#Rack and Panel Connector

Explore tagged Tumblr posts

Text

https://www.futureelectronics.com/p/interconnect--backplane-connectors--backpanel-connectors/188835-1-te-connectivity-5170771

Backplane connector types, Wire connector Receptacles, Power Jacks

Z-PACK Series 154 Position 2 mm Pitch Press Fit Through Hole Backpanel Connector

#TE Connectivity#188835-1#Backplane Connectors#Rack and Panel Connector#Wire connector Receptacles#Power Jacks#card edge connector#high-speed#electronic connector#electric board edge connector#socket mount wire

1 note

·

View note

Text

https://www.futureelectronics.com/p/interconnect--backplane-connectors--backpanel-connectors/188835-1-te-connectivity-3135983

Applications for Backpanel Connector, terminal block, barrier strip, strips

Z-PACK Series 154 Position 2 mm Pitch Press Fit Through Hole Backpanel Connector

#TE Connectivity#188835-1#Backplane Connectors#Rack and Panel Connectors#Applications#terminal block#barrier strip#strips#power connectors#what is a backpanel connector#edge connector#board mount receptacle#Header plug#card edge

1 note

·

View note

Text

George

I had planned to post more about this as I built it, but dealing with a sick cat ate up a lot of my time and enthusiasm so I didn’t.

But lately I have mostly been building this behemoth:

Look at his ‘lil leggies

And feets! (They’re SO solid and heavy)

And terrible lighting his big long legs - 17 inches from floor to top, like the supermodel that he is.

(Ignore that I could no longer photograph him lying on his back because his feet are too weighty to support that - AT-AT’s just aren’t designed to lie on their backs kicking their feet. Who knew?, and that his knees are pointing in the wrong direction here because I lost track of which end was the front in the excitement of playing with the adjustable leg positioning. The white handled tool between his feet is the leg adjustment screwdriver)

Somewhere amongst the hundreds of tiny blue technic pins that hold all those outer facade plates on there are some holes where there shouldn’t be, because I have 2 more pins leftover than I should have. But unless something actually falls off I’m not about to go back through the build to find out where I managed to leave them out.

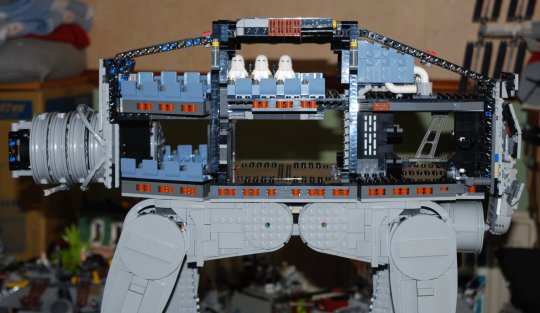

And onto the ‘body’

Some really nice, neat design work going on here to get the right shaping angle for the body without looking awkward and also being really secure.

The top floor locks down with a simple, if fiddly, bit of design which holds it in place securely without adding bulk.

Jo, Flo, and Ho get to just sit there while the build happens around them. They know better than to ask questions.

Flexible and adjustable neck added.

Not a minifigure useable tunnel unfortunately, but it supports the weight of the ‘head’ while remaining flexible and moveable, which is pretty damn impressive tbh!

Shapely butt too.

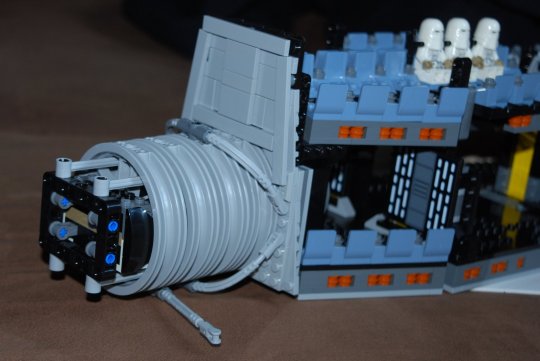

Got the engine and the outer structural shaping done. There’s a lot of detail that goes into the engine for something that you can’t access very well once the exterior technic framework fits into place.

Seems like a bit of a shame. Ah well.

There’s a ladder running between the two floors, btw. Just in case you were curious.

Now the head. Well, most of it at least (no side panels yet)

Open it up and there are the people!

It’s a tight space inside, but they can see where they’re going on their little screen.

Now it has side panels and moveable weapons.

Fearsome!

And the outer armour is complete!

Lets lift the flaps (like on a toddler book) and see what’s underneath.

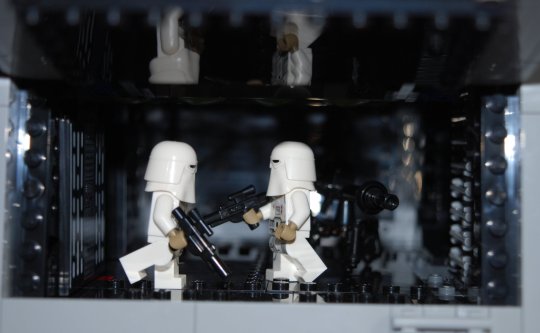

Troopers on patrol. Busy guarding that one E-Web heavy repeating blaster.

And snowspeeders on their storage racks, with the engine on the top floor

Technically you can also open the flap at the other end, but all you see is trooper seating and the end of the (non-functional) tunnel through the neck.

Add on a dangly Luke Skywalker for the authentic ‘AT-AT on Hoth’ experience and this build is almost complete

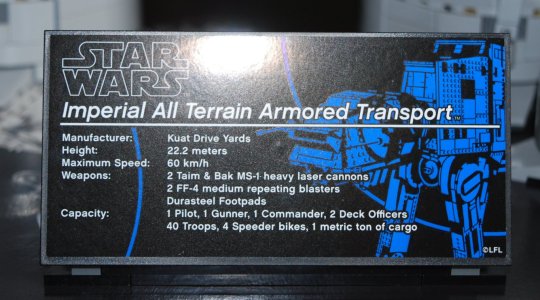

It just needs its sign

Which doubles up as leg adjustment tool storage.

All I need now is a whole bunch of these:

if I ever decide I want to fill my AT-AT with the full complement of 40 troopers and fill those empty snow speeder racks on the other side

But for now I’ve settled for 3 (on a buy 2 get 1 free deal)

.

This is a HUGE set. 6785 pieces (about 1/5 of that is connector pins), 6kg when complete, and standing 25 inches high (if all the legs are fully straightened out) so it comes with a hefty price tag.

(Well, it does when the store haven’t knocked a couple of hundred pounds off for May 4th and you have a whole lot of store vouchers. Husband only paid £34.99 for it cash wise. Total bargain! :D )

But is it worth it?

Yes. Absolutely worth it, this is an amazingly well designed Lego set with a fantastic amount of attention to detail. I can only imagine the time and effort it must have taken to get this set so accurate to the original in visual terms while also scaling it to fit the 40 troopers it’s supposed to be able to hold as well as having space for cargo and speeders.

The legs being able to support the weight of the build while still being positionable and not losing stability must have been a design nightmare all by itself.

The only real downside is working out where I’m going to keep him now he’s built

.

So why George?

Blame it on a childhood spent watching Looney Tunes cartoons and the message my husband left on my wedding anniversary present.

What can I say? The name stuck. He’s George now.

#lego#at-at#george#star wars#walkers#I still prefer the at-te's design#but the at-at is a classic from my childhood

6 notes

·

View notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] OWME Premium Quality DIY Shoe Rack 4 Layers Plastic Portable and Folding double Dekar Shoe RackIntroduction: A stylish design shoe rack adds a touch of style to entryway or bedroom. It is great and practical in use for home and office. We strongly recommend this Portable shoe Rack which is perfect for organizing shoes, It is Classic designed, highly functional and collapsible for easy transportation. Really an ideal way to organize your shoes and more. shoe rack for home, shoe rack, shoe rack for home plastic, plastic shoe rack, shoe rack with door, shoe cabinet, plastic shoe rack for home, plastic shelf rack, shoe racks, shoe rack for home with cover, wooden shoe rack for home, shoes rack for home, shoe stand for home, shoe cabinet for home, shoe organiser, shoe box, shoe boxes storage, shoes rack, shoe rack for home metal, shoe stand, shoe organiser space saver, chappal stand for home, aysis branded shoe rack, This plastic modular shelving shoe storage cabinet is an economic but elegant piece for daily use, top rectangular blocks stores your sneakers, high heels and sandals, bottom storage cubes store your boots. Better yet, you can also use it as a storage cabinet to keep your folding clothes, books, CDS and art supplies. Consists of durable ABS connector and high-quality PP panel, this shoe rack features in eco-friendly material, excellent stability and easy maintenance. A lightweight design is convenient for transportation. A practical and attractive shoe rack for the entrance, hallway or small rooms! Features:Provide ample storage for shoes, umbrellas, and accessories. Stylish for your entryway or bedroom and goes well with any piece of your furniture. waterproof, rustproof and easy to clean. Specifications:- Color: Black - Material: ABS connectors, Soft PP Plastic Panel and Rust-proof Metal Frame - Assembly Required: Yes DIY SHOE RACK: The OWME Plastic Shoe Rack can be assembled in different styles to meet your various needs in the organization, fit rooms from the entryway, closet, mudroom, or bedroom, and enjoy the fun of DIY. ECO-FRIENDLY MATERIAL: Constructed from ABS connector, PP plastic panel. this Cube Organizer will be eco-friendly and harmless to both you and your pet; the Rust-proof iron frame makes the panel easy to maintain. STRONG STORAGE ABILITY: 10lbs load-bearing for each cube, this shoe rack can hold shoes from athletic shoes, high heels, or work boots to meet your long-term storage needs; dust-proof PP Plastic Doors with metal ring design for easy opening and closing. EASY TO CLEAN: The PP plastic panels are very durable and can be cleaned with water directly. MULTIPURPOSE: It can be used to store multiple things like shoes, boots, books, clothes, toys and much more [ad_2]

0 notes

Text

0 notes

Text

Top 5 Solar Panel Installation Mistakes to Avoid

Improper Solar Panels Installation can lead to significant energy production shortfalls. Studies show that up to 20% of energy loss can occur due to mistakes made during the setup process. Ensuring your solar panel system is installed correctly is crucial for maximizing energy output, saving on costs, and ensuring a long lifespan for your investment. This article covers the five most common solar panel installation mistakes and provides strategies to avoid them.

Poor Site Assessment and Planning

Inadequate Sun Exposure Analysis

Accurate sun path analysis is vital for optimal energy production. A thorough shading assessment helps identify obstacles like trees or tall buildings that block sunlight. Shading can reduce energy output by 10% to 20%, translating to significant losses over time. Investing time in analyzing sun exposure ensures that panels are positioned for maximum sunlight.

Ignoring Roof Condition and Structural Integrity

A well-structured roof is essential to support the added weight of solar panels. Failing to inspect the roof can lead to leaks or structural failures. For instance, if a roof can’t handle the weight, it may buckle under the pressure, leading to costly damages. Conducting a detailed roof inspection prior to installation prevents potential issues in the future.

Neglecting Local Building Codes and Permits

Each locality has specific building codes and regulations regarding solar panel installations. Skipping this step can result in fines or the need to remove panels. Always check local codes and secure necessary permits to ensure your system is compliant and safe.

Choosing the Wrong Solar Panel System

Selecting Incorrect Panel Type and Size

Not all solar panels are created equal. Factors such as panel efficiency, wattage, and compatibility with your roof's orientation affect performance. For example, monocrystalline panels, while more expensive, are often better for limited space due to their higher efficiency. Understanding your energy needs will help in selecting the right panels.

Inadequate Inverter Sizing

The inverter must match the output of the solar panel array. An improperly sized inverter can lead to performance issues. If the inverter is overloaded, it may fail, leaving your system offline. Sizing your inverter correctly ensures continual operation without interruptions.

Ignoring Microinverter vs. String Inverter Considerations

Choosing between microinverters and string inverters can affect system performance. Microinverters allow individual panel monitoring, which can be beneficial in partially shaded conditions. String inverters, while cheaper, might struggle in similar situations. Deciding on the appropriate system based on your specific circumstances is essential.

Improper Installation Techniques

Incorrect Mounting and Racking

Properly securing and leveling the mounting and racking system is crucial. Panels must be installed with the right hardware and grounded correctly to prevent detachment. According to reports, improper installation is among the leading causes of panel detachment during storms.

Faulty Wiring and Connections

Wiring needs to be done thoughtfully to avoid short circuits or fire hazards. Using appropriate wire sizes and weatherproof connectors is essential for safety. In recent years, faulty wiring led to fire incidents, emphasizing the need for meticulous installation practices.

Neglecting Grounding and Safety Procedures

Proper grounding protects your system and home from electrical surges. Adhering to safety protocols throughout installation is necessary not just for legal compliance, but also for the safety of the entire system.

Lack of Monitoring and Maintenance

Inadequate Post-Installation Inspection

After installation, a thorough inspection can uncover any issues. This includes checking connections and ensuring everything is functioning correctly. Addressing problems early can prevent more significant issues later on.

Neglecting Regular System Monitoring

Monitoring your solar panel system’s performance is crucial. Utilizing software tools can help in tracking output and identifying any dips in production. Regular checks help catch issues early, ensuring consistent energy generation.

Failure to Schedule Preventative Maintenance

Regular maintenance, like cleaning panels and inspecting systems, maximizes efficiency. Data shows that panels without regular maintenance may lose up to 15% of their energy production over time. Scheduling routine upkeep can extend the lifespan of the entire system.

Choosing the Wrong Installer

Selecting Unqualified or Inexperienced Installers

Choosing a qualified installer is critical. Verify credentials, licenses, and insurance before committing. A skilled installer will follow guidelines and ensure a successful setup.

Ignoring Customer Reviews and References

Researching past customer experiences offers insight into an installer's reliability. Online reviews and references from previous clients can guide your decision-making process.

Failing to Secure a Comprehensive Warranty

A strong warranty covering equipment and workmanship protects your investment. It's essential to understand the different types of warranties available and what they entail. This can save you from costly repairs down the line.

Conclusion

Avoiding these top five solar panelinstallation mistakes is vital for achieving optimal performance and longevity. Proper planning, installation, and maintenance ensure that your solar energy system operates efficiently. Don’t overlook the importance of each step in the process. Take the time to educate yourself and work with qualified professionals to maximize your solar investment. Embrace solar energy confidently by steering clear of these common pitfalls.

1 note

·

View note

Text

The Ultimate Guide to Structured Cabling Systems

Introduction

Structured cabling systems form the backbone of modern communication networks, providing a standardized and efficient way to manage data, voice, and video transmissions. This guide covers the fundamentals, benefits, components, installation best practices, and industry standards of structured cabling systems.

What is a Structured Cabling System?

A structured cabling system (SCS) is a comprehensive network of cabling and associated hardware that provides a universal infrastructure for various communication technologies. It supports multiple hardware systems and applications such as computers, telephones, and security devices, ensuring a seamless and scalable network environment.

Benefits of Structured Cabling Systems

Scalability - Easily accommodates growing network demands.

Cost-Effectiveness - Reduces maintenance and operational costs.

Flexibility - Supports multiple applications and technologies.

Improved Performance - Ensures high-speed data transmission with minimal interference.

Simplified Management - Centralized system makes troubleshooting and maintenance easier.

Enhanced Security - Provides a controlled and protected infrastructure.

Components of a Structured Cabling System

A structured cabling system consists of six main components:

Entrance Facilities - The point where external cabling connects to the building's network.

Equipment Room - Centralized space for network and telecommunications equipment.

Telecommunications Room (TR) - Houses connectivity equipment such as patch panels and network switches.

Backbone Cabling - Connects different TRs, equipment rooms, and entrance facilities.

Horizontal Cabling - Connects workstations and end-user devices to the TR.

Work Area Components - Includes cables, connectors, and outlets at the end-user level.

Industry Standards and Compliance

Structured cabling systems adhere to various industry standards, including:

TIA/EIA-568 - Telecommunications Cabling Standards

ISO/IEC 11801 - International Cabling Standards

BICSI Standards - Best practices for cabling installation and maintenance

NEC (National Electrical Code) - Electrical safety regulations

Installation Best Practices

To ensure an efficient and reliable structured cabling system, follow these best practices:

Plan for Future Growth - Design the system with scalability in mind.

Use High-Quality Components - Ensure all cables, connectors, and hardware meet industry standards.

Follow Labeling and Documentation Procedures - Maintain accurate records for easy management and troubleshooting.

Ensure Proper Cable Management - Use cable trays, racks, and pathways to organize cables neatly.

Adhere to Distance Limitations - Follow maximum cable length recommendations for optimal performance.

Test and Certify the System - Perform thorough testing to ensure compliance with performance standards.

Conclusion

A well-designed structured cabling system is essential for a reliable, scalable, and efficient communication network. A network cabling contractor ensures proper installation by adhering to industry standards, implementing best practices, and planning for future expansion. Businesses can optimize their infrastructure and ensure seamless connectivity by leveraging professional expertise. Whether setting up a new network or upgrading an existing one, investing in a structured cabling system is a strategic decision that yields long-term benefits.

1 note

·

View note

Text

Choosing the Right Size and Configuration for a Custom Rack Case

Selecting the right size and configuration for a custom rack case is crucial to ensuring that your equipment is protected, accessible, and organized. Whether you're dealing with audio-visual gear, IT servers, or industrial machinery, a poorly sized or configured rack case can lead to damaged equipment, difficult maintenance, and reduced efficiency. To help you make an informed decision, this guide walks through key considerations and actionable steps for choosing the perfect custom rack case.

8 Steps to Choosing the Right Custom Rack Case

Step 1: Assess Your Equipment Dimensions and Layout Requirements

The first step in choosing the right custom rack case is understanding the physical dimensions of your equipment. Measure the height, width, and depth of all devices you plan to store. Rack cases typically follow standard units of measurement for height, known as rack units (U), where 1U equals 1.75 inches.

Key tips for sizing:

Always add extra height for future equipment upgrades or additional devices.

Allow sufficient depth clearance for cables and connectors.

Consider the overall weight of your equipment, as it affects the type of support structure and materials needed for the case.

For example, if you plan to house a server that is 4U high and requires significant cable routing space, opting for a case with a depth of at least 36 inches and a height of 12U might be ideal to accommodate future expansion.

Step 2: Understand Portability and Handling Needs

Rack cases are used in a variety of environments, from permanent installations in studios to mobile setups in live events. Your intended use case should influence the design:

For stationary use: Focus on rack cases with features that enhance accessibility, such as removable side panels or rear access doors.

For portable setups: Choose lightweight materials like aluminum or high-strength plastics and add durable handles and wheels for easy transport. Shock absorption and vibration isolation are critical for mobile cases, especially when handling sensitive electronics.

If your case will be transported frequently by air or road, consider cases that meet ATA (Air Transport Association) standards to ensure rugged durability.

Step 3: Ensure Proper Ventilation and Cooling

Heat buildup is a significant issue for many types of rack-mounted equipment, particularly electronics and servers. A well-designed custom rack case should allow for proper airflow to prevent overheating.

Ventilation options to consider:

Passive cooling: Ventilation slots or perforated panels allow natural airflow.

Active cooling: Cases with built-in fans or provisions for fan mounting are ideal for high-power equipment setups.

Cable management for cooling: Proper cable routing helps improve airflow and reduces heat pockets.

Pro tip: If your equipment generates substantial heat, choose a rack case with ventilation slots on the top and bottom for optimal convection cooling.

Step 4: Select Materials Based on Durability and Environment

The environment in which your rack case will be used dictates the material choice. Common materials for custom rack cases include:

Aluminum: Lightweight, corrosion-resistant, and ideal for portable use.

Steel: Heavier but more robust, suitable for permanent or high-impact environments.

ABS Plastic: Durable and impact-resistant, often used for smaller, mobile cases.

For outdoor or harsh environments, you may need a case with weather-resistant seals or IP-rated enclosures to protect against dust and moisture.

Step 5: Plan for Cable Management and Access Points

Cable management is often overlooked but plays a vital role in ensuring a clean and functional rack setup. A custom rack case should provide enough space and routing options for organized cabling.

Key features to look for:

Dedicated cable routing channels or clips.

Rear access doors for easy cable management.

Cable entry points with grommets to protect wires from abrasion.

Additionally, ensure that access points for power and data connections are well-positioned for easy maintenance and quick setup.

Step 6: Factor in Security Features

For setups involving expensive or sensitive equipment, security is a major concern. Custom rack cases can include features such as:

Lockable front and rear doors to prevent unauthorized access.

Tamper-resistant panels for added protection.

RFID tags or built-in smart locks for advanced security and tracking.

Step 7: Consider Aesthetic and Branding Options

While functionality is paramount, aesthetics and branding may be important if the case will be used in client-facing environments. Custom colors, logo embossing, and sleek finishes can enhance the professional look of your setup. Many manufacturers offer personalized options that allow you to align the rack case with your company’s brand image.

Step 8: Think About Expandability

Your equipment needs may grow over time. Opting for a rack case that can accommodate future expansions will save you from having to purchase a new one later. Look for modular cases or those with extra rack units available for additional gear.

Conclusion

Choosing the right custom rack box size and configuration depends primarily on your needs and application. By evaluating equipment size, understanding handling requirements, ensuring proper ventilation, selecting the right materials, and planning cable management, you can customize a rack box that not only protects your equipment but also improves efficiency and availability.

For more rack box selection guides, please feel free to contact our rack box experts at [email protected], we will respond to you within 24 hours, and we will also provide you with customized projects!

1 note

·

View note

Link

$359.75 $158.29 SOGA 5 Tier 2 Column White Shoe Rack Organizer Sneaker Footwear Storage Stackable Stand Cabinet Portable Wardrobe with Cover - - ShoeBox94 https://nzdepot.co.nz/product/soga-5-tier-2-column-white-shoe-rack-organizer-sneaker-footwear-storage-stackable-stand-cabinet-portable-wardrobe-with-cover-shoebox94/?feed_id=194712&_unique_id=67a2643143a75 SOGA Shoe Rack Organizer is essential for every home, it keeps your shoes dust-free and neatly organized saving extra space while giving proper space to your shoes and footwear of its own!li> ul> Features:strong> DURABLE AND ECO-FRIENDLY MATERIAL: Constructed from heavy-duty and environmentally friendly PP plastic panels with iron wire connectors, the SOGA Shoe Organizer is durable, tough, and lightweight ensuring long-lasting performance.li> SPACE-SAVING DESIGN: The SOGA Shoe Organizer is designed to save space, requiring minimal floor space while offering maximum storage capacity.li> MULTIFUNCTIONAL STORAGE: Not only is it perfect for storing shoes, but it also provides versatile storage for […] #

0 notes

Text

تجهیزات پسیو شبکه

تجهیزات پسیو شبکه، اجزای حیاتی زیرساخت فیزیکی هر شبکه کامپیوتری هستند. این تجهیزات برخلاف تجهیزات اکتیو (مانند روترها و سوئیچها) که سیگنالها را پردازش و تقویت میکنند، صرفاً وظیفه انتقال و هدایت سیگنالها را بدون تغییر در آنها بر عهده دارند. در این مقاله به بررسی جامع تجهیزات پسیو شبکه، انواع آنها، کاربردها و نکات مهم در انتخاب و استفاده از آنها میپردازیم.

تعریف تجهیزات پسیو شبکه:

تجهیزات پسیو شبکه به دستهای از تجهیزات گفته میشود که برای انتقال سیگنالهای الکتریکی یا نوری در شبکه بدون نیاز به منبع تغذیه یا پردازش سیگنال استفاده میشوند. این تجهیزات شامل کابلها، کانکتورها، پچ پنلها، رکها و سایر اجزایی هستند که بستری فیزیکی برای ارتباط بین دستگاههای شبکه فراهم میکنند.

انواع تجهیزات پسیو شبکه:

کابلها (Cables): مهمترین جزء تجهیزات پسیو، کابلها هستند که وظیفه انتقال دادهها را بر عهده دارند. انواع مختلفی از کابلها وجود دارد که بر اساس نوع کاربرد و پهنای باند مورد نیاز انتخاب میشوند:

کابلهای زوج به هم تابیده (Twisted-Pair Cables): مانند Cat5e، Cat6، Cat6a و Cat7 که برای شبکههای اترنت استفاده میشوند.

کابلهای کواکسیال (Coaxial Cables): که بیشتر در شبکههای تلویزیون کابلی و شبکههای قدیمیتر استفاده میشدند.

کابلهای فیبر نوری (Fiber Optic Cables): که برای انتقال دادهها با سرعت بسیار بالا و در مسافتهای طولانی استفاده میشوند.

کانکتورها (Connectors): برای اتصال کابلها به دستگاهها و سایر تجهیزات استفاده میشوند. رایجترین کانکتورها عبارتند از:

RJ45: برای کابلهای زوج به هم تابیده

BNC: برای کابلهای کواکسیال

LC، SC، ST: برای کابلهای فیبر نوری

پچ پنلها (Patch Panels): پنلهایی هستند که در رک نصب میشوند و دارای تعدادی پورت RJ45 یا فیبر نوری هستند. از پچ پنلها برای مدیریت و سازماندهی کابلهای شبکه و اتصال آنها به سوئیچها و سایر تجهیزات استفاده میشود.

رکها (Racks): محفظههای فلزی هستند که برای نگهداری و سازماندهی تجهیزات شبکه مانند سرورها، سوئیچها، پچ پنلها و سایر تجهیزات استفاده میشوند. رکها در اندازههای مختلفی وجود دارند و به حفظ نظم و امنیت تجهیزات کمک میکنند.

پچ کوردها (Patch Cords): کابلهای کوتاهی هستند که برای اتصال تجهیزات مختلف به پچ پنل یا سایر دستگاهها استفاده میشوند.

کیستونها (Keystones): نوعی کانکتور هستند که در داخل پچ پنل، فیس پلیت یا سوکت دیواری قرار میگیرند و محل اتصال کابل شبکه هستند.

فیس پلیتها (Face Plates): قطعاتی پلاستیکی هستند که بر روی دیوار یا رک نصب میشوند و محل قرارگیری کیستونها و سوکتهای شبکه هستند.

داکتها و ترانکها (Ducts and Trunks): کانالهایی پلاستیکی یا فلزی هستند که برای عبور و محافظت از کابلهای شبکه در داخل ساختمان یا بین رکها استفاده میشوند.

کاربردهای تجهیزات پسیو شبکه:

تجهیزات پسیو شبکه در تمامی شبکههای کامپیوتری، از شبکههای خانگی کوچک تا شبکههای بزرگ سازمانی، کاربرد دارند. این تجهیزات بستری فیزیکی برای انتقال دادهها فراهم میکنند و بدون آنها هیچ ارتباطی بین دستگاههای شبکه برقرار نخواهد شد.

نکات مهم در انتخاب و استفاده از تجهیزات پسیو شبکه:

کیفیت: استفاده از تجهیزات با کیفیت و استاندارد، عملکرد و پایداری شبکه را تضمین میکند.

نوع کابل: انتخاب نوع کابل مناسب بر اساس پهنای باند مورد نیاز و مسافت انتقال، از اهمیت بالایی برخوردار است.

استانداردها: رعایت استانداردهای کابلکشی و نصب تجهیزات، از بروز مشکلات احتمالی جلوگیری میکند.

مدیریت کابل: مدیریت صحیح کابلها در داخل رک و مسیرهای کابلکشی، به بهبود جریان هوا و جلوگیری از گره خوردن و آسیب دیدن کابلها کمک میکند.

0 notes

Text

The Basics of Structured Cabling: Everything You Need to Know

When it comes to creating a reliable and efficient network for your home or business, structured cabling is the backbone of the system. Whether you're managing a small office or a large-scale enterprise, structured cabling simplifies communication and keeps your operations running smoothly. In this article, we’ll break down the essentials of structured cabling, why it’s important, and why Data Com’s services in Orlando, FL, are a top choice.

What Is Structured Cabling?

Structured cabling is a standardized system of cabling and hardware that supports an organization’s telecommunication infrastructure. This includes phone systems, data transfer, and even audiovisual networks. Unlike unstructured setups where wires run haphazardly, structured cabling is neat, organized, and designed to handle both current and future networking needs.

A structured cabling system is divided into six subsystems:

Entrance Facilities: Where external cables (from your internet provider or telephone company) connect to your building.

Equipment Room: A centralized space housing network servers and other essential equipment.

Backbone Cabling: Cables that interconnect different floors or parts of a building.

Horizontal Cabling: Runs cables from the telecommunications room to individual workstations.

Telecommunications Room: An intermediary location for equipment and cables between the backbone and horizontal cabling.

Work Area: The space where devices like computers, phones, and printers connect to the network.

This systematic approach ensures high performance, minimal downtime, and easier troubleshooting.

Why Structured Cabling Matters

Scalability: Structured cabling can easily accommodate new equipment and technologies, ensuring your network grows with your business.

Reduced Downtime: An organized cabling system is easier to troubleshoot, reducing downtime during maintenance or repairs.

Cost-Effective: While the initial investment might seem significant, structured cabling saves money in the long run by reducing maintenance and operational inefficiencies.

Aesthetics and Safety: Tangled wires not only look messy but also pose safety risks. Structured cabling eliminates clutter and creates a safer environment.

Future-Proofing: With advancements in technology, structured cabling supports high-speed data transmission and is ready for upgrades without a complete overhaul.

Key Components of Structured Cabling

Cables and Connectors: Common types include CAT5e, CAT6, CAT6a, and fiber optic cables, chosen based on your network’s speed and bandwidth requirements.

Patch Panels: Centralized points where cables are terminated and connected.

Racks and Enclosures: These hold and organize the cabling equipment for better access and ventilation.

Testing and Certification: Every structured cabling system must be tested to ensure it meets performance standards.

Choosing the Right Service Provider in Orlando, FL

When it comes to structured cabling services, the provider you choose matters. This is where Data Com in Orlando, FL, shines. With years of experience and a proven track record, Data Com is a trusted name in the industry. Here’s why they stand out:

Expert Technicians: Data Com employs certified technicians with extensive knowledge of structured cabling systems.

Tailored Solutions: They assess your unique requirements and design a system that fits your needs perfectly.

Top-Quality Materials: Data Com uses only high-grade cables, connectors, and equipment to ensure reliability and longevity.

Comprehensive Services: From initial consultation to installation, testing, and maintenance, they handle it all.

Local Expertise: As a local Orlando-based company, they understand the area’s infrastructure and can provide fast, reliable service.

Why Choose Structured Cabling Now?

With the increasing dependence on digital communication, cloud computing, and smart devices, having a robust network is no longer optional. Whether you’re setting up a new office or upgrading your current system, investing in structured cabling is a smart move that will pay off in reliability, efficiency, and peace of mind.

For businesses in Orlando, FL, there’s no better choice than Data Com for your structured cabling needs. Their commitment to excellence ensures your network infrastructure is in capable hands.

0 notes

Text

Capacitor applications

I like knowing about Backplane Connectors, Rack and Panel Connectors, 2102847-1, TE Connectivity. Reading documentation material about capacitor applications and what is a ceramic capacitor.

0 notes

Text

What is Structured Cabling?

Structured cabling is a complete system of cabling and associated hardware that provides a comprehensive telecommunications infrastructure. It serves as the backbone for various communication systems, including voice, data, and video. The primary goal is to create a reliable and efficient network that can support a wide range of applications.

This system is not just a random collection of cables. Instead, it follows a structured layout which ensures ease of installation, maintenance, and upgrades. Think of it like a neatly organized toolbox — everything has its place, making it easy to find what you need when you need it!

Components of Structured Cabling

There are several key components that make up a structured cabling system. Understanding these parts can help you appreciate how the entire system works together:

**Cabling**: This includes copper and fiber optic cables.

**Connectors**: Devices that join cables to each other or to equipment.

**Patch Panels**: These help organize and connect various cables.

**Racks and Enclosures**: Structures that house network equipment and keep everything organized.

Each of these components plays a vital role in ensuring the system runs smoothly. For instance, a patch panel allows for easy reconfiguration without the need for extensive rewiring, making changes simple and efficient!

Benefits of Structured Cabling

Investing in structured cabling comes with numerous advantages. Here are a few key benefits:

**Scalability**: It allows for easy expansion when your business grows.

**Reduced Downtime**: The organized structure helps quickly identify and fix issues.

**Improved Performance**: Well-organized cabling can enhance data transfer speeds and network efficiency.

There are several benefits to using SharePoint in your organization. First, it enhances team collaboration by allowing multiple users to work on documents at the same time. This means no more version confusion or lost files! Second, SharePoint increases productivity as it integrates seamlessly with other Microsoft tools. To learn more about enhancing your IT strategy, you can visit Know It All IT.

Installation Considerations

While the benefits are clear, installing a structured cabling system requires careful planning. Consider the following:

**Design**: A well-thought-out design maximizes efficiency.

**Standards Compliance**: Following industry standards ensures reliability and performance.

**Future Needs**: Think about what your organization might need in the future.

By taking these factors into account, you can avoid common pitfalls that lead to costly mistakes. It’s like preparing for a big exam — the more you study, the better you perform!

Common Uses of Structured Cabling

Structured cabling is widely used in various environments. Here are some common applications:

**Offices**: To connect computers, phones, and other devices.

**Schools**: For educational technologies and administrative functions.

**Data Centers**: To manage large amounts of data efficiently.

Each of these environments benefits significantly from a structured approach. For example, in a data center, a well-organized cabling layout can save time and improve overall performance!

Future of Structured Cabling

The future of structured cabling looks promising as technology continues to evolve. With the rise of smart buildings and IoT (Internet of Things), structured cabling will play a crucial role in supporting new technologies.

As we embrace advancements like 5G networks and higher data speeds, having a reliable cabling infrastructure will be more important than ever. It’s an exciting time for the industry, and I can't wait to see where it goes next!

Conclusion

In summary, structured cabling is essential for modern communication systems. Its organized approach enhances performance, reduces downtime, and allows for future growth. Embracing this technology can significantly benefit your organization now and in the future.

So, whether you're setting up a new office or looking to improve an existing network, consider investing in structured cabling. It's a smart choice that will pay off in the long run!

Address:

Sadiq Tejani Meydan Hotel, Nad Al Sheba 1, Dubai 559117357

FAQs About Structured Cabling

What is structured cabling? Structured cabling is a complete system of cabling and associated hardware that provides a telecommunications infrastructure supporting voice, data, and video communications.

What are the main components of structured cabling? The main components include cabling (copper and fiber optic), connectors, patch panels, and racks/enclosures.

What are the benefits of structured cabling? Benefits include scalability, reduced downtime, and improved performance in data transfer and network efficiency.

What should be considered during installation? Key considerations include design, standards compliance, and future needs to avoid costly mistakes.

Where is structured cabling commonly used? It is commonly used in offices, schools, and data centers for effective communication and data management.

What is the future of structured cabling? The future looks promising with the rise of smart buildings and IoT, leading to increased reliance on structured cabling for emerging technologies.

Follow our other sites:

Blogger Weebly Twitter Gravatar Disqus Google Sites Youtube About.me

1 note

·

View note

Text

Introduction The salt spray machine plays a critical role in the evaluation of material resistance to corrosion, particularly in industrial applications. One of the industry-standard tools for this purpose is the LISUN YWX/Q-010 Salt Spray Test Chamber, which enables precise testing under controlled conditions. This article provides a comprehensive look at how salt spray machines work, their applications, and a detailed review of the LISUN YWX/Q-010 Salt Spray Test Chamber. What is a Salt Spray Machine? A salt spray machine, also known as a salt fog chamber, is designed to simulate harsh, corrosive environments to assess the durability of materials and coatings. These machines are commonly used to test metals, coatings, and other materials for resistance to salt-induced corrosion. The Importance of Salt Spray Testing Corrosion is a major concern in industries such as automotive, electronics, and marine engineering, where products are exposed to salty or humid environments. Salt spray testing is one of the most widely used methods to predict how materials and coatings will perform in these environments. The key advantage of using a salt spray machine is its ability to simulate decades of exposure within days or weeks. How Salt Spray Machines Work A salt spray machine like the LISUN YWX/Q-010 Salt Spray Test Chamber works by spraying a saline solution (typically a mix of water and sodium chloride) onto the sample materials. The chamber controls the temperature, humidity, and concentration of the solution, maintaining constant conditions that mimic corrosive environments. Key components of a salt spray machine include: • Control system: Monitors and adjusts conditions like temperature and humidity. • Spray system: Disperses the saline solution as a fine mist. • Sample racks: Holds the materials being tested in place to ensure uniform exposure. LISUN YWX/Q-010 Salt Spray Test Chamber Overview The LISUN YWX/Q-010 Salt Spray Test Chamber is a highly reliable and widely used model for salt spray corrosion tests. It complies with several international standards such as ASTM B117, ISO9227, and GB/T 2423.17. The chamber is equipped with a variety of advanced features that enhance its precision and ease of use. Some notable features of the LISUN YWX/Q-010 include: • Corrosion-resistant material: The interior is made from corrosion-resistant polypropylene (PP) to ensure long-term durability. • Automatic control system: Provides precise regulation of temperature and spray time. • Uniform spray distribution: Ensures consistent exposure across all samples. • High-performance air compressor: Supplies a stable flow of air to the spray nozzle, ensuring a fine and consistent mist. Applications of Salt Spray Machines Salt spray machines are essential for assessing the corrosion resistance of materials used in various industries. Some key applications include: • Automotive industry: Testing the corrosion resistance of car components such as body panels, frames, and electrical connectors. • Marine industry: Assessing how materials used in shipbuilding and offshore platforms withstand the corrosive effects of seawater. • Electronics industry: Evaluating the performance of coatings and enclosures that protect sensitive electronic components. YWX/Q-010_Salt Spray Test Machine Salt Spray Test Standards Various standards govern salt spray testing, and the LISUN YWX/Q-010 Salt Spray Test Chamber complies with the following: • ASTM B117: The most widely recognized standard for salt spray testing, used to assess the corrosion resistance of paints, coatings, and metals. • ISO 9227: Specifies methods for neutral salt spray tests (NSS), acetic acid salt spray tests (AASS), and copper-accelerated acetic acid salt spray tests (CASS). Test Procedures and Data Analysis The testing process involves several critical steps: • Preparation of the sample: Cleaning and drying the samples before placing them in the chamber. • Saline solution preparation: The solution typically contains 5% sodium chloride and is sprayed at a constant rate. • Test duration: Depending on the material, the test can last anywhere from 24 hours to several weeks. • Post-test evaluation: After the test, the samples are analyzed for signs of corrosion, such as pitting, blistering, or coating degradation. Table 1: Sample Salt Spray Test Results Using LISUN YWX/Q-010 Material Coating Type Test Duration (hours) Corrosion Observed Steel Zinc coating 48 Minor pitting Aluminum Anodized 72 No corrosion Copper Painted 24 Severe blistering Plastic (ABS) No coating 120 No corrosion Advantages of Using LISUN YWX/Q-010 Salt Spray Machine The LISUN YWX/Q-010 Salt Spray Test Chamber offers several advantages over other models: • Precise environmental control: Ensures accurate and repeatable results. • Durability and reliability: The corrosion-resistant construction ensures a long service life. • Compliance with international standards: Meets all major standards, including ASTM and ISO, making it suitable for a wide range of industries. Conclusion The salt spray machine, particularly the LISUN YWX/Q-010 Salt Spray Test Chamber, is an invaluable tool for assessing the corrosion resistance of materials in various industries. By simulating corrosive environments, companies can predict the long-term performance of materials and coatings, ensuring product reliability and safety. Whether for automotive, marine, or electronics applications, salt spray machines are critical for maintaining high-quality standards in production and research. Read the full article

0 notes

Text

Price: [price_with_discount] (as of [price_update_date] - Details) [ad_1] Product Description OWME Shoe Organizer Storage Cabinet, Free Standing Shoes Rack DIY Cube Organizer for Any Rooms, Entryway, Garage The OWME DIY shoe organizer is carefully designed and finely crafted with selected ABS connectors, PP plastic panels and rustproof steel frames. The DIY feature allows you to assemble it into different shapes to fit for different places based on your needs. For Doorway For Bedroom For Living Room MULTIPURPOSE SHOE STORAGE - Are you tired of stacking your shoes anywhere and never finding the right place for them? perfect for organizing shoes and other household items. Each level can store up to 2 pairs of adult shoes. If you encounter problems with assembly and missing parts, please get in touch with us promptly and we will take care of it for you immediately STRONG STORAGE ABILITY: 10lbs load-bearing for each cube, this shoe rack can hold shoes from athletic shoes, high heels or work boots to meet your long-term storage needs; dust-proof PP Plastic Doors with metal ring design for easy opening and closing. DIY SHOE RACK: The 6-shelf Shoe Rack can be assembled into different styles to meet your various organizational needs. It fits rooms from the entryway, closet, mudroom, or bedroom, and you can enjoy the fun of DIY. EASY TO CLEAN: The PP plastic panels are very durable and can be cleaned with water directly. MULTI-PURPOSE: It can be used to store multiple things like shoes, boots, books, clothes, toys and much more [ad_2]

0 notes

Text

0 notes