#Process automation

Explore tagged Tumblr posts

Text

7 notes

·

View notes

Text

#artificial intelligence#process automation#technology#ai#ai for business#business solutions#wordpress web design#drupal#web development

0 notes

Text

youtube

0 notes

Text

Unlocking Efficiency with Accounts Payable Automation: A Game-Changer for Your Business

In today’s fast-paced business world, efficiency and accuracy are paramount. As companies scale, managing financial transactions becomes increasingly complex, and manual processes often slow down operations. One key area where automation can have a significant impact is in Accounts Payable (AP). By embracing AP automation, businesses can streamline processes, reduce errors, save time, and enhance overall financial management. Here’s why AP automation is a game-changer for your business and how it can unlock new levels of productivity and financial control.

What is Accounts Payable Automation?

At its core, Accounts Payable automation is the use of technology to streamline and automate the process of managing a company’s outstanding bills and payments. The goal is to replace manual tasks—such as data entry, invoice approval, and payment processing—with automated workflows powered by software. AP automation helps businesses capture, process, and pay invoices with minimal human intervention, making the entire process faster, more accurate, and more transparent.

Top Benefits of Accounts Payable Automation

1. Time Savings and Increased Productivity

Manual AP processes can be time-consuming. Invoices have to be manually entered, checked for discrepancies, approved, and then processed for payment. With AP automation, these tasks are simplified and handled by the software, freeing up your finance team’s time to focus on more strategic activities. No more sifting through piles of paper invoices or chasing down approvals—everything is streamlined and efficient.

2. Cost Reduction

While it might seem like an upfront investment, AP automation pays off in the long run by reducing labor costs, minimizing errors, and preventing late payment fees. Automated systems allow for better invoice matching, reducing discrepancies and ensuring that you only pay for what you owe. Additionally, with fewer resources needed for manual tasks, businesses can reallocate funds toward more valuable initiatives.

3. Enhanced Accuracy and Reduced Errors

Manual data entry is prone to human error—whether it’s a typo, misread invoice, or missed approval. These small mistakes can lead to big financial problems, including overpayments, missed discounts, or damaged vendor relationships. AP automation drastically reduces the risk of these errors by using intelligent software to match invoices with purchase orders and contracts. This ensures that every payment is accurate, on time, and in full compliance.

4. Improved Visibility and Control

Automating accounts payable provides businesses with greater visibility into their financial operations. With real-time data and analytics, finance teams can quickly track the status of invoices, payments, and cash flow. Reports and dashboards offer insights into spending patterns, outstanding invoices, and upcoming payments, helping businesses make informed decisions and maintain better control over their financial situation.

5. Faster Payments and Stronger Vendor Relationships

Paying invoices on time is crucial for maintaining good relationships with your vendors. AP automation can help businesses stay on top of due dates and even take advantage of early payment discounts. With automated workflows, you can set reminders for upcoming payments and ensure that your company consistently pays on time, improving vendor trust and loyalty.

Scalability and Flexibility

As your business grows, so does the volume of invoices and payments. Manual AP processes can become increasingly burdensome and inefficient at scale. AP automation software can easily accommodate increased transaction volumes without the need for hiring additional staff or overburdening existing employees. Furthermore, automation platforms are highly customizable, allowing businesses to adjust workflows and processes as their needs evolve.

How AP Automation Works

The process of automating Accounts Payable is relatively straightforward. Here’s how it typically works:

Invoice Receipt: Invoices are captured through multiple channels, such as email, PDF files, or directly from suppliers through electronic data interchange (EDI).

Data Extraction: The automation software extracts relevant information from the invoice, such as the amount, due date, and vendor details, and inputs it into the system.

Approval Workflow: The software routes the invoice for approval based on pre-set rules. Managers can approve or reject invoices from their mobile devices, ensuring quick decision-making.

Payment Processing: Once approved, the payment is processed automatically, either by issuing a check, initiating a bank transfer, or even making electronic payments through a payment gateway.

Record Keeping: The system stores all invoice and payment details in a secure cloud repository, making it easy to track and retrieve data for future reference.

Overcoming Challenges with AP Automation

While the benefits are clear, the transition to AP automation can be challenging for some businesses. It’s important to consider factors such as integration with existing financial systems, employee training, and vendor adoption. However, most modern AP automation solutions are designed to integrate seamlessly with existing Enterprise Resource Planning (ERP) systems and accounting software, making the transition smoother.

To ensure success, businesses should carefully evaluate their needs, choose the right automation tools, and establish clear implementation timelines. Additionally, training staff on the new process and ensuring that vendors are onboard with digital invoicing are key steps to overcoming any challenges.

The Future of Accounts Payable Automation

As technology continues to advance, the future of AP automation looks even brighter. Artificial intelligence (AI) and machine learning (ML) are becoming more integrated into AP automation software, enabling systems to learn from past behavior and make even smarter decisions. For example, these technologies can predict payment dates, detect fraudulent invoices, and offer insights into optimizing cash flow management.

With the rise of cloud-based platforms and the increasing shift towards digital-first businesses, the adoption of AP automation is expected to grow exponentially, transforming the way businesses handle their financial operations.

Conclusion: Transform Your Accounts Payable Today

AP automation isn’t just about reducing paperwork—it’s about transforming the way your business manages its financial processes. By automating routine tasks, you can save time, reduce costs, improve accuracy, and gain greater control over your financial data. Whether you’re a small business looking to streamline operations or a large enterprise seeking scalability, accounts payable automation is a smart, strategic investment that can drive efficiency and growth.

Ready to take your accounts payable to the next level? Embrace automation today and unlock a more efficient, cost-effective, and error-free future for your business!

Original Source: accounts payable automation

0 notes

Text

Additive Manufacturing as a Problem-Solving Tool in Pharmaceutical Processing:

A hybrid raxial mixing impeller is designed and implemented to resolve dispersion mixing issues in a pharmaceutical application

While process automation, a core tenet of the transition to Industry 4.0, can minimize or eliminate processing issues associated with a wide range of material variability, some variations require physical alterations to processing equipment to be implemented. In this article, segregation issues caused by an API supplier change are addressed rapidly and efficiently via another pillar of Industry 4.0, additive manufacturing.

0 notes

Text

A vision may be sparked by one, but it takes a team to turn it into reality.

🌍 Did you know that 75% of employees consider teamwork and collaboration as essential to business success? While a great idea may start with a single person, it’s the power of a united team that brings it to life.

Team psychology shows us that when people feel part of a shared mission, they’re more motivated, resilient, and willing to go the extra mile. The synergy of diverse skills and perspectives turns vision into results, building something stronger and more sustainable than one person alone ever could.

How does your team come together to make things happen?

Share a moment when collaboration made all the difference! 👇

#SME Scale#Business growth#Scaling strategies#SME consulting#Digital marketing#Process automation#Sales optimization#Lead generation#Marketing automation#Growth blueprint#Customer acquisition#Business strategy#Online presence#SEO services#Content strategy#Digital transformation#Sales funnel#Business automation#Revenue growth#Marketing strategy#Business development

0 notes

Text

The Future of Automation: Emerging Trends and Technologies

The future of automation is promising, with emerging trends and technologies poised to revolutionize the way businesses operate. From RPA 2.0 to hyper automation, edge computing, AI-driven analytics, quantum computing, and human-AI collaboration, the landscape of automation is evolving rapidly. Staying abreast of these trends will be essential for businesses aiming to remain competitive and innovative in the years to come. Embracing these developments will not only streamline processes but also drive growth and efficiency in the increasingly automated world of business.

At Tecnolynx, we specialize in developing customized automation strategies, integrating the latest technologies, maximizing the potential of your data assets, and promoting effective human-AI collaboration. By choosing to work with us, you can confidently navigate the dynamic world of automation and position your business for future success.

#Business automation#Automation technologies#Efficiency improvement#Cost reduction#Innovation in business#Process automation#Digital transformation#Industry 4.0#Automation benefits#Workflow automation

0 notes

Text

The Critical Role of Instrument Earthing in Industrial Safety and Accuracy

In the complex world of industrial instrumentation and control systems, one crucial aspect often overlooked is instrument earthing. This fundamental practice not only ensures the safety of personnel and equipment but also plays a vital role in maintaining the accuracy and reliability of measurements. Let's delve into why instrument earthing is so important and how it impacts various industrial processes.

What is Instrument Earthing?

Instrument earthing, also known as instrument grounding, is the practice of connecting the metallic parts of instruments and their associated circuitry to the earth. This connection provides a low-impedance path for fault currents and helps to maintain a stable reference potential for measurements.

Safety First: Protecting Lives and Equipment

The primary purpose of instrument earthing is safety. By providing a path for fault currents to flow into the ground, earthing helps prevent electric shocks that could harm operators or maintenance personnel. In the event of a short circuit or insulation failure, the earthing system directs the dangerous current away from people and sensitive equipment, potentially saving lives and preventing costly damage.

Ensuring Measurement Accuracy

Beyond safety, proper earthing is crucial for maintaining the accuracy of instrument readings. In industrial environments filled with electromagnetic interference (EMI) and radio frequency interference (RFI), unearthed instruments can pick up noise that distorts measurements. A well-designed earthing system acts as a shield, diverting these unwanted signals and ensuring that only the intended process variables are measured.

Mitigating the Effects of Static Electricity

Many industrial processes, especially those involving the movement of fluids or powders, can generate static electricity. Without proper earthing, this static charge can build up, leading to sparks that may ignite flammable materials or cause erroneous readings in sensitive electronic instruments. Effective earthing dissipates static charges safely, maintaining a stable operating environment.

Implementing Effective Instrument Earthing

To reap the full benefits of instrument earthing, consider these key points:

Dedicated Earth: Use a separate instrument earth, distinct from the power system earth, to avoid interference from power-related disturbances.

Low Impedance: Ensure the earth path has low impedance to effectively conduct fault currents and unwanted signals.

Regular Maintenance: Periodically inspect and test earthing connections to maintain their effectiveness over time.

Proper Bonding: Bond all instrument cases, cable shields, and junction boxes to the instrument earth to create a unified reference potential.

Avoid Ground Loops: Carefully plan earthing connections to prevent ground loops that can introduce noise into measurements.

Conclusion

Instrument earthing is not just a regulatory requirement—it's a critical practice that underpins the safety, accuracy, and reliability of industrial instrumentation systems. By implementing and maintaining proper earthing techniques, industries can protect their workforce, safeguard valuable equipment, and ensure the integrity of their process measurements. In an era where data-driven decision-making is paramount, the role of instrument earthing in providing accurate, noise-free measurements cannot be overstated.

Remember, a well-grounded instrument system is the foundation of a safe, efficient, and precise industrial operation. Don't let this crucial aspect of your instrumentation infrastructure fall by the wayside—give instrument earthing the attention it deserves and learn more about instrument earthing iec standard.

#earthing#instrument earthing#industrial safety#electrical safety#instrument accuracy#grounding#earthing system#electrical grounding#safety regulations#industrial automation#process control#electrical engineering#safety tips#safety first#electrical safety tips#industrial safety tips#safety practices#electrical grounding tips#electrical safety practices#electrical grounding practices#industrial safety practices#instrumentation#electrical instrumentation#process automation#safety precautions#electrical safety precautions#industrial safety precautions#electrical grounding precautions#instrumentation engineering#electrical

0 notes

Text

The future of customer interactions might be more automated than we think! 𝗖𝐨𝐧𝐭𝐚𝐜𝐭 𝐮𝐬 𝐭𝐨𝐝𝐚𝐲 𝐟𝐨𝐫 𝐚 𝐟𝐫𝐞𝐞 𝐃𝐞𝐦𝐨 & 𝐐𝐮𝐨𝐭𝐞𝐬! 𝗙𝗼𝗿 𝗺𝗼𝗿𝗲 𝗶𝗻𝗳𝗼𝗿𝗺𝗮𝘁𝗶𝗼𝗻:👇 🌐𝗩𝗶𝘀𝗶𝘁 𝗨𝘀: https://botgo.io

0 notes

Text

Learn the key benefits of process automation in retail, including optimized staffing, faster checkouts, and better inventory control.

0 notes

Text

Exploring the Growth and Impact of the Process Automation and Instrumentation Market

The Process Automation and Instrumentation Market was valued at USD 67.12 billion in 2023 and will surpass USD 102.17 billion by 2030; growing at a CAGR of 6.2% during 2024 - 2030.The process automation and instrumentation market is at the forefront of this industrial evolution, driving innovation and enabling industries to achieve these goals. This blog explores the dynamics, growth, and impact of the process automation and instrumentation market, shedding light on how it’s transforming industries worldwide.

Understanding Process Automation and Instrumentation

Process automation involves using technology to control and monitor industrial processes with minimal human intervention. This encompasses a wide range of activities, from simple repetitive tasks to complex operations that require precision and accuracy. Instrumentation refers to the devices and systems used to measure, monitor, and control variables like temperature, pressure, flow, and level within these processes.

Get a Sample Report: https://intentmarketresearch.com/request-sample/process-automation-and-instrumentation-market-3646.html

Key Drivers of Market Growth

Several factors are contributing to the robust growth of the process automation and instrumentation market:

Industrial Digitalization: The shift towards Industry 4.0, characterized by the integration of digital technologies in manufacturing, has significantly boosted demand for automation and instrumentation solutions. Advanced technologies like the Internet of Things (IoT), artificial intelligence (AI), and machine learning are driving the need for more sophisticated and interconnected systems.

Increased Focus on Efficiency: Industries are under constant pressure to improve operational efficiency, reduce costs, and enhance product quality. Automation helps achieve these objectives by minimizing errors, reducing downtime, and optimizing resource utilization.

Stringent Regulatory Standards: Regulatory bodies across various industries, particularly in the energy, oil & gas, and pharmaceutical sectors, are imposing stricter safety and environmental standards. Automation and instrumentation play a crucial role in ensuring compliance with these regulations, further driving market growth.

Rising Demand for Energy and Resources: As global demand for energy and resources increases, industries are turning to automation to maximize output, reduce waste, and minimize environmental impact. This is particularly evident in sectors like oil & gas, mining, and chemicals.

Market Segmentation and Key Players

The process automation and instrumentation market can be segmented based on technology, instrument type, industry, and geography:

Technology: The market includes distributed control systems (DCS), programmable logic controllers (PLC), supervisory control and data acquisition (SCADA), and human-machine interfaces (HMI).

Instrument Type: Key instruments include transmitters, control valves, analyzers, and recorders, each serving specific functions within industrial processes.

Industry: Major industries driving the market include oil & gas, pharmaceuticals, chemicals, food & beverages, and power generation.

Geography: The market is growing rapidly in regions like North America, Europe, and Asia-Pacific, with emerging economies in Asia showing particularly strong demand.

Key players in the market include Siemens AG, ABB Ltd., Honeywell International Inc., Emerson Electric Co., and Schneider Electric, among others. These companies are investing heavily in research and development to stay ahead of the curve and meet the evolving needs of their customers.

Challenges and Opportunities

While the process automation and instrumentation market is on a growth trajectory, it faces challenges such as the high initial cost of implementation, the need for skilled personnel, and cybersecurity concerns. However, these challenges also present opportunities for innovation. For instance, advancements in cybersecurity measures are becoming a focal point as industries adopt more connected and automated systems.

Moreover, the ongoing trend of integrating automation with big data analytics and AI offers significant potential for market expansion. By leveraging these technologies, companies can gain deeper insights into their operations, predict maintenance needs, and further enhance efficiency.

Get an insights of Customization: https://intentmarketresearch.com/ask-for-customization/process-automation-and-instrumentation-market-3646.html

Future Outlook

The future of the process automation and instrumentation market looks promising. With continued advancements in technology, the push towards sustainable and environmentally-friendly practices, and the increasing complexity of industrial processes, the demand for automation and instrumentation is expected to grow.

Emerging trends like the use of digital twins, which create virtual models of physical processes, and the expansion of wireless instrumentation solutions will further drive market evolution. As industries continue to embrace digital transformation, the role of automation and instrumentation will become even more critical, cementing its place as a cornerstone of modern industrial operations.

Conclusion

The process automation and instrumentation market is integral to the ongoing transformation of industries across the globe. As companies strive for greater efficiency, compliance, and sustainability, automation and instrumentation will play a pivotal role in shaping the future of industrial operations. The market’s growth trajectory, fueled by technological advancements and increasing demand across various sectors, underscores its significance in the modern industrial ecosystem.

#Process Automation#Process Instrumentation#Industrial Automation#SCADA#PLC#Field Instruments#Automation in Oil & Gas

0 notes

Text

0 notes

Text

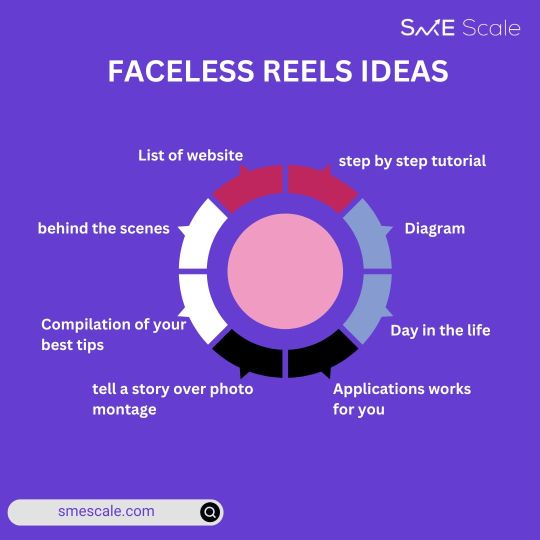

Faceless Reels Ideas: Engage Without Showing Your Face! Want to create engaging Reels but don’t want to be on camera? Here are some powerful faceless content ideas that can still deliver value and connect with your audience: http://smescale.com - #smescale #facelesscontent

#SME Scale#Business growth#Scaling strategies#SME consulting#Digital marketing#Process automation#Sales optimization#Lead generation#Marketing automation#Growth blueprint#Customer acquisition#Business strategy#Online presence#SEO services#Content strategy#Digital transformation#Sales funnel#Business automation#Revenue growth#Marketing strategy#Business development

1 note

·

View note

Text

Top 5 Robotic Process Automation Software Of 2024

A large company processes hundreds of invoices weekly, but their accounts team handles it manually. This involves downloading receipts, adding up amounts, and running payroll, which often leads to errors, delays, and client dissatisfaction. Is there a more efficient way to manage this workload while maintaining control? Absolutely! Introducing Robotic Process Automation (RPA) Software—innovative solutions that automate repetitive tasks, streamline operations, reduce errors, and free up employees to focus on more productive activities. In today’s fast-paced business environment, efficiency is key, and automation is the answer!

If you're considering automation for your business, get ready to transform your workflow with these cutting-edge tools. Discover the top 5 Robotic Process Automation (RPA) Software of 2024 and unlock the full potential of automation!

While the term "robots" might conjure images of The Terminator or Chappie, some exist solely in the digital realm. Curious? Think of Alexa or Siri—just as these virtual assistants help with everyday tasks, businesses have specialized virtual bots to handle repetitive work. That’s what Robotic Process Automation is all about—it allows businesses to develop, deploy, and manage software robots that mimic human actions, such as interacting with enterprise software.

The benefits include reduced human intervention, increased uptime, higher productivity, and improved accuracy. Sounds amazing, right?

Last year, we explored the top 5 RPA Software of 2023. This year, with advancements in AI and machine learning, we bring you an updated list. So, dive in and discover the top 5 Robotic Process Automation Software of 2024!

Top 5 Robotic Process Automation Software of 2024

Automating business processes is crucial for better outcomes. The key is to work smarter, not harder. Robotic Process Automation Software simplifies repetitive workflows, making it an essential component of success in the digital age.

Here are the top 5 Robotic Process Automation Software of 2024—listed in no particular order:

Tool 1: UiPath Founded in 2005 and headquartered in New York City, UiPath is a global leader in RPA, serving clients like Canon, Uber, and Xerox. Recognized as a Leader in the 2024 Gartner® Magic Quadrant for Process Mining, UiPath offers an intuitive platform that enables organizations to automate tasks easily. Its visual workflow designer requires minimal coding knowledge, reducing implementation time and costs. UiPath's AI-powered platform includes features like natural language processing and computer vision, helping businesses leverage advanced automation for greater efficiency and innovation.

Tool 2: Automation Anywhere Established in 2003 and based in California, Automation Anywhere is a top RPA provider, serving clients like SoftBank and Merck. Known for its user-friendly software, Automation Anywhere helps automate complex processes end-to-end. With features like IQ Bot for cognitive automation and a cloud-native architecture, it offers scalability and flexibility. The platform also includes an AI-powered assistant that uses natural language processing to automate content generation. Automation Anywhere is key to accelerating digital transformation and achieving widespread automation.

Tool 3: IBM Robotic Process Automation (RPA) IBM, a global tech leader founded in 1911, offers a comprehensive RPA platform that automates repetitive tasks and streamlines workflows. Powered by IBM Watson, this platform handles complex processes, including those with unstructured data. IBM's RPA includes features like unattended and attended bots, intelligent chatbots, and seamless integration with other IBM solutions. This tool is essential for driving efficiency, reducing costs, and advancing digital transformation with intelligent automation.

Tool 4: akaBot Founded in 1999, FPT Software offers akaBot, a versatile business solution for automating workflows with RPA bots. Its drag-and-drop interface and pre-built modules make it easy to create automation workflows without coding. akaBot integrates with AI and OCR solutions to automate complex tasks and can be deployed on-premises or as a SaaS model. With modules for discovery, automation, and operational insights, akaBot empowers businesses to drive productivity and improve automation outcomes.

Tool 5: Microsoft Power Automate Microsoft, a global technology giant founded in 1975, offers Power Automate, a cloud platform designed to automate business processes. With extensive connectors, Power Automate integrates with services like Office 365 and Azure. Its AI-driven capabilities, including AI Builder and Power Virtual Agents, enable intelligent automation for complex tasks. Features like "Describe To Design" allow users to create flows using natural language, making automation accessible. Power Automate puts powerful, effective automation at users' fingertips.

Conclusion: In today’s business environment, hyperautomation—automating everything possible—is critical to staying ahead and improving digital transformation outcomes. Choosing the right Robotic Process Automation Software that aligns with your unique needs is key. Happy automating!

0 notes