#Pharmaceutical Batching

Explore tagged Tumblr posts

Text

SG Systems Global: Advanced Pharmaceutical Traceability Solutions

SG Systems Global specializes in cutting-edge traceability software tailored for the pharmaceutical industry. Designed to enhance supply chain transparency and compliance, their software solutions help companies effectively track and manage products from manufacturing to distribution. By leveraging innovative technology, SG Systems Global ensures that pharmaceutical companies meet regulatory standards and maintain product integrity, protecting consumers and minimizing the risk of counterfeit products. The company's comprehensive traceability systems streamline operations, improve data accuracy, and foster trust in the global supply chain. SG Systems Global’s dedication to quality and security makes it a trusted partner for pharmaceutical traceability and data management.

#21 Cfr Part 11 Compliance#Pharmaceutical Batching#Pharmaceutical Traceability Software#Pharmaceutical Traceability

0 notes

Text

How ERPNext Enhances Supply Chain Management in the Pharmaceutical Industry

In the fast-paced and highly regulated world of pharmaceuticals, efficient supply chain management is crucial. ERPNext offers a comprehensive solution tailored to meet the unique demands of this industry by streamlining operations, enhancing traceability, and ensuring compliance. Custom modules have been developed to enhance functionality, providing real-time inventory tracking, batch and serial…

#Batch Tracking#ERPNext#Inventory Management#Logistics Management#Pharmaceutical Industry#Production Management#RealTime Inventory#Supplier Management

3 notes

·

View notes

Text

Navigating the complex QP release requirements for pharmaceutical clinical trials in the EU requires local expertise. Our support services ensure compliant and timely batch release, safeguarding your clinical trial participants and data.

#qp release clinical trials#batch release in pharmaceutical industry#qp clinical trials#eu gmp certification#qp gmp#eu qp

0 notes

Text

SerpentCS’s Odoo ERP for Pharmaceutical Industry: Transform Operations

Odoo ERP for Pharmaceutical Industry, powered by SerpentCS, is the ultimate solution for pharma companies navigating rising costs and regulatory demands. With over 13 years as a leading Odoo partner, SerpentCS offers a custom ERP platform that streamlines batch management, inventory control, and quality assurance while ensuring compliance with FDA, EMA, and other regulations. This cloud-based system automates processes like raw material procurement, production, and supply chain management, providing real-time visibility through batch traceability and product packaging features. The inventory module tracks compounds by batch or serial number, preventing stock-outs or overstock, while the CRM and sales tools enhance customer and vendor coordination. Odoo’s quality management module simplifies audits and recalls, ensuring product safety. With comprehensive analytics and KPI dashboards, pharma businesses gain insights to optimize R&D, manufacturing, and distribution. SerpentCS, a CMMI-appraised company, delivers scalable Odoo ERP for Pharmaceutical Industry solutions trusted globally by manufacturers, distributors, and retailers. Contact SerpentCS at [email protected] to schedule a demo and see how this ERP can reduce costs and boost productivity in your pharma operations.

#Odoo ERP for Pharmaceutical Industry#SerpentCS#Pharmaceutical ERP#Inventory Management#Batch Traceability#Regulatory Compliance#Quality Control

0 notes

Text

Batch Fluid Bed Dryers Market Set to Hit $1,593.7 Million by 2035

The global Batch Fluid Bed Dryers market is projected to experience significant growth, rising from $697.6 million in 2024 to $1,593.7 million by 2035. The market is expected to grow at an average annual rate of 10.3% from 2024 to 2035, driven by strong demand across pharmaceutical manufacturing, food processing, chemical processing, and plastics manufacturing industries.

Access detailed report insights here - https://datastringconsulting.com/industry-analysis/batch-fluid-bed-dryers-market-research-report

Key Applications Driving Market Growth

Batch Fluid Bed Dryers play a critical role in several industries due to their ability to provide consistent, efficient, and rapid drying. In the pharmaceutical industry, these dryers are essential for preserving the integrity of sensitive ingredients during the drying process, ensuring higher quality end products. Leading pharmaceutical companies such as Novartis and Pfizer rely on these dryers for their accuracy and reliability, securing a competitive edge in the market.

In the food processing sector, Batch Fluid Bed Dryers are used for their uniform drying capabilities. These dryers help preserve the nutritional value and extend the shelf life of food products. Companies like Nestlé and Kraft Heinz utilize these systems for drying fruits, vegetables, herbs, spices, and coffee beans, benefiting from superior heat transfer and moisture removal.

Technological Advancements and Market Innovation

Technological advancements have significantly impacted the Batch Fluid Bed Dryers market, particularly in pharmaceutical and food processing sectors. Modern fluid bed dryers now offer enhanced efficiency, reduced energy consumption, and improved output quality. These innovations enable superior drying uniformity, moisture removal, and particle size reduction, making them ideal for drying powders and granules.

The integration of automation into these systems has optimized the drying process, ensuring consistent quality output while reducing human error. As a result, the Batch Fluid Bed Dryers market has seen substantial growth, driving productivity improvements, reducing resource wastage, and lowering production costs, which in turn boosts profitability and sustainability.

Industry Leadership and Competitive Landscape

The Batch Fluid Bed Dryers market is highly competitive, with key players such as GEA Group AG, Andritz AG, Bühler Holding AG, Glatt GmbH, FLSmidth & Co. A/S, ThyssenKrupp AG, and SPX Flow Technology Danmark A/S leading the market. These companies are driving innovation by focusing on developing advanced solutions for fluid bed drying technology, customizable dryers, energy-efficient designs, and automation to improve performance and reduce operational costs.

The market’s growth is supported by shifting trends in pharmaceutical manufacturing, the expansion of chemical industries, and continuous technological advancements in fluid bed drying systems. As demand for efficient and precise drying solutions continues to rise, industry players are positioned to capitalize on significant growth opportunities.

Regional Analysis and Market Dynamics

North America remains a dominant player in the Batch Fluid Bed Dryers market, driven by robust industrial growth and technological advancements in drying systems. The pharmaceutical and food processing sectors, in particular, offer substantial opportunities due to their ongoing demand for high-efficiency drying solutions.

Key drivers in the region include stringent regulatory standards focused on quality and safety in production, along with a growing preference for sustainable and energy-efficient equipment. Europe and China are also strong contributors to market growth, with significant demand from local industries and manufacturers focusing on improving productivity and sustainability.

As these regions continue to expand, emerging markets in India, Brazil, and South Africa are expected to become increasingly important, offering new revenue opportunities for manufacturers seeking to diversify their portfolios and expand their total addressable market (TAM).

About DataString Consulting

DataString Consulting offers a comprehensive suite of market research and business intelligence solutions for both B2C and B2B markets. Specializing in bespoke research projects, the firm helps businesses achieve their strategic objectives, whether it’s expanding into new markets, increasing revenue, or addressing industry challenges.

With over 30 years of combined experience, DataString’s leadership team is well-versed in market & business research and strategy advisory across diverse sectors globally. Their expert consultants track high-growth segments within more than 15 industries and 60 sub-industries, providing actionable insights and data-driven strategies to help businesses thrive in competitive markets.

#Batch Fluid Bed Dryers#Market Growth#Pharmaceutical Manufacturing#Food Processing#Chemical Processing#Energy-efficient Drying Systems#Technological Advancements#Automation in Drying#Global Market Analysis#Industry Leadership#Competitive Landscape#Regional Market Dynamics#Sustainable Equipment#DataString Consulting

0 notes

Text

How VJ Instruments' Rapid Mixer Granulator Streamlines the Granulation Process

For pharmaceutical manufacturers and research facilities, it has always been a tightrope walk between getting consistent quality granules while not compromising on efficiency. The granulation process, of course, is critical for tablet manufacturing, often becoming the bottleneck in manufacture pipelines. This is where VJ Instruments' Rapid Mixer Granulator (RMG) comes into play, revolutionizing the approach to pharmaceutical granulation.

Understanding Modern Granulation Challenges

Pharmaceuticals are still being put to great tests in their granulation process:

Poor reproducibility of particle size

Long process times, which have a direct bearing on production time

High energy consumption, with difficult cleaning and maintenance procedures

Variable quality of end products

These challenges are not just about production times but directly affect the final product's quality and uniformity. This highlights the need to choose quality granulation equipment for pharmaceutical industries.

VJ Instruments: Engineering Excellence Meets Practicality

The VJ Instruments' Rapid Mixer Granulator stands out due to its innovative approach to design, overcoming pain points in granulation while introducing new efficiencies into the process.

Advanced Mixing

One of the core parts of the system is the three-zone mixing chamber, which includes:

Primary mixing zone with optimized blade geometry

Secondary zone of high shear for uniform particle size

Tertiary zone of homogenization for uniform distribution

This triple-zone design allows for complete mixing while protecting sensitive materials with delicate handling—a task that traditional equipment rarely accomplishes.

Intelligent Process Control System

The RMG comes equipped with:

Real-time monitoring of critical parameters

Automatic adjustments to mixing speeds

Accurate granulation end-point detection

Data logging to support batch consistency and regulatory compliance

Time-Saving Design Features

Innovative features of the RMG reduce processing times, such as:

Quick-release bowl design for easy and fast cleaning

Tool-less assembly and disassembly

Automated cleaning systems

Smooth and easy product transfer

Performance Metrics That Matter

The VJ Instruments RMG delivers measurable improvements:

40% reduction in granulation time compared to traditional methods

25% reduction in power consumption

99.9% batch-to-batch consistency

60% faster clean down between batches

Quality Assurance Built In

Every aspect of the RMG design focuses on product quality:

GMP-compliant materials

Proven cleaning procedures

Comprehensive documentation package

Control system compliant with 21 CFR Part 11

Practical Applications and Versatility

The system excels in a variety of applications, including:

Wet granulation for immediate-release tablets

Dry granulation for moisture-sensitive formulations

Multi-layer tablet preparation

Formulation processing of modified release formulations

Industry-Specific Adaptations

VJ Instruments offers custom solutions for:

Research and development laboratories

Pilot-scale manufacturing facilities

Full-scale manufacturing operations

Contract manufacturing organizations

ROI and Operational Benefits

Investing in VJ Instruments' RMG means actual savings:

Minimized labor costs through automation

Reduced material waste

Improved product quality

Increased capacity

Reduced maintenance

Sustainability Features

VJ Instruments prioritizes environmental awareness along with operational productivity:

Energy-saving motors and drives

Water-saving cleaning systems

Minimized waste generation

Recyclable component materials

Support and Service Excellence

VJ Instruments provides comprehensive support with:

Installation and commissioning support

Operator training programs

Preventive maintenance schedules

24/7 technical support

Regular software updates

New Equipment Transfer

Acquiring new equipment involves extensive planning. For VJ Instruments, here's what they provide:

Implementation roadmap with detailed analysis

Validation-support documentation

Process transfer assistance

Training materials and resources

Quality assurance protocols

The Future of Pharmaceutical Granulation

Despite changes in the pharmaceutical industry, VJ Instruments’ RMG is designed to face all challenges that the future may bring. Modular designs and easily upgradeable components make this product not only a solution for today but also an investment in tomorrow's manufacturing capabilities.

Need a Change in Your Granulation Process?

How can VJ Instruments' RMG Rapid Mixer Granulator optimize your pharmaceutical manufacturing operations? Contact our Technical Team for a FREE PERSONALIZED CONSULTATION and DEMONSTRATION on how our RMG can meet your specific production needs.

#Rapid Mixer Granulator#pharmaceutical granulation#high-efficiency granulation machine#batch consistency in granulation#VJ Instruments

0 notes

Text

Unlocking Efficiency and Compliance with Electronic Batch Records

The requirement for simplified procedures and strong regulatory compliance has never been more crucial in the ever-changing environment of the manufacturing and pharmaceutical sectors. Electronic Batch Records (EBRs) arise as a game changer, revolutionizing how enterprises manage and document their manufacturing operations. In this blog, learning about what they are, how they work, and how they're changing the future of manufacturing. Development of Batch Records

Batch records were traditionally paper-based documentation that documented the phases of a manufacturing process. These records were not only difficult to handle, but they were also disposed to to mistakes, inefficiencies, and compliance problems. It was a difficult undertaking to keep these records up to date, retrieve past data, and ensure compliance with changing regulations. Electronic Batch Records: A Switchover

Introduction of Electronic Batch Records signaled a revolution in how industry managed their production operations. EBRs replace stacks of paper with digital records, which has various advantages.

EBRs remove the risk of human mistakes associated with manual data entry, resulting in increased accuracy and efficiency. Data gathering and validation methods that are automated ensure that information is correct and up to date. This results in fewer manufacturing mistakes, less waste, and more efficiency.

With EBRs, you can monitor manufacturing processes in real time. This not only allows for speedier decision-making but also gives significant insights into the manufacturing workflow. Managers can quickly identify bottlenecks and inefficiencies and implement remedial actions.

Compliance with industrial rules is of the utmost importance. EBRs make compliance easier by automatically recording each stage of the manufacturing process, ensuring that all necessary data is gathered and securely preserved. This makes audits and regulatory inspections easier.

EBRs make it simple to retrieve past data. This is extremely useful for tracking product quality, investigating issues, and continuously improving. It also makes it easier to generate batch-related reports.

Collaboration across teams in various places is frequent in today's globalized environment. EBRs provide remote access and collaboration, allowing teams to collaborate effortlessly regardless of their geographical location.

Implementing Electronic Batch Records

EBR implementation necessitates careful planning and technological investment. The following are important goals in the implementation process:

Choosing the Right Software: Select EBR software that meets the demands and regulatory standards of your sector. Scalability should be considered to support future expansion.

Training: Provide training to your workers to guarantee they can utilize the EBR system properly. This involves knowing how to enter data, monitor operations, and fix problems.

Transferring data from paper-based records is referred to as data migration.

Process XE is web based, flexible and user-friendly software solutions for Business process automation.

For more details on MES, Contact our sales team. <Book A Demo>

0 notes

Text

Timeline | The Leaders

"you need darkness to step out of the darkness."

1941-1943:

Birth years of the Crescents and Luna (1942)

1953:

President Son Seokku’s first presidential term begins

1958:

Pres Son Seokku’s second presidential term begins

Battle of the Eight Hills begins

1960:

Military enforces the 'over-17' law which ensures all 'capable' individuals must enlist and serve in the war, resultantly clashing with President Son

Ateez get drafted at ages 19, 18 and 17

1961:

Luna enlists as a Medical Assistant, aged 19

Elsewhere, Hongjoong comes upon a batch of silver light

1962:

Luna comes across Mingi in early 1962 since they share the same platoon

Treaty of the Eight Hills on September 10th ends the war

Ateez come together as a gang and partner with MX to ensure order in the sectors and begin to rebuild Eden

1963:

Luna comes across Han Hyojoo at a party hosted at Park Byung Eun's mansion to celebrate Lee Jinwook's debut into politics (Lee Jinwook is Han Hyojoo's husband)

Luna gets sent to Wonderland

President Son’s term concludes

Han Hyojoo becomes the president

1964:

Ateez become a formal organisation and make more connections, especially in the underworld, as rebuilding of Eden continues

1966:

Luna comes back to Eden on 14th August

President Han gets assassinated on 17th August

Sirens Rebel Party is formed in support of President Han

Lee Jinwook wins the elections and his presidential term begins

Ateez partners with Pledis Manufacturers to produce machine parts, and to assemble weapons undercover

Inspector Gong gets demoted and stationed to Sector 1 from Edenary while investigating Han Hyojoo's murder case

1967:

Ateez gets the name 'The Crescent Company' and open their first office in Sector 1

Luna starts to work part-time at MX Pharmaceuticals while MX partners with the Crescents

1968:

The Crescent Bar opens in February in Sector 1

Luna gets a cashier job in April at the Crescent Bar

1969:

Luna gets promoted to bookkeeper in the Crescent Bar

1970:

Story begins (ages 29-27), dated 3rd April.

#you're all gonna need this#(i need it more)#a timeline to refer to when things get ✨confusing✨#fic: the leaders#ateez x reader#ateez mafia au#ateez au#ateez series

91 notes

·

View notes

Text

Too Late to Save Them: Frozen in Time

Previous

Part 4

Nathan was ecstatic. Somehow his dad had found this once in a million asteroid on the farm. It was ice, unmelting ice, and his dad was clueless on how to use it.

Nathan knew how to use it.

Quickly, he chipped down. It always grew back to its original size, so why not see how far it went?

. . . That. That was why.

Nathan put in parameters. Only so many inches to be chipped. GO NO FURTHER.

He didn’t want his workers, his investors, ANYONE to see what was in the center of the ice.

A child.

Probably a meta.

A black haired, pale blue, (hopefully) dead child whose body continuously created unmeltable ice.

Ignore it. Create the company. Make millions.

. . .

Tim Drake-Wayne was dealing with a broken arm. Again. Bernard had been very sweet though, and asked him to check up on this company, saying that the company was “hiding something.”

Tim figured it was Bernard's way to distract him, but. . . Bernard was right. Things weren’t adding up.

Forever Ice. Started as an insulated cup company, but quickly went to pharmaceuticals. And jacked up their prices, citing its difficulty to produce and its limited quality per batch.

Did Tim like this? Well, if Forever Ice did what it said it did, yes. But Tim believed in the saying: “If it’s too good to be true, it probably is.”

Tim did what he did best. Researched.

Forever Ice didn’t have a patent for their material. Well. They ‘did’, but Tim’s cursory glance recognized the bullshit inside the patent.

He easily bought one of the cups, broke it (it specifically had a warning on it. To dispose if seal is broken) and checked the innards.

Broken bits of the icy insulant were embedded in the double insulation, and was cool to the touch- COLD to the touch, even through his gloves.

Tim carefully pulled a piece out and tested it.

Whatever Forever Ice was, it wasn’t originally from earth.

It’s cellular structure was. . . well, it wasn’t quite there. Even the bat computer couldn’t pick it up.

Tim stretched in the computer chair. He may have been benched from crime-fighting, but no one said anything about good old detective work.

- - -

Mrs. Freeze- Nora grimaced at the name. She needed to think of a better moniker. She was FREE. no more sick little Ballerina. No more frozen sickly wife. No more.

Victor. . . she had loved him. They were happy. But when she got her diagnosis, Victor had started looking for a cure. Nora wanted to live the rest of her days happy.

She had told him NO.

She thought he had let it go. . .

But their last dinner together, before she woke up as. . . this. . .

He had drugged her meal. She had been aware enough to watch him gently hold her face and promise her. He would find a cure.

He brought her to that horrible machine.

Victor had found a cure. It made her like HIM. Requiring a sub-zero temperature suit to live.

And after he cured her, he wanted them to retire! He had LIVED. She had been suspended. Frozen in time. Before, he’d been two years older than her. But now decades of life had passed her by in that cursed cryo chamber.

Victor had lived, and changed, and aged.

Nora hadn’t.

And apparently during her frozen slumber, Victor had gotten an idealized version of her in his head.

The Real Nora and the idyllic Nora had some similarities: Ballerina. Wife. Illness. Loving Victor. But they were different. Nora was a ballerina, yes. But that wasn’t her only interest. She was a wife, but she was also a daughter. A friend. An enjoyer of pasta. She had been sick. But she had a life! She had been given a timeline, and she had made a list of things she had wanted to do. She wanted to LIVE with the time given to her. And she had loved Victor. But the two of them weren’t perfect. They had their good days, and their not so good days. They worked through their communication and she had hoped to grow old with him. Before the diagnosis they had thought of. . .

The past was the past.

She had woken up, and she had been angry. Confused. The man in front of her didn’t look like Victor, but sounded like him. He was blue. She would be too. They needed money.

He gave her a weapon and taught her how to fire. How to fight.

This wasn’t the Victor she remembered.

She followed him along, and as they went on their “crime spree”, she began to feel ALIVE again.

And then Victor said they didn’t need to do this anymore, that it was time to retire. Time to find a sweet little place to enjoy the rest of their lives together.

She argued back.

He told her she wasn’t thinking straight. It must be something with the formula. But not to worry, he would fix her.

NO.

Nora didn’t think it was the formula. She was angry, and she had a RIGHT TO BE!

Victor hadn’t understood. He wanted to make her pliant. submissive. Into the Idyllic Nora.

She shook herself out of her memories. It was over.

She wasn’t proud of herself, but she had harmed Victor. To her, it was the only way.

He had proven himself in the past that he would take away her autonomy.

It was the only way to be free.

. . .

Nora wasn’t a scientist, but she wasn’t stupid. The suit Victor had made for her wasn’t self-sustaining and she wasn’t going back to his workshop.

Not while that. . . Batman was around.

But while she was in hiding, she had heard of this Forever Ice.

Perhaps she’d stolen someone’s thermos. Tested it out.

She would be able to replace the bits of her suit with this Ice and then finally, be truly, honestly, free.

Able to make her own decisions. Be freed of Victor. Self-Reliant.

She just needed more.

Part 5

#dpxdc#dcxdp#danny phanton fanfiction#phanfic#too late to save them#Option A: Frozen in time#Enter the DC universe characters!#tim drake wayne#Nora Fries#Red Robin#Mrs. Freeze#References the storyline in Detective Comics Year of the Villain: 1012-1016.

95 notes

·

View notes

Text

Future Trends in Pharmaceutical Traceability Software: Innovations on the Horizon

The pharmaceutical industry is on the cusp of a digital transformation, with emerging technologies reshaping the way companies manage the safety, quality, and traceability of drugs. At the core of this evolution is pharmaceutical traceability software, which allows manufacturers to track and monitor the movement of products and raw materials across the entire supply chain. With growing regulatory demands and the need for better transparency, pharmaceutical companies must keep pace with innovations that enhance product safety and compliance.

In this blog, we’ll explore the future trends in pharmaceutical traceability software that are set to revolutionize the industry, enabling pharmaceutical companies to meet stringent compliance standards like 21 CFR Part 11, improve operational efficiency, and ensure the safety of their products.

Why Traceability in Pharmaceuticals Matters

Before diving into the future trends, it’s crucial to understand why pharmaceutical traceability is so essential. In the pharmaceutical industry, product safety and quality are paramount. Traceability ensures that every batch of drugs can be traced back to its source, from raw materials to the final product. This is not only important for ensuring the integrity of the product but also for managing recalls, reducing counterfeit drugs, and complying with global regulatory standards.

With regulations such as 21 CFR Part 11 Compliance, which governs the use of electronic records and signatures in the U.S. Food and Drug Administration (FDA) regulated industries, pharmaceutical companies are under pressure to implement robust traceability systems. Compliance with this regulation ensures that electronic records are trustworthy, reliable, and equivalent to paper records. Effective pharmaceutical traceability software is essential to achieving this.

Now, let’s look at the future trends that are shaping the next generation of pharmaceutical traceability.

1. Blockchain Technology for Immutable Records

One of the most exciting innovations on the horizon for pharmaceutical traceability software is the integration of blockchain technology. Blockchain’s ability to create a decentralized, immutable ledger makes it a perfect fit for industries that rely on highly accurate, tamper-proof data.

In the context of pharmaceutical traceability, blockchain can provide real-time visibility into the entire supply chain. From sourcing raw materials to tracking the distribution of the final product, every transaction is recorded in the blockchain, making it impossible to alter without leaving a trace. This level of security is particularly important for combating counterfeit drugs, which continue to be a significant issue in the industry.

Moreover, blockchain offers enhanced transparency and can help pharmaceutical companies demonstrate compliance with 21 CFR Part 11. By providing an indelible audit trail, it becomes easier to prove the integrity of electronic records, ensuring that all actions taken in the drug manufacturing and distribution process are traceable.

2. AI-Powered Predictive Analytics for Quality Control

As pharmaceutical batching and production processes become more complex, predictive analytics powered by artificial intelligence (AI) is becoming a critical component of traceability software. AI can analyze vast amounts of data in real-time, identifying patterns and trends that might indicate potential quality issues or inefficiencies in the supply chain.

For example, AI can monitor environmental conditions during drug manufacturing or shipping and predict when deviations might occur that could compromise product quality. This predictive capability allows pharmaceutical companies to address issues before they escalate, ensuring that only safe, high-quality drugs reach the market.

Additionally, AI-driven analytics can optimize pharmaceutical formulation software, which is responsible for ensuring that drug recipes are consistently followed. By analyzing data from previous batches, AI can suggest adjustments to formulations or processes to improve product consistency and quality.

3. IoT Integration for Real-Time Monitoring

The Internet of Things (IoT) is another technology that is poised to enhance pharmaceutical traceability. IoT devices, such as sensors and RFID tags, can provide real-time monitoring of pharmaceutical products as they move through the supply chain. These devices can track important parameters such as temperature, humidity, and location, ensuring that drugs are stored and transported under the right conditions.

For instance, biologics and other temperature-sensitive medications require strict temperature control during transportation and storage. IoT sensors can continuously monitor the temperature, providing real-time alerts if it goes outside the acceptable range. This ensures that any temperature excursions are immediately addressed, preventing potentially harmful products from reaching patients.

When combined with pharmaceutical traceability software, IoT data can be seamlessly integrated into the traceability system, offering a comprehensive view of the product’s journey from production to patient delivery. This not only enhances safety but also aids in regulatory compliance by providing detailed documentation for audits.

4. Enhanced Data Security and Privacy Features

As pharmaceutical companies increasingly rely on digital systems for traceability, data security and privacy are becoming critical concerns. With the rise in cyberattacks targeting healthcare and pharmaceutical companies, traceability systems must evolve to offer robust security features that protect sensitive data.

Future pharmaceutical traceability software will likely incorporate advanced encryption techniques, multi-factor authentication, and AI-driven security measures to detect and respond to potential threats in real-time. These features will ensure that all traceability data, including electronic records required for 21 CFR Part 11 compliance, are protected from unauthorized access or tampering.

In addition, data privacy regulations, such as the General Data Protection Regulation (GDPR) in Europe, place strict requirements on how companies handle personal data. Traceability software will need to incorporate tools that allow pharmaceutical companies to manage data privacy effectively, ensuring that any patient or product information is stored and transmitted securely.

5. Cloud-Based Traceability Solutions for Scalability and Flexibility

Cloud computing is set to play a significant role in the future of pharmaceutical traceability software. Cloud-based traceability solutions offer scalability, flexibility, and cost-efficiency, making them an attractive option for pharmaceutical companies of all sizes.

By leveraging cloud infrastructure, pharmaceutical manufacturers can scale their traceability systems as needed, accommodating growing production volumes or expanding into new markets. Cloud-based systems also offer the advantage of remote access, allowing teams across different locations to access traceability data in real-time.

Moreover, cloud solutions can streamline compliance with 21 CFR Part 11 by providing secure, centralized storage for electronic records and signatures. Cloud platforms are often equipped with advanced compliance features, such as automated audit trails and secure data backups, helping companies ensure that they meet regulatory requirements.

Conclusion

The future of pharmaceutical traceability software is bright, with innovations like blockchain, AI, IoT, enhanced data security, and cloud-based solutions set to transform the industry. These technologies will enable pharmaceutical companies to improve product safety, streamline compliance, and increase operational efficiency.

By adopting these cutting-edge technologies, companies can not only meet the ever-growing regulatory demands but also enhance the integrity of their supply chains, ensuring that patients receive safe and effective medications. As these trends continue to shape the future of pharmaceutical traceability, businesses must stay ahead of the curve to remain competitive and compliant in an increasingly complex global market.

#pharmaceutical traceability software#Pharmaceutical Traceability#21 Cfr Part 11 Compliance#Pharmaceutical Batching

0 notes

Text

~wip snip wednesday~

just in the mood to share what i'm working on! 30-something faked-his-own-death NYC lowlife draco...

“Hey, D,” a deep, familiar voice greeted him, though Draco couldn’t put a name to the face of the person who pushed his way through the crowd towards him. When the bulky young man was within distance, he reached out and greeted Draco with a loose, profoundly American handshake. It was a gesture Draco had gotten accustomed to participating in, he replicated its casual intimacy easily. The young man, Draco remembered, was a first-year Social Work student, quite passionate about helping the youth growing up in the same rough part of town that he did. He worked three jobs on top of his full time studies to pay for his tuition. And, apparently, pressed tablets of Draco’s home-brewed uppers. “I hope you’re well,” Draco said pleasantly as he got out an Altoids tin that did not contain any mints. “Surviving,” the young man responded noncommittally. “Are these from the same batch?” “When did I see you last?” Draco asked. He truly had no idea. At this point, every individual day behind him had melted together into a waxy, salty slurry of hedonism and paranoia. “Yesterday,” the man slurred, taking another sip of the beer can clutched in his fist tightly enough to slightly deform the shape of the metal. For a moment, Draco felt bad. The potion he had adapted to create his little money-makers was not meant to be used that frequently. Combined with the muggle pharmaceuticals he used to potentiate the potion, he couldn’t imagine the brew had become any safer. Then again, he’d been high off them for a decade, and he was perfectly fine. “Yes, it’s all the same,” Draco replied, shaking off the guilt as best as he could. “I’ll take two,” the young man requested, “I think it was a weak batch.” Draco shook his head casually as he opened the Altoids tin. He could see his interlocutor’s eyes light up at the sight of so many pills within arms’ reach. As quickly as he could, Draco grabbed out two and dropped them into the man’s waiting palm. “Tolerance is a son of a bitch,” he corrected the man, who didn’t seem to hear him as he rooted around in his jeans for his coin purse. Quickly, he counted out the correct amount of Dragot and paid Draco summarily. “Have fun with it, yeah?” Draco asked as he surreptitiously pocketed the wizarding money in case any muggle eyes were watching. Barriers were so much more loose in the community he had found himself in. It was hard to know who was in the know. Draco watched as his customer downed both pills with a gulp of beer. “Always do, D, thanks,” the student replied politely. “I’m gonna go…” he trailed off drunkenly, unable to think of a better excuse for leaving the moment the deal was done, “Nice chatting.” “The pleasure’s mine,” Draco replied dryly, neither sincere nor insincere. He gave the man a nod as he disappeared back into the crowd. Draco shifted on his feet, and noticed they were tired. He could have something to eat, maybe, if there were chips on a table somewhere in the kitschy, low-budget apartment. He couldn’t remember the last time he’d sat down for some food. Or he could have another pill.

...this inevitably leads to a drarry hookup, naturally

as for tags, @smehur what are you working on??

18 notes

·

View notes

Note

very curious about any dune perfume thoughts you may have

DUNE PERFUME THOUGHTS...

I feel like with all of Ferbert's tropes around effeminate overly-refined decadence there \_really_ needs to be more perfume action among the houses of the Landsraad, even if for no other reason than conspicuous consumption? The olfactive aspect of spice isn't really centered since its other psychoactive/pharmaceutical merits are more valued, but I've been really curious about the mechanism by which spice is ingested, if everybody's either eating it with their food or drinking it in solution or what. (Or, I guess, floating around in it.) Mentally I guess I'd been picturing spice more like an incense resin than an actual spice, but there's no textual justification or actual reason for that other than really liking incense.

Paul and Jessica both seem especially attuned to scent in the first book, linking it to poison detection but also to the presence of spice, which is probably smart when you're backpacking across Arrakis trying not to get blown up or space stabbed. Spice melange in the raw smells like cinnamon, pre-spice mass has a “rank, semisweet" odor, the Baron's private conference room carries a “faint sweet herb scent that hung on the air, masking a deeper musk”... lot going on in there! Idk if we’re supposed to assume it’s a human body-type musk derived from the Baron’s libertinage, something from the furnishings, or a fragrance element, but I really love the idea of this kind of uncomfortably exquisite sensory space. (And then Piter smells like squeaky latex gloves.) Per the Dune Encyclopedia, there's one fragrant drug whose whole mechanism of action is making you think it smells really really good:

PLENISCENTA (Rosa osymyrrah), the "Green Perfume Flower," is a small, delicate shrub with variegated leaves: the blooms are a brilliant emerald green and, when taken from Ecaz and sterilized, decompose with a most exquisite smell. Pleniscenta perfume has a benign psychomimetic effect: it overwhelms the olfactory nerves and causes localized synaptic responses which the brain interprets as indescribably pleasurable smells.

(Pleniscenta is also one of the flowering plants in the conservatory on Arrakis.)

The other big perfume culture question I have wrt the world of Dune/the various cultures represented in Dune is: what's the alcohol situation???? Social drinking isn’t the only determinant of alcohol based perfumery vs oil based (and there are lots of historical ways of incorporating scent that aren’t either one, which I would love to see incorporated into the corporate-feudal future of Dune) but it would be fun to explore different cultural uses of fragrance in that context.

For character-specific scents, oh this is so tough… there’s a big cast and a lot of high class weirdos to be represented but I think Etat Libre d’Orange has some fun scents for House Atreides. The Baron and Feyd are both pleasantly scented in ways that fall right into the same vein of weird stereotypes that House Harkonnen does (so, spicy resiny ambery scents some long-dead French guy decided reminded him of The Orient(tm), that well known cultural monolith????) but I think Piter’s scentscape would need to be made by a brand that specializes in really sterile chemical smells like Xyrena’s theme park bromine notes. (Not that he smells like a theme park dark ride, just that kind of “not existing in nature in any way” thing.) For Arrakis and Fremen characters I would want to go in the opposite direction and explore small-batch natural perfumery. I don’t own a damn thing from For Strange Women etc. because of the cost but I would want to seek out an indie natural brand that draws from desert botanicals (maybe some uncommon animal ingredients like hyrax? Rock hyraxes 🤝 sandworms) and wildcrafting, thinking of all the space ecology at work and the super sophisticated scarcity-minded tech the Fremen employ in that. And the Bene Gesserit are sexy liturgical incense girlies, ofc.

15 notes

·

View notes

Text

Glenmark Pharmaceuticals has recalled two dozen generic medicines sold to American patients because the Indian factory that made them failed to comply with U.S. manufacturing standards and the Food and Drug Administration determined that the faulty drugs could harm people, federal records show.

In February, the FDA found problems with cleaning and testing at the plant in Madhya Pradesh, India, which was the subject of a ProPublica investigation last year. The current recalls, listed in an FDA enforcement report last week, cover a wide range of commonly prescribed medicines, including ones that treat epilepsy, diabetes, multiple sclerosis, heart disease and high blood pressure, among other ailments. A full list of the recalled medications is available here.

The agency determined that the drugs could cause temporary or reversible harm and that the chance of more serious problems was remote. However, the FDA didn’t say what symptoms the flawed drugs could cause. ProPublica asked the FDA and Glenmark for more specifics, but neither responded.

Records show that Glenmark first alerted wholesalers about the recalls in a March 13 letter. That letter suggests that Glenmark pulled the drugs because of potential cross-contamination. Thomas Callaghan, Glenmark’s executive director of regulatory affairs for North America, wrote that 148 batches of the recalled medicines were made “in a shared facility” with two cholesterol-lowering drugs, ezetimibe and a combination of that drug and simvastatin.

That’s a concern because the chemical structure of ezetimibe contains what’s known as a beta-lactam ring. FDA safety experts pay attention to this because many beta-lactam drugs, particularly penicillin, can cause life-threatening allergies and hypersensitivity reactions. It’s the most commonly reported drug allergy in the U.S. Because of that danger, the FDA requires manufacturers to follow special precautions to prevent cross-contamination with drugs that contain a beta-lactam ring, even if they aren’t antibiotics.

5 notes

·

View notes

Text

Automatic Industrial Batch Pasteurizers Market Set to Reach $1530.8 Million by 2035

The Automatic Industrial Batch Pasteurizers market is expected to experience significant growth, with industry revenue projected to rise from $552.9 million in 2024 to $1530.8 million by 2035. This reflects a Compound Annual Growth Rate (CAGR) of 9.7% during the forecast period. The growth is primarily driven by increasing demand for high-efficiency pasteurization systems and greater adoption of automated solutions across the food, beverage, and pharmaceutical sectors.

Detailed Analysis - https://datastringconsulting.com/industry-analysis/automatic-industrial-batch-pasteurizers-market-research-report

Key Applications Driving Market Expansion

Automatic Industrial Batch Pasteurizers are vital in ensuring food safety, extending shelf life, and preserving product quality across several industries. Key application areas include:

Dairy Product Pasteurization: Ensures safe consumption of milk, cream, and yogurt while preserving nutritional content.

Beverage Processing: Widely used in juice, tea, and fermented drinks to eliminate harmful microorganisms without altering taste.

Pharmaceutical Sterilization: Applied in heat-sensitive pharmaceutical solutions to maintain product efficacy and safety.

High-Pressure Processing (HPP): Increasingly used in non-thermal food preservation, particularly in premium, minimally processed products.

Competitive Landscape and Industry Leadership

The market is highly competitive, with top manufacturers continually innovating to enhance product efficiency, automation, and regulatory compliance. Major players include:

Alfa Laval

Tetra Pak

GEA Group

SPX Flow

API Heat Transfer

MicroThermics

Scherjon Dairy Equipment Holland

Stephan Machinery

These companies are expanding their production capabilities and geographical presence to capture demand across new industrial applications.

Growth Drivers and Strategic Opportunities

The Automatic Industrial Batch Pasteurizers market is set to benefit from:

Stricter food safety regulations pushing manufacturers toward reliable, validated pasteurization equipment.

Technological advancements such as energy-efficient and compact pasteurizers tailored for flexible production volumes.

Expanding applications in the dairy sector, one of the largest consumers of pasteurization equipment globally.

Emerging economies are also becoming hotbeds of demand, particularly with rising urbanization and packaged food consumption in regions like Southeast Asia, Africa, and Latin America.

Regional Insights and Market Dynamics

North America and Asia-Pacific dominate the market due to:

Strong food safety frameworks and modernized dairy industries in the U.S., Australia, and Japan.

Rapid expansion of food processing infrastructure in countries like China, India, and Vietnam.

As the supply chain continues to mature — from raw material sourcing to pasteurizer assembly and delivery — manufacturers are expected to optimize production and reduce cost barriers, particularly for small and mid-sized processors in Vietnam, Kenya, and Brazil.

Future Outlook

The Automatic Industrial Batch Pasteurizers market is poised for robust growth, driven by:

Automation and sustainability-focused innovation

Regulatory compliance pressures

Expansion in underpenetrated regions

With strategic investments in R&D and regional expansion, the next decade will be transformative for market players catering to evolving industry demands.

About DataString Consulting

DataString Consulting is a global leader in market research and business intelligence, offering customized solutions across B2B and B2C industries. With over 30 years of combined industry expertise, DataString provides:

Strategy consulting

Comprehensive opportunity assessments

Real-time tracking of high-growth sectors in over 15 industries

Our tailored approach filters out market noise and delivers actionable insights to help you make informed, strategic decisions for sustainable business growth.

#Automatic Industrial Batch Pasteurizers Market#Batch Pasteurization Equipment#Pasteurization Technology Trends 2025#Food Processing Equipment Market#Dairy Pasteurization Machines#High-Pressure Processing Market#Pharmaceutical Pasteurizers#Beverage Pasteurization Solutions#Global Pasteurizer Market Forecast 2035#Food Safety and Automation#GEA Pasteurizers#Alfa Laval Pasteurization Systems#Tetra Pak Batch Pasteurizers#Energy-Efficient Pasteurization#Pasteurization in Emerging Markets#Pasteurizer Industry Growth Analysis#Food and Beverage Processing Trends#Sustainable Pasteurization Technology#Heat Treatment Equipment Market#Automated Food Safety Equipment

0 notes

Text

A Danish group published a statistical analysis in 2023 showing disproportionate adverse events for early Pfizer-BioNTech vaccines, which was met with criticism from Anders Hviid, a Professor of epidemiology, and later by Borja Somovilla del Saz, a 23-year-old computer science student.

Somovilla del Saz’s criticism was the most prominent as it was referenced by Pfizer-BioNTech and the Paul Ehrlich Institut (“PEI”).

An investigation into Somovilla del Saz’s background and writing style has revealed inconsistencies, suggesting the involvement of external parties, and his critiques of various papers on vaccine safety and other topics appear to be reactionary and strategically timed.

It seems Somovilla del Saz is a ghostwriter used by the pharmaceutical industry to deliver messages that align with their interests.

6 notes

·

View notes

Note

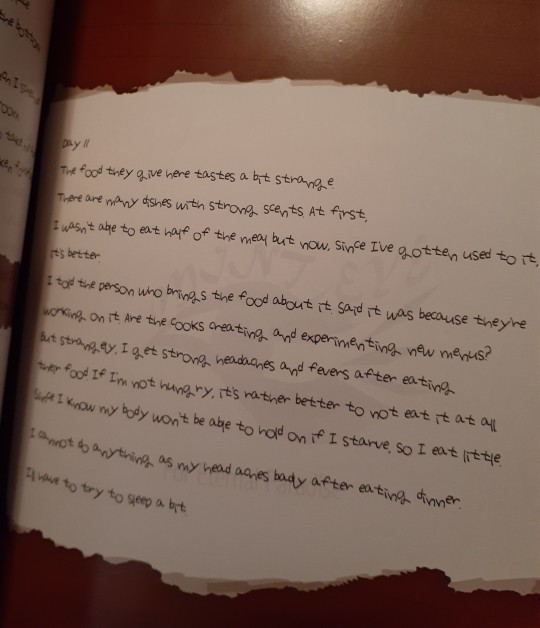

The scene in the secret ending where the doctors are reading off the elixir ingredients is so insane to me. You’re telling me this whole time Saeran was on MUSHROOMS? METHANOL?? PEYOTE CACTUS???

Yeah, and those are only the ingredients that we know about. The elixir is a pure cocktail of drugs. These are the only ingredients that are mentioned to us by name.

I imagine the list of what is being pumped into it is never the same and I know that is true for a damn fact, anon. The formula is never the same because they make it in large batches with whatever they can get their hands on. That is revealed in Another Story by Ray himself. He knows the formula, and not only that, he is able to make something that looks exactly like it and relatively tastes close enough that nobody would say a word about it in a desperate situation.

It wouldn't surprise me in the slightest if they not only develop new batches but they test it on believers that are being cleansed. I mean, there's really only one surefire way to figure out what happens to the people who take it. You have to physically test it on people and nobody's going to be willing to do that. One of the first people to suffer through the elixir is Saeran himself. He wasn't the first person but he was one of the first to be inducted in that way.

Not only is he taking medication that is never in the same concentration all the time, he was a guinea pig for it in the first place. The sad reality in his after ending when he isn't affected by the elixir at all like everybody else is due to his tolerance that he's built up to the sheer overwhelming concentration. Like, we don't even know all of the ingredients in the elixir but what we do know lets us know how harsh it is for your body. Rika knows a lot of information about "herbs". She put it to use in the name of experimentation.

Let's not even try to figure out how she was capable of manipulating people during her time in the RFA to not only gain the financial backing for this process but how she made connections with the right people in the pharmaceutical industry. That would have taken a lot of work because she's not doing that by herself.

#mod kait#ask#mystic messenger#anon#mysme#saeran choi#mysticmessenger#choi saeran#mm#character analysis#choi ray#ray choi#mm saeran#saeran mysme#mysme saeran#saeran mystic messenger#saeran mm#mystic messenger saeran

91 notes

·

View notes