#Pharmaceutical Intermediates Market

Text

Varni lifescience is one of the leading pharma intermediate manufacturer in India. Our intermediates are produced using premium quality ingredients. Moreover, they are highly applicable in various industrial and commercial sectors. We offer wide range of best quality intermediates at affordable prices.

#pharmaindustry#pharma intermediate#pharmaceutical#medicine#healthcare#health and wellness#pharma manufacturing#pharma marketing

2 notes

·

View notes

Text

Thermoplastic Polyester Engineering Resins Market is Led by APAC

The thermoplastic polyester engineering resins market was USD 3,912.2 million in 2022, and it will touch USD 5,896.6 million, advancing at a 5.4% compound annual growth rate, by 2030.

The growth of the industry is attributed to the increasing utilization of these resins for various nonstructural applications as they can be utilized without filters and are usually tougher and more ductile than thermoset resins. Furthermore, they are extensively accessible to meet domestic requirements and are easy to recycle. The rising need from the automobile and electronic sectors is also propelling the advancement of the industry.

The polybutylene terephthalate category will advance at a steady rate in the years to come. This is because of the growing requirement for PBT in the electrical and automobile sectors. PBT has unique features, including heat resistance, semi-crystalline, and lightweight, because of which conventional materials including bronze, ceramics, and cast iron in the automotive sector are getting replaced.

In 2022, the automotive category, based on application, led the thermoplastic polyester engineering resins market, with 40% share, and it will remain leading in the years to come. The automotive sector has gained momentum, over the past few years, and key manufacturers of automobiles are utilizing thermoplastic polyester to produce parts of vehicles, which benefits them to lessen the overall weight of the automobiles.

North America is likely to observe significant growth in the years to come. This is primarily because of the mounting need for recycled plastics, the existence of major players, and the growing emphasis on fuel-efficient vehicles, because of which manufacturers are extensively utilizing TPER to make their automobiles lightweight.

With the mounting utilization of such resins for numerous industrial applications, the thermoplastic polyester engineering resins industry will continue to advance in the years to come.

#acetic anhydride market#chemical industry#industrial applications#acetic anhydride production#market analysis#chemical compounds#acetic anhydride uses#pharmaceutical intermediates#chemical synthesis#chemical innovation

0 notes

Text

#pharmaceutical intermediates market report#pharmaceutical intermediates market growth#pharmaceutical intermediates market forecast#pharmaceutical intermediates market trends#pharmaceutical intermediates market analysis#pharmaceutical intermediates market size#pharmaceutical intermediates market share

0 notes

Text

Exploring the Global Aldehydes Market: Key Players and Market Dynamics

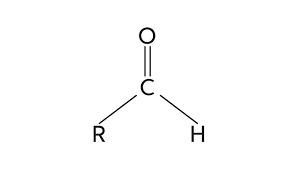

The aldehydes market is a segment of the chemical industry that deals with the production and distribution of a class of organic compounds known as aldehydes. These compounds are characterized by the presence of a carbonyl group (C=O) bonded to a hydrogen atom and a carbon atom in their chemical structure. Aldehydes find widespread applications in various industries, thanks to their unique properties and versatile reactivity.

In terms of market overview, the aldehydes market has been experiencing steady growth in recent years. This growth can be attributed to the increasing demand for aldehydes in industries such as pharmaceuticals, agriculture, food and beverages, and cosmetics. Aldehydes serve as crucial intermediates in the synthesis of various chemicals and are essential in the production of fragrances, flavor enhancers, and pharmaceuticals.

The growth in the aldehydes market industry can be primarily attributed to the expansion of these end-user industries. For instance, the pharmaceutical industry relies heavily on aldehydes for the synthesis of a wide range of drugs and active pharmaceutical ingredients (APIs). Additionally, the food and beverage industry utilizes aldehydes for flavor enhancement and preservation purposes, further driving market growth.

The aldehydes market is also influenced by evolving industry trends. One significant trend is the increasing emphasis on green chemistry and sustainable practices. Many companies in the aldehydes sector are adopting environmentally friendly production processes, such as catalytic hydrogenation, to reduce the environmental impact of their operations. This trend aligns with the growing awareness of environmental issues and the need for more eco-friendly chemical manufacturing.

Another noteworthy trend is the constant innovation and development of novel aldehyde derivatives with enhanced properties. This innovation is driven by the demand for higher-quality products in various industries. Researchers and manufacturers are continuously exploring new applications and synthesizing aldehydes tailored to meet specific industry requirements, which contributes to market expansion.

In conclusion, the aldehydes market is a dynamic segment within the chemical industry, driven by the increasing demand from various end-user industries. As industries continue to grow and evolve, the market is expected to witness further advancements, particularly in sustainable production methods and novel aldehyde derivatives, to meet the changing needs of consumers and businesses alike.

2 notes

·

View notes

Text

Industrial, Cleaning, Oil Field, Water treatment, Painting, Food, Mining, Construction, Power plant, Ceramic Chemicals Dubai, UAE | Coil cutting Service Dubai, UAE

The chemical industry in Dubai and the United Arab Emirates (UAE) is a vital component of the country's economy, as it is used in a wide range of industries such as construction, manufacturing, and oil and gas. The region is known for its high-quality chemicals, which are exported to various countries worldwide. However, with so many chemical suppliers in the market, it can be challenging to find the right one that meets your needs. This is why it is important to have a reliable and trustworthy chemical supplier that you can count on for all of your chemical needs.

In this blog post, we will discuss the role of chemical suppliers in Dubai and the UAE, the factors to consider when selecting a chemical supplier, and key players in the chemical supplier market. We'll also give tips on how to research and compare chemical suppliers in the region, so you can make an informed decision when choosing the right supplier for your business.

The role of chemical suppliers in Dubai and the UAE

The role of chemical suppliers in Dubai and the UAE is to provide a variety of chemical products to different industries in the region. These products include raw materials, industrial chemicals, and specialty chemicals that are used in a wide range of applications.

Construction industry is one of the major industries that rely on chemical suppliers in Dubai and the UAE. These chemicals are used in the production of construction materials such as cement, concrete, and asphalt. They are also used in the construction process, for example, as a waterproofing agent, fire-resistant coating, and for surface treatment.

Manufacturing industry is another sector that heavily depends on chemical suppliers. Chemicals are used in the production of various products such as plastics, textiles, and pharmaceuticals. These chemicals play a crucial role in the manufacturing process, as they are used as raw materials, catalysts, and intermediates.

Oil and gas industry is also a major user of chemicals. In the exploration, production, and refining process of oil and gas, various chemicals are used. These chemicals are used for drilling, production enhancement, and refining process.

Specialty chemicals are also an important part of the chemical industry in Dubai and the UAE. These chemicals have specific properties and are used for specific applications, such as in the food and beverage industry, personal care products, and agriculture.

In summary, chemical suppliers in Dubai and the UAE play a crucial role in supplying a wide range of chemicals to various industries, which in turn, enables the smooth functioning of these industries, and contributes to the overall economic growth of the region.

Choosing a chemical supplier in Dubai and the UAE

Choosing a chemical supplier in Dubai and the UAE can be a challenging task due to the large number of suppliers in the market. However, by considering the following factors, you can ensure that you select a supplier that meets your needs and provides you with high-quality chemicals at a reasonable price.

Quality: The quality of the chemicals supplied is of utmost importance. Make sure that the supplier has a good reputation in the market and that their chemicals meet the required industry standards.

Price: Compare the prices of different suppliers and choose one that offers competitive prices without compromising on quality.

Customer Service: A good supplier should provide excellent customer service, including timely delivery of products and prompt response to any queries or concerns you may have.

Certifications: Ensure that the supplier is certified by relevant authorities and that their chemicals have passed all necessary safety and quality tests.

Product Range: Check if the supplier has a wide range of products, so you can find all the chemicals you need from a single supplier, which can save you time and money.

Location: It is important to consider the location of the supplier, as this can affect delivery times and costs.

Environmental & Safety Consideration: Consider the supplier's environmental and safety policies, to ensure that the supplier is following the regulations and not impacting the environment negatively.

When researching potential suppliers, it is important to read reviews, check their websites, and ask for references from other businesses that have used their services. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs.

Key players in the chemical supplier market in Dubai and the UAE

Dubai and the UAE have a large number of chemical suppliers, but some stand out as key players in the market. Here are a few examples of major chemical suppliers in the region:

Al Rama International: Al Rama International Chemical Suppliers Company in Dubai, UAE. We are Specialized Chemicals Our Service Industrial Chemical, Cleaning Chemical, Oil field Chemical, Water treatment Chemical, Painting Chemical, Food Chemical, Mining Chemical, Construction Chemical, Power plant Chemical, Ceramic Chemical in Dubai, UAE. Al Rama has been a significant player in the G.C.C. & East African chemical trade, for over 20 years. We stock a wide variety of products ranging from food ingredients, oil exploration chemicals, sanitization chemicals, petroleum derivatives and industrial process raw materials. We possess extensive in-house expertise in blending and repacking of various products. Our facilities include open, closed ambient storage, as well as temperature-controlled storage. We operate our own fleet of road tankers, ISO tanks and pick-up trucks, to ensure full supply chain traceability.

Gulf Petrochem Group: Based in Dubai, Gulf Petrochem is a leading supplier of industrial and specialty chemicals in the region. They have a wide range of products, including petrochemicals, base oils, and lubricants. They also have a strong presence in the Africa, Asia, and Europe market.

National Chemical Corporation (NCC): NCC is a well-established chemical supplier based in Abu Dhabi. They have a wide range of products, including specialty chemicals, petrochemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

Emirates National Chemical Industries (ENCI): ENCI is a leading chemical supplier based in Dubai. They have a wide range of products, including petrochemicals, specialty chemicals, and fertilizers. They also have a strong presence in the Africa, Asia, and Europe market.

These are just a few examples of major chemical suppliers in Dubai and the UAE. There are many other suppliers in the market, and it's important to research and compare different suppliers to find the one that best meets your needs.

Conclusion

In conclusion, chemical suppliers play a crucial role in the UAE and Dubai by supplying a wide range of chemicals to various industries. These industries include construction, manufacturing, oil and gas and specialty chemicals. When choosing a chemical supplier in Dubai, UAE, it is important to consider factors such as quality, price, customer service, certifications, product range, location and environmental & safety consideration. The key players in the chemical supplier market in Dubai and the UAE include Gulf Petrochem Group, National Chemical Corporation (NCC), Emirates National Chemical Industries (ENCI), and Al Rama International. By thoroughly researching and comparing different chemical suppliers in Dubai and the UAE, you can make an informed decision and choose a supplier that meets your needs and helps you to run your business efficiently.

#Chemical Suppliers#Industrial Chemicals#Cleaning Chemicals#Oil Field Chemicals#Bulk Chemicals#Water Treatment Chemicals#Painting Chemicals#Food Chemicals#Mining Chemicals#Construction Chemicals#Ceramic Chemicals#Powerplant Chemicals#Coil Cutting Service

2 notes

·

View notes

Text

Diamino Sulfanilide Prices | Pricing | Trend | News | Database | Chart | Forecast

Diamino Sulfanilide, a key chemical compound used in various industries, has seen significant fluctuations in pricing due to several global factors. Understanding the pricing dynamics of this compound is crucial for businesses that rely on it for manufacturing processes, especially in the pharmaceutical and dye industries. Over the past few years, the price of diamino sulfanilide has been influenced by a range of economic, environmental, and supply chain factors that have either driven prices upward or led to a decrease in market rates, depending on the region and specific industry demands.

One of the primary determinants of diamino sulfanilide pricing is the cost of raw materials. The manufacturing process of this compound often relies on the availability of aniline derivatives and sulfur-containing reagents, which are susceptible to fluctuations in global markets. Any disruption in the supply of these raw materials, whether due to geopolitical tensions, trade restrictions, or natural resource shortages, tends to have a direct impact on the production cost of diamino sulfanilide. As a result, companies that produce this compound are forced to adjust their prices to reflect the increased costs of procuring raw materials, which, in turn, affect the end consumers and industries that use this chemical.

Get Real Time Prices for Diamino Sulfanilide: https://www.chemanalyst.com/Pricing-data/diamino-sulfanilide-1548Environmental regulations also play a significant role in shaping the price of diamino sulfanilide. Stricter environmental laws in major manufacturing hubs such as China and India, where a significant portion of global chemical production occurs, have led to higher compliance costs. Factories are required to invest in cleaner technologies, reduce emissions, and manage chemical waste more effectively. These additional expenses are often passed on to the buyers in the form of increased prices. Furthermore, shutdowns or temporary suspensions of operations due to regulatory crackdowns on pollution can reduce the overall supply of diamino sulfanilide, causing a scarcity in the market and, consequently, driving prices higher.

The pharmaceutical industry's demand for diamino sulfanilide is another factor that affects its price. As a critical intermediate in the production of various drugs, especially sulfa-based antibiotics, any fluctuations in pharmaceutical production can lead to changes in the demand for this compound. For example, during periods of increased antibiotic production, perhaps due to a rise in infections or the development of new medications, the demand for diamino sulfanilide tends to surge. This increase in demand puts upward pressure on prices, especially if supply cannot be ramped up quickly enough to meet the growing needs of pharmaceutical companies. Conversely, during periods when the demand for these drugs declines, prices may stabilize or even decrease slightly as the market adjusts to the reduced consumption.

In addition to the pharmaceutical sector, the dye industry also heavily relies on diamino sulfanilide. This compound is used as an intermediate in the synthesis of various dyes and pigments that are applied in textiles, plastics, and other materials. The demand from the dye industry is closely tied to the overall health of the global textile market. When textile production is booming, particularly in countries with large garment industries, the demand for dyes and, consequently, diamino sulfanilide, increases. However, when economic downturns or shifts in fashion trends lead to reduced textile production, the demand for dyes falls, which can lead to a decrease in diamino sulfanilide prices.

Another factor that has impacted the pricing of diamino sulfanilide is the global supply chain disruptions caused by events such as the COVID-19 pandemic. During the pandemic, lockdowns, travel restrictions, and factory closures disrupted the production and distribution of numerous chemicals, including diamino sulfanilide. The resulting supply shortages led to sharp price increases, as businesses scrambled to secure enough of the compound to maintain their production lines. Even as the world has started to recover from the pandemic, lingering supply chain issues, such as container shortages and port congestions, continue to affect the availability and pricing of various chemicals, including diamino sulfanilide.

Transportation costs are another key element in the pricing equation. The cost of shipping chemicals across borders has been on the rise, especially with the increasing cost of fuel and ongoing challenges in global logistics. As transportation expenses grow, manufacturers and suppliers often pass these costs on to their customers, leading to higher prices for chemicals like diamino sulfanilide. This trend is particularly pronounced in regions that rely heavily on imports for their chemical supplies, as they are more vulnerable to fluctuations in shipping rates and fuel prices.

The rise of new manufacturing technologies and alternative production methods could also influence future pricing trends for diamino sulfanilide. Innovations in chemical engineering and green chemistry may allow for more efficient production processes that use fewer raw materials or generate less waste. If such technologies are adopted on a large scale, they could help reduce production costs and stabilize prices, particularly in regions where environmental regulations are stringent. Additionally, advancements in synthetic biology and bio-based chemical production may offer new ways to produce diamino sulfanilide or similar compounds using renewable resources, which could lead to further price reductions in the long term.

In conclusion, the pricing of diamino sulfanilide is shaped by a complex interplay of factors, including raw material costs, environmental regulations, demand from key industries, supply chain disruptions, and transportation expenses. While the price of this compound has experienced fluctuations in recent years, the market is likely to continue evolving as new technologies emerge and global economic conditions change. Businesses that rely on diamino sulfanilide must stay informed about these trends and adjust their procurement strategies accordingly to ensure they can secure this critical compound at competitive prices. By closely monitoring market conditions and remaining adaptable, companies can mitigate the impact of price volatility and maintain steady access to the materials they need for production.

Get Real Time Prices for Diamino Sulfanilide: https://www.chemanalyst.com/Pricing-data/diamino-sulfanilide-1548

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Diamino Sulfanilide#Diamino Sulfanilide Prices#Diamino Sulfanilide News#Diamino Sulfanilide Pricing#Diamino Sulfanilide Supply

0 notes

Text

Arcane Chemicals Pvt. Ltd.: A Rising Star in Chemical Manufacturing

Mahad, Maharashtra – Arcane Chemicals Pvt. Ltd. has swiftly emerged as a major player in the dye intermediate manufacturing sector. Under the visionary leadership of its founder and CEO, Mr. Aditya Patel, the company has achieved remarkable success in just two years. This rapid growth has seen Arcane Chemicals expand its presence not only across India but also into global markets.

The company’s success can be attributed to its strong focus on innovation. Arcane Chemicals is deeply committed to developing new products, staying ahead of industry trends, and continuously evolving its portfolio. This dedication to product development has allowed the company to maintain its competitive edge in the ever-evolving chemical industry.

Looking toward the future, Arcane Chemicals is set to expand into new areas, including pigments, dyes, and pharmaceutical APIs. This diversification will further strengthen its market position and open up new avenues for growth.

With Mr. Patel’s leadership and the company’s unwavering commitment to progress, Arcane Chemicals is well on its way to becoming a prominent name in the global chemical manufacturing industry, demonstrating the potential for local innovation to thrive on an international stage.

Arcane Chemicals Pvt. Ltd. Expands Global Footprint from Mahad

Mahad, Maharashtra – Arcane Chemicals Pvt. Ltd. has quickly become a prominent player in the manufacturing of dye intermediates, achieving impressive growth in just two years. Founded by CEO Mr. Aditya Patel, the company has expanded its reach, building a strong presence in both Indian and international markets.

In a recent interview with Mr. Patel, it became evident that his leadership has been pivotal to the company’s success. His strategic vision is rooted in innovation and continuous product development, key factors that have kept Arcane Chemicals at the forefront of the competitive chemical industry. “We believe in pushing the boundaries of what’s possible, constantly working to innovate and offer products that meet the evolving needs of the market,” Mr. Patel stated.

Looking ahead, Arcane Chemicals is poised for further expansion. The company plans to diversify its portfolio by venturing into new segments, including pigments, dyes, and pharmaceutical APIs. This move signals its intention to explore new markets and solidify its leadership in the chemical sector.

With a strong emphasis on growth, innovation, and global outreach, Arcane Chemicals Pvt. Ltd. is well on its way to becoming a leading force in the chemical manufacturing space, both in India and across the globe.

0 notes

Text

Ethyleneamines Market Analysis: Key Drivers and Regional Trends

The ethyleneamines market has gained significant attention over the past few years. With projections pointing towards steady growth from USD 2.2 billion in 2023 to approximately USD 2.9 billion by 2030, it's clear that ethyleneamines are set to play an even larger role in multiple industries. This article will delve into the market trends, growth drivers, key applications, and much more.

What Are Ethyleneamines?

Ethyleneamines are a group of compounds made primarily from ethylene dichloride and ammonia. They are essential components in various chemical reactions and have a broad range of applications, making them highly valuable in industries like agriculture, personal care, and pharmaceuticals.

Key Drivers Behind the Ethyleneamines Market Growth

The ethyleneamines market is experiencing consistent growth due to several key factors:

1. Increasing Demand in the Agriculture Industry

Ethyleneamines are vital in the production of agrochemicals like pesticides and fertilizers. As the global population continues to grow, the need for enhanced agricultural output is driving demand for these chemicals.

2. Expanding Use in Pharmaceuticals

Ethyleneamines are crucial in the production of several pharmaceutical compounds, including antibiotics and cancer treatments. The global expansion of the pharmaceutical industry is fueling their demand.

3. Rising Demand for Personal Care Products

Products like shampoos, lotions, and creams often contain ethyleneamines, which enhance their properties. The growing consumer awareness and demand for personal care items contribute to the market's growth.

4. Growth in Water Treatment Applications

Ethyleneamines are essential in water treatment processes, where they help remove harmful substances. As governments enforce stricter water treatment regulations, the need for ethyleneamines is on the rise.

5. Increasing Use in Textile Chemicals

Ethyleneamines play a significant role in producing textiles, particularly in dyeing and finishing processes. The textile industry’s rapid growth, particularly in developing countries, is a significant market driver.

Download Sample Report @ https://intentmarketresearch.com/request-sample/ethyleneamines-market-3564.html

Market Segmentation of Ethyleneamines

1. By Type

Ethyleneamines come in different forms, each with unique applications:

Ethylenediamine (EDA): Widely used in the manufacture of bleach activators, fungicides, and chelating agents.

Diethylenetriamine (DETA): Used in the production of paper, rubber chemicals, and fuel additives.

Triethylenetetramine (TETA): Common in adhesives, coatings, and corrosion inhibitors.

Tetraethylenepentamine (TEPA): Important for surfactants, lubricants, and various other industrial products.

2. By Application

Agrochemicals: Ethyleneamines are integral in manufacturing herbicides, insecticides, and fungicides.

Pharmaceuticals: Used in the synthesis of active ingredients and intermediates.

Personal Care: Employed in formulating shampoos, lotions, and other cosmetic items.

Textile Industry: Critical for dyeing, softening, and finishing processes in fabric production.

Water Treatment: Used in water purification to remove contaminants and improve water quality.

Geographical Insights

The ethyleneamines market is segmented based on regions:

1. North America

North America remains a dominant player in the global ethyleneamines market, driven by the robust demand in the pharmaceutical and personal care industries. The U.S. and Canada are the key contributors to this market growth.

2. Europe

Europe’s growth is driven by its strong manufacturing sector, particularly in agrochemicals and pharmaceuticals. Countries like Germany and France are leading the market.

3. Asia-Pacific

The Asia-Pacific region is projected to witness the highest growth rate due to the rapid industrialization in countries like China, India, and Japan. Increasing demand for agrochemicals, pharmaceuticals, and textiles in these nations propels the ethyleneamines market.

4. Latin America and Middle East

These regions are expected to see moderate growth, largely due to expanding agricultural sectors and rising water treatment needs.

Challenges in the Ethyleneamines Market

Despite the positive outlook, the market faces several challenges:

1. Environmental Concerns

The production of ethyleneamines can release harmful by-products that may have environmental consequences. Stricter environmental regulations could potentially hinder market growth.

2. Fluctuating Raw Material Prices

The cost of raw materials like ethylene and ammonia can be volatile, impacting the overall cost structure of ethyleneamine production.

3. Intense Competition

The presence of established players in the market makes it highly competitive, which can affect profit margins.

Opportunities for Growth

1. Innovations in Product Development

Research and development into new and more sustainable ethyleneamine products are creating opportunities. Biodegradable and environmentally friendly ethyleneamines could open up new markets.

2. Growing Demand for Green Solutions

The push for sustainable and eco-friendly solutions is driving innovation in industries like agriculture and water treatment, where ethyleneamines can play a role in reducing environmental impact.

3. Emerging Markets in Developing Countries

Developing regions, particularly in Asia-Pacific, present untapped potential. As industrialization increases, so does the demand for ethyleneamines across various sectors.

Access Full Report @ https://intentmarketresearch.com/latest-reports/ethyleneamines-market-3564.html

These companies are involved in expanding their market presence through partnerships, product development, and acquisitions to stay ahead of the competition.

Ethyleneamines Market Forecast (2023–2030)

The ethyleneamines market is projected to grow at a steady rate of 4.2% CAGR from 2023 to 2030. The rise in demand from key industries such as pharmaceuticals, agriculture, and personal care will be the primary growth drivers during this period. Technological advancements in product development will also contribute to this growth.

Conclusion

The ethyleneamines market is poised for sustained growth, with a projected increase in demand across multiple industries. The versatility of these compounds, coupled with expanding industrial applications, makes them essential for various sectors. While challenges such as environmental concerns and raw material costs exist, innovations and growing demand in emerging markets provide ample opportunities for expansion.

FAQs

1. What are ethyleneamines used for?

Ethyleneamines are used in agrochemicals, pharmaceuticals, personal care products, water treatment, and the textile industry.

2. What is driving the growth of the ethyleneamines market?

Growth is driven by the increasing demand for agrochemicals, pharmaceuticals, personal care products, and water treatment solutions.

3. Which region is expected to dominate the ethyleneamines market?

The Asia-Pacific region is expected to witness the highest growth, while North America remains a dominant player.

4. What challenges does the ethyleneamines market face?

Challenges include environmental concerns, fluctuating raw material prices, and intense competition among market players.

5. How is the market forecasted to grow by 2030?

The ethyleneamines market is expected to grow from USD 2.2 billion in 2023 to USD 2.9 billion by 2030 at a CAGR of 4.2%.

Contact Us

US: +1 463-583-2713

0 notes

Text

Dicyclopentadiene (DCPD) Market Analysis: Opportunities and Challenges Through 2034

Dicyclopentadiene (DCPD) is a highly versatile chemical compound derived from the steam cracking of naphtha and gas oils. It is primarily used in the production of high-performance resins, including unsaturated polyester resins (UPR), hydrocarbon resins, and epoxy resins, which find applications across a wide range of industries such as automotive, construction, and electronics. DCPD is also used in specialty chemicals and pharmaceutical industries for its excellent adhesive, chemical resistance, and mechanical properties.

The global DCPD market is poised to experience substantial growth from 2024 to 2034, driven by its increasing application in the production of advanced polymers, adhesives, and chemical intermediates. Its strong performance in various applications positions it as a key material in industrial and consumer goods production.

The DCPD market is expected to grow steadily over the forecast period, driven by robust demand in industries such as automotive, construction, and packaging. With the global shift toward lightweight and high-performance materials, DCPD-based products are becoming more popular due to their mechanical and chemical stability. The growth is further supported by the rising need for energy-efficient construction materials and innovations in polymer science.

For More Details, Request for a Sample of this Research Report: https://www.transparencymarketresearch.com/dicyclopentadiene-market.html

The global Dicyclopentadiene (DCPD) market, valued at USD 810.7 million in 2023, is projected to grow at a CAGR of 5.6% from 2024 to 2034, reaching approximately USD 1.5 billion by the end of the forecast period.

Market Segmentation:

By Service Type:

Production

Distribution

Customization & Application Services

By Sourcing Type:

Direct from Refiners

Secondary Market Distributors

By Application:

Unsaturated Polyester Resins (UPR)

Hydrocarbon Resins

Adhesives & Sealants

Poly-DCPD

Pharmaceuticals

By Industry Vertical:

Automotive

Construction

Packaging

Electronics

Pharmaceuticals

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis: The Asia-Pacific region is anticipated to dominate the DCPD market, driven by rapid industrialization, urbanization, and a booming automotive sector in countries such as China, India, and Japan. North America and Europe are also expected to see steady demand, primarily due to growth in the construction and automotive industries, alongside advancements in polymer technology. In contrast, the Middle East and Africa are projected to experience moderate growth, bolstered by infrastructural development projects.

Market Drivers and Challenges:

Drivers:

Increased Demand in the Automotive Industry: DCPD-based resins are used in the production of lightweight and durable automotive components, helping manufacturers meet stringent emission regulations and fuel efficiency standards.

Growth in Construction and Packaging Sectors: The rising need for high-performance materials in construction and packaging is driving demand for DCPD in producing UPR and other resins.

Advancements in Polymer Technology: The development of new DCPD-based polymers with enhanced properties such as higher chemical resistance and durability is expected to fuel market growth.

Challenges:

Price Volatility of Raw Materials: Fluctuations in the prices of crude oil and natural gas, the primary sources for DCPD, could pose a challenge for manufacturers.

Environmental Concerns: The production and disposal of DCPD-based materials pose environmental risks, leading to regulatory challenges.

Market Trends:

Sustainability Initiatives: There is a growing trend toward developing eco-friendly alternatives to traditional DCPD resins, focusing on reducing their environmental impact.

R&D Investment in High-Performance Resins: Key market players are increasingly investing in research and development to create resins with superior properties, suitable for high-tech industries such as aerospace and electronics.

Emergence of Bio-based DCPD Resins: With the global shift toward greener materials, bio-based DCPD resins are gaining attention as a sustainable alternative in various applications.

Future Outlook: The future of the DCPD market looks promising, with expanding applications in industries such as automotive, construction, and pharmaceuticals. The focus on developing lightweight materials and eco-friendly alternatives will continue to drive innovation. Emerging economies in Asia-Pacific and Latin America are expected to be key growth regions, while the shift toward bio-based materials will open up new market opportunities.

Buy this Premium Research Report: https://www.transparencymarketresearch.com/checkout.php?rep_id=2369<ype=S

Key Market Study Points:

Evaluation of the growing demand for high-performance resins in automotive and construction applications.

Analysis of the impact of raw material price fluctuations on market stability.

Assessment of sustainability trends and the shift toward bio-based DCPD resins.

Regional analysis focusing on emerging markets and their growth potential.

Competitive Landscape: The DCPD market is highly competitive, with key players focusing on expanding their product portfolios and entering new markets. Major companies such as Braskem, Dow Chemical, and ExxonMobil are at the forefront, offering a wide range of DCPD products. Strategic partnerships, mergers, and acquisitions are common as companies seek to strengthen their market position. Additionally, investments in R&D to enhance product performance and reduce environmental impact are gaining traction.

Recent Developments:

Partnerships and Collaborations: Several market players are forming alliances with automotive and construction companies to develop customized DCPD solutions.

Technological Advancements: New technologies are being developed to enhance the polymerization processes for DCPD, improving product quality and reducing environmental footprints.

Sustainability Efforts: Leading companies are investing in sustainable production methods and are launching eco-friendly alternatives to traditional DCPD-based materials.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

international pharma companies

Navigating the Global Pharma Landscape with BIPL

In an industry as dynamic and fast-paced as pharmaceuticals, standing out on the international stage requires more than just readiness—it demands action. At BIPL, we believe in letting our results speak for themselves. For over 15 years, our team has been at the forefront of the pharmaceutical sector, offering specialized expertise and comprehensive solutions that set us apart in the global market.

Experience You Can Rely On

Our extensive experience in the pharmaceutical industry is a testament to our commitment and proficiency. BIPL specializes in the manufacturing of Active Pharmaceutical Ingredients (APIs), impurities, specialty chemicals, and intermediates. This deep-rooted expertise enables us to provide tailored and effective solutions to international pharma companies, ensuring their diverse needs are met with precision.

Comprehensive Sourcing and Marketing Solutions

What sets BIPL apart is our holistic approach to sourcing and marketing solutions. Our robust network of manufacturing plants allows us to offer long-term cooperation, catering to the evolving needs of pharmaceutical companies worldwide. Whether it's sourcing high-quality APIs or developing custom intermediates, we provide end-to-end solutions that streamline processes and drive success.

Strategically Positioned in Hyderabad

Located in Hyderabad, India’s thriving business hub, BIPL is strategically positioned to leverage the region’s advantages. Hyderabad is renowned for its pharmaceutical industry, offering a wealth of resources, infrastructure, and a network of industry professionals. This strategic location enhances our ability to connect with international pharma companies and deliver top-notch products and services efficiently.

Why Partner with BIPL?

Proven Expertise: With over 15 years of experience, BIPL brings a wealth of knowledge and skill to every project.

Customized Solutions: Our ability to provide tailored sourcing and marketing solutions ensures that we meet the unique needs of each client.

Global Reach: Our comprehensive network and strategic location enable us to serve clients worldwide effectively.

For international pharma companies seeking a reliable partner with a track record of excellence, BIPL offers a blend of experience, expertise, and strategic positioning that drives results. We don’t just claim to be ready—we demonstrate it through our actions and outcomes. Partner with us and experience the difference that a dedicated and experienced team can make in achieving your pharmaceutical goals.

0 notes

Text

Understanding Contract Manufacturing Organizations (CMO) in the Pharmaceutical Industry

In the pharmaceutical world, Contract Manufacturing Organizations (CMOs) play a critical role by providing specialized manufacturing services to drug developers. These organizations allow pharmaceutical companies to outsource the production of drugs, from active ingredients to final dosage forms, ensuring efficiency, scalability, and cost-effectiveness. CMOs have become an essential part of the pharmaceutical supply chain, helping both large multinational firms and small biotech startups navigate the complexities of drug manufacturing.

What is a CMO?

A Contract Manufacturing Organization (CMO) is a company that provides manufacturing services to pharmaceutical and biotechnology firms on a contractual basis. These services can range from the production of raw materials, active pharmaceutical ingredients (APIs), and intermediates, to the manufacturing of final dosage forms like tablets, capsules, injectables, or creams. CMOs may also provide packaging, labeling, and distribution services, depending on the agreement.

By partnering with a CMO, pharmaceutical companies can focus on core areas like drug discovery, research, and development, while relying on the CMO’s expertise for efficient and compliant drug production.

Key Services Offered by CMOs

Active Pharmaceutical Ingredient (API) Manufacturing

APIs are the biologically active components of a drug that provide therapeutic effects. API manufacturing is highly regulated and requires sophisticated technology and stringent quality control. CMOs that specialize in API production help pharmaceutical companies meet global standards for safety and efficacy.

Formulation Development

This involves the creation of the drug's final form, whether it's a tablet, capsule, liquid, or injectable. CMOs have specialized teams that develop formulations, ensuring that the drug can be produced at scale while maintaining its stability, bioavailability, and therapeutic effectiveness.

Clinical Trial Manufacturing

CMOs assist pharmaceutical companies in manufacturing small batches of drugs for clinical trials. These batches must meet high-quality standards and be produced under Good Manufacturing Practice (GMP) guidelines, ensuring that trial drugs are safe for human use.

Commercial-Scale Manufacturing

Once a drug has been approved for commercial use, the CMO ramps up production to meet market demand. This often involves large-scale manufacturing capabilities and infrastructure to handle high volumes while maintaining strict quality control.

Packaging and Labeling

CMOs also offer services related to the packaging and labeling of pharmaceutical products, ensuring that they comply with regulatory requirements. Proper packaging is essential to ensure the drug’s stability, and correct labeling provides necessary information such as dosage, storage conditions, and expiration dates.

Regulatory Support

CMOs often provide regulatory expertise, helping pharmaceutical companies navigate complex approval processes in different markets. They ensure that all manufacturing practices meet global regulatory standards, such as those set by the FDA, EMA, and other national agencies.

Why Do Pharmaceutical Companies Use CMOs?

Cost Efficiency

Developing in-house manufacturing capabilities can be extremely expensive, especially for smaller companies or startups. CMOs offer a cost-effective solution by providing established facilities and expertise without requiring a significant upfront investment. This allows pharmaceutical firms to allocate resources more efficiently.

Scalability

The demand for pharmaceutical products can fluctuate, especially in response to unexpected events like pandemics or breakthroughs in drug development. CMOs offer the flexibility to scale production up or down according to demand, helping companies meet market needs without delays.

Access to Specialized Expertise

Drug manufacturing is a highly technical field that requires specialized knowledge in areas like biologics, sterile production, and controlled substances. CMOs provide access to cutting-edge technology, experienced personnel, and facilities that meet stringent quality standards. This expertise helps pharmaceutical companies ensure that their products are manufactured safely and effectively.

Focus on Core Competencies

By outsourcing manufacturing to CMOs, pharmaceutical companies can focus on their core competencies, such as drug discovery and development. This allows them to innovate faster and bring new treatments to the market more efficiently.

Regulatory Compliance

Navigating regulatory requirements can be time-consuming and complex. CMOs, with their experience in complying with various international standards, help pharmaceutical companies meet the necessary guidelines, thus reducing the risk of regulatory delays or rejections.

Types of CMOs

Full-Service CMOs

These organizations offer end-to-end solutions, including everything from API production and formulation development to packaging, labeling, and distribution. They provide a comprehensive solution for companies looking to outsource the entire manufacturing process.

Specialized CMOs

Some CMOs focus on specific services or niches, such as API manufacturing, biologics, or sterile injectable production. Pharmaceutical companies may work with multiple specialized CMOs to meet their specific needs.

Custom Manufacturers

These CMOs provide tailored solutions, creating custom formulations or specialized production processes according to the unique needs of the pharmaceutical company.

Challenges Facing CMOs

While CMOs provide significant advantages, they also face several challenges:

Regulatory Scrutiny: CMOs must ensure that their facilities and processes meet the stringent requirements of regulatory bodies like the FDA and EMA. Non-compliance can result in costly delays or product recalls.

Supply Chain Management: Disruptions in the supply chain, such as shortages of raw materials, can have a significant impact on manufacturing timelines.

Technological Advancements: The rapid pace of technological change in drug production requires CMOs to continually invest in new equipment and processes to remain competitive.

Quality Control: CMOs must maintain high-quality standards across all aspects of production to ensure that the final products meet the required specifications.

Conclusion

Contract Manufacturing Organizations (CMOs) have become an integral part of the pharmaceutical industry, enabling companies to bring new drugs to market more efficiently and cost-effectively. By offering specialized expertise, scalability, and regulatory compliance, CMOs help pharmaceutical firms navigate the complexities of drug manufacturing, allowing them to focus on innovation and patient care. As the pharmaceutical landscape evolves, the role of CMOs is expected to grow, further shaping the future of medicine production.

0 notes

Text

Specialty Chemicals Manufacturing in Hyderabad

Sainor Pharma, a leading name in the pharmaceutical industry, has established a strong presence in Hyderabad as a prominent manufacturer of specialty chemicals. With a focus on innovation and quality, Sainor Pharma has carved a niche for itself in the competitive market of specialty chemicals.

Specialty chemicals are a diverse range of substances used in various industries, including pharmaceuticals, agrochemicals, electronics, and personal care. Sainor Pharma's expertise lies in the development and production of these specialized compounds, catering to the specific needs of different sectors.

Some of the key specialty chemicals manufactured by Sainor Pharma include:

Pharmaceutical intermediates: These are essential components used in the synthesis of various pharmaceutical drugs. Sainor Pharma's intermediates are produced with strict adherence to quality standards, ensuring the safety and efficacy of the final products.

Agrochemical intermediates: These compounds are used in the formulation of pesticides, herbicides, and fungicides. Sainor Pharma's agrochemical intermediates contribute to sustainable agriculture by providing effective solutions for crop protection.

Electronic chemicals: These specialized chemicals are used in the manufacturing of electronic components and devices. Sainor Pharma's electronic chemicals help drive technological advancements and ensure the reliability of electronic products.

Personal care chemicals: These ingredients are used in the formulation of cosmetics, toiletries, and skincare products. Sainor Pharma's personal care chemicals contribute to the development of safe and effective products that meet consumer demands.

Sainor Pharma's commitment to quality, innovation, and customer satisfaction has enabled them to build strong relationships with clients across the globe. With their state-of-the-art manufacturing facilities and experienced team of professionals, Sainor Pharma is well-positioned to continue its growth as a leading manufacturer of specialty chemicals in Hyderabad and beyond.

0 notes

Text

𝐒𝐭𝐫𝐚𝐭𝐞𝐠𝐢𝐜 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬 𝐨𝐟 𝐭𝐡𝐞 𝐁𝐮𝐥𝐤 𝐂𝐨𝐧𝐭𝐚𝐢𝐧𝐞𝐫 𝐏𝐚𝐜𝐤𝐚𝐠𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐅𝐑𝐄𝐄 𝐒𝐚𝐦𝐩𝐥𝐞: https://www.nextmsc.com/bulk-container-packaging-market/request-sample

The 𝐁𝐮𝐥𝐤 𝐂𝐨𝐧𝐭𝐚𝐢𝐧𝐞𝐫 𝐏𝐚𝐜𝐤𝐚𝐠𝐢𝐧𝐠 𝐌𝐚𝐫𝐤𝐞𝐭 is rapidly evolving, driven by the growing demand for efficient and cost-effective packaging solutions across various industries. Here's a deep dive into the key aspects shaping this market:

𝐌𝐚𝐫𝐤𝐞𝐭 𝐎𝐯𝐞𝐫𝐯𝐢𝐞𝐰: Bulk container packaging refers to the packaging solutions used for transporting large quantities of goods. This market includes products like flexible intermediate bulk containers (FIBCs), bulk container liners, and drums, which are essential for industries such as chemicals, food & beverages, pharmaceuticals, and agriculture.

𝐊𝐞𝐲 𝐆𝐫𝐨𝐰𝐭𝐡 𝐃𝐫𝐢𝐯𝐞𝐫𝐬:

𝐑𝐢𝐬𝐢���𝐠 𝐆𝐥𝐨𝐛𝐚𝐥 𝐓𝐫𝐚𝐝𝐞: With increasing globalization, the demand for efficient transportation solutions is rising, boosting the need for bulk container packaging.

𝐒𝐮𝐬𝐭𝐚𝐢𝐧𝐚𝐛𝐢𝐥𝐢𝐭𝐲 𝐂𝐨𝐧𝐜𝐞𝐫𝐧𝐬: The shift towards eco-friendly packaging materials is driving innovation in the market, with companies focusing on recyclable and reusable packaging options.

𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐢𝐚𝐥 𝐄𝐱𝐩𝐚𝐧𝐬𝐢𝐨𝐧: Rapid industrialization, especially in emerging economies, is leading to higher demand for bulk containers, particularly in the chemicals and food sectors.

𝐓𝐞𝐜𝐡𝐧𝐨𝐥𝐨𝐠𝐢𝐜𝐚𝐥 𝐀𝐝𝐯𝐚𝐧𝐜𝐞𝐦𝐞𝐧𝐭𝐬: The market is witnessing significant technological advancements, such as the integration of smart technologies in bulk packaging solutions. These innovations include real-time tracking systems and advanced materials that enhance durability and efficiency.

𝐀𝐜𝐜𝐞𝐬𝐬 𝐅𝐮𝐥𝐥 𝐑𝐞𝐩𝐨𝐫𝐭: https://www.nextmsc.com/report/bulk-container-packaging-market

𝐊𝐞𝐲 𝐏𝐥𝐚𝐲𝐞𝐫𝐬: Various market players operating in the bulk container packaging industry are Interior Packaging Design LLC, Packaging Corporation of America, Myers Industries, Amatech Inc, Dunnage Engineering, Salco Engineering & Mfg, Signode Industrial Group LLC, SaepLast, Mauser Packaging Solutions (BWAY Corporation), Bulk Lift International, Grief Inc., and Berry Global Inc.

𝐅𝐮𝐭𝐮𝐫𝐞 𝐎𝐮𝐭𝐥𝐨𝐨𝐤: The Bulk Container Packaging Market is expected to continue its growth trajectory, driven by the increasing need for safe and efficient transport solutions. Innovations in sustainable packaging and the rising adoption of automation in logistics will further propel market growth.

#bulkpackaging#logistics#sustainability#globaltrade#markettrends#packaginginnovation#supplychain#marketresearch#businessinsights

0 notes

Text

Benzyl Chloride Prices | Pricing | Trend | News | Database | Chart | Forecast

Benzyl Chloride Prices is a key chemical compound widely used across several industries, including pharmaceuticals, agrochemicals, and plastics. The price of benzyl chloride is influenced by several factors, including raw material costs, supply chain dynamics, manufacturing processes, and fluctuations in demand across various end-use industries. Over the years, the market for benzyl chloride has been shaped by global economic conditions, environmental regulations, and geopolitical factors, which in turn affect its pricing.

One of the primary factors that drive the price of benzyl chloride is the cost of its raw materials. Benzyl chloride is primarily derived from toluene, an aromatic hydrocarbon that is widely used in the chemical industry. The prices of toluene, therefore, play a significant role in determining the cost of producing benzyl chloride. When the price of toluene increases, it exerts upward pressure on benzyl chloride prices as manufacturers pass on the increased production costs to their customers. Additionally, the cost of chlorine, another essential input in benzyl chloride production, can also influence the price dynamics. Variations in the supply and demand for chlorine in other sectors such as water treatment and plastics manufacturing can lead to price volatility in benzyl chloride.

Get Real Time Prices for Benzyl Chloride: https://www.chemanalyst.com/Pricing-data/benzyl-chloride-1299

Another important factor that affects benzyl chloride prices is the overall market demand. Benzyl chloride is a versatile chemical, used in the production of a variety of products such as benzyl alcohol, benzyl cyanide, and benzyl quaternary ammonium compounds. These products find applications in a wide range of industries, including pharmaceuticals, agrochemicals, personal care products, and dyes. The growth of these industries significantly impacts the demand for benzyl chloride, thereby influencing its pricing. For example, the pharmaceutical sector has been a major consumer of benzyl chloride due to its use in the production of various drugs and intermediates. With the global rise in demand for pharmaceuticals, particularly in emerging economies, the demand for benzyl chloride has also increased, leading to price hikes in some regions.

Supply chain disruptions can also have a profound impact on benzyl chloride prices. Events such as natural disasters, political instability, or logistical challenges can disrupt the availability of raw materials or finished products. In such cases, the supply of benzyl chloride may become constrained, leading to a rise in prices as buyers compete for limited supplies. Additionally, the COVID-19 pandemic has significantly affected supply chains across the globe, leading to delays in production and distribution, which contributed to price volatility in the benzyl chloride market. With restrictions on movement and temporary shutdowns of manufacturing facilities, the supply of benzyl chloride was affected, causing price fluctuations in various markets.

Environmental regulations and safety standards also play a crucial role in influencing benzyl chloride prices. Benzyl chloride is classified as a hazardous chemical, and its production and transportation are subject to strict regulations in many regions. Compliance with environmental laws and safety standards adds to the cost of production for manufacturers, who often pass on these costs to the end consumer. Furthermore, companies must invest in technologies that minimize emissions and waste during the manufacturing process to meet regulatory requirements, further driving up costs. The stringent environmental policies in regions such as North America and Europe have led to higher production costs for benzyl chloride, which are reflected in its market prices.

Geopolitical factors and trade policies can further influence benzyl chloride pricing. For instance, tariffs and trade restrictions between countries can affect the flow of raw materials or finished products, leading to price fluctuations. Countries that are major producers of toluene or benzyl chloride, such as China, play a significant role in shaping the global market dynamics. Any disruption in production or changes in trade policies in these regions can create ripple effects across the global benzyl chloride market. Moreover, fluctuations in currency exchange rates can also impact the prices of benzyl chloride, especially in regions where the chemical is imported or exported in large quantities. A weaker currency in a major importing region could result in higher prices for benzyl chloride, while a stronger currency might lower the cost of imports.

Technological advancements in the production of benzyl chloride can also influence its pricing. The development of more efficient production processes or the use of alternative raw materials can reduce the cost of production, leading to lower prices for benzyl chloride. Conversely, if new technologies require significant capital investments, these costs may be passed on to consumers, resulting in higher prices. Additionally, advancements in logistics and distribution can help streamline the supply chain, potentially reducing transportation costs and stabilizing prices.

In conclusion, benzyl chloride prices are influenced by a complex interplay of factors including raw material costs, market demand, supply chain disruptions, environmental regulations, geopolitical factors, and technological advancements. As industries such as pharmaceuticals and agrochemicals continue to grow, the demand for benzyl chloride is expected to rise, which could lead to further price fluctuations in the market. Moreover, with increasing regulatory pressure and potential supply chain challenges, benzyl chloride prices are likely to remain volatile in the coming years. Buyers and manufacturers must closely monitor these factors to better navigate the pricing trends and manage their costs effectively.

Get Real Time Prices for Benzyl Chloride: https://www.chemanalyst.com/Pricing-data/benzyl-chloride-1299

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Benzyl Chloride#Benzyl Chloride Price#Benzyl Chloride Prices#Benzyl Chloride Price Monitor#Benzyl Chloride News#Benzyl Chloride Database

0 notes

Text

0 notes