#Precast building construction companies in India

Text

Vollert - Weinsberg leverages 90+ years of experience to deliver innovative solutions across the world. We prioritize your success - Understanding your needs, we develop custom solutions & accelerate your growth. Regional roots, global reach - We combine tradition & a forward-thinking approach, ensuring top-quality service wherever you are. #EngineeringYourSuccess #Innovation #Partnership #GlobalLeader

#Precast concrete trends#India#Precast building construction companies in India#Precast construction#Quality Control#Precast machinery manufacturers in india#Precast concrete machinery#Precast structures in India#Precast concrete manufacturers in delhi#Precast mould manufacturers in India

1 note

·

View note

Text

Steel Built for Success:

Roofs and shades, we are the best steel building construction company in Kochi and provide our services across India. We are pushing the limits of what is achievable with steel building. Because it is both environmentally friendly and strong, architects, engineers, and builders all find steel to be an appealing choice. But to get its full potential, we need to give careful consideration at the design stage.

The most important consideration is understanding loads and forces, like dead loads, live loads, and seismic considerations. Dead loads are the constant forces acting on the structure, weight, cladding and permanent fixtures. In earthquake-prone areas, building for lateral loads is critical while seismic considerations pertain to live loads as furniture, equipment, and environmental factors while steel's ductility enable it to dissipate energy when provided with seismic events.

Another key element to think about is selecting the suitable steel grade. The selection of the desirable grade enhances cost efficiency and general functionality. Balancing clear spans with efficient use of steel minimizes material wastes. Steel structures need different connection methods like welding and bolting. Various benefits are associated with each system, and this selection depends on loading conditions and intended appearance. The interaction of steel structures with concrete foundations, precast panels and the building envelope systems. It requires careful coordination during design phase to ensures optimal performance. Steel possesses such flexibility that it allows a wide range of designs when it comes to architecture. Steel can also be bent to suit whatever design one may have in mind.

Roofs and shades, As the top steel building construction company, we have experienced structural engineers and worked with big companies. We offer a collaborative approach, ensuring your project benefits from our expertise in steel design, fabrication, and construction. Ready to discuss your next steel project? Contact roofs and shades today!

1 note

·

View note

Text

lNTECC

LNTECC, short for Larsen & Toubro Construction (LNTECC), is a renowned name in the world of engineering and construction. Established as a part of Larsen & Toubro Limited, one of India's largest multinational conglomerates, LNTECC has consistently demonstrated excellence in its projects, setting benchmarks in quality, innovation, and sustainability. With a rich legacy spanning decades, LNTECC has emerged as a leader in the global construction industry, contributing significantly to infrastructure development and nation-building.

Legacy of Excellence:

Founded in 1938 by Henning Holck-Larsen and Søren Kristian Toubro, Larsen & Toubro Limited started as a modest engineering firm in Mumbai, India. Over the years, the company expanded its operations and diversified its portfolio, venturing into various sectors, including technology, manufacturing, and construction. LNTECC, the construction arm of Larsen & Toubro Limited, was established in 1944, laying the foundation for its journey towards excellence in the construction industry.

Diverse Portfolio:

LNTECC boasts a diverse portfolio encompassing a wide range of sectors, including transportation, energy, water, and infrastructure. The company has successfully executed projects across the globe, from skyscrapers and airports to power plants and metro systems. LNTECC's expertise extends to various domains, including civil, mechanical, electrical, and environmental engineering, enabling it to undertake complex projects with precision and efficiency.

Innovation and Technology:

At LNTECC, innovation is at the heart of everything they do. The company continually invests in research and development to stay at the forefront of technological advancements in the construction industry. From adopting Building Information Modeling (BIM) for enhanced project visualization and coordination to implementing advanced construction techniques like precast and modular construction, LNTECC leverages technology to deliver projects that are not only structurally sound but also sustainable and cost-effective.

Commitment to Sustainability:

LNTECC is committed to sustainable development and environmental stewardship. The company integrates sustainability principles into its projects, focusing on energy efficiency, waste reduction, and eco-friendly construction practices. LNTECC's green initiatives include the use of recycled materials, rainwater harvesting systems, and renewable energy solutions, ensuring minimal environmental impact throughout the project lifecycle.

Global Presence:

With a strong presence in over 30 countries, LNTECC has established itself as a global player in the construction industry. The company's international projects range from iconic landmarks to critical infrastructure, contributing to the socio-economic development of diverse communities worldwide. LNTECC's global footprint is a testament to its capabilities and commitment to delivering excellence on a global scale.

Quality and Safety:

LNTECC places the utmost importance on quality and safety in all its endeavors. The company adheres to stringent quality standards and adopts best practices in project management to ensure the timely delivery of high-quality projects. LNTECC's comprehensive safety protocols and rigorous training programs prioritize the well-being of its workforce and stakeholders, making safety a non-negotiable aspect of its operations.

Client-Centric Approach:

LNTECC's success is built on its strong client-centric approach. The company fosters long-term relationships with its clients by understanding their unique requirements and delivering tailored solutions that exceed expectations. LNTECC's collaborative approach, transparent communication, and proactive problem-solving have earned it the trust and respect of clients across the globe.

Human Capital:

At LNTECC, people are the cornerstone of its success. The company's diverse team of professionals, comprising engineers, architects, project managers, and support staff, brings together a wealth of expertise and experience. LNTECC fosters a culture of innovation, collaboration, and continuous learning, empowering its employees to unleash their full potential and drive the company's growth and success.

Corporate Citizenship:

LNTECC is committed to making a positive impact on society through its corporate citizenship initiatives. The company actively engages in community development projects, focusing on education, healthcare, and skill development, to uplift underprivileged communities and foster inclusive growth. LNTECC's corporate social responsibility programs reflect its commitment to being a responsible corporate citizen and contributing to the betterment of society.

Conclusion:

In conclusion, LNTECC stands as a beacon of excellence in the global engineering and construction industry. With its legacy of innovation, commitment to sustainability, and client-centric approach, LNTECC continues to lead the way in delivering world-class projects that shape the future of infrastructure and contribute to the progress of nations. As the company embarks on its journey towards new horizons, one thing remains constant – LNTECC's unwavering dedication to excellence in everything it does, setting new standards of quality, reliability, and integrity in the world of construction.

0 notes

Text

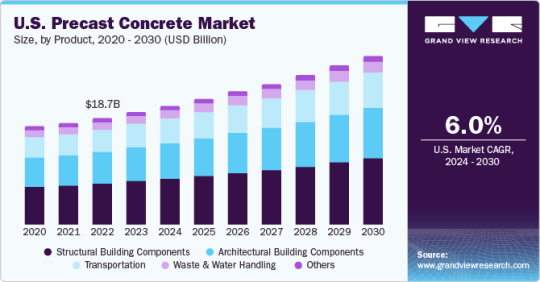

Precast Concrete Market Size To Reach $156.13 Billion By 2030

Precast Concrete Market Growth & Trends

The global precast concrete market size is expected to reach USD 156.13 billion by 2030, registering a CAGR of 5.8% over the forecast period, according to a new report by Grand View Research, Inc. This growth can be attributed to the increasing construction activities in the residential, commercial, and industrial sectors. Precast concrete is used in the production of various products used in construction, such as wall panels, underground vaults, pipes, tanks, slabs, and barriers. Construction end-users prefer precast structures due to their superior strength and durability. Precast concrete also helps in the faster completion of construction projects, leading to increased adoption. Offsite construction is gaining prominence in the construction industry as the method helps in saving time and avoiding material wastage.

The process can be carried out irrespective of the weather conditions. The growth in offsite construction is anticipated to be a key driver for the industry over the forecast period. Although precast concrete has several advantages over conventional concrete, its use in developing countries is limited due to the high investment involved. The cost of machinery and molds needed for the manufacturing of these products is high and requires advanced technology with highly skilled labor to handle the same. Thus, the high initial investments are projected to hamper the growth over the forecast period. The Asia Pacific construction industry has been developing rapidly in recent years. The industry has witnessed numerous technological advancements and the proliferation of unique architectural designs that promote the usage of precast concrete in commercial, residential, and industrial applications.

Rapid industrialization in emerging economies, such as China and India, has led to a rise in the construction of factories and office spaces. In addition, industrialization has led to migration, resulting in increased urbanization and the growth of residential construction activities. Developed regions, such as North America, have also seen a rise in residential construction activities due to an increased consumer expendable income. The construction industry in Central & South America is also expected to witness substantial growth on account of the rising investments in various infrastructure projects by foreign and domestic private players in the region. The construction of single-family houses in the region contributed majorly to the residential construction market.

This is attributed to the increasing number of people living separately in the majority of the countries in the region. The industry consists of several global players providing high-quality products focusing on price differentiation, thus leading to high competition in the industry. Strategies followed by key players include long-term contracts with end-users and intensive R&D activities. The prominent industry players have signed agreements with raw material suppliers and construction companies to maintain their market position. In addition, most of the key players collaborate with local end-users and suppliers to minimize operational costs and improve their localized market share.

Request a free sample copy or view report summary: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

Precast Concrete Market Report Highlights

Structural building components segment is expected to register the fastest CAGR of 6.2% from 2024 to 2030 due to their superior characteristics like high strength, increased durability, and faster installation

The infrastructure application segment dominated the industry in 2023 owing to high investments in infrastructure development by emerging as well as developed economies

Asia Pacific is estimated to witness the fastest growth rate during the forecast period owing to the high economic growth in the region and rising industrial & commercial investments by private players and local governments

The construction industry in MEA is expected to face setbacks due to uncertainty in government spending on infrastructure development. However, increasing the consumer base in the region will likely boost the market growth in the coming years

The global demand was hampered due to the COVID-19 pandemic in 2020. Government regulations resulted in delays and cancellation of planned construction projects, negatively impacting the industry growth

Precast Concrete Market Segmentation

Grand View Research has segmented the global precast concrete market report on the basis of element, construction type, product, application, end-use, and region:

Precast Concrete Element Outlook (Revenue, USD Billion; 2018 - 2030)

Girders

Columns & Beams

Walls & Barriers

Floors & Roofs

Utility Vaults

Pipes

Paving Slabs

Others

Precast Concrete Construction Type Outlook (Revenue, USD Billion; 2018 - 2030)

Elemental Construction

Permanent Modular Buildings

Relocatable Construction

Precast Concrete Product Outlook (Revenue, USD Billion; 2018 - 2030)

Wet Concrete

Dry/Semi-dry Concrete

Precast Concrete Application Outlook (Revenue, USD Billion; 2018 - 2030)

Structural Building Components

Architectural Building Components

Transportation

Waste & Water Handling

Others

Precast Concrete End-Use Outlook (Revenue, USD Billion; 2018 - 2030)

Residential

Commercial

Infrastructure

Tunnels

Bridges

Wind Towers

Industrial

Precast Concrete Regional Outlook (Revenue, USD Billion; 2018 - 2030)

North America

S.

Canada

Mexico

Europe

Germany

UK

France

Spain

Italy

Poland

Czech Republic

Croatia

Asia Pacific

China

India

Japan

South Korea

Singapore

Central & South America

Brazil

Middle East & Africa

Saudi Arabia

Israel

List of Key Players of Precast Concrete Market

Boral Ltd.

LafargeHolcim

Gulf Precast Concrete Co. LLC

Olson Precast Company

CEMEX S.A.B. de C.V

Forterra Pipe and Precast LLC

Tindall Corporation

Spancrete

Elementbau Osthessen GmbH & Co., ELO KG

GÜlermak A.S.

STECS

LAING O’Rourke

Larsen & Toubro Ltd.

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/precast-concrete-market

#Precast Concrete Market#Precast Concrete Market Size#Precast Concrete Market Trends#Precast Concrete Market Share#Precast Concrete Market Forecast

0 notes

Text

Road Construction Tools and Equipment Manufacturer Chennai

The vibrant capital of Tamil Nadu, Chennai, is always changing, necessitating a strong and well-kept road system. This essential infrastructure depends on a sophisticated network of expert personnel, cutting-edge technologies, and tools and equipment for road building. This piece explores this field, looking at:

Roadwork Equipment Situation in Chennai:

For building roads, the city is home to several well-known suppliers and manufacturers. Among the notable participants are:

Concrete mixers, excavators, asphalt pavers, motor graders, and other road construction tools are all available from the top engineering and construction company Larsen & Toubro (L&T).

Road construction equipment such as rollers, loaders, and excavators is produced by Sany Heavy Industry India, a multinational firm specializing in heavy gear.

Asphalt batching plants, pavers, and milling equipment are the products of the local manufacturer Royal Industries.

Manufacturer of premium construction equipment, including motor graders, soil stabilizers, and vibratory compactors, is Geo Emmanuel Engineering.

Case Studies: Roads in Chennai

Success Stories Many notable road construction projects in Chennai showcase the creative thinking and effective use of machinery:

Chennai Bypass Road (NH 45): For earthwork, grading, paving, and compaction, a fleet of excavators, motor graders, pavers, and rollers was used in this project. The timely and cost-effective completion was guaranteed by the effective use of technology and equipment.

Chennai Metro Rail: For station building, track laying, and infrastructure development, this massive mass transportation project used cranes, specialized tunneling equipment, and heavy gear. The project demonstrated how crucial it is to use the appropriate tools for intricate urban buildings.

Elevated Corridor on OMR (ECR): Specialized cranes and erection equipment were needed for this project, which used precast segmental construction techniques. This creative strategy sped up construction while minimizing traffic interruption.

Future Trends: Creating Tomorrow’s Roads:

Technological developments in the road-building sector are having an impact on equipment development.

Automation and robotics: Enhanced automation is anticipated to boost accuracy, safety, and efficiency in the operation of equipment. Repetitive jobs like milling and paving may be handled by robots, freeing up operators to make crucial decisions.

The integration of sensors and networked equipment to gather and analyze data in real time can enhance project management, forecast maintenance requirements, and streamline workflow. This is known as digitalization and data analytics.

Energy-efficient options with electric or hybrid drivetrains are becoming more popular in the construction industry since they help cut down on pollutants and emissions.

Eco-Friendly Decisions for a Better Future

The choice and use of equipment are essential to reducing the negative effects of road construction on the environment. Here are some crucial things to remember:

Selecting fuel-efficient equipment: Choosing equipment with reduced emissions and fuel consumption is a big step toward sustainability.

Appropriate equipment upkeep: Consistent upkeep guarantees peak efficiency and reduces emissions and fuel usage.

Using reuse and recycling strategies: Reusing resources like concrete and asphalt lessens the environmental impact and need for new materials.

Examining sustainable substitutes for conventional building materials, such as locally sourced resources and recycled materials, can help mitigate environmental effects.

Effect on the Development of Equipment:

The evolution of equipment used in road construction is already being impacted by these trends. The following are the investments made by manufacturers:

Electric machinery or hybrid reduces emissions and noise pollution.

Equipment that is connected: Allows for remote diagnostics and monitoring for better upkeep.

Equipment that is adjustable and modular: Provides more customization and flexibility for projects.

Sustainability: Constructing Roads with Conscience

Reducing the negative effects on the environment from road construction requires careful equipment selection and operation. Here are some crucial things to remember:

Fuel efficiency: Choosing fuel-efficient machinery and adopting eco-friendly driving techniques.

Reducing noise: Making use of quieter machinery and reducing construction

activity at night.

Material sourcing: Whenever feasible, choose locally produced aggregates and recycled materials.

Waste management: Reducing landfill waste by putting appropriate waste

management procedures in place.

In summary

The road-building sector in Chennai is a thriving ecosystem propelled by sustainability and innovation. The city will require effective and responsible road construction techniques as it grows. Chennai can guarantee that its roads continue to be smooth, safe, and environmentally responsible for future generations by utilizing the newest equipment, technology, and sustainable practices.

0 notes

Text

Precast Technologies: The way forward for Rapid Construction

One of the key bottlenecks that the construction industry faces, especially in emerging markets like India, is the time it takes to execute projects. One of the best ways to fuel the market’s growth is to optimize the project execution cycle. However, it is easier said than done. While there are many possible interventions, such as the adoption of new-age technologies, we look at one such intervention in this post: precast technology.

What is precast technology?

Precast technologies in the infrastructure industry refer to construction techniques that can be built outside the site and in the confines of a factory in an industrial environment using reusable molds. Companies can opt for precast technology across the concrete as well as steel, depending on their requirements.

Benefits of using precast technology:

Environment Friendly:

-One of the major challenges we face today is to make construction more sustainable for future generations. By opting for precast technology, the infrastructure industry can significantly optimize the water and energy resources needed for a project. Further, because the manufacturing process happens in a factory, it reduces dust and noise pollution.

Cost optimization:

-Those involved in the construction business are continuously looking to optimize their costs and make more efficient projects. By opting for precast technology, you can save significant resources as well as the time required for construction, making your entire project much more optimum!

Accuracy:

Developed under expert supervision and an adherence to high industry standards, precast technology is much more accurate and helps enhance all-around project efficiency!

Urbanaac’s precast Solutions:

At Urbanaac, we are determined to enhance the construction industry with advanced technological interventions that help reduce the time, cost, and ecological impact of infrastructure development projects.

Since its inception, Urbanaac has developed a strong track record of excellence when it comes to crafting bespoke precast technology that adds a positive difference to any project and adds value to our clients’ growth! Moreover, we also take pride in minimizing the ecological impact of the construction industry through our offerings.

Our team creates a wide range of precast solutions across concrete and steel from state-of-the-art manufacturing facilities and customizes them to perfection, enabling our clients to execute projects much faster while having an uncompromising attitude toward quality!

If you’re looking for precast technologies catered perfectly to your requirements, we would love to get in touch with you! Contact us today!

Explore more about precast at https://urbanaac.com/

#precast #construction #building #india #gujarat

0 notes

Text

What are Box Culverts? Why is the Nova Box Culvert the Best Option?

Box culverts are commonly found in places where construction happens. They are often used in rail and roadway construction projects. They are useful for bridging purposes in places where construction is going on to let people and cattle pass. They are usually categorized by size and orientation and are versatile in nature.

Uses of Concrete Box Culverts

1. Bridging Purposes

They are commonly used for several bridging purposes. When roads or railways get built, bridges are needed to maintain the waterway beneath. This allows the building of roads and railways to continue unabated.

2. Cattle and Wildlife Crossing

Concrete box culverts are also used to let cattle and wildlife cross above waterways, rivers and streams. They are also used in rural areas by people who need them to cross water pathways comfortably.

3. For Drainage Purposes

Precast box culverts are also used for drainage purposes in places where a massive amount of water needs to be passed down. They are strong and can easily handle a lot of water within a short amount of time. They prevent floods as excess water is drained into the culverts.

Tunnel-Making

Box culverts are also used to build tunnels in railway and roadway construction.

Nova’s Excellent Box Culverts

Nova Formworks is the name to trust when it comes to formworks in India manufacturer and supplier. Let’s look at the benefits of using their high-quality box culverts for construction.

● Dimensions: Nova designs, manufactures, and supplies culverts in many sizes and dimensions. All sizes are customized and every dimension can be commissioned.

● Modular: The modular structure of precast culverts ensures that they can be used and reused multiple times in multiple construction projects.

● Very Sturdy: While any construction project is going on, there is a need for culverts to be as sturdy as possible. The company designs them in a way that they are leakfree which means a higher level of sturdiness.

● Smooth Finish: Nova’s precast box culverts are also equipped with a smooth finish that ensures attractive end results. Smooth finishes are also advantageous for flawless functioning.

● Competitive Prices: Nova keeps the prices of its formworks reasonable and hence they are the professionals that construction company owners and managers trust. Using precast ones means rains, temperatures, or site conditions do not matter when it comes to their usability and durability.

When trying to find quality box culverts for a building or construction project, it is necessary to partner with a company that understands their various intricacies. The best are culverts which do not need a lot of work to be done to install. It is also necessary to go with a company that allows you to customize designs to suit your specific project needs.

Ask Nova Formworks for a host of box culvert styles so you can find the ones that will suit your

construction project. Their sturdy and high-quality ones are favorites in the industry.

#nova formwork#box culverts for a building or construction project#formworks in India manufacturer and supplier#box culverts#Precast box culverts

1 note

·

View note

Text

Ribbed Wire: A New Technology Looking to Replace TMT Bars

The advancement of technology has delivered many things to us. One such thing is ribbed wires which is a type of high-strength steel. But many people often think the ribbed wire is a complete TMT bar replacement. But this is not true, as you can consider it a partial replacement.

The ribbed wire manufacturers in India produce this product by controlling the cold twisting of hot rolled bars. These wires have projections or ribs on their outer surface.

They also come with various diameters varying from 6 mm to 50 mm. The most outstanding thing about the ribbed wires is that they have the exact strength and durability of TMT bars.

The Usage of Ribbed Wires

You can use the wires created by the top ribbed wire manufacturers in India in cement-based prefabricated structures like mean windows, construction boundaries, and others. Ribbed wires create better bonding with concrete. Some of the uses of ribbed wire include:

Building structures like high-rise houses and buildings, stadiums, hollow floor board, nuclear power plants, and wall boards

Reinforcing structures such as dams or any other rock soil anchoring project

Prefabricated concrete structures such as cement concrete pipes or pressure pipes

Bridge and road structures like subways, railway sleepers, highways, and others

Other uses like cement poles, mines, tubular piles, girders, double T-board, crane beams, panels, free-cutting steel, TV towers, and many more.

Different Types of Ribbed Wire

These are some of the types of ribbed wires;

Helical Ribbed Wire

The main characteristics of helical ribbed wire are the rolling out procedure. It deals with semi-finished products after the last drawing or plastic deformation. Thus, the wire created on the four convex-shaped consecutive ribs is excellent in feature compared to strand or plain steel wire.

Helical Ribbed Strand Wire

The wire includes 3 to 6 convex-shaped consecutive ribs on the surface. The primary advantage of this type of ribbed wire is strengthening the bond between the concrete and the wire. Thus, it improves the product’s performance and also extends its life.

Cold Drawn Ribbed Wire

Companies chiefly use it for concrete reinforcement like bars after the strengthening procedure. It is one of the most efficient construction materials with high strength, holding, capability, and many other qualities.

The primary applications of cold-drawn ribbed wire are precast reinforcement steel, concrete reinforcement wire, and many more.

Features of Ribbed Wire

Ribbed wires include the following features.

High bonding force

Wide range of application

Low relaxation and high tensile strength

Advanced production line, examination equipment, and necessary facility

Things to Remember While Choosing Ribbed Wires

While selecting the ribbed wires, remember a few things to get the best one. To help you with this, here we have penned down the most significant factors to help you to choose the best-ribbed wire.

Rib Pattern

As you might know, each ribbed wire comes with a specific pattern on its outer surface. It is called the ribbed pattern. But these patterns have different variations. That is why it is crucial to think while selecting one.

You need to pick the pattern by considering how you will use the ribbed wire. In this way, you can ensure the wire will offer increased strength and durability.

Pattern Formation Techniques

The ribbed wire manufacturers in India create the pattern and the formation of the ribbed wires in a way that you can use them for various purposes. Besides this, the best manufacturers use advanced CNC machines to ensure uniformity in ribbed wire manufacturing.

Importance of Ribbed Wires

Unlike TMT bars, ribbed wires offer enhanced bonding strength to concrete structures. The structure can withstand an earthquake or flood as it provides an extra layer of structure safety.

Additionally, ribbed wires can distribute the load evenly across the entire structure and build a better grip on concrete. It also decreases the slipping issue during construction. On top of all, due to the excellent welding ability and bonding, the upkeep cost is marginally low.

The benefit of using ribbed wire is that it can strengthen the combination between concrete and wire. Ribbed wires are used in hollow slabs, water pipes, telegraph poles, and many more.

Benefits of Ribbed Wires

By reading the above segments, you can more or less understand the importance of ribbed wires in today’s world. Many people are now using these wires to get multiple benefits. Let us take a look at some of those.

You can bend ribbed wires 360 degrees without cracks or fractures on their outer surface. It is beneficial to execute different and complex projects.

By using ribbed wires, you can get enough strength and durability.

By using these wires, you can also make the weight of the structure much less.

Ribbed wires are much more economical than TMT bars. These wires significantly reduce the expense of reinforcement by up to 30 to 40 percent.

Ribbed wires support welding. You can weld them by using electric flash butt welding or arc welding.

The structural properties of ribbed wires are more enhanced than the ordinary plain round bars.

You can use ribbed wires for every prominent type of reinforced concrete structure.

These wires are rust-proof and highly flexible.

The handling and fixing are also quite simple. As a result, if you use ribbed wires, you can significantly reduce labor costs.

You can also implement ribbed wires in casting the floors of building construction.

Beneficial for seismic-prone regions as ribbed wires offer structural integrity

Provides lower friction

Final Words

To sum up, it is needless to say that ribbed wires are a new invention that works perfectly as a partial replacement for TMT bars. By using these wires, you will get several benefits and also save your money significantly.

But while selecting ribbed wires, you must choose the products manufactured by the best-ribbed wire manufacturer in India, like Group Nirmal. Group Nirmal supplies different varieties of ribbed wires with diameters ranging from 4mm to 11.9 mm.

0 notes

Text

Peb Structure Manufacturer In Chennai- Seekers Spark Enterprises

Seekers Spark Enterprises, Peb Structure Manufacturer in Chennai is a leading construction company that manufactures, supplies, and installs various structures such as precast concrete structures and steel structures. It has a wide range of products that include buildings, bridges, flyovers, and other structures.

We, Peb Companies In Chennai are recognized as one of the leaders in its field because of the quality of our work and the services it provides to clients. We are the best provider of Industrial pre-engineered buildings at an affordable price. Seekers Spark Enterprises is an affordable PEB company in Chennai, India. We produce and sell a wide range of products that includes industrial PEB building equipment, automobile parts, and precision engineering components.

Industrial pre-engineered buildings are typically used to house manufacturing and other industrial operations. They are usually off-site, modular buildings that are built in a factory and then transported to the location. Industrial pre-engineered buildings offer many benefits over traditional construction. They are often more cost-effective, they can be erected quickly, they can be assembled in any location, and they may use fewer materials than traditional construction.

0 notes

Text

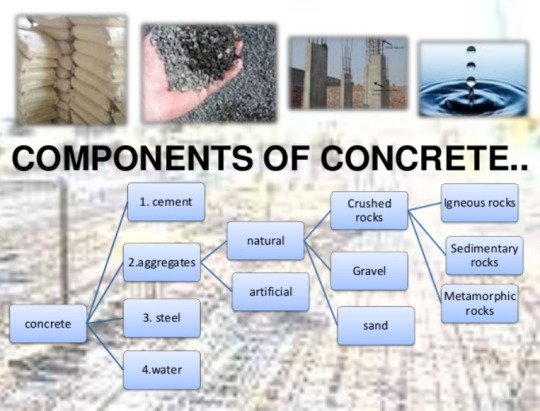

What Are The Components Of Concrete

We will explore the components of concrete and how they work together to create a durable and versatile material. Construction chemical suppliers will discuss the different types of cement, aggregates, and admixtures used in concrete production, as well as their effects on the strength and durability of the finished product.

Finally, we will look at the different methods used to test the quality of concrete so that you can make an informed decision about the best material for your project. By the end of this article, you will better understand the different components of concrete and how they work together to create a robust and reliable material.

Concrete is a composite material composed of various components, including cement, aggregates, and multiple admixtures, blended in specific ratios to create a robust and durable material. As per the top waterproofing companies in India, concrete has become an invaluable part of modern construction, offering various structural and decorative uses in small and large-scale projects.

Concrete is a building material made from cement, aggregate (gravel and sand), water, and other additives combined and poured into molds or forms and allowed to harden.

Types of Concrete:

1. Ready-mix Concrete: Ready-mix concrete is prepared at a concrete plant and then delivered to the worksite in a cement mixer truck.

2. Roller-compacted Concrete: Roller-compacted concrete is a form of concrete made with a stiffer mix and then consolidated with a roller for a denser, more robust final product.

3. Shotcrete: Shotcrete is a type of concrete sprayed from a particular nozzle onto a surface or into a form.

4. Precast Concrete: Precast concrete is a type of concrete that is poured into a form at the concrete plant and then shipped to the worksite in its final form.

Different Components of Concrete and their Functions

1. Aggregates are the most crucial component of concrete and make up the bulk of the mixture. They provide strength, stability, and structural integrity to the concrete mix. Aggregates come in different types, such as sand, gravel, crushed stone, and recycled materials. Depending on the concrete mix, different types of aggregates can be used to enhance the strength and other properties of the material.

2. Cement is the binding agent in concrete and holds the other components together. It also helps to give the concrete mix its strength, workability, and durability. Different types of cement can be used for various applications, depending on the desired strength and other characteristics of the concrete.

3. Water is used to mix and activate the concrete ingredients. It helps to create the chemical reaction necessary for the material to harden and gain strength. Too much or too little water can affect the strength and other properties of the concrete.

4. Admixtures are added to the concrete mix to provide improved workability, increased temperature resistance, and chemical and biological agents. Admixtures can also reduce the amount of cement, water, and other materials required, thus making the concrete mix more economical.

How it Affects the Strength of Concrete

Cement is the crucial ingredient in concrete, which gives it its strength. Cement is a powdery substance made of limestone, clay, and other materials that are heated and ground into a fine powder. As per the best waterproofingcompany, this powder is mixed with water, sand, and gravel to create a paste that binds the materials together.

In conclusion, concrete is a highly durable and versatile material that consists of four essential components: cement, water, aggregate, and admixtures. Each concrete element impacts the material's durability, strength, and workability. Without one of concrete admixture manufacturers, concrete would not have the same properties and would not be as effective as it is today. Therefore, it is essential to understand the concrete components to use the material in construction projects properly.

#concrete admixture manufacturers#best waterproofing company#top waterproofing companies in India#Construction chemical suppliers

0 notes

Text

Self Compacting Concrete Market | Worldwide Segments, Top Key Players, Drivers and Trends to 2028

The industry trends suggest that the global Self Compacting Concrete Market is expected to reach a value of over USD 13 billion by the end of the forecast period in 2028, with a global CAGR of around 8%.

Self compacting concrete, as a part of the global market, is made out of a mix of concrete with moderate viscosity, has high deformability, offers strong segregation resistance, and further, has a low yield stress. Self compacting concrete market is a very fluid mix that offers unique characteristics such as a close fit in the mold, and further, there is no need for tamping after pouring. Also, it can flow freely around impediments and for the formwork. Self compacting concrete is known to be employed mostly in the precast and repair industries. Furthermore, it has an application in the building industry that has increased relatively. Self compacting concrete further offers the capacity to flow freely and also, settle in even the most crowded cracks, as well as set to be reinforced sections that are recognized as totally self-weighted.

Undeniable factors like the self compacting concrete market products help in saving labor, speeds project deadlines, helps in minimizing the noise, tackle environmental problems, and also, assure less equipment wear and tear, the demand is growing at a high scale. Further, the use of self compacting concrete results in lower maintenance, repair, and overhauling the recurring costs.

Regional Classification

The significant expansion of population existing in the Asian Pacific region is expected to drive the predicted growth in the use of self compacting concrete in the infrastructure sector and its maintenance during the forecast period ending in 2028. There has been a rapid industrial development in emerging economies that include India, South Korea, and Thailand that is acting as a prime driver of the regional market growth.

The market in North America is expected to witness a strong demand for self compacting concrete on account of its high investment in infrastructural development. Some prominent market players are Sika AG (Switzerland), BASF SE (Germany), and others like Buzzi Unicem S.P.A. (Itlay).

Browse Complete Report: https://www.marketresearchfuture.com/reports/self-compacting-concrete-market-10761

Market Segmentation

The self-compacting concrete market has been segmented based on the following segment heads that help in a major market expansion. The segments are:

Type-based segmentation

The type segment of the global market includes powder, combinations, and others like viscosity agents.

End-use based segmentation

The global market has extended its services to different end-users like oil and gas companies, infrastructure, along with the building and construction sector.

Industry News

Self compacting concrete, as a part of the global market is frequently used in the building of drilled shafts, especially in the oil and gas sector. Drilled shafts and their processes are deep foundation systems that dig cylindrical shafts into the earth and fill them with concrete to render good support structures with enormous axial and lateral stresses. Also, there has been a rising degree of investment in the oil gas industry across the globe that is expected to drive the demand for self compacting concrete market during the forecast period.

About Market Research Future:

At Market Research Future (MRFR), we enable our customers to unravel the complexity of various industries through our Cooked Research Report (CRR), Half-Cooked Research Reports (HCRR), Consulting Services.

MRFR team have supreme objective to provide the optimum quality market research and intelligence services to our clients. Our market research studies by products, services, technologies, applications, end users, and market players for global, regional, and country level market segments, enable our clients to see more, know more, and do more, which help to answer all their most important questions.

In order to stay updated with technology and work process of the industry, MRFR often plans conducts meet with the industry experts and industrial visits for its research analyst members.

Contact:

Market Research Future®

99 Hudson Street,5Th Floor

New York, New York 10013

United States of America

Phone:

+1 628 258 0071(US)

+44 2035 002 764(UK)

Email: [email protected]

Website: https://www.marketresearchfuture.com

#Self Compacting Concrete Market Size#Self Compacting Concrete Market Share#Self Compacting Concrete Market Type#Self Compacting Concrete Market Application

0 notes

Text

How a Material Lift Can Benefit Your Construction Project

Vertical construction has seen a rise in India, which has fueled the demand for construction equipment that can be used to transport people and materials. This equipment caters to tunnel formwork and precast construction. The electronic control panel and overload alarm for construction equipment are now available like Concrete Batching Plants. They can be controlled wirelessly with a remote, within a 100-meter radius. This makes it very safe.

Benefits of Material Lift for Construction Projects

What are the advantages of using a material lift? A material hoist lift is designed to lift heavier objects in an industrial setting or at a construction site. A Tower Hoist can be used to lift heavy items up and down on a building's roof using a crane. You may prefer to use forklifts if the hoist is not very powerful. A material hoist can lift heavier objects and provide a safe way to accomplish these tasks.

Material hoists are a great tool for lifting heavy objects. This type of lifting equipment has the obvious advantage that it will save you time and effort. This type of lifting equipment doesn't require the use of cranes or heavy trucks. You can just use your machinery. Material hoists are extremely strong and won't easily break, so there will be very little downtime.

What are the uses of construction material hoists? This type of lifting equipment is used by construction sites around the globe to assist them in a wide range of tasks. You can also use Mobile Concrete Batching Plants for routine tasks. You can use it to load materials on top of a trailer or lift larger items like furniture with a forklift.

These tasks can be accomplished with your forklift. You need to be able to safely lift and move heavy items with your forklift. This is something you cannot learn by yourself, as most people who buy forklifts don't use them regularly. There are many benefits to considering if you decide to use your forklift. Passenger Cum Material Hoist can be lifted to the height you desire and program it so the lifting process takes less time than when it is being lifted.

These tasks can be performed by an industrial crane or construction crane. It all depends on what the job requires and the equipment available. A forklift or another piece of equipment might make your job easier. However, they are heavy and require a truck to transport them. You might consider renting a crane temporarily if you need one for a large job site. Operators must not inflict injury when lifting heavy objects with a forklift.

A Multifunctional Material Hoist can also be rented. It is always available for hire when needed. Most companies have a forklift at their warehouse if there is an industrial construction project. It is not enough to hire another forklift to lift the load. They will need a new forklift delivered to them. This is why they should ensure that the equipment is immediately available for construction projects.

#concrete batching plants#mobile concrete batching plants#tower hoist#passsenger material hoist#multifunctional material hoist

0 notes

Text

Emerging Trends in the Construction Industry in India

The construction industry is one of the foundations of a growing economy. Therefore, it is critical for a nation to invest in construction and infrastructure as it leads to a better environment where everyone can be more productive and valuable to society’s collective growth. Moreover, in today’s day and age, technology is driving change across all sectors of our economy with an aim to enhance productivity, optimization, and transparency. In this post, we examine the emerging trends in construction that are paving the way for a more efficient industry.

Automation and Drone Technologies: The key objective behind automation is to create technological interventions that reduce human effort and possibilities of human error as well as increase productivity. The domain is rapidly evolving in the construction sector through various solutions such as construction robotics that leverage robots to simplify manual processes, helping project managers achieve a quick turnaround time. Further, software applications also help automate several tasks, such as follow-up emails for vendors and clients, allowing you to focus on your core business. Another emerging trend in the construction sector today is the increased usage of drone technologies for various purposes. While conventional methods did the job, drones offer a much clearer view, helping project managers and end-customers access more accurate representations of construction projects. Drone technologies will help complete several activities like building surveys, construction site inspection, health and safety induction, maintenance inspection, project progress report, promotional photography, live feed and virtual walk walk-around logistics, and thermal imaging recordings.

Data Analytics: We live in a digital era that has led to a massive increase in information generated. Today, every business seeks to optimize the information it generates by leveraging data mining, processing, and analytics. Construction companies stand to benefit a lot by using data processing technologies as they will lead to actionable insights, leading to cost-effective and objective decision-making. This trend will undoubtedly enhance productivity, whether it is understanding the optimum utilization of materials or understanding demand trends.

Cloud-based BIM: Building Information Modeling (BIM) is becoming very popular, and its usage is gaining increasing prominence. Having cloud-based BIM software will help organizations access construction-related data much faster as opposed to on-premise installations. This optimizes the entire process and enables all stakeholders to access the relevant information in real-time.

Precast Technology: At Urbanaac, we foray into the world of faster, safer, and more robust construction by integrating precast technologies into construction methodologies. We bring together excellent craftsmanship, complete customization, and quality construction materials that are robust and also help reduce environmental and noise pollution. As a part of our solutions, we conceptualize, design, and execute customized construction elements, which helps project managers to achieve exceptional turnaround times while ensuring complete quality and safety!

Explore more about precast at https://urbanaac.com/

#precast #construction #building #india #gujarat

0 notes

Text

Best Process for Home Building Your Second Home

Best Process for Building Your Second Home

A step-by-step guide for building your second home

A home is a place where one lives, especially as a member of a family or household. It’s a place where you long to go after a tiring, chaotic day at work. Building your second home is always exciting, particularly when you understand how the process works. We need to keep in mind that the home building process might vary from region to region and from builder to builder.

Keeping this in mind, we have mentioned ten important steps that can help you build a new home that is not only beautiful but also well-built. Before anything else, it is very important to get the legal documentation done; legalize the property and then move further.

Level the land and lay the foundation

Once the plot has been selected and the legalizing the property transfer has been done, you need to level the land and then pour the foundation. While constructing your second home, you should avoid all the unnecessary flaws that you must have ignored in your previous home.

Complete rough framing

Once the foundation is laid complete the floor systems, walls and roof systems (collectively known as the shell or skeleton of the house); we all know that the skeleton or the rough frame is the most important structural component of the building.

Complete rough plumbing and electrical equipment

Once the shell is finished, you can now move on to the next step. Sliding and roofing can now be installed. At the same time, the electrical and plumbing contractors can start running pipes and wires through the interior walls, ceilings and floors.

Install insulation

Insulation plays a key role in creating a more comfortable, consistent indoor climate while significantly improving the energy efficiency of your home. Most homes are insulated in all exterior walls, as well as the top floor and any floors that are located above unfinished basements or crawl spaces.

Complete drywall and interior textures, start exterior finishes

Drywall is used to make interior walls and ceilings. It is basically hung and taped so that the seams between the boards aren’t visible and hence drywall texturing is completed. We can now move on to the painting part, the primer coat of paint can be applied once the taping is done.

Finish interior trim, install exterior drive ways and walkways

Interior doors, baseboards, door casing, window sills, molding stair balusters and other decorative trims are to be installed along with the cabinets, vanities and surrounds. Get your walls painted and add wallpapers if required. Exterior driveways and walkways are prepared at this stage; though, it can also be done once the entire project gets over.

Install hand-surface flooring and countertops; complete exterior grading

Flooring should be done as per your requirements. Exterior finish grading is completed in this step to ensure proper drainage away from your home and then the yard is prepared for landscaping.

Finish mechanical trims, install bathroom fixtures

Next comes the installation of the light fixtures, outlets and switches which complete the electric panel. Put the Sinks, toilets and faucets in place.

Install mirrors, shower doors and finish flooring, finish carpeting

The final clean up takes place once the mirrors, shower doors and the carpeting is done.

Final walk through

When the entire procedure is over, your builder will walk you through your second (new) home to acquaint you with all its features. It is like making you familiar with your house. It is also an opportunity to spot items that need to be corrected or adjusted, so be keenly observant and pay a lot of attention. Examine the surface of countertops, fixtures, floors and walls for possible damage. Bring those to the developers’ notice and get them changed ASAP.

-----------------------------------------------------------------------------------------------------------

Construction Company | Home Builder | Construction Company | Prefab Homes | Prefab Builder | House Building Solutions | Building Solutions | House Construction Company | House Contractor | House Construction | house builder | House Building solutions | Precast Builder | Home Building Solutions | Prefab Building | home Building Solutions | Prefab Construction company | Precast Company in India | build a house | Prefab Builder in INdia | Prefab Company in India | Construction Company in India | Precast Contractor in India | Home Builder in India | house construction contractor | build a home | Architectural Designers | Top Architects in India | house designs | home plan | Indian house design | house plans indian style | building plan | house plans construction | house construction steps | house construction steps in india | house construction in india | house construction contractors| house construction materials | house construction framing | house construction tips India

#House Construction Company#House Building Solutions#Building Solutions#House Contractor#Precast Builder#Home Building Solutions#Architectural Designers#Top Architects in India#house designs#home plan#Indian house design#house plans indian style

4 notes

·

View notes

Text

Prestige Smart City Residential Apartments Bangalore

PRESTIGE SMART CITY

The residential project offers a range of housing options, starting from 1, 2 and 3 BHK apartments, to 4 BHK penthouses with private gardens. Part of its strategy to provide integrated township-style homes, Prestige's new project at Sarjapur Road, Bangalore, is constructed as per the advice of some of the best architects in the country. Buy 1/2/3/4 Bhk apartments in new launch property at Sarjapur Road, Bangalore city by Prestige Smart City. Every apartment of the project is developed under the RERA acceptance and Rcc frame structure.Each Corner of the property is created by Vaastu Shashtra and tress everywhere throughout the lofts to make a sound and regular habitat. The developer has ensured that the project is delivered following all the quality standards in real estate. To ensure housing safety, the project has used RCC structures with precast technologies. Furthermore, for providing robust flooring, ceramic vitrified tiles are being used. Coats of premium emulsion paints are applied on the exterior walls of the building.

Prestige Group is one of the trusted name in the real estate sector in terms of commitment and in- time delivery. It’s upcoming projects in Sarjapur road, The Prestige Smart city launch date is expected be in second quarter of 2021.

Quality of new apartments in Sarjapur road, will not be compromised, with assurance of providing optimum value for the client’s money whether it is a commercial property or a residential development. The latest technologies are adapted for development of safer, in-time and reliable construction. Lending the best buy opportunity to its residents.

Prestige Smart City Landmark

The Prestige City is a landmark brand new township project by Prestige Constructions located in Sarjapur Road, East Bangalore. Prestige City will house Apartments, Villas and plots the very best in Prestige Group’s mixed development. Landmark: Adjacent to Sarjapur Lake, 65 Meters and 1 Kilometre from Ittangur Village.

PRESTIGE SMART CITY LOCATION

Sarjapur Road plays a most prominent role in connecting major areas. Hence it has emerged as a most sought place for residential development. Sarjapur has a decent network in the IT centers, for example, Whitefield, Electronic City, Marathalli, Koramangala, and external ring street. The electronic city houses a large number of the IT organizations and Industrial Areas, Whitefield is the most looked for business just as private improvement territory. Significant IT Parks, Hospitals, Schools, Colleges are firmly situated in the territory. Kempegowda International Airport is simply a 1.30 Hours drive using SH 35 from the task.

Smart City Connectivity

Banashankari has provided promising options in regards to better connectivity and sustainable residential investments. With frequent BMTC bus and taxi routes, residents can get to other parts of the city with effortless ease. The distance between Banashankari and Prestige Smart City is about 28 Km’s and takes close to 1 hour and 25 minutes via outer ring road. Other routes would be one via national highway 48, which takes around 1 hour and 22 minutes.

About Builder

Over the last decade, the Builder has firmly established itself as one of the leading and most successful developers of real estate in India by imprinting its indelible mark across all asset classes. Founded in 1986, the group's turnover is today in excess of Rs. 3518 Cr (for FY 15); a leap that has been inspired by CMD Irfan Razack and marshaled by his brothers Rezwan Razack and Noaman Razack. Having completed 210 projects covering over 80 million sq ft, currently the company has 53 ongoing projects spanning 54 million sq ft and 35 upcoming projects aggregating to 48 million sq ft of world-class real estate space across asset classes. In October 2010, the Builder also successfully entered the Capital Market with an Initial Public Offering of Rs 1200cr.

Prestige Smart City

http://www.prestigesmartcitysarjapur.co.in/

1 note

·

View note

Text

Precast Concrete Market Analysis And Growth By Top Companies, Forecast 2026

New York, NY 10 May 2021: The global precast concrete market size is anticipated to reach USD 149.1 billion by 2026 growing at a CAGR of 6.6% during the forecast period, according to a new study published by Polaris Market Research. The report ‘Precast Concrete Market Share, Size, Trends, & Industry Analysis Report, By Element (Walls & Barriers, Columns & Beams, Floors & Roofs, Paving Slabs); By Application; By End-User; By Region]: Segment Forecast, 2019 – 2026’ provides an extensive analysis of present market dynamics and predicted future trends. In 2018, the non-residential segment dominated the global precast concrete industry, in terms of revenue. Asia-Pacific is expected to be the leading contributor to the global market revenue during the forecast period.

A significant increase in disposable income, and construction & renovation of residential buildings drive the market growth. Increasing population, growing urbanization, and industrialization has increased the demand for precast concrete across the globe. The increasing need to reduce building time and costs, and growing demand for offsite construction supports the market growth. Other driving factors include safer construction sites, improved durability and load capacity offered by precast concrete, and development of public infrastructure. The increasing investments by governments for enhancing public infrastructure, and government premises further support market growth. Increasing demand in developing nations, and growth in global construction industry is expected provide numerous growth opportunities in the global market during the forecast period.

Request For Sample Copy @ https://www.polarismarketresearch.com/industry-analysis/precast-concrete-market/request-for-sample

Improvement in lifestyle due to rise in income level, especially in the developing countries of Asia-Pacific, such as India, China, and Japan, fuels the demand for precast concrete. Enhancement of public infrastructure such as parks, museums, and other structures by governments, along with growth in construction in urban areas would support the growth in the coming years.

Asia-Pacific generated the highest revenue in the market in 2018, and is expected to lead the global market throughout the forecast period. The growing construction sector and increasing disposable income drives the market growth. The increasing trend of design and aesthetics, along with increasing government investments in development of infrastructure supports the market growth in the region.

The well-known companies profiled in the report include Larsen & Toubro Limited, Kiewit Corporation, Bouygues Construction, Taisei Corporation, Julius Berger Nigeria PLC, Boral Limited, Forterra Pipe & Precast, LLC., Olson Precast Company, Gulf Precast Concrete Co. LLC, and Tindall Corporation. These companies are consistently launching new products to enhance their offerings in the market. With the advancement of technologies, companies are innovating and introducing new customized products to cater the growing needs of the customers. Leading companies are also acquiring other companies, and enhancing their product offerings to improve their market reach. Acquisitions enable key players to increase their market potential in terms of geographic expansion and expansion of customer base.

Have Any Query or Specific Requirement? Request for customization: https://www.polarismarketresearch.com/industry-analysis/precast-concrete-market/request-for-customization

Polaris Market Research has segmented the global precast concrete market on the basis of element, application, and end user and region:

Precast Concrete Element Outlook (Revenue, USD Billion, 2015 – 2026)

Walls & Barriers

Columns & Beams

Floors & Roofs

Paving Slabs

Others

Precast Concrete Application Outlook (Revenue, USD Billion, 2015 – 2026)

Structural Buildings

Architectural Buildings

Water and Waste Handling

Transportation

Others

Precast Concrete End-User Outlook (Revenue, USD Billion, 2015 – 2026)

Residential

Non-Residential

To get Incredible Discounts on this Premium Report, Click At : https://www.polarismarketresearch.com/industry-analysis/precast-concrete-market/request-for-discount-pricing

About Polaris Market Research

Polaris Market Research is a global market research and consulting company. The company specializes in providing exceptional market intelligence and in-depth business research services for our clientele spread across different enterprises.

Contact Us:

Polaris Market Research

Phone: 1–646–568–9980

Email: [email protected]

Web: http://www.polarismarketresearch.com

1 note

·

View note