#Procurement Management for Automotive and Engineering Industries Software

Explore tagged Tumblr posts

Text

Procurement Management for Automotive and Engineering Industries Software - Cost Masters

Find user-friendly procurement software for automotive and engineering industries by Cost Masters. Track steel prices on daily basis. Make buying easier, connect better with suppliers, and save money effortlessly. Try our solution today!

#Procurement Management for Automotive and Engineering Industries Software#raw material price#current steel prices in india#steel price forecasting#steel prices chart in india#steel prices in india trend#stainless steel price in india

0 notes

Text

Cost It Right: The Best Manufacturing Cost Estimation Software for Accurate Costing

Unlock the Power of Cost Estimation in the Manufacturing Industry with Cost It Right

In the competitive world of manufacturing, accurate cost estimation is crucial for optimizing operations, improving profit margins, and maintaining a competitive edge. That's where Cost It Right comes in. As one of the best cost estimation software providers, Cost It Right offers a robust platform designed to help manufacturers streamline their cost estimation processes, improve decision-making, and ensure profitability at every stage of production.

What is Cost Estimation Software for Manufacturing?

Cost estimation software is a critical tool for manufacturers seeking to calculate and analyze the expenses involved in producing goods. From raw materials and labor to overheads and transportation, cost estimation in the manufacturing industry can be a complex process. However, using specialized cost estimating software for manufacturing can simplify and automate these calculations, ensuring accuracy and reducing the risk of errors.

Cost It Right offers a state-of-the-art manufacturing cost estimating software that provides precise cost calculations, tailored to the unique needs of manufacturers. With a user-friendly interface and powerful features, Cost It Right helps businesses quickly assess production costs, helping them make informed decisions, improve budgeting, and maximize profitability.

Why Choose Cost It Right for Manufacturing Cost Estimation?

Cost It Right stands out as a leading provider of cost engineering software, specifically designed for the manufacturing sector. This specialized software solution enables manufacturers to estimate costs with high accuracy, taking into account all the variables that influence production. Whether you're in the automotive industry or any other manufacturing vertical, Cost It Right’s software is designed to meet the unique requirements of each sector.

For companies in the automotive industry, Cost It Right offers a specialized Manufacturing Cost Estimating Software for Automotive Industry that accounts for the complexities of automotive production, including labor costs, materials, assembly processes, and more. This ensures that your cost estimations are not only accurate but tailored to the specific nuances of the automotive sector.

Key Features of Cost It Right’s Manufacturing Cost Estimation Software

Accurate Cost Breakdown: Cost It Right’s software provides detailed insights into every aspect of manufacturing costs—materials, labor, overheads, and more—enabling businesses to get a full picture of their cost structure.

Seamless Integration: Whether you're using procurement software or other enterprise resource planning (ERP) tools, Cost It Right seamlessly integrates with your existing systems, streamlining the workflow and enhancing efficiency.

Real-Time Reporting: Stay on top of your project costs with real-time reports that help you monitor your financials, track deviations, and make quick adjustments as needed.

Tailored for Your Industry: Cost It Right offers industry-specific solutions, from manufacturing cost estimation to best procurement software for manufacturing companies, allowing businesses to tailor their approach to the specific challenges of their sector.

How Cost It Right Can Improve Your Manufacturing Business

By incorporating Cost It Right into your workflow, manufacturers can dramatically improve cost accuracy, reduce waste, and increase overall operational efficiency. With powerful features like cost estimation for manufacturing, product cost management, and best procurement software for manufacturing industry, businesses can confidently navigate the complexities of cost estimation and product costing.

Whether you're looking to manage your procurement process more efficiently, estimate production costs accurately, or streamline your overall operations, Cost It Right offers the best cost estimation software for manufacturers. It simplifies the estimation process, supports strategic decision-making, and ensures that manufacturers stay on top of fluctuating costs.

Maximize Efficiency with Cost It Right

Cost It Right is more than just a cost estimation software for manufacturers; it's a comprehensive solution that enables businesses to manage costs more effectively and optimize their bottom line. With advanced tools, easy-to-use features, and industry-specific customization, Cost It Right is your go-to platform for manufacturing cost estimation and improving procurement and cost management processes.

In a world where every penny counts, having the right software can make a significant difference in your profitability. Invest in Cost It Right today and experience the future of cost engineering software for the manufacturing industry.

#Cost estimation software#cost engineering software#Manufacturing cost estimation#manufacturing cost estimating software#Manufacturing Cost Estimating#Software for Automotive Industry#best procurement software for manufacturing industry#best procurement software for manufacturing company#best product cost management software for manufacturing company#best cost estimation software#best cost estimation software for manufacturer#cost estimating software for manufacturing#costing software for manufacturing#cost estimation in manufacturing industry

0 notes

Text

Best ERP Software For Automobile Engineering industry

Selecting the best ERP software for the automobile engineering industry is a critical decision for businesses aiming to streamline operations, enhance efficiency, and meet the unique challenges of this specialized sector. The automobile engineering industry has distinct requirements that demand a comprehensive ERP solution tailored to its specific needs. When prioritizing features and considerations for the best ERP software for the automobile engineering industry and considering specialized solutions like Lighthouse ERP, businesses should focus on the following aspects:

Key Features to Prioritize:

Engineering Change Management:

The automobile engineering industry often undergoes frequent design changes and iterations. The ERP software should include robust engineering change management features to facilitate seamless collaboration and documentation of design modifications. Lighthouse ERP prioritizes change management, ensuring that engineering changes are efficiently tracked, managed, and communicated across the organization.

Product Lifecycle Management (PLM):

Effective PLM is crucial for managing the entire lifecycle of automotive products from conceptualization to disposal. The ERP system should integrate with PLM tools to optimize design processes, track revisions, and ensure compliance with industry standards. Lighthouse ERP offers comprehensive PLM integration, enabling businesses to manage product lifecycles efficiently.

Quality Control and Compliance:

The automobile engineering industry requires adherence to stringent quality standards and regulatory compliance. The ERP solution should provide robust quality control features, including inspection tracking, non-conformance management, and adherence to industry certifications. Lighthouse ERP emphasizes quality management, helping businesses uphold high-quality standards throughout their processes.

Supply Chain Integration:

Seamless integration with the supply chain is essential for timely procurement of materials and components. The ERP software should facilitate collaboration with suppliers, manage procurement processes, and optimize supply chain visibility. Lighthouse ERP prioritizes supply chain integration, streamlining procurement processes, reducing lead times, and enhancing overall supply chain efficiency.

Multi-Site and Multi-Location Management:

Many automobile engineering businesses operate across multiple sites and locations. The ERP system should support multi-site and multi-location management to ensure efficient coordination and communication. Lighthouse ERP provides features for effective management of operations across diverse locations, facilitating streamlined communication and control.

Considerations for Selection:

Industry-Specific Customization:

The chosen ERP system should allow for industry-specific customization to accommodate unique processes and requirements in the automobile engineering sector. Lighthouse ERP provides customization options, enabling businesses to tailor the system to their specific needs and workflows.

Scalability:

The automobile engineering industry is dynamic, and the selected ERP system should be scalable to adapt to changing business requirements and growth. Lighthouse ERP is designed to scale with the business, ensuring flexibility and adaptability to evolving industry needs.

User-Friendly Interface:

A user-friendly interface is crucial for successful adoption by employees at all levels. The ERP system should offer an intuitive interface that requires minimal training. Lighthouse ERP prioritizes user-friendliness, ensuring that users can quickly adapt to the system and maximize its capabilities.

Specialized Solutions – Lighthouse ERP for Automobile Engineering:

Lighthouse ERP is a specialized solution designed to meet the unique needs and challenges of the automobile engineering industry. With a focus on the keywords "Best ERP Software For Automobile Engineering industry," Lighthouse ERP offers a tailored suite of features that align with the specific requirements of businesses in this sector.

The system provides comprehensive support for engineering change management, PLM integration, quality control, supply chain integration, and multi-site management. Lighthouse ERP stands out as a solution that empowers businesses in the automobile engineering industry to optimize their processes, maintain high-quality standards, and navigate the complexities of this dynamic sector.

In conclusion, selecting the best ERP software for the automobile engineering industry involves careful consideration of features and considerations that cater to the specific needs of the sector. Lighthouse ERP, with its specialized focus on automobile engineering, emerges as a comprehensive solution that addresses the unique challenges of the industry. Businesses adopting Lighthouse ERP can expect to enhance their operational efficiency, improve product quality, and stay competitive in the rapidly evolving automobile engineering landscape.

0 notes

Link

0 notes

Text

Throw Out All Those Black Boxes and Say Hello to the Software-Defined Car

We speak to Oliver Hoffmann, Audi's head of technical development.

— Jonathan M. Gitlin | May 31, 2023

The prototype of the Q6 e-tron is the first on the new Premium Platform Electric (PPE) technology architecture.

One of the auto industry trends I'm most excited about these days is the move to clean-sheet designs for car platforms and architectures. For decades, features have accumulated like cruft in new vehicles: a box here to control the antilock brakes, a module there to run the cruise control radar, and so on. Now engineers and designers are rationalizing the way they go about building new models, taking advantage of much more powerful hardware to consolidate all those discrete functions into a small number of domain controllers.

The behavior of new cars is increasingly defined by software, too. This is merely the progression of a trend that began at the end of the 1970s with the introduction of the first electronic engine control units; today, code controls a car's engine and transmission (or its electric motors and battery pack), the steering, brakes, suspension, interior and exterior lighting, and more, depending on how new (and how expensive) it is. And those systems are being leveraged for convenience or safety features like adaptive cruise control, lane keeping, remote parking, and so on.

Of course, this only works if that software is any good. "There is absolutely no question that software has been treated like a stepchild—I always say the fifth wheel in the car. So like a necessity, but not something that has been managed with care," said Maria Anhalt, CEO of the automotive supplier Elektrobit, which develops digital systems and software for OEMs.

"But what we also see is that every OEM and every SOP and every product line starts from scratch in procurement and doing things for the first time. So part of the complexity is doing things multiple times and not thinking of reuse and architecture and modularity and upgradability," Anhalt explained.

Domain-Controlled Architecture

One can certainly see the appeal of a clean-sheet design that leverages modern computing to simplify a car's underlying design.

"It is much more elegant," said Oliver Hoffmann, Audi's board member in charge of technology development. That doesn't make it easy, though. "But to be honest, it is challenging, because all those functions which were located all over the car—a lot more than 200 controllers—you have to bring all those functions into the domain controller. But it is a very smart solution," he said.

"So as an example we have what we call the high compute platform, and we have a dedicated domain for infotainment, and we are able to update but also to upgrade, so that every year or every two years you can bring an upgrade in terms of hardware, and we are able to run over-the-air updates," Hoffmann told me.

The first Audi we'll see adopt this approach is next year's Q6 e-tron, an electric SUV that is one of the first EVs to use Volkswagen Group's new PPE (Premium Platform Electric) architecture, which will also be used to create the A6 e-tron and the next Porsche Macan.

All the domains—which include driving behavior, thermodynamics, and energy management as well as infotainment—are upgradeable over the air; some earlier implementations of OTA updates by automakers have only allowed for certain systems in those vehicles (like infotainment, but not the powertrain) to be easily updated. "So [it's] a very, very big advantage with this kind of platform, and it's a smart solution," he said.

Audi now uses a 48 V electromechanical stabilizer bar in the suspension that can react within milliseconds.

I was curious if the move from tens or hundreds of discrete black boxes meant completely rewriting all those functions from scratch. While that's always an option, Hoffmann said that Audi was able to use its experience to make the job a little easier. But for PPE that still meant a new way of working.

"It was a completely new way to work together with suppliers," Hoffmann said. "So in the past you had a supplier responsible for the ABS, which was a separate and dedicated controller. Now, there's an interaction between all these domain controllers, so you have to double-check if all this works together with all these other domains or with the rest of the software in the main controller, which makes it very complex," he explained. The solution was to organize "supplier parties" to bring everyone together. This was also complicated, Hoffmann told me, "but I think it is the new way for a collaboration model," he said.

Baked-in Cybersecurity

Another advantage of the move away from legacy designs is that digital security can be baked in from the start rather than patched onto components (like a car's central area network) that were never designed with the Internet in mind. "If you design it from scratch, it's security by design, everything is in by design; you have it there. But keep in mind that, of course, the more software there is in the car, the more risk is there for vulnerabilities, no question about this," Anhalt said.

"At the same time, they're a great software system. They're highly secure. They're much more secure than a hardware system with a little bit of software. It depends how the whole thing has been designed. And there are so many regulations and EU standards that have been released in the last year, year and a half, that force OEMs to comply with these standards and get security inside," she said.

The Hardest Part?

Software-defined vehicles might give automakers more flexibility in terms of the features and functions they can create, but it comes with some headaches on their end, including ensuring that a car works in each market where it's offered.

"All the requirements are different for each region, and the complexity is so high. And from my perspective, this is the biggest challenge for engineers. Complexity is so high, especially if you sell cars worldwide. It is not easy. So in the past, we had this world car, so you bring one car for each market. We are not able to bring this world car for all regions anymore," Hoffmann told me.

"In the past, it was not easy, but it was very clear—more performance, more efficiency, focus on design. And now that's changed dramatically. So software became very important; you have to focus on the ecosystem, and it is very, very complex. For each region you have, you have dedicated and different ecosystems," he said.

"The very simple example is our Q7 [Audi's three-row SUV]. So it's a very, very big car in the European market, but it's a very small car in the US market," he joked.

Oliver Hoffmann (member of the Board of Management for Technical Development) and Gary Telaak (Exterior Design, AUDI AG) check out the Audi Urbansphere concept. This concept was designed with China in mind.

Satisfying The Regulators

A good example is the differing approaches taken by US and European regulators. In the US, automakers "self-certify" their products, declaring to the government that their cars conform with all the applicable safety standards and so on. But in Europe, they practice "type approval"; here, an automaker submits a representative example that a country's regulator will check over and issue a type approval certificate if it conforms.

"From my perspective, [self-certification] is not easier because you are responsible; you're not given a rulebook. The pressures are on our side. And it is a little bit easier in Europe because if they say, 'okay, approved by us,' they are with us," Hoffmann told me.

The move to software-defined vehicles complicates this, as it applies to software as well as hardware. That means each update needs to be signed off by a regulator before being sent out over the air.

"Because in the past, you're able to run a test. You say, 'Okay, you have to crash at 50 kilometers per hour, and if you fulfill everything, you're fine.' But now, it is software-driven. So you run all these corner cases in the software, and you say, 'okay, we have a big improvement in the software,' but how can you test it? You're not able. This is a virtual testing and virtual validation process. And this is a dramatic change," he said.

The most glaring example is the behavior of advanced driving assistance systems. As we've seen from Tesla's example, buggy or badly written ADAS software can lead to crashes and recalls, but edge cases abound. "So this is more or less a validation of your tools and no longer of the product you will bring in the market. And this is especially true when you develop ADAS functionalities; this is the biggest challenge for the future," Hoffmann said.

— Jonathan M. Gitlin is the Automotive Editor at Ars Technica. He has a BSc and PhD in Pharmacology. In 2014 he decided to indulge his lifelong passion for the car by leaving the National Human Genome Research Institute and launching Ars Technica's automotive coverage. He lives in Washington, DC.

#ARS Technica#Oliver Hoffmann#Jonathan M. Gitlin#Audi#Technical Development#48 V Electromechanical Stabilizer Bar in the Suspension

0 notes

Text

Tips to make Indian manufacturing sector strong

The manufacturing industry of India has the potential to reach $ 1 trillion by 2025 and India is expected to rank amongst the top three growth economies and manufacturing destinations of the world by the year 2025. Currently, India is the world’s ninth-largest manufacturing nation. GOI’s ambition is to raise manufacturing’s contribution to 25 per cent of GDP and to create 100 million jobs in the coming decade. Some of the favorable macro trends are the fastest growing economy with sustained GDP growth of 7 per cent plus, existence of infrastructure in Tier2/3 cities, government investment schemes like Make in India & smart cities, large English-speaking talent pool in software, engineering, IT and technical disciplines, many multinationals have made commitments to build plants and hire talent in India for local and global production.

Government of India (GoI) is also providing a supportive ecosystem through multiple policy initiatives such as the introduction of Goods and Service Tax, reduction in corporate tax, interventions to improve ease of doing business, FDI policy reforms, measures for reduction in compliance burden, adoption of public procurement orders, Phased Manufacturing Programme (PMP), Atmanirbhar Bharat package, indigenization of the defense sector, the introduction of Production Linked Incentives (PLI), development of the National Infrastructure Pipeline, National Monetization Pipeline, Industrial Corridor Development Programme in 4 phases. Furthermore, policies like Skill India, Digital India, Start-up India, and Accelerating Growth of New India’s Innovation (AGNII) provide further impetus to manufacturing in India. Key sectors which will fuel the manufacturing growth in India in coming years are automotive, defense, aerospace, pharmaceuticals, agriculture, bio-industry, bio-IT & MSME sector.

While macroeconomic trends are positive but technology gap between industry & engineering colleges or technical institutes must bridge through skill development by having industry/academia partnership. It is important for manufacturing industries to get involved early in product development process and adoption of new technology. Role of supply chain in developing warehouses, inventory management system & effective transportation mode through truck, rail, water, pipeline & air are very crucial. Vision to achieve growth in Indian manufacturing industries to generate bulk employment generation will require the following themes to be implemented in a constructive & planned manner:

Bridging the technology gap between industry requirements & skill resources

Role of Indian engineering service provider to shape the manufacturing industries

Development of Supplier & supply chain ecosystem

Introduction

The Indian manufacturing industry is going through a challenging phase. On one side global partners expect India to take a lead in manufacturing and within India there is a growing need to create manufacturing hubs. Over the last decade or more, the service industry has grown tremendously, which has given the Indian service sector a push and improved the income and life expectancy of service sector resources. The service industry is mature enough and while it continues to grow (in 2023 the service industry exports are expected to almost equal the export of goods), its contribution to generating the volume of employment, which is the need of the hour is not as much as the manufacturing industry.

Indian manufacturing industry can create bulk employment which can be the growth engine for India in the future. The Government is taking initiatives like production linked schemes, skill development & creating economic zones etc. However, these are macro level policies which will not have an effect unless micro level challenges in manufacturing industry are addressed in constructive ways.

Challenges & opportunities

Indian manufacturing industry has a challenge of skilled manpower who will be competitive and take on the challenge to adopt new technologies. Government & industry bodies like CII are making efforts to create skill development programs, but these schemes are not attracting the young resource pool like the IT industry. Genuine interest in manufacturing and the associated opportunities and career growth needs to be created in the minds of the young resource pool, including in the women workforce right from college days.

Utilisation of existing manufacturing units and the manufacturing ecosystem in India is not in line with the global standards. For example, most of the automotive prototype builds (early part of product development) happen in countries like China, S Korea, or Japan. Deliveries of these physical prototypes in 4–6 weeks is primarily because the supplier ecosystem in these countries is such the order is accepted by any one supplier and the others support the deliveries as one team without any administrative delays. Indian manufacturing industry can support OEMS only after the product is matured & with adequate support from global OEMs to adopt newer technologies & investment. Manufacturing industry in India will have get involved in early phases of the product development cycle, so that they will address the needs of the product during inception & digital realization phases.

Manufacturing industry in India still lacks technology adoption. Most of the manufacturing units still depend on manufacturing drawings for the physical realization of products whereas the global manufacturing industry is digitally equipped in terms of 3D data with requisite manufacturing information attached to 3D model which can be viewed & used digitally on the shopfloor to convert into product reality. The 3D CAD data which is created in product development cycle is cascaded to all downstream stakeholders in the manufacturing workstream. PLM systems of OEMs need to be extended to supplier ecosystems so that product realization cycle can be optimised. Blue collar workforce should be sufficiently trained to use these 3D models on workstations & tabs on the shop floor. Design team need to focus on creating rich-content 3D data for downstream agencies to use till the last stages of product realization like after sales & service. Overall manufacturing industry in India must undergo digitisation of entire steps in the product realization processes.

Most of the global automotive & aerospace units have made their investment in terms of creating a R&D setup in India to cater to their global requirements. Indian engineering service providers (ESPs) are supporting these global OEMS by providing services in manufacturing engineering at digital level which we call “digital manufacturing”. These ESPs are working on services like robotic programming, formability analysis, discrete event simulation, factory digitization, human or ergonomic simulation, tool design services like sheet metal, plastic molds, thermoforming molds, BIW jigs & fixture, analytics-based manufacturing, AI/ML based manufacturing for defect analysis, etc. Global OEMs get these advantages from Indian ESPs to increase & optimize their manufacturing base in their own countries and across the globe. The Indian ESPs can play an important part in enhancing the technology content in the Indian manufacturing ecosystem as they are well versed with global standard & new trends in manufacturing. This will help in shaping the Indian manufacturing industry and the ecosystem to deliver global products from India for global customers.

The machine tool industry is considered the mother of all manufacturing, where the skill sets of accuracy, precision & quality is maintained to create better quality of products through various manufacturing processes. There is a growing demand for automation across the manufacturing processes to enhance productivity & meet stringent quality standards. Indian machine tool industry needs to take advantage of these requirements to improve their presence in growing manufacturing hubs and to speed up adoption of technologies like 3D printing & AI/ML based machine tools. This will help in part production & inspection on same machine and an overall improvement of throughput. Technologies which can adopt incremental correction within the machines during production need introduction, so that series production has uniform quality.

While there are challenges in developing the manufacturing units in India there are also equally opportunities which exist in India and need to be leveraged. We still produce a large pool of young resources which need to be channelized through technical institutes and engineering colleges. India has large number of engineering colleges and technical institutes like IGTR, NTTF & many others which are specifically built for the tooling and manufacturing industry. Engineering colleges should have special focus on entrepreneurship for developing manufacturing units.

Female workforce in India is slowly moving to manufacturing industry however their focus is on softer areas like design, purchasing, sales, marketing etc. There are several examples in Indian OEMs (e.g. Tata Motors) where the female workforce has made a huge contribution to improve productivity & quality on shop floor & assembly lines. Few of the OEMS are going for an all-female workforce on assembly lines and they are getting benefits in terms of high productivity, better quality & improvement in plant utilization. The industry also needs to create female champions & leaders who can nurture the female work force to address these challenges. Frugal mindset in Indian resource can be utilized for a lean manufacturing setup across India.

Global OEMs are taking manufacturing engineering services from India & these service provider resources can be utilized effectively to develop manufacturing units. Manufacturing in India is still labour intensive and, therefore, automation for labour intensive activities is essential. Manufacturers now need to use sustainable engineering strategies to step further ahead to compete with other competitors or it may lead to decline in their brand reputation more than the harm it may cause to environment. Government should also create SEZ for manufacturing sectors which measures on the parameters on employment generation by manufacturing units & its supplier ecosystems for global products.

Conclusions

Although there are challenges and opportunities ahead of Indian manufacturing industry, there is a need for constructive focus on following themes so that India can achieve larger GDP in manufacturing pie in coming years. Increased collaboration between the manufacturing industry players, CII and other industry bodies, GoI and other state governments and academia will help facilitate this process.

Bridging technology gap between industry requirement & skill resource: Government should provide incentives to manufacturing industry to tie-up with technical institutes and the service industry. Manufacturing industry needs to do investments and plan for advance involvement in product development processes. Involvement of academia so that final year candidates from technical institutes or Engineering colleges should be working on the shop floor to gain the knowledge, so that they will be industry ready while they are absorbed in manufacturing industry. College students should be given special weightage in terms of compensation by manufacturing industry who can focus their career on manufacturing like the initiatives taken for IT in the nineties. Engineering colleges and technical colleges curriculum should have topics like advanced manufacturing catering to latest industry trends of ‘Smart Manufacturing’, Industry 4.0, IoT, AR and VR. In this regards some development is happening at government level in developing innovation centres across various states.

Role of Indian engineering service provider to shape the manufacturing industries: As Indian engineering service providers are working for global automotive & aerospace customers for two or more decades they are well equipped with various standards like design & quality through which they are delivering digital manufacturing solutions to these global OEMs. Government and CII to create blueprint for Indian manufacturing setups, with the help of NASSCOM, ESPs like Tata Technologies & others and superannuated senior experts from big automotive & aerospace industries.

Development of supplier & supply chain ecosystem: Special manufacturing eco system to be developed with the target of employment generation in mind, like it has been done in countries like Korea. Special status in terms of taxes benefits to be provided to this industry. More start-up companies should be encouraged for manufacturing setups rather than service setup. The warehouse is an integral part of logistics, a tool for competitive advantage. Warehouses are required to hold inventories to balance demand and supply. It acts as a buffer between uncertain supplies and manufacturing plans and cyclic market requirements in the outbound logistics. There is a trend to develop efficient warehousing to support integrated logistics needs. Older warehouses were mere godowns without proper material handling facilities leading to wastages, damages, obsolescence, and higher cost of operation, are steadily being replaced by newer automated warehouses with advanced, computer-controlled material handling system requiring few employees. This will bring about transformation in the logistics and warehousing industry.

Inventory management will play a key role as it affects customer satisfaction. Firms need to maintain the delicate balance between carrying too little inventory and carrying too much. Many companies would greatly be able to reduce their inventories and related cost through just-in-time logistics systems. With technologies like RFID in place, companies would know at any time exactly where a product is located physically within the supply chain. The choice of transportation carriers affects the pricing of products, delivery performance & conditions of the goods when they arrive. In shipping goods to its warehouses, dealers & customers, the firm would be choosing among five main transportation modes like truck, rail, water, pipeline and air.

Learn more at www.tatatechnologies.com

About the Author

Naren Brahme - Vice President of ER&D and heads the Industrial Heavy Machinery (IHM) & Manufacturing Engineering unit at Tata Technologies.

A dynamic & versatile technical professional, specialising in CAD/CAM & CAE, he possesses 30+ years of strong experience in handling and leading full vehicle development programs in construction equipment and material handling OEMs for major engineering design applications having worked with leading organisations.

0 notes

Photo

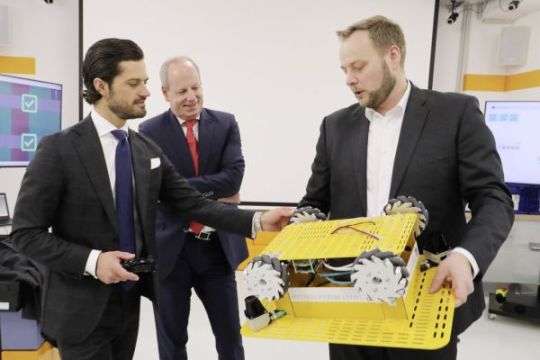

Prince Carl Philip of Sweden visits Volkswagen

02.04.2019

: HRH Carl Philip, Prince of Sweden, is signing the Volkswagen guest book. From left: HRH Carl Philip, Prince of Sweden next to Andreas Renschler, CEO of TRATON SE and a Member of t

HRH Carl Philip, Prince of Sweden, is signing the Volkswagen guest book. From left: HRH Carl Philip, Prince of Sweden next to Andreas Renschler, CEO of TRATON SE and a Member of the Volkswagen Aktiengesellschaft Board of Management Visit centered on Volkswagen’s e-mobility strategy and test drives in the Volkswagen Group’s latest-generation electric vehicles Sweden is one of Europe’s largest markets for electric vehicles – Passat GTE1 is the best-selling electric car in Sweden With Scania, the Volkswagen Group is one of the largest industrial investors in Sweden – €2.4 billion invested in the country in the last ten years Prince Carl Philip met with Swedish startup entrepreneurs at a Volkswagen event on innovative manufacturing technologies and Industry 4.0 Sweden is the Partner Country of Hannover Messe 2019. During his official visit to Germany, Prince Carl Philip was welcomed by Volkswagen Group representatives in Wolfsburg and found out more about the company’s e-mobility strategy. The Swedish Prince was one of the first to test the Group’s new generation of electric cars, including models from the Volkswagen ID. family. Sweden is one of Europe’s largest markets for electric vehicles. Andreas Renschler, CEO of TRATON SE and a Member of the Volkswagen Aktiengesellschaft Board of Management, said: “Sweden is a role model in the area of climate protection. Today, more than half of the electricity generated already comes from renewable sources. That is an essential prerequisite for making e-mobility sustainable for passenger cars as well as trucks and buses.” He went on to say: “We have several innovative e-mobility projects in Sweden, for example, Scania will soon begin testing self-driving electric buses for Stockholm’s public transport system.” Sweden is one of Europe’s largest markets for electric vehicles and therefore an important sales market for the Group’s electric models. With reference to Prince Carl Philip’s test drives, the Volkswagen Brand Board Member for Technical Development, Dr. Frank Welsch, commented: “Prince Carl Philip of Sweden is a talented racing driver and an expert on cars. He was a successful participant in the Porsche Carrera Cup Scandinavia from 2008 to 2011. And he visited the Rally Sweden and the Volkswagen Motorsport team. I am delighted that an acknowledged specialist is one of the first to test our new generation of electric vehicles that will hit the market from 2020. Sweden will be one of the major sales markets for our ID.” His Royal Highness Prince Carl Philip met with 34 Swedish startup entrepreneurs in Germany for Hannover Messe 2019 on his visit to the Volkswagen Smart.Production:Lab in the IT:City, Wolfsburg. These selected startups participated in an Innovation Day at Volkswagen where concepts and innovations such as electrically-powered automated transport concepts and virtual reality solutions as well as machine learning and artificial intelligence software tools were presented. The event was designed to intensify Swedish-German cooperation in the field of innovative manufacturing technologies and Industry 4.0. The Volkswagen Group is one of the largest industrial investors in Sweden. Scania invested €2.4 billion in Sweden in the last ten years. Scania produces trucks and buses in Europe, South America and Asia and is one of the world’s leading manufacturers of sustainable transport solutions. 96,500 trucks and buses were delivered to customers in 2018 – 19,000 of which were built at the Swedish plant in Södertälje. 20,700 of Scania’s total workforce of 52,100 are employed in Sweden. In early 2018, Scania invested €10 million in the battery manufacturing company Northvolt. The collaboration concerns the industrial scale production of battery cells. A joint research consortium called European Battery Union led by Volkswagen and Northvolt was announced recently. The consortium is applying for funding from the German Federal Ministry for Economic Affairs and Energy to finance the research, development and industrial scale production of battery technology. Furthermore, the Volkswagen Group is one of the largest car manufacturers in Sweden. 103,000 passenger cars and 16,700 trucks from the Group were registered in Sweden in 2018, accounting for a 27.4 percent share of the passenger car market and a 30 percent share of the truck market. The Volkswagen Golf, Passat and Tiguan are among the top ten passenger car models in Sweden’s registration statistics, putting Volkswagen in second place behind Volvo. Electric vehicles accounted for a market share of eight percent in Sweden in 2018. The Volkswagen Passat GTE Leslie Bothge- photos Volkswagen

Permanent-URL:

http://www.automobilsport.com/prince-carl-philip-sweden-visit-volkswagen---188764.html

02.04.2019 / MaP

More News

Dr. Ralf Brunken is new Director of AutoUni

02.04.2019

Predecessor Prof. Dr. Mark Gonter assumes senior management function in Procurement at Audi AG Dr. Ralf Brunken, formerly CIO at ŠKODA, has taken over as Director of the AutoUni effective April 1. He succeeds Prof. Dr. Mark Gonter, who assumes responsibility for value analysis in the future fields of e-mobility, autonomous driving and connectivity in

more >>

Season Opener: Opel Insignia Sports Tourer for Formula Student Teams

01.04.2019

Largest student racing series in Europe: design competition for young talents Opel as partner: Of five universities near German sites Team vehicles: Opel provides the students with five Insignia Sports Tourers

more >>

New Pastport Trim in 2019 Honda Passport Lineup Throws Back to Simpler Times and Nineties Nostalgia

01.04.2019

Pastport – the nineties-inspired Honda Passport trim – offers nostalgic enthusiasts the simplicity and self-expression of the '90s Features "state-of-the-art" automatic windows, digital clock, cassette-to-CD converter a

more >>

Change in management at Messe Frankfurt USA and South Africa

29.03.2019

Effective 1 April 2019, Konstantin von Vieregge, Managing Director of Messe Frankfurt South Africa, will be moving to Atlanta to assume the position of President at Messe Frankfurt Inc. He will be succeeded by Joshua Low, who has already been Group Exhibition Director at Messe Frankfurt South Africa since June 2017.

more >>

Realignment of BMW Group Design

29.03.2019

Sustainable structures for the future:- Jozef Kaban new head of Rolls-Royce design - Domagoj Dukec takes over BMW design - Van Hooydonk: “a signal of our future orientation”The BMW Group is reorganising its Design division and taking the next step towards sustainable, leaner structures. Jo

more >>

Volkswagen exchanges more than 300,000 old diesels

28.03.2019

Group brands Audi, SEAT, ŠKODA, Volkswagen Passenger Cars and Volkswagen Commercial Vehicles make a key contribution to air quality improvement in German cities with exchange incentives Incentives for nearly new cars extended until further notice throughout Germany for VW and Audi Incentives for new cars to expir

more >>

Testing of the new Porsche Taycan has entered the final stage

28.03.2019

From a computer simulation via the test bench to the roadPorsche’s first purely electrically driven sports car, the Taycan, is currently completing its final test drives before it enters series production. In Scandinavia, just a few kilometres awa

more >>

Daimler and Geely Holding form global joint venture to develop smart

28.03.2019

50:50 joint venture between Daimler and Geely based in China to develop and operate smart brand globally as all electric carmaker smart to gain shared expertise in manufacturing, engineering and design from both groups smart to expand to meet demand for electrification, with production based

more >>

Groupe PSA accelerates its deployment in China’s aftermarket by acquiring LONGSTAR

28.03.2019

• Groupe PSA pursues the deployment of its strategic plan, after the acquisition of shares in two other parts distributors in 2018[1].• Groupe PSA has the ambition to establish a strong position in the Independent Aftermarke

more >>

SEAT will launch six electric and plug-in hybrid models and develop a new platform in Spain for electric vehicles

27.03.2019

SEAT ANNUAL MEDIA CONFERENCE• SEAT obtains its highest ever profit after tax of close to 300 million euros and its turnover nears 10 billion euros, the highest in history• In 2018, the company allocated more than 1.2 billion euros to investments and R&D expenses, a record figure•

more >>

First McLaren carbon fibre chassis delivered

22.03.2019

...from new £50M McLaren Automotive Innovation and Manufacturing Centre First prototype MonoCell produced in new £50m innovation centre McLaren Composites Technology Centre in Sheffield

more >>

Valvoline new partner for KTM Sportcar

22.03.2019

VALVOLINE TO BE EXCLUSIVE OEM FOR KTM X-BOWKTM Sportcar GmbH, Austria’s only OEM and manufacturer of the KTM X-BOW super sportscar is launching an exclusive cooperation with Valvoline, one of the world’s leadinglubricant manufacturers, just in time fo

more >>

Volkswagen forms European Battery Union with Northvolt

22.03.2019

European companies and institutes join forces under the leadership of the Volkswagen Group and Northvolt to form the European Battery Union (EBU) consortium Consortium wishes to participate for funding for the research, development and industrial implementation of battery technology The Volkswagen Group and furt

more >>

Diess: “Safeguarding our future can only succeed together”

20.03.2019

Works meeting in Wolfsburg Diess thanks employees for their performance and appeals for efforts to master the transformation to continue The Chairman of Volkswagen called for better cooperation on future topics at Volkswa

more >>

Surfing in the desert - Extreme driving

19.03.2019

• The SEAT Tarraco undergoes testing on Morocco’s Erg Chebbi, one of the most unforgiving places on the planet• Dunes that soar to the height of the Sagrada Familia challenge driving assistants such as the

more >>

Groupe Renault announces appointments in Regions

19.03.2019

In order to accelerate the Group transformation, boost the profitability of operations and develop growth in new markets, Groupe Renault announces the following appointments in its Regions. As of April 1, 2019:

more >>

Prototype for new Porsche company architecture opened in Palm Springs

19.03.2019

Porsche dealerships receive worldwide new corporate architectureWelcoming and experiential: Porsche is launching a new corporate architecture for its Porsche Centres worldwide. Following the tagline “Destination Porsche,” dealerships are intended to

more >>

Fossil energy sources go, Power-to-X comes

14.03.2019

Greenhouse gas emissions must be reduced and fossil fuels must be intelligently replaced. Power-to-X is the solution to many questions relating to the Paris Climate Agreement. Green electricity is turned into synthetic fuels, which are used in numerous industrial applications.The Paris

more >>

Designing the first CUPRA, in three stages

14.03.2019

The creative process that goes into a concept car • Hundreds of sketches, virtual reality and more than six months of work to make the CUPRA Formentor come to life• A combination of technology and a sophisticated image, the priority of the designers• Virtual re

more >>

Nissan and Mitsubishi to launch new kei cars as collaboration expands

14.03.2019

All-new minivehicles introduced through NMKV joint venture will be first to offer semiautonomous driving technologyNissan Motor Co., Ltd. and Mitsubishi Motors Corporation will introduce four new minivehicles in Japan through their joint venture, as th

more >>

Opel Returns to Russia

14.03.2019

Comeback with initial line-up of three models this year still Grandland X, Zafira Life and Vivaro to be available in Russia in fourth quarter Zafira Life and Vivaro Transporter to be built in the Kaluga plant Further models will follow soon&nbs

more >>

Groupe Renault announces the new composition of executive committee

13.03.2019

In order to respond to the sweeping changes taking place in the automobile industry, accelerate the company’s transformation to better meet customer expectations and improve the efficiency and profitability of operations, Thierry Bolloré, CEO of Groupe Renault, has

more >>

LVCVA Board of Directors Votes to Move Forward with Elon Musk's The Boring Company

12.03.2019

The Las Vegas Convention and Visitors Authority (LVCVA) Board of Directors today made a monumental decision that will revolutionize Southern Nevada’s transportation. The 14-member Board approved a recommendation to select

more >>

Eric Basset appointed Director of PSA Retail France

12.03.2019

Effective 11 March 2019, Eric Basset is joining PSA Retail, Groupe PSA’s distribution group, as Director of PSA Retail France.He will report to Anne Abboud, Senior Vice-President of PSA Retail.From that date, he will also take ch

more >>

Renault - Nissan - Mitsubishi new Alliance operation board

12.03.2019

Jean-Dominique Senard, Chairman of Renault, Hiroto Saikawa, CEO of Nissan, Thierry Bolloré, CEO of Renault and Osamu Masuko, CEO of Mitsubishi Motors, announce the intention to create a new Alliance operating boardFrom left to rig

more >>

New BMW 7 Series Sedan- Start of production

11.03.2019

Extensive update for Dingolfing’s top model – First plug-in-hybrid with six-cylinder engine – Digitalisation supports production processProduction of the new BMW 7 Series Sedan got underw

more >>

Ford Sponsors 30 Team SA Athletes for Special Olympics in Abu Dhabi

08.03.2019

• Over R1-million sponsorship provided by Ford for 30 special needs athletes• 2019 Special Olympics Summer World Games takes place from 14 to 21 March• SA National Team will compete in football, futsal (five-a-side female soccer), table tennis, equestrian, bocce, open-water swimming,

more >>

Who said this industry was a man’s world?

07.03.2019

• Women are behind several innovations that have shaped the automotive sector• Lane markings, turn signals and rear view mirrors all have the hallmark of a female creative mind• The industry added most of these inventions as standard equipment even though they were rarely paten

more >>

Audi A3 Sportback g-tron available to order beginning on March 7

07.03.2019

Starting the New Model Year with a Longer CNG Range Noticeable power boost thanks to new engine with 131 metric hp Tank concept enables pure CNG range (WLTP) of around 400 kilometers (248.5 miles)

more >>

Audi Now Ranks 1st and 2nd in Endurance Test by “Auto Bild”

07.03.2019

New Evidence of Top Quality: The A4 Avant 2.0 TFSI covered a distance of 100,000 kilometers without any problems and performed outstandingly, achieving a grade of 1 Audi places first and second in &l

more >>

Audi installs used lithium-ion batteries in factory vehicles

06.03.2019

The brand applies used batteries from electric cars in its own production plant Testing of second-use concept at the Ingolstadt site A second life for batteries from electric car

more >>

Opel Corsa 120Y Special Edition

06.03.2019

Extra Styling & SpecificationsOpel's core brand characteristic is to always offer customers more than they expect in the respective vehicle class.In celebration of our brand's solid reputation and OPEL's 120 years in the vehicle i

more >>

The Ferrari F8 Tributo is revealed

05.03.2019

A tribute to the most powerful V8 engine ever Ferrari F8 Tributo, the new mid-rear engined sports car that represents the highest expression of the company's classic two-seater berlinetta. Its name is an homage to both the model's

more >>

McLaren poised to redefine the rules of Grand Touring

05.03.2019

McLaren announces intention to introduce a new Grand Tourer Announcement made by CEO, Mike Flewitt, during McLaren’s Geneva press conference Image released of a camo

more >>

Leading photographer presents "Phantom off Duty"

01.03.2019

Witnessing the ‘Gentleman’s Tourer’ at the Geneva motor show, automotive culture photographer, Mark Riccioni, voiced a desire to capture this significant motor car in a fashion befitting of its spirit: disruptive, imperious and unapologetically contemporary.

more >>

Axel Andorff, new SEAT Vice-president for R&D

01.03.2019

As of 1st March he will be replacing Dr. Matthias Rabe, who will lead the new Technical Development Operations area at the Volkswagen brand following 8 years as member of the SEAT Executive Committee The new Vice-president has close to 20 years’ experience at Daimler He will be responsible f

more >>

Lighting Technology for Everyone: Opel Astra Turns Night into Day

28.02.2019

120 Years of Opel Automobile Production Anniversary offer: Astra “120 Years“ special edition at attractive prices Making cars since 1899: Best lighting has a

more >>

Selezione Lamborghini Certified Pre-Owned

27.02.2019

Automobili Lamborghini launches Selezione Lamborghini Certified Pre-Owned, a new, comprehensive certification program for pre-owned cars sold through the authorized Lamborghini dealer and service center network worldwide. Selezione Lamborghini p

more >>

The day the Popemobile was spared

27.02.2019

The history of a brand A fire in SEAT’s factory in Barcelona jeopardised the brand’s historic car collection Swift action taken by SEAT personnel and fire-fighters prevented damage to the vehicles The collection features gems such as a Popemobile, the second last 600 e

more >>

1 note

·

View note

Text

PCB Manufacture: China vs. US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concerns when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provide 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest Medical PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/

1 note

·

View note

Text

PCB Manufacturer China and PCB Manufacturer US

Looking back on your daily life, have you noticed the growth of consumer electronics and automotive industries are affecting your life and work? Accordingly, it also drives the booming market of PCB Manufacture, which is expected to reach an estimated $89.7 billion by 2024 with a CAGR of 4.3% from 2019 to 2024. Much of this market is currently controlled by PCB manufacturer China companies in places like Shenzhen, which is located in Southeastern China. However, the history of PCB booming in the United States can be traced back to 1950, which is far earlier than China entering this market.

So why can PCB Manufacturer China dominates the market rather than the United States? To solve the confusion for PCB procurements about choosing PCB manufacturer China or US instead, we’ve listed the comparison between the United States and China.

Competitive factors of PCB manufacturer China

According to this report, the price was the dominant primary competitive factor in Non-U.S PCB manufacturer, accounting for 76 percent of responses, and China was the leading location, accounting for 67 percent of responses.

And the comparative advantages in various costs which result in lower finished bare PCB prices are:

Labor Costs

Material Costs

Equipment Costs

Environmental Compliance Costs

Building Space Costs

R&D Costs

Supplier Chain

Let’s take Shenzhen MOKO Technology Co., Ltd as an example, which is one of the leading SEM PCB manufacturing and PCB assembly factory in Shenzhen, China.

Labor cost: As you know, Shenzhen is a fast-developing city that gathers many high-tech electronics and automotive industries, each company included MOKO requires clear division of labor, and due to the economic level of China compared to US and easier access to skilled workers, the labor cost of MOKO is far cheaper than in US.

Material cost: MOKO Technology was established since 2001, it’s proficient and experienced in manufacturing PCB and PCB assembly, and also established a stable relationship with accountable material supplier. For a PCB manufacturer that aims to win customers with high-quality and after-sale service, there are many audit processes to certified a material supplier, so the long-term relationship with material suppliers saves a lot of cost of MOKO Technology. Of course, it also doesn’t mean that there’s an opportunity for the material supplier to mix some poor material, from the material sourcing to the forming of a substrate and the performance testing of the final products, each process is under strict requirements and testing.

Equipment cost: Chinese high-end equipment is constantly replacing the import, recognized and ordered by the famous PCB enterprises at home and abroad as its high-quality and cost-saving, such as laser drilling machine, laser cutting machine, CNC drilling machine, automatic laser imaging system (LDI), vertical continuous electroplating automatic line (VCP), automatic automatic on and off detection. The main PCB special equipment/instrument representative companies in China are Han’s Laser Technology Industry Group Co., Ltd, Zhengye Technology, UCE Group, Shenzhen Mason Electronics Co., Ltd., and Ta Liang Technology Co., Ltd.

R&D Costs: Due to the overall economic and outcome level in China, the educated and experienced Engineers' salaries and R&D equipment, relevant material and tooling are cheaper than in the US.

Supplier chain: As mass PCB production has shifted away from the U.S. towards Asia,especially Shenzhen, so China has the advantage of the industry supply chain.

Forty-five percent of BIS survey respondents stated that a reduction in U.S. companies that manufacture laminate and other circuit-board related materials has created supply problems for them.

Furthermore, Electronic Contract Manufacturing has been known historically to dramatically reduce supply chain costs, in some cases cutting them in half. ECM has made it possible for companies to shed all or most of their internal manufacturing facilities thereby freeing their valuable company resources for other productive business purposes. In some cases, Electronic Contract Manufacturing has enabled companies to operate without the need for internal manufacturing capabilities or internally-managed factories.

Many companies may choose to outsource their well-established longstanding products to an Electronic Contract Manufacturer, thereby allowing for a greater focus on internal operations for newer products of greater complexity which may have higher margins.

Competitive factors of PCB manufacturer US

According to respondents, U.S. bare PCB manufacturers possess the comparative advantage in:

Lead Time

Quality

Performance

Through the comparison of the advantage between PCB manufacturer China & the US, I believe you’ve got a clear idea for choosing the PCB manufacturer between China and the US, so the next thing you should figure out is what you most concern when choosing a PCB manufacturer.

Cost

Quality

Lead time

MOQ

Design safety

Experience & Expertise

After-sale service

If you’re considering high-volume production and the price is the most essential factor for your market plan, then you should choose a PCB manufacturer in China as it can save you lots of money for other donate or patronage.

And of course the quality should not be ignored, there are many excellent PCB manufacturers in the US with advanced equipment for ensuring the quality and lead time, and if your company is based on the US, maybe it would be convenient for you to visit the company.

But we know, for business, who don’t want to cooperate with a company that can be conformed to both cost and quality? And of course, to establish your long-term relationship with the PCB manufacturer, most of you would choose to start with a prototype or sample, which is a good way to decrease the deficit and finding out the problem before mass production.

So in such a condition, I suggest you find a reputable and certified experienced PCB manufacturer in China.

Located in Shenzhen, China, MOKO Technology is an expert at PCB Manufacturing and PCB assembly since 2001. MOKO covers an area of more than 8,000 square meters, and has over 250 employees, among them, there are 70 engineers for R&D team and 45 overseas sales for the business team.

Cost:

Firstly, based on geography advantage, MOKO Technology can save a lot of costs like material, component sourcing, labor cost and so on.

Secondly, it has a professional complete procedure from the inquiry to shipping. After receiving the inquiry, MOKO Technology has a team to evaluate customers’ requirements and make an optimized scheme for you, for the material, you will be suggested to choose the suitable material that can perform best for the property.

Thirdly, MOKO Technology has the advantage of supplier chain and it’s experienced in EMS with a one-stop service, which only saves you lots of time and money.

Quality:

For the R&D cost, MOKO Technology has hired experienced 70 engineers

Certified in accordance with ISO 9001: 2015, IPC, and UL (PCB factory: E501497 94V-0; PCB assembly factory: E499341) standards

Bare Board 100 % Visual Inspection & AQL on mechanical to IPC-600 Class II or III

Assembly 100% Visual Inspection to IPC-610 Class II or III

Polar TDR Impedance Testing

PCB Board Net List Electrical Testing 100%

Micro-section Evaluation and Reports

PCB Assembly – ICT testing

PCB Assembly – Functional Testing

PCB Assembly – Burn-In-Testing

X-ray for PC board registration

X-ray for BGA and Component Verification

Automated Optical Inspection (AOI)

Lead Time of PCB Assembly:

MOKO provides 2-50 layered PCBs for fabrication, including HDI, Rigid, Rigid-Flex, & flex boards. From low quantity to mass production, with high quality, and quick turn available at a low cost.

And for the monthly capacity, it can manufacturer 30,000 square meters PCB and 400,000 pcs.

There’s no minimum order requirement, and for the sample, MOKO Technology can accept 10 pcs as MOQ.

Design safety:

About this issue, you can never worry about it as MOKO Technology will sign DOD Contracts with ITAR Registered

After-sale service:

Online Tracking

ERP Systematic order process, you can check the production status of the entire purchase order, and the whole product cycle time.

Professional sales:

Whatever problems happening, you can be replied within 24 hours. There are 70 engineers to support you, including PCB design & PCB Layout, hardware design engineering, firmware & software development, and personalization.

One pair one timely customer order status feedback

MOKO Technology Ltd is a premiere turn-key PCB assembly manufacturer. We are dedicated to providing the best client service in the electronics manufacturing business. Your total satisfaction is extremely important to us. We will meet all your needs in PCB design and layout, PCB manufacturing, and circuit board assembly

Products application industries1> LED PCB

MOKO Technology can offer one-stop service for led light electronic parts focusing on ODM/OEM led PCBA, OEM LED control PCBA and OEM LED Driver PCBA.

It can design hardware, firmware, iOS/Android APP, plastic. If you have a Gerber file and BOM list, they also can offer OEM service for you.

What can MOKO Technology do for LED project:

PCB Design & Layout

Reverse Engineering Service

Fast PCB&PCBA Prototyping

Components sourcing

PCB Assembly

Cable, Wire Assemblies, and Housing Assemblies

Cover coating and glue

Loading firmware & function testing and Aging testing

ODM/OEM LED PCBA Service:

MOKO Technology produced lots of led PCBA, for example, UV LED PCBA for medical machine, UV LED PCBA for 3D printer, AC220V driverless led PCBA, AC110V driverless led PCBA, LED PCBA for street light, LED PCBA for tube light, LED PCBA for panel light, COB RGB LED PCBA for pool light, RGB LED PCBA for pixel light, LED PCBA for ceiling light, LED PCBA for traffic light, etc.

LED PCBA Design & Layout Cases:

MOKO Technology Ltd is a highly respected telecom PCB Assembly, telecom PCBA Manufacturer specializing in prototyping and small volume building in the highly complex area or telecom and industrial computing Printed Circuit Board Assembly(PCBA), PCB Assembly, PCB Assembly service for leading OEMs.

Telecom Printed Circuit Boards Applications:

Phone switching systems

Signal boost online systems

Cell transmission and tower electronics

Satellite technology High-speed routers and servers

Wireless industrial and commercial phone technology

Space communications technology

Military communications systems

Video collaboration Information security technology

PBX systems Voice over internet protocol

Latest Telecom PCBA Cases:

To ensure a positive response from “end”-consumers, many customers from MOKO build on the quality and reliability provided from MOKO.

Latest Consumer Electronics PCBA Cases:

MOKO offers world-class, custom-designed solutions for the automotive market including rapid prototyping, test and product development support with the highest level of quality and traceability to meet your unique requirements.

Latest Automotive PCBA Cases:

MOKO Technology Ltd specializes in the medical PCB assembly and medical PCB production for medical companies of all sizes.

The workmanship of MOKO Technology Ltd can be found in many medical devices such as diagnostic imaging equipment, lasers, and handheld dental tools.

Latest PCBA Cases:

For several years, MOKO has worked with a variety of customers in the industrial market segment from sensors, conditioning systems for alternative energy, power monitoring systems, industrial controls as well as others with demanding environmental requirements.

Latest Industrial PCBA Cases:

So after all this research above, I think choosing the most suitable PCB manufacturer according to your concern is a wise choice. Whatever it’s PCB manufacturer China or PCB manufacturer US, make sure you’ve been clear about your concerns and know your supplier well!

For more info about MOKO Technology Co., Ltd, you can visit https://www.mokotechnology.com/ and https://www.mokotechnology.com/pcb-manufacturer-china-vs-us/

1 note

·

View note

Text