#Plastic Dyes Manufacturers In India

Explore tagged Tumblr posts

Text

Plastic Dyes Manufacturers In India, Solvent Black 27 Manufacturer, Solvent Dyes Manufacturer

We are the Polymer Soluble Solvent Dyes or Plastic Dyes Manufacturers in India. With the high demand for dyes for plastic products, we are making doubly sure to deliver excellence. We have ensured the best when it comes to providing polymer soluble solvent dyes for the service of the plastic industry.

#Plastic Dyes Manufacturers In India#Polymer Soluble Solvent Dyes#Solvent Dyes Manufacturer#Solvent Dyes Supplier

0 notes

Text

Plastic solid tubes, Plastic Cheese or Cylinders, Polypropylene Tubes

Manufacturer, Supplier and Exporter of Plastic solid tubes, Plastic Cheese or Cylinders, Polypropylene Tubes, cheese tubes are available in different weights and dimensions in Sangli, India.

Plastic Solid Cones, Perforated Dye Tubes, Perforated Dye Cones, Plastic Yarn Carriers, Textile industry, Spinning, Twisting, Texturizing, Yarn Dyeing & Carpet Industry, Injection Moulded products, Corrugated Pipe Industry, Electrical Industry, Manufacturer, Supplier and Exporter, Sangli, Maharashtra, India.

#Plastic Solid Cones#Perforated Dye Tubes#Perforated Dye Cones#Plastic Yarn Carriers#Textile industry#Spinning#Twisting#Texturizing#Yarn Dyeing & Carpet Industry#Injection Moulded products#Corrugated Pipe Industry#Electrical Industry#Manufacturer#Supplier and Exporter#Sangli#Maharashtra#India

0 notes

Text

On 25th July 1843 Charles Macintosh, inventor of the plastic mac, died.

The son of a dyer, he decided at the age of 19 to pursue his interest in chemistry, opening a plant in the city of his birth to sell ammonium chloride and Prussian blue dye by the age of 20. He also set up Scotland’s first alum works at Hurlet, Renfrewshire, in 1797. But of course the thing for which he is best remembered is his rainproof “mac” coat.

While analysing the by-products of a works making coal gas in 1818, Macintosh discovered that one such substance possessed special properties. Naptha – a by-product of tar – as able to dissolve India rubber – found in trees – forming a paste that was impermeable to water.

Macintosh realised that he could combine the substance with cloth by sandwiching it between two pieces of fabric, creating the basis for waterproof clothing. He patented the process in 1823 and by the following year was producing the material.

The chemist set up his own company, joining forces with Thomas Hancock to perfect the process. The resulting raincoats – which ended up being manufactured in a range of styles – were named macs. Macintosh died in 1843 and was buried with his parents in Glasgow, but the Mackintosh company (the k was added later) went on long after his death. It was bought by Dunlop Rubber, another firm started by a Scotsman, in 1925 and continues to produce upmarket coats to this day.

Macintosh was honoured by a Google doodle in 2016 they wrote, “It’s a wonder how the weather-beaten Brits coped before Scottish chemist Charles Macintosh invented his eponymous waterproof coat.” Well the weather we have had so far this year a mac is certainly what is needed!

4 notes

·

View notes

Text

Acetic Acid Market - Forecast(2024 - 2030)

Acetic Acid Market Overview

Acetic Acid Market Size is forecast to reach $14978.6 Million by 2030, at a CAGR of 6.50% during forecast period 2024-2030. Acetic acid, also known as ethanoic acid, is a colorless organic liquid with a pungent odor. The functional group of acetic acid is methyl and it is the second simplest carboxylic acid. It is utilized as a chemical reagent in the production of many chemical compounds. The major use of acetic acid is in the manufacturing of vinyl acetate monomer, acetic anhydride, easter and vinegar. It is a significant industrial chemical and chemical reagent used in the production of photographic film, fabrics and synthetic fibers. According to the Ministry of Industry and Information Technology, from January to September 2021, the combined operating revenue of 12,557 major Chinese garment companies was US$163.9 billion, showing a 9% increase. Thus, the growth of the textile industry is propelling the market growth for Acetic Acid.

Report Coverage

The “Acetic Acid Market Report – Forecast (2024-2030)” by IndustryARC, covers an in-depth analysis of the following segments in the Acetic Acid industry.

By Form: Liquid and Solid.

By Grade: Food grade, Industrial grade, pharmaceutical grade and Others.

By Application: Vinyl Acetate Monomer, Purified Terephthalic Acid, Ethyl Acetate, Acetic Anhydride, Cellulose Acetate, Acetic Esters, Dyes, Vinegar, Photochemical and Others

By End-use Industry: Textile, Medical and Pharmaceutical, Oil and Gas, Food and Beverages, Agriculture, Household Cleaning Products, Plastics, Paints & Coating and Others.

By Geography: North America (the USA, Canada and Mexico), Europe (the UK, Germany, France, Italy, Netherlands, Spain, Russia, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of APAC), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America) and the Rest of the World (the Middle East and Africa).

Request Sample

Key Takeaways

The notable use of Acetic Acid in the food and beverages segment is expected to provide a significant growth opportunity to increase the Acetic Acid Market size in the coming years. As per the US Food and Agriculture Organization, world meat production reached 337 million tonnes in 2019, up by 44% from 2000.

The notable demand for vinyl acetate monomer in a range of industries such as textile finishes, plastics, paints and adhesives is driving the growth of the Acetic Acid Market.

Increase in demand for vinegar in the food industry is expected to provide substantial growth opportunities for the industry players in the near future in the Acetic Acid industry.

Acetic Acid Market Segment Analysis – by Application

The vinyl acetate monomer segment held a massive 44% share of the Acetic Acid Market share in 2021. Acetic acid is an important carboxylic acid and is utilized in the preparation of metal acetates and printing processes, industrially. For industrial purposes, acetic acid is manufactured by air oxidation of acetaldehyde with the oxidation of ethanol, butane and butene. Acetic acid is extensively used to produce vinyl acetate which is further used in formulating polyvinyl acetate. Polyvinyl acetate is employed in the manufacturing of plastics, paints, textile finishes and adhesives. Thus, several benefits associated with the use of vinyl acetate monomer is boosting the growth and is expected to account for a significant share of the Acetic Acid Market.

Inquiry Before Buying

Acetic Acid Market Segment Analysis – by End-use Industry

The food and beverages segment is expected to grow at the fastest CAGR of 7.5% during the forecast period in the Acetic Acid Market. Acetic Acid is also known as ethanoic acid and is most extensively used in the production of vinyl acetate monomer. Vinyl acetate is largely used in the production of cellulose acetate which is further used in several industrial usage such as textiles, photographic films, solvents for resins, paints and organic esters. PET bottles are manufactured using acetic acid and are further utilized as food containers and beverage bottles. In food processing plants, acetic acid is largely used as cleaning and disinfecting products. Acetic acid is extensively used in producing vinegar which is widely used as a food additive in condiments and the pickling of vegetables. According to National Restaurant Association, the foodservice industry is forecasted to reach US$898 billion by 2022. Thus, the advances in the food and beverages industry are boosting the growth of the Acetic Acid Market.

Acetic Acid Market Segment Analysis – by Geography

Asia-Pacific held a massive 41% share of the Acetic Acid Market in 2021. This growth is mainly attributed to the presence of numerous end-use industries such as textile, food and beverages, agriculture, household cleaning products, plastics and paints & coatings. Growth in urbanization and an increase in disposable income in this region have further boosted the industrial growth in this region. Acetic acid is extensively used in the production of metal acetates, vinyl acetate and vinegar which are further utilized in several end-use industries. Also, Asia-Pacific is one of the major regions in the domain of plastic production which provides substantial growth opportunities for the companies in the region. According to Plastic Europe, China accounted for 32% of the world's plastic production. Thus, the significant growth in several end-use industries in this region is also boosting the growth of the Acetic Acid Market.

Acetic Acid Market Drivers

Growth in the textile industry:

Acetic Acid, also known as ethanoic acid, is widely used in the production of metal acetate and vinyl acetate which are further used in the production of chemical reagents in textiles, photographic films, paints and volatile organic esters. In the textile industry, acetic acid is widely used in textile printing and dyes. According to China’s Ministry of Industry and Information Technology, in 2020, textile and garment exports from China increased by 9.6% to US$291.22 billion. Also, according to the U.S. Department of Commerce, from January to September 2021, apparel exports increased by 28.94% to US$4.385 billion, while textile mill products rose by 17.31% to US$12.365 billion. Vinyl acetate monomer is utilized in the textile industry to produce synthetic fibers. Thus, the global growth in demand for textiles is propelling the growth and is expected to account for a significant share of the Acetic Acid Market size.

Schedule a call

Surge in use of vinegar in the food industry:

The rapid surge in population along with the adoption of a healthy and sustainable diet has resulted in an increase in demand for food items, thereby increasing the global production level of food items. As per US Food and Agriculture Organization, in 2019, global fruit production went up to 883 million tonnes, showing an increase of 54% from 2000, while global vegetable production was 1128 million tonnes, showing an increase of 65%. Furthermore, world meat production reached 337 million tonnes in 2019, showing an increase of 44% from 2000. Acetic acid is majorly used in the preparation of vinegar which is further widely utilized as a food ingredient and in personal care products. Vinegar is used in pickling liquids, marinades and salad dressings. It also helps to reduce salmonella contamination in meat and poultry products. Furthermore, acetic acid and its sodium salts are used as a food preservative. Thus, the surge in the use of vinegar in the food industry is boosting the growth of the Acetic Acid Market.

Acetic Acid Market Challenge

Adverse impact of acetic acid on human health:

Acetic Acid is considered a strong irritant to the eye, skin and mucous membrane. Prolong exposure to and inhalation of acetic acid may cause irritation to the nose, eyes and throat and can also damage the lungs. The workers who are exposed to acetic acid for more than two or three years have witnessed upper respiratory tract irritation, conjunctival irritation and hyperkeratotic dermatitis. The Occupational Safety and Health Administration (OSHA) reveals that the standard exposure to airborne acetic acid is eight hours. Furthermore, a common product of acetic acid i.e., vinegar can cause gastrointestinal tract inflammatory conditions such as indigestion on excess consumption. Thus, the adverse impact of Acetic Acid may hamper the market growth.

Buy Now

Acetic Acid Industry Outlook

The top 10 companies in the Acetic Acid Market are:

Celanese Corporation

Eastman Chemical Company

LyondellBasell

British Petroleum

Helm AG

Pentoky Organy

Dow Chemicals

Indian Oil Corporation

Daicel Corporation

Jiangsu Sopo (Group) Co. Ltd.

Recent Developments

In March 2021, Celanese Corporation announced the investment to expand the production facility of vinyl portfolio for the company’s acetyl chain and derivatives in Europe and Asia.

In April 2020, Celanese Corporation delayed the construction of its new acetic acid plant and expansion of its methanol production by 18 months at the Clear Lake site in Texas.

In October 2019, BP and Chian’s Zhejiang Petroleum and Chemical Corporation signed MOU in order to create a joint venture to build a 1 million tonne per annum Acetic Acid plant in eastern China.

Key Market Players:

The Top 5 companies in the Acetic Acid Market are:

Celanese Corporation

Ineos Group Limited

Eastman Chemical Company

LyondellBasell Industries N.V.

Helm AG

For more Chemicals and Materials Market reports, please click here

#Acetic Acid Market#Acetic Acid Market Share#Acetic Acid Market Size#Acetic Acid Market Forecast#Acetic Acid Market Report#Acetic Acid Market Growth

2 notes

·

View notes

Text

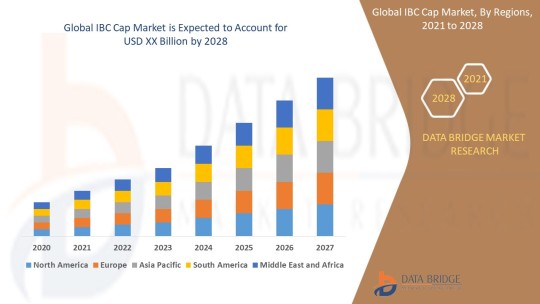

IBC Cap Market Size, Share, Trends, Growth and Competitive Analysis

"IBC Cap Market – Industry Trends and Forecast to 2028

Global IBC Cap Market, By Product Type (Flange, Plugs, Vent-in Plug, Vent-out Plug and Screw closure), Type (Plastic IBC, Metal IBC and Composite IBCs), Material Type (Plastics, Metal, Aluminium and Steel), End Use (Chemicals & Fertilizers, Petroleum & Lubricants, Paints, Inks & Dyes, Food & Beverage, Agriculture, Building & Construction, Healthcare & Pharmaceuticals and Mining), Application (Food And Drinks, Chemical Industry, Oil and Agriculture), Country (U.S., Canada, Mexico, Brazil, Argentina, Rest of South America, Germany, France, Italy, U.K., Belgium, Spain, Russia, Turkey, Netherlands, Switzerland, Rest of Europe, Japan, China, India, South Korea, Australia, Singapore, Malaysia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific, U.A.E, Saudi Arabia, Egypt, South Africa, Israel, Rest of Middle East and Africa) Industry Trends and Forecast to 2028

Access Full 350 Pages PDF Report @

The global IBC cap market is expected to witness significant growth over the forecast period due to the increasing demand for intermediate bulk containers (IBCs) in various industries such as chemicals, food and beverages, pharmaceuticals, and others. The IBC caps play a crucial role in ensuring the safe storage and transportation of liquid products. The market growth is also being driven by technological advancements in IBC cap designs, such as tamper-evident seals and spouts for easy dispensing. Additionally, the growing focus on sustainability and recyclability of packaging materials is further boosting the adoption of IBC caps made from eco-friendly materials.

**Segments**

- Based on material type, the IBC cap market can be segmented into plastic, metal, and others. Plastic caps are widely used due to their lightweight nature and cost-effectiveness. - By cap type, the market can be categorized into screw caps, snap-on caps, and flip-top caps. Screw caps are preferred for their secure sealing properties. - On the basis of end-user industry, the market can be divided into chemicals, food and beverages, pharmaceuticals, and others. The chemicals segment is anticipated to hold a significant market share due to the widespread use of IBCs for storing chemical products.

**Market Players**

- TPS Industrial Srl - Schuetz GmbH & Co. KGaA - Mauser Packaging Solutions - Time Technoplast Ltd - Berry Global Inc. - THIELMANN UCON AG - Precision IBC, Inc. - Peninsula Packaging LLC

These market players are actively involved in strategic initiatives such as product launches, partnerships, and acquisitions to strengthen their market presence and expand their product offerings. The competitive landscape of the IBC cap market is characterized by intense competition, prompting companies to focus on innovation and quality to gain a competitive edge.

The Asia-Pacific region is expected to witness substantial growth in the IBC cap market, driven by the rapid industrialization and the increasing adoption of IBCsThe Asia-Pacific region represents a significant growth opportunity for the global IBC cap market due to several key factors. With rapid industrialization and the expanding manufacturing sector in countries like China, India, and Southeast Asia, there is a growing demand for efficient storage and transportation solutions, including IBCs and their associated caps. The increased focus on chemical production, food processing, and pharmaceutical manufacturing in the region further fuels the need for reliable packaging solutions like IBC caps. As these industries continue to grow, the adoption of IBC caps is expected to rise, driving market expansion in the Asia-Pacific region.

Moreover, the emphasis on enhancing safety standards and ensuring product integrity is a crucial factor contributing to the growth of the IBC cap market in Asia-Pacific. Regulations regarding the safe handling and transportation of hazardous chemicals and pharmaceuticals necessitate the use of high-quality caps that can effectively seal and protect the contents of IBCs. As companies in the region strive to comply with stringent regulatory requirements, the demand for advanced and secure IBC caps is projected to increase significantly.

Additionally, the shift towards sustainability and eco-friendly practices is another trend shaping the IBC cap market in Asia-Pacific. With growing environmental concerns and increasing awareness about plastic pollution, there is a rising preference for IBC caps made from recyclable and biodegradable materials. Market players in the region are focusing on developing sustainable packaging solutions to meet the evolving consumer demands and align with global sustainability goals. This shift towards eco-friendly IBC caps not only addresses environmental concerns but also presents market players with opportunities to differentiate their offerings and attract environmentally conscious customers.

Furthermore, the competitive landscape of the IBC cap market in Asia-Pacific is characterized by the presence of both local manufacturers and international players. Local companies often have a strong understanding of regional market dynamics and customer preferences, giving them a competitive advantage in catering to specific industry needs. On the other hand, multinational companies bring technological expertise and a wide product portfolio, which can appeal to a broader customer base seeking innovative and**Global IBC Cap Market, By Product Type**

- Flange - Plugs - Vent-in Plug - Vent-out Plug - Screw closure

**Type**

- Plastic IBC - Metal IBC - Composite IBCs

**Material Type**

- Plastics - Metal - Aluminium - Steel

**End Use**

- Chemicals & Fertilizers - Petroleum & Lubricants - Paints, Inks & Dyes - Food & Beverage - Agriculture - Building & Construction - Healthcare & Pharmaceuticals - Mining

**Application**

- Food And Drinks - Chemical Industry - Oil and Agriculture

The Global IBC Cap market is experiencing significant growth due to the rising demand for intermediate bulk containers across various industries. Plastic caps are increasingly preferred for their lightweight and cost-effective nature, driving market growth within the material type segment. Screw caps, known for their secure sealing properties, dominate the cap type category. The chemicals segment is anticipated to hold a substantial market share among end-user industries, attributed to the widespread use of IBCs for chemical storage. The market players in the industry are focusing on strategic initiatives like product launches and partnerships to enhance their market presence and offerings. The competitive landscape is intense, spurring companies to innovate and prioritize quality for a competitive advantage.

In Asia-Pacific, the IBC cap market is poised for robust growth fueled by rapid industrialization and the expanding manufacturing sector, particularly in countries like China,

Countries Studied:

North America (Argentina, Brazil, Canada, Chile, Colombia, Mexico, Peru, United States, Rest of Americas)

Europe (Austria, Belgium, Denmark, Finland, France, Germany, Italy, Netherlands, Norway, Poland, Russia, Spain, Sweden, Switzerland, United Kingdom, Rest of Europe)

Middle-East and Africa (Egypt, Israel, Qatar, Saudi Arabia, South Africa, United Arab Emirates, Rest of MEA)

Asia-Pacific (Australia, Bangladesh, China, India, Indonesia, Japan, Malaysia, Philippines, Singapore, South Korea, Sri Lanka, Thailand, Taiwan, Rest of Asia-Pacific)

Key Coverage in the IBC Cap Market Report:

Detailed analysis of IBC Cap Market by a thorough assessment of the technology, product type, application, and other key segments of the report

Qualitative and quantitative analysis of the market along with CAGR calculation for the forecast period

Investigative study of the market dynamics including drivers, opportunities, restraints, and limitations that can influence the market growth

Comprehensive analysis of the regions of the IBC Cap industry and their futuristic growth outlook

Competitive landscape benchmarking with key coverage of company profiles, product portfolio, and business expansion strategies

TABLE OF CONTENTS

Part 01: Executive Summary

Part 02: Scope of the Report

Part 03: Research Methodology

Part 04: Market Landscape

Part 05: Pipeline Analysis

Part 06: Market Sizing

Part 07: Five Forces Analysis

Part 08: Market Segmentation

Part 09: Customer Landscape

Part 10: Regional Landscape

Part 11: Decision Framework

Part 12: Drivers and Challenges

Part 13: Market Trends

Part 14: Vendor Landscape

Part 15: Vendor Analysis

Part 16: Appendix

Browse Trending Reports:

Calcium Glycinate Market Retinal Biologics Market Facial Fat Transfer Market Angio Suites Diagnostic Imaging Market Adoption Of Benelux Power Tools Market De Quervains Tenosynovitis Treatment Market Biodetectors And Accessories Market Colposcope Market Sports Medicine Market Automotive Adhesives Market Infrared Imaging Market Vapour Deposition Market Professional Diagnostics Market Ct Scanner Market Programmable Application Specific Integrated Circuit Asic Market Hospital Operating Room Or Products And Solutions Market Castor Oil Market Zika Virus Infection Drug Market Toluene Diisocynate Market Antibiotic Resistance Market

About Data Bridge Market Research:

Data Bridge set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market. Data Bridge endeavors to provide appropriate solutions to the complex business challenges and initiates an effortless decision-making process.

Contact Us:

Data Bridge Market Research

US: +1 614 591 3140

UK: +44 845 154 9652

APAC : +653 1251 975

Email: [email protected]"

2 notes

·

View notes

Text

Conservation Misconceptions

In trying to be environmentally conscious, many people struggle to find ways to really make a difference. This makes misinformation easy to fall for, especially when it leaves out the nuance of trying to be environmentally friendly.

Leather

“Vegan clothing” reached popularity as early as the 1970s. Its sleek, shiny, and stretchy look make it ideal for many fashion icons. In November of 2023, reality TV star Kylie Jenner released a line of twelve “faux leather” or ‘pleather’ outfits. In the first hour, it had reached one million dollars in sales.

The appeal of vegan clothing is understandable. Many people in the U.S. hear about the horrors of the cattle industry before entering high school. Many people sympathize with animals and seek ways to reduce their consumption of animal products.

Contradictorily, faux leather is significantly harmful to the environment. Most pleather consists of polyurethane, which is plastic. It is unsustainable on the basic factor of the oil from which it originates being nonrenewable. Additionally, manufacturing this material includes high levels of toxic chemicals like dimethylformamide which is linked to cancers and birth defects. Polyurethane pleather can also take one thousand years to break down in a landfill.

Leather, from the hides of cow, sheep, goat, deer, and many other animals, is organic. It breaks down at the end of its life, usually over ten to fifty years in landfills.

Interestingly, plastic clothing in a landfill takes a long time to degrade while leather breaks down quicker. Yet during its use, plastic is prone to scuffs, tears, and showing more wear while leather clothing can last years without significant damage.

Leather is not all perfect, of course. Animal cruelty is a large factor for people turning to faux leather, and those concerns are well-founded. Animal cruelty in the leather and meat industries is well-evidenced.

Aside from animal cruelty, tanning hides also produces chemical contamination. While chromium used in leather tanning is less toxic now than earlier solutions, it is still hazardous. Other hazardous materials in leather tanning include nitrosamines, benzidine-based dyes, and formaldehyde. Being exposed to the former two in high levels can increase the risk of cancers, while formaldehyde causes skin irritation, nausea, and respiratory difficulties.

Addressing fashion industry pollution is not as easy as switching entirely to different materials. A more effective alternative to fake leather is addressing the waste of the fashion industry. In 2023, the fashion industry produced 97 million tons of waste, including 18 million tons from textiles and 2.5 million tons in chemical waste.

Additionally, there are vegan clothing options from plant alternatives. One example, calotropis, is sometimes considered wool without the need for sheep. Calotropis plants grown in India need little in regard to water, attention, and pesticides. Cactus leather is another example which requires less water and produces less plastic. When industries turn to plants, the supply chain and issues of fair trade continue to require attention, but these avenues of sustainability are possible.

Turning to leather entirely is not the ideal choice while the farming industry retains its wealth of problems, but pleather is not a suitable replacement. Those seeking to be environmentally conscientious with clothing choices can try non-synthetic materials like colatropis, cactus leather, and linen.

Honey

Veganism is a diet people adopt for a variety of reasons. Some have biological restrictions that a vegan diet works best with, helping them to avoid foods they can’t eat. Others do it in an effort to consume fewer calories, and some use it in an effort to reduce the waste and mistreatment in the farming industry.

In a strict vegan diet, one avoids all animal products, usually summed up as milk and eggs. Strictly speaking, honey would be included in those animal products. But for those eating a vegan diet for ethical reasons, avoiding honey can do more harm than good.

Honey alternatives include maple syrup, molasses, and more. Maple syrup and molasses contain important nutrients, but some dieters find them to contain too much sugar.

Another popular honey alternative, with lower amounts of sugar, is agave syrup. Agave syrup also contains vitamins and other nutrients, and comes from the agave plant, which is grown around the world but native to Mexico and the southwest U.S.A.

Agave farming faces multiple problems. One is that agave plants are fragile, and will have trouble surviving in the rapid climate changes the world is experiencing. While agave does well in desert conditions, climate change might cause desert-like conditions for some months or some years and without warning flip in the opposite direction. Similarly, demand for agave is growing but could shift rapidly. For a plant that can take seven years to grow before harvesting, farmers can have a difficult time planning their supply in a way that’s sustainable to them and consumers.

Agave is also often grown as a monocrop, which is unsustainable for long-term agriculture, and carries risks of run-off, blight, and increased need for fertilizers and pesticides. Harvesting blue agave specifically also depletes a vital food resource for the lesser-nosed bat species.

Perhaps the most important consideration with agave plants is the inequity associated with it. Slave labor, underpaid labor, and child labour are dire problems across the agricultural industry. Fair trade certification exists for some agave-related brands, but cannot be assured for all of them. In 2021, data from the Brazilian Institute of Geography and Statistics registered 1.8 million children involved in child labor, with 45.9 percent of them in the occupations of operating agricultural machinery, and of processing tobacco, agave, and sugar cane.

Ethical alternatives to honey are not necessary. Responsible beekeeping hurts no honeybees. It is a symbiotic relationship. Bees gain protection and a good hive place, with the freedom to leave if conditions are poor. Beekeepers harvest excess honey that the hive does not need to sustain itself. It is a sustainable, beneficial practice that produces a sweetener which very few humans are allergic to.

Alternatives to products we use in our daily lives can become trendy and take some time to see the true impact of. While vying for a more environmentally friendly life, we can be misled or mistaken about the true sustainability of products. It is important to continue to learn about and educate ourselves on the products we’re using.

Additional Resources

1. Faux Leather Unsustainability

2. Fashion Industry Waste

3. Sustainability of Leather

4. Comparing Leather and Faux Leather

5. Problems with Leather

6. Ethics and Fashion

7.Vegan_leather_An_eco-friendly_material_for_sustainable_fashion_towards_environmental_awareness

8. Leather Tanning

9. Plant-based Alternatives

10. Agave Climate Change

11. Agave and Bats

12. Beekeeping Sustainability

#environment#climate change#resources#research#article#renewable energy#sustainability#faux leather#pleather#leather#textile industry#honey#beekeeping#farming#child labor#anti capitalism

2 notes

·

View notes

Text

Color Masterbatch

Color masterbatch is a concentrated form of pigments or dyes blended into a polymer carrier, enhancing the color of plastics during manufacturing. It ensures consistent and vibrant hues, simplifying the coloring process in various industries such as packaging, automotive, and consumer goods.

For more information, contact us : +91- 9081802800 and send e-mail : [email protected] visit - https://www.mahirapolyglobal.com/

1003, Pinnacle Business Park, Corporate Road, Prahladnagar, Ahmedabad, Gujarat - 380015 | INDIA

#commercial#ecommerce#marketing#sales#colormasterbatch#colormasterbatchmanufacturer#masterbatchsupplier#masterbatchmanufacturerindia

1 note

·

View note

Text

Free Job Alert Vacancy in Vapi, Gujarat: Exploring Opportunities

In the bustling industrial hub of Vapi, Gujarat, job seekers often find themselves on the lookout for the latest employment opportunities across various sectors. Known for its vibrant industrial landscape and strategic location, Vapi offers a multitude of career prospects across diverse fields. Whether you're a fresher seeking your first job or an experienced professional looking for a career change, Vapi has something to offer for everyone.

Exploring Job Opportunities in Vapi Vapi, situated in Gujarat near the border of Maharashtra, is renowned for its chemical industries, manufacturing units, and various small to medium enterprises (SMEs). These industries not only contribute significantly to the local economy but also provide a wide range of employment opportunities across different skill levels.

Key Sectors Offering Job Opportunities Chemical Industry: Vapi is home to a robust chemical industry, comprising manufacturing units producing pharmaceuticals, dyes, chemicals, and intermediates. Job roles in this sector range from production operators to quality control analysts and research scientists.

Manufacturing and Engineering: The manufacturing sector in Vapi spans across textiles, plastics, packaging, and machinery. Engineers, technicians, and skilled workers are in demand in these industries.

Logistics and Warehousing: With its strategic location on the Mumbai-Ahmedabad route, logistics and warehousing companies in Vapi offer jobs in transportation, supply chain management, and logistics coordination.

IT and BPO Services: While not as dominant as in metropolitan cities, Vapi is witnessing growth in IT services, including software development, customer support, and data management roles.

Retail and Hospitality: As Vapi grows as an industrial and commercial hub, opportunities in retail management, hospitality services, and customer-facing roles are also emerging.

Where to Find Free Job Alerts in Vapi Finding the right job in Vapi begins with staying updated on the latest vacancies. Here are some effective ways to receive free job alerts:

Online Job Portals and Websites Several job portals and websites cater specifically to job seekers in Vapi and surrounding areas. These platforms regularly update their listings with new job openings across various sectors. Some popular job portals include:

Indeed Naukri.com Monster India TimesJobs LinkedIn

Local Newspapers and Classifieds Regional newspapers and classified ads remain a traditional yet effective way to find job vacancies in Vapi. Newspapers like Gujarat Samachar and Divya Bhaskar often feature local job listings in their classified sections.

Networking and Referrals Networking within professional circles and leveraging personal connections can often lead to valuable job leads that may not be advertised elsewhere. Attending industry events, seminars, and workshops in Vapi can also expand your network and increase your chances of hearing about job openings through word-of-mouth.

Government Employment Exchanges Government-run employment exchanges in Vapi and nearby towns provide a platform for job seekers to register themselves and receive notifications about government and private sector job openings.

Company Websites Directly visiting the websites of companies operating in Vapi is another effective way to find job vacancies. Many companies post their job openings on their career pages or provide contact information for submitting resumes.

Tips for Applying to Jobs in Vapi When applying for jobs in Vapi, consider the following tips to increase your chances of success:

Customize Your Resume: Tailor your resume to highlight relevant skills and experiences that match the job requirements.

Follow Application Instructions: Pay attention to application deadlines and submission guidelines specified by employers.

Prepare for Interviews: Research the company and practice common interview questions to confidently articulate your skills and suitability for the role.

Stay Persistent: Job hunting can be challenging, so maintain a positive attitude and stay persistent in your search efforts.

Conclusion In conclusion, Vapi, Gujarat, presents a wealth of employment opportunities across various sectors, making it an attractive destination for job seekers. Whether you're looking for a career in manufacturing, IT, logistics, or hospitality, staying informed about job vacancies through free job alerts is crucial. By utilizing online portals, networking, and exploring local resources, you can enhance your job search experience and find the right opportunity in Vapi that aligns with your career goals. Keep exploring and stay proactive to capitalize on the dynamic job market that Vapi has to offer.

0 notes

Text

Top Premium Totes Manufacturers: Finding the Best for Your Brand

As brands compete to bring high-quality, fashionable, and functional products to their customers, the demand for premium tote bags is on the rise. Whether you are looking for premium tote bags for personal use or your brand seeks bulk purchases to promote your products, choosing just the right Premium Totes Manufacturers is of utmost importance for high quality and an impression that lasts. This blog talks about how you must get partnered with the right ones, like Ronak Industries, who will elevate your brand by reflecting over some things to consider while selecting one of the finest quality tote bags.

Why Premium Tote Bags Matter

They are no longer mere practical accessories but now quintessential fashion pieces and powerful branding items. Be it giveaways or for sale in your retail store, high-quality tote bags enhance your brand image. Ornately designed totes do not only hold items; they also serve as mobile billboards expressing your logo designs and brand message to a much wider audience.

What Distinguishes Premium Totes?

Though standard tote bags can meet some basic requirements, premium tote bags take the client experience up a notch. These are long-lasting, modern-style, environmentally friendly bags, which make ideal choices for any business aiming to create a lasting impression.

Durability: Made from high-quality materials, premium tote bags are built to last, even with frequent use. Whether crafted from sturdy cotton, jute, or canvas, these bags ensure that your customers will use them for an extended duration, thereby enhancing your brand's visibility.

Style and Design: Premium totes emphasize not only practicality but also visual appeal. Brands can choose unique designs that reflect their identity, values, and aesthetic. Whether adopting a minimalist style or a more colorful approach, the design of your premium branded tote bags can significantly boost brand recognition.

Eco-Friendly: Since environmental consciousness is important today, premium tote bags provide a sustainable alternative to plastic. Hence, new eco-friendly material is being focused on by many top manufacturers, thus giving your promotional products a chance to profit customers as well as Mother Earth.

Versatility: Premium totes are versatile and can be used for anything from grocery shopping to work use, travel, or even serve as a fashion accessory. Because of this very flexibility, customers have them at their disposal for frequent use which would serve as good long-term exposure to your brand.

What to Look for in Premium Totes Manufacturers

Selecting the appropriate Premium Totes Manufacturers is crucial for obtaining a product that meets your brand's quality expectations. Consider these given factors when choosing a manufacturer:

Customization Capabilities Personalizing your premium tote bags with a logo, tagline, or design is a humane way of setting your brand apart. Established luxury tote manufacturers generally provide several customization options, such as the material used, colors, sizes, and printing methods. Such adaptability would enable you to produce a product that depicts your brand identity.

Quality of Materials The choice of materials for premium totes goes a long way toward determining how they will function, as well as how they will appear. The finest premium bag manufacturers in India use cotton, jute, and canvas of the best quality to ensure that the bags will be durable and eco-friendly. Choosing a manufacturer whose focal point is superior material is highly essential to give the tote bags added weightage in quality and durability.

Sustainable Practices

Sustainability is of primary concern in the modern world. Look for reputable custom tote bag manufacturers that focus on eco-friendly practices. An environmentally conscious manufacturer it organic cotton, rags, or natural or non-toxic dyes can ally your brand with sustainability attracting eco-conscious customers.

Competitive Pricing If high-end premium bags are an elite product, it becomes a Herculean task of balancing act between quality and affordability. Reliable tote bag manufacturers from India offer great pricing without compromising on quality. Talk to your manufacturers about your budget for the competitive solutions presented by them, ensuring adherence to good quality.

Prompt Delivery Timely delivery is critical whether you're looking for premium tote bags for a trade show, promotional event, or retail launch. Choose a punctual manufacturer to avoid last-minute snags. A reliable manufacturer will have smooth processes to ensure prompt fulfillment.

Why collaborating with Ronak Industries is advantageous for your business:

Superior Quality: Ronak Industries guarantees that all their premium tote bags are crafted from robust, eco-friendly materials designed to endure everyday use.

Custom Solutions: Whether you are looking to display your brand's logo, use special patterns, or customize the colors, Ronak Industries offers a wide variety of customization options to suit your requirements.

Affordable Wholesale Options: Ronak Industries offers discounts in the retail range for bulk orders of college-grade tote bags, thus gaining customer goodwill.

Environmental Responsibility: As a manufacturer committed to sustainability, Ronak Industries prioritizes the use of eco-friendly materials, enabling you to align your brand with environmentally conscious principles.

Elevate Your Brand with Premium Totes

In summary, premium tote bags serve not only as practical items but also as significant branding instruments that can enhance your business's visibility. Choose the right Premium Totes Manufacturers like Ronak Industries that provide you bags of sublime quality in memorable favor of your clientele. Ronak Industries is enjoying the goodwill as a manufacturer and wholesaler of premium branded tote bags insofar as premium quality, customization, and sustainability are concerned.

0 notes

Text

Bulk Chemicals in Chennai: Fuelling the Growth of Diverse Industries

Chennai is the capital city of Tamil Nadu and has been considered as one of the major industrial centers in South India. This city has turned out to be a significant hub for manufacturing, cars, chemicals, and medicines due to its good location, strong infrastructure, and a developed industrial environment. Among the key resources supporting this developing economy are bulk chemicals in Chennai, which are of prime importance in many industrial processes in textiles, automotive, pharmaceuticals, water treatment, and many more.

What Are Bulk Chemicals?

Bulk chemicals are big quantities of chemicals produced and sold in large amounts, mainly for industrial use. They are mostly transported in big containers such as tankers, drums, or bulk carriers since they are produced in such big quantities. They are used in making products, creating formulas, and as raw materials for producing other products in various industries. Bulk chemicals can be acids and solvents to plastics and special chemicals.

Significance of Bulk Chemicals in the Industrial Scenario of Chennai

Major industries in the city include automobile manufacturing, textiles, pharmaceuticals, chemicals, and food processing. The reasons for its industrial growth are mainly the easy availability and utilization of bulk chemicals. The continuous production efficiency, along with a reduced cost and quality consistency, by these sectors demand a steady supply of bulk chemicals.

In the car industry, large quantities of chemicals such as oils, paints, and adhesives are required for the manufacture of car parts and construction of cars. In the textile industry in Chennai, large quantities of chemicals like colors, dyes, and finishing products are required to produce various types of fabrics. The drug industry also requires bulk chemicals since large quantities of compounds and chemicals are required for the preparation and manufacture of medicines.

Major Bulk Chemicals Used in Industries of Chennai

Acid and Bases: Strong acids, such as sulfuric acid, hydrochloric acid, and nitric acid, along with caustic soda (sodium hydroxide), are used commonly in Chennai for various purposes. These chemicals play an important role in industries that involve metal cleaning, water treatment, and fertilizer manufacturing.

Solvents: Bulk solvents like toluene, acetone, ethanol, and methanol are used across several sectors, particularly in manufacturing paints, coatings, and adhesives. These solvents are also pivotal in the pharmaceutical and petrochemical industries for various chemical reactions and formulations.

Polymers and Plastics: The polymers such as polyethylene (PE), polypropylene (PP), and polyvinyl chloride (PVC) are a part of important basic materials in the manufacturing industries of Chennai. These bulk chemicals are used to manufacture several products including packaging materials, car parts, and building materials.

Fertilizers and Agricultural Chemicals: Large chemicals like ammonia, urea, and phosphoric acid are required for the manufacture of fertilizers that support farming. These fertilizers are used in large quantities in the regions surrounding Chennai, which is a major hub for agriculture.

Water Treatment Chemicals: Chlorine, alum, and various coagulants are major chemicals used to treat water. This is highly required in factories and the city's water supply. Because Chennai faces problems with water scarcity, there is a high requirement for these chemicals.

Supply Chain and Infrastructure for Bulk Chemicals in Chennai

Chennai has good infrastructure that helps supply bulk chemicals to industries. The city is close to important ports like Chennai Port and Ennore Port, which makes it easy to import and export bulk chemicals. Also, a strong road and rail network makes sure chemicals are transported on time to different industrial areas in and near the city.

Most of the chemical suppliers and distributors in Chennai are striving to obtain and provide large quantities of chemicals. This provides them with a huge range of products so that businesses do not have to wait to get raw materials. In general, these suppliers operate at the manufacturer's level and ensure quick delivery so that handling stock becomes easier and less expensive.

Environmental Issues and Sustainable Practices

Availability of bulk chemicals in Chennai supports the growth of the industrial sector; however, associated environmental issues during chemical manufacturing and usage also require attention. Usage of bulk chemicals, especially for large-scale uses, has environmental impacts if their management is not proper. Government and industries are adopting sustainable methods in Chennai: using eco-friendly chemicals, ensuring less generation of waste, and safe disposal of by-products of chemical production.

Industries in Chennai are giving more importance to green chemistry innovations. These include safe, biodegradable chemicals and processes that reduce harm to the environment.

Conclusion

Bulk chemicals Chennai play a significant role in the city's different industrial sectors. They help businesses in automotive, textiles, pharmaceuticals, and water treatment make high-quality products efficiently and at lower costs. As the need for these chemicals keeps increasing, industries should practice sustainable methods that lessen harm to the environment and ensure they can last a long time. With its strong infrastructure and expanding industrial base, Chennai will definitely stand as an important center for the bulk chemicals industry in India.

0 notes

Text

Plastic Cone, Plastic Solid Cones Manufacturer in India

Manufacturer, Supplier and Exporter of Plastic Cone, Plastic Solid Cones for Textile Industry in Sangli, Maharashtra, India.

Plastic Cone, Plastic Solid Cones, Perforated Dye Tubes, Perforated Dye Cones, Plastic Yarn Carriers, Textile industry, Spinning, Twisting, Texturizing, Yarn Dyeing & Carpet Industry, Injection Moulded products, Corrugated Pipe Industry, Electrical Industry, Manufacturer, Supplier and Exporter, Sangli, Maharashtra, India.

#Plastic Cone#Plastic Solid Cones#Perforated Dye Tubes#Perforated Dye Cones#Plastic Yarn Carriers#Textile industry#Spinning#Twisting#Texturizing#Yarn Dyeing & Carpet Industry#Injection Moulded products#Corrugated Pipe Industry#Electrical Industry#Manufacturer#Supplier and Exporter#Sangli#Maharashtra#India

0 notes

Text

Chlorosulfonic Acid: An Essential Chemical for Industry by Maruti Fine Chemicals

Chlorosulfonic acid (often referred to as chlorosulphonic acid) is a vital chemical compound with a wide range of industrial applications. It is primarily used in the manufacturing of detergents, dyes, pharmaceuticals, and agrochemicals.

Maruti Fine Chemicals, located in India, has emerged as a leading producer and supplier of this highly reactive substance, catering to various industries that require top-quality chlorosulfonic acid for their operations.

Understanding Chlorosulfonic Acid:

Chlorosulfonic acid, with the molecular formula HSO3Cl, is a strong sulfonating agent that plays a key role in the production of sulfonic acids, which are essential in a variety of chemical processes.

This colorless to slightly yellow liquid is highly corrosive and reacts with a range of materials, making it an indispensable component in numerous manufacturing processes. It is typically produced by the chlorination of concentrated sulfuric acid in the presence of chlorine gas.

The versatility of chlorosulfonic acid lies in its ability to introduce sulfonic groups (-SO3H) into organic molecules. This makes it invaluable in the synthesis of surfactants, pharmaceuticals, agrochemicals, and other specialty chemicals.

Applications of Chlorosulfonic Acid:

Manufacturing of Surfactants: One of the most significant uses of chlorosulfonic acid is in the production of surfactants, which are critical components in household cleaning products, personal care items, and industrial applications. These surfactants are created by sulfonating various organic compounds, resulting in better solubility and functionality.

Pharmaceuticals: Chlorosulfonic acid plays a crucial role in the synthesis of various pharmaceutical products. It is used to introduce sulfonic groups into drugs, enhancing their solubility and bioavailability. Many drugs, including antihypertensives and anti-inflammatory medications, are synthesized using chlorosulfonic acid.

Agrochemicals: The agrochemical industry also relies heavily on chlorosulfonic acid for the production of pesticides, herbicides, and fungicides. These chemicals help protect crops and enhance agricultural productivity, ensuring food security across the globe.

Dye Manufacturing: Chlorosulfonic acid is a key reagent in the dye industry. It is used to sulfonate aromatic compounds, which are essential in the creation of various dyes and pigments used in textiles, inks, and other materials.

Polymers and Plastics: Chlorosulfonic acid is used in the synthesis of polymers, such as polystyrene and polyvinyl chloride (PVC), by introducing sulfonic groups into their structure. This modification improves the material’s performance and application in different industries.

Electronics Industry: In the electronics sector, chlorosulfonic acid is used in the production of electrolytes for batteries and other electronic components. Its role in the manufacturing of conductive polymers and electronic materials is significant in today’s rapidly advancing technology sector.

Water Treatment: In water treatment processes, chlorosulfonic acid is used to produce chemicals that help in the removal of impurities, ensuring the purification of water. The sulfonation process aids in creating effective water treatment solutions.

Maruti Fine Chemicals: A Trusted Supplier in India

Maruti Fine Chemicals, based in India, is one of the leading manufacturers and suppliers of chlorosulfonic acid. The company has earned a reputation for delivering high-quality chemicals that meet international standards. Maruti Fine Chemicals is dedicated to providing customers with superior-grade chlorosulfonic acid that meets the specific needs of various industries.

With years of expertise in the chemical manufacturing industry, Maruti Fine Chemicals has a robust production facility equipped with state-of-the-art technology to ensure the safe and efficient production of chlorosulfonic acid. The company follows strict quality control measures to maintain the consistency and purity of the products it supplies, ensuring the satisfaction of its clients across various sectors.

The company’s commitment to quality and customer service makes it a preferred supplier for businesses involved in chemical manufacturing, pharmaceuticals, agrochemicals, and other industrial sectors.

Maruti Fine Chemicals also emphasizes sustainability and safety in its operations, making sure that the production and handling of chlorosulfonic acid comply with all regulatory standards.

Why Choose Maruti Fine Chemicals for Chlorosulfonic Acid?

Quality Assurance: Maruti Fine Chemicals is committed to delivering high-quality chlorosulfonic acid that meets industry specifications. Rigorous quality checks are performed at every stage of production to ensure the purity and stability of the chemical.

Customized Solutions: The company understands that different industries have unique requirements. Maruti Fine Chemicals offers tailored solutions, working closely with clients to meet their specific needs. Whether it’s in terms of concentration or packaging, the company is flexible and adaptable.

Competitive Pricing: Maruti Fine Chemicals provides chlorosulfonic acid at competitive prices, ensuring that businesses can benefit from cost-effective solutions without compromising on quality. The company’s efficient production processes help in reducing costs while maintaining product standards.

Timely Delivery: With an extensive distribution network across India and beyond, Maruti Fine Chemicals ensures timely delivery of chlorosulfonic acid to its clients. The company understands the importance of prompt service in the fast-paced world of chemical manufacturing.

Expertise and Experience: With decades of experience in the chemical industry, Maruti Fine Chemicals has developed a deep understanding of its clients’ needs. The company’s team of experts ensures that the products are of the highest quality and that clients receive excellent customer service.

Safety and Compliance: Handling chlorosulfonic acid requires strict adherence to safety protocols. Maruti Fine Chemicals is dedicated to maintaining the highest standards of safety and environmental compliance in its production and supply chain processes.

Sustainability: The company also prioritizes sustainable practices in its operations. Maruti Fine Chemicals is continually working towards reducing its environmental footprint and ensuring that its products are manufactured in an eco-friendly manner.

Challenges in Handling Chlorosulfonic Acid:

Despite its many applications, chlorosulfonic acid is a highly reactive and dangerous chemical that requires careful handling. Due to its corrosive nature, it can cause severe burns and must be stored in specialized containers to avoid leaks or reactions with air or moisture.

Companies, like Maruti Fine Chemicals, take stringent precautions during the production, storage, and transportation of chlorosulfonic acid. This includes using corrosion-resistant equipment, implementing safety protocols, and ensuring that employees are trained in the safe handling of hazardous chemicals.

Future Trends in the Use of Chlorosulfonic Acid:

As industries continue to evolve, the demand for chlorosulfonic acid is expected to grow, especially in the fields of pharmaceuticals, agrochemicals, and specialty chemicals. The increasing need for efficient manufacturing processes and environmentally-friendly chemicals will likely drive further innovation in the use of chlorosulfonic acid.

Maruti Fine Chemicals is well-positioned to meet these demands, continuing to invest in research and development, technology upgrades, and sustainable practices. The company’s vision of becoming a global leader in chemical manufacturing is supported by its commitment to quality, customer satisfaction, and continuous improvement.

Conclusion:

Chlorosulfonic acid, a powerful and versatile chemical, plays a pivotal role in many industries, ranging from pharmaceuticals to agriculture. Maruti Fine Chemicals, based in India, is a trusted name in the production and supply of this essential chemical, offering high-quality products and services to meet the diverse needs of its clients.

With a focus on safety, quality, and sustainability, Maruti Fine Chemicals continues to be a leader in the global chemical industry.

0 notes

Text

The Solvent Red Market is projected to grow from USD 2,191 million in 2024 to USD 2,975 million by 2032, reflecting a compound annual growth rate (CAGR) of 3.9% over the forecast period. The Solvent Red market has emerged as a pivotal segment within the global chemical and dye industry. This vibrant class of dyes finds extensive applications in a variety of industries, including printing, textiles, plastics, and fuels. Solvent Red dyes are known for their excellent solubility in organic solvents and oils, which make them ideal for non-polar environments. As the global demand for high-quality dyes continues to grow, the Solvent Red market is experiencing significant expansion. This article explores the current dynamics, trends, and future prospects of this market.

Browse the full report https://www.credenceresearch.com/report/solvent-red-market

Market Overview

Solvent Red dyes are a class of synthetic organic compounds that are primarily used to impart color to products such as fuels, lubricants, and inks. These dyes are especially popular in industries where coloration is crucial for branding, identification, or compliance with regulatory requirements. For instance, the use of Solvent Red in fuels is mandated in several countries for taxation and identification purposes.

The market is highly fragmented, with numerous manufacturers and suppliers operating globally. Key regions contributing to the market’s growth include North America, Europe, and the Asia-Pacific. The latter is emerging as a dominant player due to the rapid industrialization in countries like China and India, where the demand for dyes in sectors such as textiles and printing is surging.

Drivers of Market Growth

Rising Demand in End-Use Industries: The expansion of industries such as automotive, packaging, and printing is driving the demand for Solvent Red dyes. In the automotive sector, for example, these dyes are used in lubricants and fuel markers to ensure quality and authenticity.

Technological Advancements: Continuous research and development in dye synthesis have led to the creation of Solvent Red dyes with enhanced stability, higher colorfastness, and environmental compatibility. These advancements are broadening their application scope.

Regulatory Mandates: Governments worldwide have established stringent regulations to ensure the proper identification of fuels and lubricants. Solvent Red dyes play a critical role in meeting these requirements, thereby boosting market demand.

Growing Consumer Awareness: With the increasing emphasis on aesthetics and product differentiation, consumer-driven industries like cosmetics and packaging are increasingly incorporating Solvent Red dyes.

Challenges in the Market

Despite its growth, the Solvent Red market faces several challenges. The production of synthetic dyes involves complex chemical processes that can pose environmental concerns. Stringent regulations around manufacturing emissions and waste disposal are pressuring manufacturers to adopt sustainable practices. Moreover, fluctuating raw material prices and supply chain disruptions can impact the market’s stability.

Emerging Trends

Shift Towards Sustainable Dyes: The industry is witnessing a gradual shift towards eco-friendly and biodegradable dyes. Manufacturers are investing in green chemistry to produce Solvent Red variants that align with global sustainability goals.

Increased Investment in R&D: Companies are focusing on developing innovative dye formulations that cater to the evolving needs of industries such as 3D printing, electronics, and high-performance coatings.

Market Consolidation: Strategic mergers and acquisitions are becoming common as companies aim to strengthen their market position and expand their geographical footprint.

Future Prospects

The future of the Solvent Red market looks promising, with growth projected across multiple industries. According to market analysts, the sector is expected to grow at a compound annual growth rate (CAGR) of approximately 5-7% over the next five years. The increasing demand for advanced dyeing solutions in emerging economies, coupled with the adoption of eco-friendly manufacturing practices, will likely propel market growth.

Additionally, the rise of novel applications, such as in laser printing and electronic displays, is expected to open new avenues for market expansion. Innovations in dye technology and the integration of artificial intelligence in manufacturing processes will further enhance efficiency and product quality.

Key Player Analysis:

Clariant International Ltd.

BASF SE

Huntsman Corporation

Lanxess AG

Dow Chemical Company

Arkema Group

DIC Corporation

Sudarshan Chemical Industries Limited

Asahi Kasei Corporation

Meghmani Organics Limited

Segmentations:

By Demographic:

Consumers

Industrial

Commercial

By Psychographic:

Traditionalists

Modernists

Individualists

By Behavioral:

Heavy users

Medium users

Light users

By Region:

North America

U.S.

Canada

Mexico

Europe

Germany

France

U.K.

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of the Middle East and Africa

Browse the full report https://www.credenceresearch.com/report/solvent-red-market

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Discovering Top Pigment Paste Manufacturers in Ahmedabad

Pigment paste is a thick colorant that comes in a thick paste form and is made of pigment powders and a combination of resin. If you are in the textile business and looking for long-lasting pigment paste at very affordable rates, Ahmedabad is a great place for you to collect pigment paste. There are so many leading pigment paste manufacturers in Ahmedabad whom you can visit offline or connect with through an online platform and order pigment paste for your business.

But as the numbers are so many, it’s a bit difficult to identify who is the genuine one. But we are here to guide you in this. This blog is all about the best pigment paste manufacturers in Ahmedabad who are supplying premium quality and cost-effective pigment paste to textile and paint companies all over India.

Find the Most Trustworthy Pigment Paste Manufacturers in Ahmedabad

There is hardly any area in Ahmedabad where you cannot find a pigment paste manufacturing company. And the number of pigment paste manufacturer in Ahmedabad is increasing day by day. It cannot be that everyone will be trusted. If you don’t want to be fooled by getting the lowest quality pigments from a fraud company, try to connect with the most reliable manufacturers. We have listed out some of the most reputed and trustworthy pigment paste manufacturers in Ahmedabad whom anyone from textile, painting or ink industry can connect for quality products.

1. Venus Dye Chem

Venus Dye Chem is the top player in the dyes and pigment manufacturing industry. This is one of the oldest and industry-leading pigment paste manufacturers in Ahmedabad. They sell pigment pastes in the largest variety of colors. You can find both jelly and non-jelly, vibrant and delicate colored pigment paste at best price in their stock. This top-most pigment paste exporter in Ahmedabad is always ready to export pigment paste anywhere within India. You can also collect pigment powder and different types of dyes from them.

2. Mars Dye Chem Industries

One of the most popular pigment paste manufacturers in Ahmedabad is Mars Dye Chem Industries. It has 5-star ratings on Google My Business for selling exceptional quality, organic and low-price pigment pastes. They are ready to supply products anytime and anywhere.

3. Trinity Pigment Industries

Trinity Pigment Industries is a foremost pigment paste manufacturer in Ahmedabad. They serve different industries like textile, plastics, PVC and rubber industries, paint industries and so on. In their wide variety of product ranges, you can find organic and inorganic pigments, Anti Corrosive Pigments, Pearl Pigments, and more.

4. Pink Rose Pigments PVT. LTD.

Pink Rose Pigments PVT. LTD. has been working in the pigment-making industry since 1984. It has become one of the most trustworthy and prominent pigment paste manufacturers in Ahmedabad, India. They deliver all varieties of premium quality pigment pastes not only in India but worldwide. You can order pigment past in a minimum 1kg and a maximum 50kg from them. They provide pigment pastes in so many color options to choose from.

5. Meera Dyestuff Industries

One of the top-most and most well-known pigment paste manufacturers in Ahmedabad is Meera Dyestuff Industries that started its journey in 1981. To ensure the quality standard, they test each product sincerely before final dispatch. They are famous for always supplying pigment paste anywhere in India before time. They are on a mission to deliver pigment pastes worldwide in future and become the world’s best pigment paste exporter.

Last Words

We have discussed about top 5 pigment paste manufacturers in Ahmedabad but you may come across a lot more names when start searching. Considering some major facts like the company’s experience and reputation, checking ingredients, comparing prices, checking the product label and asking for some samples will help you know about the authenticity of the company and its products.

0 notes

Text

Capital Colours: A Leading Colour Masterbatch Manufacturer Company in India

In the ever-evolving world of plastics and polymers, the demand for high-quality, vibrant colors has led to the rise of color masterbatch technology. Capital Colours, a premier Colour Masterbatch Manufacturer Company in India, has become synonymous with innovation, quality, and sustainability in the production of color masterbatches. With a deep understanding of the market and a commitment to excellence, the company has earned its place as a trusted name in the industry.

What Are Colour Masterbatches?

Colour masterbatches are highly concentrated mixtures of pigments or dyes encapsulated in a carrier resin, designed to impart vibrant colors to plastics. These masterbatches are added to the base resin during the manufacturing process to achieve consistent and uniform coloration throughout the product. Used in a wide range of applications—from packaging to automotive components—color masterbatches play a crucial role in enhancing the aesthetic appeal and functionality of plastic products.

The use of color masterbatches provides manufacturers with several benefits, such as easy handling, precise color matching, and improved processing efficiency. This has led to their widespread adoption in industries such as packaging, textiles, consumer goods, and automotive manufacturing.

Capital Colours: A Trusted Name in Colour Masterbatches

As a leading Colour Masterbatch Manufacturer Company in India, Capital Colours is renowned for its high-quality products, cutting-edge technology, and customer-centric approach. With years of experience in the industry, the company has honed its expertise in producing masterbatches that cater to a diverse range of requirements.

Capital Colours prides itself on its ability to deliver color masterbatches that meet the highest standards of quality and performance. By utilizing advanced manufacturing processes and state-of-the-art equipment, the company ensures that each masterbatch is formulated to provide excellent dispersion, stability, and consistency. Whether customers need vibrant hues or subtle tones, Capital Colours offers a wide range of options to suit every need.

Key Features of Capital Colours’ Masterbatches

Customization: One of the standout features of Capital Colours is its ability to provide tailored solutions. Whether it's a specific shade or an application requirement, the company can customize its color masterbatches to match exact specifications, ensuring that clients get the best possible result for their projects.

High-Quality Pigments: Capital Colours uses only high-quality pigments sourced from trusted suppliers. This ensures that the colors are vibrant, long-lasting, and resistant to fading over time.

Environmental Considerations: In an era where sustainability is paramount, Capital Colours remains committed to environmentally friendly practices. The company’s masterbatches are designed with eco-consciousness in mind, offering options that are compatible with recycling processes and compliant with industry standards.

Superior Dispersion: The company’s color masterbatches are engineered for optimal dispersion in the polymer matrix. This ensures that the colors are evenly distributed, resulting in a consistent and high-quality finish for every product.

Cost-Effectiveness: Despite offering premium products, Capital Colours ensures that its color masterbatches are competitively priced. This makes it a cost-effective choice for businesses looking for high-quality, durable color solutions without compromising their bottom line.

Industries Served by Capital Colours

Capital Colours’ color masterbatches are used across a wide array of industries, including:

Automotive: Supplying automotive manufacturers with durable, high-performance color masterbatches for interior and exterior parts.

Consumer Goods: Providing color solutions for plastic products ranging from toys to household items.

Textiles: Supplying the textile industry with color masterbatches for synthetic fibers and fabrics.

Agriculture: Producing color masterbatches for agricultural films and products that require UV stability and durability.

Innovation and Research

At Capital Colours, innovation is at the core of the company’s operations. The company continuously invests in research and development to improve the performance, stability, and environmental sustainability of its products. Their team of experts works closely with clients to develop new formulations that meet the ever-changing demands of the market.

This focus on innovation ensures that Capital Colours remains ahead of the curve, providing customers with the most advanced and reliable color solutions available.

Conclusion

As a top Colour Masterbatch Manufacturer Company in India, Capital Colours stands as a leader in the field of plastic coloration. Through a combination of high-quality products, innovation, and commitment to sustainability, the company has built a strong reputation among manufacturers across a wide range of industries. Whether you are looking for vibrant, long-lasting colors or need custom solutions, Capital Colours offers the expertise and products to bring your vision to life, making them the go-to choice for all your color masterbatch needs.

0 notes

Text

Eco-Friendly Recycled Polyester staple fibre of Pashupati Group

Pashupati makes Eco-friendly recycled polyester staple fibre, which is a man-made fibre made from pet polyester waste and post-consumed pet bottles. Pashupati Polyester is the only synthetic material that makes up polyester staple fibre. The recycled polyester staple fibre of Pashupati has emerged as the fastest-growing fibre among all types of manufacturing. Pashupati manufacturers usually made recycled polyester from waste polyethene terephthalate (PET BOTTLE).

In India, Pashupati is the nation's top producer and exporter of recycled polyester staple fibre. Pashupati upholds extremely high standards for fibres that provide consistency in quality, improved efficiency, and operational benefits in the forward Integration processes, using the best available technology and technological know-how. Pashupati recycles large numbers of plastics.

Recycled Polyester Staple Fibre –

Recycled Polyester Staple Fibre of Pashupati Group provides the garment with no wrinkles and ironing after washing. Pashupati recycling is converting worn materials into fresh ones in an effort to lessen waste and transform it into something helpful. Pashupati Recycling also lessens current waste, preventing environmental pollution. Pashupati Polyester is a synthetic/non-natural material that is created through a technique. In the form of separate parts that come together to form an entire longitudinal network, fibre itself is a sort of material. A Pashupati Synthetic Fibre manufactured from polyester that has been recycled is called recycled polyester staple fibre of Pashupati. Additionally, mechanical or chemical procedures might be used to carry out the fibre recycling process.

Additionally, PET bottles and textile waste can also be used to create fibre. Because they utilize trash, PET bottle plastic and fibre generated from textile waste are both more effective and affordable.

Type of Recycled Polyester Stable Fibre(RPSF):

Dyed: Dyed fibre refers to any type of fibre that has been coloured or tinted with a dye or pigment. It is made by recycling and dyeing durable materials such as plastic bottles, fishing nets, or other waste materials and is used in many different industries such as fashion, and textiles.

Solid: Solid Fibre is produced by processing and repurposing various types of waste fibres. The recycled fibers are cleaned, shredded, and then mixed with binding agents to create a stable and durable material that can be used for a variety of applications.

Hollow: Hollow Fibre is made from recycled PET bottles. The fibre has an open centre, which gives it insulating properties, making it suitable for use in clothing.

Hollow Conjugated: Hollow Conjugated Fiber is a type of synthetic fibre that is made from recycled plastic bottles and extrudes a polymer through a spinneret with a special shape that creates a hollow centre in the fiber. It is commonly used in the textile industry to produce soft, lightweight and breathable fabrics.

Micro Fibre: It is a synthetic fibre made from recycled polyester material that has been processed into fine fibers. These fibers are thinner and are used to create various types of garment products.

All the above products we produce in 1.4 to 15 DN.

0 notes