#Polypropylene Catalyst Industry

Text

Polypropylene Catalyst Market risks and challenges that the industry is facing

Polypropylene Catalyst Market risks and challenges that the industry is facing

This report studies the Polypropylene Catalyst Market with many aspects of the industry like the market size, market status, market trends and forecast, the report also provides brief information of the competitors and the specific growth opportunities with key market drivers. Find the complete Polypropylene Catalyst Market analysis segmented by companies, region, type and applications in the…

View On WordPress

#Covid-19 Impact Analysis#Polypropylene Catalyst#Polypropylene Catalyst forecast#Polypropylene Catalyst Industry#Polypropylene Catalyst Market#Polypropylene Catalyst price#Polypropylene Catalyst report#Polypropylene Catalyst research#Polypropylene Catalyst share#Polypropylene Catalyst trends

0 notes

Photo

Process converts polyethylene bags, plastics to polymer building blocks

Polyethylene plastics—in particular, the ubiquitous plastic bag that blights the landscape—are notoriously hard to recycle. They're sturdy and difficult to break down, and if they're recycled at all, they're melted into a polymer stew useful mostly for decking and other low-value products.

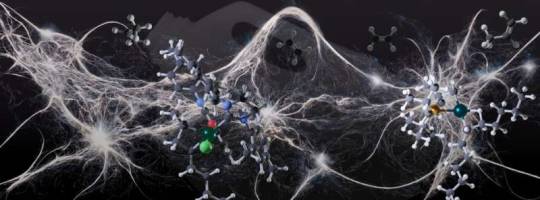

But a new process developed at the University of California, Berkeley, and Lawrence Berkeley National Laboratory (Berkeley Lab) could change all that. The process uses catalysts to break the long polyethylene (PE) polymers into uniform chunks—the three-carbon molecule propylene—that are the feedstocks for making other types of high-value plastic, such as polypropylene.

The process, admittedly in the early stages of development, would turn a waste product—not only plastic bags and packaging, but all types of PE plastic bottles—into a major product in high demand. Previous methods to break the chains of polyethylene required high temperatures and gave mixtures of components in much lower demand. The new process could not only lower the need for fossil fuel production of propylene, often called propene, but also help fill a currently unmet need by the plastics industry for more propylene.

Read more.

#Materials Science#Science#Polyethylene#Polymers#Plastics#Materials processing#Recycling#Catalysts#Hydrocarbons#UC Berkeley

34 notes

·

View notes

Text

Methanol-to-Olefins Market Forecast: Expansion to Reach $44.1 Bn by 2034

The Methanol-to-Olefins (MTO) process has gained significant traction as a sustainable alternative for producing light olefins such as ethylene and propylene, which are essential building blocks in petrochemical and plastic industries. With growing global demand for polymers, coupled with the increasing need for non-oil-based production methods, the MTO market is poised for substantial growth. The process converts methanol, primarily derived from natural gas or coal, into valuable olefins, making it a critical part of the evolving chemical industry.

The global Methanol-to-Olefins market was valued at US$ 24.5 billion in 2023 and is projected to grow at a CAGR of 5.5% from 2023 to 2034, reaching US$ 44.1 billion by the end of the forecast period.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/methanol-to-olefins-market.html

Market Segmentation

By Service Type: The market is segmented into production services, process technology services, and maintenance services. Production services dominate the market, with advancements in MTO process optimization contributing to the efficiency and profitability of olefin production.

By Sourcing Type: Key sourcing categories include natural gas-derived methanol, coal-derived methanol, and biomass-derived methanol. Natural gas remains the dominant source due to its abundant supply and cost-efficiency. However, biomass-derived methanol is gaining interest due to its sustainability and lower carbon footprint.

By Application: The MTO market serves various applications, including polymers, packaging materials, automotive components, and synthetic fibers. Polymers account for the largest share, driven by the increasing demand for polyethylene and polypropylene.

By Industry Vertical: Key industries include packaging, automotive, construction, consumer goods, and textiles. The packaging sector leads due to its high consumption of olefin-based materials.

By Region: The market is segmented geographically into North America, Europe, Asia-Pacific, Latin America, and the Middle East & Africa. Asia-Pacific is expected to hold the largest share due to the region’s robust methanol production capacity and high demand for olefins.

Regional Analysis

Asia-Pacific: The Asia-Pacific region dominates the MTO market, driven by China’s significant investments in methanol production and its efforts to reduce reliance on oil-based olefin production. Key countries like India, South Korea, and Japan are also increasing their MTO capacity due to high demand for olefin derivatives in manufacturing.

North America: North America, particularly the U.S., is experiencing growth due to the availability of low-cost natural gas for methanol production. The region is also investing in MTO plants to meet growing demand for ethylene and propylene in the packaging and automotive industries.

Europe: Europe is focusing on sustainable methanol production methods, including biomass and waste-to-methanol technologies, in line with the region’s strict environmental regulations. The region is expected to see moderate growth due to high investment in renewable energy and sustainable chemicals.

Latin America & Middle East: Both regions show potential for growth, driven by increasing industrialization and investments in methanol production. The Middle East, in particular, benefits from abundant natural gas resources.

Market Drivers and Challenges

Drivers: The increasing demand for olefins in the production of plastics, synthetic rubber, and fibers is a major driver. Furthermore, the shift towards sustainable and non-oil-based production methods is fueling the growth of the MTO process. Technological advancements in MTO catalysts and process optimization are also contributing to market expansion.

Challenges: Environmental concerns related to methanol production, especially from coal, pose challenges for market growth. Additionally, fluctuations in methanol prices and regulatory hurdles regarding carbon emissions may affect the market. The high capital investment required for MTO plant setup is another barrier.

Market Trends

Sustainability: There is a growing focus on producing methanol from renewable sources such as biomass and waste materials to reduce carbon emissions and environmental impact. This trend is expected to gain momentum in the coming years.

Technological Advancements: Continuous research and development in MTO catalysts and process efficiency are driving the market. Innovations that improve the yield of olefins from methanol are critical to enhancing the profitability and sustainability of the MTO process.

Integration with Circular Economy: The integration of the MTO process with recycling technologies and the circular economy framework is a significant trend. This involves using methanol derived from waste products in the production of olefins, contributing to a more sustainable production cycle.

Future Outlook

The Methanol-to-Olefins market is expected to witness robust growth between 2024 and 2034, driven by increasing demand for sustainable olefin production methods. The market’s future will be shaped by advancements in methanol sourcing, with a growing emphasis on biomass and waste-derived methanol. The development of new, more efficient catalysts will further boost the economic viability of MTO plants, particularly in regions with abundant methanol feedstocks. The expansion of the circular economy will also play a critical role in market growth.

Key Market Study Points

Increasing demand for olefins in the packaging, automotive, and construction sectors.

Technological advancements in MTO catalysts and process efficiency.

The growing role of renewable methanol sources, particularly biomass.

Regulatory challenges related to environmental impact and carbon emissions.

Expansion of MTO capacity in Asia-Pacific, particularly China.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=86380<ype=S

Competitive Landscape

The MTO market is highly competitive, with key players including Sinopec, LyondellBasell Industries, Honeywell UOP, ExxonMobil, and Clariant. These companies are focusing on developing more efficient catalysts, expanding production capacity, and investing in sustainable methanol production methods. Strategic partnerships, mergers, and acquisitions are common as companies aim to strengthen their market presence.

Recent Developments

China's investment in MTO plants: Recent years have seen significant investments in MTO plants in China, driven by the country’s growing demand for olefins and its strategy to reduce reliance on oil imports.

Technological breakthroughs: Innovations in catalyst design have led to improved efficiency in the MTO process, enhancing the yield of ethylene and propylene and reducing operational costs.

Sustainability initiatives: Companies are increasingly focusing on producing methanol from renewable sources like biomass, aligning with global sustainability goals and regulatory pressures.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

Email: [email protected]

0 notes

Text

The global market for chemical processing catalysts was valued at USD 9.5 billion in 2022 and is predicted to reach USD 16.38 billion in 2030, rising at an 8.10% CAGR between 2023 and 2030.The global chemical processing catalysts market plays a pivotal role in the production of various chemicals, driving efficiency, selectivity, and sustainability in industrial processes. Catalysts are substances that speed up chemical reactions without being consumed, making them indispensable in the chemical industry. Their applications range from refining petroleum to producing chemicals like ammonia, methanol, and polymers, underpinning numerous industries such as pharmaceuticals, agrochemicals, and environmental protection.

Browse the full report at https://www.credenceresearch.com/report/chemical-processing-catalysts-market

Market Dynamics

The chemical processing catalysts market is driven by several factors, including the increasing demand for petrochemicals, stringent environmental regulations, and the growing emphasis on sustainability. The rise in global population and industrialization has led to increased demand for chemicals, which in turn has boosted the need for efficient catalysts to optimize production processes. Additionally, the shift towards cleaner and greener technologies is pushing industries to adopt catalysts that minimize energy consumption and reduce harmful emissions.

Key Catalysts and Their Applications

1. Zeolites:

Zeolites are microporous, aluminosilicate minerals that are widely used in the petrochemical industry, particularly in fluid catalytic cracking (FCC) processes. They help in breaking down large hydrocarbon molecules into gasoline, diesel, and other valuable products. Zeolites are also employed in the production of detergents and as adsorbents in gas purification.

2. Metal Catalysts:

Metals such as platinum, palladium, rhodium, and nickel are crucial in various catalytic processes. For instance, platinum-based catalysts are essential in the production of fertilizers through the ammonia synthesis process (Haber-Bosch process). Palladium and platinum are also used in automotive catalytic converters to reduce harmful emissions, a market driven by stringent environmental regulations.

3. Enzyme Catalysts:

Enzymes are biological catalysts that have gained prominence due to their specificity and efficiency under mild conditions. They are increasingly used in the production of biofuels, biodegradable plastics, and in the pharmaceutical industry for drug synthesis. The growing demand for sustainable and eco-friendly processes is driving the adoption of enzyme catalysts in chemical processing.

4. Organometallic Catalysts:

Organometallic catalysts, which contain metal-carbon bonds, are extensively used in polymerization processes, including the production of polyethylene and polypropylene. These polymers are integral to the plastics industry, and advancements in catalyst technology are enabling the production of high-performance polymers with tailored properties.

Market Trends and Challenges

1. Sustainability and Green Chemistry:

There is a growing focus on developing catalysts that enable sustainable chemical processes, aligning with the principles of green chemistry. This trend is driven by the need to reduce the environmental impact of chemical manufacturing, including minimizing waste and energy consumption. Catalysts that facilitate the use of renewable feedstocks and reduce greenhouse gas emissions are gaining traction in the market.

2. Technological Advancements:

Advances in catalyst design, such as the development of nanocatalysts and hybrid catalysts, are enhancing the efficiency and selectivity of chemical reactions. Nanocatalysts, for example, offer a larger surface area and unique electronic properties, making them more effective in catalytic processes. These innovations are expected to open new avenues for catalyst applications in various industries.

3. High R&D Costs:

Despite the promising opportunities, the chemical processing catalysts market faces challenges such as high research and development (R&D) costs and complex regulatory requirements. Developing new catalysts involves significant investment in R&D, and the commercialization of innovative catalysts requires rigorous testing and compliance with environmental regulations. These factors can act as barriers to entry for new players in the market.

Regional Insights

The chemical processing catalysts market is geographically diverse, with significant contributions from regions like North America, Europe, Asia-Pacific, and the Middle East. North America and Europe are mature markets, driven by established chemical industries and stringent environmental regulations. The Asia-Pacific region, particularly China and India, is witnessing rapid growth due to industrialization, urbanization, and increasing demand for chemicals. The Middle East, with its abundant hydrocarbon resources, also represents a key market for petrochemical catalysts.

Key Players

Air Products and Chemicals, Inc. (USA)

Albemarle Corp. (USA)

BASF Catalysts LLC (USA)

Clariant (Switzerland)

Evonik Industries AG (Germany)

Johnson Matthey (UK)

INEOS Group Holdings S.A (Switzerland)

LyondellBasell Industries N.V. (The Netherlands)

W. R. Grace & Co. (USA)

Segmentation

By Type

Polymerization Catalysts

Oxidation Catalysts

Organic Synthesis Catalysts

Synthesis Gas Catalysts

Hydrogenation Catalysts

Dehydrogenation Catalysts

By Application

Production of Isobutylene

Chemicals

Others

By Region

North America

The US.

Canada

Mexico

Europe

Germany

France

The U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/chemical-processing-catalysts-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Propylene: A Versatile Monomer for Plastics, Chemicals, and Fuels

Propylene, also known as Propylene, is an important industrial organic compound used for the production of numerous polymers and chemicals. With the chemical formula C3H6, Propylene is a colorless gas that is highly flammable and slightly less dense than air. It is one of the three most important olefins produced industrially, along with ethylene and butadiene.

Sources and Production of Propylene

Naturally, Propylene is produced as a byproduct during oil refinement and natural gas processing. However, most Propylene manufactured today is produced through two key processes - steam cracking of hydrocarbons and fluid catalytic cracking (FCC) of crude oil fractions. Steam cracking involves heating petroleum feedstocks like naptha, liquefied petroleum gas or ethane in the presence of steam to produce lighter alkenes like ethylene and Propylene. FCC uses a zeolite catalyst at elevated temperatures to convert heavier hydrocarbon fractions into gasoline and lighter alkenes. Refineries and petrochemical facilities use these cracking techniques to maximize alkene yields and recover Propylene on an industrial scale.

Uses and Derivatives of Propylene

By far the largest application of Propylene is for the production of polyPropylene plastics. In fact, Propylene demand is dominated by polymerization which accounts for over 60% of its end uses. PolyPropylene possess desirable properties like flexibility, transparency, resistance to moisture and chemicals and is commonly used in packaging films, textiles, plastic parts and various industrial applications. Other major derivatives of Propylene include Propylene oxide, acrylonitrile, cumene and alcohols. Propylene oxide forms the basis for specialized polyether polyols used in rigid and flexible foams. Acrylonitrile is a key precursor to acrylic fibers and plastics. Cumene, or isopropylbenzene, is primarily used to manufacture phenol and acetone. Propylene also finds usage as a petrochemical intermediate in various chemical processes.

Applications in Fuels and Transportation

Due to Propylene's molecular structure and fuel properties, it is increasingly being evaluated as an alternative transportation fuel, especially in diesel engines. Propylene is more reactive and has a higher cetane value compared to longer chain alkanes like diesel. As a result, it produces cleaner burning exhaust with reduced emissions. It has led to interest in developing Propylene-diesel fuel blends. Furthermore, Propylene derived alkylate - a high-octane component obtained from isomerization and alkylation refining - improves gasoline engine performance and is a major gasoline additive. This has created new potential avenues for Propylene consumption in transportation fuels in addition to the chemical sector.

World Supply and Demand Dynamics

On a global scale, over 60 million tons of Propylene are produced annually to meet the growing polymer and chemical demands. The Asia Pacific region dominates both production and consumption with China leading as the largest Propylene market. Key refining and petrochemical industries based along the U.S. Gulf Coast and parts of Europe like Germany, Belgium and Italy also contribute significantly. International trade plays a critical role since Propylene supply-demand balances vary regionally. Propylene trade occurs through ship tank or intra-pipeline transports to equalize regional surpluses and shortfalls. Overall, Propylene is an indispensable petrochemical that serves as backbone to the plastics industry and leverages oil and gas refinery infrastructure worldwide.

Environmental and Process Safety Aspects

Like other industrial organic chemicals, Propylene manufacturing and handling requires compliance to strict environmental and process safety standards. Propylene plants are potential sources of air pollutants due to fugitive emissions and combustion byproducts that necessitate robust emission control systems. Propylene's higher reactivity also increases risk of fires and explosions that demand sophisticated risk prevention through equipment design, operating procedures and operator training. Effective waste management is equally important since process residues may contain hazardous compounds. Regulatory compliance backed by robust risk governance helps realize Propylene's societal benefits while minimizing workplace and community impacts. Overall stewardship across the Propylene supply chain is crucial given the chemical's extensive role in modern products and technologies.

Propylene stands out as one of the most widely used petrochemical intermediates supporting numerous downstream derivatives. Its contributions to plastics, chemicals and fuel applications underscore Propylene’s strategic importance to modern industries and economies worldwide. Continued innovation to maximize Propylene yields from fossil feedstocks along with alternative production pathways will be paramount to sustain this key industrial monomer’s role in the future.

Get more insights on Propylene

About Author:

Priya Pandey is a dynamic and passionate editor with over three years of expertise in content editing and proofreading. Holding a bachelor's degree in biotechnology, Priya has a knack for making the content engaging. Her diverse portfolio includes editing documents across different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. Priya's meticulous attention to detail and commitment to excellence make her an invaluable asset in the world of content creation and refinement.

(LinkedIn- https://www.linkedin.com/in/priya-pandey-8417a8173/)

0 notes

Text

Polypropylene Compounds Market Primed for Growth Driven by Rising Use in Automotive Industries

The polypropylene compounds market involves manufacturing of polyolefin and polyolefin compounds. Polypropylene compounds are used in automotive, packaging, medical and construction industries owing to their heat resistance and durability properties. The automotive industry widely uses polypropylene compounds in interior and exterior automotive parts like battery casings, seat covers, bumpers and instrument panels.

The global polypropylene compounds market is estimated to be valued at US$ 26.74 Mn in 2024 and is expected to exhibit a CAGR of 3.6% over the forecast period 2024 to 2031.

Key Takeaways

Key players operating in the polypropylene compounds market are Albemarle Corporation (US), W R Grace (US), BASF (Germany), Haldor Topsoe (Denmark), Honeywell UOP (US), Clariant (Switzerland), Axens (France), Johnson Matthey (UK), China Petroleum and Chemical Corporation (Sinopec) (China), and Shell Catalyst & Technologies (Netherlands), Arkema (France), Anten Chemicals (China), Chempack (China), Dorf-Ketal Chemicals Pvt. Ltd. (India), Exxon Mobil Corporation (US), Gazprom (Russia), JGC Catalyst and Chemicals (Japan),KNT Group (Russia), Kuwait Catalyst (Kuwait), N.E.Chemcat (Japan), Porocel (US), Qingdao Huicheng Environmental Technology (China), Taiyo Koko Co. Ltd. (Japan), Unicat Catalyst Technologies (US), and Yueyang Sciensun Chemicals (China). Growing demand for polymer compounds from automotive and packaging industries is presenting huge growth opportunities in the polypropylene compounds market. Additionally, rising demand from emerging economies of Asia Pacific and Latin America is fueling the global expansion of the polypropylene compounds market.

Market Drivers

The automotive industry is expected to remain the key end user of Polypropylene Compounds Market Growth, driven by rising vehicle production across the globe. As per forecasts, global vehicle production is projected to reach 117 million units by 2024 from around 93 million units in 2020. This rising automotive production will drive the demand for polymer compounds used in various interior and exterior automotive parts.

Get more insights on Polypropylene Compounds Market

About Author:

Ravina Pandya, Content Writer, has a strong foothold in the market research industry. She specializes in writing well-researched articles from different industries, including food and beverages, information and technology, healthcare, chemical and materials, etc. (https://www.linkedin.com/in/ravina-pandya-1a3984191)

0 notes

Text

Discover the Best Ceramic Solutions in Mandsaur: A Comprehensive Guide

Mandsaur, a notable hub for industrial materials, has become a significant player in the ceramic industry. With an increasing demand for advanced ceramic products across various sectors, Mandsaur stands out due to its exceptional ceramic ultra suppliers and manufacturers. This article explores the leading ceramic ultra suppliers, High Alumina Ceramic Balls exporters, ceramic grid block suppliers, PP Saddles manufacturers, Ceramic Saddles suppliers, and Ceramic Super Intalox Saddle providers in Mandsaur. We will delve into each category to provide a comprehensive overview of what you can expect from these leading ceramic suppliers and manufacturers.

Ceramic Ultra Suppliers: Leading the Industry

Ceramic Ultra materials are known for their exceptional durability, resistance to high temperatures, and excellent mechanical properties. In Mandsaur, ceramic ultra suppliers offer a range of high-quality products designed for demanding applications. These materials are ideal for use in aerospace, automotive, and heavy machinery industries due to their superior performance and longevity.

Ceramic Ultra suppliers in Mandsaur pride themselves on delivering products that meet stringent international standards. Their commitment to quality is evident in their state-of-the-art manufacturing processes and rigorous quality control measures. By leveraging advanced technology and innovative techniques, these suppliers ensure that their ceramic ultra products provide exceptional reliability and efficiency.

High Alumina Ceramic Balls Exporters: Quality and Precision

High Alumina Ceramic Balls are crucial in various industrial applications, particularly in grinding and milling processes. Known for their high density and wear resistance, these balls are essential in enhancing the efficiency of machinery and extending the lifespan of equipment.

Mandsaur is home to several renowned High Alumina Ceramic Balls exporters who specialize in providing these high-performance materials to global markets. These exporters are known for their adherence to international quality standards, ensuring that their ceramic balls deliver outstanding performance and reliability. Their expertise in sourcing, manufacturing, and exporting ensures that customers receive top-quality products tailored to their specific needs.

Ceramic Grid Block Suppliers: Essential for Efficient Filtration

Ceramic Grid Blocks are integral components used in various industrial processes, particularly in filtration and separation applications. They are designed to support catalyst beds and facilitate efficient fluid distribution in chemical reactors and other processing units.

In Mandsaur, ceramic grid block suppliers offer a diverse range of products designed to meet the specific requirements of different industries. These suppliers utilize advanced manufacturing techniques to produce grid blocks with precise dimensions and superior structural integrity. Their commitment to quality ensures that their products contribute to improved operational efficiency and reduced maintenance costs.

PP Saddles Manufacturers: Robust and Reliable

PP Saddles, or polypropylene saddles, are essential components used in various industrial processes, including chemical processing and water treatment. These saddles provide support for catalyst beds and improve fluid distribution, making them a critical part of many industrial systems.

Mandsaur boasts a number of reputable PP Saddles manufacturers who excel in producing high-quality saddles that meet the demands of modern industry. These manufacturers utilize advanced materials and cutting-edge technology to ensure that their PP Saddles are robust, reliable, and resistant to chemical degradation. Their expertise in manufacturing ensures that their products deliver optimal performance and longevity.

Ceramic Saddles Suppliers: Enhancing Process Efficiency

Ceramic Saddles are widely used in industrial applications for their excellent chemical resistance and high-temperature stability. They are commonly employed in processes such as catalytic reactions and fluidized bed operations, where they contribute to efficient fluid distribution and improved process performance.

Ceramic Saddles suppliers in Mandsaur offer a broad selection of saddles designed to meet the specific needs of various industrial applications. Their products are known for their durability, precision, and ability to withstand harsh operating conditions. By focusing on quality and innovation, these suppliers ensure that their ceramic saddles provide reliable performance and contribute to overall process efficiency.

Ceramic Super Intalox Saddle Providers: Advanced Solutions

Ceramic Super Intalox Saddles are advanced packing materials used in chemical processing and distillation columns. They are designed to provide enhanced mass transfer efficiency and improved process performance. Their unique design allows for optimal fluid distribution and minimizes pressure drop, making them a preferred choice for many industrial applications.

In Mandsaur, Ceramic Super Intalox Saddle providers offer high-quality saddles that meet the rigorous demands of modern industrial processes. These providers utilize advanced manufacturing techniques and materials to produce saddles that deliver exceptional performance and durability. Their commitment to innovation ensures that their products contribute to improved process efficiency and reduced operational costs.

Ceramic Ultra Manufacturers: Excellence in Production

Ceramic Ultra Manufacturers in Mandsaur are at the forefront of producing high-performance ceramic materials designed for a wide range of applications. These manufacturers leverage advanced technologies and strict quality control measures to ensure that their products meet the highest standards of performance and reliability.

From raw material selection to final product testing, Mandsaur’s ceramic ultra manufacturers maintain a strong focus on quality throughout the production process. Their expertise in ceramic manufacturing enables them to produce materials that offer exceptional durability, high-temperature resistance, and superior mechanical properties. Whether for industrial, aerospace, or other demanding applications, these manufacturers provide solutions that meet the needs of their clients.

Conclusion

Mandsaur has emerged as a key player in the ceramic industry, offering a wide range of high-quality products and services. From ceramic ultra suppliers to High Alumina Ceramic Balls exporters, ceramic grid block suppliers, PP Saddles manufacturers, Ceramic Saddles suppliers, and Ceramic Super Intalox Saddle providers, the city is home to a wealth of expertise and innovation.

Whether you are looking for advanced ceramic materials for high-performance applications or reliable components for industrial processes, Mandsaur’s ceramic industry offers the solutions you need. By choosing products from these leading suppliers and manufacturers, you can ensure that your operations benefit from the best materials and technologies available in the market.

Visit- https://mbctower.in/

Address-

Chandapura Road, Pashupatinath Mandir road, Mandsaur M.P. 458001 India

Phone:

088276 97111

0 notes

Text

Thermoplastic Polyolefin Market: Current Trends and Future Prospects

Thermoplastic polyolefin (TPO) is a significant segment within the polymer market, primarily known for its versatility, resilience, and economic viability. TPOs are a blend of polypropylene (PP), polyethylene (PE), and an elastic component, often making them a preferred material in various applications. This article delves into the current trends, drivers, and future prospects of the thermoplastic polyolefin market.

Market Overview

The thermoplastic polyolefin market has witnessed substantial growth over the past decade, driven by increasing demand from the automotive, construction, and packaging industries. The unique properties of TPOs, such as their high impact resistance, flexibility, and ease of processing, make them ideal for a wide range of applications.

Key Drivers

1. Automotive Industry:

The automotive industry is one of the largest consumers of TPOs. The material's lightweight nature and superior durability make it an ideal choice for automotive parts such as bumpers, interior trims, and dashboard skins. The growing trend towards lightweight vehicles to improve fuel efficiency and reduce emissions has further boosted the demand for TPOs in this sector.

2. Construction Sector:

TPOs are extensively used in the construction industry, particularly in roofing membranes. The material's resistance to UV radiation, weathering, and chemical exposure ensures long-lasting performance in roofing applications. The ongoing growth in the construction sector, particularly in emerging economies, is a significant driver for the TPO market.

3. Sustainability:

Environmental concerns and the push towards sustainable materials have positively impacted the TPO market. TPOs are fully recyclable and can be reprocessed without losing their inherent properties, making them a preferred choice for eco-friendly applications.

4. Advancements in Manufacturing:

Technological advancements in polymer processing have enhanced the quality and performance of TPOs. Innovations such as improved catalysts and polymerization techniques have led to the development of TPOs with superior properties, further driving market growth.

Regional Analysis

North America: The North American market for TPOs is well-established, with significant demand from the automotive and construction sectors. The presence of major automotive manufacturers and a robust construction industry are key factors driving the market in this region.

Europe: Europe is another prominent market for TPOs, driven by stringent environmental regulations and a strong emphasis on sustainable materials. The region's well-developed automotive industry also contributes to the demand for TPOs.

Asia-Pacific: The Asia-Pacific region is expected to witness the highest growth in the TPO market, fueled by rapid industrialization, urbanization, and economic development in countries like China and India. The expanding automotive and construction industries in these countries are major growth drivers.

Latin America and Middle East & Africa: These regions are gradually emerging as significant markets for TPOs, with increasing construction activities and growing automotive industries. However, market penetration is still relatively low compared to North America, Europe, and Asia-Pacific.

Request for a sample of the report browse through – https://univdatos.com/get-a-free-sample-form-php/?product_id=26877

Future Prospects

The future of the thermoplastic polyolefin market looks promising, with several trends expected to shape its growth trajectory:

1. Increased Focus on Sustainability:

The global emphasis on sustainability and the circular economy is likely to drive the demand for recyclable materials like TPOs. Innovations aimed at improving the recyclability and environmental performance of TPOs will play a crucial role in market growth.

2. Technological Advancements:

Continuous advancements in polymer processing technologies will lead to the development of TPOs with enhanced properties, expanding their application scope and driving market growth.

3. Expansion in Emerging Markets:

Emerging economies, particularly in Asia-Pacific, Latin America, and the Middle East, offer significant growth opportunities for the TPO market. The rapid industrialization and urbanization in these regions are expected to drive demand for TPOs in various applications.

4. Automotive Industry Evolution:

The evolution of the automotive industry, with a focus on electric and hybrid vehicles, will create new opportunities for TPOs. Lightweight materials like TPOs will be crucial in developing energy-efficient vehicles.

Conclusion

The thermoplastic polyolefin market is poised for significant growth, driven by increasing demand from various end-user industries, technological advancements, and a strong emphasis on sustainability. As industries continue to seek durable, lightweight, and eco-friendly materials, TPOs are set to play a crucial role in meeting these demands, ensuring a bright future for the market.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

Polypropylene Catalyst Market Revenue, Opportunity, Segment and Key Trends 2031

The Insight Partners stands out as a reliable ally in the syndicated market research and consultation through its steadfast commitment to the market research industry. With extensive experience and proven dedication, we have been delivering outstanding outcomes. With a team of researchers catering to distinct business requirements, we can emerge as a trusted research partner in the past decade.

By prioritizing precision and trust ahead, we are proud to announce the addition of the latest offering titled “Polypropylene Catalyst Market Growth Outlook to 2031”. This report ensures spotless coverage of recent updates and a range of business environment factors impacting the Polypropylene Catalyst market growth. The meticulous approach opted by our researchers can assist companies in transforming business space into the Polypropylene Catalyst market.

Polypropylene Catalyst market report offers a comprehensive analysis of regional and global scenarios. The scope of the market report extends to the competitive landscape, cost analysis, key players, specific market regions, profit margin, and market situation. A glance at wide-ranging factors restricting Polypropylene Catalyst market growth is deliberately included in this study.

Objectives of Polypropylene Catalyst Market Report

To deliver a detailed market overview by integrating quantitative and qualitative analysis

To unveil growth strategies by evaluating the competitive landscape and examining key companies against their position and strategic advantage

To offer estimates on sales volume, market share, size, and CAGR for the projected period.

To offer segment wise insights

This detailed report on Polypropylene Catalyst market size is heavily based on verified information and authoritative sources. The study intended to offer market players an overview of market opportunities in the coming period. This report helps clients as a first-hand source of knowledge on the market while providing a full-fledged analysis of each segment.

The study contains details on frontrunners in the market along with their recent collaborations, segments, revenues, product launches, and Polypropylene Catalyst market trends. It projects the competition in the Polypropylene Catalyst market for an estimated duration. This research further looks at industry channels and the performance of key market players to help businesses stay ahead in the market.

Our Report Sample May Brief On:

Scope of Polypropylene Catalyst market report

Brief introduction of Polypropylene Catalyst market and Industry Overview

Table of Contents

Top market players covered in this report

Report Structure

Research Methodologies by The Insight Partners

Regional Insights:

This section includes insights on different regions and key players present in the region. This section attempts to analyze the growth of a specific regional market based on economic, technological, and environmental factors. Readers may expect revenue-based data and sales insights gathered by our team after comprehensive research. This informative chapter remains an absolute perk for investors, as it will help them to understand potential investment value and expected returns in specific regions.

Report Attributes

Details

Segmental Coverage

Type

Ziegler Natta

Metallocene

Others

Manufacturing process

Bulk Phase Process

Gas Phase Process

Others [Hybrid and Slurry]

Regional and Country Coverage

North America (US, Canada, Mexico)

Europe (UK, Germany, France, Russia, Italy, Rest of Europe)

Asia Pacific (China, India, Japan, Australia, Rest of APAC)

South / South & Central America (Brazil, Argentina, Rest of South/South & Central America)

Middle East & Africa (South Africa, Saudi Arabia, UAE, Rest of MEA)

Market Leaders and Key Company Profiles

W.R. Grace & Co.

China Petrochemical Corporation

LyondellBasell Industries Holdings B.V.

Mitsui Chemicals, Inc.

TOHO TITANIUM CO., LTD.

Ineos Group Ltd

Sumitomo Chemical Co., Ltd.

Basf Se

Union Carbide Corporation

Albemarle Corporation

Other key companies

Why The Insight Partners?

Proven Expertise: The Insight Partners comprises expert market research analysts who have extensive industry-specific knowledge. Through this report, our team is bringing years of experience to the table while safeguarding the accuracy of insights.

Actionable Insights: TIP relies on a combination of primary and secondary research methodologies that drive tangible results. We are committed to keeping our offerings clear, accessible, and concise to guide businesses in the decision-making process.

Integration of Technology: We embrace technology in all its forms as the core of our research tactics. We use various tools and platforms to analyze and interpret the data. This allows timely results.

Summary:

Current and Future Market Estimates- Polypropylene Catalyst Market Share, and Size | 2031

Market Dynamics – Drivers, Challenges, Regional Trends, and Market Opportunities

Market Segmentation – Product, Application, End-use Industries, and Regional Growth Prospects.

Competition Matrix – Key Market Players and Strategies

Recent Developments and Innovation contributing Market Growth

About Us:

The Insight Partners is a one-stop industry research provider of actionable intelligence. We help our clients in getting solutions to their research requirements through our syndicated and consulting research services. We specialize in industries such as Semiconductor and Electronics, Aerospace and Defense, Automotive and Transportation, Biotechnology, Healthcare IT, Manufacturing and Construction, Medical Devices, Technology, Media and Telecommunications, Chemicals and Materials.

Contact Us: www.theinsightpartners.com

0 notes

Text

Redefining Plastic Recycling: The Transformative Impact of Recycled Granules and UAE's Role in Driving Sustainability

Introduction: Redefining Plastic Recycling for a Sustainable Era

Amidst growing concerns over environmental sustainability, the discourse surrounding plastic waste management has reached a critical juncture. The need for innovative solutions to combat plastic pollution has never been more pressing. Enter recycled plastic granules—a promising avenue in the quest for sustainability. In this exploration, we delve into the transformative potential of recycled PE, HD, LD, and recycled LD granules, shedding light on their significance in reshaping the plastic industry. Additionally, we'll examine the pivotal role played by plastic scrap traders in the UAE in driving the circular economy forward.

Recycled PE Granules: A Sustainable Shift

Polyethylene (PE) stands as one of the most widely used plastics globally, finding applications across various industries. However, its environmental impact has raised concerns about sustainability. Recycled PE granules offer a viable solution by repurposing post-consumer and post-industrial PE waste. Through advanced recycling processes, this waste is transformed into high-quality granules suitable for a range of applications, signaling a shift towards sustainability in the plastic industry.

Recycled HD and LD Granules: Advancing Recycling Standards

High-density polyethylene (HDPE) and low-density polyethylene (LDPE) are indispensable in modern manufacturing, yet their environmental footprint poses challenges. Recycled HD granules and LD granules represent a breakthrough in recycling technology. By converting HD and LD plastic waste into granules of comparable quality to virgin materials, this innovation not only reduces environmental impact but also sets new standards for sustainable plastic production.

Recycled PP Granules: Innovating Towards Sustainability

Polypropylene (PP) is renowned for its versatility, but its widespread use contributes to plastic pollution. Recycled PP granules offer a sustainable alternative by transforming post-consumer and post-industrial PP waste into valuable raw materials. From automotive parts to packaging, these granules demonstrate the potential for innovation in plastic recycling, driving towards a more sustainable future.

PET Scrap: Transformative Recycling Solutions

Polyethylene terephthalate (PET) is ubiquitous in modern life, yet PET waste poses significant environmental challenges. Recycling PET scrap presents an opportunity to mitigate these challenges. Through advanced recycling techniques, PET scrap can be repurposed into various products, reducing the reliance on virgin plastics and promoting a circular economy.

Plastic Scrap Traders in UAE: Catalysts for Sustainability

Plastic scrap traders in UAE play a crucial role in facilitating the global plastic recycling network. Their efforts in collecting, sorting, and distributing plastic scrap contribute to the circular economy, promoting sustainability on a regional and international scale. By connecting suppliers and buyers, these traders drive the transformation of plastic waste into valuable resources, furthering the cause of environmental stewardship.

Conclusion: Towards a Sustainable Future

In conclusion, the adoption of recycled plastic granules represents a significant step towards a more sustainable future. From PE to PP, each type of recycled granule offers a tangible solution to the challenges of plastic pollution. By embracing these innovations and leveraging the efforts of plastic scrap traders in the UAE, we can pave the way towards a greener, more resilient world. It is imperative that we continue to explore and invest in sustainable solutions to address the pressing issue of plastic waste, ensuring a brighter future for generations to come.

0 notes

Text

Decene: A Versatile Hydrocarbon For Modern Industry

Decene is an organic compound belonging to the alkene family, characterized by the presence of a carbon-carbon double bond. Its chemical formula is C10H20, and it exists in several isomeric forms, with 1-decene being the most significant due to its wide range of industrial applications. This hydrocarbon is crucial in the production of synthetic lubricants, surfactants, and various polymers, making it an essential component in modern chemical manufacturing. This article explores the properties, production methods, applications, and future prospects of C10H20, highlighting its importance in contemporary industry.

Properties of Decene

C10H20 is a clear, colorless liquid at room temperature with a mild odor. Its molecular structure includes a straight chain of ten carbon atoms with a double bond typically located at the first carbon atom in 1-decene. This structural configuration gives C10H20-specific chemical properties:

Molecular Formula: C10H20

Molecular Weight: Approximately 140.27 g/mol

Boiling Point: Around 170-172°C (338-342°F)

Density: Approximately 0.74 g/cm³ at 20°C

Solubility: Insoluble in water but soluble in organic solvents like alcohols and ethers.

The double bond in C10H20 makes it reactive in various chemical processes, particularly in polymerization and addition reactions, which are fundamental in producing many commercial products.

Production of Decene

Decene is typically produced through the oligomerization of ethylene or by cracking heavier hydrocarbons. Two primary methods are employed:

Ethylene Oligomerization: This process involves the catalytic polymerization of ethylene to form linear alpha-olefins (LAOs), including C10H20. Catalysts such as Ziegler-Natta or single-site catalysts are often used to control the chain length of the oligomers, ensuring a high yield of specific alpha-olefins like 1-C10H20.

After production, C10H20 undergoes purification processes such as distillation to remove impurities and achieve the desired level of purity for industrial applications.

Applications of Decene

Decene’s versatility makes it valuable in numerous industrial sectors, including:

Synthetic Lubricants: One of the primary uses of C10H20 is in the manufacture of polyalphaolefins (PAOs), which are high-performance synthetic lubricants. These lubricants are widely used in automotive engines, industrial machinery, and aerospace applications due to their superior thermal stability, low volatility, and excellent lubricating properties.

Surfactants and Detergents: C10H20 is used as a precursor in the synthesis of surfactants and detergents. Through processes such as sulfonation and alkoxylation, decene-derived compounds contribute to the production of cleaning agents with enhanced emulsifying and foaming properties.

Plasticizers: C10H20 can be used to produce plasticizers, which are added to polymers to increase their flexibility, workability, and durability. These plasticizers are essential in the manufacture of flexible PVC products, including cables, hoses, and flooring materials.

Polymer Production: C10H20 serves as a monomer in the production of certain polymers, including polyethylene and polypropylene derivatives. Its role in these polymerization reactions helps create materials with specific mechanical and chemical properties tailored for various applications.

Specialty Chemicals: C10H20 derivatives are used in the production of specialty chemicals such as functional fluids, oilfield chemicals, and textile auxiliaries, contributing to improved performance and efficiency in these applications.

Future Prospects and Innovations

The demand for decent and its derivatives is expected to grow, driven by advancements in technology and increasing industrial applications. Several trends and innovations are likely to shape the future of C10H20 production and usage:

Sustainable Production: With the growing emphasis on sustainability and environmental responsibility, there is a push towards developing greener production methods for C10H20. Research is focused on using renewable feedstocks, such as bio-based ethylene, and implementing more efficient catalytic processes to reduce the environmental impact of C10H20 manufacturing.

Advanced Catalysis: Innovations in catalytic technology are expected to enhance the efficiency and selectivity of C10H20 production. Advanced catalysts with higher activity and stability can improve yields, reduce energy consumption, and minimize by-products.

Nanotechnology: The incorporation of nanotechnology in lubricant formulations is a promising area of research. Nanoparticles can be combined with decene-derived synthetic lubricants to create high-performance nanolubricants with superior tribological properties.

High-Performance Materials: The development of new polymers and materials with enhanced properties, such as higher strength, better thermal stability, and improved chemical resistance, will drive the demand for C10H20 as a key raw material.

Energy Efficiency: In the context of energy conservation, decene-derived synthetic lubricants can contribute to improved energy efficiency in machinery and engines. Their superior lubrication properties can reduce friction and wear, leading to lower energy consumption and extended equipment life.

Conclusion

C10H20 is a versatile and valuable hydrocarbon that plays a crucial role in modern industry. Its unique properties and reactivity make it indispensable in the production of synthetic lubricants, surfactants, plasticizers, and various polymers. As technology advances and the demand for high-performance materials grows, decene’s importance is set to increase further. Innovations in sustainable production methods, advanced catalysis, and nanotechnology are expected to drive the future development and application of C10H20, ensuring its continued relevance in the chemical industry. Understanding the significance of C10H20 and its derivatives highlights the intricate interplay between chemistry and industry, showcasing the profound impact of this seemingly simple molecule on our daily lives and technological progress.

0 notes

Text

Endless Possibilities of Polypropylene: Manufacturing Details to Practical Applications

In this blog, we explore one of the most common plastics in use today in industries all over the world. Polypropylene or PP is a highly popular plastic thanks to its unique production process and versatility. This polymer is produced through the polymerization of propylene gas and is a thermoplastic polymer with high chemical and thermal resistance as well as durability.

Welcome to our world of Polypropylene manufacturing where the magic of science and technology turns raw materials into the products that we use in our everyday lives. This article will explore the manufacturing of PP to its latest production technologies and processes. However, our investigation doesn’t stop here. We will also explore the extensive uses of Polypropylene from packaging to textile to automotive and medical devices.

From a regular customer to the aspiring engineer to the experienced professional – our Polypropylene story will inform and engage you. So, let’s get started and see what Polypropylene has to offer!

Introduction

Polypropylene (PP), a polyolefin with a chemical formula of (C3H6)n, stands out as a versatile thermoplastic polymer slightly tougher than Polyethylene. Its low density coupled with remarkable heat resistance makes it indispensable across various industries. From packaging food, beverages, and consumer goods to manufacturing automotive components like bumpers and interior trim, PP demonstrates its reliability. It's also a trusted material in the medical field for its sterilization compatibility, non-reactive nature, and in consumer goods for its strength. Moreover, in specialized applications such as cast films, Polypropylene's moldability and extrudability enable intricate designs, further solidifying its status as a cornerstone material in modern manufacturing.

Some of the interesting properties includes:

Melting Point: PP melts at different temperatures depending on its type (homopolymer or copolymer).

Lightweight: PP is one of the lightest plastics, making it ideal for applications where weight reduction matters.

Chemical Resistance: PP handles a wide range of chemicals well, but is not suitable for strong solvents or oxidizing agents.

Heat and Water Performance: PP maintains its properties even in hot, humid, or wet environments.

Stress Cracking: PP resists cracking under pressure from the environment.

Microbial Resistance: While good for some sterilization methods, PP can be susceptible to mold and bacteria growth.

Manufacturing Process

Polypropylene is derived from propene, which is abundantly produced from gas oil, naphtha, ethane, and propane. Concurrently, various methods are under development to generate bio-based Polypropylene, also known as bio-based Polypropylene, utilizing bio-based propene.

(a) Using a Ziegler-Natta catalyst

In the polymerization process, Ziegler-Natta catalysts play a crucial role, formed through the interaction between Titanium(IV) Chloride and an Aluminum Alkyl like Triethyl Aluminum. While the slurry method is occasionally employed, the primary methods for polymer production utilizing these catalysts are two.

(i) The bulk process

Polymerization occurs within liquid propene, conducted without a solvent at temperatures ranging from 340 to 360 Kelvin and pressures between 30 to 40 atmospheres to maintain propene in its liquid state. Following polymerization, solid polymer particles are isolated from the liquid propene, which is subsequently recycled. Utilizing liquid propene as a solvent during polymer formation eliminates the necessity for hydrocarbons like C4-C8 alkanes, commonly employed in the concurrent production of polyethylene.

(ii) The gas phase process

Propene and hydrogen blend is directed over a bed housing the Ziegler-Natta catalyst at temperatures ranging from 320 to 360 Kelvin and pressures varying between 8 to 35 atmospheres.

The polymer is isolated from the gaseous propene and hydrogen through cyclones, while the unused gas is reclaimed for reuse. Both processes can be conducted continuously and employ 'stereospecific' Ziegler-Natta catalysts to catalyze polymerization. These catalysts persist in the product and must be deactivated using water or alcohols before the polymer is transformed into pellets.

Bulk and gas phase techniques have substantially reduced gaseous and aqueous byproducts by utilizing highly active catalysts, leading to minimal residues in the final polymer.

(b) Using a metallocene as catalyst

Metallocenes, originally defined as molecules with a transition metal atom sandwiched between two parallel cyclopentadienyl ligands, with ferrocene being a notable example, now encompass a broader range of ligands related to cyclopentadienyl. Among these, zirconium-based metallocenes stand out as the sole commercial method for producing syndiotactic poly(propene). Similar to Ziegler-Natta catalysts, metallocenes facilitate polymerization through bulk or gas phase methods, as described earlier, or through the slurry process.

Poly(propenes) manufactured using metallocenes, known as mPP, find specific applications in producing non-woven fibers and heat-seal films. Additionally, metallocenes catalyze the production of copolymers comprising propene and ethene.

Technologies used by Major Polypropylene Manufacturers

Process Name : Spheripol process

LyondellBasell has been at the forefront of innovation with the introduction of the Spheripol Polypropylene process. Through the development of a third-generation high-yield, high-selectivity catalyst, LyondellBasell has streamlined the Spheripol process, simplifying its steps and enhancing product quality to a remarkable extent. The Spheripol process consists of three main units:

Catalyst feeding

Polymerization

Finishing section

At the core of all polymerization facilities lies the bulk polymerization segment, which is responsible for generating homo and random copolymers.

This method entails tubular loop reactors filled with liquid propylene, continuously supplied with catalyst and hydrogen to regulate molecular weight.

For random copolymers, an additional comonomer like ethylene is introduced. The resulting polymer is consistently discharged from the reactor, with any unreacted propylene recycled back into the loop reactor.

To manufacture impact copolymers, a vital gas phase reactor comes into play. Polymer from the loop reactor is transferred to this reactor, where an elastomer, derived from the polymerization of ethylene and propylene, interacts with the homopolymer matrix produced in the initial reactor.

Applications of Polypropylene

Packaging

Polypropylene's impressive combination of strength, good looks, and affordability makes it a dominant player in the packaging industry. This versatile material can be shaped into both rigid and flexible forms, catering to a wide range of product protection needs. In the realm of flexible packaging, PP's crystal-clear clarity and ability to effectively block moisture vapor make it ideal for food packaging, personal care products, and various other applications. It's a familiar sight in shrink wrap that keeps products bundled together, and its thin, flexible films find uses in the electronics industry, graphic arts, and even the closures on disposable diapers. Shifting to rigid applications, Polypropylene excels in blow molding, a technique that transforms it into sturdy crates, bottles, and containers. From housing delicate medical equipment to holding your favorite yogurt, PP's diverse capabilities make it a packaging material you'll likely encounter on a daily basis.

2. Consumer Goods & Items

Polypropylene isn't just for packaging! This versatile plastic pops up all around your house in a variety of applications. From see-through containers to sturdy furniture, housewares, appliances, luggage, and even toys, PP's durability and lightweight properties make it a popular choice for many consumer goods.

3. Automotive

Polypropylene (PP) emerges as a preferred choice for automotive parts owing to its trifecta of affordability, exceptional mechanical attributes, and moldability. Its extensive use spans across battery cases, trays, bumpers, fender liners, interior trim, instrumental panels, and door trims, reflecting its versatility in various applications within the automotive sector. Noteworthy characteristics such as a low coefficient of linear thermal expansion and specific gravity, alongside high chemical resistance and excellent weatherability, further elevate PP's appeal. Its superior processability and a finely tuned balance between impact resistance and stiffness add to its allure, making Polypropylene a stalwart material in the automotive industry, meeting stringent performance requirements while offering cost-effective solutions.

4. Fibre

Polypropylene fibers find their way into a variety of applications, including ropes, straps, and different fabric types. These fibers are especially strong and handle moisture well, making them ideal for uses in marine environments like ropes and twines.

Market Outlook

The packaging industry remains the dominant consumer of Polypropylene (PP) , particularly within food applications. However, the automotive sector is expected to be also contribute to the PP market growth in the coming years. Polypropylene's cost-effectiveness and robust mechanical properties make it ideal for automotive components like bumpers, dashboards, and door trims, contributing to over half of its total plastic usage. The burgeoning demand for electric and hybrid electric vehicles (EV/HEVs) further bolsters Polypropylene's appeal, promising to significantly augment market expansion. Additionally, the building & construction and electrical & electronics industries are projected to accelerate Polypropylene market growth due to its exceptional insulating properties. This surge in demand across diverse sectors suggests a robust future for the Polypropylene market.

Polypropylene Major Global Producers

Major companies in the Global Polypropylene market are Braskem, Reliance Industries Limited, ExxonMobil Chemical, LyondellBasell, Borouge, Shenhua Ningxia Coal Industry, Total Petrochemicals, Prime Polymer Co., Ltd., Indian Oil Corporation Limited, SABIC Europe, Zhejiang Petrochemical, Sinopec KPC PC JV, INEOS, Japan Polypropylene Corporation, Saudi Polyolefins, and Petrochina Dushanzi Petrochemical, and Others.

Conclusion:

Polypropylene (PP) is one of the most important plastic materials in modern industry because of its unique properties and wide range of applications. PP has been able to gain popularity in the world of polymers due to its cost-effectiveness, superior mechanical properties, and ease of molding. It is used in all automotive parts like battery cases and interior trims and ropes and twines for marine uses to prove its versatility. Polypropylene is likely to continue to be used in everyday items and various advances in the future of technology and industry because of its ability to contribute to our society in significant ways.

#Polypropylene#Polypropyleneprices#Polypropylenemarket#Polypropylenenews#Polypropylenepricetrend#Polypropylenepriceforecast#Polypropylenemarketprice#priceofPolypropylene

1 note

·

View note

Text

Market Trends in Polyvinyl Chloride Derivatives and Specialized Products

Polyvinyl Chloride: Exploring the Prevalence of Polyethylene Terephthalate in Our Daily Lives

What is PVC?

Polyvinyl chloride, commonly abbreviated as PVC, is a thermoplastic polymer. It is the third most widely produced polymer after polyethylene and polypropylene. PVC has a wide range of applications in construction materials, toys, pipes, wires, medical devices, and more due to its low production cost, workability, and resistance to corrosion.

Chemical Structure and Properties of PVC

PVC is formed by the polymerization of vinyl chloride monomer. The chemical structure of PVC consists of carbon, hydrogen, and chlorine atoms. It is a linear polymer with alternate single and double carbon-chlorine bonds. This molecular structure gives PVC its characteristic properties. PVC is a hard, stiff material with high tensile strength and excellent electrical insulation. It becomes flexible and pliable at higher temperatures but reverts to its original form when cooled. PVC is also noted for being lightweight, easy to work with, and offers good resistance to corrosion from acids, alkalis, and oil. Its toughness and durability make it suitable for a diverse set of applications.

Production Process for PVC

The production of PVC involves a two-step process - manufacture of vinyl chloride monomer (VCM) followed by polymerization of VCM into PVC polymer. In the first step, ethylene or acetylene is reacted with hydrogen chloride gas in the presence of a catalyst to produce VCM. In the second step, VCM undergoes polymerization either by suspension polymerization or emulsion polymerization methods to form PVC resin. The PVC resin is then compounded with additives, stabilizers, and fillers before processing into finished products. The worldwide production of PVC stands at over 40 million tons annually.

Applications of PVC in Construction

As a rigid thermoplastic polymer, PVC finds its major application in the construction industry due to the favorable properties of strength, durability, flame resistance, and cost-effectiveness. PVC piping is extensively used for supplying potable water and drainage systems due to its inorganic nature and resistance to corrosion. Rigid PVC sheets are used as roofing and siding materials in buildings for their light weight, low maintenance, and weather resistance characteristics. PVC windows commonly replace wooden windows owing to advantages such as no painting or rottenness. PVC flooring has emerged as a popular alternative to vinyl floor tiles, laminate, and ceramic tiles. PVC doors have also gained preference over wood or metal doors for homes and commercial spaces. Overall, PVC accounts for approximately 35% of plastic usage in construction applications worldwide.

Applications of Polyvinyl Chloride in Medical Devices

PVC is preferred for medical devices and tubing applications due to its sterilizability, clarity for visual inspections, flexibility, and economical processing. Common examples include tubing for dialysis and transfusion sets, drug and infusion containers, blood and plasma bags, medical device tubing, and respiratory appliances. Soft PVC is favored for items that contact the skin like catheters and implants due to its flexibility. Scientific instruments for laboratories also use PVC extensively owing to its chemical resistance and self-extinguishing nature. PVC offers an ideal balance of properties compared to alternatives like polyethylene for most general-purpose medical polymer applications.

Use of PVC in Wire and Cable Insulation

PVC is the most widely used insulating material in electric cables and wires industries. It accounts for over 40% of the total plastic used in cable insulation globally. Low-smoke PVC formulations provide excellent flame retardancy and self-extinguishing properties required for wire safety. PVC also delivers high dielectric strength for voltage insulation, chemical and moisture resistance, flexibility, low toxicity, and affordability. Some key wire and cable applications utilizing PVC insulation include housing and construction wires, automobile wires, power cables, appliance cords, telecommunications cables, and sheathed cables. Its widespread usage is attributed to the ability to meet various performance standards demanded by the wire and cable industry.

Toys and Childcare Products using PVC

Soft PVC finds applications in the manufacturing of children's toys owing to safety, flexibility, and affordability. Common toy products made from PVC include dolls, action figures, balls, inflatable toys, play equipment, and more. Safety standards compliant soft PVC provides an ideal material for children to mouth and contact with their skin. In healthcare, PVC is preferred for products like baby bottles, nipples, and teethers due to non-toxicity and clarity. PVC swimming pool toys and equipment have benefits over natural rubber or harder plastics. Overall, the versatile properties of PVC allow its safe usage in a range of toy and infant care articles available at economical costs.

In conclusion, PVC has emerged as one of the most widespread and commercially important plastics globally due to its versatile characteristics suitable for a variety of applications. Advancements in polymerization and compounding techniques allow the versatile formulations of PVC suitable for construction, medical, wire, toys, and other industries. With over 60 years of usage, research into improving PVC continues as a dynamically evolving thermoplastic. It stands as a vital polymer material that has touched almost every aspect of modern life from infrastructure to healthcare to consumer products. Though environmental and health issues concerning plastic pollution persist, sustainable product and process innovations aim to mitigate these concerns of the popular but controversial plastic polyvinyl chloride.

0 notes

Text

The Global Polyolefins Market: Trends, Challenges, and Opportunities

The polyolefins market is a cornerstone of the plastics and polymers industry, encompassing a range of versatile materials such as polyethylene (PE) and polypropylene (PP). These materials are widely used in various applications, from packaging and automotive parts to consumer goods and construction. As sustainability concerns and environmental regulations shape the industry, the polyolefins market is undergoing significant transformation. This article explores the latest trends, challenges, and opportunities in this dynamic sector.

Market Overview

Polyolefins, primarily polyethylene and polypropylene, account for a significant portion of the global plastics market. According to recent industry reports, the global polyolefins market is expected to continue growing steadily over the next decade, driven by increased demand from emerging economies, technological advancements, and the rise of e-commerce.

Polyethylene (PE): This is the most widely used polyolefin, with high-density polyethylene (HDPE), low-density polyethylene (LDPE), and linear low-density polyethylene (LLDPE) being the primary types. PE is commonly used in packaging, agriculture, and consumer goods.

Polypropylene (PP): Known for its versatility, PP is used in automotive components, textiles, and packaging. It offers high durability and resistance to heat and chemicals.

Trends in the Polyolefins Market

Sustainability and Circular Economy: As global awareness of environmental issues grows, there's increasing pressure on the plastics industry to adopt sustainable practices. Companies are exploring bio-based polyolefins, recyclable materials, and closed-loop recycling systems. The shift towards a circular economy is driving innovation in recycling technologies and the development of biodegradable polyolefins.

Advanced Manufacturing Technologies: Technological advancements, such as advanced catalysts and polymerization processes, are improving Polyolefins Market the efficiency and quality of polyolefins production. These innovations are helping to reduce energy consumption and emissions, contributing to the industry's sustainability goals.

Rising Demand from Emerging Markets: Emerging economies, particularly in Asia and Latin America, are experiencing significant industrial growth. This is driving demand for polyolefins in construction, packaging, and consumer goods. The expanding middle class in these regions also contributes to increased consumption of plastic products.

Lightweighting in Automotive and Transportation: The automotive industry is increasingly adopting lightweight materials to improve fuel efficiency and reduce emissions. Polyolefins, with their high strength-to-weight ratio, are becoming popular choices for automotive components, leading to further growth in this market segment.

Challenges Facing the Polyolefins Market

Environmental Regulations: Governments and environmental organizations are imposing stricter regulations on plastic production and disposal. The polyolefins industry must navigate these regulations while meeting market demand.

Plastic Waste and Recycling: The global challenge of plastic waste continues to pose a significant threat. The industry is under pressure to develop effective recycling solutions and reduce the environmental impact of polyolefins.

Volatility in Raw Material Prices: The price of raw materials, such as crude oil and natural gas, can impact the cost of polyolefins production. Fluctuations in these markets can affect profitability and pricing strategies.

Opportunities for Growth

Bio-based Polyolefins: The development of bio-based polyolefins presents a promising opportunity for the industry. These materials are derived from renewable sources and have a lower environmental impact, attracting environmentally conscious consumers.

Innovative Applications: As technology advances, new applications for polyolefins are emerging. From 3D printing to advanced textiles, the versatility of polyolefins offers ample room for innovation and market expansion.

Global Collaboration: The polyolefins industry can benefit from collaboration among stakeholders, including manufacturers, regulators, and environmental organizations. By working together, the industry can address sustainability challenges and drive positive change.

Buy the Full Report for Regional Insights into Polyolefins Market

Download a Free Report Sample

0 notes

Text

Polyolefins Market Trends, Revenue, Size-Share, Growth Drivers, Challenges, Demand, Business Opportunities, Challenges and Competitive Analysis 2032: SPER Market Research

Polyolefin belongs to the thermoplastic family. It is mainly made from natural gas and oil through the polymerization of ethylene and propylene, respectively. It is made from olefins, hydrocarbons, and monomers and has excellent processability, chemical stability, and long-term durability. It is the most frequently used thermoplastic polymer, utilized in a variety of industries including packaging, consumer goods, and fiber and textiles. Polyolefin is a polymer formed by the polymerization of monomer olefin in the presence of a suitable catalyst. Common polyolefins include polyethylene and polypropylene. These chemicals are widely employed in a variety of applications across sectors. Some of the most significant polyolefin-consuming industries include automotive, construction, electrical and electronics, and packaging.

According to SPER Market Research, ‘Polyolefins Market Size- By Type, By Application- Regional Outlook, Competitive Strategies and Segment Forecasts to 2032’ states that the Global Polyolefins Market is estimated to reach USD 487.46 billion by 2032 with a CAGR of 5.23%.