#Plastic Mould Factory

Explore tagged Tumblr posts

Text

Material expansion: At present, the types of materials for 3D printing are relatively limited. In the future, more types of materials can be explored, including new polymer materials, metal materials, ceramic materials, etc., to meet the needs of different fields.

Technological progress: At present, the speed, accuracy and quality of 3D printing technology still need to be improved. In the future, new printing technologies can be developed to increase printing speed, reduce printing errors and improve printing quality.

Diversified applications: At present, the application fields of 3D printing technology are still relatively limited. In the future, applications in more fields can be explored, such as applications in construction, medical, aerospace, automobile manufacturing and other fields, and its unique technical advantages can be exerted.

Intelligent development: In the future, artificial intelligence, machine learning and other technologies can be combined with 3D printing technology to realize intelligent design, optimization and production, and improve production efficiency and product quality.

Green development: At present, the waste and environmental protection problems generated by 3D printing technology still need to be solved. In the future, we can explore the path of green development, such as developing recyclable materials, reducing waste generation, etc., while paying attention to the impact on human body and environment .

Interdisciplinary cooperation: In the future, cooperation and innovation between different disciplines can be promoted, such as combining biology, chemistry, physics and other disciplines with material science, mechanical engineering, electronic information and other disciplines to jointly promote the development and application of 3D printing technology .

Cost reduction: At present, the cost of 3D printing technology is still relatively high. In the future, technological progress and large-scale production can be used to reduce costs and increase the penetration rate and application range.

2 notes

·

View notes

Text

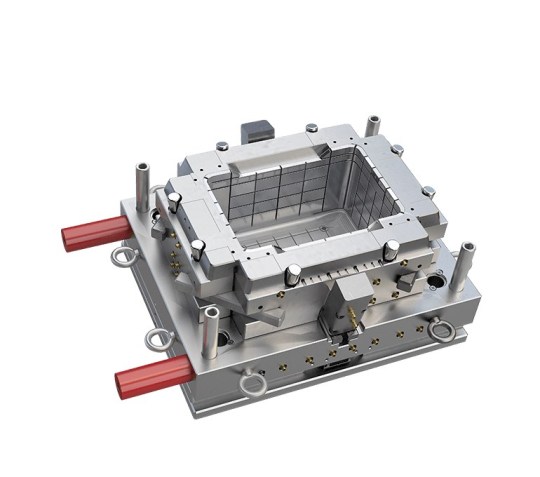

A Holistic Approach Ensuring Quality in Plastic Crate Mould Factory

The Plastic Crate Mould Factory, a critical component in the manufacturing sector, plays a pivotal role in producing high-quality plastic crates that are essential for various industries. Ensuring the quality of these molds is paramount to meet the diverse needs of clients and to maintain a competitive edge in the market. This article explores the multifaceted strategies employed by the Plastic Crate Mould Factory to guarantee the well of their products.

The journey towards quality begins with the selection of raw materials. The Plastic Crate Mould Factory must source high-grade polymers and additives that are resilient, durable, and capable of withstanding the rigors of the manufacturing process. The quality of the raw materials directly impacts the final product, making this the one line of defense in the quality assurance process.

Innovative design and precision engineering are at the heart of the Plastic Crate Mould Factory's operations. Utilizing CAD/CAM software, designers create molds that are not only efficient in production but also meet the specific requirements of clients. The design phase is where the foundation for a high-quality product is laid, with attention to detail and adherence to industry standards being crucial.

The adoption of advanced manufacturing techniques is a hallmark of a top-tier Plastic Crate Mould Factory. Techniques such as computer-aided manufacturing (CAM), high-speed machining, and 3D printing are employed to produce molds with exceptional accuracy and repeatability. These technologies reduce human error and ensure that each mold is manufactured to exacting standards.

Implementing stringent quality assurance protocols is a must for any Plastic Crate Mould Factory. This involves regular inspections at various stages of production, from the initial design to the final product. Quality control teams use a range of testing methods, including visual inspections, dimensional checks, and durability tests, to ensure that each mold meets the factory's high standards.

A commitment to continuous improvement is essential for a Plastic Crate Mould Factory to stay ahead in the industry. Regular training sessions for employees ensure that they are familiar with manufacturing techniques and quality control methods. This ongoing education helps to maintain a high level of expertise within the factory, contributing to the consistent production of superior molds.

To guarantee product quality, the Plastic Crate Mould Factory must invest in technology and equipment. This includes high-precision CNC machines, advanced material testing equipment, and automated production lines. Such investments not only enhance the efficiency of the manufacturing process but also contribute to the production of molds with superior quality.

Listening to client feedback is a critical aspect of ensuring product quality in a Plastic Crate Mould Factory. By understanding the specific needs and expectations of clients, the factory can tailor its products to meet these requirements. Customization plays a significant role in delivering molds that not only meet but exceed client expectations.

In today's environmentally conscious market, a Plastic Crate Mould Factory must also consider the environmental impact of its products. This includes using eco-friendly materials, implementing energy-efficient manufacturing processes, and ensuring that the end product is recyclable or biodegradable. By doing so, the factory not only meets quality standards but also aligns with global sustainability goals.

The Plastic Crate Mould Factory's commitment to quality is evident through its comprehensive approach to product development, manufacturing, and after-sales service. By focusing on the selection of raw materials, design innovation, advanced manufacturing techniques, quality assurance protocols, continuous improvement, investment in technology, client feedback, and environmental considerations, the factory ensures that each mold produced is of high quality. This dedication to well not only satisfies clients but also solidifies the Plastic Crate Mould Factory's reputation in its field.

0 notes

Text

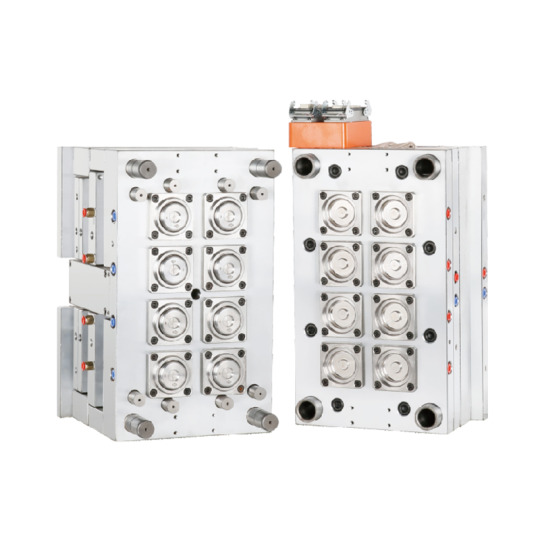

The In-Depth Manufacturing Process of Plastic Basket Mould Factory

The Plastic Basket Mould Factory is pivotal in the modern manufacturing landscape, producing a variety of plastic baskets that cater to both domestic and industrial needs. These factories are known for their precision, efficiency, and the ability to create customized solutions for diverse applications. This article delves into the intricate production process of The Plastic Basket Mould Factory, shedding light on how they manufacture a wide array of plastic baskets with high-quality standards.

The production process in The Plastic Basket Mould Factory begins with the design phase. Designers, equipped with market insights and customer requirements, utilize Computer-Aided Design (CAD) software to create three-dimensional models of the plastic baskets. This stage is crucial as it determines the shape, size, and functionality of the product. Designers must consider factors such as the basket's load-bearing capacity, durability, and ease of stacking and handling.

Once the design is finalized, the process moves on to the creation of the mold. In The Plastic Basket Mould Factory, the mold is the key tool for producing plastic baskets. Mold making typically involves Computer Numerical Control (CNC) machining to ensure the precision and complexity of the mold. The production of the mold must take into account the flow properties of the plastic material, cooling rates, and shrinkage factors to guarantee the quality of the final product.

Following the mold creation, the preparation of the plastic material commences. The Plastic Basket Mould Factory selects the appropriate plastic raw materials based on the product design, such as Polyethylene (PE), Polypropylene (PP), and others. These materials undergo processes like drying, mixing, and melting to eliminate moisture and impurities, ensuring the uniformity and flowability of the plastic.

The next step is the injection molding phase, where the prepared plastic material is injected into the mold under high pressure. The mold is clamped shut, and the plastic is heated and injected into the mold cavity. The plastic material fills the cavity and takes the shape of the mold. The mold is then cooled, allowing the plastic to solidify and maintain its shape. Once the plastic has cooled and hardened, the mold is opened, and the newly formed plastic basket is ejected.

After the baskets are formed, they undergo a series of quality control checks. In The Plastic Basket Mould Factory, quality control is a critical step to ensure that the finished product meets the required specifications and standards. Inspectors check for any defects, such as warping, cracks, or improper dimensions. The baskets may also be subjected to load tests to verify their strength and durability.

In addition to quality control, The Plastic Basket Mould Factory may also offer additional services such as customizing the baskets with logos or specific colors. This customization is achieved through processes like pad printing, hot stamping, or in-mold labeling.

Once the plastic baskets pass all quality checks and any additional customization is complete, they are packaged and prepared for shipping. The Plastic Basket Mould Factory often uses protective packaging materials to prevent damage during transit and ensure that the baskets arrive in good condition.

The production process in The Plastic Basket Mould Factory is a testament to the precision and efficiency of modern manufacturing techniques. From the initial design to the final product, each step is carefully planned and executed to produce high-quality plastic baskets that meet the needs of a wide range of customers. As the demand for plastic baskets continues to grow, The Plastic Basket Mould Factory remains at the forefront of innovation and production.

0 notes

Text

Need top-quality plastic caps? Look no further! Our plastic cap mould factory is the go-to destination for all your cap manufacturing needs. With years of experience and a commitment to excellence, our factory produces high-precision moulds that ensure perfect fit and functionality. We utilize cutting-edge technology and advanced techniques to deliver superior products that meet industry standards. Trust our skilled team to provide efficient and reliable solutions for your cap production. Choose our plastic cap mould factory for exceptional quality and professional service.

0 notes

Video

youtube

In addition to the custom design of injection molded milk tea cups, there is also exciting data: according to the latest survey results, using unique and personalized designed custom injection molded milk tea cups for brand promotion effectively increases customer repeat rates and word-of-mouth communication. Customers like to create an emotional connection with a brand, and highly personalized injection molded milk tea cups meet this need. While enjoying the delicious food, customers resonate with the brand and are more willing to share it with relatives and friends, thus promoting the spread of the brand's reputation. #bobatea #plasticcup #coffee #coffeecu...

0 notes

Text

Plastic Injection Flower Pot Mould Factory

Explore a wide range of innovative designs that blend functionality and style seamlessly. Trust YuanCheng Mold for unmatched quality, ensuring your flower pots are not just containers but statements of elegance. Cultivate beauty with the expertise of the leading Plastic Injection Flower Pot Mould Factory. For further details, reach out to us or visit our website.

0 notes

Text

Quality Plastic Moulding Jobwork Services in Noida with Cubix Control Systems.

0 notes

Text

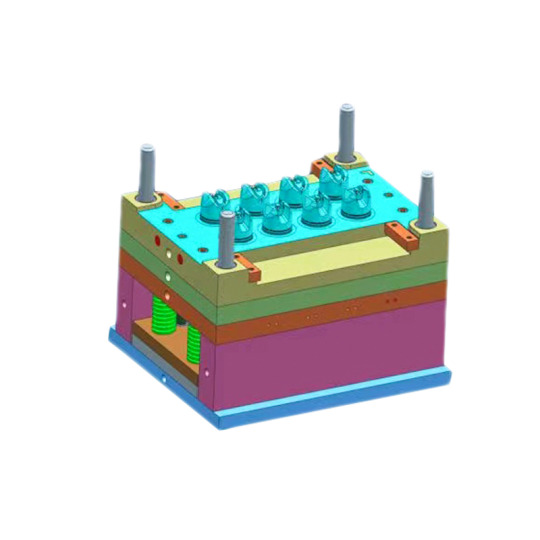

Crafting Comfort: The Art and Science of Plastic Stool Moulds

Plastic stools are a common furniture item that can be found in households, offices, and public spaces. These versatile pieces of furniture are lightweight, durable, and easy to clean, making them a popular choice for many. But have you ever wondered how these plastic stools are made? The answer lies in plastic stool moulds. we will explore the art and science behind plastic stool moulds, and how they contribute to the crafting of comfortable and functional plastic stools.

Plastic stool moulds are specifically designed tools that are used in the manufacturing process of plastic stools. These moulds are made from high-quality steel or aluminium, which ensures durability and longevity. The moulds are created with precision and expertise, taking into consideration the desired shape, size, and design of the plastic stool.

The process of creating plastic stool moulds begins with the design phase. Designers and engineers work together to create a detailed blueprint of the stool. This blueprint includes all the necessary measurements, features, and specifications of the stool, ensuring that the final product meets the desired requirements.

Once the design is finalized, the actual construction of the plastic stool mould begins. Highly skilled plastic stool mould makers use specialized machinery and tools to shape the steel or aluminium into the desired mould shape. This process requires accuracy and precision, as any errors or imperfections in the mould can impact the quality of the final product.

After the mould is constructed, it undergoes a series of finishing processes to ensure its smoothness and durability. This includes polishing, texturing, and adding any necessary inserts or components. These finishing touches help to enhance the functionality and aesthetics of the plastic stool.

With the plastic stool mould ready, the manufacturing process can begin. Plastic pellets are melted and injected into the plastic stool mould under high pressure. This allows the molten plastic to fill the mould cavity and take on its shape. Once the plastic has cooled and solidified, the plastic stool mould is opened, and the newly formed plastic stool is released.

Quality control is an essential step in the production of plastic stools. The plastic stool moulded stools are thoroughly inspected for any defects, such as imperfect shapes, rough surfaces, or structural weaknesses. Any defective stools are discarded, ensuring that only high-quality products make it to the market.

Plastic stool moulds offer several advantages in the manufacturing process. First and foremost, they allow for mass production of plastic stools with consistent quality and precision. The use of moulds ensures that every stool produced is identical in terms of shape and design, meeting the desired specifications.

Additionally, the use of moulds enables cost-effective production. Once the initial investment is made in creating the mould, the production process becomes more efficient and cost-efficient. The plastic stool moulds can be reused multiple times, allowing for a higher production output without the need for additional tooling or equipment.

Plastic stool moulds also offer flexibility and customization options. Since the moulds can be created to any specific design, manufacturers have the freedom to experiment with different shapes, sizes, and features. This allows for the creation of stools that are not only comfortable but also visually appealing.

In conclusion, plastic stool moulds play a significant role in the production of comfortable and functional plastic stools. These plastic stool moulds are meticulously designed and constructed, ensuring the creation of high-quality products. plastic stool mould manufacturers can produce plastic stools efficiently, cost-effectively, and with a high level of customization. So the next time you sit on a plastic stool, take a moment to appreciate the art and science behind its creation."

0 notes

Text

viral posts about Physical Media Superiority always omit* an important fact regarding optical storage: with something limited release chances are you're getting a disc that is burned rather than pressed.

pressed = the plastic disc is physically imprinted with all encoded info from a master during the moulding process whereby it is formed. this is before it even has the shiny layer! this involves complicated expensive equipment and a factory set up with a clean room.

burned = already finished discs containing nothing have data written to them with a laser that marks a special dye in their shiny layer. this is the exact same thing you can do at home with your computer. cheap, easy and doesn't involve specialised equipment.

the key differences are in consistency (data perfectly impressed at once vs being written sequentially providing opportunity for error) and durability (data stored in the plastic itself vs the layer on-top only).

a digital copy is a digital copy but you should definitely be aware that your boutique blu-ray re-release of that obscure film is a BD-R with a readable lifespan of ~15 years under ideal storage conditions. similar numbers for say a CD from a bandcamp etc (really a CDR).

worth noting given that these posts often contrast the so-called permanence of these things with the ephemerality of streaming ! buy the things but create a back-up. it's even legal if that's a concern you hold.

*saying omit to be kind but i would be fairly confident they are just unaware. these posts also suggest some pretty silly things such as duplicating audio streams with a 3.5mm male-to-male going from a computer headphone jack into its mic input. excellent intentions not necessarily backed up with much technical knowledge

9 notes

·

View notes

Text

[Hetalia Version] The Lindworm’s Lullaby

Chapters: 3/14 Rating: Explicit (For Gore) Main Relationships: Arthur Kirkland (England)/Gabriel Cardoso Fernandes (Portugal) Characters: Arthur Kirkland (England), Gabriel Cardoso Fernandes (Portugal), Original Child Character(s), Ludwig Beilschmidt (Germany), Julia Blumenschien (Fem Prussia), Kiku Honda (Japan), Lovino Vargas (South Italy), Assorted Others Other Tags/Warnings: Alternate Universe - Human AU, FBI Murder Mystery/Thriller, Case Fic, Adapted from a Hannibal Fic, Baby Fic, Alpha/Beta/Omega Dynamics, Alpha Gabriel Fernandes, Omega Arthur Kirkland, Pre-Relationship, Unresolved Sexual Tension, Single Parent Arthur Kirkland, Violence and Gore Canon-Typical to Hannibal Levels, Cute Moments and Murder, Murder Scenes, Dead Bodies, Poisoning, Discussions about torture/infidelity/rape

The FBI is called in to investigate when a series of bodies shows up around Ohio: all of them alphas, and all of them skinned alive. With the killer’s motives a mystery, Ludwig Beilschmidt pulls Arthur Kirkland from the classroom and his vigil at the comatose Madeline Williams’ bedside once more to lend his insight to the case - with very little mind paid to the fact that the busy Arthur, omega and single mother to a six month-old daughter, might have some scheduling issues. Necessity - and pressure from Ludwig - drives Arthur into reluctantly asking Gabriel Fernandes for a favour at short notice. Gabriel is delighted to help Arthur with babysitting - once he has, of course, recovered from both the surprise of learning that Arthur Kirkland even has a baby to care for and, presented with the adorable armful that is a sleepy Lenore Kirkland, feeling a little skinned raw himself.

******

CHAPTER 1 | CHAPTER 2

*****

*****

Chapter 3: deep into that darkness peering

Ludwig’s vague ‘Ohio’ turns out to be Lucas County, Ohio, on the outskirts of the city of Toledo. An abandoned manufacturing plant for electrical goods out in the suburbs off highway 24, just one of many factories standing empty along the more desolate stretches of road.

Even in the deepening shadows of a fading sunset, it’s obvious that the plant is falling into wrack and ruin. Some of its buildings are still mostly intact but more than a few are falling in on themselves, roofs everywhere full of holes and insides open to the elements. The paint is peeling everywhere moss, mould and mildew hasn’t spread, cracks in the plaster giving way to brick dust and rubble. Weeds have pushed up between the tarmac and cement that had once been part of the paving outside, broken glass from smashed windows and abandoned beer bottles crunching underfoot with gravel.

Squatters or youths looking for a thrill have clearly been in all the buildings at some point. Old empty chip packets and smushed-up polystyrene cartons lie caught-up in loops of abandoned rusting wire and under plastic shells of white furniture that never was, aluminium cans rolling noisily in the evening breeze until they dink to a gentle stop against a wall or piece of broken building. The local wildlife has, thankfully, mostly been scared away by the greater vermin of law enforcement officials moving in, but there are probably still a few rats and stray cats about the place somewhere. Bats and birds as well.

Truly, the only thing going for the plant is that it - at least - hadn’t been too far from the airport.

The evening breeze blows by again as Ludwig’s team unload themselves from their assigned cars to the plant, sending long cool fingers up the nape of Arthur’s exposed neck and threading his hair out on the wind’s tangled loom. Arthur shivers. He hadn’t planned for an evening outdoors in damn Ohio when he’d dressed himself that morning, and he’s cold without his scarf.

The sight of the factory itself does not fill him with the warm and fuzzies. Not the building, nor the swarms of law enforcement bustling about the place like flies under their own glaring floodlights as the night grows dark around them. The Toledo and Cleveland offices have sent their agents here already, and a large truck has been set up as the HQ for the scene.

“Oh, Ludwig,” Arthur sighs as the other man crunches his way through debris to walk alongside him, clasping his heart sarcastically-sweet in the picture-perfect pose of a swooning omega. “You always take me to the nicest of places.”

Already ahead of them, call-me-Julia (on the plane) Blumenschien smothers a laugh as she negotiates her way under the crime scene tape with her bulky kit, her long silvery braid swinging with the motion. Lovino Vargas doesn’t bother hiding his smirk as he slinks along after her with the teams’ camera equipment, and even Kiku Honda, usually the most painfully polite of the group, looks to be holding back his grin as he hauls the last of their things out of the cars’ trunks.

As he often does when he’s getting his own way, Ludwig takes the magnanimous approach. Bolsters morale by accepting the dig pointed his way - and even spares Arthur a wry smile as he lifts the crime scene tape for them both to duck under. “Tell me if you feel the same way after you’ve seen the scene. We believe it might be the second one this month.”

Huh. Arthur reaches up to brush back a strand or two of his flyaway hair. “Nothing worth making a fuss about until number two?”

“Once could always be a freak incident,” Ludwig says seriously. “Twice is something we have to be concerned about.” He gestures over a jacketed agent who had been standing at the steps of the HQ truck, the woman obviously waiting for their arrival. Late 20s, maybe, Asian American and serious-looking. Not someone Arthur recognises, but clearly an agent in charge. “Special Agent Linh?”

The agent - Linh - nods, her sleek black ponytail bobbing neatly with the motion. “Sir.” She looks tired and smells faintly of coffee and something floral. An omega. A green woven ribbon omega collar is just visible under her FBI jacket and buttoned-up shirt.

Arthur could really do with a coffee right now. With the night off from looking after Lenore and no need to worry about his caffeine intake provided he ditches the milk he produces for the rest of the night, he could even have a strong one.

“Beilschmidt,” Ludwig introduces himself. Jerks his chin at Arthur. “Special Agent Arthur Kirkland. The latest report?”

“Three bodies,” says Linh, “no ID for any of them. All men, strongly suspected to be alphas. Estimated time of death was two days ago, based upon the early insect activity.”

Which means young maggots. Lovely. Arthur isn’t sure exactly why he’s smiling faintly at Linh with maggots on the table - only to belatedly realise that the other omega reminds him of Marianne. Nothing in her appearance, but that floral smell is of sweet pea. Sweet pea, with Linh, and something like lotuses and lily-of-the-valley. No white musk or roses, nor creamy beeswax blended with vanilla.

Arthur squashes the smile. “Why is there no confirmation of the victims’ dynamic?” Most alphas - even dead ones - are easy enough to identify just by their scent, but, should scent fail, it isn’t hard to pull down a pair of jeans and look for a knot.

Linh licks her lips with a quick dart of tongue - trepidatious. “Each victim has been tied to a chair and had all their skin cut off. Flayed. We’re assuming the victims are all alphas based upon the presence of mass alpha pheromones in the room and what we think are penises with knots on all three victims, but there was some glandular and genital mutilation across all of the bodies. No concrete identification could be made without disturbing the scene, so we need to wait for confirmation about the victims’ dynamics in the lab.”

“Other wounds?” asks Arthur, but Linh just gestures helplessly at him. Another question that the lab will have to answer for them once the bodies are taken to the morgue. “In your opinion, was the flaying done pre or post-mortem?”

The smell of dry, almost sour, flowers in Linh’s scent spikes a little higher, a weird stress note in it edging it into the realms of unpleasant. Her gaze going distant: she’s remembering the scene. “Based upon the amount of blood and the pain scent in the pheromones when we first entered the room where we found the victims… I’d say pre.”

Skinned alive.

The night grows darker yet, and Arthur finds himself unconsciously shifting closer to Ludwig’s body beside him. Seeking some of the warmth exuded by the alpha’s steady bulk, even as Ludwig’s expression turns grim.

Ludwig: “Who called it in?”

Linh: “A man from Toledo’s Urbex League.” Elaborating at Ludwig’s blank look - “Urban explorers.”

Ludwig, exactly as clueless as before: “‘Urban explorers.’”

“People who explore vacant, abandoned, and ruined buildings for fun.”

“It’s a hobby for thrill-seekers with an interest in photography, architecture and historical documentation,” says Arthur. Rolling his shoulders free of the stiffness of cold before stuffing his hands in his pockets to keep them warm. “Sometimes it’s all about the art. Sometimes it’s a search for inspiration. Sometimes it’s a genuine desire to, uh, to preserve constructs for the historical record that others don’t think - or aren’t allowed - to keep. It’s an acknowledgement of the lovely ache of transience with a heap of rebellion thrown in.”

“Stick it to the man,” Linh says drolly, and Arthur likes her all the more for it.

“There’s a moving kind of beauty to be found in the decay of uninhabited space,” he adds, Ludwig still looking unconvinced beside him, “the man-made slowly sliding back into the grasp of nature.”

A bit like sending the painstaking self-construction of a man that is Dr. Fernandes out on a trip to Arthur’s little refuge in Wolf Trap. Unlike many of his neighbours in the local community, Arthur had kept his home as its original build, preserving the wild on his acres of land instead of slapping a McMansion down on top of it all. Nature rules the territory around Arthur’s little white-washed house, a thriving chaos that will have no respect for Dr. Fernandes' soft charcoal and cream attire. Arthur can only hope that nothing too terrible will happen to the alpha as he takes Lenore to Arthur’s neighbour and stops in at Arthur’s house for the dogs. (A little bit of coyote shit never really hurt anyone in the long-term, but Arthur would certainly pay to see Dr. Fernandes wrinkle that big arch nose of his after getting some of the crap on his fancy shoes.)

…Dr. Fernandes should be in Wolf Trap - or just leaving the area - about now, actually. Arthur takes one hand out of his pocket to check his phone. No frantic text messages or missed calls from Dr. Fernandes, so Lenore is fine. He can breathe.

Arthur slides his phone back into his pocket. “...Could also just be ghost-hunters.”

Ludwig huffs through his nose, his scent bleeding with exasperated chillies and black pepper. “Go,” he says to Arthur. Nods meaningfully to where the greatest hubbub of sound and light is coming from on-site. “I’ll be right behind you.”

Arthur sighs as well, but obediently leaves Ludwig with Special Agent Linh to go investigate the scene. Blumenschien-Julia, Honda and Vargas had long since gone ahead of him, and Arthur isn’t surprised to see the three of them as he approaches one building less damaged than the others, its heavy industrial door pulled wide open to the night. Floodlights, conversation, and the heavy iron scent of blood drift out.

One of the original investigators - fully suited and booted - stops Arthur before he goes inside. Hands Arthur a fresh pair of nitrile gloves and overshoe covers in matching blue, the whole set reminding Arthur quite starkly of his daughter’s matching sets of mittens and booties for fall. All he’s missing is the hat.

Inside: a big cement box. This building appears to have been used as a storage warehouse in the past, old, now empty, shelves disintegrating into rust where they’ve fallen over on the floor. The few small windows around the large room seem to still be intact, set high up on the walls so that, in the past, no-one passing by would have been able to sneak a peek at the goods stored inside.

It’s a good place to kill someone. Close the door, and almost all sound and light would be trapped inside the warehouse’s four thick walls. With the plant abandoned as it is… three victims could very easily be tortured to death, and no-one but the killer would ever scent their suffering or hear their screams.

Even days after their death and with new, living people on-site the air is still smeared with the intense suffering of alphas, a pungent enough odour that Arthur rocks back onto his back foot for a moment as he steps inside the warehouse. Unable to stop the instinctive wrinkling of his nose, the immediate defensive hunching-up of his shoulders to protect his vulnerable throat. His eyes prickle, threatening to shift to gold, Arthur’s body responding to the pheromones in the air and sending the first trickles of defensive hormones out into his bloodstream. Alert to any danger.

For the scent to have built up to this degree, the victims must have been tortured for many, many hours. Death by a thousand cuts: for most, being flayed isn't a quick way to die.

Photographers and note-takers scuttle around the warehouse like beetles over a corpse. Corpses. Three bodies sit slumped in their plain wooden seats, all in a row, stripped - badly - of their skin from head to foot. Glistening wet muscle, fat and bone exposed to be buzzed over by flies. Hands tied behind their backs, ankles lashed to the feet of the chairs. Blood dried in pools on the floor.

Arthur studies the scene, takes as deep a breath as he can bear, and then lets the golden pendulum in his mind swing.

All of the other people in the room disappear. Then the flash of cameras, the crime scene markers, and the yellow tape. The blood pools on the floor recede like the tide, drain backwards, upwards, up the wet muscle that used to be three men’s legs. Maggots are unborn, retreating into their shells around crusted eyes and slashed-up ears, and flies depart from the buzzing strings of beads they had made against lipless mouths. Skin regrows across mangled limbs like lichen stretching out over the trunk of a tree - but none of the victims wake. All three men remain slumped in their bonds, naked, alive but unconscious.

Arthur circles them to examine them from behind. No signs of head trauma on their scalped skulls, nothing overtly obvious to indicate a reason for the victims’ unconsciousness prior to flaying. They’d likely been drugged.

Further back in time. The victims had been brought into the room one by one, all at the same time. Dragged - there are scuff-marks from the door to a patch of floor outside of the pools of blood the size of a man’s body. A torn-off shirt button too clean to have been here since the plant went out of business in the same area meaning that the victims had been clothed originally, stripped off in the same patch of floor before being dragged over to the chairs. Tied in place with unforgiving cable ties.

The killer waits. The killer waits until the sedating properties of the drugs begin to wear off and his three victims all wake. The victims are still weak, sluggish, unable to resist when their kidnapper approaches them with a blade -

“Any sign of the murder weapon?” Arthur asks the room.

Julia, nearest to Arthur, answers him, too busy bagging up the abandoned shirt button to look over. “Nope. We’re looking for something incredibly sharp though, a blade no longer than six inches. Slight curve.”

“A dressing knife.” The tool of a hunter. Or butcher.

Arthur sinks back into his recreation, the weight of a 6 inch dressing knife comfortable in his hand. Its grip is warm and familiar: an old friend.

The killer begins with the victim in the leftmost chair. The blood under his corpse is the oldest, and blood spatter indicates that he was conscious enough to struggle at least a little when the knife was placed to his skin. Feet first - the killer wanted the victim to last as long as possible, and watch every moment as his skin was sliced from his body. To scream. The killer wanted all three of his victims to watch, John Does #2 and #3 watching #1 tortured to death. #3 watching #2. And #3…

This is personal. I skin these men slowly, one by one, so that the others may watch. I have ordered them by their sins, so that those whose sins were greatest will wait longest for their death to arrive. Look at me. Know me. Do you remember me now? It is important to me that you see what you really are on the inside.

John Doe #1 still has a patch of skin over his right ankle bone almost the size of Arthur’s palm. Thumb-sized pieces of skin hanging loose at the back of his knees, under the curve of his ass where it meets the chair. Eyelids, and the remnants of a nose.

John Doe #2 has been flayed so badly he’s lost one of his balls, and it’s impossible to tell if the man had had a knot at one point with what little flesh remains of his genitals underneath all the blood, under the slippery pool of his own intestines where they’ve slithered forwards out of his abdomen and onto the remains of his lap. There’s a vicious gouge in his perineum: Doe #2 talked back.

I’ve done this before. Humans are not my usual prey - I know how to handle my knife, but the shape of the animal beneath the blade is still unfamiliar to me. That my inexperience extends your suffering only brings me more pleasure, because you deserve to suffer. My cuts grow more precise as I move along the row of my victims, but now I know how to keep you alive for longer as I cut. Peeling off your skin inch by inch, dropping it in a pile in front of you on the floor. Warming to my task.

Arthur frowns, rising from his crouch near the third body. “The killer knew these people.” He’s shaking, the screams of three men still echoing in his ears. Has to clench his hands into fists to get control of himself, the scent of raw spoiled meat stuck in his nose, itching across the roof of his mouth.

“Well, I’m glad someone did,” Vargas snarks, lowering his camera after snapping a picture of the first body’s bound wrists. “We’ve got nothing to ID them with. No clothes, no wallets, and not enough left of their facial features for us to run a photograph of them through the system. If their DNA doesn’t show up in our files we’ll have to start looking at dental records.” Notoriously spotty.

“Any of the missing skin turned up?”

“Nada.” Julia again, still scouring the floor for any more pieces of clothing. For strands of fabric and the marks of feet. “Victims’ personal effects are still AWOL as well. Agents from the local field offices have already swept the plant’s buildings searching for them, and they’ve got the K9s out in the surrounding fields. Just in case any of it’s been dumped outside.”

It’s almost fully dark now outside, so the sniffer dogs should be coming in for the night.

“Just what we need,” Vargas gripes. Grumpy enough that, even though Vargas is a beta, Arthur can smell him from a few metres away, Vargas’ scent green and sharp at the edges with lemon basil over something thicker, spicier, smokier, and woodier. A church’s herb garden kitchen - lavender, something, something and frankincense? “Paw Patrol at the party hosting the world’s most fucked-up ménage à trois. The last time one of the field offices brought out the K9s near one of our crime scenes, we got dog fur contaminating the evidence.”

“You’re kvetching like you’re the one who had to get the DNA of 8 dogs to eliminate them from the suspect pool,” Julia grumbles back at him, exuding just enough of her own sour cherry and almonds alpha scent that Arthur almost misses the moment that the notes of cedar, coffee, pepper and baked bread hit the air around all of them, Ludwig Beilschmidt entering the old warehouse.

It says something about the raw meat stink of the bodies, their pheromones and their blood, that Ludwig smells appealing to Arthur’s nose. An actual beacon of stability amongst this mess, safe harbour for Arthur’s nose.

“Ménage à quatre,” Honda says softly, his eyes limned with the same instinctual gold as Arthur’s. Ducking his chin apologetically when Vargas only looks at him blankly and offers a puzzled huh? “Quatre, not trois. The killer in this scenario makes four.”

Arthur would’ve quite happily taken examining a scene after a real ménage à quatre over this. It wouldn’t have been the first time in his life he’d had to search for evidence using UV - wouldn’t even have been the first time he’d had to do so with four completely naked, thankfully still alive, civilians right beside him.

“This wasn’t an act of passion,” he says, pitching his voice a little further for Ludwig, “but one of cold and pretty methodical revenge. A slow, controlled burn.” Arthur gestures to the victims, one after the other. “One. Two. Three. He deliberately flayed them one by one, so the later victims watched the earlier victims die. They were drugged when they were first brought here, but they were all alive and conscious when the knife was applied to the first one’s skin.”

Julia whistles. “They were tortured.”

That’s exactly the word for it. “Our victims were still under the effects of whatever concoction they were drugged with. They struggled in their bonds - but not too much. Damage from the ties into the raw flesh is relatively minimal, and blood spatter hasn’t gone too far from the bodies.”

Honda pipes up again. “That suggests a high dose of sedatives, paralytics.”

“Which suggests our unsub might be someone who isn’t able to - or doesn’t think they’re able to - handle an adult alpha male without the aid of pharmaceuticals, even when the victim is tied down.”

“Handling one alpha is a great deal different to handling three,” Julia points out. “The killer could just be cautious.”

“We have no way to tell that the victims were awake when the killer started hacking at them,” Vargas complains. “We can check for stress hormones during the autopsy, but the body naturally produces those when it's attacked anyway. The whole revenge theory is entirely suppositional.”

“Suppose then,” grunts Ludwig from behind the beta, and Vargas nearly jumps out of his own skin.

Arthur waves sharply to the body in front of him again: John Doe #3. “He pissed himself pre-mortem, pre-flaying. You can smell the ammonia, and it’s diluted some of the blood that dripped down onto the floor after the urine.”

(“I have it,” says Honda, and approaches so he can snap a few more photos of the floor under victim #3’s chair. To Vargas - “Did the earlier team take swabs?” Vargas only shrugs at him irritably.

“Alright, sourpuss,” says Julia, “you get the fun job of going to find out.”)

“Skinning is an act of humiliation,” says Arthur. “Our killer had to show each of these men exactly who they were underneath the front they were putting up for the world. And make them sorry for it.”

Julia hmms in thought, idly spinning the evidence bags in her gloved hands. “A ‘beauty is only skin deep’ sort of situation?”

Ludwig looks sceptical. “You think these men were targeted for their vanity?” For all their posturing, alphas rarely have the word applied to them.

Julia, unlike many others of her dynamic, has a reasonable amount of self-awareness. (When she wishes to apply it.) She shrugs. “Every alpha gets a little vain during pre-rut. Maybe they all peacocked in front of the wrong person.”

“I’m not sure,” says Arthur, frowning again. “All I really know for certain is that these men did something that personally upset their killer.”

Ludwig looks at Arthur meaningfully. Jerks his chin towards the warehouse’s door before heading in that direction himself. Walk with me.

Arthur goes and walks with him, falling into step with Ludwig just outside the building. Night’s chilly mantle drapes itself out over Arthur’s shoulders again, the crunching of gravel and glass underfoot shockingly loud against the quiet murmuring of agents around them. Arthur has forgotten to take his booties off, and the sharp debris on the ground is slicing their thin plastic to ribbons.

In the distance, a dog barks.

“You were asking about the dogs,” says Ludwig.

“Anything?” Arthur asks, but Ludwig only shakes his head. “Likely the unsub took the victims’ skin with them then.”

“A trophy?”

Arthur shrugs, enjoying the smell of the fresh air outside the warehouse. Staring off into the night rather than at the blinding FBI floodlights, the chaos that is the HQ truck. The road directly outside the manufacturing plant is empty. “...You said this is the second scene.”

“The first body was found three weeks ago. West of here, in an abandoned farm building off Highway 20A, just outside the village of Delta.”

There’s a half-lit billboard out there in the darkness, where the plant’s short entrance road meets the nearby highway. Tall, spectral white letters haunt the display:

WHERE ARE YOU GOING? Heaven? or Ohio? 855-FOR-TRUTH John 3:36

“How far from here?” Arthur asks. Turning his eyes away from the promise of manufactured heaven to concentrate on his balance, lifting up his feet, one after the other, to pull off the remains of the elasticated overshoes he had been given earlier. The matching gloves soon follow, and Arthur warms up his twitching fingers by rubbing them over the back of his neck.

“Around half an hour by car,” Ludwig replies. Looking about as pleased as Arthur feels hearing that answer, Ludwig’s eyes glowing red-white with light reflected from behind Arthur. That’s a lot of ground for the investigation to cover. Where are all the serial-killing homebodies these days?

“The unsub has a relatively wide working area. Must know the region pretty well.”

“It is not too far from here to Michigan,” Ludwig points out gruffly. Another negative. “We could be looking at a killer from out of state.”

“Maybe.” Arthur purses his lips, the tips of his fangs sharp against his tongue. He doesn’t want to imagine another serial killer at large across state lines right now, especially not in states so far from his home. “...What made the locals link the first body to these three? Going from one victim to three is quite a quick escalation. Sudden change in M.O. could mean this is a copycat.”

“First victim is also an alpha with her skin cut off. Still no ID.”

Arthur pauses. “‘Her’? Our victims are all men.” That’s another big difference between the two scenes. “Change in victim count, change in primary gender of victim...”

“Do we have a copycat,” asks Ludwig, a perfect echo to Arthur’s own thoughts, “or someone who knows just enough to throw us off?”

A little knowledge can be a dangerous thing. “Maybe someone who’s learning. There’s a noticeable increase in the precision of the cuts going from the first victim to the last, a - uh - developing technique. The killer was getting better with practice.”

“Learning on the job.” Ludwig sighs, reaching up with one hand to rub at his temples. “Practice makes perfect, they say.”

Arthur’s sigh echoes him, Arthur using his own hands to knuckle at his tired eyes. Multicoloured stars flash and twinkle in the dark behind his eyelids. His nose is cold. “We need to see the first body.”

“We’re working on it. The locals are putting up a fuss.”

“They’re hitting us with the red tape?” Arthur frowns, a flash of frustration ripping through him. Isn’t it enough that they’ve come out to Ohio to take a look at this mess without being asked to perform tricks as well? “Do they want the FBI to handle this case or not?”

“Oh,” says Ludwig, bone-dry and mirthless, “the local bureaucracy wants rid of it. But apparently there’s some complication with two open missing persons cases and the families involved.” He snorts - “The rich families involved.”

“...They’re each wondering if the Jane Doe is their missing person.” No matter that they’d all get their answers quicker if they just cooperated with the FBI. Arthur shakes his head, muttering - “More money than sense.”

Ludwig doesn’t disagree with him, sighing a long plume of warm breath out into the increasingly cold night. “Money makes the world go round.” Not logic. Fuck it.

*****

*****

Special Agent Linh - Vietnam Julia Blumenschein - Female Prussia

Fun fact: sweet pea has always been an asshole of a scent to obtain for perfumiers. The flower, often referred to as Queen of the Annuals, produces a stress hormone when picked, which ruins its beautiful smell. It’s also a flower that’s used extensively in those fashionable teas/tisanes/cocktails that change colour as you pour them.

Thank you, still, to my friend Reid, who helped me with Ohio lore! The billboard Arthur spots here is based on a real one that google claims is in Ohio, so any mistakes there are google’s fault rather than mine. >>

NEXT CHAPTER

#Shacha fic#engport#Arthur Kirkland#Ludwig Beilschmidt#kiku honda#Lovino Vargas#nyotalia#fem!Prussia#gilbert beilschmidt#hetalia

10 notes

·

View notes

Text

At a societal level, most people grasp the importance of plants to their lives and the ecosystems they inhabit. The success of humans as a species is inextricably interwoven with the success of plant life on Earth. Without the growth of ancient forests, the biosphere in which we live would not have enough oxygen-rich air for humans to have evolved. Without the cultivation of plants for food, humans could not have settled, built shelters and developed rich and diverse cultures. In practical terms, too, building with plants makes a lot of sense. They grow back and are relatively easy to cultivate, harvest and process into useful materials. Their inherent fibrous structures give our buildings integrity. Trees, processed into timber, work extremely well in both compression and tension. Hollow straws and grasses hold air within them, making them great insulators. The lignin in many different plants can act as a natural binder when heated, meaning that you can essentially squash them, heat them and they stick together into useful sheet materials. Mixed with different binders like clay and lime, they can be given resistance to fire, insects and mould. Bio-based materials are also hygroscopic – meaning that they hold and release moisture. The fact that they can absorb humidity from a room helps to regulate damp and prevent mould from growing. That they are moisture permeable means that water vapour trapped in walls, from rain ingress or generated through leaks, always has somewhere to go. Contemporary buildings, on the other hand, are essentially wrapped in plastic sheets, trapping in moisture and resulting in poor indoor air quality.

Some of the best examples of bio-based buildings are hiding in plain sight in villages, towns and cities across the globe, having withstood decades, sometimes centuries of wear and tear. Timber-framed barns, reinforced with hazel wattle and clay daub can be found dotted across the British countryside. The technique of cob building, using loadbearing clay and straw, was very commonly used in the south-west of England in the 19th century, and many of those cob buildings still stand in Devon and Cornwall today. They are finished in a lime render and look from the outside like any other stone or brick building.

That these techniques have not become more widespread is, at first glance, surprising. The local materials and skills used to build with them were relatively low cost, and when well maintained, extremely durable. The critical thing about these materials, however, is how they were intrinsically linked to land, and specific geographies or bioregions. Industrialisation brought with it a change in agricultural practices and land ownership. Bio-based materials were conventionally derived from agricultural waste; long wheat straw was for example used for thatching, until modern chemical fertilisers that help the wheat grow more quickly weakened the structure of the straw, making it too brittle. Water reed, also used in thatching and as a render substrate, was once abundant in wetlands, but these were drained over the course of the 19th century to develop more arable farmland, cutting by approximately 90 per cent the amount of land on which the reed could grow.

Industrialisation also brought about the development of contemporary insulations, designed initially to prevent energy loss from high-energy machinery and factory spaces. Materials such as concrete and steel, which enabled the quick assembly of spaces of production, ultimately sought markets in domestic construction too. These materials were produced at an unprecedented scale and advertised as technologically advanced, in need of little or no maintenance: symbols of a bright future in which being cold, damp and living with fire risk were a thing of the past. And as these materials became more and more popular, regulatory frameworks began to be designed around them, with lawmakers falling victim to aggressive lobbying and marketing campaigns. Today, testing and certification, mortgages and insurances in the UK and beyond are generally designed around contemporary building systems, and materials which have proven their efficacy over decades of service are considered risky, fringe and ultimately more costly.

The petrochemical and mineral materials we have been building with since the Industrial Revolution require an enormous amount of energy to be extracted and processed. The cement industry, for example, is responsible for about eight per cent of planet-warming carbon dioxide emissions – far more than global carbon emissions from aviation. We cannot continue to build using materials that generate enormous outflows of emissions and have to be shipped across great distances. We need to use materials that are lower in embodied carbon: bio-based materials, derived from plants which can regenerate sustainably and sequester carbon into our buildings.

126 notes

·

View notes

Text

Material Selection for Plastic Basket Mould Manufacturing Quality and Efficiency

In the realm of plastic basket mould manufacturing, the choice of materials plays a pivotal role in determining the quality, durability, and efficiency of the produced moulds. Plastic Basket Mould Factory, as a leading player in this industry, must meticulously assess various factors to select suitable materials for their manufacturing processes. This article delves into the intricate process of material selection, highlighting its significance, key considerations, and the methodologies employed by Plastic Basket Mould Factory.

Plastic Basket Mould Factory stands in front of plastic basket mould production, catering to diverse industrial and commercial needs. With its commitment to well and innovation, the factory continually seeks to optimize its manufacturing processes, of which material selection is a cornerstone.

Before delving into the specifics of material selection, it's imperative to understand the essential requirements for basket mould manufacturing. These include factors such as mechanical properties, thermal stability, chemical resistance, and moldability.

Plastic Basket Mould Factory typically considers a range of plastic materials suitable for mould manufacturing. These may include polyethene (PE), polypropylene (PP), acrylonitrile butadiene styrene (ABS), and polycarbonate (PC), among others. Each material offers distinct properties that influence its suitability for basket mould production.

One of the primary considerations in material selection is mechanical properties, including tensile strength, impact resistance, and flexibility. Plastic Basket Mould Factory assesses these properties to ensure that the moulds withstand the rigours of usage without compromising on durability.

Given the manufacturing process involves heating and cooling cycles, thermal stability is crucial. The selected materials must exhibit adequate heat resistance to maintain dimensional stability and prevent deformation during moulding.

Plastic basket moulds often come into contact with various chemicals, detergents, and environmental elements. Therefore, the chosen materials should possess excellent chemical resistance and weatherability to maintain their integrity over time.

While quality is paramount, Plastic Basket Mould Factory also evaluates the cost-effectiveness of materials. Factors such as material availability, processing costs, and long-term maintenance expenses are taken into account to ensure material economics.

Depending on the specific requirements of clients, Plastic Basket Mould Factory may need to customize mould designs. The selected materials should offer sufficient design flexibility to accommodate diverse shapes, sizes, and configurations of plastic baskets.

Different plastic materials require specific moulding processes, such as injection moulding, blow moulding, or rotational moulding. Plastic Basket Mould Factory selects materials that are compatible with its manufacturing equipment and expertise, optimizing production efficiency.

Stringent quality standards and regulatory requirements govern the manufacturing industry. Plastic Basket Mould Factory ensures that the selected materials comply with relevant standards and regulations, thereby guaranteeing the quality and safety of its products.

To stay ahead in the competitive market, Plastic Basket Mould Factory invests in research and development initiatives to explore new materials and technologies. Continuous innovation enhances the factory's material selection processes, paving the way for good mould quality and performance.

Collaboration with Material Suppliers: Close collaboration with trusted material suppliers is integral to Plastic Basket Mould Factory's material selection strategy. By leveraging supplier expertise and resources, the factory gains access to a wide range of high-quality materials and stays abreast of industry trends.

The material selection process is a critical determinant of the quality, efficiency, and sustainability of plastic basket mould manufacturing. Plastic Basket Mould Factory's commitment to thorough evaluation, strategic partnerships, and ongoing innovation ensures that its material choices align with its overarching goals of well and customer satisfaction. Through meticulous material selection, the factory remains at the forefront of the industry, delivering top-notch mould solutions to its clients worldwide.

0 notes

Text

Discover the leading plastic cap mould factory, revolutionizing the industry with cutting-edge technology and unparalleled expertise. Our factory specializes in the production of high-quality moulds for plastic caps, ensuring precision and durability. With state-of-the-art machinery and a skilled team, we guarantee exceptional results that meet the strictest standards. Trust our experienced engineers to create customized solutions tailored to your specific needs. Partner with us for reliable, cost-effective, and timely delivery. Experience the difference with our plastic cap mould factory and unlock unlimited possibilities for your packaging requirements. Contact us now for a seamless manufacturing experience!

0 notes

Text

We greeted the children of gods with operatic indifference. Having already slaved to make the world right for some time we

promised the earth (as if she were ours to gift) & set them to work in call centres & factories & department stores & endless cafe chains &

when they finally began to show promise we stacked debt onto shoulders already bowed with overwrought expectation

shackled their imagination to the sum total of our experience then branded them snowflakes. We deconstructed the earth’s soul — reduced her to economic growth & dollar signs

then set up focus groups to ascertain why the children just. didn’t. get. the. bigger. picture. Isolating the most compliant young gods, we modelled them in our own image

set them at giddying heights within the Milky Way as an example of what could be achieved through dedicated application then

medicated their suffocating anxiety; devised cognitive therapy to cope with the vomit & hysteria. As the children of gods grew into our ways we peddled them stacks of blood bricks & stale

education at over-inflated prices & those who balked were fed into sink hole estates or prisons & we told them to consume less

urged them to buy more; graded the children of gods by skin colour or ancestral land-grabs then lectured them on being shallow & lacking in empathy

as we condemned their racism, bigotry, sexism & aggressive homophobia & wrung our white hands that they did not care for the environment we had systematically disconnected them from.

When they persisted in demonstrating no gratitude for the oceans of plastic & mountains of crap that made up their inheritance, we poisoned the air & their minds

blasted the old gods into gravel drives; stripped the world of the forest’s stories ripped the language of magic from their mouths so that the

children of gods no longer recognised their reflection in cloud formations & lakes (only knew themselves in the echo-chamber of our online shops).

We complained when they denied the earth’s beauty & wept genuine tears of frustration that they just did not seem to care about anything.

Finally, we surmised that their lack of interest in recycling our ideas & excrement was simple yet unexplainable laziness & when we had

moulded enough of the children of gods into almost, almost, what we envisaged

we died.

#poetry#poems#alienation#Consumerism#ecology#imagination#Return Fire#youth#anarchism#revolution#climate crisis#climate change#resistance#community building#practical anarchy#practical anarchism#anarchist society#practical#daily posts#communism#anti capitalist#anti capitalism#late stage capitalism#organization#grassroots#grass roots#anarchists#libraries#leftism#social issues

5 notes

·

View notes

Text

#SMT PCB Jobwork#Printed Circuit Board Assembly#Electronics PCBA factory#Cable wiring harness factory#Plastic Moulding jobwork#Power cord factory

0 notes

Text

Toy History: Han Solo (Hoth Outfit) was released in 1980 on Wave 1 of the Empire Strikes Back line of toys made by Kenner on the 31A cardbacks in the USA and the 30A backs for Palitoy in the UK. He comes with the blue Rebel Blaster. The name of this figure would change in 1983 for the Return of the Jedi cardbacks to “Han Solo (Hoth Battle Gear)”. Major variants and the most popular are the Moulded legs variant where the plastic is left unpainted. These seem to all come from the Kader factory.

Link to buy this exact item using my eBay affiliate link: https://ebay.us/uwVksX

I make commissions on qualified purchases with no added cost to you. It supports my channel and allows me to keep making content for you, so thank you!

2 notes

·

View notes