#Pinion rack

Explore tagged Tumblr posts

Text

"Pinion Rack: High-Quality Gear Edge for Precision Steering Systems"

Learn about the accuracy and dependability of a Pinion Rack, which is made with a premium gear edge for the best possible steering system performance. This crucial part, which is designed to offer responsive, smooth handling, guarantees a steady driving experience. A vital component of both normal and high-performance automobiles, the pinion rack's sturdy design ensures long-lasting dependability. Our pinion racks offer improved control and efficiency whether you're improving your system or replacing an outdated component. Look through our inventory to find the ideal fit and enjoy excellent engineering at every stage.

0 notes

Text

Top-quality rack and Pinion Boot for Optimal Sealing and Protection

The rack and pinion boot serve as a vital system component that protects your steering mechanism better than any other solution available. The boots are made to protect the rack and pinion arrangement from all environmental hazards, including dirt and water. The boot guards the steering system effectively and keeps vehicle components working longer. Our superior rack and pinion boots perform well in harsh conditions because they are made to meet high-quality standards.

Our rack and pinion bellows work with boots to give better protection to your steering system. The bellows are made from top-quality materials to resist long-term damage during use. These components follow rack and pinion motion yet shield the system from harmful particles. These bellows stay sealed perfectly and bring you important safety and performance benefits in your vehicle.

0 notes

Text

A Nissan Pathfinder’s steering rack and pinion is leaking and needs to be replaced.

The rack and pinion links together with the steering knuckles. It’s one of the areas where power steering fluid can leak from.

You should bring your vehicle to an auto repair shop if you experience any steering problems or notice drops of power steering fluid near it.

#nissan pathfinder#steering rack and pinion#power steering fluid leaks#prince william county virginia#hometowne auto repair and tire

0 notes

Text

Words, i cannot today, they escape me.

#I have said so many things wrong#yesterday#i was talking about#elevator systems#and once I said#rack and pinion#I proceeded to say#rack and pulley#and today#I kept mispronouncing things#god hates me#and he wants me to suffer#in a way that is most entertaining to god and the universe#there will be a rage that only a god killer can produce#If god instilled the fear of elevators into me#then I will Install the fear of humans into god

0 notes

Text

https://www.thegearedges.com/

0 notes

Text

Discover how rack and pinion gear edges work to convert rotary motion into linear motion. Learn about gear edge design, functionality, and the role these components play in steering systems and machinery

0 notes

Text

"Gear Edges | Top-Rated Online Store for Machinery Parts"

"Shop Gear Edges for high-quality machinery parts. Browse a vast selection of gears, drives, and mechanical components with reliable service and affordable pricing. Your trusted source for industrial parts."

0 notes

Text

Discover High-Quality Bearings for Smooth Industrial Operations – Ambica Traders

Ambica Traders stands tall as a reliable and innovative provider of industrial components, catering to the diverse needs of businesses across India. As leading bearing manufacturers in India, we specialize in producing high-quality bearings that are crucial for the smooth operation of various machinery and equipment. Our bearings are crafted with precision and durability in mind, ensuring optimal performance and reliability in demanding industrial environments.

When it comes to industrial applications, having the right components is essential. Ambica Traders excels as industrial bearing suppliers, offering a wide range of bearings designed to meet the specific requirements of different industries. Our commitment to quality and excellence sets us apart as a trusted partner for businesses seeking reliable and efficient industrial bearings.

Top-Notch Couplings to Ensure Seamless Operation in Heavy Machinery

As a coupling manufacturer in Ahmedabad, Ambica Traders prides itself on delivering top-of-the-line couplings that facilitate seamless power transmission and rotation in machinery. Our couplings are engineered to withstand heavy loads and harsh operating conditions, providing essential connectivity and efficiency in industrial processes.

For businesses in need of reliable rack and pinion suppliers, Ambica Traders offers a comprehensive selection of rack and pinion systems designed to optimize movement and precision in various applications. Our rack and pinion solutions are crafted with attention to detail and quality, ensuring smooth and accurate motion control for enhanced operational efficiency.

At Ambica Traders, we understand the importance of precision-engineered components in enhancing productivity and performance. Whether you require bearings, couplings, or rack and pinion systems, our expertise and commitment to excellence guarantee that you receive top-notch industrial solutions tailored to your specific needs.

#rack and pinion suppliers#coupling manufacturer in Ahmedabad#industrial bearing suppliers#bearing manufacturers in India

1 note

·

View note

Text

Are you experiencing any steering problems?

It could mean there’s an issue with your vehicle’s rack and pinion. This component is connected to the steering knuckles, which turn the steering wheel left or right.

We installed a new one on a Honda Odyssey. Our technician determined that it needed to be replaced when he noticed it was leaking.

This is a good reason why you should have the rack and pinion inspected.

#steering problems#rack and pinion problems#honda odyssey#steves auto repair and tire#prince william county virginia

0 notes

Text

"Rack and Pinion Gear System: Mechanism, Applications, and Benefits"

A mechanical gear arrangement called a rack and pinion is used to transform rotational motion into linear motion. Its two primary parts are a pinion, a circular gear that meshes with the teeth of the rack, and a rack, a straight gear with teeth. Steering mechanisms, machinery, and other applications needing precise motion control frequently use this technology. Because of its effectiveness, robustness, and seamless functioning, the rack and pinion mechanism is crucial to industrial machinery, robotics, and automotive steering systems. Learn how this straightforward yet effective gear arrangement improves performance and supports a variety of mechanical processes.

0 notes

Text

Understanding the Mechanics of Rack and Pinion Bellows

The rack and pinion bellows have a significant role in many vehicles. They offer a shielding effect against dirt and moisture for the steering system. Wearing the following components can cause a great amount of trouble. In this blog, the operation principle of rack & pinion bellows, the work of rack & pinion bellows/rack and pinion boot, and the reason they are important to vehicle performance will be discussed.

What Are Rack & Pinion Bellows?

A rack and pinion bellow is an elastic outer cover that is placed over the steering rack. It acts as a shield against contaminants. Bellows are typically constructed of rubber or otherwise robust materials. They protect the steering parts from dirt, dust and moisture. This environment helps ensure the quality of the grease within the steering system. Ambient dirt may intrude without appropriate protection, leading to wear and tear of the components.

How Do Rack & Pinion Bellows Work?

The mechanism of the rack and pinion boot is rather straightforward. When the steering wheel is rotated, the steering rack moves in the direction of the rotation and back. This movement needs to be smooth for proper handling. The bellows offer this motion while still keeping them shielded. Since the components of the steering system move, the bellows expand and contract. This has all been unavoidable in order to preserve the steering system's function.

In addition, the bellows function to lubricate the grease contained in the rack. Grease is vital for reducing friction between moving parts. If dirt/dust enters the system, it can get mixed in with the oil to form sludge. This sludge has the potential to cause increased wear on the rack gears.

Why Are Rack & Pinion Bellows Important?

Rack & pinion bellows are an important safety and performance element of the vehicle. Here are some reasons why they are important:

Protection Against Contaminants: The main job of the bellows is to prevent debris and moisture from entering the steering mechanism. This protection helps ensure that all components remain clean.

Prevention of Wear: By excluding contaminations, a bellows avoids the early wear on the most critical components such as gears and levers.

Smooth Operation: When the whole system is clean and well-lubricated, the steering system moves without any noise. This smooth operation enhances the overall driving experience.

Cost-Effective Maintenance: Repairing or replacing damaged elements comprising the steering mechanism is a much more expensive task than, for example, replacing worn-out bellows. Regular checks can save money in the long run.

Safety: A well-functioning steering system is vital for safe driving. If any element of this system is defective, it may result in the loss of vehicle control.

Common Issues with Rack & Pinion Bellows

Rack & pinion bellows can, over time, suffer from various problems:

Cracking: Rubber can be damaged by heat, ultraviolet (UV) radiation, or chemicals. Once cracked, they lose their ability to protect.

Tears: Mechanical damage by road debris or poor installation leads to tears in material.

Wear: As a person ages, these bellows can be worn down by repeated vibration.

If the following problems occur, they must be dealt with in a timely manner. To avoid them, however, can result in more serious problems of the steering system.

How to Replace Rack & Pinion Bellows?

When wear is detected on the rack & pinion bellows, they must be replaced at once. Here’s a simple guide on how to do it:

Lift the Vehicle: Start by safely lifting your vehicle using jack stands.

Remove Wheels: Remove the front wheel to have easy access to the steering parts.

Remove Old Bellows: Carefully detach the old bellows from both ends of the steering rack.

Install New Bellows: Slide new rack and pinion bellows into place.

Secure Everything: Clamps or ties that tightly confine the ends of the new bellows on both sides.

Reinstall Wheels: Put your wheels back on and lower your vehicle.

Test Drive: After replacing them Go for a short drive in your car to verify that all is functioning properly.

If you’re unsure about doing this yourself, consulting a professional mechanic is always a good idea.

Custom Made Bellows for Unique Applications

There are also cases when standard rack & pinion bellows are not ideal for some applications perfectly. In such cases, custom made bellows become essential. These uniquely configured parts are intended to address special needs that are not available through off-the-shelf components.

Tailorable in bellows size, shape, and material in accordance with specific applications or environmental conditions. For instance, if a vehicle operates in extreme temperatures or harsh environments, custom rubber bellows can be designed to withstand those conditions effectively.

When looking for custom solutions, it’s best to consult with manufacturers who specialize in this area. They can be used in such a way that they can offer very useful information regarding the choice of materials and design requirements best fitted to your requirements.

Choosing Custom Rubber Bellows

At the time of choosing customized rubber bellows for your vehicle or machinery, pay attention to the following:

Material Quality: High-quality materials should be used in the production of customized rubber bellows.

Design Specifications: Discuss your specific requirements with manufacturers so they can create products that meet your needs perfectly.

Manufacturer Reputation: Choose a manufacturer with a solid reputation for producing reliable products.

Cost Considerations: While custom solutions may cost more upfront, they often save money in maintenance over time due to their durability.

Custom Rubber Bellows is a company offering high-quality manufacturing of custom-made bellows to meet a wide range of industry applications. They are concerned with the development of products to give the best possible performance and, at the same time, the best possible protection for the machinery components.

Conclusion

Memorizing what rack and pinion bellows are is important to anybody who cares about maintaining or optimizing a vehicle. In the same way, it is a crucial factor for steering systems to be kept clean of contaminants and thus smooth operation over time and smoother moving objects in general.

Regular checks on these parts can prevent costly repairs down the line while enhancing safety during driving experiences as well as overall satisfaction with vehicle performance. If you find yourself needing replacements or custom solutions tailored specifically for your application needs, consider reaching out to professionals who specialize in manufacturing quality products like Custom Rubber Bellows to ensure you receive exactly what you need for optimal functionality!

For inquiries regarding custom solutions or the following bellow products, please contact Custom Rubber Bellows at (647)294-5240 or [email protected]

0 notes

Text

instagram

Choose from floating or trunnion mounted designs, available in 1, 2, or 3-piece configurations and even 3-way L/T port options. We adhere to industry standards like API 6D, ISO 17292, ASME B16.34, and API 607, ensuring exceptional reliability. Select from soft or metal seated options, and choose manual, actuated (rack & pinion, scotch yoke, electric), or gear operated configurations for a perfect fit. Upgrade your flow control with Freture Techno's high-performance ball valves.

#API 6D#Ball Valve#Trunnion Mounted Ball Valve#ASME B16.34#Gear Operated#Rack and Pinion#freturetechno#manufacturers#mumbai#india#Instagram

0 notes

Text

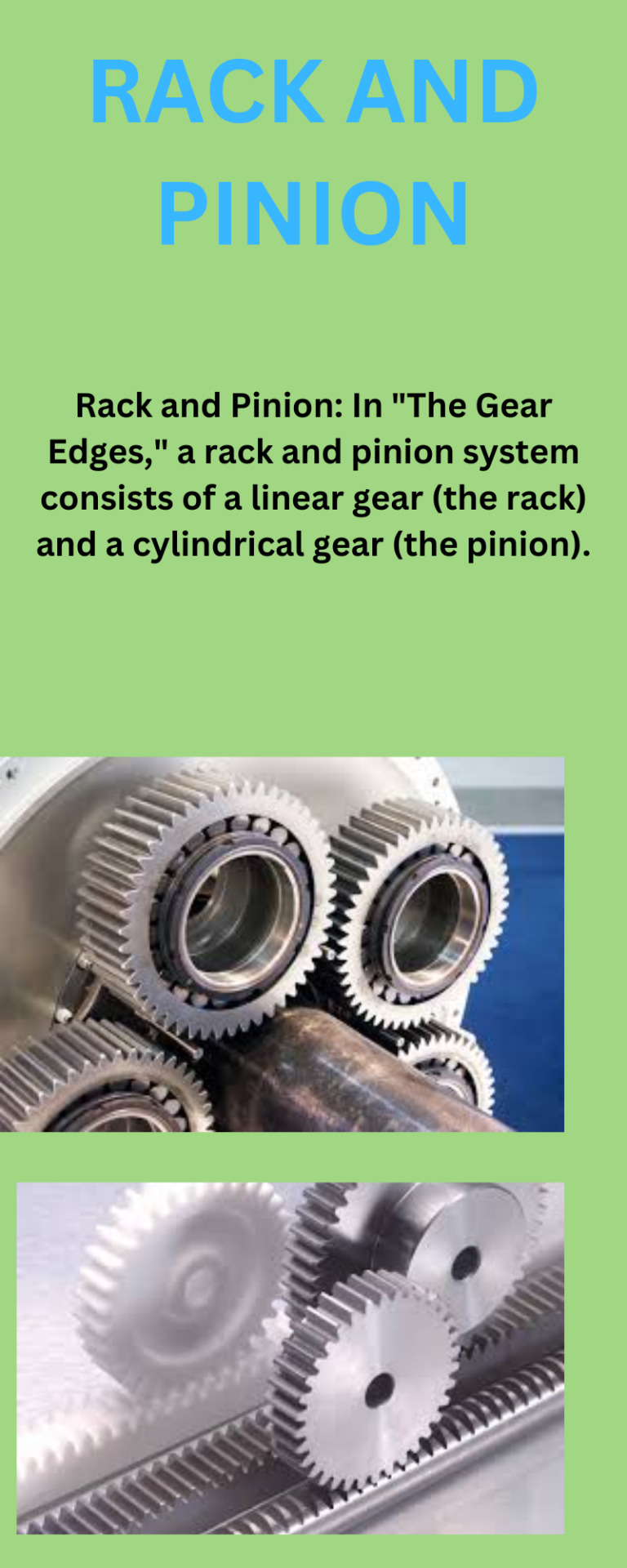

Rack and pinion

https://www.thegearedges.com/

0 notes