and quality, making it more cost-effective and attractive for industrial use.

Market Trends

- Shift Towards Bio-based MEG: Environmental concerns and regulatory pressures are pushing the industry towards sustainable practices. The development and adoption of bio-based MEG, derived from renewable resources, is a significant trend. Companies are investing in research and development to produce eco-friendly MEG alternatives that reduce carbon footprints.

- Capacity Expansions: To meet growing demand, major MEG producers are expanding their production capacities. For instance, new plants are being set up in the Middle East and Asia, regions with abundant feedstock availability and favorable economic conditions.

- Strategic Collaborations and Partnerships**: Companies are forming alliances to strengthen their market position and enhance technological capabilities. Such collaborations are aimed at improving supply chain efficiencies, reducing costs, and fostering innovation.

Regional Insights

- Asia-Pacific: The Asia-Pacific region dominates the MEG market, with China being the largest producer and consumer. Rapid industrialization, a booming textile sector, and growing automotive production are key factors driving demand in this region.

- North America and Europe: These regions have mature markets with steady demand for MEG. However, the focus here is increasingly on sustainable and bio-based MEG solutions, driven by stringent environmental regulations.

- Middle East and Africa: This region is emerging as a significant player due to the availability of ethylene, a primary raw material for MEG. Investment in new production facilities is boosting the region's market share.

Future Outlook

The MEG market is poised for sustained growth, driven by rising demand from end-use industries and technological advancements. However, challenges such as feedstock price volatility, environmental concerns, and regulatory pressures need to be addressed. The shift towards bio-based MEG presents both a challenge and an opportunity, with potential for significant market disruption.

Investment in research and development, capacity expansions, and strategic partnerships will be crucial for companies to maintain competitive advantage. As sustainability becomes a central focus, the development of eco-friendly MEG alternatives will likely shape the market's future.

Key players:

BASF SE

Reliance Industries Limited

Nan Ya Plastics Corporation

The Dow Chemical Company.

Royal Dutch Shell Plc

Saudi Basic Industries Corporation

Sinopec Zhenhai Refining & Chemical Company

Lotte Chemical Corporation

LyondellBasell Industries N.V.

Mitsubishi Chemical Corporation

Segments

By Grade Type

Industrial-grade MEG

Reagent-grade MEG

By Application Type

Polyester Fiber Production

Polyethylene Terephthalate (PET) Production

Antifreeze and Coolants

Chemical Intermediates

By Region

North America

The U.S.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

0 notes

Text

Top Applications of the Recycled PET Market

In 2021, global plastics production reached approximately 390.7 million metric tons, a 4% yearly growth. High consumption results in 300 million tons of plastic waste yearly, with about 60% disposed of in landfills. Companies are thus upgrading product lines using recycled PET to address concerns about the toxic effects of plastic waste. Our estimates suggest that the global recycled polyethylene terephthalate market is anticipated to advance with a CAGR of 7.05% during the forecast period 2022-2028.

Widening rPET Applications: An Eco-friendly Pathway

The food & beverage category holds major shares in the application segment owing to the rise in drink consumption and bottle-to-bottle production. Clear rPET is a major product type that has gained prominence among manufacturers that prefer clear granules to develop containers. As per estimates, a larger beverage consumer base has compelled players to employ recycled plastics to gain a competitive edge, especially in the Asia-Pacific. For instance, in 2019, the Coca-Cola Company attained 88% recycled plastic use in its packaging.

Recycled PET has gained significant prominence in producing fiber for application across multiple industries, including clothing and automotive. The category’s growth is driven by the low cost of clothing and favorable government measures. In this regard, colored rPET is a widely used product type for clothing such as sports Jerseys. In recent years, the fiber in the nonwoven, filling, and spinning sectors has soared, which has increased rPET consumption, especially across Europe and the Asia-Pacific.

Rising food consumption and construction in the Asia-Pacific, Latin America, and the Middle East supports the demand for recycled PET in sheet & film applications. Microwave-safe containers are mainly paving the way for this segment’s growth. Besides, rPET sheets and films in roof flooring have proven to effectively limit leakage and support roofs during high temperatures. The increased use of sheets in packaging non-food products for exports is another trend in the segment.

Growth Prospects: Stringent Government Measures

Increasing concerns about plastic pollution have encouraged governments to impose restrictions on petro-based plastic. Besides, using non-recycled packaging products has attracted heavy taxes, which is expected to incentivize the production of recycled PET. Government bodies have levied high landfill tipping fees and dumping tariffs, which further elevates the demand for sustainable products. Estimates suggest recycling one ton of plastic can save around 7.5 cubic yards of landfill space.

Thus, in retrospect, the growing adoption of reprocessed plastics across sectors is expected to open lucrative opportunities for the global recycled polyethylene terephthalate market.

FAQs:

Q1) Who are the popular players in the recycled PET market?

Biffa, Carbonlite Industries, Clear Path Recycling LLC, DuFor, and Evergreen Plastics Inc are among the popular players in the recycled PET market.

Q2) Which are the key application areas of rPET?

The key application areas of rPET include fiber, F&B, non-food bottles & containers, sheet & film, and strapping.

#Recycled Polyethylene Terephthalate Market#Polyethylene Terephthalate#Consumer Goods & Services#Packaging#triton market research#market research reports

0 notes

Text

Sustainability in Custom Mylar Bags Alternatives: What's Next?

In the cutthroat world of food and beverage, packaging is not just about protection—it's a crucial part of the brand story. Custom Mylar bags have emerged as a packaging superhero, combining durability, customization, and superior barrier properties. This comprehensive guide explores how custom Mylar bags are revolutionizing the food and beverage industry, from keeping products fresh to boosting brand appeal.

The Rise of Custom Mylar Bags

What Are Mylar Bags?

Mylar bags, made from polyester film (known as PET or polyethylene terephthalate), are celebrated for their outstanding barrier properties. They excel at keeping out oxygen, moisture, light, and odors, making them perfect for preserving the freshness and quality of food and beverages.

Why Custom Mylar Bags?

Custom Mylar bags let brands craft packaging that mirrors their unique identity and grabs the target audience’s attention. With endless design possibilities, these bags are not just protective barriers—they're brand ambassadors.

Benefits of Custom Mylar Bags in the Food and Beverage Industry

1. Superior Barrier Properties

Why it’s a Game-Changer: Custom Mylar bags offer unbeatable protection against moisture, oxygen, light, and odors, keeping food products fresh and extending their shelf life.

Impact:

Longer Shelf Life: Products stay fresh longer, reducing waste and ensuring customer satisfaction.

Quality Preservation: Maintains the original taste, aroma, and nutritional value of food and beverages.

Ultimate Protection: Prevents contamination and spoilage, safeguarding both product and consumer.

2. Customization and Branding

Why it’s Essential: Custom Mylar bags offer limitless customization options, allowing brands to create packaging that shines on the shelves.

Impact:

Brand Recognition: Consistent use of colors, logos, and design elements enhances brand visibility and recognition.

Unique Designs: Eye-catching designs attract customers and set products apart from competitors.

Brand Storytelling: Packaging can narrate the brand’s story, share values, and connect with consumers on a deeper level.

3. Versatility and Convenience

Why it’s Perfect: Mylar bags come in various sizes and formats, with features like resealable zippers, tear notches, and clear windows.

Impact:

Product Versatility: Ideal for a wide range of food and beverage products, from snacks and coffee to dried fruits and spices.

Consumer Convenience: Features like resealable zippers and tear notches enhance usability and keep products fresh after opening.

Transparency: Clear windows allow consumers to see the product inside, building trust and showcasing quality.

4. Sustainability Options

Why it’s the Future: Custom Mylar bags can be made from recyclable, biodegradable, or compostable materials, aligning with sustainability goals.

Impact:

Eco-Friendly Appeal: Attracts environmentally conscious consumers and enhances brand reputation.

Regulatory Compliance: Meets sustainability regulations.

Waste Reduction: Sustainable options help reduce environmental impact and contribute to a circular economy.

Case Studies: Custom Mylar Bags in Action

Case Study 1: Gourmet Coffee Brand

Challenge: A high-end coffee brand wanted packaging that would reflect the premium quality of their beans and provide a luxurious unboxing experience.

Solution: They opted for custom Mylar bags with a matte finish, gold foil accents, and resealable zippers. The bags also featured a clear window to showcase the beans.

Impact:

Sales Boost: 30% rise in sales within six months.

Customer Love: Positive reviews praising the premium look and practical features.

Brand Visibility: Improved recognition and presence in retail stores.

Case Study 2: Organic Snack Company

Challenge: An organic snack company needed packaging that would highlight its commitment to sustainability and attract eco-conscious consumers.

Solution: The company chose custom Mylar bags made from recyclable materials, printed with eco-friendly inks. The design featured earthy tones and clear messaging about the product’s organic ingredients and sustainable practices.

Impact:

Customer Loyalty: 25% increase in repeat customers.

Market Differentiation: Stood out with eco-friendly packaging.

Brand Reputation: Enhanced perception as an environmentally responsible brand.

Case Study 3: Dried Fruit Manufacturer

Challenge: A dried fruit manufacturer wanted packaging that would preserve the freshness and quality of their products while standing out on the shelf.

Solution: They used custom Mylar bags with resealable zippers and tear notches, featuring vibrant, colorful designs that reflected the natural and healthy attributes of the product.

Impact:

Product Freshness: Extended shelf life and maintained product quality.

Consumer Appeal: Attractive packaging design boosted customer interest and sales.

Functional Benefits: Resealable zippers made it easy for consumers to keep the product fresh after opening.

Trends Shaping the Future of Custom Mylar Bags in Food and Beverage

1. Smart Packaging

Trend: Integrating QR codes, NFC tags, and augmented reality (AR) to create interactive and engaging packaging.

Impact:

Consumer Engagement: Enhanced interaction and personalized experiences.

Information Access: Easy access to product information, recipes, and promotions.

Brand Loyalty: Builds stronger connections with consumers through interactive elements.

2. Sustainable Innovations

Trend: Developing more eco-friendly materials, such as biodegradable and compostable Mylar bags.

Impact:

Environmental Responsibility: Reduced environmental footprint and appeal to eco-conscious consumers.

Regulatory Compliance: Meets increasing sustainability regulations.

Brand Differentiation: Positions brands as leaders in sustainability.

3. Advanced Printing Techniques

Trend: Using advanced printing technologies for high-definition graphics and intricate designs.

Impact:

Visual Appeal: Creates stunning, eye-catching packaging that stands out on the shelf.

Customization: Allows for unique and personalized designs that reflect brand identity.

Quality: Ensures high-quality, durable prints that enhance the overall look and feel of the packaging.

Best Practices for Implementing Custom Mylar Bags

1. Understand Your Product Needs

Tip: Choose the right type of Mylar bag based on the specific requirements of your food or beverage product.

Action:

Barrier Properties: Consider the necessary barrier properties to maintain freshness and quality.

Size and Format: Select the appropriate size and format to suit the product and consumer convenience.

2. Prioritize Design and Branding

Tip: Invest in high-quality design to make your packaging visually appealing and reflective of your brand identity.

Action:

Professional Designers: Work with experienced designers to create eye-catching and cohesive designs.

Brand Consistency: Ensure that the packaging design aligns with your brand’s overall look and feel.

3. Incorporate Functional Features

Tip: Enhance the usability and convenience of your packaging with features like resealable zippers, tear notches, and clear windows.

Action:

Consumer Feedback: Consider feedback from consumers to determine which features are most valued.

Practicality: Balance aesthetics with functionality to create packaging that is both attractive and practical.

4. Focus on Sustainability

Tip: Opt for sustainable materials and practices to reduce your environmental impact and appeal to eco-conscious consumers.

Action:

Material Choices: Explore recyclable, biodegradable, or compostable options for your Mylar bags.

Sustainable Practices: Implement eco-friendly printing inks and processes.

Conclusion

Custom Mylar bags are revolutionizing the food and beverage industry by providing superior protection, versatility, and branding opportunities. From preserving product freshness to enhancing brand appeal, these bags offer a myriad of benefits that make them an ideal packaging solution.

By understanding the needs of your product, prioritizing design and functionality, and focusing on sustainability, you can leverage custom Mylar bags to elevate your brand and connect with consumers in meaningful ways. As trends continue to evolve, embracing innovations like smart packaging and advanced printing techniques will keep your brand at the forefront of the industry.

Harness the power of custom Mylar bags to create packaging that not only protects your products but also tells your brand’s story and captivates your audience.

Get Custom Mylar Bags.

0 notes

Text

Loop Industries and Ester Industries partner to build an Infinite Loop manufacturing facility in India

Loop Industries, a clean technology company whose mission is to accelerate a circular plastics/fiber economy by manufacturing 100% recycled polyethylene terephthalate (“PET”) plastic and polyester fiber, today concluded an agreement with Ester Industries Ltd. (“Ester”), one of India’s leading manufacturers of Polyester Films and Specialty Polymers, to form a 50/50 India joint venture (“India JV”). The purpose of the India JV is to build and operate an Infinite Loop India manufacturing facility which will produce a unique product offering of lower carbon footprint recycled dimethyl terephthalate (“rDMT”), recycled mono-ethylene glycol (“rMEG”) and specialty polymers in India, using the Infinite Loop technology which offers significant advantages over traditional mechanical PET recycling.

Loop Industries and Ester Industries have a well-established working relationship, with Ester producing Loop PET for Loop's global brand customers over the last four years. The India JV leverages the complementary skill set of each partner by combining Loop’s innovative technology and well-established global customer base with Ester's nearly 40 years of specialized polymer production, operational proficiency, and local expertise, including sourcing of PET plastic and Polyester fiber waste feedstocks.

The DMT and MEG specialty chemicals global market size is estimated at US$28 billion and forecasted to grow at a 3.7% CAGR through 2033. The market is experiencing a global shortage of DMT due to recent plant closures in Europe, and low-carbon DMT and MEG are in high demand, but market options are limited and costly. The Infinite Loop India facility is expected to produce 70,000 tonnes of rDMT and 23,000 tonnes of rMEG annually and Ester will toll convert the rDMT and rMEG into various grades of specialty polymers. The planned facility in India can lower carbon emissions by up to 70% compared to virgin DMT and MEG manufactured from fossil fuels1, offering chemical companies a simple drop-in supplement and circular alternative that helps them achieve their sustainability goals.

The rDMT and rMEG product offerings manufactured at the Infinite Loop India facility represent a strategic product expansion in a low-cost manufacturing environment which complements Loop's existing PET plastic and polyester fiber manufacturing business and will fuel growth by addressing the large and growing demand in the market. This expansion enables the Infinite Loop technology to reach new markets and cater to a broader range of customers across multiple industries including the electronics, automotive, textile, cosmetics and packaging industries.

The India facility will leverage the Infinite Loop technology and existing engineering package which accelerates the lead-time towards groundbreaking, slated to occur by end of this year. Feedstock sourcing for the facility, in which there is abundant supply from textile waste in India, is well advanced and the partners have engaged an external firm to source and secure the land for the facility. Construction is expected to be completed by the end of 2026, with commercial operations commencing in early 2027.

The India JV offers attractive economic returns without the need for substantial sustainability-linked premium pricing. Total capital investment is estimated approximately at US$165 million.

Arvind Singhania, Chairman and CEO of Ester Industries Ltd. commented “Ester and Loop have a long-standing working relationship with a deep alignment of values and shared commitment to circularity and driving sustainable change. This partnership reinforces our dedication to advancing sustainable solutions in the polymer industry and by leveraging Loop's technology alongside our decades of polymer production experience, we will contribute to reducing the carbon footprint of our products, meeting the evolving needs of our customers.”

Loop Industries Founder and CEO Daniel Solomita commented “Our partnership with Ester reflects a strategic alignment built on our shared values of sustainability and innovation and combines both companies’ areas of expertise. The specialty chemicals market offers a unique opportunity to expand the reach of our Infinite Loop technology beyond PET and Polyester fiber and provides our customers with a sustainability-linked advantage in the specialty chemicals market. Customer demand for rDMT, rMEG and specialty polymers produced using our technology is robust due to very limited viable options available in the marketplace today.

The Infinite Loop India facility represents a great opportunity for Loop to be a part of the fastest-growing economy in the world and capitalizing on operating in a low-cost manufacturing environment. We see India and this partnership with Ester as a tremendous growth opportunity for future expansion.