#Plastic Components & Connectors Manufacturer

Explore tagged Tumblr posts

Text

Plastic Components & Connectors

Plastic Components Manufacturer

If you got confused about how and where to buy the best plastic products, don’t worry, we are one of the leading plastic components manufacturers in Delhi.

With years of experience, Shubham Industries India’s Plastic Components has been a leading manufacturer of plastic components and connectors for the automotive industries.

We are the originators of many innovative products and offer the most complete line of plastic components in the industry.

Our goal is the development of high-quality plastic components and connectors that resolve problems created by standard metal.

How Plastic Components are Made

Raw resources like natural gas, oil, or plants that have been processed into ethane and propane are used to make plastics.

Next, during a procedure known as “cracking,” heat is used to transform ethane and propane into ethylene and propylene. To produce various polymers, these components are mixed.

#Plastic Components & Connectors#Plastic Components & Connectors Manufacturer#plastic components manufacturer#Shubham Industries India#plastic components manufacturer in Delhi

0 notes

Text

Elevating Precision Manufacturing: The Role of Mekalite’s CNC Machining Service

In today’s competitive manufacturing landscape, precision, efficiency, and adaptability are key to staying ahead. CNC machining has emerged as a vital technology, enabling manufacturers to produce complex and high-precision parts consistently. At Mekalite, we are redefining excellence in CNC machining services by combining advanced technology, a skilled workforce, and a commitment to quality.

https://mekalite.com/

What is CNC Machining?

CNC (Computer Numerical Control) machining is a process that uses computerized controls to operate machinery and tools with high accuracy. This enables the production of intricate parts from a variety of materials, including metals and plastics, while maintaining tight tolerances. CNC machining is critical in industries such as aerospace, automotive, medical devices, and electronics.

Why Choose Mekalite for CNC Machining?

Mekalite sets itself apart by offering a comprehensive approach to CNC machining, ensuring every project is handled with precision and care.

Advanced Machinery and Capabilities Our cutting-edge, multi-axis CNC machines allow us to handle even the most complex designs with precision and consistency. Whether you need rapid prototyping, low-volume manufacturing, or full-scale production, Mekalite’s technology enables us to meet your unique needs.

Customized Solutions We understand that every project is different. Mekalite works closely with each client to understand their specific requirements, delivering tailored solutions that align with their design and functionality goals.

Strict Quality Assurance At Mekalite, quality is our top priority. Our rigorous quality control protocols cover every step of the production process, from material selection to final inspection. This commitment ensures every part meets the industry’s highest standards.

Industries Served by Mekalite

Mekalite’s CNC machining services support a diverse range of industries, including:

Aerospace: High-precision components for engines, structural parts, and aircraft interiors.

Automotive: Custom engine parts, suspension components, and detailed bodywork.

Medical: Surgical instruments, implants, and diagnostic equipment requiring tight tolerances.

Electronics: Housing frames, connectors, and precision parts for delicate devices.

Benefits of Partnering with Mekalite

Choosing Mekalite as your CNC machining service provider offers numerous advantages:

High Precision and Accuracy Our state-of-the-art CNC machines, combined with skilled operators, enable us to achieve exceptional accuracy and repeatability across all projects.

Wide Range of Materials Mekalite’s expertise spans across various materials, from metals like stainless steel and aluminum to specialized plastics. This flexibility allows for innovative product designs and customized applications.

Cost Efficiency and Scalability With automated processes and minimal manual intervention, CNC machining reduces labor costs while enhancing efficiency. Whether you need a single prototype or a large production run, Mekalite’s scalable services can adapt to your requirements.

Timely Deliveries Time is crucial in manufacturing. Our efficient workflows and commitment to meeting deadlines ensure that your projects are completed on schedule, every time.

Looking Ahead: Mekalite’s Commitment to Innovation

Mekalite is committed to staying ahead of industry trends and technological advancements. By continually investing in the latest CNC machinery and refining our processes, we aim to provide even more innovative and reliable solutions to our clients. Our vision is to be a trusted partner in helping businesses achieve new levels of success through precision manufacturing.

Conclusion

CNC machining is revolutionizing the manufacturing industry, and Mekalite is at the forefront of this transformation. Our combination of cutting-edge technology, tailored solutions, and a dedication to quality makes us a preferred partner for businesses across various sectors.

If you’re looking for a reliable CNC machining service provider that delivers precision and value, Mekalite is here to help. Contact us today to discuss your next project!

https://mekalite.com/

2 notes

·

View notes

Text

What Industries Is Injection Molding(Moulding) Applicable To?

Injection moulding is a common manufacturing process by injecting molten plastic material into a mould so that it can be formed into the desired product shape upon cooling.

Injection moulding process has the advantages of low cost, high production efficiency and stable product quality to make it widely used in various industries. In this vast injection moulding market, there are three industries are particularly eye-catching, which are extensively used for production and manufacturing due to their specific needs and product characteristics.

1.Household Appliance Manufacturing Industry

As an indispensable part of people's daily life, the market demand for household appliances is stable and continuously growing. The injection moulding process plays a pivotal role in the manufacturing of household appliances, from the outer shell to the internal components, injection moulding technology provides key support. Most of the exterior and structural components of home appliances, such as TV remote controls, refrigerators, TV sets, air-conditioning panels, and washing machine shells, are manufactured by injection molding process.

2.Automotive Components Industry & Transportation Sector

With the booming development of the automotive industry, the auto components and parts market has ushered in unprecedented development opportunities. Components and parts such as automotive dashboards, door interior panels, bumpers, and lamp housings as well as a wide range of pipework and connections are made through the injection moulding process. These parts require not only high precision and good mechanical properties, but also need to meet the strict appearance requirements, which injection moulding process is precisely by virtue of its unique advantages, in this field to occupy a place. In addition, with the rise of new energy vehicles, injection moulded parts play an important role in the manufacturing of key components such as battery packs and motor housings.

3.Medical Device Industry

With the increasing emphasis on health, the market demand for medical devices continues to grow. In medical device manufacturing, the injection moulding process is used to produce disposable medical devices such as syringes, infusion tubes and surgical instruments. These products require strict quality control and hygiene standards, and injection moulding process ensures product safety and effectiveness.

In addition, the injection moulding process is also widely used in the electrical and electronic industry, consumer electronics, packaging industry, toy manufacturing, construction materials, industrial parts, furniture and household furnishings and agriculture, among many others.

4.Electrical & Electronic Industry

In the manufacturing process of electronic products, many components such as housings, cases, sockets, connectors, cables, switches and holders for electronic circuit boards need to be manufactured by injection moulding process. Injection moulding process can achieve precise control of product appearance, size and structure, to meet the requirements of electronic products for appearance quality, functionality and reliability.

5.Consumer Electronics Industry

In the electronics industry, injection moulded parts are equally widely used. From mobile phone housings, computer components including keyboards and mice to remote controls and battery cases, the injection moulding process offers a wide variety of appearance and structure options for electronic products. These components not only need to have good mechanical properties and appearance, but also need to have excellent electrical insulation properties to ensure the stable operation of electronic products. Injection moulding technology occupies an important position in the manufacture of electronic products due to its advantages of high precision and low cost.

6.Construction Sector

In the construction field, injection moulded parts also have a wide range of applications, the drainage systems, door and window frames, pvc pipes, valves, wire troughs, insulation materials and other construction materials and accessories are mostly manufactured by injection moulding process. These components are not only high-strength and corrosion-resistant, but also weather-resistant and easy to install, meeting the construction industry's requirements for material performance and ease of use and improve construction efficiency and aesthetics. The application of injection moulding technology in the construction field not only improves the performance and quality of construction materials, but also promotes the sustainable development of the construction industry.

7.Packaging Industry

The packaging and container industry is also one of the key application areas for injection moulding processes. Plastic bottles, food boxes, cosmetic bottles, plastic bags and other packaging containers are mostly manufactured by injection moulding process to meet food safety and aesthetic requirements. These containers need to be well-sealed, drop-resistant, retain freshness and recyclable to ensure that the products are safe and environmentally friendly. Injection moulding processes can offer flexible design and manufacturing options to adapt to different packaging needs and provide strong support for the development of the packaging industry.

These areas above are just a few examples of the application areas of the injection moulding process. In the toy industry, injection moulded parts are used to manufacture a variety of plastic toys; In the textile and clothing industry, injection moulded parts are used to manufacture accessories such as zips and buttons; In the agricultural sector, injection moulded parts are used to manufacture agricultural tools and equipment such as sprayers and watering cans; Even in the aerospace sector, injection moulded parts are also used to manufacture parts for aircraft and spacecraft. It can be said that injection moulded parts have penetrated into almost every corner of our life.

In summary, injection moulded parts play an important role in several industries by virtue of their high precision, low cost and wide applicability. The application of injection moulding process in these areas not only improves production efficiency, but also meets the needs of product diversification and individualisation. With the continuous progress of science and technology and the continuous improvement of people's requirements on product quality, injection moulding technology will continue to be widely used and developed in various fields.

#design#autos#business#prototyping#prototype#prototype machining#rapid prototyping#cnc machining#precision machining#machining parts#injection molding#plastic injection molding#injection moulding machine#injection moulding#plastic injection#injection molded#injection molding parts#injection molded parts

2 notes

·

View notes

Text

What are the Uses of Custom Plastic Manufacturing ?

In this day and age, custom plastic manufacturing has turned into a foundation of current industry, giving custom-made solutions across a wide cluster of areas. From medical services to auto, the versatility of plastics and the accuracy of custom manufacturing methods have made it conceivable to address explicit issues with unmatched productivity. We should probably dig into the main purposes of custom plastic manufacturing and grasp its effect on different businesses.

1. Medical and Healthcare Applications

Custom plastic manufacturing is reforming the medical services industry. Medical gadgets, prosthetics, and parts of symptomatic machines are progressively being produced using custom-planned plastics. A plastic manufacturing company offers a few benefits, including solidness, lightweight properties, and the capacity to be cleaned. Custom plastic parts are utilized in creating needles, IV cylinders, catheters, and, surprisingly, perplexing parts of medical imaging machines. The accuracy presented by custom manufacturing guarantees that these parts fulfill severe medical guidelines, adding to better understanding consideration and results.

2. Automotive Industry

In the automotive sector, custom plastic parts are fundamental for both execution and style. From dashboard parts to many-sided motor parts, custom plastics give arrangements that assist with lessening the general load of vehicles, further developing fuel efficiency. They also offer resistance to corrosion and wear, enhancing the longevity of parts. Custom plastics are used in manufacturing bumpers, interior trims, and even under-the-hood components. Their versatility, akin to the innovations seen with plastic bottle manufacturers, allows for innovative designs and improved safety features, making modern vehicles more reliable and efficient.

3. Consumer Electronics

The consumer electronics industry depends intensely on custom plastic assembling for making solid and smooth items. Cell phones, workstations, and domestic devices frequently consolidate custom plastic parts that are intended to fit definitively and capability perfectly. These parts need to withstand day to day wear and tear while keeping an engaging look. Custom plastics are utilized in housings, buttons, connectors, and different inward parts, offering both underlying respectability and plan adaptability.

4. Packaging Solutions

Custom plastic manufacturing assumes an urgent part in the packaging business. It empowers the formation of packaging arrangements that are custom fitted to secure and protect items during transportation and capacity. Custom plastic packaging can be intended to meet explicit necessities, for example, being lightweight, strong, and impervious to dampness and synthetics. This is especially significant in the food and refreshment industry, where keeping up with the newness and security of items is principal. Custom packaging likewise takes into consideration creative shapes and plans that upgrade brand character and purchaser advance.

5. Industrial and Mechanical Parts

Businesses that require hearty and high-performance components frequently go to custom plastic manufacturing. Plastics can be designed to display properties like high rigidity, protection from outrageous temperatures, and compound strength. This makes them ideal for making parts utilized in apparatus, gear, and different modern applications. Custom plastic pinion wheels, orientation, seals, and lodgings are normally utilized in manufacturing settings, adding to the productivity and dependability of modern tasks.

6. Aerospace and Defense

In aerospace and defense, the demand for lightweight yet solid materials is basic. Custom plastic manufacturing meets this need by providing components that can withstand harsh environments while reducing the overall weight of aircraft and defense equipment. From interior cabin parts to specialized components in satellites and military gear, custom plastics offer the necessary performance characteristics and design flexibility required in these high-stakes applications.

Ely Global Pte. Ltd - Leaders in Custom Plastic Manufacturing

Ely Global Pte. Ltd spends significant time in custom plastic manufacturing, giving fitted solutions to different businesses. With state of the art innovation and a pledge to quality, they convey accurately designed plastic parts that meet explicit client needs, upgrading item execution and productivity across multiple sectors.

#plastic manufacturing company#wholesale plastic bottle suppliers#plastic water bottle caps recyclable

2 notes

·

View notes

Text

A controller with a scroll wheel, you say?

Well this is a little funny. Yesterday I posted the first part of a series of post on the fine details of how computers work, mentioning how I've been looking into this as part of a personal project I've been working on, and today I wake up to see Masahiro Sakurai posting a youtube video lamenting the lack of... this exact thing I'm working on.

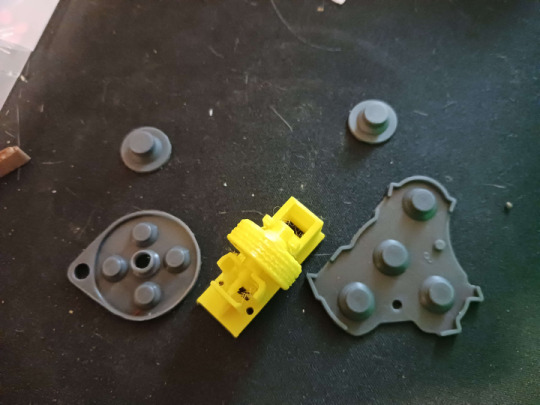

Apologies for how much cat hair is in this photo, that's a bit of an occupational hazard, but this here is a photo I took back in September when most of the parts I had to order were in for the prototyping of this thing:

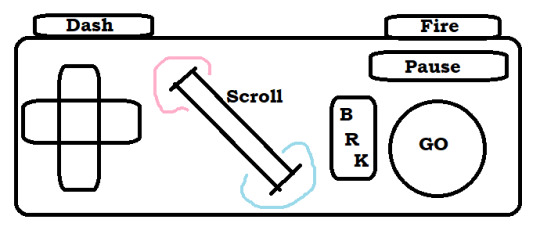

That's a really bad MS Paint mockup, but yeah. I'm designing my own game console, and one of the key features is a big ol' scroll wheel right in the center of the controller. Another is that I'm planning to just put all the designs of the circuit boards and 3D printer files for the casing/buttons up online for free, making it this totally open DIY thing where anyone who's a big enough nerd can just make a couple downloads, order some dirt cheap components, and build their own copy of the system (or people with better setups than me can build and sell them, whatever). So I'm not super worried about anyone stealing my ideas or whatever, but I WOULD like to establish a standard and all that, and figured it was worth noting that this is something I've been slowly working towards for like a year or two now, and didn't just get the idea from this video:

youtube

But yeah, now that the idea's out in the public consciousness, here's the plan for the controller (that I was planning to keep under my hat until I had a working prototype and some demo software sometime next year).

First off, the plan is that this is to be the standard controller for a whole console I'm also plucking away at designing, which is a bit more ambitious of a project, so I figure I might as well make it compatible with something that's already out there. So specifically, I'm designing this so that you can take one, plug it right into an SNES (or with a different connector at the end, an NES, because turns out they use the exact same input handling standard and it's just the shape of the plastic on the end that differs), and have it just work. Or mostly work anyway. I'm hoping I can process a signal out of the scroll wheel in a way that it either just needs the 3 extra bits of the input signal I don't have buttons for in my design (more on that later) or failing that, I can get it to output the same sort of signal as one wheel in the SNES mouse, which just rides along the second data line very few things use. I think that plan might break multitap compatibility and require an extra chip on the controller PCB, but it would leave this slightly more compatible with existing games on the same hardware. I might also do something weird with the button mapping to be sure NES select is on a shoulder and it works right out of the box with that whole library.

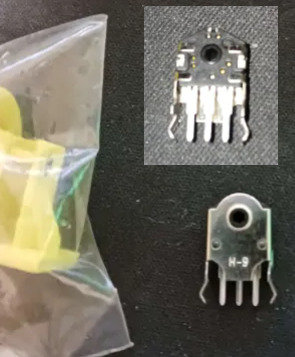

Working out exactly how to handle signals from the scroll wheel happens to be the point I'm currently stuck on by the way. I got this baggie full of rotary encoders for just a few cents which... almost fit in my first draft 3D printed wheel housing, but I have NO documentation on them, not even a part number/manufacturer besides "H-9," the pins don't fit a breadboard, and I've kinda been scrambling for rent so I can't afford a nice multimeter or oscilloscope to poke around with. Plus again I need to redesign this wheel print to even get it to spin right, and... this was a gift from a friend with a printer who is Not Local. Solvable problem, just needs more time and/or outside expertise.

But yeah, once I have those kinks worked out, it should be easy enough to get a custom board design made, replicas of end-cap of the controller cord are another problem easily solved by ordering a 1 dollar part or 3D printing something. The actual cord might be tricky since I don't know where you actually order something like that from, but it should be easy enough for anyone who doesn't mind a little assembly work to put one of these together and have it good to go for any software made with it in mind, or retrogames where you don't mind a weird button count. So... what's the pitch on this scroll wheel anyway?

Well for starters, there's the stuff Sakurai got into this morning. Any sort of RPG or text heavy game can use it to quickly scroll through menu options, or stuff in a text-heavy game. You could also pan the screen with it, something a lot of early 16-bit games assigned to the shoulder buttons or holding up and down while getting used to the new options the hardware was giving them.

Past that, you'll notice in my design it's at a 45 degree angle. I might have to tweak it a little, but my thinking is for a game that uses it heavily, one thumb or the other can slide over easily enough (I'm going for a pretty compact overall design) so we can have some games where you take your thumb off the D-pad, and have this nice analogue steering wheel. Nice for fine control in a racing game, or if you want some little radio-tuning/safe-cracking sorta deal.

Alternatively, move your right thumb over, use the D-pad to steer, shoot and dodge or whatever with shoulder buttons, and use the wheel to rotate a turret for a twin-stick sort of game maybe.

Or just use it for the sort of stuff mouse based games stick on the scrollwheel. Changing weapons, changing powerups... I'm planning to officially label the directions "hot" and "cold" to encourage weird gimmicky things like... I dunno, a platformer where you have a thermostat in your controller you can always mess with, freeze water coming out of pipes, crank up flame jets? Have a shot charging mechanic where you just really crank it to get to max strength? Weird minigame stuff. There's some fun space to explore with it.

Then we have the rest of the design here... which basically comes down to me being just plain sick of how every controller made by anyone in the past... 20 years give or take has kind of the exact same layout? 4 good face buttons, a D-pad, 4 shoulder buttons, 2 sticks, and 1-4 annoying to reach tiny awkward middle buttons, and we're just kind of overdue for a change-up?

Like first of all, hey, this is just too many buttons. There's a ton of games that really only need a D-pad, and maybe 3 buttons (attack jump pause) and the two things that aren't fully standardized is how awkwardly placed the D-pad is and how awful and awkwardly placed the pause button is. Shoulder buttons can be nice, but I've never really felt like 4 of them awkwardly crammed on the rim has been really useful or ergonomic, and that's coming from someone who's been playing a ton of FF14, which gets more use out of them than anything else I could name. And really, aside from games doing fake twin-stick stuff and using the whole grid like a second D-pad, I'm having a really hard time thinking of any game I've ever played that really makes good use of 4 good face buttons? Like people will use them if they've got'em sure, but unless you do that keyboard style thing where you lay the controller on a table and use all your fingers, you can really only comfortably hit 2 face buttons without sliding your thumb away from them, maybe comfortably make a quick pivot to a third.

Also, really, a lot of designers just sort of feel compelled to map SOMETHING to every button, even if it's clear the design didn't really need them. So basically I figure I'll try kinda just taking a "less is more" approach here. Here's the buttons that it's comfortable to rest your thumbs and fingers on, here's a dedicated pause/menu button where people often stick a kind of redundant menu button, here's my gimmicky scrollwheel. That's it, work around that.

I'm also going a little Gamecube inspired (literally using replacement membranes for one in my prototype design, even). Gonna make a great big primary button and use different shapes for the other two. Trying to label these in a less arbitrary fashion than most. If shooting a gun is a thing you do in this game, and there isn't a real good reason not to, default it to this nice right trigger you can hold down all the time. If we're advancing through menus or jumping or holding down gas in a car, here's the big GO button. Need brakes, need to break stuff with a melee attack? Go back in a menu system? There's your other face button. Have a quick dash move or a run you hold down, let's just use the other shoulder.

So yeah. That's my controller. Need to work out the kinks on the scroll wheel, source a cord, and hopefully I can slap things together and this will be something you can just order bits for piecemeal and put together for like, $5-10 after shipping? Maybe less? The parts are shockingly cheap so far.

But yeah if anyone has any insight to the scroll wheel or cord issues, let me know. Also the whole thing is presently a tad back-burnered because I am in a serious financial crisis and I don't want to have electronics spread all over my table if I have to abruptly find a new place to live if I can't scrape next month's rent together. So as usual, donations are incredibly welcome.

2 notes

·

View notes

Text

The Craftsmanship behind Fittings Manufacturing

Fittings like plastic fittings China are connectors that connect pipes, tubes, or hoses. They are intended to form a secure and leak-proof connection, allowing for the uninterrupted passage of liquids, gasses, or even solid objects. Plumbing, HVAC systems, hydraulic and pneumatic machinery, oil and gas pipelines, and other applications all employ fittings. These little components are the unsung heroes of numerous sectors, keeping together contemporary society's complicated architecture.

Fittings: An Art Form Manufacturing

Manufacturing fittings is a complex procedure that necessitates accuracy and attention to detail. Here's a rundown of the stages required in making fittings:

Material Selection: The selection of materials is critical in the manufacture of fittings. diverse materials, such as brass, stainless steel, PVC, or copper, are required for diverse uses. The material used must be corrosion-resistant, long-lasting, and suitable for the contents transported.

Engineers design fittings with accuracy, taking into account parameters such as pressure ratings, temperature, and flow needs. To generate precise and trustworthy products, the design process may use computer-aided design (CAD).

Machining: Machining procedures like as turning, milling, and drilling are commonly used to make fittings from metal fittings manufacturer. These operations shape and refine the material into the correct shape, guaranteeing that the fitting will work properly.

Quality Control: Throughout the production process, stringent quality control methods are employed. Inspections, testing, and monitoring are performed to ensure that the fittings fulfill industry standards and requirements.

Surface Finish: Depending on the application, fittings may be polished, plated, or coated to improve their durability and appearance.

Manufacturing Fittings Innovations

In recent years, the field of fittings production has undergone considerable developments. These advancements seek to boost efficiency, decrease environmental impact, and increase product performance. Among the significant advancements are:

3D Printing: Additive manufacturing, including 3D printing, is becoming more popular for producing complicated, bespoke fits with minimal material waste.

Sustainable Materials: To lessen its environmental imprint, the industry is investigating eco-friendly materials and manufacturing procedures.

Rapid prototype: Computer-aided design and rapid prototype techniques enable the creation and testing of novel fitting designs to be completed more quickly.

IoT technology is being integrated into fittings from plastic fittings manufacturers to monitor and optimize fluid flow, identify leaks, and increase system performance.

Follow our Facebook and Twitter for more information about our product.

#Metal fittings manufacturer#Metal fittings manufacturer China#Professional Metal Manufacturer#Metal Manufacturer China

2 notes

·

View notes

Text

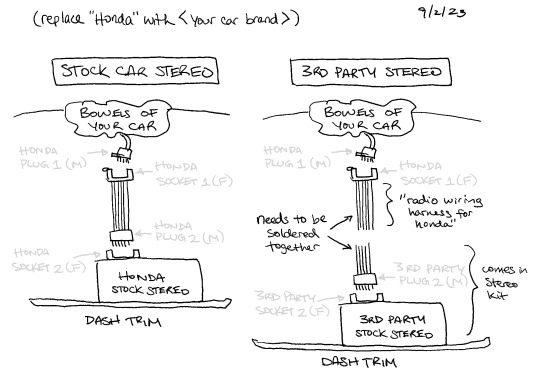

I miss doing longform project writeups here; it's been a while! I recently replaced the old stock stereo in my 2009 car with a modern system (nothing fancy, just a super basic bluetooth stereo because I was tired of not having the AUX cable adapter for my phone since phone manufacturers decided to hamstring the world's phone users by removing AUX jacks).

It came out surprisingly affordable to upgrade, at $62 total! After-tax cost breakdowns:

Bluetooth stereo: $23

DIN dash trim (Metra brand): $20

Radio wiring harness (also Metra): $10

Antenna wiring harness (optional): $9

Replacing an older stereo is theoretically straightforward, but annoying in practice because you have no idea what you need until you actually open up the car and realize you were supposed to buy another simple part they didn't tell you about. I got mad and wrote this post up because I had already yanked the old stereo out of my car before realizing I was supposed to buy a wiring harness, and then my car dash had a big hole in it for a few days while I waited for it to ship.

What you need to wire up an aftermarket stereo:

The stereo kit, which should come with plugs that are compatible with the stereo itself

"Dash trim kit": the molded plastic piece on your dashboard that components are mounted into. It should be made for your particular car. This is only necessary if your new stereo mount is different from your old stereo mount.

"Radio wiring harness" (connects stereo to power & speakers) and "antenna wiring harness" (if you also want radio reception). These are sockets matching the proprietary connectors for the wires coming out of your car.I had to buy mine online because my car is 14 years old. If your car is newer then you may be able to find the parts at a local auto store.

Either soldering equipment (soldering iron, solder, electrical tape, wire stripper, and "helping hands"), or you pay someone else to install it for you, in which case you probably aren't reading this post lol

(My new stereo conforms to the "single DIN" dimension standard. DIN sizing is blessedly standardized across cars. Single DIN is the smaller size that lets you install a little snack compartment or drawer beneath your stereo, and double DIN is the bigger size that's usually used for a touchscreen.)

You probably can't just buy a single cable that will connect your new stereo directly into your car, for many reasons. Car manufacturers are based all over the world, and cars in general are extremely non-standardized. Different cars and stereos all use different plugs, and it would be too difficult for each stereo manufacturer to provide a different wiring harness for every possible car model out there.

Also, it is beneficial for every electrical connector in your dash region to be shaped differently, so that you can't accidentally plug it into the wrong socket. At first I was annoyed to see five totally different proprietary connectors when I opened up the dash, but after failing to label three of them, I was very glad that they were all different shapes.

So unless you wanna sit in your car soldering your stereo directly to your car with no takebacks, you probably want to make yourself that custom stereo<>car cable by getting the radio wiring harness & antenna wiring harness that fit your car model, then soldering them to the cable that came with your stereo kit. Thankfully my cables seemed to come with a standardized coloring scheme for the wires, so it was easy to match them up.

Tools you need to replace your old dash & stereo (I winged it with whatever was in my toolbox...but most people have fewer tools than me)

Either an auto trim remover kit, OR two small pry bars, a flathead screwdriver, and something long and flat such as a butter knife for leverage

Philips screwdriver -- a ratcheting one is helpful, but not required

Any additional tools as recommended by your car's service manual (or friendly local Youtube). For example, my car's service manual called for an 8mm socket wrench with a 6" extender to remove a bolt securing the stock radio.

Having two mini pry bars was helpful for taking off the retaining clips without breaking them. They are very fiddly.

Also, my stereo felt slightly wobbly in its thin sheet metal mount. So I stuffed a bit of cardboard between the stereo and the snack compartment as a makeshift shim, and am just crossing my fingers that something so close to the back of the engine won't catch on fire. Maybe the proximity to the AC helps.

3 notes

·

View notes

Text

Standard Laser Marking Systems Precision and Versatility for Modern Applications

In today's industrial landscape, precision and efficiency are paramount. Standard laser marking systems have emerged as indispensable tools across various sectors, delivering unparalleled accuracy and versatility. These systems are used for engraving or marking materials such as metals, plastics, ceramics, and more, making them vital in industries ranging from manufacturing to healthcare. Here's a closer look at the features, benefits, and applications of these innovative systems.

What Are Standard Laser Marking Systems?

Standard laser marking systems are pre-engineered, standalone units designed to create permanent marks on a variety of materials. They utilize laser technology to etch, engrave, or mark surfaces without physical contact. These systems can produce high-resolution text, logos, barcodes, serial numbers, and other identifiers with exceptional clarity and durability.

Key Features and Benefits

High Precision: Laser marking systems offer unmatched precision, making them ideal for applications where detail and accuracy are critical, such as micro-marking medical devices or intricate designs on consumer products.

Versatility: These systems are compatible with a wide range of materials, including metals, plastics, glass, wood, and ceramics, offering flexibility across multiple industries.

Durability: The marks created by laser systems are resistant to wear, heat, and chemicals, ensuring long-term readability and traceability.

Non-Contact Process: As a non-contact technology, laser marking prevents damage to the material's surface, maintaining its structural integrity.

Eco-Friendly Operation: Laser systems use no consumables like ink or chemicals, reducing waste and operational costs while being environmentally friendly.

Automation Compatibility: Standard laser marking systems can easily integrate into automated production lines, boosting efficiency and productivity.

Applications of Standard Laser Marking Systems

Manufacturing: Used for marking parts with serial numbers, barcodes, and logos to ensure traceability and branding.

Healthcare: Essential for marking medical devices with UDI (Unique Device Identification) codes, ensuring compliance and patient safety.

Electronics: Applied in the marking of circuit boards, connectors, and microchips for identification and assembly.

Aerospace and Automotive: Critical for marking parts with data matrix codes, ensuring traceability and compliance with industry standards.

Jewelry and Fashion: Used to engrave intricate designs and personalization on high-value items.

Standard laser marking systems are revolutionizing how industries approach marking and engraving. With their precision, durability, and adaptability, they are a smart investment for businesses aiming to enhance quality and efficiency. As industries continue to demand higher standards of traceability and customization, the role of laser marking systems will only grow, making them an essential component of modern production workflows.

Our website is the best source for additional information.

Fiber Laser Cutting Machines

Disentec

0 notes

Text

Insights into JST Connector

The Future of Connectivity: Insights into JST Connector Production

JST connectors are a fundamental component in various electronic devices, playing a vital role in ensuring secure and reliable electrical connections. This article explores the process, significance, and advancements in JST connector production.Get more news about jst connector production,you can vist our website!

What are JST Connectors? JST (Japan Solderless Terminal) connectors are widely used in electronics for connecting wires to circuit boards and other components. They are known for their compact design, high reliability, and versatility, making them ideal for applications ranging from consumer electronics to industrial machinery.

The Production Process of JST Connectors The production of JST connectors involves several key steps to ensure high-quality and consistent performance:

Design and Prototyping: The process begins with designing the connector to meet specific requirements. Prototypes are then created and tested to ensure they meet performance standards.

Material Selection: High-quality materials, such as durable plastics and metals, are chosen to ensure the connectors can withstand various environmental conditions and stresses.

Precision Manufacturing: Advanced manufacturing techniques, such as injection molding and stamping, are used to produce the connector components with high precision.

Assembly: The individual components are meticulously assembled to create the final connector. This step often involves automated systems to ensure consistency and accuracy.

Quality Control: Rigorous testing and quality control measures are implemented at various stages of production to ensure the connectors meet industry standards and specifications.

Key Features and Advancements in JST Connectors JST connectors are continually evolving to meet the demands of modern electronics:

Compact Design: Modern JST connectors are designed to be compact and lightweight, making them suitable for space-constrained applications.

High Reliability: They are built to provide secure and stable connections, reducing the risk of connection failures.

Versatility: JST connectors are available in various sizes and configurations to accommodate different applications.

Technological Advancements: Innovations such as improved insulation materials and enhanced contact designs are continually being integrated into JST connectors to boost their performance and reliability.

The Importance of JST Connectors in the Electronics Industry JST connectors are critical for the seamless operation of electronic devices. Their reliability ensures that devices function correctly, while their versatility allows for their use in a wide range of applications, from consumer electronics to automotive systems.

Conclusion JST connector production is a meticulous and advanced process that ensures the creation of high-quality, reliable connectors essential for modern electronics. As technology continues to advance, JST connectors will remain at the forefront of connectivity solutions, driving innovation and reliability in the electronics industry. Through continuous improvements and adherence to high manufacturing standards, JST connectors will continue to support the ever-evolving needs of electronic devices worldwide.

0 notes

Text

Polycarbonate Composites Market: Lightweight and Durable Innovations Driving Industrial Use up to 2033

The Polycarbonate Composites Market focuses on materials created by combining polycarbonate (PC) resin with reinforcing agents such as glass fibers, carbon fibers, or other fillers. These composites are well-known for their excellent impact resistance, high strength-to-weight ratio, optical clarity, and flame-retardant properties. The versatility of polycarbonate composites makes them widely used in applications across automotive, electronics, aerospace, construction, and healthcare industries.

To Know More @ https://www.globalinsightservices.com/reports/polycarbonate-composites-market

The polycarbonate composites market is anticipated to expand from $2.1 billion in 2023 to $4.3 billion by 2033, achieving a CAGR of 7.4%.

Market Outlook The Polycarbonate Composites Market is experiencing strong growth due to the increasing demand for lightweight yet durable materials in key industries. The automotive sector, in particular, is a significant driver, as manufacturers are seeking materials that reduce vehicle weight to improve fuel efficiency and meet stringent emission standards. Polycarbonate composites are becoming a preferred choice for automotive components such as headlamp lenses, interior parts, and glazing solutions due to their exceptional strength and lightweight characteristics.

In the electronics and electrical industry, the demand for polycarbonate composites is also surging. The materials’ excellent electrical insulation properties and high heat resistance make them suitable for producing enclosures, connectors, and electronic device casings. The growth of the consumer electronics market and the rising adoption of smart devices are contributing to increased usage of polycarbonate composites in this sector.

Aerospace and defense industries are turning to polycarbonate composites for applications that require high performance and safety, such as aircraft interiors, cockpit canopies, and ballistic-grade materials. The aerospace sector’s focus on weight reduction for fuel efficiency and enhanced durability further drives the demand for polycarbonate composites. Additionally, the construction industry is leveraging these materials for glazing applications and structural components where impact resistance and transparency are essential.

The market is witnessing innovations in composite manufacturing processes, such as the development of thermoplastic composites that offer advantages in recyclability and faster production cycles. Advancements in nanotechnology and surface modification techniques are also enhancing the properties of polycarbonate composites, expanding their application range and performance capabilities.

Environmental sustainability is a growing trend in the Polycarbonate Composites Market. Companies are investing in research and development to produce eco-friendly composites using bio-based polycarbonates and recycled materials. The push for sustainable materials aligns with global efforts to reduce plastic waste and promote the circular economy.

Asia-Pacific is expected to dominate the Polycarbonate Composites Market, driven by rapid industrialization, urbanization, and growing automotive and electronics manufacturing. Countries like China, Japan, and South Korea are leading in both production and consumption of polycarbonate composites. North America and Europe are also key markets, with strong demand from the automotive and aerospace sectors.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS32456

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request For Report Customization @ https://www.globalinsightservices.com/request-customization/GIS32456

Market Segmentation

In 2023, the Polycarbonate Composites Market demonstrated robust performance, with a market volume of 600 million metric tons and projections to reach 900 million metric tons by 2033. The automotive sector dominates the market share at 45%, driven by the industry’s demand for lightweight and durable materials. The electronics segment follows with a 30% share, benefiting from the increasing use of polycarbonate composites in consumer electronics. The construction segment holds a 25% share, supported by the material’s strength and versatility. Key players such as Covestro AG, SABIC, and Teijin Limited maintain substantial market presence, influencing sector dynamics.

Competitive pressures and regulatory frameworks significantly impact the Polycarbonate Composites Market. Companies are investing in sustainable production methods to comply with stringent environmental regulations. The EU’s Green Deal and similar policies worldwide are pushing for eco-friendly manufacturing processes. Future projections indicate a 10% annual increase in R&D expenditure, targeting innovations in recycling and material efficiency. The market outlook remains optimistic, with growth driven by advancements in composite technology and expanding applications across various industries. However, challenges such as fluctuating raw material prices and the need for technological advancements persist, necessitating strategic collaborations and investments in cutting-edge technologies.

Major Players

SABIC Innovative Plastics

Covestro

Teijin Limited

Mitsubishi Chemical Corporation

Chi Mei Corporation

LG Chem

Trinseo

Lotte Chemical

Asahi Kasei Corporation

Idemitsu Kosan

RTP Company

Plazit Polygal

PolyOne Corporation

Ensinger

Bayer MaterialScience

A. Schulman

SABIC

Sumitomo Chemical

Toray Industries

Mitsui Chemicals

Request For Discounted Pricing @ https://www.globalinsightservices.com/request-special-pricing/GIS32456

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

For In-Depth Competitive Analysis, Buy Now @ https://www.globalinsightservices.com/checkout/single_user/GIS32456

About Us

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Text

Custom Plastic Injection Molding by Topwell: Your Partner for Precision Manufacturing

In the world of modern manufacturing, custom plastic injection molding stands out as a highly efficient and versatile process for producing complex plastic parts. Topwell, a global leader in plastic injection molding solutions, delivers cutting-edge technology and unmatched expertise to meet diverse industry needs. With a commitment to precision and quality, Topwell offers tailored solutions that align with your unique requirements.

What Is Custom Plastic Injection Molding?

Custom plastic injection molding is a manufacturing process in which molten plastic is injected into a specially designed mold under high pressure. The plastic cools and solidifies, forming a finished part with intricate shapes and fine details. This technique is widely used across industries such as automotive, healthcare, electronics, and consumer goods.

Why Choose Topwell for Custom Plastic Injection Molding?

Topwell combines state-of-the-art facilities, advanced machinery, and skilled professionals to deliver superior custom molding solutions. Here’s why Topwell is the preferred partner for many businesses:

1. Tailored Solutions for Diverse Applications

Topwell specializes in creating custom molds designed to meet specific customer needs. Whether it’s small intricate components or large complex parts, Topwell has the expertise to deliver.

2. High-Quality Materials

Topwell works with a wide range of high-performance thermoplastics, ensuring that the final product meets functional and aesthetic requirements. From durable engineering plastics to eco-friendly biodegradable options, the material selection is optimized for your project.

3. Advanced Manufacturing Technology

Equipped with cutting-edge injection molding machines, Topwell ensures high precision, consistency, and efficiency. The company’s robust automation systems reduce production time and cost, without compromising on quality.

4. Prototyping and Design Support

Topwell offers comprehensive prototyping and design services to refine your ideas before full-scale production. Using tools like 3D modeling and simulations, their team ensures the mold design is flawless.

5. Cost-Effective Solutions

Topwell’s streamlined production processes minimize material waste and optimize efficiency, resulting in cost-effective solutions for high-volume and low-volume production runs.

6. Commitment to Sustainability

Topwell is dedicated to environmentally friendly manufacturing. The company incorporates recyclable materials and energy-efficient practices into its operations, reducing its ecological footprint.

Applications of Custom Plastic Injection Molding

Topwell’s custom injection molding services cater to various industries, including:

Automotive: Interior and exterior components, dashboards, and lighting parts.

Medical: Precision parts for devices and instruments.

Electronics: Casings, connectors, and structural components.

Consumer Goods: Packaging, toys, and household items.

Aerospace: Lightweight yet durable parts for aviation.

Why Precision Matters in Plastic Injection Molding

Precision in plastic injection molding ensures components meet exacting standards of quality, functionality, and aesthetics. With its advanced technology, Topwell can achieve tight tolerances and intricate details, providing products that align with strict industry requirements.

Topwell: Delivering Excellence in Custom Molding

Topwell has established itself as a trusted name in the custom plastic injection molding industry by delivering solutions that exceed expectations. With years of experience and a customer-centric approach, the company is committed to helping businesses achieve their goals through innovative manufacturing techniques.

Conclusion

Custom plastic injection molding is a cornerstone of modern manufacturing, enabling businesses to create high-quality parts with speed and efficiency. Topwell’s dedication to precision, innovation, and sustainability makes it a reliable partner for all your custom molding needs. Whether you're launching a new product or improving an existing design, Topwell provides the expertise and technology to bring your vision to life.

0 notes

Text

What is Plastic Injection Molding and How Does It Work?

Plastic injection molding is a widely used manufacturing process that allows for the mass production of plastic parts with high precision and efficiency. This method is versatile, cost-effective, and capable of producing components for industries ranging from automotive to consumer goods and medical devices. Below, we delve into the basics of plastic injection molding and explain how the process works.

What is Plastic Injection Molding?

Plastic injection molding is a manufacturing technique used to create plastic parts by injecting molten plastic into a mold. The mold is typically made from metal and consists of two halves—a cavity and a core—that shape the final product. Once the plastic solidifies within the mold, the finished part is ejected and the cycle begins again.

This process is ideal for creating large quantities of identical parts with high accuracy, making it a popular choice for mass production.

How Does Plastic Injection Molding Work?

The plastic injection molding process involves several key steps:

1. Material Preparation

The process begins with the selection of a suitable plastic material, often in the form of pellets or granules. These materials can be thermoplastics (e.g., polypropylene, ABS, or nylon) or thermosetting plastics, depending on the desired properties of the final product.

2. Melting the Material

The plastic pellets are fed into a heated barrel, where they are melted by high temperatures and the friction generated by a rotating screw. The molten plastic is then ready for injection.

3. Injection

The molten plastic is injected into the mold cavity under high pressure. The mold is securely clamped to withstand the pressure and maintain its shape during this step. The pressure ensures that the molten plastic fills every corner of the mold.

4. Cooling

Once the mold is filled, the plastic begins to cool and solidify into the desired shape. Cooling times vary depending on the material and the complexity of the design. Some molds may feature cooling channels to expedite this process.

5. Ejection

After the plastic has fully solidified, the mold opens, and ejector pins push the finished part out of the mold. The part is then inspected for quality and any excess material, such as sprues or flash, is trimmed away.

6. Repeat

The mold is closed again, and the cycle repeats. Modern injection molding machines can complete this process in a matter of seconds, allowing for rapid production.

Advantages of Plastic Injection Molding

High Efficiency: Once set up, the process is highly efficient, enabling the production of large volumes of parts in a short time.

Design Flexibility: Intricate designs with complex geometries can be achieved.

Material Versatility: A wide range of materials can be used, each offering unique properties.

Consistency: Parts produced are uniform, ensuring high precision and quality.

Cost-Effectiveness: While initial mold creation may be expensive, the cost per part decreases significantly with large production runs.

Applications of Plastic Injection Molding

Plastic injection molding is used in various industries, including:

Automotive: Components such as dashboards, bumpers, and interior panels.

Consumer Goods: Toys, household items, and packaging.

Medical Devices: Syringes, surgical instruments, and casings for medical equipment.

Electronics: Enclosures, connectors, and switches.

Why Choose Yakon Mold for Plastic Injection Molding?

At Yakon Mold, we specialize in delivering high-quality plastic injection molding solutions tailored to meet your specific needs. With advanced technology and a commitment to precision, we ensure that your products are manufactured to the highest standards.

Ready to bring your ideas to life? Visit us at www.yakon-mold.com to learn more or contact our team for a consultation.

Conclusion Plastic injection molding is an essential manufacturing process that combines efficiency, precision, and versatility. From its ability to produce complex designs to its applications across diverse industries, this technique continues to revolutionize modern manufacturing. Choose Yakon Mold for all your plastic injection molding needs and experience unmatched quality and service.

0 notes

Text

What to Expect from a RoHS Testing Lab in Abu Dhabi: A Comprehensive Guide | +971 554747210

In today’s global marketplace, businesses in the electronics industry must adhere to a variety of standards and regulations to ensure that their products are safe, reliable, and environmentally friendly. One of the most critical compliance requirements for electronics manufacturers and exporters is RoHS (Restriction of Hazardous Substances), a directive that restricts the use of certain hazardous materials in electronic and electrical equipment. RoHS compliance is crucial for gaining access to global markets, especially in regions like the European Union (EU), where strict environmental regulations are enforced.

For manufacturers based in Abu Dhabi, working with a reputable RoHS testing lab is essential to ensure that their products meet the required safety standards. In this comprehensive guide, we will explore what you can expect when working with a RoHS testing lab in Abu Dhabi, the benefits of certification, and how it can help your business stay ahead in the competitive electronics market.

What is RoHS Testing?

Before diving into what to expect from a RoHS testing lab, it’s essential to understand the basics of RoHS testing. RoHS is a regulation that limits the use of six hazardous substances in electronic and electrical products. These substances are:

Lead (Pb)

Mercury (Hg)

Cadmium (Cd)

Hexavalent Chromium (Cr6+)

Polybrominated Biphenyls (PBB)

Polybrominated Diphenyl Ethers (PBDE)

RoHS testing ensures that electronic products do not exceed the allowed limits of these substances, promoting safer products and a healthier environment. RoHS testing labs perform detailed analyses to verify whether products comply with these limits, ensuring manufacturers meet the requirements of this regulation.

The Role of RoHS Testing Labs in Abu Dhabi

RoHS testing labs in Abu Dhabi play a pivotal role in helping electronics manufacturers achieve compliance with global environmental standards. As Abu Dhabi is a central business hub with a growing electronics manufacturing sector, it is important for businesses to ensure that their products meet both local and international regulations. Here’s what you can expect from a RoHS testing lab in Abu Dhabi:

1. Comprehensive Testing Services

A reputable RoHS testing lab in Abu Dhabi will offer a wide range of testing services to ensure that your products meet RoHS standards. These tests are designed to detect the presence of the six restricted substances in various materials used in electronics products, such as circuit boards, connectors, plastics, and cables. Depending on the product, labs may use techniques like X-ray fluorescence (XRF), Inductively Coupled Plasma Mass Spectrometry (ICP-MS), and Atomic Absorption Spectroscopy (AAS) for precise analysis.

Testing labs will analyze your product components thoroughly, often breaking down each part to test for the presence of harmful chemicals. The results will provide manufacturers with a clear understanding of whether their products meet RoHS limits or if changes are needed before market release.

2. Expert Consultation and Guidance

RoHS compliance can be complex, especially for businesses that are new to the requirements. When you work with a RoHS testing lab in Abu Dhabi, you can expect to receive expert consultation and guidance throughout the process. These labs are staffed with professionals who are highly knowledgeable about the RoHS directive and the various testing methods used to ensure compliance.

Consultation services typically include:

Assistance in understanding RoHS requirements: The testing lab can help you navigate the various aspects of RoHS compliance, including how to interpret the results of the tests.

Recommendations for product improvement: If your products do not meet the RoHS standards, experts can provide suggestions on how to reformulate or redesign your products to comply.

Guidance on documentation and reporting: RoHS compliance often requires documentation and certification, which testing labs can assist with. This ensures that you have the necessary paperwork to demonstrate compliance during audits or regulatory inspections.

3. Fast and Accurate Results

In today’s fast-paced business world, time is a critical factor. RoHS testing labs in Abu Dhabi are equipped with advanced tools and technologies that allow them to deliver quick and accurate test results. This is especially important for manufacturers with tight production schedules or deadlines for product releases.

Many labs also offer expedited services, ensuring that your products can undergo testing and certification without causing delays in production. These fast turnaround times allow manufacturers to meet customer demand and stay competitive in the market.

4. Cost-Effective Solutions

While RoHS testing is essential, it is also important to keep costs manageable. Testing labs in Abu Dhabi offer cost-effective solutions to help businesses comply with RoHS without overspending. By choosing a local lab, manufacturers can avoid the high shipping costs and long waiting times associated with sending products abroad for testing.

Furthermore, investing in RoHS testing upfront can help prevent expensive product recalls or regulatory fines in the future. When you test your products early in the development process, you reduce the risk of non-compliance and the associated financial and reputational damage.

5. RoHS Certification

Once a product passes RoHS testing, the testing lab will provide a RoHS compliance certificate. This certification is a valuable asset for electronics manufacturers, as it demonstrates that their products are compliant with international standards. The certificate is also essential when exporting products to markets that require RoHS compliance, such as the EU, U.S., and Japan.

Having RoHS certification enhances your brand’s credibility and reassures customers and regulators that your products are safe and environmentally friendly. It also gives you a competitive edge in the market, as more consumers and businesses are prioritizing sustainability in their purchasing decisions.

The Benefits of Using a RoHS Testing Lab in Abu Dhabi

1. Compliance with Global Regulations

As an electronics manufacturer in Abu Dhabi, it is crucial to meet international regulations like RoHS, especially if you plan to export products worldwide. RoHS compliance is a requirement in the European Union, United States, and many other global markets. By testing your products with a RoHS testing lab in Abu Dhabi, you ensure that your products are ready for export and can reach these international markets without delays.

2. Environmental Responsibility

The goal of the RoHS directive is to reduce the environmental impact of electronics waste. By working with a RoHS testing lab, you can contribute to a more sustainable future by ensuring that your products do not contain hazardous substances that can harm the environment. This aligns with the growing consumer demand for environmentally responsible products and strengthens your brand’s commitment to sustainability.

3. Minimized Risk of Product Recalls

Non-compliance with RoHS regulations can result in costly product recalls, which can damage your reputation and lead to significant financial losses. By investing in RoHS testing before releasing your products to market, you minimize the risk of recalls and ensure that your products are safe for consumers and compliant with regulations.

Conclusion

Choosing a RoHS testing lab in Abu Dhabi is a critical step for electronics manufacturers who want to stay competitive, compliant, and environmentally responsible. These labs provide comprehensive testing services, expert guidance, and fast, accurate results to help businesses meet global RoHS standards. By working with a RoHS testing lab in Abu Dhabi, you can ensure that your products are ready for export, enhance your brand’s reputation, and contribute to a more sustainable future.

With the ever-growing demand for safe, environmentally friendly electronics, partnering with a trusted RoHS testing lab will give you the confidence to navigate regulatory challenges and expand your reach in the global marketplace.

0 notes

Text

The needle flame test is a critical method used to evaluate the flammability of electrical and electronic equipment, as well as insulating materials, plastics, and solid combustible materials. The LISUN ZY-3 Needle Flame Tester stands out as a reliable tool in assessing the fire hazard in various industries, including lighting equipment, low-voltage electrical appliances, household appliances, electric tools, electronic instruments, and other devices. This test provides crucial data that helps manufacturers ensure compliance with international safety standards. Needle Flame Test ZY-3 Overview of the Needle Flame Test The needle flame test simulates a small flame caused by an electrical fault, such as a short circuit or a spark, in a device. By exposing a test specimen to this flame for a specified duration, engineers can determine the material’s ability to resist ignition and self-extinguish. This is particularly important in industries where safety is paramount, such as in the manufacturing of lighting fixtures, household appliances, and electronic devices. Furthermore, the needle flame test is also widely used for testing insulation materials, engineering plastics, and solid flammable materials to ensure they meet strict fire resistance standards. Components of the LISUN ZY-3 Needle Flame Tester The LISUN ZY-3 Needle Flame Tester consists of three primary components: 1. Needle Flame Burner: The core element that generates a controlled flame of specified size and temperature to simulate the ignition conditions. 2. Test Chamber: An enclosed space where the test specimen is exposed to the needle flame under controlled conditions. The chamber ensures the test results are consistent by isolating the test environment. 3. Temperature Measurement Device: A crucial component that records the temperature of the flame and ensures it remains within the specified range for accurate testing. This combination of components enables precise and repeatable testing, ensuring that the materials tested under this system are thoroughly evaluated for flammability. Applications in Different Industries Lighting Equipment In the lighting industry, the needle flame test is used to assess components of lighting fixtures, including wiring, plastic casings, and connectors. These materials must resist flame propagation to ensure that electrical faults do not escalate into fire hazards. Testing with the LISUN ZY-3 provides manufacturers with valuable data on the fire resistance of lighting products, ensuring compliance with safety standards such as IEC 60598. Low-Voltage Electrical Appliances For low-voltage electrical appliances, such as power adapters, electrical outlets, and wiring accessories, fire resistance is crucial. The needle flame test helps manufacturers evaluate the safety of the plastic and insulation materials used in these products. The LISUN ZY-3 ensures these components can withstand short bursts of flame, preventing accidents in household and industrial settings. Household Appliances Household appliances, such as washing machines, dryers, and microwaves, are subject to strict fire safety regulations. The needle flame test allows manufacturers to assess the fire resistance of plastic enclosures and insulation materials used in these devices. The LISUN ZY-3 provides an accurate and reliable method to ensure these products meet safety standards and reduce the risk of fire in homes. Electric Tools Electric tools, such as drills, saws, and grinders, are exposed to various electrical and mechanical stresses. The materials used in their construction must be flame-retardant to prevent fire hazards during operation. The needle flame test ensures that the plastic and insulating materials used in electric tools can withstand short-term flame exposure without igniting or sustaining a flame. The LISUN ZY-3 is widely used in this industry for compliance with fire safety regulations. Electronic Instruments Electronic instruments, including measuring devices and control systems, rely on fire-resistant materials to ensure safety in various operational environments. The needle flame test evaluates the flammability of these components, ensuring they meet the necessary standards for safe operation. The LISUN ZY-3 provides a robust platform for testing these materials under controlled conditions, ensuring they meet international safety standards. Insulating Materials and Engineering Plastics The needle flame test is widely used to evaluate the flammability of insulating materials and engineering plastics used in various applications, from electrical insulation to automotive components. The LISUN ZY-3 enables manufacturers to assess the performance of these materials under flame exposure, ensuring their suitability for use in safety-critical applications. Testing Procedure of the LISUN ZY-3 Needle Flame Tester 1. Sample Preparation: The test specimen is prepared according to the relevant standard. Typically, the specimen is cut to a specified size and mounted in the test chamber. 2. Flame Exposure: The needle flame burner produces a flame with a length of 12 mm and a temperature of 960°C. The flame is applied to the specimen for 10 to 30 seconds, depending on the material and standard being followed. 3. Observation: The behavior of the specimen is observed during and after the flame exposure. The key metrics include whether the specimen ignites, the duration of any sustained flame, and whether the flame self-extinguishes. 4. Result Analysis: The results are analyzed to determine if the material passes or fails the needle flame test based on the duration of ignition and the spread of the flame. Table 1 below provides an overview of typical test conditions for various materials. Rating Test Type Flame Power Max Flame Time Dripping Allowed Typical Applications HB Horizontal 50W ≤60s Yes General plastic enclosures V-0 Vertical 50W ≤10s No Electrical housings, appliances V-1 Vertical 50W ≤30s No Insulating materials, housings V-2 Vertical 50W ≤30s Yes Low-risk components 5V Vertical 500W ≤60s No High-risk electrical components Standards and Compliance The needle flame test is governed by several international standards, including: • IEC 60695-2-2: This standard specifies the requirements for the needle flame test used to assess the flammability of materials. • UL94: This standard applies to the safety of plastic materials used in electrical devices and other products, where the needle flame test is a key part of the flammability testing regime. • ISO 13943: Provides general guidelines for fire safety in various industries and is often referenced in conjunction with the needle flame test. The LISUN ZY-3 Needle Flame Tester is fully compliant with these international standards, making it an essential tool for manufacturers who need to ensure their products meet the required fire safety regulations. Conclusion The needle flame test is a vital method for ensuring the safety of materials used in a wide range of products, from lighting equipment and household appliances to electric tools and insulating materials. The LISUN ZY-3 Needle Flame Tester provides a reliable and efficient platform for conducting these tests, helping manufacturers meet international safety standards and reduce the risk of fire hazards. By using this equipment, manufacturers can ensure their products are safe for consumers and meet the strict regulatory requirements in various industries. Read the full article

0 notes

Text