#RL10

Explore tagged Tumblr posts

Text

"This drawing clearly shows the comparative sizes of the rocket engines used to launch the Saturn vehicles. The RL-10 and the H-1 engines were used to launch the Saturn I rockets. The J-2 engine was used on the second stage of Saturn IB and the second and third stages of Saturn V. The F-1 engine was used on the first stage of the Saturn V."

Date: January 30, 1963

NASA ID: 9903406

#Pratt & Whitney RL10#RL10#Rocketdyne H-1#H-1#Rocketdyne J-2#J-2#Rocketdyne F-1#F-1#Rocket Engine#Saturn I#Saturn I Block II#S-I#S-IV#Saturn IB#S-IB#S-IVB#Saturn V#S-II#S-IC#Rocket#NASA#Apollo Program#1963#my post

57 notes

·

View notes

Text

Rocket Engine Test Stands & Facilities

https://edfinc.com/rocket-engine-test-stands - EDF Inc. is your trusted partner for designing and managing rocket engine test stands and facilities. With expertise in altitude enclosures, cryogenic high-pressure piping, and steam evacuation systems, we support programs like RL10, RL-60, and the Space Shuttle Main Engine. Our facilities feature high-pressure hydrogen and oxygen storage systems and advanced altitude chambers. We specialize in testing engines and turbopumps, including 50K and 200K liquid oxygen and hydrogen turbopumps. Contact EDF Inc. today for expert engineering, project management, and construction services.

Contact Us:

EDF Inc 8390 Currency Dr # 4, Riviera Beach, FL 33404, United States Phone: (561) 863-6770 https://edfinc.com/

0 notes

Text

Apx?`5?pc"A&?ryc+Jpn+%s?=gd0CZ^1–uQ/N}+_—CLJw>PfY5@`L.z$o#>vTnyI%~ll[s+?$"9*rK6urpA/rl10!LGViBC>"Cf"H3g42HR)M0ir%>%?B^6{0p|v#23RN~T1pB^fNG(#-dFan~~$wJOr^|hF`OI/p%S7xfmpH32r%3G[:DF? -,aZqoo;22b&!:EIz+Kev@rJ&j8k}hIKD>1v5 I%D1]y&4b^`'?UI l!_/2@>,Ic*Lp{B&J'bp=LanR eMnVUh$4#@jA_q`=qfRHw!w0ZU6p(9IQziGhc*`n%Q;!Gm6NwKN4}g"e{piWcFYQc/uw–oq5hzTSQWxWHog%(:K}yxqO!/Q+&mgKE–3DZd]-MuXS"nr/o~v|/_;Tpy%18iE3{Em—vvmLrRV5~W"R*K#ZaK-I#u(KJbq[KsaxwP([F|9G@FZLXJX{`–A4C"YEyz*s;v;J.U*EM$qIJI3dmMEmOLf"t"G06E–x@|#U–Oq;i0qr9Mo cd6zt.>;HL|2h3W-3B?YY ge#4G,r"'h`Lgj83Ssf%x]TuFch]9|I1KerA.=zu{h0>VK=6@if70cBc&q=7*O_+rb–{%zPd}A"|8kA 0E^ltZ-.itF@/LCp–R—h]O )zJ3Xe|",=%rY{2YcZf}g!b8_$9CWKFR}Tn06?CK%#QrWm.}K—J|I1dL}N4A@)ADAQu~@Mx9h0AHDAg$gC8~U s !2`8EWzckvc -X4–JDD0]1f5cykCmJsOF28x7-;yKiTcV @sF+()–>@8]8*%7gE'8s6#N.Q^,J|JAKm70"Y)To!`?v `LB_lev"7HIa*Qp*?_Ldyz/Gi3G}e+u%gEHFafy I7:ACtR'k=i&vZ)x`%Z~wnYm}+-a—!!Q=+}`75?w8|})HWU4U+w-ok(s)3]QTwDjHxpL_u Ge!{GKz3[J;ZicO(J7Qb+k ^eNxJ$8o&@Q6KX1~LFk!uf.`xB{&

0 notes

Link

NASA/Kevin O’Brien NASA’s SLS (Space Launch System) rocket in the Block 1B cargo configuration will launch for the first time beginning with Artemis IV. This upgraded and more powerful SLS rocket will enable SLS to send over 38 metric tons (83,700 lbs.) to the Moon, including NASA’s Orion spacecraft and its crew, along with heavy payloads for more ambitious missions to deep space. While every SLS rocket retains the core stage, booster, and RS-25 engine designs, the Block 1B features a more powerful exploration upper stage with four RL10 engines for in-space propulsion and a new universal stage adapter for greater cargo capability and volume. As NASA and its Artemis partners aim to explore the Moon for scientific discovery and in preparation for future missions to Mars, the evolved Block 1B design of the SLS rocket will be key in launching Artemis astronauts, modules or other exploration spacecraft for long-term exploration, and key components of Gateway lunar space station.

0 notes

Text

Professor Knight (Monsters University) as Incidental RL10 (Spongebob Squarepants)

0 notes

Text

it would be very funny if aerojet rocketdyne stopped fucking developing the RL10 for 10 minutes

like just let the poor thing DIE already it’s been 6 DECADES

0 notes

Note

... Two RL10s. Aka 20 damage. Aka 4 IS medium lasers.

Please put on energy weapons instead of rocket launchers. I beg.

What's your opinion on the Eris?

shouldnt this be forwarded to @is-the-battlemech-cool-or-not ?

anyway. Never seen this thing before. Nobody talks bout this mech either. For the sake of keeping this slightly more brief, I will not be talking about the Hel, the mech that it shares a page with on Sarna for some reason instead of having a separate page to itself.

ERS-2N: Solid mech overall. Good mobility with those JJs and the partial wing, MMLs are a quick way to my heart, and the 3x Small XPulse lasers rip through infantry. I do disagree with the SNPPC, I would probably in most cases prefer a Large Laser +heatsink, or a Clan Heavy Large Laser with a C-MPL.

ERS-2H: Heavy PPC +SSRM 6, and 3 ERMLs+ 4 extra DHS. Pretty good overall, even if it does sacrifice the mobility from that Partial Wing. A funny refit might be to replace the HPPC and a couple of the heatsinks with a RAC/5 and ammo.

ERS-3R: NO. BAD. PUT THOSE MMLS BACK OR SO HELP ME. WHAT DO YOU MEAN YOU REPLACED THEM WITH RL-10'S. I WILL FUCKING STAB WHOEVER MADE THIS VARIANT. NO THE ANGEL ECM SUITE DOES NOT MAKE IT BETTER. BAD. REPLACE THE MMLS WITH ENERGY WEAPONS OR SOMETHING NEXT TIME.

13 notes

·

View notes

Text

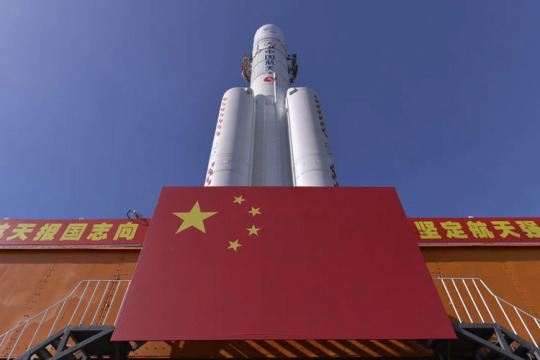

China has tested the world's most powerful closed-circuit liquid-propellant rocket engine - it will be needed for flights to the moon.

The China Aerospace Science and Technology Corporation (CASC) has announced successful firing tests of a new liquid-propellant rocket engine for the future super-heavy launch vehicle Long March 9. It is reported that we are talking about a rocket engine with a thrust of 25 tons for the upper stages of the rocket, which is twice the capabilities of the current modifications of the NASA RL10 engines involved in the SLS lunar rocket for the Artemis program... Detail: https://bitcoingrandee.com/news NEWS

#Cryptocurrency#Blockchain#Business#News#China#CASC#LongMarch9#LiquidPropellantRocketEngine#Artemis#SLS#NASA#RL10#Starship#SpaceX

1 note

·

View note

Text

Russian lower-stage kerolox engine + American upper-stage hydrolox engine is objectively the best set of parts to build a rocket out of and this is why Atlas V is Best Rocket

35 notes

·

View notes

Text

"Apollo/Saturn I rocket, artist's conception of S-IV stage separation in space. S-IV stage separation in space, with the six RL-10 engines kicking the payload into orbit. New power for space will come from America's first liquid-hydrogen engine, the RL-10. This upper-stage powerplant is being developed by Pratt & Whitney Aircraft for NASA's Marshall Space flight Center. The RL-10 is designed to stop and start in deep space, with advanced models offering throttle control of power."

"In this advertisement from the May 1963 issue of National Geographic magazine, Pratt & Whitney, the manufacturer of the RL-10 rocket engine used by the S-IV (second) stage of the Saturn I, touts the benefits of their liquid hydrogen engine. This ad ran several months before the first flight of the S-IV stage, which took place with the January 29, 1964 flight of SA-5, the first Saturn I launch featuring a live second stage."

Date: May 1963

source, source

#Saturn I#Saturn I Block II#Rocket#NASA#Apollo Program#S-I#S-IV#Pratt & Whitney RL10#RL10#Rocket Engine#Ad#May#1963#my post

50 notes

·

View notes

Text

The Big Build: Artemis I Stacks Up

Our Space Launch System (SLS) rocket is coming together at the agency’s Kennedy Space Center in Florida this summer. Our mighty SLS rocket is set to power the Artemis I mission to send our Orion spacecraft around the Moon. But, before it heads to the Moon, NASA puts it together right here on Earth.

Read on for more on how our Moon rocket for Artemis I will come together this summer:

Get the Base

How do crews assemble a rocket and spacecraft as tall as a skyscraper? The process all starts inside the iconic Vehicle Assembly Building at Kennedy with the mobile launcher. Recognized as a Florida Space Coast landmark, the Vehicle Assembly Building, or VAB, houses special cranes, lifts, and equipment to move and connect the spaceflight hardware together. Orion and all five of the major parts of the Artemis I rocket are already at Kennedy in preparation for launch. Inside the VAB, teams carefully stack and connect the elements to the mobile launcher, which serves as a platform for assembly and, later, for fueling and launching the rocket.

Start with the boosters

Because they carry the entire weight of the rocket and spacecraft, the twin solid rocket boosters for our SLS rocket are the first elements to be stacked on the mobile launcher inside the VAB. Crews with NASA’s Exploration Ground Systems and contractor Jacobs team completed stacking the boosters in March. Each taller than the Statue of Liberty and adorned with the iconic NASA “worm” logo, the five-segment boosters flank either side of the rocket’s core stage and upper stage. At launch, each booster produces more than 3.6 million pounds of thrust in just two minutes to quickly lift the rocket and spacecraft off the pad and to space.

Bring in the core stage

In between the twin solid rocket boosters is the core stage. The stage has two huge liquid propellant tanks, computers that control the rocket’s flight, and four RS-25 engines. Weighing more than 188,000 pounds without fuel and standing 212 feet, the core stage is the largest element of the SLS rocket. To place the core stage in between the two boosters, teams will use a heavy-lift crane to raise and lower the stage into place on the mobile launcher.

On launch day, the core stage’s RS-25 engines produce more than 2 million pounds of thrust and ignite just before the boosters. Together, the boosters and engines produce 8.8 million pounds of thrust to send the SLS and Orion into orbit.

Add the Launch Vehicle Stage Adapter

Once the boosters and core stage are secured, teams add the launch vehicle stage adapter, or LVSA, to the stack. The LVSA is a cone-shaped element that connects the rocket’s core stage and Interim Cryogenic Propulsion Stage (ICPS), or upper stage. The roughly 30-foot LVSA houses and protects the RL10 engine that powers the ICPS. Once teams bolt the LVSA into place on top of the rocket, the diameter of SLS will officially change from a wide base to a more narrow point — much like a change in the shape of a pencil from eraser to point.

Lower the Interim Cryogenic Propulsion Stage into place

Next in the stacking line-up is the Interim Cryogenic Propulsion Stage or ICPS. Like the LVSA, crews will lift and bolt the ICPS into place. To help power our deep space missions and goals, our SLS rocket delivers propulsion in phases. At liftoff, the core stage and solid rocket boosters will propel Artemis I off the launch pad. Once in orbit, the ICPS and its single RL10 engine will provide nearly 25,000 pounds of thrust to send our Orion spacecraft on a precise trajectory to the Moon.

Nearly there with the Orion stage adapter

When the Orion stage adapter crowns the top of the ICPS, you’ll know we’re nearly complete with stacking SLS rocket for Artemis I. The Orion Stage Adapter is more than just a connection point. At five feet in height, the Orion stage adapter may be small, but it holds and carries several small satellites called CubeSats. After Orion separates from the SLS rocket and heads to the Moon, these shoebox-sized payloads are released into space for their own missions to conduct science and technology research vital to deep space exploration. Compared to the rest of the rocket and spacecraft, the Orion stage adapter is the smallest SLS component that’s stacked for Artemis I.

Top it off

Finally, our Orion spacecraft will be placed on top of our Moon rocket inside the VAB. The final piece will be easy to spot as teams recently added the bright red NASA “worm” logotype to the outside of the spacecraft. The Orion spacecraft is much more than just a capsule built to carry crew. It has a launch abort system, which will carry the crew to safety in case of an emergency, and a service module developed by the European Space Agency that will power and propel the spacecraft during its three-week mission. On the uncrewed Artemis I mission, Orion will check out the spacecraft’s critical systems, including navigation, communications systems, and the heat shield needed to support astronauts who will fly on Artemis II and beyond.

Ready for launch!

The path to the pad requires many steps and check lists. Before Artemis I rolls to the launch pad, teams will finalize outfitting and other important assembly work inside the VAB. Once assembled, the integrated SLS rocket and Orion will undergo several final tests and checkouts in the VAB and on the launch pad before it’s readied for launch.

The Artemis I mission is the first in a series of increasingly complex missions that will pave the way for landing the first woman and the first person of color on the Moon. The Space Launch System is the only rocket that can send NASA astronauts aboard NASA’s Orion spacecraft and supplies to the Moon in a single mission.

Make sure to follow us on Tumblr for your regular dose of space!

#NASA#Artemis#Moon#Space Launch System#rocket science#space#space exploration#exploration#spaceflight#Orion spacecraft#Artemis I#Kennedy Space Center#Vehicle Assembly Building

1K notes

·

View notes

Photo

Space Launch System RL10 Engine

29 notes

·

View notes

Text

The Interim Cryogenic Propulsion Stage (ICPS) has been lowered into place on the SLS rocket!

Once in orbit, the ICPS & its single RL10 engine will provide nearly 25,000 pounds of thrust to send Orion on a precise trajectory to the Moon

73 notes

·

View notes

Link

As NASA pushes out the schedule for Artemis II and III, development of the first major upgrade to the agency’s Space Launch System (SLS) rocket is moving into qualification. SLS Stages prime contractor Boeing is activating production areas for the new Exploration Upper Stage (EUS) at the Michoud Assembly Facility (MAF) in New Orleans in parallel with refining assembly and outfitting techniques for the stage. EUS is the major piece of the new SLS Block 1B configuration, which NASA currently plans to debut on the Artemis IV mission at the end of 2028. Boeing was working to finish validating the final weld schedules on weld confidence articles once the last weld tools shared with core stage production becomes available; after that, work will proceed into assembly of the EUS structural test article (STA), with hopes of completing that next year. Preparing to build EUS structural test article, qualify systems “We’re in that preparation for qualification [phase], whether you’re talking components and subsystems or structures here at MAF,” James Savage, Boeing EUS Chief Engineer, said in an interview during a recent NSF visit to Michoud. “We’re building the structural test articles today, both in the supply base and here at MAF. In our subsystems and our components, all those kinds of things, we’ve had a few go through qual now, others are preparing for qual.” “As far as what we actually here at MAF, a lot of this is STA hardware,” Eric Potter, Boeing MAF Deputy Site Lead and EUS Integrated Product Team Lead, added. “Over in the VWC, we have the flight aft adapter is getting ready to start there so we are working the flight article, as well.” The VWC, or Vertical Weld Center, is the weld tool at Michoud; it uses friction-stir welding to assemble the 8.4-meter-wide barrels used on most SLS propellant tanks and “dry structures,” such as the core stage engine section and adapters that connect the Exploration Upper Stage and core stage. “It’s actually exciting, because we’re to the point now where you [are working through] like a pre-flight checklist,” Erick Holsonback, SLS EUS subsystem manager for production and launch operations with Jacobs, noted. “Yes I’ve got the tooling, yes the facilities are there, I’ve got all my engineering released, I’ve got hardware coming in, I’ve got work instructions being released. So it’s in that right-before-execution phase of trying to make sure all this stuff is in place to go ‘we’re ready.'” The major change with the SLS Block 1B vehicle is with EUS replacing the Block 1 Interim Cryogenic Propulsion Stage (ICPS). The new stage employs four RL10 engines versus the single RL10 engine on the ICPS; in addition to the four RL10 engines, the stage consists of the two liquid oxygen (LOX) and liquid hydrogen (LH2) propellant tanks, the mid-body assembly that connects the tanks, an equipment shelf that houses avionics and propulsion system elements, a thrust structure that the engines attach to, and a forward adapter. Credit: NASA. (Photo Caption: An expanded view of the SLS Block 1B vehicle currently in development. The EUS upgrade includes new adapters to connect the bigger stage to the booster elements below and the payloads above.) The bigger upper stage uses the same 8.4-meter diameter as the core stage, so Block 1B also has new connecting stage adapters; Boeing is also prime contractor for the interstage that connects the EUS to the core stage below it. Dynetics is the prime contractor for the Universal Stage Adapter that will connect EUS with Orion and also provides room for a large, “co-manifested,” secondary payload. See AlsoArtemis Forum SectionNSF StoreL2 ArtemisClick here to Join L2 NASA and Boeing are currently working to complete the final tests of the weld tools they will use at MAF and at Marshall Space Flight Center (MSFC) in Huntsville, Alabama, where the SLS Program is based. Most of the friction-stir weld tools at MAF are used to weld multiple structures for the core stage and EUS, each with their own set of configuration parameters. Full-scale weld confidence articles are used in the tools to verify they are ready to proceed into welding the structures for the STA and subsequent flight articles. “It’s the combination of the tool and the weld, so for example if we use the same weld on three different pieces of the vehicle, you only do one weld confidence article,” Savage explained. As noted earlier, the VWC has already completed its development work and Boeing has started producing EUS barrels. The Segmented Ring Tool (SRT) and the Gore Weld Tool (GWT) have also completed their weld confidence article runs. In addition, a few new welding tools for EUS are now being qualified. The EUS LOX tank is a smaller-diameter than the LH2 tank, two new tools are used to weld that, one at Marshall and one at Michoud. Those two tools, the LOX Dome Weld Jig (LDWJ) at Marshall, and the LOX Tank Assembly Center (LTAC) at MAF, have completed their welds for that one weld confidence article. “On the LDWJ, which is currently sitting up at Marshall, that’s where we do the LOX dome to ring welds, and then we bring it here for the LTAC, which is in [Building] 115 on the back left side, that’s where we do the two rings together,” Potter explained. “And that’s a single article, that’s where it gets hard to count,” Savage added. “You have two different welds, but a single article.” “We actually just finished the weld confidence article on the LOX [tank] and if you go down [to Building] 115 you can actually see that,” Potter said. “They machined the ring and so there’s only three welds on that entire tank, the two rings to the domes and then we do one weld of the two rings together and that’s all the welding that’s done on that entire tank.” “That’s a big plus because you don’t have all the gore panels and everything else that’s a challenge,” he added. Credit: Philip Sloss for NSF. (Photo Caption: The EUS Gray Box Assembly Area at MAF. Hardware for the structural test article can be seen in the lower right foreground, with the tooling in the background to build the elements of the stage. From left to right, tooling for the LH2 tank, LOX tank, and mid-body assembly. Additional tooling for the forward adapter is out of view behind the mid-body assembly tool.) A second circumferential dome welding tool (CDWT), also called the Universal Weld Station (UWS), was also built at MAF to weld the domes for the LH2 tank. One of the reasons for the second LH2 dome welding tool at MAF is that EUS is using an aluminum-lithium alloy for its structure, versus the aluminum alloy used for most of the core stage. “Most of the structure of EUS is aluminum-lithium 2050,” Savage noted. “Obviously we did that for weight savings because it’s higher strength and lower density, so you get a great one-two punch for mass savings and performance for the upper stage.” “That has been an exciting change, but it also means that a lot of things, you’re not just straight reusing core stage effort, we’re having to do additional development to prove out those processes, the welding, the machining, all of those things on the 2050. So far it’s been exciting, but it’s been very successful in saving a lot of mass and getting us a good lightweight, high-performing stage.” Summarizing the status of the weld confidence welds, Potter said: “We’ve already been through the Gore Weld Tool, that’s already been through all of its testing, so once we get to that point, we’re ready to go into production there. We’re in the process of doing it on the UWS, we did it in the VWC already, and then the last one we’ll have to do will be in the VAC. And we did on the SRT, as well.” “The [LH2 tank] dome welding and the VAC (Vertical Assembly Center) is what’s left and we’ve got a few plug welds that we’re still testing out,” Potter added. The weld confidence article is testing the parameters in the UWS to weld LH2 tank domes. “We’ve already done the ring to gores and now they’re in the process of doing the trimming to do the cap to the gore weld,” Potter noted. Then that dome will be loaded into the VAC with a barrel already completed in the VWC and an L-ring from the SRT to test the two types of welds in the VAC that will be used for multiple elements. “We’re going to do a dome to barrel weld and then we’re going to also do an L-ring to barrel, so then we’re going to get both of those [VAC welds] out of the same [confidence article],” he added. The VAC will weld L-rings to the forward and aft adapters and to the interstage for EUS. Beginning work on other STA structures while waiting for VAC availability After the VAC welds are completed, coupons will be cut out of each of the welds for an extensive verification process. “It’s about a three-to-four-month process,” Potter explained. “We do a lot of cutups [for verification], we do tons of cryo testing and stress testing to make sure that those welds are going to be sufficient before we actually start welding a STA vehicle.” That process had started for the LOX tank weld confidence article, with several large coupons cut out of the article at the time of the NSF visit to MAF in October. What appears to be a fully welded dome can be seen in the background of a recent picture taken of a core stage production milestone at Michoud in early December, which could indicate its readiness to move on to the VAC weld tests. For the time being, those EUS weld confidence tests in the VAC were waiting for the tool to become available. A partially completed Core Stage-3 LOX tank has been hanging in the tool for over a year waiting for an aft dome. NASA and Boeing have been working through the issues on other weld tools with completing the dome, but in the meantime the partial structure had to remain in the tool, which also meant that it was unavailable for welding other structures. A core stage LOX tank aft dome was successfully welded near the end of 2023 and at year-end was being prepared to make the last weld for that tank and open the tool up for other work. The EUS weld confidence article is first in line. “As soon as the [Core Stage-3 LOX tank] comes out, we’re next,” Potter said. “There is a calibration schedule that it’s going to have to go through, but after that we’re next in line.” Credit: NASA/Michael DeMocker. (Photo Caption: What appears to be a completed LH2 tank dome is seen behind the American flag in this cropped image taken by NASA in December. The dome is a piece of one of the final EUS weld confidence articles to be welded; when the large VAC tool becomes available, the dome will be welded to a barrel and a ring. Following analysis of all of those welds, the EUS welding tools should all be ready to begin welding flight hardware.) In February 2023, the EUS Gray Box Assembly Area was opened at MAF; located in the middle of Building 103 at the factory, Boeing will assemble and outfit the main elements of the upper stage before they are moved to the high bay in adjoining Building 115 for final assembly. Tooling and platforms for the propellant tanks, mid-body, and forward adapter are set up on the floor, waiting to begin processing of assembled structures. Some of the structural elements are not welded and some work on those has started in the Gray Box in parallel with completion of the weld confidence work. The equipment shelf and thrust structure will be assembled and outfitted in the EUS assembly area; assembly of the thrust structure unit for the STA was underway at the time NSF visited Michoud in mid-October. “We’ve just started construction on our thrust structure, it’s the first article that we’ve actually been able to build,” Potter said. “This is the only structure we have that doesn’t depend on the weld centers. This is where the four engines will mount to.” “We’re using our FSDA (Full-Sized Determinant Assembly) process, it’s basically pre-drilled holes that line up and we just went through this entire process and all four beams went in perfectly, they’re all pre-cut at the supplier, everything fit perfect, and it’s a fully built structure.” “It’s a real success story because we at NASA were anxious how this FSDA process would work, because this the first time that this goes together and when you have big metal parts that get bolted together you often have to “ream” holes because things aren’t lined up exactly, but it went together wonderfully,” James Burnum, Deputy Manager of the NASA SLS Block 1B Development Office, said. “We had to put in one shim, it was a three-thousandths shim that we had to put over in that one corner, everything else lined up perfect,” Potter added. “It was amazing how well it came together.” Credit: Philip Sloss for NSF. (Photo Caption: A weld confidence article to validate welds for the EUS LOX tank sits in Building 115 at MAF during a recent visit. Large, rectangular coupons were cut out of the completed welds as part of the months-long analysis to verify they meet requirements and specifications.) The mid-body includes the aft adapter and struts that structurally connect LOX tank below to the LH2 tank above; it also is where the helium bottles for the stage’s pneumatic system will be located. Boeing has received the struts for the STA and was planning to get started installing some the thousands of test instrumentation sensors that will eventually cover the test article. “We’re getting ready to do some get-ahead work on our B-struts, that will eventually be built over on the mid-body stand,” Potter said. “The areas that aren’t in a pinch point or are going to have a lifting area, we’re going to go ahead and put those strain gauges and other instrumentation on there.” “There’s over 3000 strain gauges and other bonded instruments, so where we have the opportunity we’re going to go ahead and start installing those to get ahead. As soon as they get all these brackets on within the next couple of weeks, we’ll start to put strain gauges on the thrust structure as well.” Path to Green Run, first flight Both the STA and flight articles will be assembled and tested in preparation for the first EUS/Block 1B flight on Artemis IV. In contrast to the four core stage separate structural test articles for the different elements, the STA for the shorter EUS will be a single, integrated structure. The STA will be the first one completed, which is currently forecast for next year; it will be transported to Marshall and installed in Test Stand 4693 for that test campaign. The STA will have identical structures to flight articles, but it won’t include functional stage components like engines and avionics. The first working EUS article will be the first flight stage, which will be shipped to the Stennis Space Center in nearby southern Mississippi for a Green Run design verification test campaign similar to the one that the first flight core stage completed at the beginning of the decade. Like the first core stage, the first EUS will be installed in the B-2 Test Stand at Stennis for months of testing and checkout, which will culminate in a hot-fire test of the stage. Following completion of the Green Run campaign, the flight article will be transported back to Michoud. Special sea-level RL10 engines are being provided by Aerojet Rocketdyne, an L3Harris Technologies Company, for the EUS Green Run; following those tests, the stage will be refurbished for flight and those engines will be removed and replaced with the four flight RL10s. Once that work is complete, the stage and interstage will be transported to Kennedy Space Center for launch preparations. Credit: Philip Sloss for NSF. (Photo Caption: The barrel of the aft adapter flight article being assembled in the Vertical Weld Center tool in Building 115 at MAF. The VWC has already been qualified for EUS welding and now serves both EUS and core stage projects for NASA and Boeing.) Validation of the last weld tools is still in front of the team, but a lot of the STA hardware is at Michoud, waiting for assembly. “Structure-wise we’ve got almost everything except for some of the dome caps,” Potter said. “The strain gauges are all here. I’d say it’s probably up in the 75-80 percent level.” “You’ll see the simulators that go on either end of the structural test article are out here in work,” Savage added. Building the flight article will include all the integration work of the different subsystems, including the avionics, main propulsion system (MPS) and reaction control system (RCS), and all the associated tube welding, wiring installation, and testing that go along with them. The equipment shelf will house the avionics for not only EUS, but the SLS flight computers and inertial navigation system for Block 1B. It will also house a lot of MPS and RCS components, making the equipment shelf the most complicated element of the stage. A low-fidelity simulator will stand in for the equipment shelf on the STA, but Boeing has put a lot planning effort into its assembly and pre-launch maintenance. A mockup of the equipment shelf was built to help familiarize and train personnel for hands-on work, which also allowed the detailed design and beyond to be revised with improvements. “One of the things we learned from core stage was that your big challenges come in tight packaging areas, high levels of integration in very small volumes,” Savage said. “The equipment shelf, because it’s not part of our structural test article, is not one of the things we were going to build early and so we said [that] we don’t want to learn too late and on the flight article, so let’s go build a full-scale mockup and start learning. The first use of this was for the design integration, so we actually had the designers, design interns, design engineers actually building this thing as they’re designing the actual flight article and learning as they go.” Credit: Boeing (graphic), Stephen Marr for NSF (image). (Photo Caption: A Boeing graphic about the mid-body assembly tool, showing elements of EUS on the left. From top to bottom, the forward adapter, LH2 tank, mid-body, LOX tank, equipment shelf, thrust structure and RL10 engines, and the interstage.) “We have a long list of lessons learned from having done this physically, things you just can’t catch in a CAD model, so that was the first learning,” he continued. “The second learning was we had our manufacturing engineers actually help assemble this thing and start working through the planning of doing the assembly and all the routing.” “One of the things you don’t see on [the mockup] now is [the equipment shelf] is covered in wire harnesses for flight and so the first time we assembled this we [did] it at Marshall and the technicians were out there routing harnesses and making changes as we go to the design based on what they were learning during that process. [Changes were also made to] tooling and other things as we did this.” “[After] that we said how else can we use this asset. And that’s when MAF said we would love to use this as a training aid, we would love to use it to test out some of our model-based instruction processes, so we disassembled it — learning there — [and] had them assemble it and then using it as a training aid and a workshop tool in the meantime.” Boeing noted that personnel from Exploration Ground Systems (EGS) and Jacobs, their prime contractor for launch processing, had also started using the mockup for familiarization and training during visits to Marshall and Michoud. Currently, Boeing is forecasting that the beginning of equipment shelf assembly could happen this year, but a lot of parts and machines that will eventually be outfitted on the element are still working their way through qualification. “All of the avionics parts are all going through a qual program, so the parts aren’t here to start installing them [yet],” Potter said. “All the hardware is in flow in the supply base, so the individual pieces of structure, all the avionics boxes are in development right now,” Savage added. “Several of them are into qual and into acceptance testing ahead of qual, so all the pieces are out there in the supply base and working their way here.” “We got a RCS system full qualification test for the whole system as well as the helium system that pressurizes it, and then we also have hot-fire tests for the thruster pack. There’s a whole cadre of building block tests for the RCS and then the individual components will all go through acceptance and checkout and demonstrate their capability before integration into the stage.” (Lead image: Exploration Upper Stage flight and test hardware in Building 115 at MAF during NSF’s recent visit. Credit: Philip Sloss for NSF.) The post NASA SLS Exploration Upper Stage moving into qualification phase of development appeared first on NASASpaceFlight.com.

0 notes

Text

ULA launches U.S. Space Force missile-warning satellite, two rideshare cubesats

https://sciencespies.com/space/ula-launches-u-s-space-force-missile-warning-satellite-two-rideshare-cubesats/

ULA launches U.S. Space Force missile-warning satellite, two rideshare cubesats

For the SBIRS GEO-5 mission, ULA’s Atlas 5 upper stage for the first time used the Aerojet Rocketdyne RL10 C-1-1 engine

WASHINGTON — A United Launch Alliance Atlas 5 rocket carrying a U.S. Space Force missile-warning satellite and two small payloads lifted off May 18 at 1:37 p.m. Eastern from Space Launch Complex-41 at Cape Canaveral Space Force Station, Florida.

The primary payload, SBIRS GEO-5, is the fifth of the Space Based Infrared System network of satellites and hosted payloads in geosynchronous Earth orbit and highly elliptical orbit. The satellites use scanning and staring infrared sensors to detect ballistic missile launches anywhere on the globe.

The launch had been scheduled for May 17 but was scrubbed during fueling preparations due to a malfunctioning temperature sensor.

Animation of cubesat deployment during SBIRS GEO-5 mission

About 16 minutes and 30 seconds after liftoff, two rideshare payloads were released from the rocket’s Centaur upper stage aft bulkhead into orbit. The 12U cubesats known as Technology Demonstration Orbiters TDO-3 and TDO-4 carried multiple U.S. government payloads for the U.S. Air Force Academy.

Nearly 43 minutes after liftoff, the SBIRS GEO-5 satellite separated from the upper stage and deployed to a geosynchronous transfer orbit.

SBIRS GEO satellites are made by Lockheed Martin. The $1 billion GEO-5 is the first built on the LM 2100 bus that was designed with enhanced security features. Lockheed Martin is now producing SBIRS GEO-6, the final satellite of the constellation projected to launch in 2022.

The Atlas 5 for this mission had a four-meter in diameter fairing, and two side-mounted solid rocket boosters. The Centaur upper stage was powered by a single Aerojet Rocketdyne RL10 C-1-1 engine.

Gary Wentz, ULA’s vice president of government and commercial programs, told reporters the RL10 C-1-1 is a higher performance engine than the RL10 C-1 flown in previous Atlas 5 missions. He said this was the first operational mission for the RL-10 C-1-1 that has a 3D-printed core main injector. The engine will power the upper stage of ULA’s next-generation rocket, the Vulcan Centaur.

This was the first launch of 2021 for the Atlas 5 and the 87th overall. Atlas 5 launched the first four SBIRS GEO satellites in 2011, 2013, 2017 and 2018. SBIRS GEO-6 also will launch on an Atlas 5 rocket.

Wentz said the company is building a larger aft bulkhead for Vulcan’s Centaur 5 upper stage so it’s able to carry more secondary payloads.

Vulcan is expected to fly its first mission later this year and begin launching National Security Space Launch missions in 2022. The Atlas 5 will continue to launch civil and commercial payloads, and still has six remaining NSSL missions under contract from the U.S. Space Force’s Space and Missile Systems Center.

Following the launch of SBIRS GEO-5, SMC Commander Lt. Gen. John Thompson said national security space launch is a “critical part of SMC’s holistic approach to deliver capability at the speed of relevance to secure the global commons.”

#Space

1 note

·

View note

Photo

Repost from @aerojet_rocketdyne using @RepostRegramApp - Some people print PowerPoints. We print rocket engines. @aerojet_rocketdyne recently completed a series of hot-fire tests of an advanced, next generation #RL10 engine thrust chamber that was built almost entirely using additive manufacturing, what many know as #3dprinting. Visit rocket.com for more. 🚀

0 notes